Section 11 HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1440 of 2189

Troubleshooting

Gompressor (cont'dl

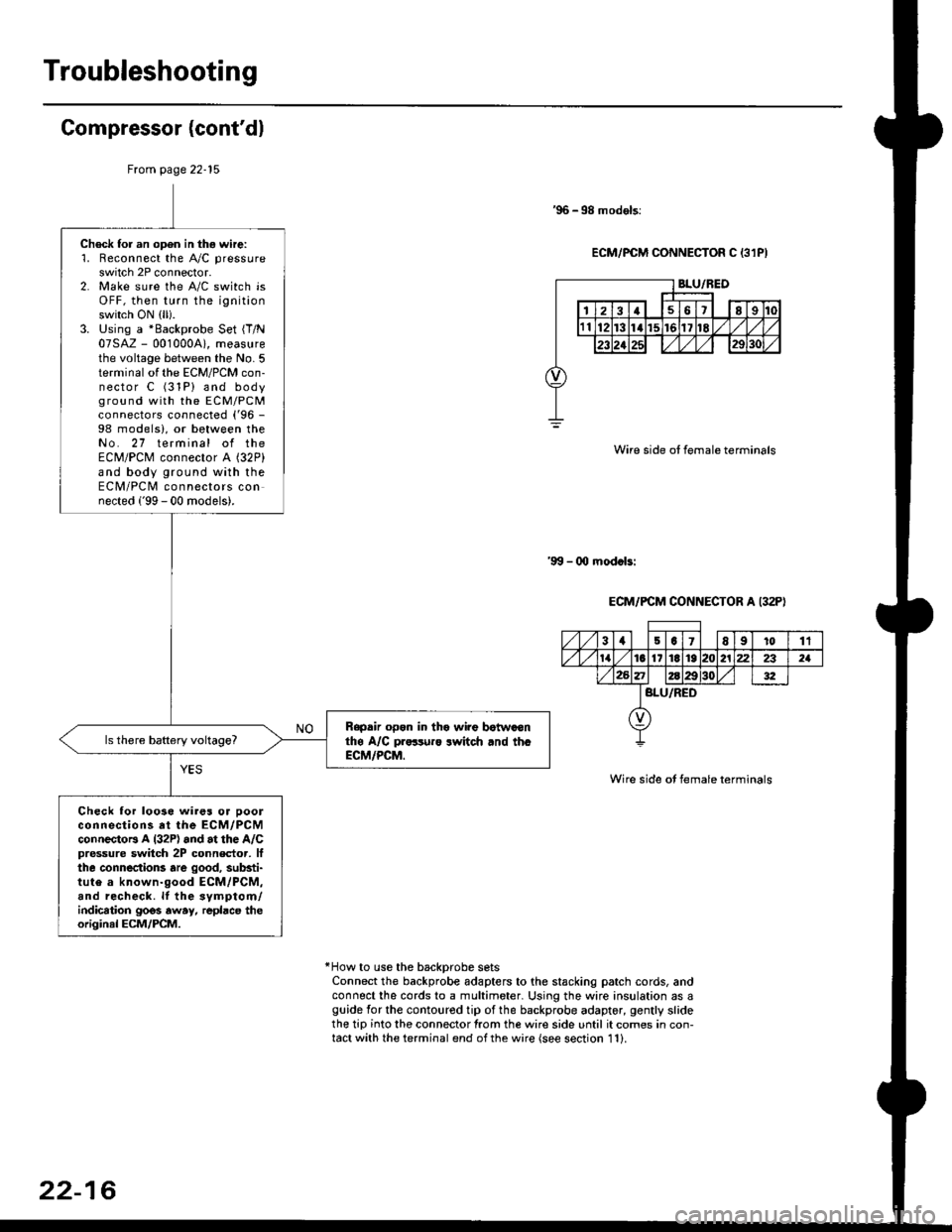

'96 -98 models:

ECM/PCM CONNECTOR C 13lPI

Wire side ot female terminals

'9!t - 00 mod.bi

ECM/PCM CONNECTOR A I32P)

Wire side ot female terminals

*How to use the backprobe setsConnect the backprobe adapters to the stacking patch cords, andconnect the cords to a multimeter. Using the wire insulation as aguide for the contoured tip of the backprobe adapter, gently slidethe tip into the connector from the wire side until it comes in con-tact with the terminal end ofthe wire {see section 11}.

From page 22-15

Check for an open in thg wire:'1. Reconnect the A"/C pressure

switch 2P connector.2. Make sure the A/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set {T/N07SAZ - 001000A), measurethe voltage between the No. 5terminal of the ECM/PCM con-nector C (31P) and bodyground with the EcM/PcMconnectors connected ('96 -

98 models), or between theNo. 27 terminal of theECM/PCM connector A (32P)

and body ground with theECM/PCM connectors connected ('99 - 00 models).

Rapdir open in tho wi?e botwaonthe A/C pr..-ruro lwitch rnd th.ECM/PCM.

Check lor loo3e wires or ooolconnections at the ECM/PCMconnectoB A l32P) and at the A/Cpressure switch 2P connector, lfthe connections are good, substi-tute a known-good ECM/PCM,and recheck. lf the svmptom/indication goos away, repbce theoriginal ECM/PCM.

