Exhaust System HONDA CIVIC 1998 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 433 of 2189

PGM-FI System

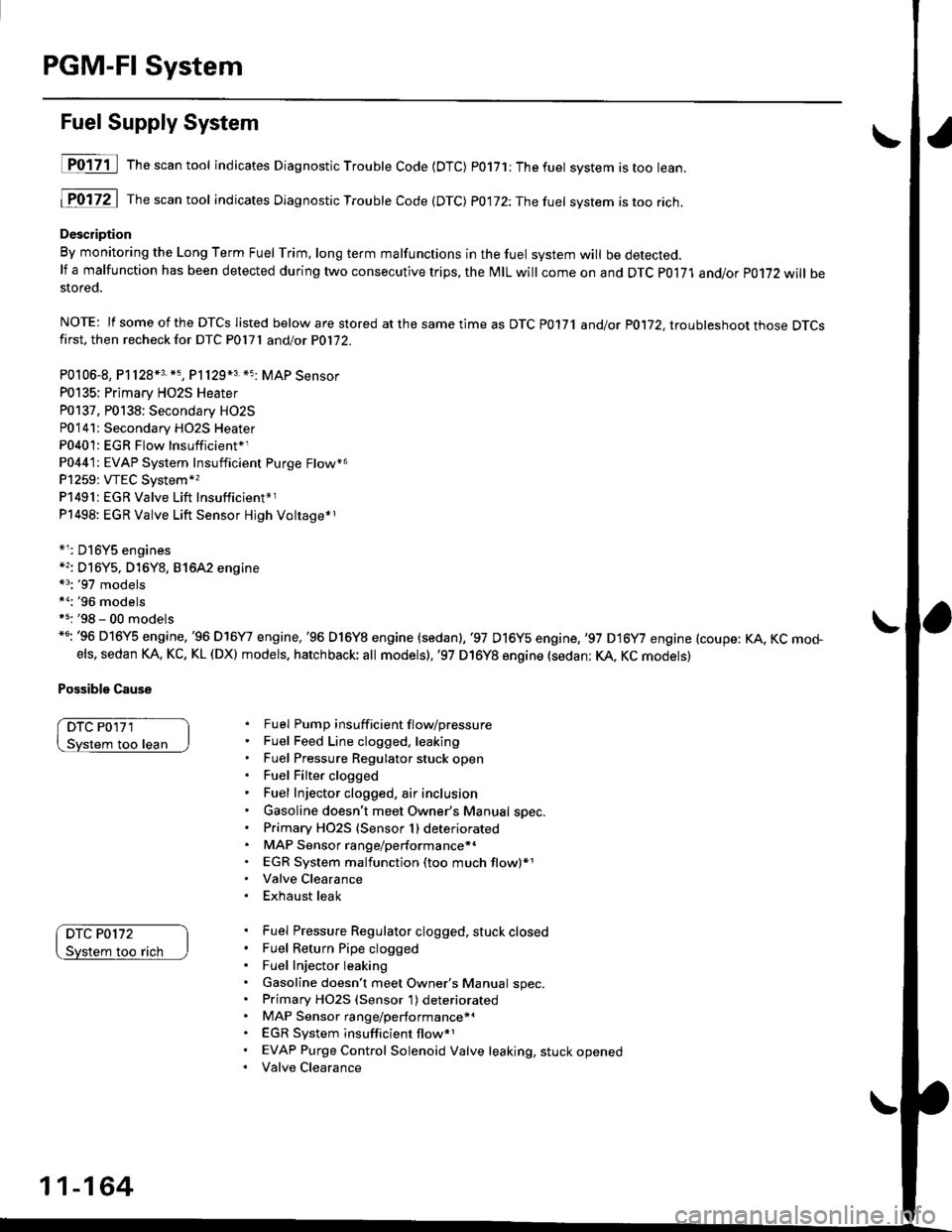

Fuel Supply System

D017-il Th""""ntool indicates Diagnostic Troubte Code {DTC) p0171;Thefuet system istoo lean.

