3-23 HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 46 of 2189

Specifications

Standards and Service Limits "'.".'.""' 3-2

Design Specif ications,..'....,.'..'.... "... ""' 3-20

Body Specifications "'."'." 3-23

Page 581 of 2189

\

S40 Model (All except'99 - 00 2-door Si' SiR)

Manual Transmission

Special Tools ..'.......... 13-2

Maintenance

Transmission Oil .............................. 13-3

Back-up Light Switch

Replacement ......... 13-3

Troubleshooting '....... 13-4

Transmission AssemblY

Removal ................. 13-5

lnstallation ............. 13-8

lllustrated Index ...............'........."........ 13-10

Transmission Housing

I Removaf .."""""""' 13-12

J R"rr"r"" Shift Holder

Clearance lnspection ....................... 13-13

Reverse ldler Gear

Removal ....'.........." 13-14

Mainshaft, Countershaft, Shift Fork

Disassembly ......'... 13-14

Mainshaft AcsemblY

Index ............... ....... 13-15

Clearance Inspection ..'.................... 13-16

Disassembly .......... 13-17

Inspection ....'......... 13-18

Reassembly ........... 13-19

Countershaft AssemblY

lndex ................ ...... 13-20

Clearance lnspection ."..........'......." 13-21

Disassembly ..."""' 13-22

Inspection .............. 13-23

Reassembly ..'.""... 13-23

Shift Fork AssemblY

lndex ............... ."'... 13-25

Clearance lnspection ."......."........'.. 13'26

MBS Shift Piece Inspection ....-.....'.. 13'27

Synchro Sleeve, Synchro Hub

f nspection/lnstallation .......'...... ".... 13'27

