ect sensor HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 681 of 2189

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 691 of 2189

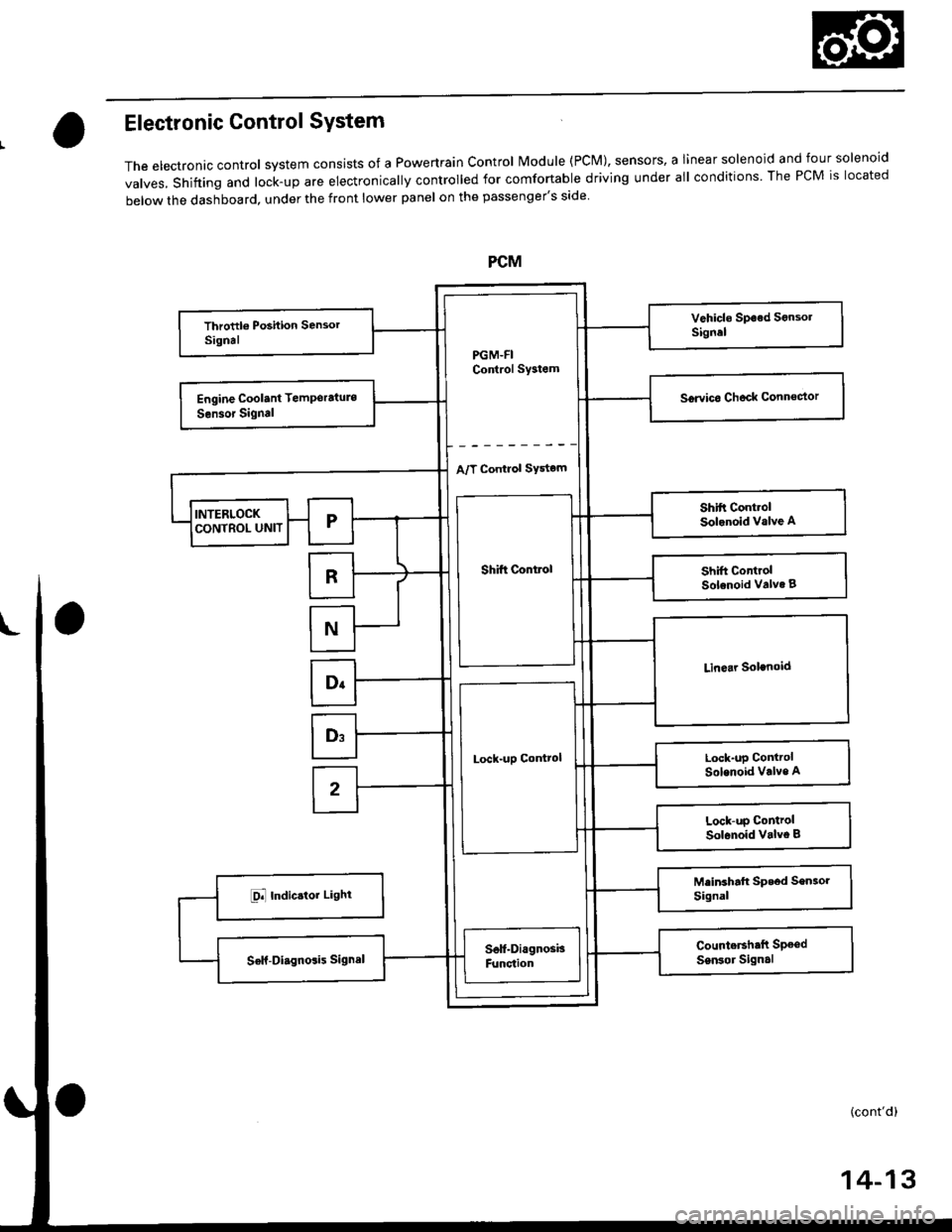

Electronic Control SYstem

The electronac controt system consrsts of a Powertrain control Module (PcM), sensors, a Iinear solenoid and four solenoid

valves, shifting and lock-up are electronically controlled for comfortable driving under all conditions The PCM is located

below the dashboard, under the front lower panel on the passenger's side

PGM-FIControl Sy3tem

A/T Control SYstom

Shift Control

Lock-uD Control

14-13

Page 692 of 2189

Description

Electronic Control System (cont'd)

