Radiator removal HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 110 of 2189

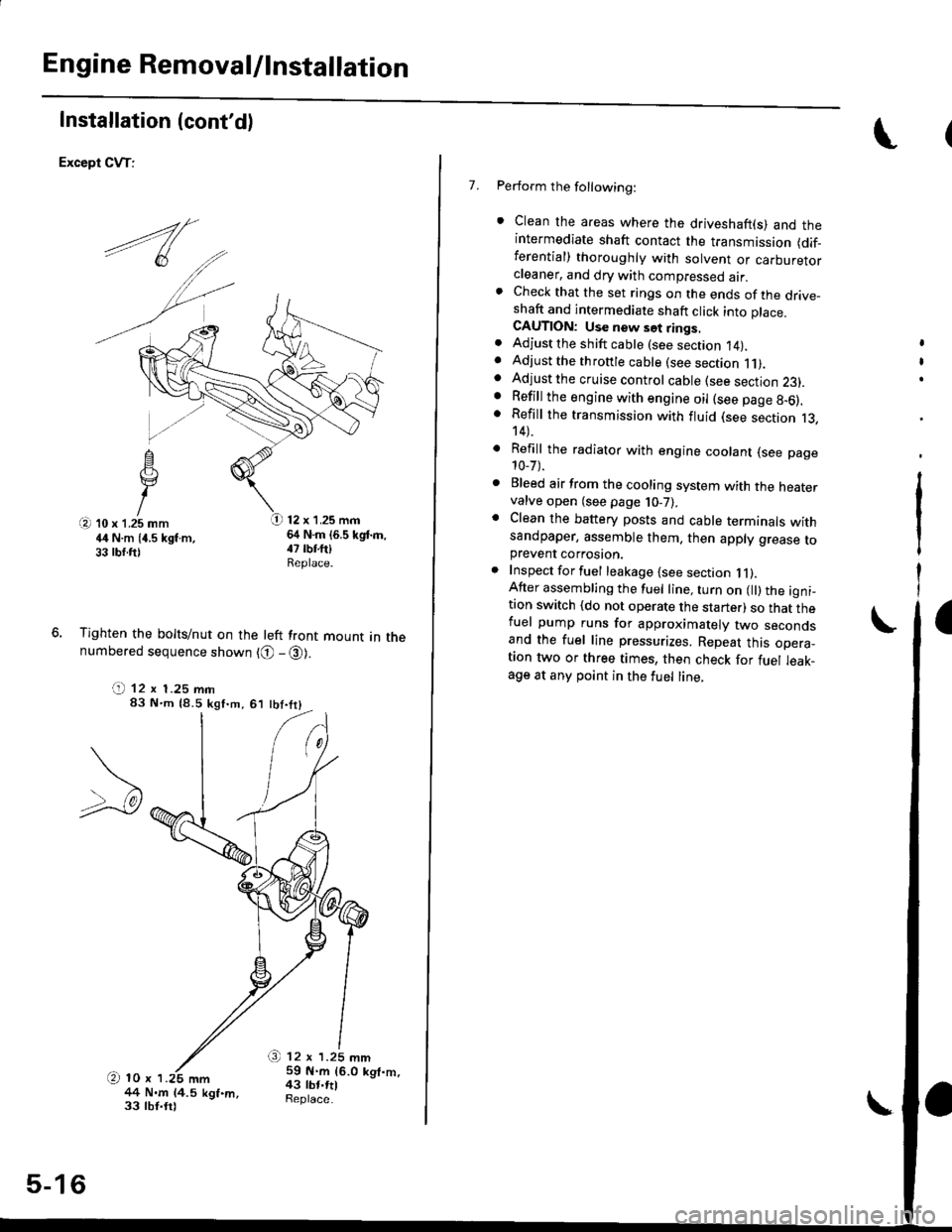

Engine Removal/lnstallation

Installation (cont'd)

Except CVT:

12 x 1.25 mm64 N.m (6.5 kgd.m,

Tighten the bolts/nut on the left front mount in thenumbered sequence shown {O - @).

(t 12 x 1.25 mm83 N'm (8.5 kgf.m,61 tbt.trl

/+4 N.m 14.5 kgf.m,33 lbt.trl

O 12 r 1.25 mm59 N.m 16.0 kgt.m,43 tbt.rtlSeplace.