Synchro Ring, Gear

Inspection '....'..".... 13'28

Shift Rod

Removal .'......".""" 13'29

Differential

lndex ......."'...... .'."' 13-30

Backlash Inspection ..........."......."... 13-30

Bearing Beplacement'.............'.".... 13'31

Final Driven Gear Replacement '..... 13-31

Thrust Shim Adiustment ..."........... 13-32

Clutch Housing Bearing

Replacement .......'. 13-34

Mainshaft Thrust Shim

Adiustment '....'..".. 13-36

Transmission

Reassembly ........... 13-39

Oil Seals

Replacement ......... 13-43

Gearshift Mechanism

Overhaul ................ 13-44

\

Page 600 of 2189

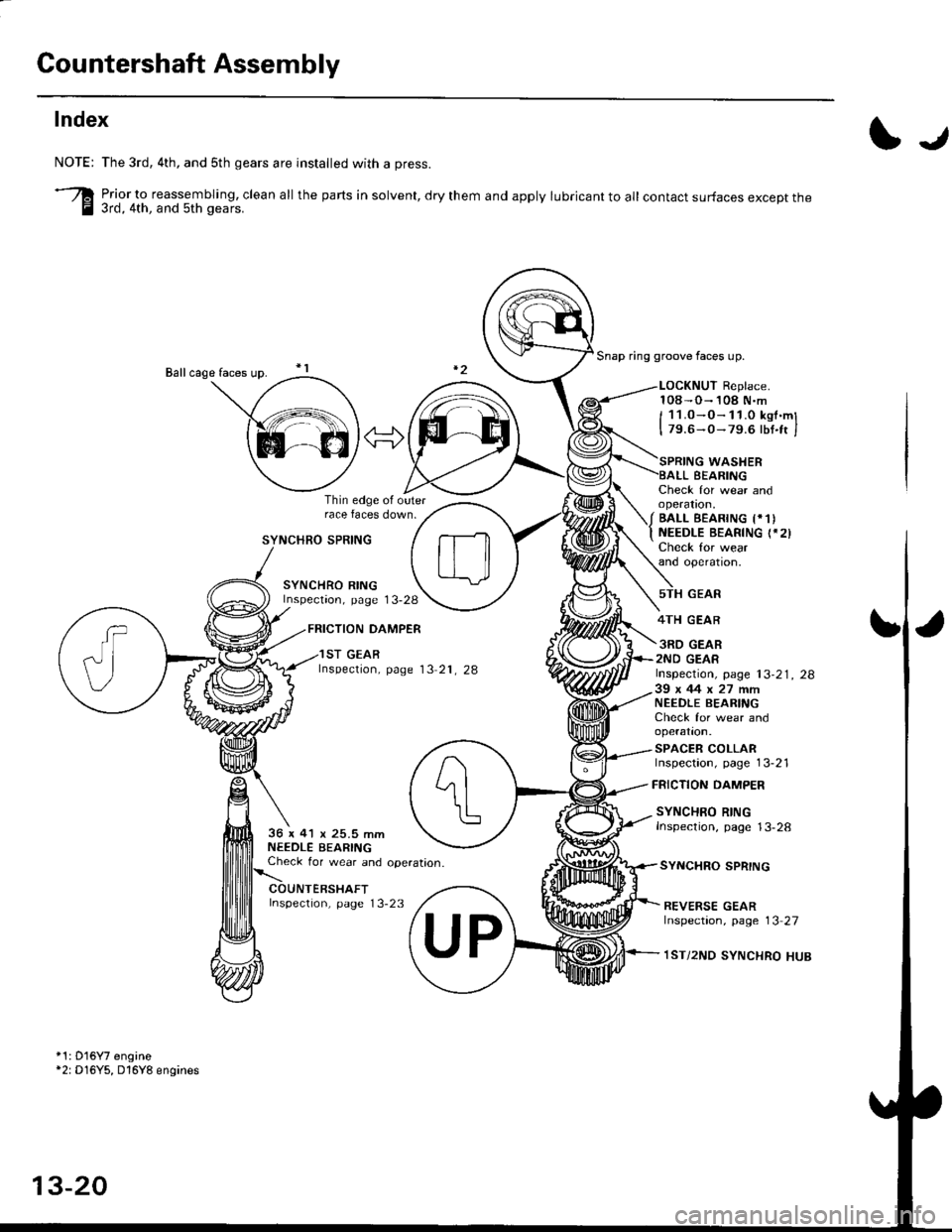

Countershaft Assembly

Index

I.r

NOTE:

-re

The 3rd, 4th, and sth gears are installed with a press.

Prior_to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces except the3rd, 4th, and 5th gears.

Snap ring groove faces up.

LOCKNUT Replace.108-O- 108 N.m

I 11.0-O-11.0 kst.ml

I 79.6-0- 79.6 lbt.ft I

SYNCHRO SPRING

SYNCHRO RINGInspectaon, page 13-28

FRICTION DAMPER

Thin edge ol outerrace faces down.

Check for wear andoperatron,

/ BALL EEAR|NG t*1)

t NEEDLE BEARTNG (.2)

Check for wearand operatron,

WASHERBEARING

GEAR

4TH GEAR

3RD GEAR2ND GEAR

FRICTION DAMPER

SYNCHRO SPRING

SYNCHRO RINGInspection, page 13-2836 x 41 x 25.5 mmNEEDLE BEARINGCheck for wear and operataon.

Inspection, page 13-23

1ST GEARlnspection, page 13 21, 28lnspection, page 13-21, 2839x44x27m�mNEEDLE BEARIfI'GCheck for wear andoperation.