1P0172 | fne scan tool indicates Dlagnostic Trouble Code (DTC) P0172:Thefuel system istoo rich.

Description

By monitoring the Long Term Fuel Trim, long term malfunctions in the fuel system will be detected.lf a malfunction has been detected during two consecutive trips, the MIL will come on and DTC P0171 and/or P0172 will bestored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC P0171 andlot P0172, ltouhleshoot those DTCSfirst. then recheck for DTC P0l7l andlot P0172.

P0106-8, P1128*3. *5, P1129*3 *5 MAP Sensor

P0135; Primary HO2S Heater

P0137. P0138: Secondary HO2S

P0'141: Secondary HO2S Heater

P0401: EGR Flow Insufficient*1

P0441: EVAP System Insufficient Purge Flow*6

P1259: VTEC System*,

P1491:EGR Valve Lift Insufficient*r

P1498: EGR Valve Lift Sensor Hjgh Voltage*r

*r: D16Y5 engines*'�: Dl6Y5, D16Y8, 81642 engine*3: '97 models*a:'96 modelsf 5: '98 - 00 models*6: '96 D16Y5 engine,'96 D16Y7 engine,'96 D16Y8 engine (sedan),'97 D16y5 engine,,97 D16y7 engine (coupe: KA, KC mo+els, sedan KA. KC, KL (DX) models. hatchback; all models),'97 D16Y8 engine (sedan: KA, KC models)

Possible Cause

DTC P0'171

loo lean

DTC P0172

too rach

Fuel Pump insuff icient f lovpressure

Fuel Feed Line clogged, leaking

Fuel Pressure Regulator stuck open

Fuel Filter clogged

Fuel Injector clogged, air inclusion

Gasoline doesn't meet Owner's Manual spec.

Primary HO2S (Sensor 1) deteriorated

MAP Sensor range/performance*.