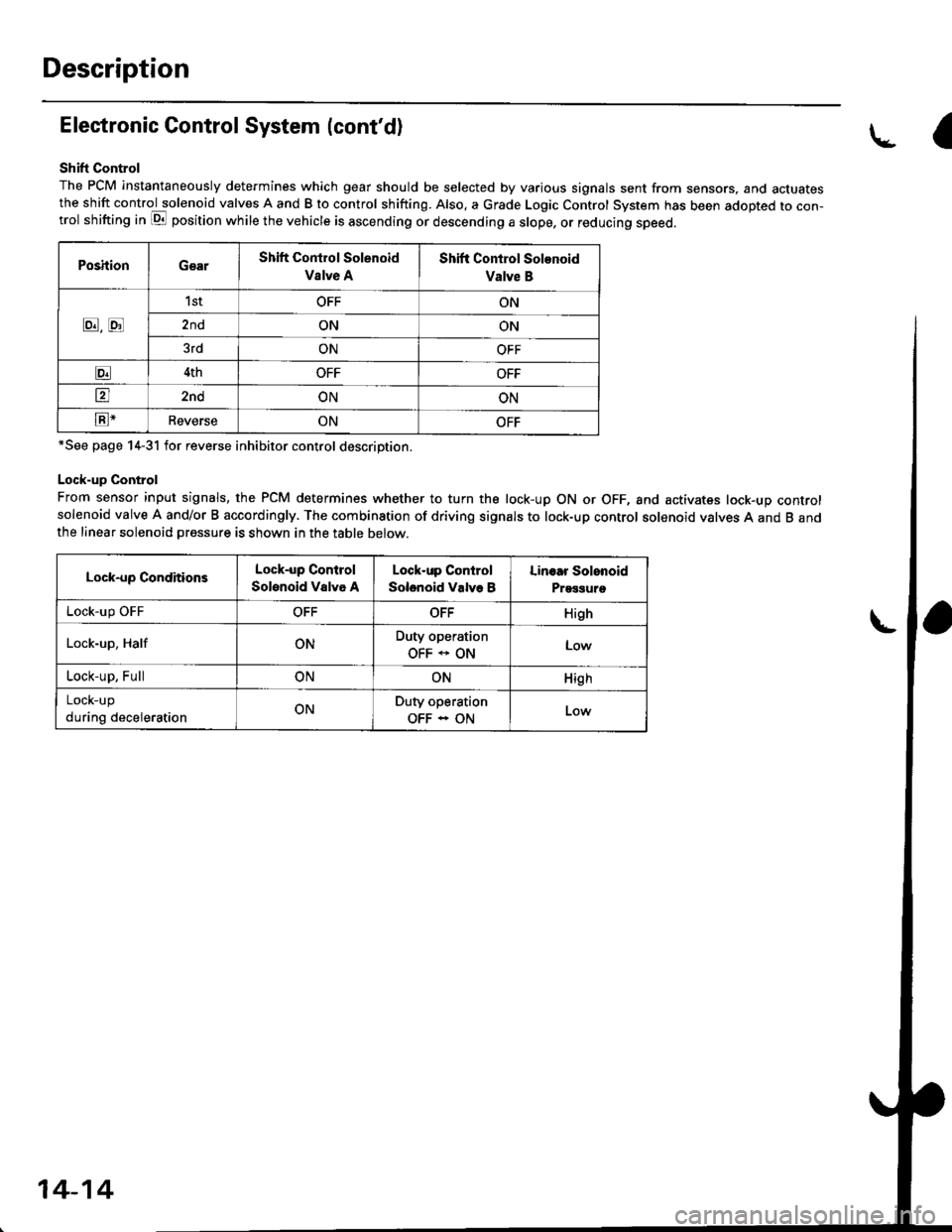

Shift Control

The PCM instantaneously determines which gear should be selected by various signals sent from sensors, and actuatesthe shift control solenoid valves A and B to control shifting. Also. a Grade Logic Control System has been adopted to con-trol shifting in E position while the vehicle is ascending or descending a slope, or reducing speed.

PoshionGearShift Control Solenoid

Vslve A

Shift Control Solenoid

Valve B

8,tr

1stOFFON

2ndONON

3rdONOFF

E4thOFFOFF

tr2ndONON

E-ReverseONOFF

*See page 14-31 for reverse inhibitor control description.

Lock-up Control

From sensor input signals, the PCM determines whether to turn the lock-up ON or OFF, and activates lock-up controlsolenoid valve A and/or B accordingly. The combination of driving signals to lock-up control solenoid valves A and B andthe linear solenoid pressure is shown in the table below.