31501E91011

tat6l11E1921222321

BLU/RED

22-16

Page 1443 of 2189

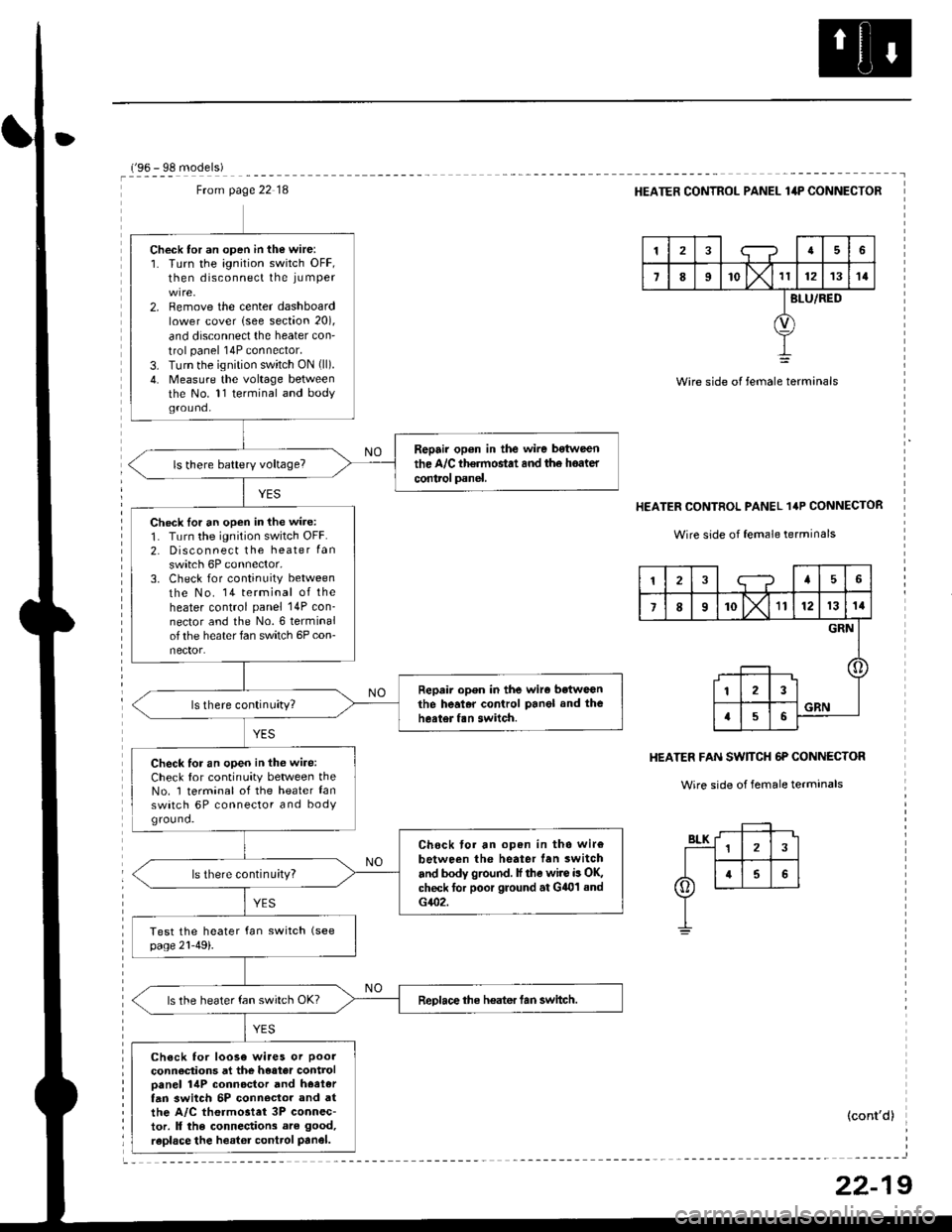

Ftom page 22 18

Check tor an open in the wire:1. Turn the ignition switch OFF,then disconnect the iu mper

2. Remove the center dashboardlower cover lsee section 20),

and disconnect the heater con'

trol panel 14P connector.

3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe No. 11 terminal and bodyground.

Repair op6n in the wire bstween

the A/C th€rmostat and th6 hoater

control panel.

Check lor an open in the wire:

1. Turn the ignition switch OFF.2. Disconnect the heater Ian

switch 6P connector,3. Check for continuity between

the No. 14 terminal of theheater control panel 14P con_nector and the No.6 terminalof the heater fan switch 6P con-nector.

Repair open in the wiro betweGnthe heal.r control Panel and theheater fan switch.

Check for an open in thG wire:Check for continuity between theNo. 1 terminal of the heater lanswatch 6P connector and bodYground.

Chock tor an open in tho wir€

between the heater lan switch

and body ground. lf the wire is OK,check for poor ground at G401 sndG402.

ls there continu;ty?

ReDlace the heater tan switch.ls the heater fan switch OK?

Check for loose wiaes or poor

connections at the heater controloanel 14P connoctor and hoetertan 3witch 5P conn€clor and atthe A/C thermostet 3P connec-tor. ll the connections are good,

raplace the heator control Panel.

r'oA - qe m^.lalal

HEATER CONTROL PANEL lilP CONNECTOR

tra6

7II'o lx't1121314

BLU/RED

Wire side of female terminals

HEATER CONTROL PANEL 1'P CONNECTOR

Wire side of female terrninals

HEATER FAN SW]TCH 6P CONNECTOR

Wire side of female terminals

(cont'd)