5-16

\

7. Perform the following:

. Clean the areas where the driveshaft(s) and theintermediate shaft contact the transmission (dif_ferential) thoroughly with solvent or carburetorcteaner, and dry with compressed air.. Check that the set rings on the ends of the drive_shaft and intermediate shaft click into place.CAUTION: Use new set rings,. Adjust the shift cable (see section 14).. Adjust the throttle cable (see section 11).. Adjust the cruise control cable (see section 23).. Refill the engine with engine oil (see page 8-6).. Refill the transmission with fluid (see section 13,14).

. Refill the radiator with engine coolant (see page10-7).

. Bleed air from the cooling system with the heatervalve open (see page j0-7).

. Clean the battery posts and cable terminals withsandpaper, assemble them, then apply grease toprevent corrosaon.. Inspect for fuel leakage (see section j l).After assembling the fuel line, turn on l) the igni_tion switch (do not operate the starter) so that thefuel pump runs for approximately two secondsand the fuel line pressurizes. Repeat this opera_taon two or three times, then check for fuel leak_age at any point in the fuel line,

Page 138 of 2189

Removal

Engine removal is not required for this procedure

!!!s@ Make sure iacks and salety stands are

f ta"eata"ea propetty and hoist brackets are attached to the

correct positions on the engine.

CAUTION:

. Use tender covels to avoid damaging painted sul-

faces.

o To avoid damage, unplug the wiling connectors

carefully while holding the connector portion to

avoid damage.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F

{38"C} before loossning the tetaining bolts.

NOTE:

o Mark all wiring and hoses to avoid misconnectlon

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

. Inspect the timing belt before removing the cylinder

h ead.

. Turnthe crankshaft pu lley so that the No. lpistonisat

top dead center (see Page 6-21)

'1. Disconnect the negative terminal from the battery'

Drain the engine coolant (see page'10-7).

a Remove the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing

(see page 5 3).

Remove the mounting bolt and lock bolt. then

remove the power steering (P/S) pump belt and

pump (see page 5'5).

Loosen the idler pulley center nut and adjusting

bolt' then remove the air conditioning (A'lc) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt. then

remove the alternator belt (see page 6-19).

Remove the P/S pump bracket (see page 5-12).

3.

4.

2.

6.

1.