SPACER COLLARInspection, page 13-21

REVERSE GEARlnspection, page 13 27

1ST/2ND SYNCHRO HUB

*1: D'16Y7 engine*2: D16Y5, D16Y8 engines

13-20

Page 603 of 2189

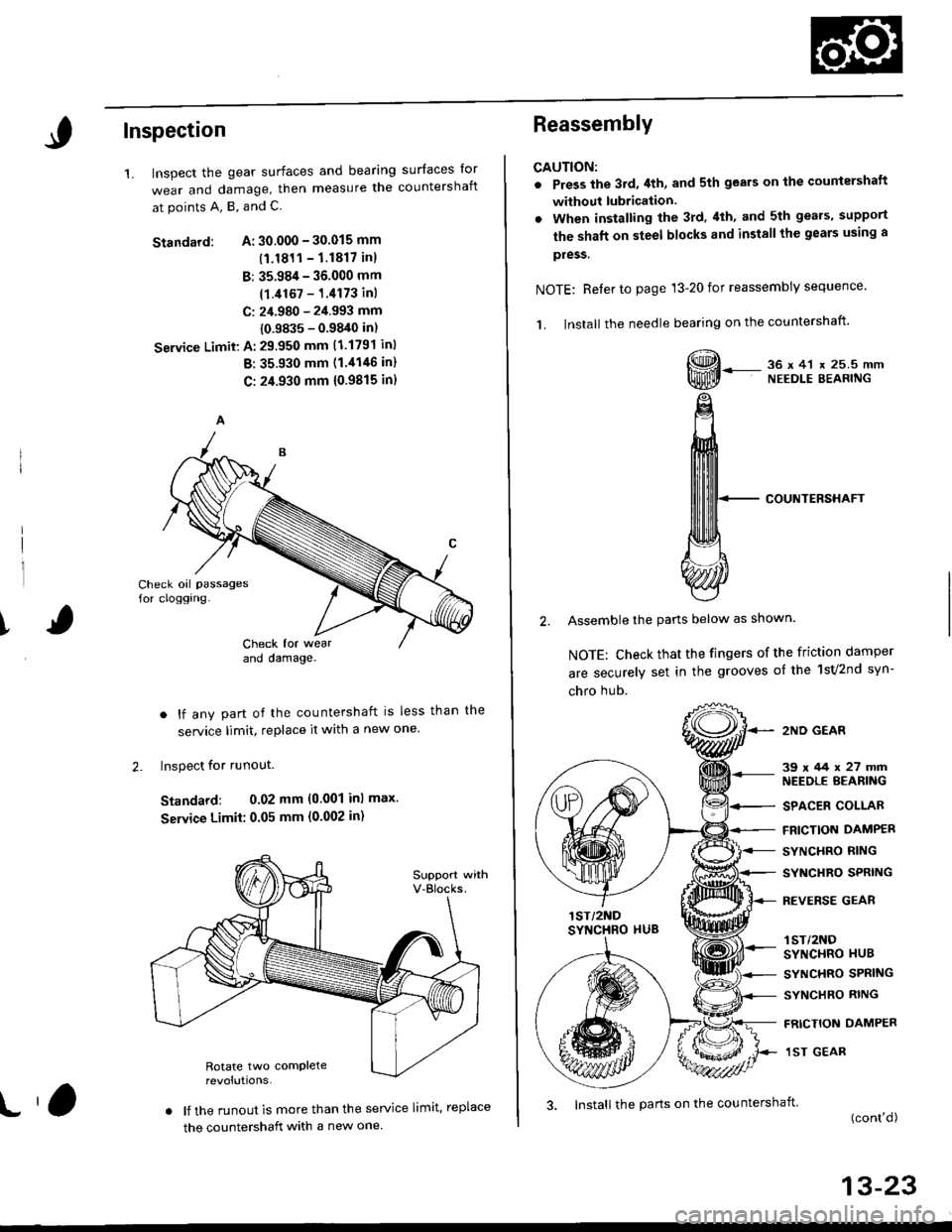

Inspection

1.surfaces lor

countershaftInspect the gear surfaces and bearang

wear and damage, then measure tne

at points A, B, and C.

Standard: A: 30.000 - 30.015 mm

(1.1811- 1.1817 inl

B: 35.984 - 36.000 mm

(1.i1167 - 1.4173 inl

C: 24.980 - 2i1.993 mm

{0.9835 - 0.9840 in)

Seryice Limit: A: 29.950 mm (1.1791 inl

B: 35.930 mm (1 '1146 in)

C: 24.930 mm 10.9815 in)

Check oil passages

for cloggrng-

ICheck for wearano oamage.

. lf any part of the countershaft is less than

service limit, replace it with a new one.

Inspect for runout.

Standard: 0.02 mm (0.001 inl max.

Seryice Limit: 0.05 mm {0'002 in)

. lf the runout is more than the service limit. replace

the countershaft with a new one.

the

2.

t,3. Install the parts on the countershait

Reassembly

CAUTION:

. Press the 3rd,4th, and sth gears on the countershaft

without lubrication.

. When installing the 3rd. 4th, and 5th geals, support

the shaft on steel blocks and installthe gears using a

pless.

NOTE: Reler to page 13-20 for reassembly sequence'

1. lnstall the needle bearing on the countershaft'

, 36x41 x 25.5mmNEEDLE BEARING

COUNTERSHAFT

2. Assemble the pans below as shown.

NOTE: Check that the fingers of the friction damper

are securely set in the grooves of the 1sv2nd syn-

chro hub.

2ND GEAR

39x/+4x27mmNEEDLE BEARING

SPACER COLLAR

FRICTION DAMPER

SYNCHRO RING

SYNCHRO SPRING

REVERSE GEAR

lST/2NOSYNCHRO HUB

SYNCHRO SPRING

SYNCHRO RING

FRICTION DAMPER

1ST GEAR

(cont'd)

13-23

Page 1471 of 2189

l'f .