12;--?45

7I10X'll121314

GRN

123

a56GRN

22-19

Page 1452 of 2189

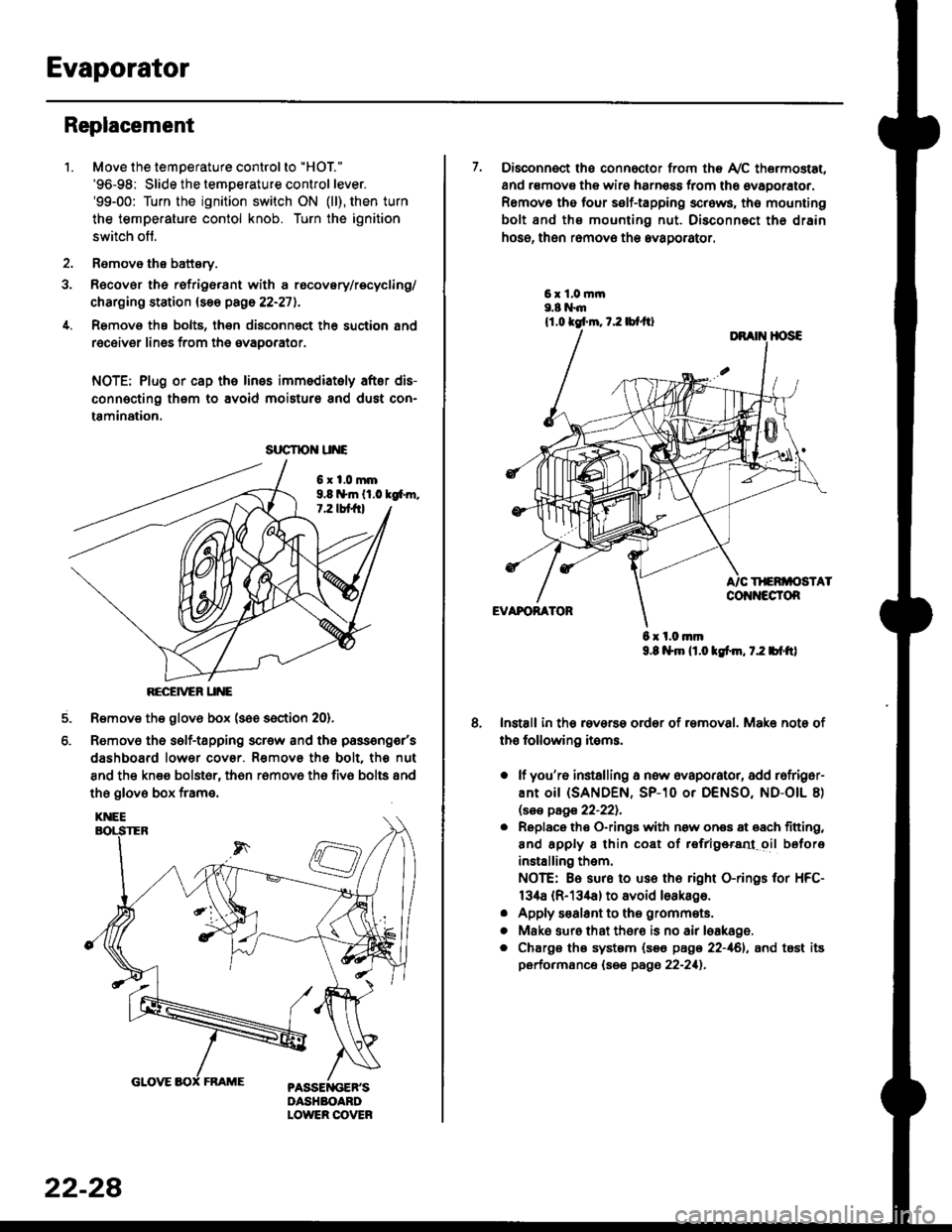

Evaporator

1.

Replacement

4.

Move the temperature control to "HOl"

'96-98: Slide the temoerature control lever.'99-00: Turn the ignition switch ON (ll), then turn

the temperature contol knob. Turn the ignition

switch off.

Remove the battsry.

Rgcover the refrigerant with a rocovery/recycling/

charging station (see page 22-271.

Remove the bolts, then disconnect th6 suction 8nd

receiver lines from th6 evaoorator.

NOTE: Plug or cap the lines imm€diatoly after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm9.8 n*ln ll.0 tg6m.7.2 lbt frl

RECEiVER UNE

Remove the glov6 box (see section 20).

Removo the self-tapping scr€w and the passeng€r's

dashboard lower cover. Removs the bolt. the nut

8nd the kn€e bolst6r, th6n r6mov6 th6 fiv6 bolts and

the glove box frame.

6.

srrcrrc u E

22-28

7. Disconnect the connector from th€ Ay'C thermostat,

and r€movs the wire harness from the ovaporator.

Remov6 tho four self-tapping screws, tho mounting

bolt and ths mounting nut. Disconnect th€ drain

hose, then remov€ th6 avagorator.

6 x l.0.nm9.8 l$m lt.o ldm, 7.2 bl.tt)

Install in the reverse order of removal. Make note of

th€ following items.

o lf you'r6 installing a new evaporator, add rofriger-

ANt OiI {SANDEN, SP-10 Or DENSO, ND-OIL 8)

lsas page 22-221.

. Replace the O-rings with now ones 8t 68ch titting,

and apply 8 thin coat of r€frlgersd oil before

installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid loakago.

. Apply s€alant to tha grommets.

. Mske sure that ther€ is no air leakage.

. Chargs ths system {s€€ page 22-161, and tost its

performance (see pags 22-211.