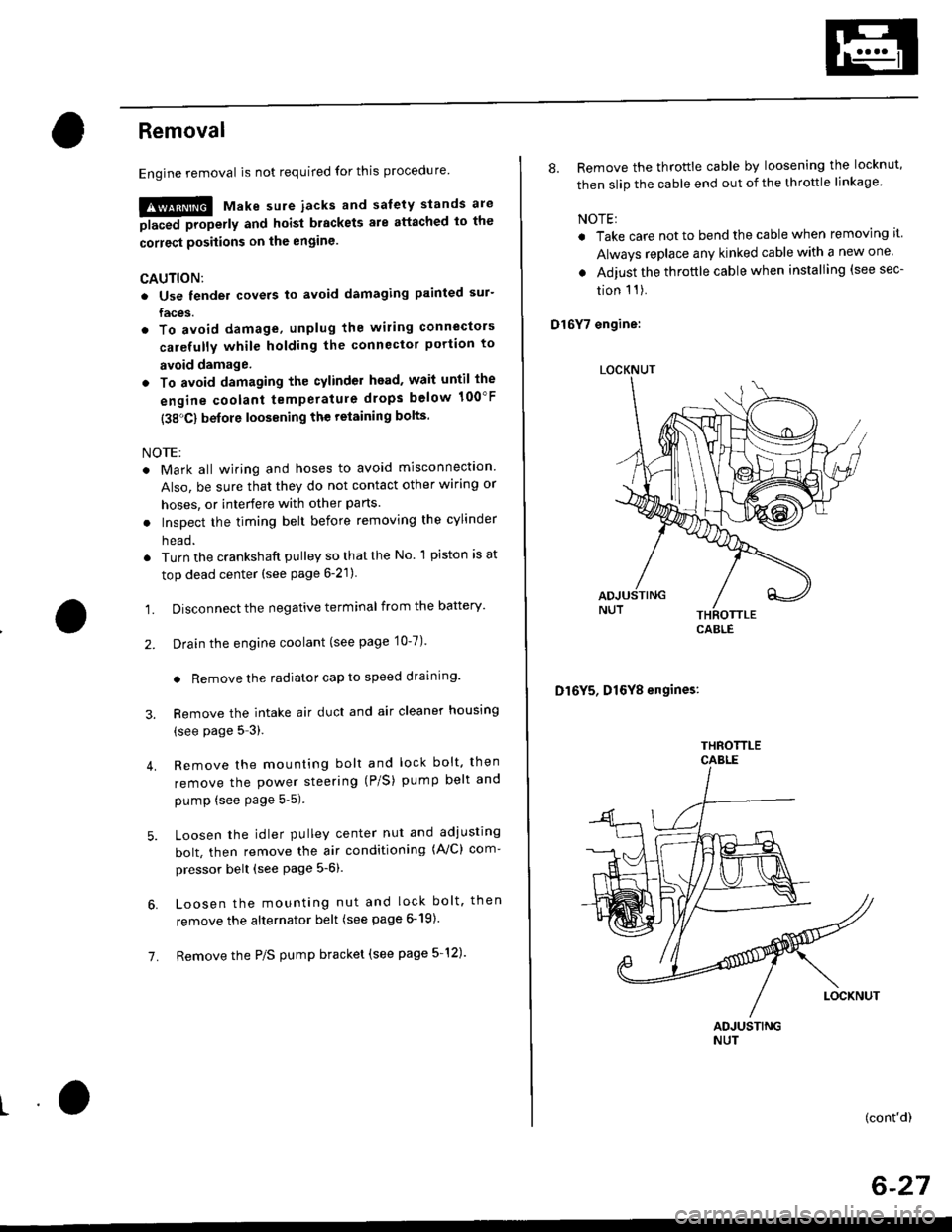

8. Remove the throttle cable by loosening the locknut,

then slip the cable end out of the throttle linkage

NOTE:

. Take care not to bend the cable when removing it

Always replace any kinked cable with a new one

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

Dl6Y5, Dl6Y8 engines:

THFOTTLECABLE

(cont'd)

6-27

LOCKNUT

CABLE

Page 177 of 2189

Removal

Engine removal is not required for this procedure.

!@@ Make sure jacks and safety stands are placed

properly and hoist brackels are attached to correst posi-

tion on the engine,

CAUTION:

o Use fender covers to avoid damaging painted sur-

faces.

To avoid damage, unplug the wiling connectors

carelully while holding the connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F {38'Cl

before loosening the retaining bolt.

NOTE:

. Unspecified items are common.

. Mark all wiring and hoses to avoid misconnection.

AIso, be sure that they do not contact other wiring or

hoses or interfere with other parts.

o Inspect the timing belt before removing the cylinder

n eao.

. Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (see page 6-64).

1. Disconnect the negative terminal from the battery.

Drain the engine coolant {see page 10-7).

. Remove the radiator cap to speed draining.

Remove the strut brace (see page 5-2).

Remove the intake air duct and air cleaner housing

(see page 5-3).

Remove the adjusting bolt and mounting bolt, then

remove the power steering (P/S) pump belt and pump

(see page 5 5).

2.

3.

4.