Lock-up ConditionsLock-up Control

Solenoid Valvo A

Lock-up Control

Solenoid Valve B

Linoar Solonoid

Prggguro

Lock-up OFFOFFOFFHigh

Lock-up, HalfONDuty operation

OFF * ONLow

Lock-up, FullONONHigh

LOCK-Up

during decelerationONDuty operation

OFF - ON

a

14-14

Page 693 of 2189

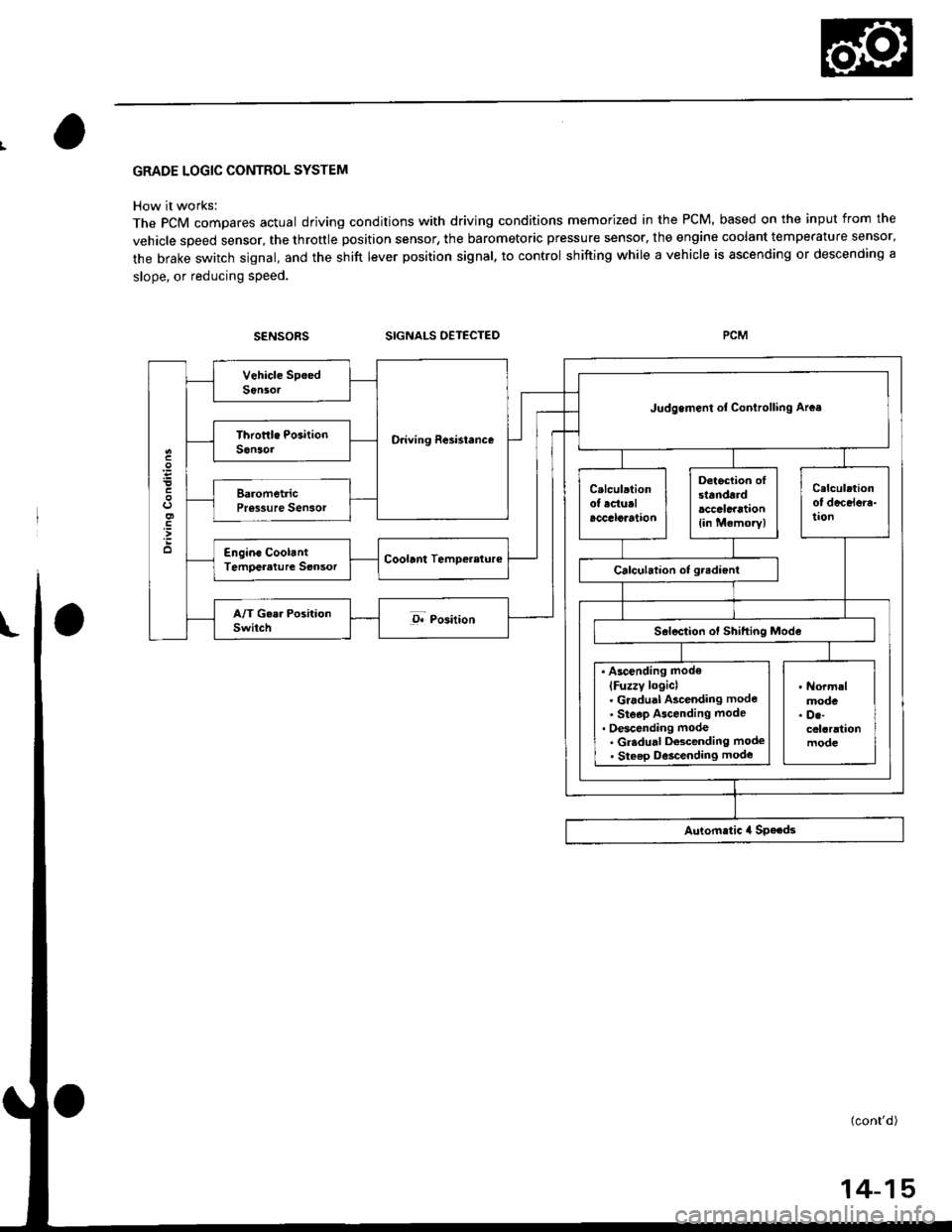

GRADE LOGIC CONTROL SYSTEM

How it works:

The pCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, the throttle position sensor, the barometoric pressure sensor, the engine coolant temperature sensor,

the brake switch signal, and the shift lever position signal, to control shifting while a vehicle is ascending or descending a

slope, or reducing speed.

SIGNALS OETECTED

O.iving Resi3lence

Judgemenl ot Conirolling Arca

. Ascending mod€

lFuzzy loqicl. Gradual Ascending mode' Ste€p Ascending mode. Oescending mode. Gr.du.l Descending mode. Steep D6cending mode

14-15

Page 719 of 2189

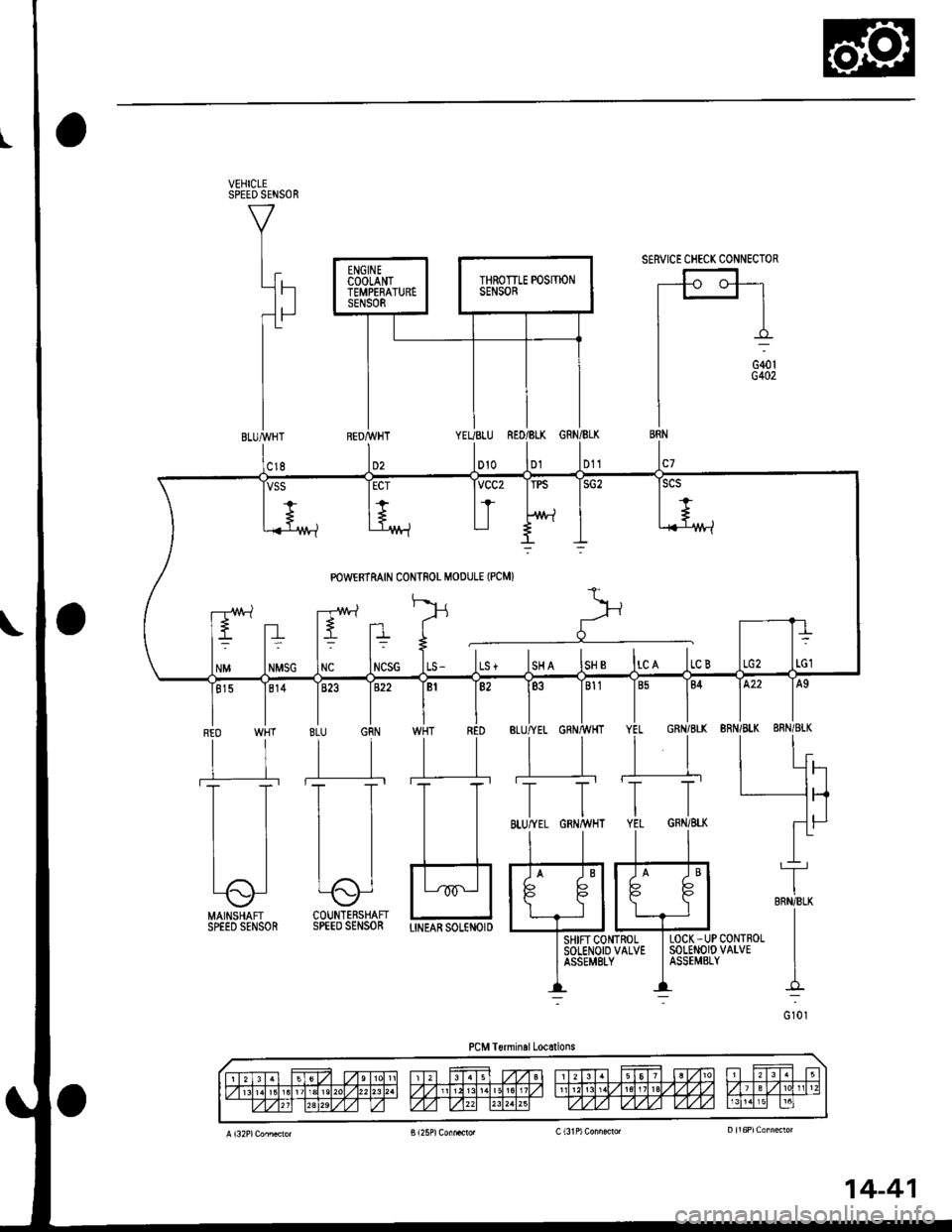

SERVICE CHECK CONNECTOR

LOCK -UP CONTROLSOLENOIO VALVEASSEMELY

RED WHT

tlll'