Page 1454 of 2189

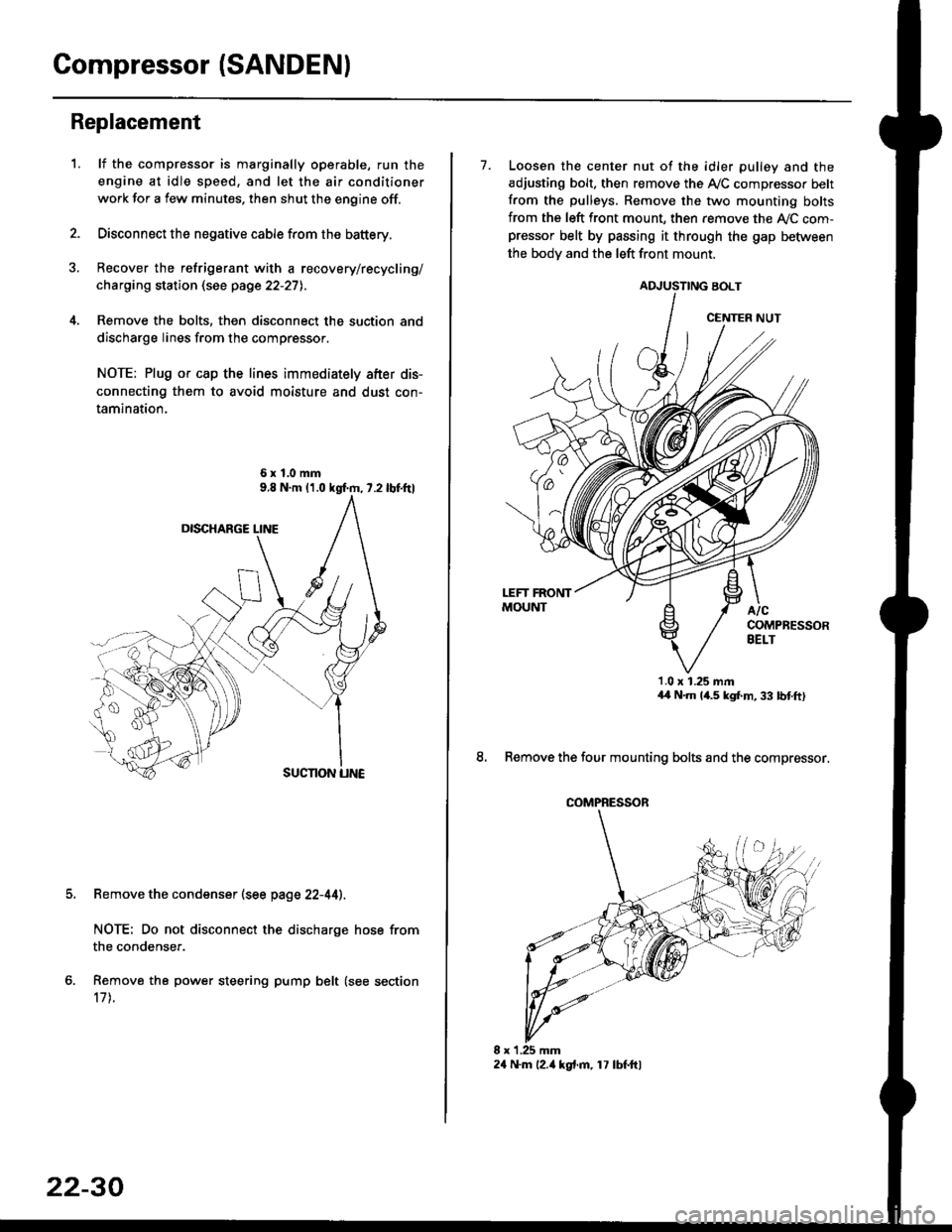

Compressor (SANDENI

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-27l..

Remove the bolts, then disconnect the suction and

discharge lines from the compressor.

NOTE: Plug or cap the lines immediately after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm

Remove the condenser (see page 22-44).

NOTE: Do not disconnect the discharge hose from

the condenser.

Remove the power steering pump belt (see section

17 t.

22-30

24 N.m l2.ia kgt.m, 17 lbf.ftl

7. Loosen the center nut of the idler pulley and the

adjusting bolt. then remove the A,/C compressor belt

from the pulleys. Remove the two mounting bolts

from the left front mount, then remove the ly'C com-pressor belt by passing it through the gap befiiveen

the bodv and the left front mount.

ADJUSTING BOLT

1.0 x 1.25 mmaa N.m 14.5 kgf,m, 33 bnft)