\

ADJUSTING

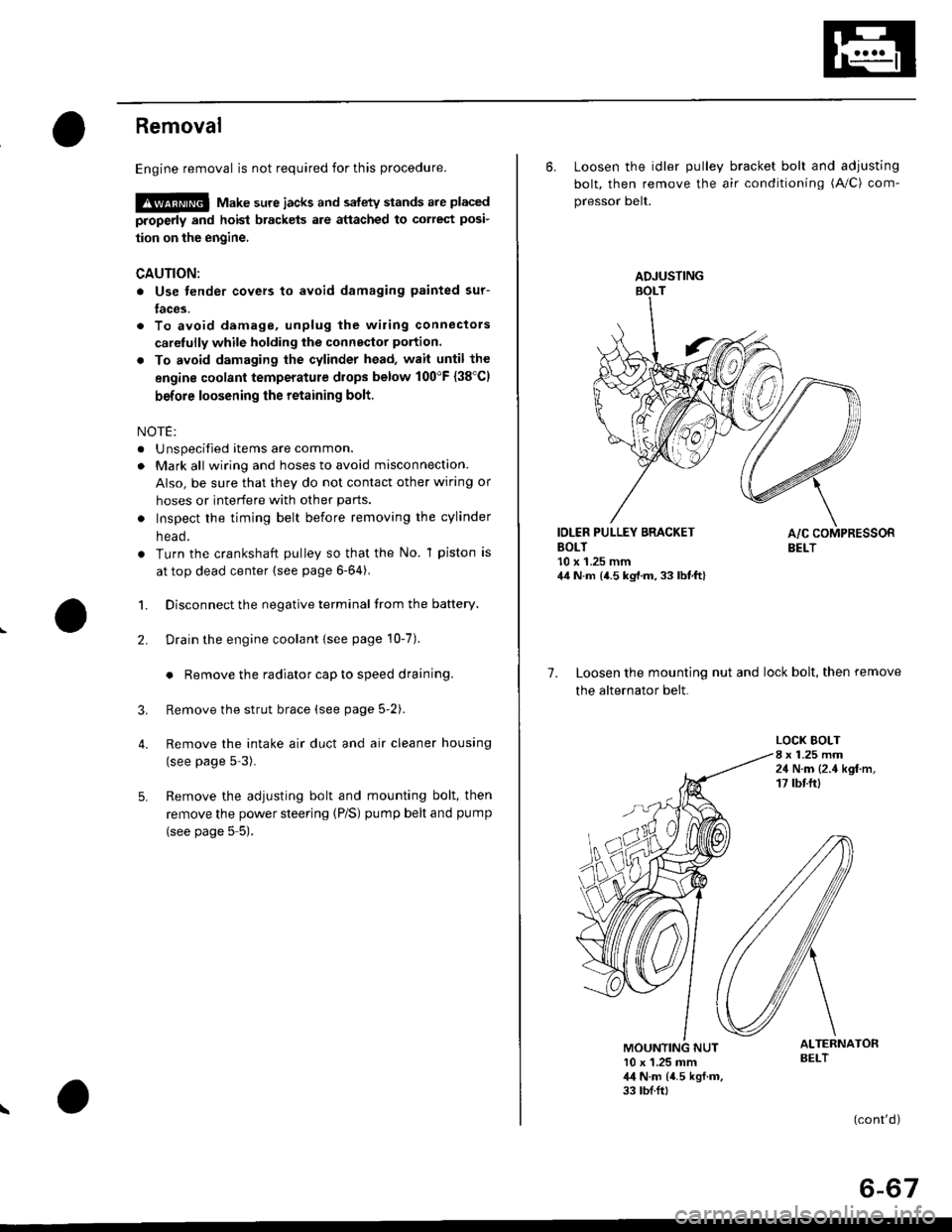

6. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A/C) com-

pressor belt.

IDLER PULLEY BRACKETBOLT10 x 1.25 mm44 N.m {4.5 kg,l.m, 33 lbt.ft}

7. Loosen the mounting nut and lock bolt, then remove

the alternator belt.

LOCK BOLT8 x 1.25 mm24 N.m {2.4 kgf.m,17 tbtftl

ALTERNATORBELT10 x 1.25 mm,l,l N.m {4.5 kgf.m,33 tbf.ft,

(cont'd)