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1493 of 2189

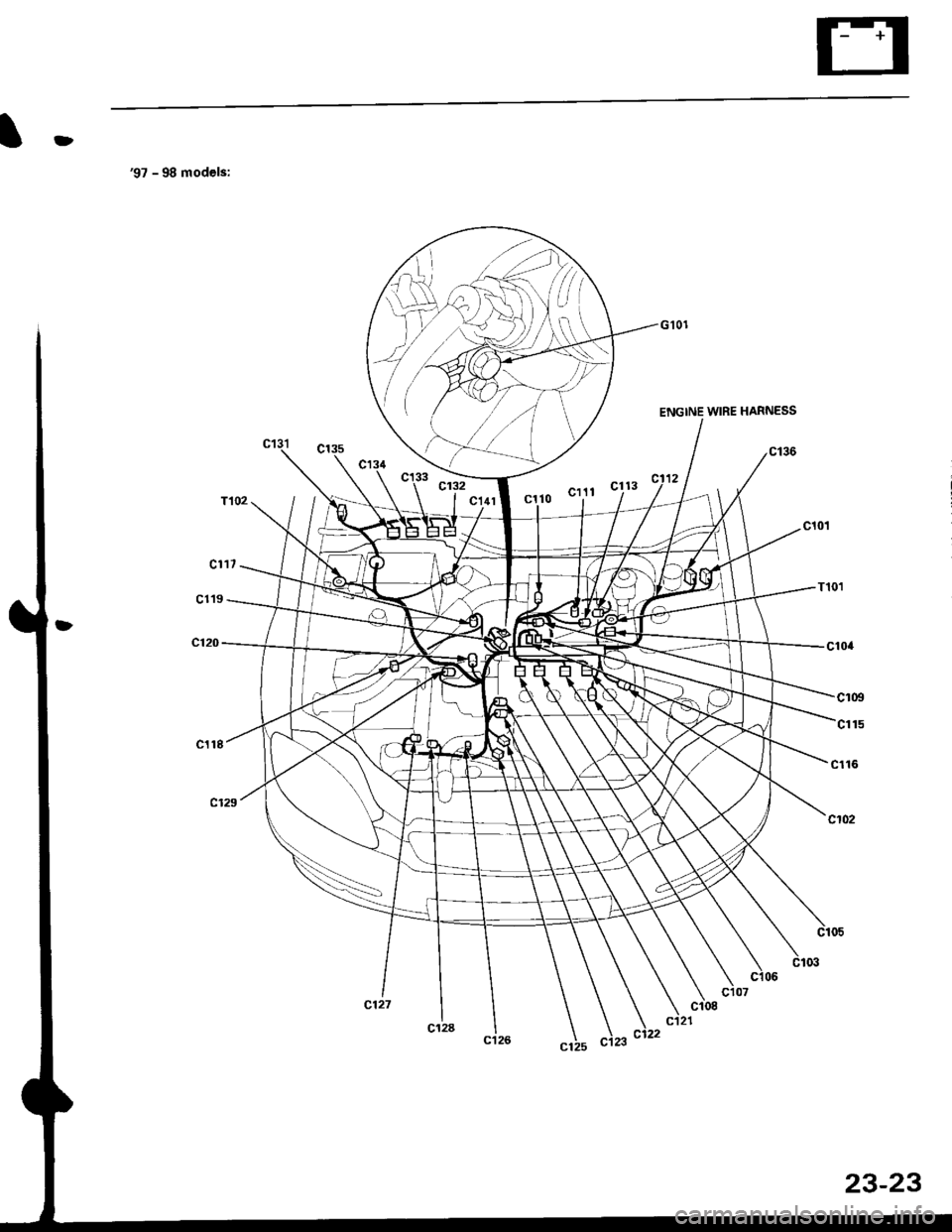

D

'97 - 98 models:

WIRE HARNESS

23-23

Page 1690 of 2189

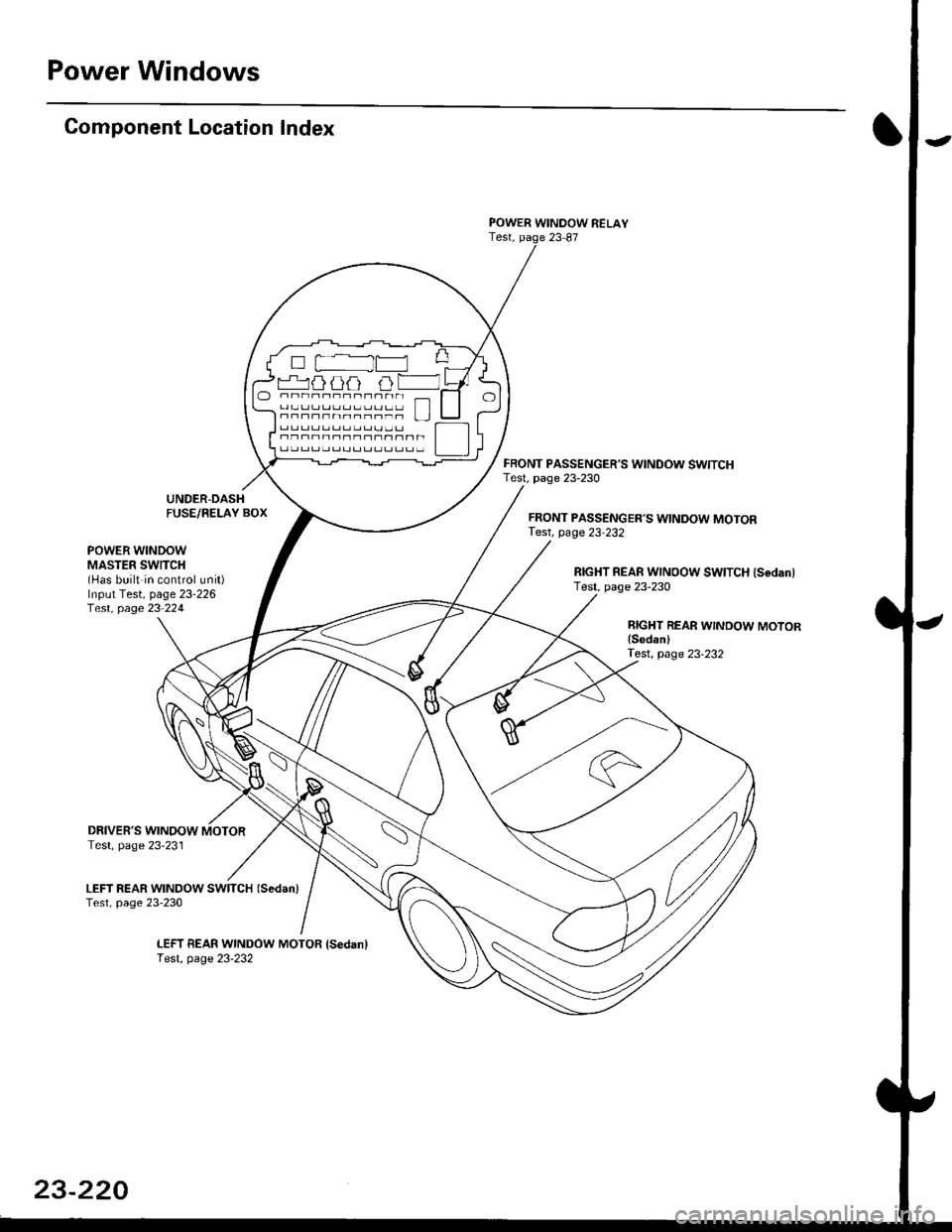

Power Windows

Gomponent Location Index

UNDER-DASHFUSE/RELAY BOX

POWER WINDOW RELAYTest, paqe 23 87

FRONT PASSENGER'S WINDOW SWITCHTest. page 23-230

FRONT PASSENGER'S WINDOW MOTORTest, page 23-232

POWER WINDOWMASTER SWITCH(Has built in control unit)Input Test, page 23-226f e$, page 23 224

RIGHT REAR WINOOW SWITCH {SedanlTest, page 23-230

BIGHT REAR WINDOW MOTORlSedanlTest, page 23-232

DRIVER'S WINOOW MOTORTest, page 23-231

LEFT REAR WINDOW SWITCH (Sedan)