IT

tl

ll

Lo-l

MAINSHAFTSPEED SENSOR

TBRNiBLK

I

I

I-

G 101

NCSG ILS - ILS + ISH A ISH B ltc A ltc B

SHIF'CONTROLSOTENOID VALVEASSEMEI-Y

PCM Terminel Locations

14-41

Page 721 of 2189

I

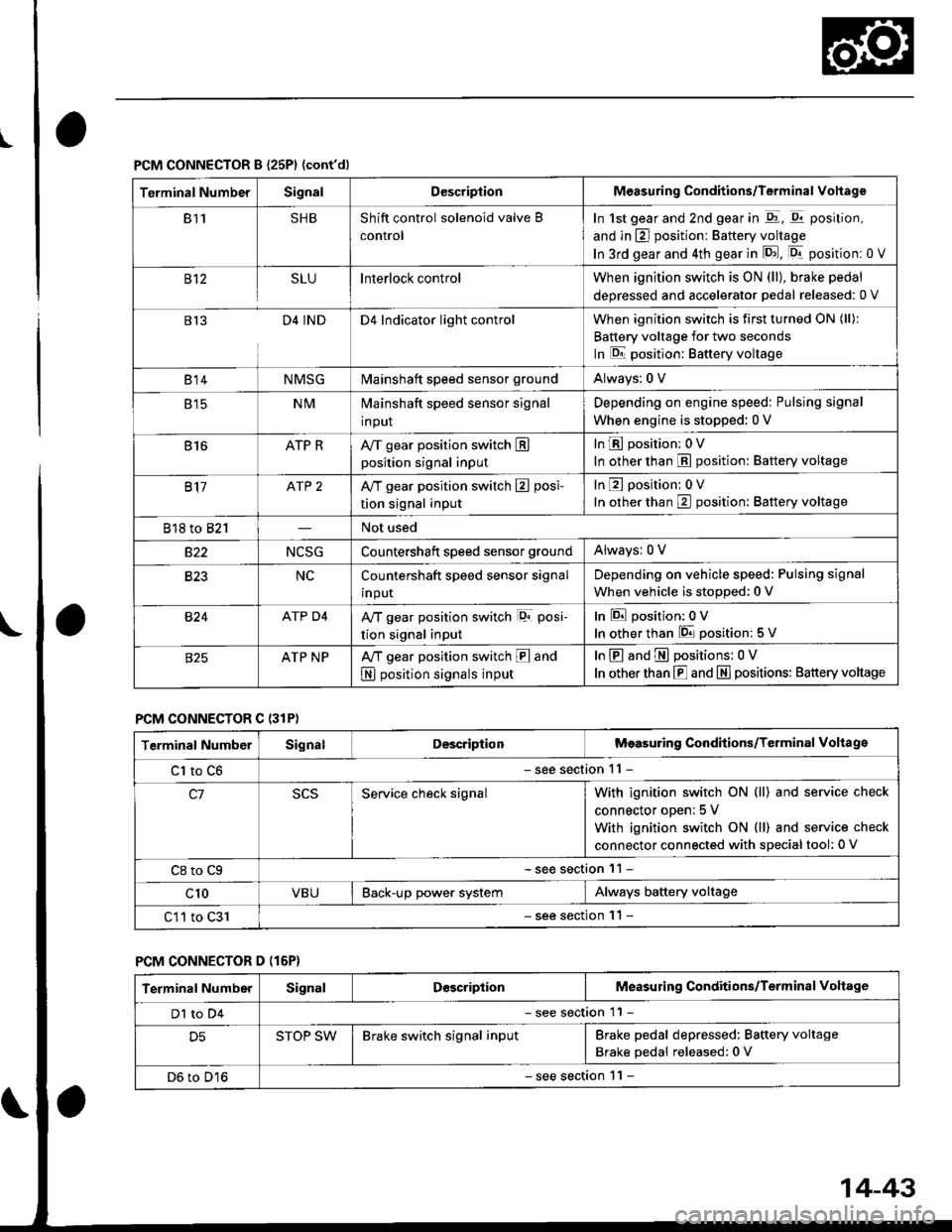

PCM CONNECTOR B {25P1 {cont'dl

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Vohage

811SHBShift control solenoid valve B

control

In 1st gear and 2nd gear in -q1, q11 position,

and in E] position: Battery voltage

In 3rd gear and 4th gear in lD.J, [Dr- position: 0 V

B't2SLUInterlock controlWhen ignition switch is ON (ll), brake pedal

deoressed and accelerator Dedal released: 0 V

813D4 INDD4 Indicator light controlWhen ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Baftery voltage