6-67

Page 261 of 2189

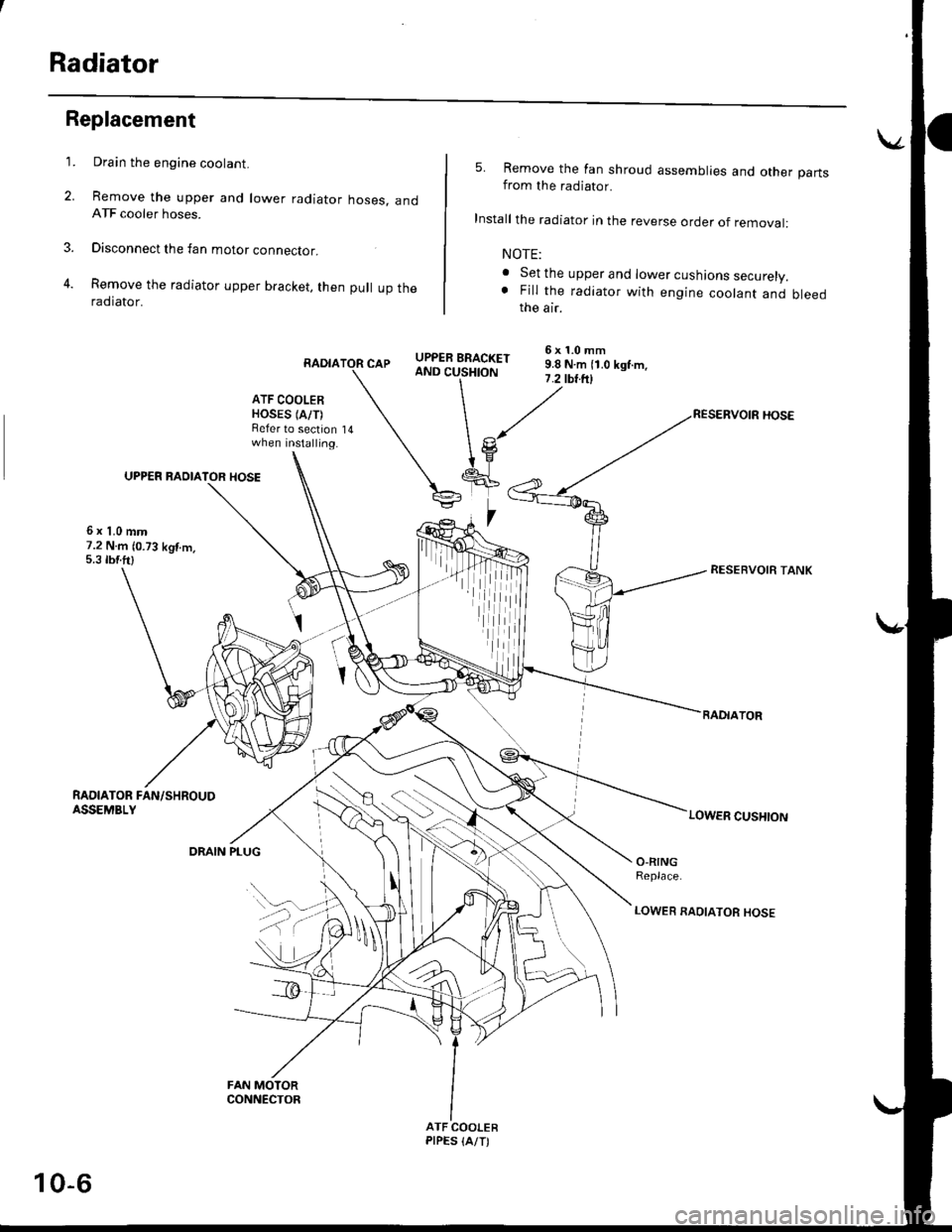

Radiator

Replacement

Drain the engine coolant.

Remove the upper and lower radiator hoses, andATF cooler hoses.

Disconnect the fan motor connector.

Remove the radiator upper bracket, then pull up theraotator,

RADIA

ATF COOLERHOSES (A/T)Refer to sectionwhen installing.

UPPER RAOIATOR HOSE

6x1.0mm7.2 N.m (0.73 kgf.m.5.3 tbf.ft)

1.

2.

3.

5. Remove the fan shroud assemblies and other partsfrom the radiator.

Install the radiator in the reverse order of removal:

NOTE:

. Set the upper and lower cushions securely.. Fill the radiator with engine coolant and bleedthe air.

6x1.0mmCAPY|lT,PS:|" i.i ru- ii b rgr.-,AND CUSHION7.2 tbr.ftl

14

(

I

RESEBVOIR TANK

RADIATOR

LOWER CUSHION

RAOIATOR FAN/SHROUDASSEMBLY

DRAIN PLUGO-RINGReplace.

LOWER RAOIATOR HOSE

ATF COOLERPIPES {A/T)