Test, page 23-230

LEFT BEAR WINDOW MOTOR {Sedanlf e$, page 23-232

O -rr----r---- _ fl]l O-.---,---;-; n-n--n-nn--r- ! l

Page 1700 of 2189

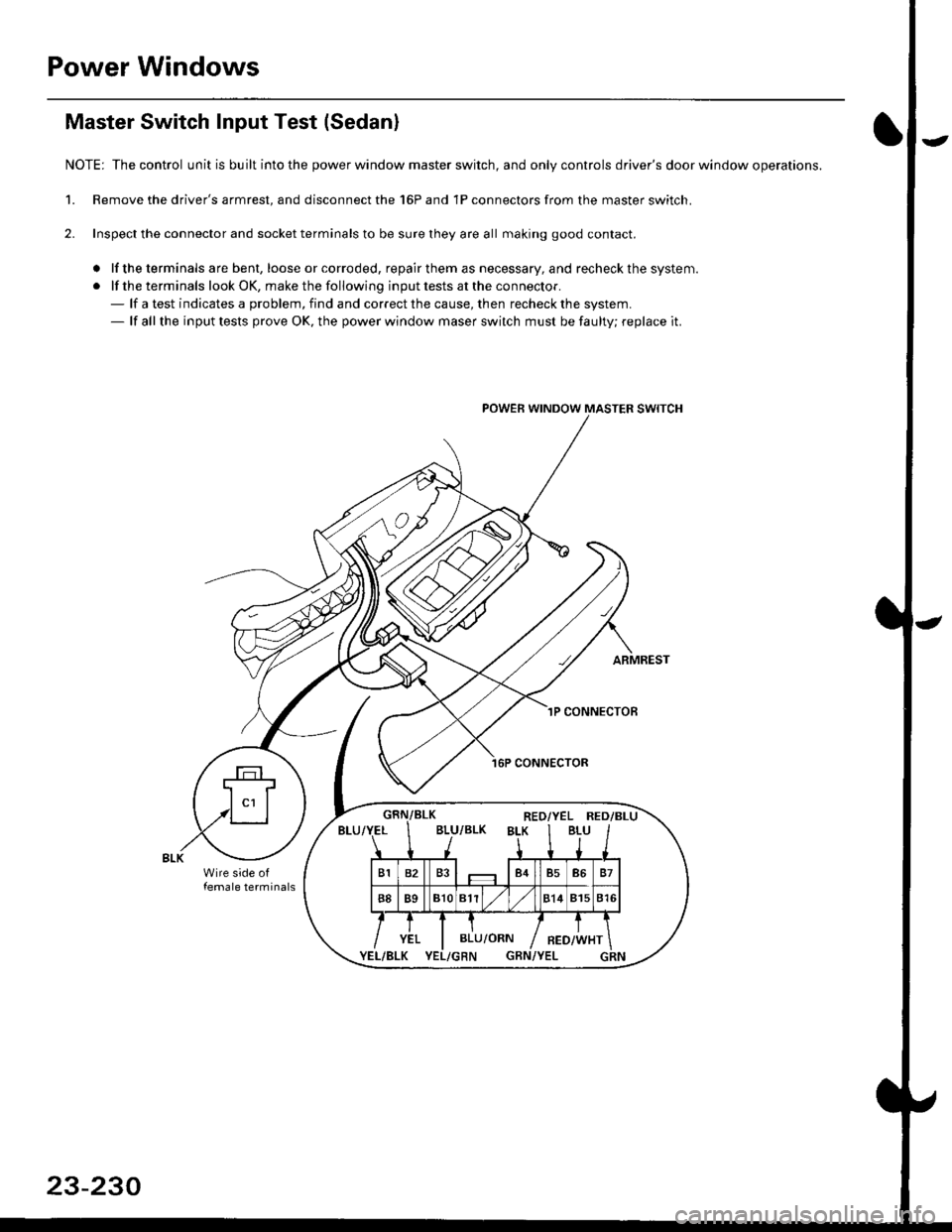

Power Windows

Master Switch Input Test (Sedan)

NOTE: Thecontrol unit is built intothe power window master switch, and only controls driver's door window operations.

1. Remove the driver's armrest, and disconnect the 16P and 1P connectors from the master switch.

2. Inspect the connector and socket terminals to be sure they are all making good contact.

a lf the terminals a re bent, loose orcorroded, repairthem as necessary, and recheck the system.

. lf the terminals look OK, make the following input tests at the connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK. the power window maser switch must be faulty; replace it.