B't 4NMSGMainshaft speed sensor groundAlways: 0 V

E tcNMMainshaft speed sensor signal

input

Depending on engine speed: Pulsing signal

When engine is stopped: 0 V

816ATP RAy'T gear position switch Eposition signal input

InE position: 0V

In other than E position: Battery voltage

817ATP 2A/T gear position switch E posi-

tion signal input

InE position: 0V

In orher than E position: Battery voltage

818 to 821Not used

s22NCSGCountershatt speed sensor groundAlwaysr 0 V

B�23NCCountershaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stopped: 0 V

B�24ATP D4Ay'T gear position switch lor posi-

tion signal input

InEposition:0V

In other than 6 position: 5 V

ATP NPA,/T gear position switch E and

N position signals input

InE and E positions: 0V

In otherthan E and N] positions: Battery voltage

PCM CONNECTOR C {31P)

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

Cl to C6- see section 11 -

c1Service check signalWith ignition switch ON (ll) and service check

connector oDen; 5 V

With ignition switch ON (ll) and service check

connector connected with sDecial tool: 0 V

C8 to Cg- see section 11 -

c10VBUBack-up power systemAlways battery voltage

C11 to C31- see section '11 -

PCM CONNECTOR D (16P}

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

Dl to D4- see section 11 -

D5STOP SWBrake switch signal inputBrake pedal depressed: Battery voltage

Brake pedal released: 0 V

D6 to D16- see section 1 l -

14-43

Page 725 of 2189

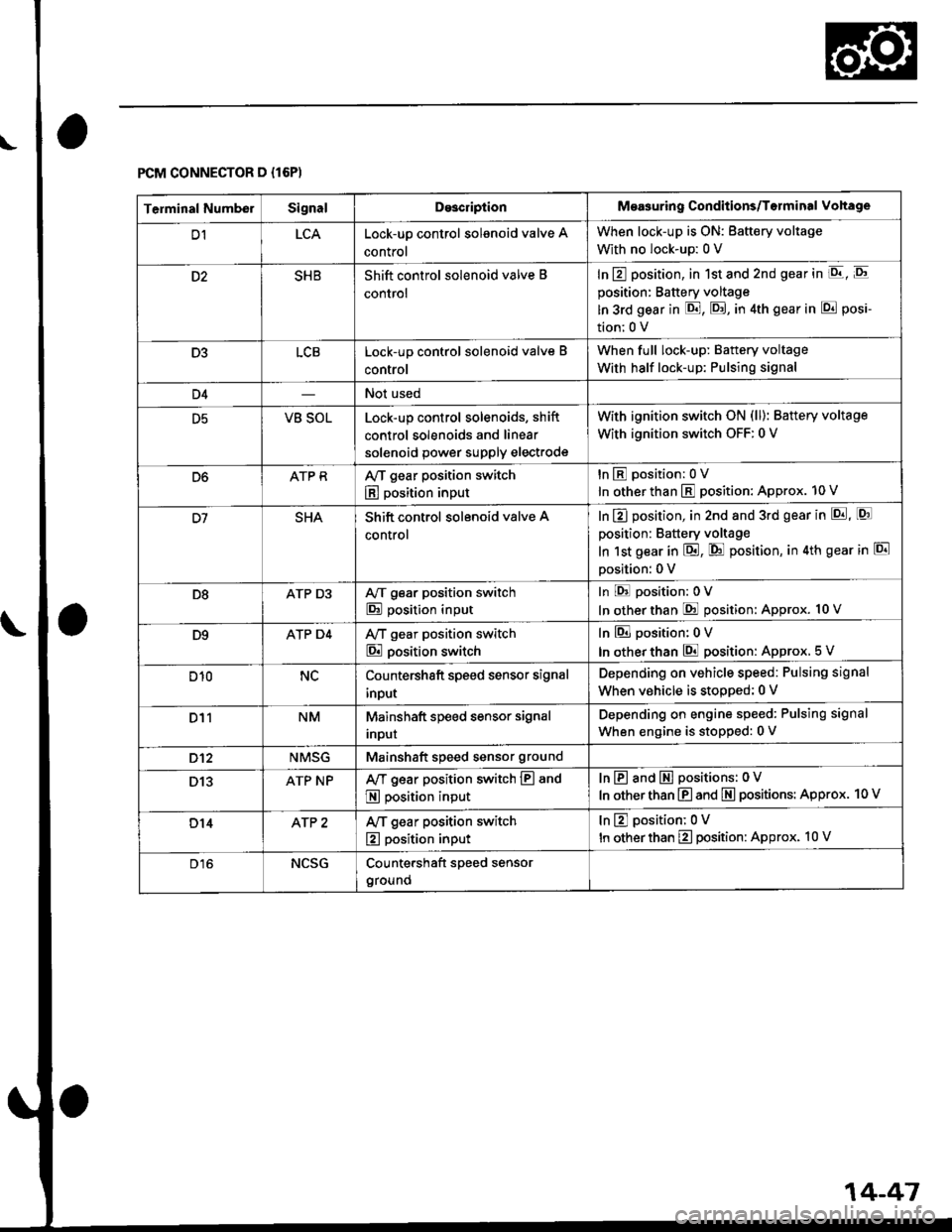

FCM CONNECTOR D {16P)