,iiiiii

10-6

Page 628 of 2189

Transmission Assembly

l

,

{

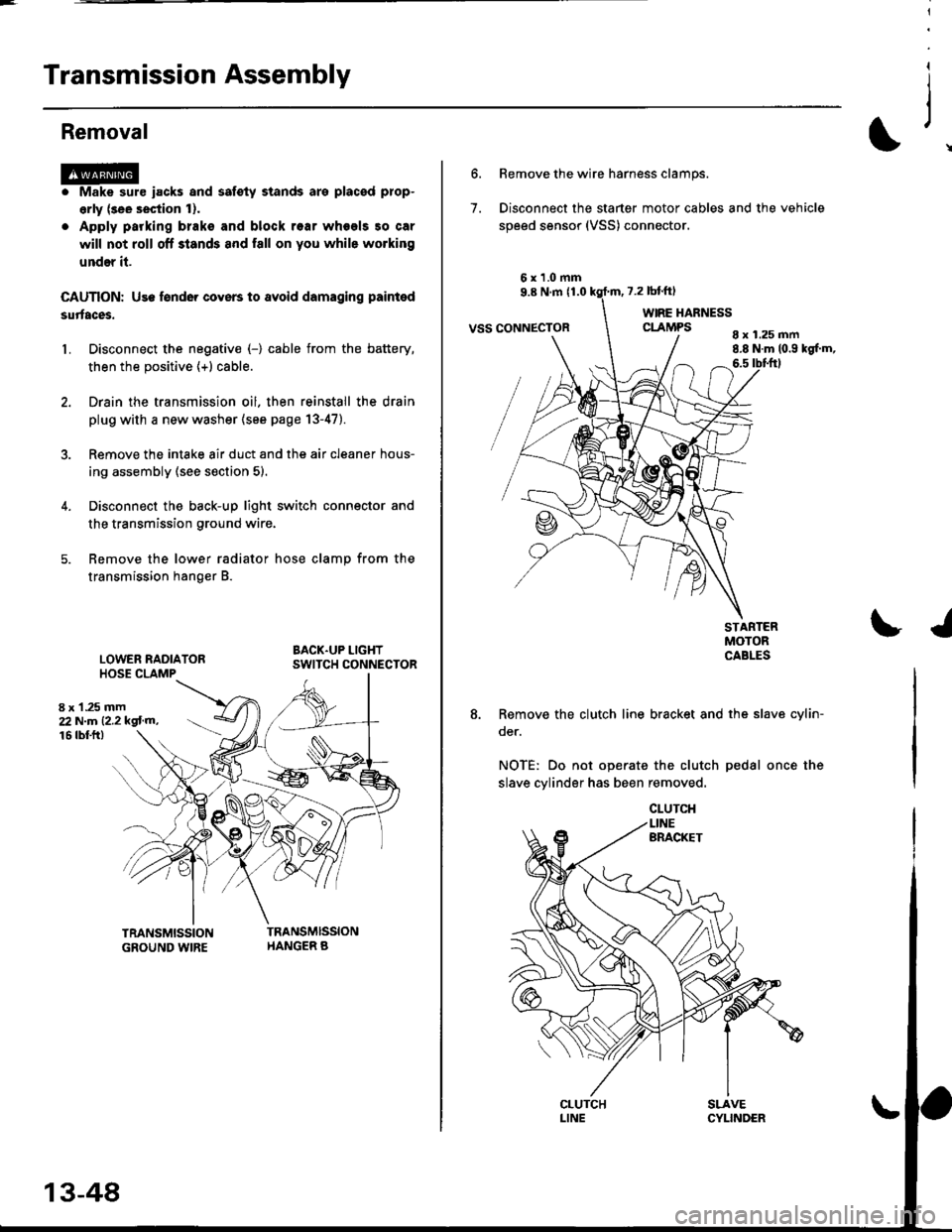

Removal

@Make sure iacks and safoty stands are placad plop-

erly (3ee section l).

Apply parking braks and block rear wheels so car

will not roll off stands and fall on you while working

under il.

CAUTION: Us6 fonder cove6 to avoid damaging painted

sudaces.

Disconnect the negative (-) cable from the battery,

then the positive (+l cable.

Drain the transmission oil. then reinstall the drain

plug with a new washer (see page 13-47).

Remove the intake air duct and the air cleaner hous-

ing assembly (see s€ction 5).

Disconnect the back-up light switch connector and

the transmission ground wire.

Remove the lower radiator hose clamp from the

transmission hanger B.

L

8 x 1 .25 mm22Nm12.2kgl'm�,

LOWER RADIATORHOSE CLAMP

16 rbtft)

13-48

7.

Bemove the wire harness clamps.

Disconnect the starter motor cables and the vehicle

speed sensor (VSS) connector.

8 x 1.25 mm8.8 N.m (0.9 kgf.m,6.5 tbtftl

STARTERMOTORCABLES

8. Remove the clutch line bracket and the slav6 cylin-

oer.

NOTE: Do not operate the clutch pedal once the

slave cylinder has been removed.