POWEB WINDOW MASTER SWITCH

23-230

Page 1701 of 2189

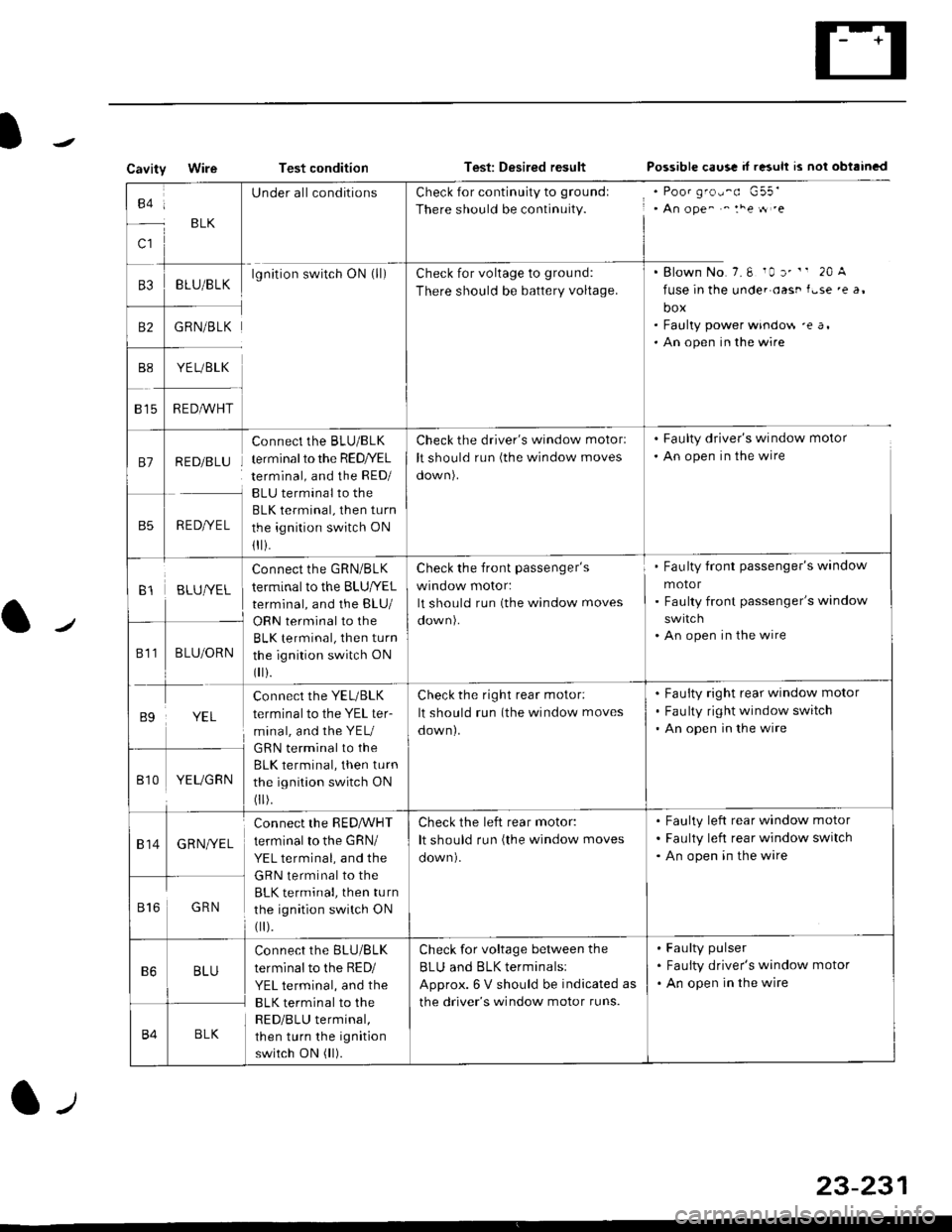

CavityWireTest conditionTest: Desired resultPossible caus! d r"suh rs nol obtrincd

to:

c1

BLK

UnderallconditionsCheck for continuity to groundl

There should be continuity., An ope^ ^ :he tt .e

. Blown No.7.6 10 r' " 20 A

fuse in the unde. oast f.se 'e a,

box. Faulty power windo$ 'e a,. An open in the wire

B3BLU/BLKlgnition switch ON (ll)Check for voltage to grou nd:

There should be battery voltage.

B2GRN/BLK

YE L/BLK

R EDA/VHT815

81RED/BLU

RED/YEL

Connect the BLU/BLK

terminal to the RED/YEL

terminal, and the RED/

BLU terminal to the

BLK terminal, then turn

the ignition switch ON

1I i.

Check the driver's window motorl

It should run (the window moves

oown).

. Faulty driver's window motor

. An open in the wire

B1BLUIVEL

Connect the GRN/BLK

terminal to the BLU|YEL

terminal, and the BLU/

Check the front passenger's

wrnoow motor:

It should run (the window moves

Fau lty front passenger's window

motor

Faulty front passenger's window

An open in the wire

811BLU/ORNBLK terminal, then turn

the ignition switch ON

0 r).

B9YEL

connect the YEL/BLK

terminal to the YEL ter-

minal, and the YEU

GRN terminal to the

BLK terminal, then turn

the ignition switch ON

0 r).

Check the right rear motor:

It should run (the window moves

down).

Fauity right rear window motor

Fau lty right window switch

An open in the wire

Bt0YEUGRN

814GRNI/EL

connect the RED,ryVHT

terminal to the GRN/

YEL terminal, and the

GRN terminal to the

BLK terminal, then turn

the ignition switch ON

0 r).

Check the left rear motor:

It should run (the window moves

Faulty left rear window motor

Faulty left rear window switch

An open in the wire

816GRN

B6BLU

Connect the BLU/BLK

terminal to the RED/

YEL terminal, and the

BLK terminal to the

RED/BLU terminal,

then turn the ignition

switch ON (ll).

Check for voltage between the

BLU and BLK terminalsl

Approx. 6 V should be indicated as

the driver's window motor runs.