8. Remove the four mounting bolts and the compressor.

CENTER NUT

COMPRESSOR

Page 1455 of 2189

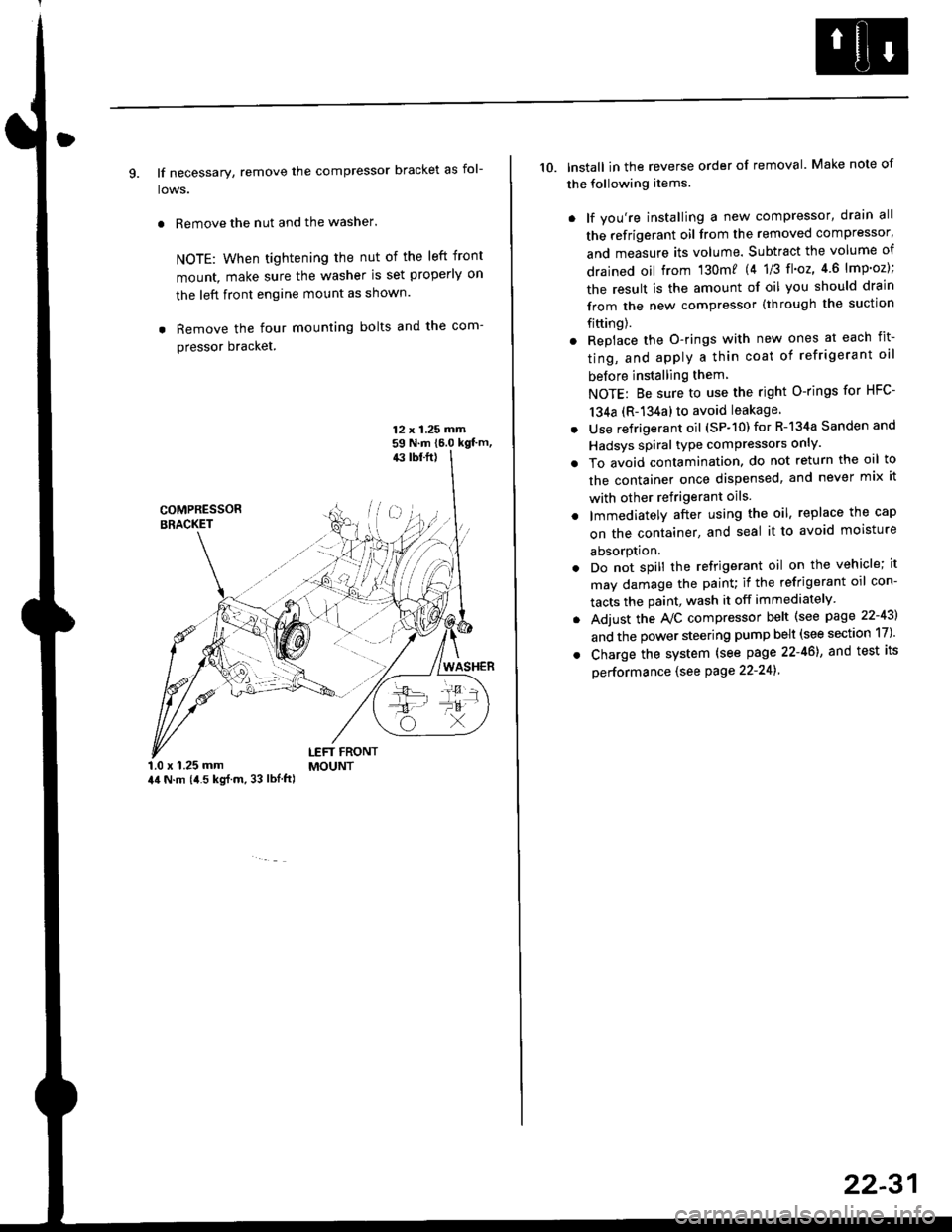

9. lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer.

NOTE: When tightening the nut of the left front

mount, make sure the washer is set properly on

the left front engine mount as shown.

. Remove the four mounting bolts and the com-

pressor bracket.

12 x 1.25 rrirn59 N.m 16.0 kgt'm,43 tbf.ft)

COMPRESSORBRACKET

WASHER

1.0 x 1.25 mm44 N.m (i1.5 kg{.m, 33 lbl.ft)

LEFT FRONTMOUNT

10. lnstall in the reverse order of removal. Make note of

the following items.

. lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume. Subtract the volume of

drained oil from '130m? 14 1/3 tl'o2,4 6 lmp'oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

fifting).

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage

. Use refrigerant oil (SP-10) for R-134a Sanden and

Hadsys spiral type compressors only'

o To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediatelY after using the oil, replace the cap

on the container, and seal it to avoid moisture

absorption.

. Do not spill the refrigerant oil on the vehicle; it

may damage the painu if the refrigerant oil con-

tacts the paint, wash it off immediately

. Adjust the Ay'C compressor belt (see page 22-43)

and the power steering pump belt (see section 17)'

. Charge the system (see page 22-46), and test its

oerformance (see Page 22-241

22-31

Page 1462 of 2189

Compressor (DENSOI

Replacement (cont'd)

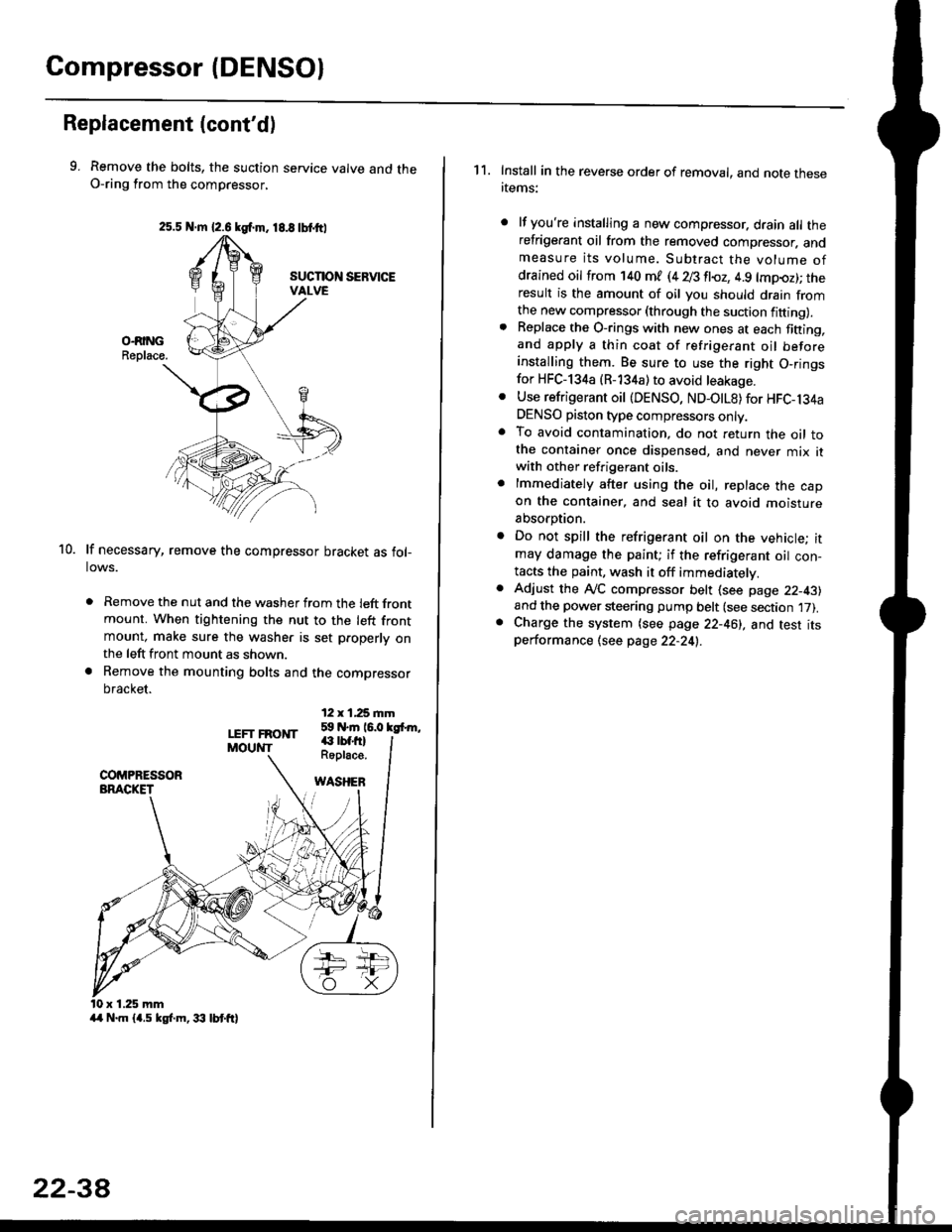

9. Remove the bolts, the suction service valve and theO-ring from the compressor,

lf necessary, remove the compressor bracket as fol-lows.