\J

Page 1596 of 2189

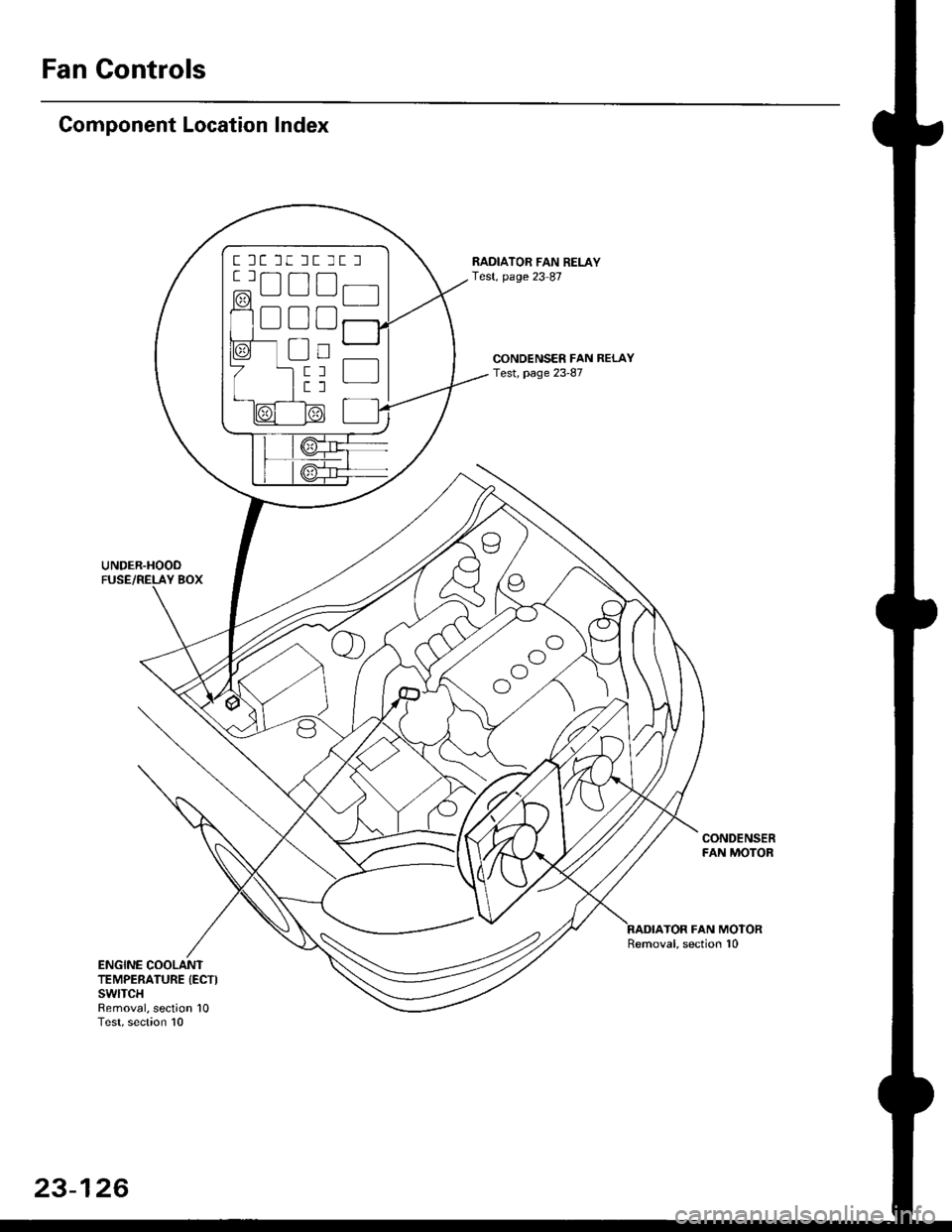

Fan Controls

Component Location Index

UNDER.HOOO

CONDENSER FAN RELAYTest, page 23-87

RADIATOR FAN RELAYTest, page 23 87

CONDENSERFAN MOTOR

TOR FAN MOTORRemoval, section 10

ENGINE COOLANTTEMPERATURE (ECTI

swtTcHRemoval, section 10Test, section l0

t lt lt lt tt l

tlTtlnr-l

mU!L-Jfl_l'1 - f-t t-_l -

I L--J L__J LJ f-----"1

o

^o

o"l

23-126

Page 1718 of 2189

Cruise Control

t

D=

t

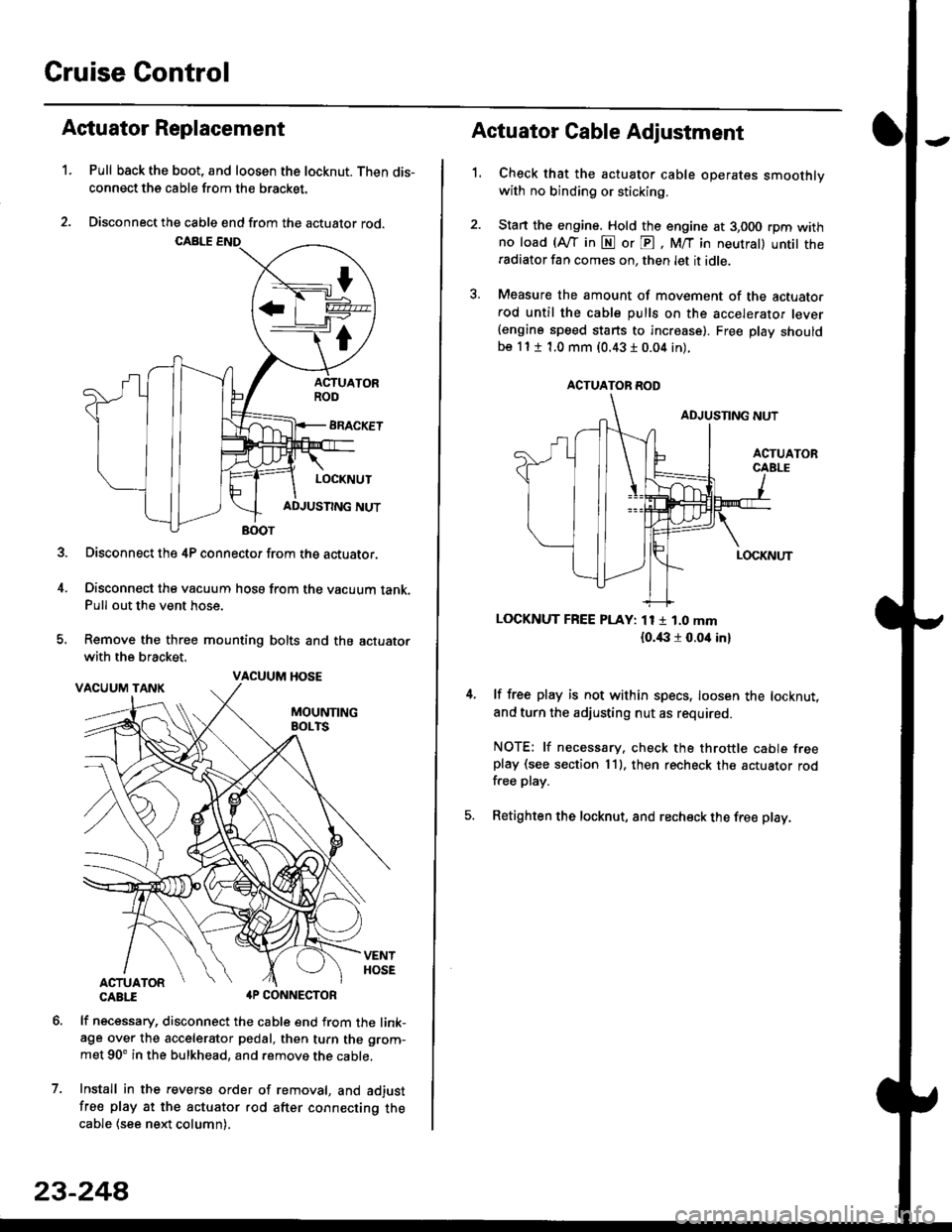

Astuator Replacement

1.Pull back the boot, and loosen the locknut. Then dis-

connect the cable from the bracket.

Disconnect the cable end from the actuator rod.

Disconnect the 4P connector from the actuator.

Disconnect the vacuum hosa from the vacuum tank.Pull out the vent hose.

Remove the three mounting bolts and the actuator

with the bracket.

CABTI aP CONNECTOR

lf necessary, disconnect the cable end from the link-age over the accelerator pedal, then turn the grom-

met 90' in the bulkhead, and remove the cable,

Install in the revers€ order of removal, and adjust

free play at the actuator rod after connecting thecable (see ne)d column).

7.

VACUUM HOSE

23-244

1.

Actuator Cable Adjustment

Check that the actuator cable operates smoothlywith no binding or sticking.

Stan the engine. Hold the engine at 3,000 rpm withno load (Afl'in N or E, M/T in neutral) untit theradiator fan comes on, then let it idle.

Measure the amount of movement of the actuato.rod until the cable pulls on the accelerator lever(engine speed starts to increase). Free Dlay shouldbe 11 t 1.0 mm (0.43 I 0.04 in).

LOCKNUT FREE PLAY: 11 1 1.0 mm

{o.i|:l r 0.oit in}

lf free play is not within specs, loosen the locknut,

and turn the adjusting nut as required.

NOTE: lf necessary. check the throttle cable freeplay (see section 11). then recheck the actuator rodfree play.

Retighten the locknut, and recheck the free play.

ACTUATOR ROD