Faulty pulser

Faulty driver's window motor

An open in the wire

B4BLK

23-231

Page 1702 of 2189

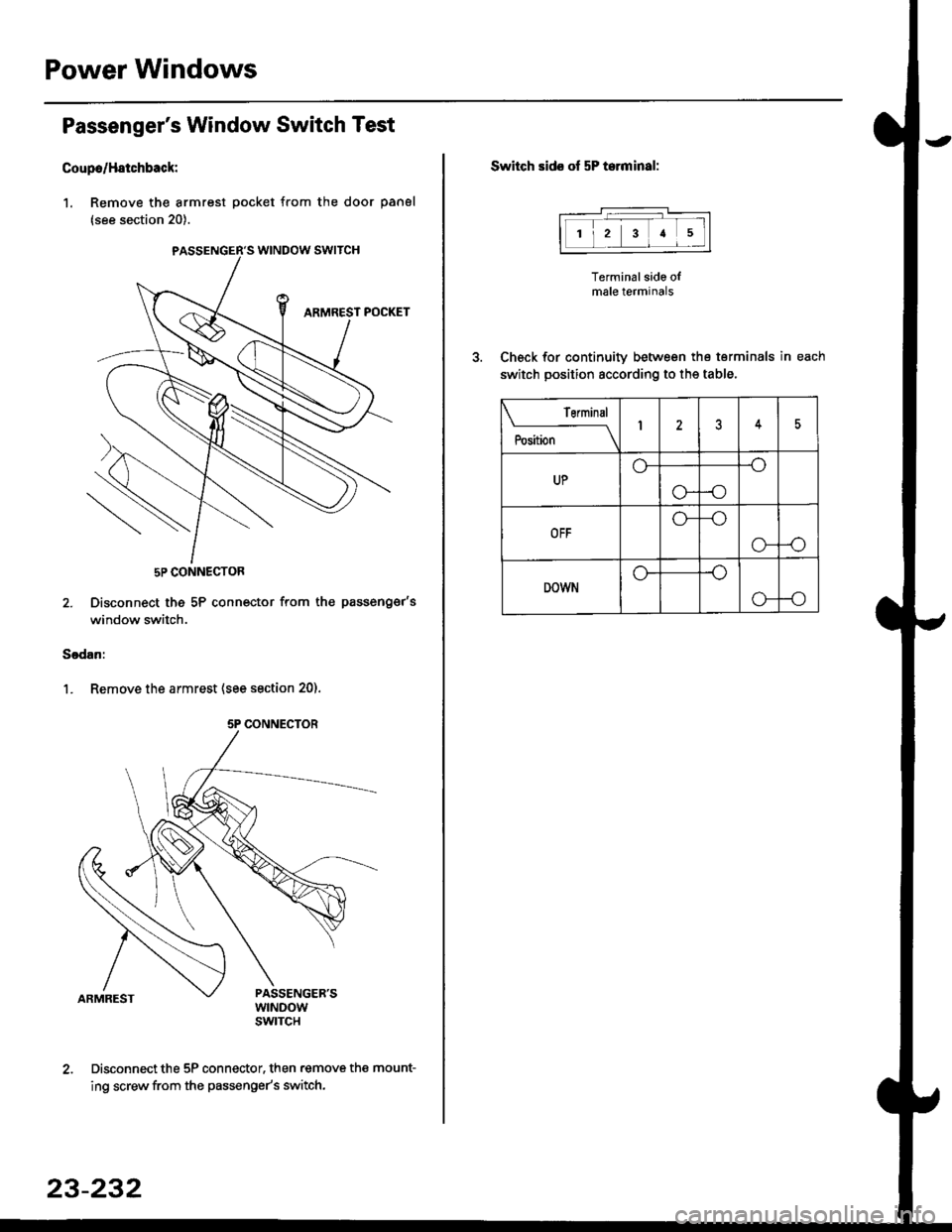

Power Windows

Passenger's Window Switch Test

Coupo/H8tchback:

1. Remove the armrest pocket from the door panel

{see section 20}.

5P CONNECTOR

2. Disconnect the 5P connector from th€ passenger's

window switch.

Sodan:

1. Remove the armrest (see section 20).

Disconnect the 5P connector, then .emove the mount-

ing screw from the passenge/s switch.

PASSENGER'S WINDOW SWITCH

5P CONNECTOR

23-232

Switch sids of 5P t.rminal:

Terminal side olmale terminals

Check for continuity between the terminals in each

switch position according to the table.

12a5

Terminal

il;--lI25

UP

-o

-o

OFF

-o

o--o

DOWNo--o