. Remove the nut and the washer from the left frontmount. When tightening the nut to the left frontmount, make sure the washer is set p.operly onthe left front mount as shown.

a Remove the mounting bolts and the compressor

bracket.

12 x 1,25 rnm59 N.m 16.0 kgfrm,

10.

LEFT FRONTMOUNT€ rbf.fi)Roplace.

WASHEB

x 1.25 mm

2s.5 N.m {2.6 kgf.m. 18.8 tbtttl

4/r N.m {4.5 kgf.m, 33 lbt ft}

22-3A

1 1. Install in the reverse order of removal, and note thesertems:

lf you're installing a new compressor. drain all therefrigerant oil from the removed compressor. andmeasure its volume. Subtract the volume ofdrained oil from '140 ml (4 28 fl{,z, 4.9 lmpoz); theresult is the amount of oil you should drain fromthe new compressor (through the suction fifting).Replace the O-rings with new ones at each fining,and apply a thin coat of refrigerant oil beforeinstalling them. Be sure to use the right O,ringsfor HFC-134a (R-134a) to avoid leakage.

Use refrigerant oil {DENSO, ND-OtL8) for HFC-134aDENSO piston type compressors only.To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refrigerant oils.

lmmediately after using the oil, replace the capon the container, and seal it to avoid moisture

absorption.

Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediatelv.

Adjust the ly'C compressor belt (see page 22-43)and the power steering pump belt (see section 17).Charge the system (see page 22-46), and test itsperformance (see page 22-24!..

Page 1471 of 2189

l'f .

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1555 of 2189

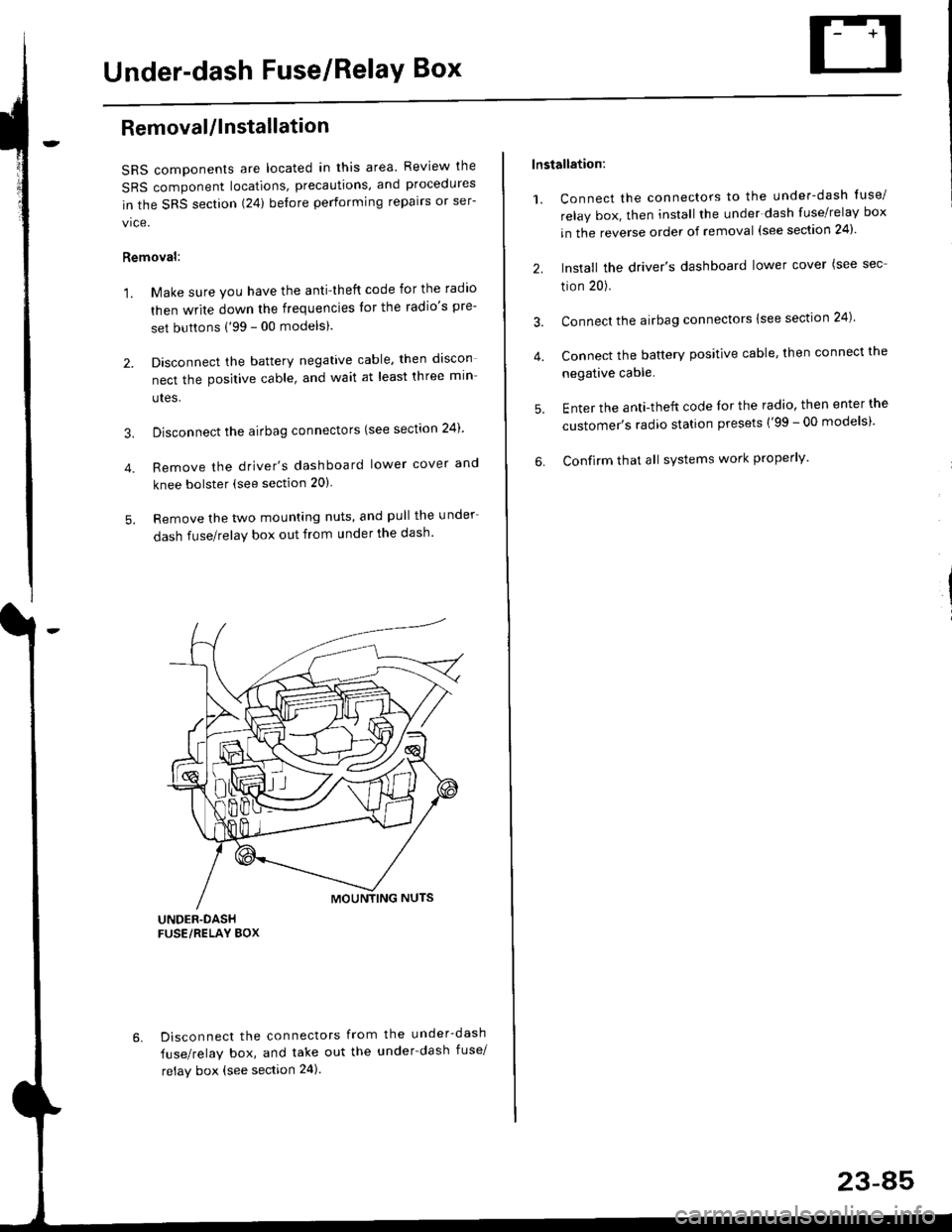

Under-dash Fuse/RelaY Box

Removal/lnstallation

SRS components are located in this area. Review lhe

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vice.