\o

14-47

Terminal NumberSignalDo3criptionMeasuring Conditions/Torminal Vohage

D1LCALock-up control solenoid valve A

control

When lock-up is ON: Battery voltage

With no lock-up: 0 V

SHBShift control solenoid valve B

control

In E position, in 1st and 2nd gear in E, E

position: Battery voltage

ln 3rd gear in E, E, in 4th gear in E posi-

tion;0 V

D3LCBLock-up control solenoid valve B

control

When full lock-up: Battery voltage

With half lock-up: Pulsing signal

D4Not used

D5VB SOLLock-up control solenoids, shift

control solenoids and linear

solenoid power supply electrode

with ignition switch oN (ll): Battery voltage

With ignition switch OFF: 0 V

D6ATP RAy'T gear position switch

E position input

tnEposition:0V

In other than E position: Approx. 10 V

SHAShift control solenoid valve A

control

In E] position, in 2nd and 3rd gear in p!, [Q]

position: Battery voltage

In 1st gear in E, @ position, in 4th gear in El

Dosition: 0 V

D8ATP D3A/T gear position switch

E position input

In E position:0V

In otherthan @ position: Approx. 10 V

D9ATP D4Ay'T gear position switch

E position switch

In El position: 0 V

In other than E position: Approx. 5 V

D10NCCountershaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stooped: 0 V

D11NMMainshaft speed sensor signal

Inpur

Depending on engine speed: Pulsing signal

When engine is stopped: 0 V

D't2NMSGMainshaft speed sensor ground

D13ATP NPAy'T gear position switch E and

E position input

InE and E positions: 0V

In other than E and E positions: Approx. 10 V

D14AfP 2Ay'T gear position switch

E position input

tnEposition;0V

In other than E position: Approx. 10 V

D16NCSGCountershaft speed sensor

ground

Page 730 of 2189

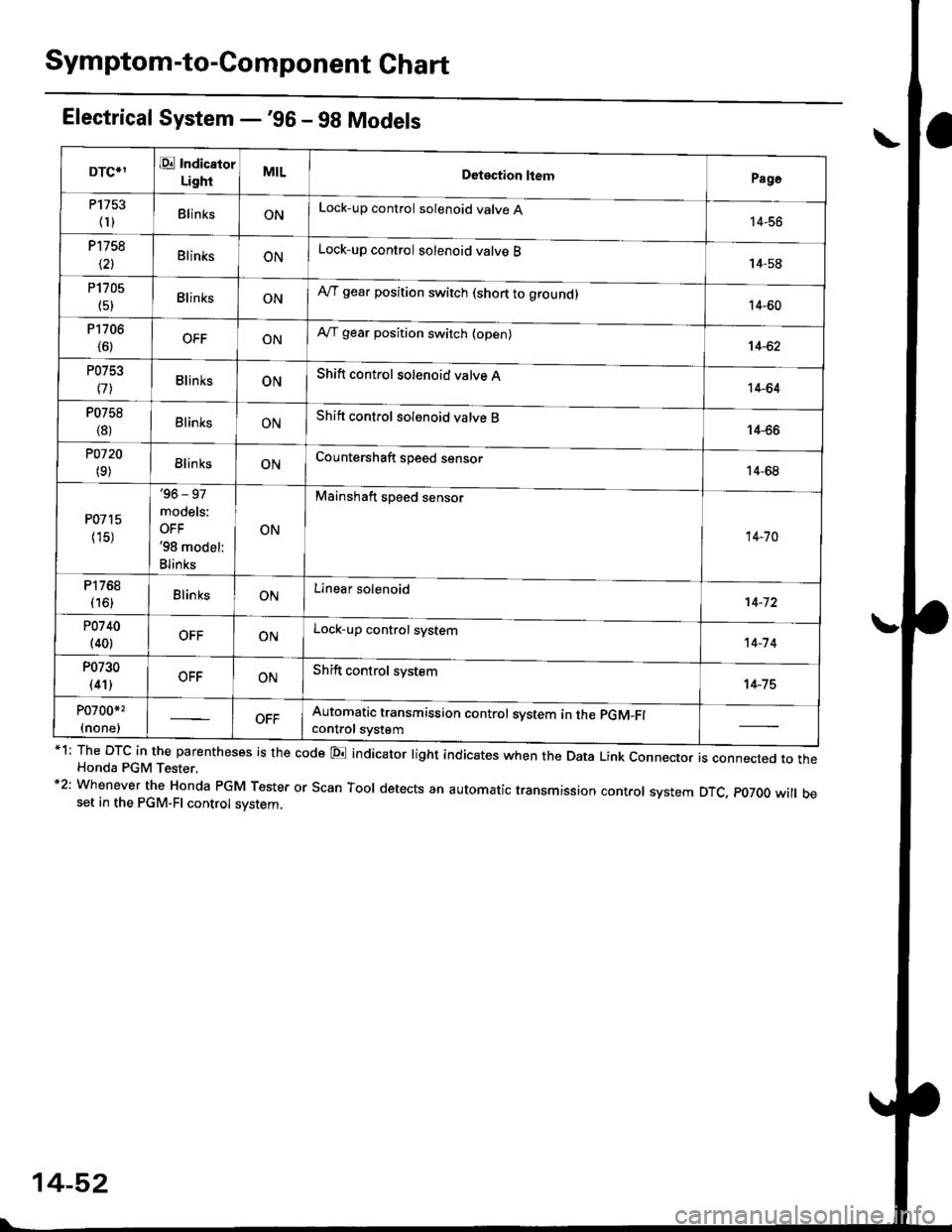

Symptom-to-Component Ghart

Electrical System -'gG - 98 Models

*1: The DTC in the parentheses is the code E indicator light indicates when the Data Link connector is connected to theHonda PGM Tester.*2: Whenever the Honda PGM Tester or Scan Tool detects an automatic transmission control system DTC, p07OO will beset in the PGM-FI control svstem.