Removal:

1. Make sure you have the anti-lheft code for the radio

then write down the frequencies lor the radio's pre-

set buttons ('99 - 00 modelsl.

2. Disconnect the battery negative cable. then discon

nect the positive cable, and wait at least three min

utes,

3. Disconnect the airbag connectors (see section 24)'

4. Remove the driver's dashboard lower cover and

knee bolster (see section 20)

5. Remove the two mounting nuts, and pull the under

dash fuse/relay box out from under the dash'

6. Disconnect the connectors from the under-dash

fuse/relay box, and take out the under-dash fuse/

relay box (see section 24).

lnstallation:

1. Connect the connectors to the under-dash tuse/

relay box, then install the under dash fuse/relay box

in the reverse order of removal (see section 24)'

2. Install the driver's dashboard lower cover (see sec

tion 20).

3. Connect the airbag connectors {see section 24)

4. Connect the battery positive cable, then connect the

negative cable.

5. Enter the anti-theft code lor the radio, then enter the

customer's radio station presets ('99 - 00 models)'

6. Confirm that all sYstems work properly'

23-45

Page 1559 of 2189

lgnition Switch

4.

Test

SRS components are located in this area Review the

SRS component locations. precautions. and procedures

in the SRS section {24} before performing repairs or ser-

1. i/ake sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and

knee bolster (see section 20).

Disconnect the 5P connector from the under dash

fuse/relay box and the 7P connector from the main

wire harness.

Check for continuity between the terminals in each

switch position according to the table.

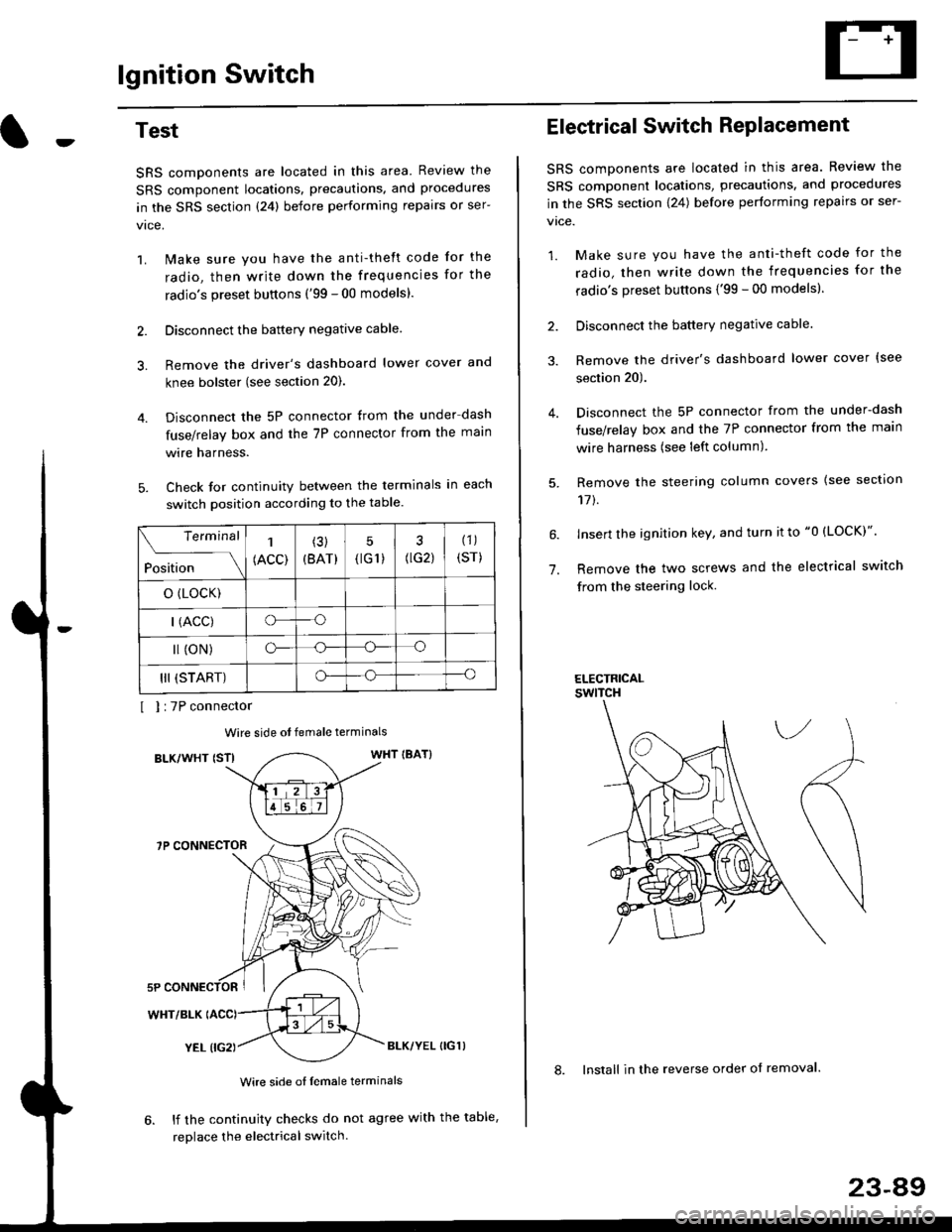

I I :7P connector

Wire side ot female terminals

BLK/WHT {STIWHT IBAT}

7P CONNECTOR

WHT/BLK

YEL (IG2}BLK/YEL {IG1)

Wire side of female terminals

6. lf the continuity checks do not agree with the table,

replace the electrical switch.

Terminal

Position

1

(ACC)

(3)

(BAT)

5

{tG1) G2)

(1)

(sr)

o (LocK)

| (ACC)o--o

l (oN)o-o

III (START)o--o

1.

Electrical Switch RePlacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section \24) belore performing repairs or ser-

vtce.

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons {'99 - 00 modelsl.

2. Disconnect the battery negatlve cable.

3. Remove the driver's dashboard lower cover {see

section 20).

Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connector from the main

wire harness (see left column).

Remove the steering column covers {see section

11t.

lnsert the ignition key, and turn it to "0 {LOCK)".

Remove the two screws and the electrical switch

from the steering lock.

ELECTRICALswtTcH

8. Install in the reverse order of removal.

23-a9

Page 1560 of 2189

lgnition Switch

Steering Lock Replacement

SRS components are located in this area. Review theSRS component locations. precautions, and procedures

in the SRS section (24) before performing repairs or ser-vtce.

Remove:

LMake sure you have the anti-theft code for theradio, then wire down the frequencies for theradio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable.

Remove the driver's dashboard lower cover andknee bolster (see section 20).

Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connector from the mainwire harness (see previous page).

Remove the steering column covers, then removethe mounting bolts and nuts from the steering col-umn (see section l7).

Lower the steering column assembly,

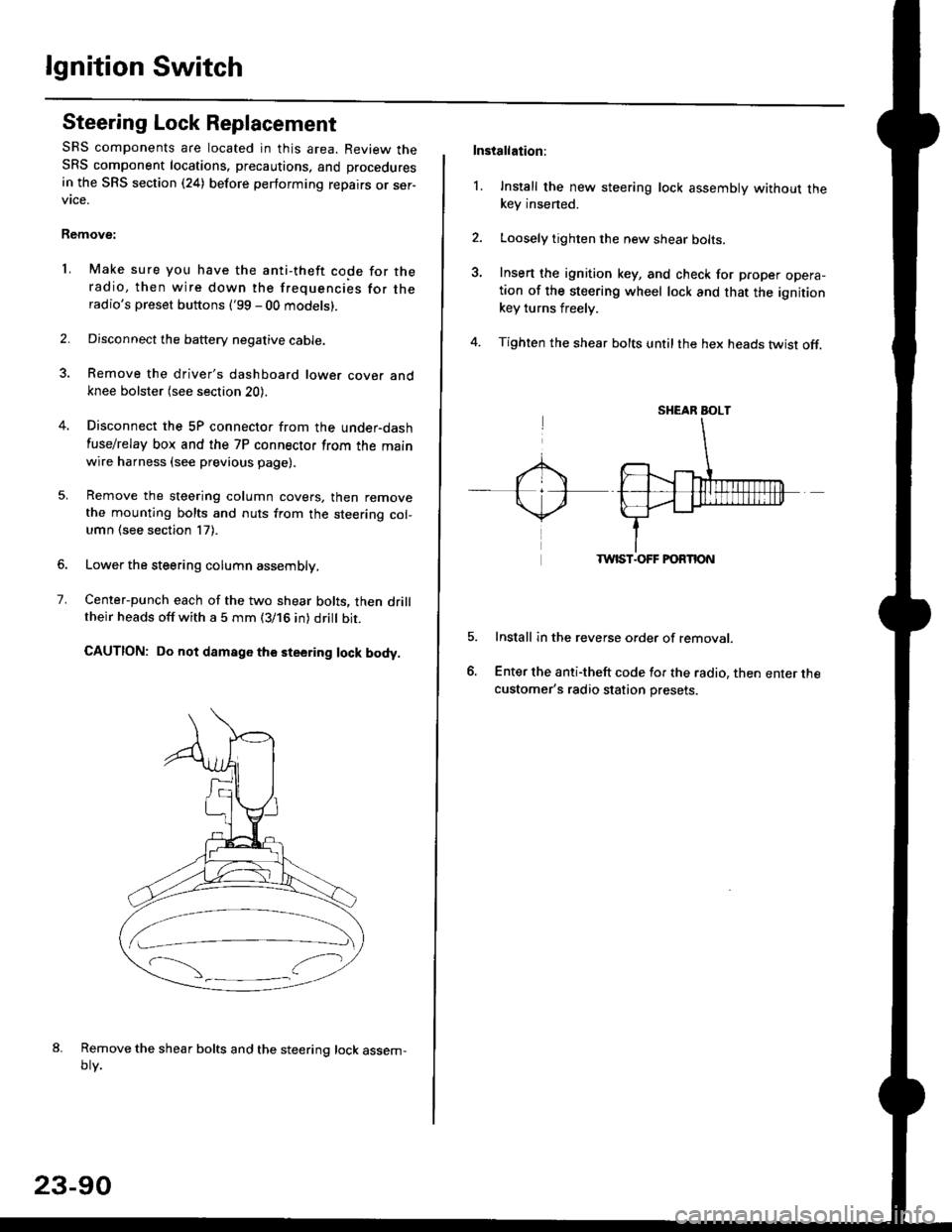

Center-punch each of the two shear bolts, then drilltheir heads off with a 5 mm (3/16 in) dritt bit.

CAUTION: Do not damago the steering lock body.

Remove the shear bolts and the steering lock assem,oty.

2.

1.

23-90

Installation:

l. Install the new steering lock assembly without thekey insened.

Loosely tighten the new shear bolts-

Insert the ignition key, and check for proper opera-tion of the steering wheel lock and that the ignitionkey turns freely.

Tighten the shear bolts untilthe hex heads twist off.

TWIST.OFF FORTION

Install in the reverse order of removar.

Enter the anti-theft code for the radio, then enter thecustomer's radio station presets.

sr{€aR SroLT