DTCIIE Indicaior

LightMILDotection ltemPage

P1753

fl)BlinksONLock-up control solenoid valve A14-56

P1758

\21BlinksONLock-up control solenoid valve B14-58

P1705

(51BlinksONAy'T gear position switch (short to groundl14-60

P1706

(6)OFFONA,/T gear position switch (open)14-62

P0753

l7lBlinksONShift control solenoid valve A14-64

P0758

{8)ElinksONShift control solenoid valve B14-66

POl20

(9)BlinksONCountershaft speed sensor14-68

P0715

{15)

'96 - 97

models:

OFF'98 model:

Blinks

ON

Mainshaft speed sensor

14-70

P1768

{16)BlinksONLinear solenoid't 4-72

P0740

(40)OFFONLock-up control system14-7 4

P0730

(41)OFFONShift control system14-75

P0700*,

(none)Automatic transmission control svstem in the pGM-Fl

control svstem

14-52

Page 732 of 2189

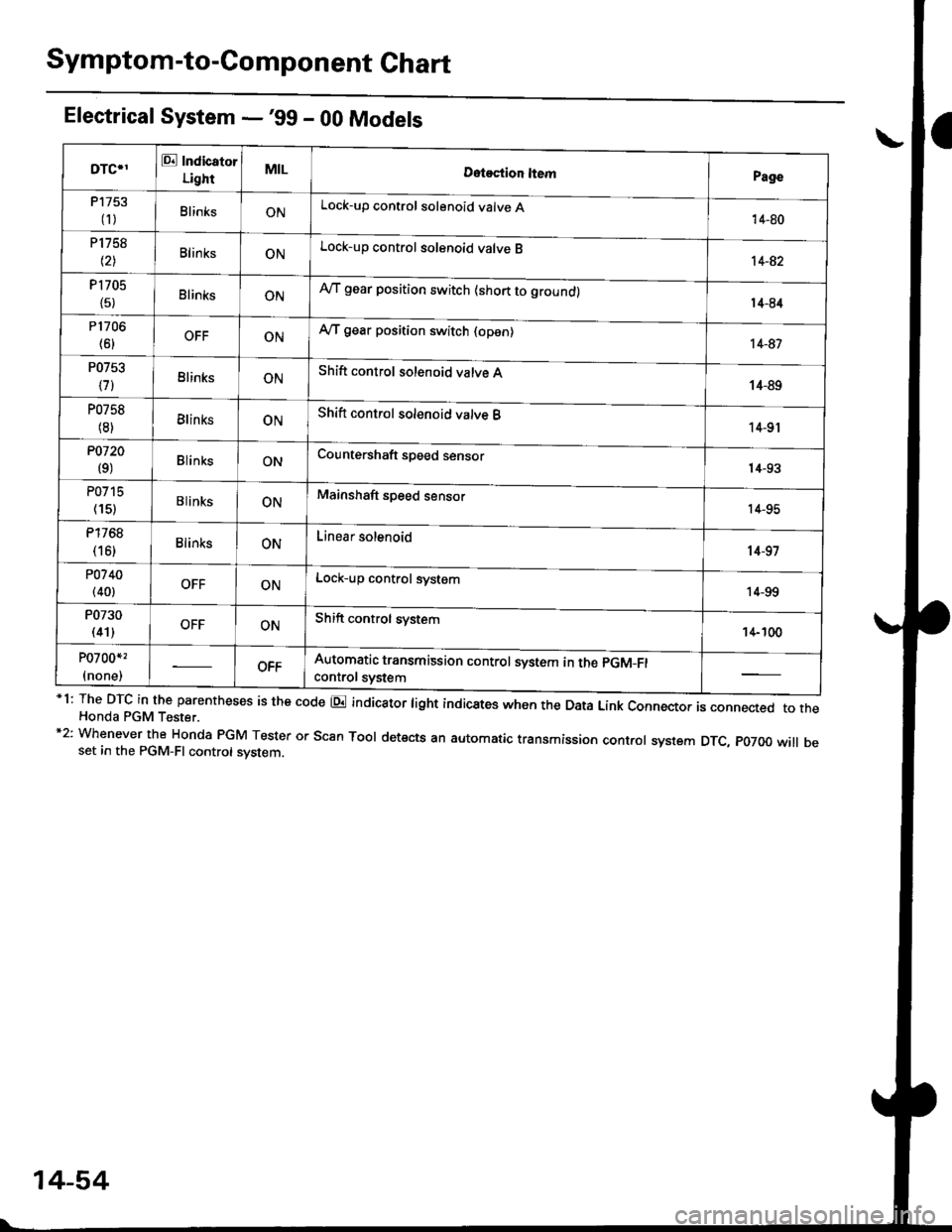

Symptom-to-Component Chart

Electrical System -'99 - 00 Models

*1: The DTc in the parentheses is the code E indicator tight indicates when the Data Link connector is connected to theHonda PGM Tester.*2: Whenever the Honda PGM Tester or scan Tool detects an automatic transmission control system DTc, p07oo will beset in the PGM-FI control svstem

DTC*IE Indicator

LightMILDotostion ltemPage

P1753

fi)BlinksONLock-up control solenoid valve A'14-80

P1758

t2lBlinksONLock-up control solenoid valve B14-82

P1705

{5}BlinksONAy'T gear position switch {short to ground)14-84

P1706

(6)OFFONy'VT gear position switch {open)14-81

P0753

\71BlinksONShift control solenoid valve A14-89

P0758

(8)BlinksONShift control solenoid valve B14-9r

P0720

(9)BlinksONCountershaft speed sensorr4-93

P0715

(15)B linksONMainshaft speed sensor14-95

P1768

(16)BlinksONLinear solenoid't 4-97

PO7 40(40)OFFONLock-up control system14-99

P0730

(41)OFFONShift control svstem14- 100

P0700*,

(none)OFFAutomatic transmission control system in the pGM_Fl

controt svstem

14-54

Page 746 of 2189

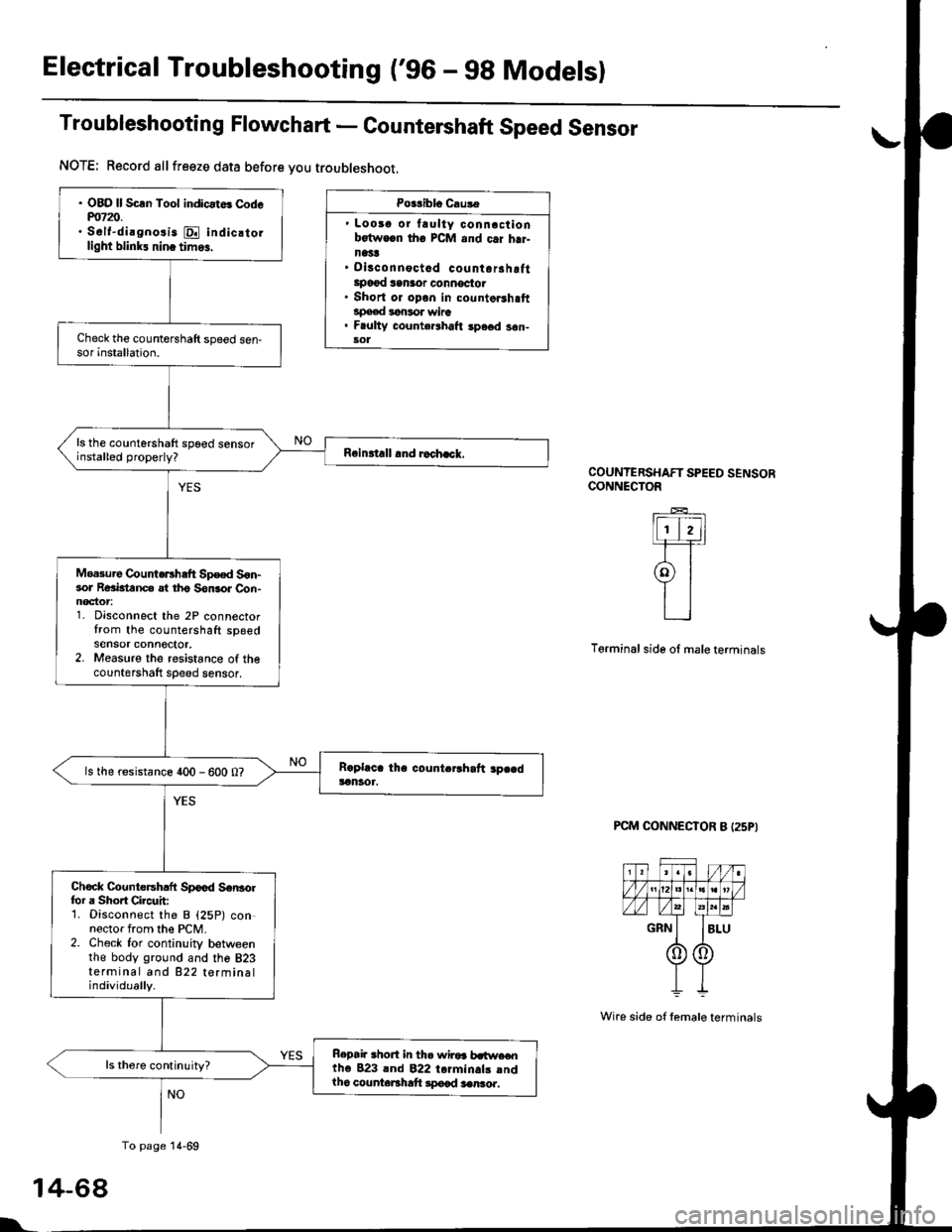

Electrical Troubleshooting ('gO - 98 Modelsl

Troubleshooting Flowchart - Countershaft Speed Sensor

Po$iblo Causa

' Loosg or laulty conncctionbotwocn tho PCM and c.i hrr-n1't!' Disconnoctad countorahottlpo€{ san3or oonnoctot. Short or opon in countorshaftspeed lonsor wire. F ulty counte.lhalt spe6d s6n-sol

COUNTERSHAFT SPEED SENSORCONNECTOR

lFI,]1-F=r

9l

L_l

Terminal side ol male terminals

PCM CONNECTOR B I25P}

1

l'

NOTE; Record allfreeze data before you troubleshoot.

. OBO ll Scln Tool indicat6 Codem7z).. S6lt-dirgnosis E indic.tollight blink! nin. tim6,

ls the countershaft spoed sensorinstalled properly?

Moa3ure CountoEhaft Sp€ed S6n-sor Reaktanc€ at tho Son3or Con-noctor1. Disconnect the 2P connectortrom the countershaft spgedsensor connector,2. Measure the resistance of thecountershaft sDeed sensor,

ls the resistance 400 - 600 0?

Chock Countersh.ft Spood Scr|3olfor a Shoft Circuit:1. Disconnect the B {25P) connector from the PCM.2. Check for continuity betweenthe body ground and the 823terminal and 822 terminalindividually.

Repai. .hort in th. wiroa b.t$re€ntho 823 lnd 822 torminals .ndlho counteBhaft lpocd aenro..

To page 14-69

4-68

Wire side of temale terminals