EGR System malfunction (too much flow)*1

Valve Clearance

Exhaust leak

Fuel Pressure Regulator clogged, stuck closed

Fuel Return Pipe clogged

Fuel Injector leaking

Gasoline doesn't meet Owner's Manual spec.Primary HO2S (Sensor 1) deteriorated

MAP Sensor range/performance*a

EGR System insufficient flow*1

EVAP Purge Control Solenoid Valve leaking, stuck opened

Valve Clearance

11-164

Page 521 of 2189

Emission Gontrol System

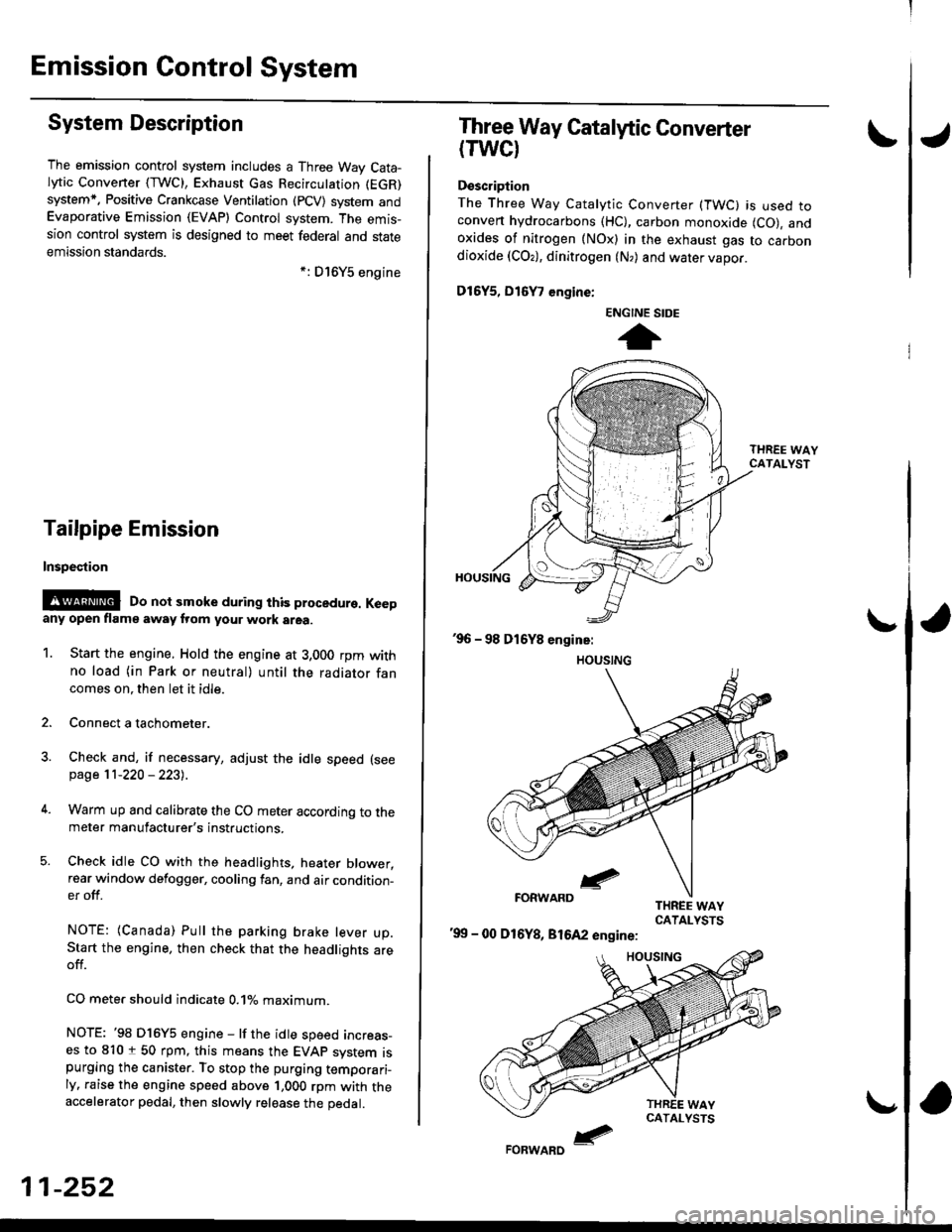

System Description

The emission control system includes a Three Way Cata-lytic Convener (TWC), Exhaust Gas Recirculation (EGR)

system,. Positive Crankcase Ventilation (pCV) system andEvaporative Emission (EVAP) Control system. The emis-sion control system is designed to meet federal and stateemission standards.*: D16Y5 engine

Tailpipe Emission

Inspestion

@@ Do not smoke during ihis procedure. Keepany open flame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm withno load (in Park or neutral) until the radiator fancomes on. then let it idle.

2. Connect a tachometer.

Check and, if necessary, adjust the idle speed (see

page 11-220 - 223).

Warm up and calibrate the CO meter according to themeter manufacturer's instructions.

Check idle CO with the headlights, heater blower,rear window defogger, cooling fan, and air condition-er off.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

CO mete. should indicate 0.1% maximum.

NOTE: '98 Dl6Y5 engine - lf the idle speed incress-es to 8101 50 rpm, this means the EVAp system ispurging the canister. To stop the purging temporari-ly. raise the engine speed above 1,000 rpm with theaccelerator pedal, then slowly release the pedal.

11-252

eFORWARD -

Three Way Catalytic Converter

(TWCI

Doscription

The Three Way Catalytic Converter (TWC) is used toconven hydrocarbons (HC), carbon monoxide (CO), andoxides of nitrogen (NOx) in the exhaust gas to carbondioxide (COr), dinitrogen (N,) and water vapor.

D15Y5, D16

, engine:

'99 - 00 D16Y8, 81642 engine:

ENGINE SIDE

t

Page 522 of 2189

\

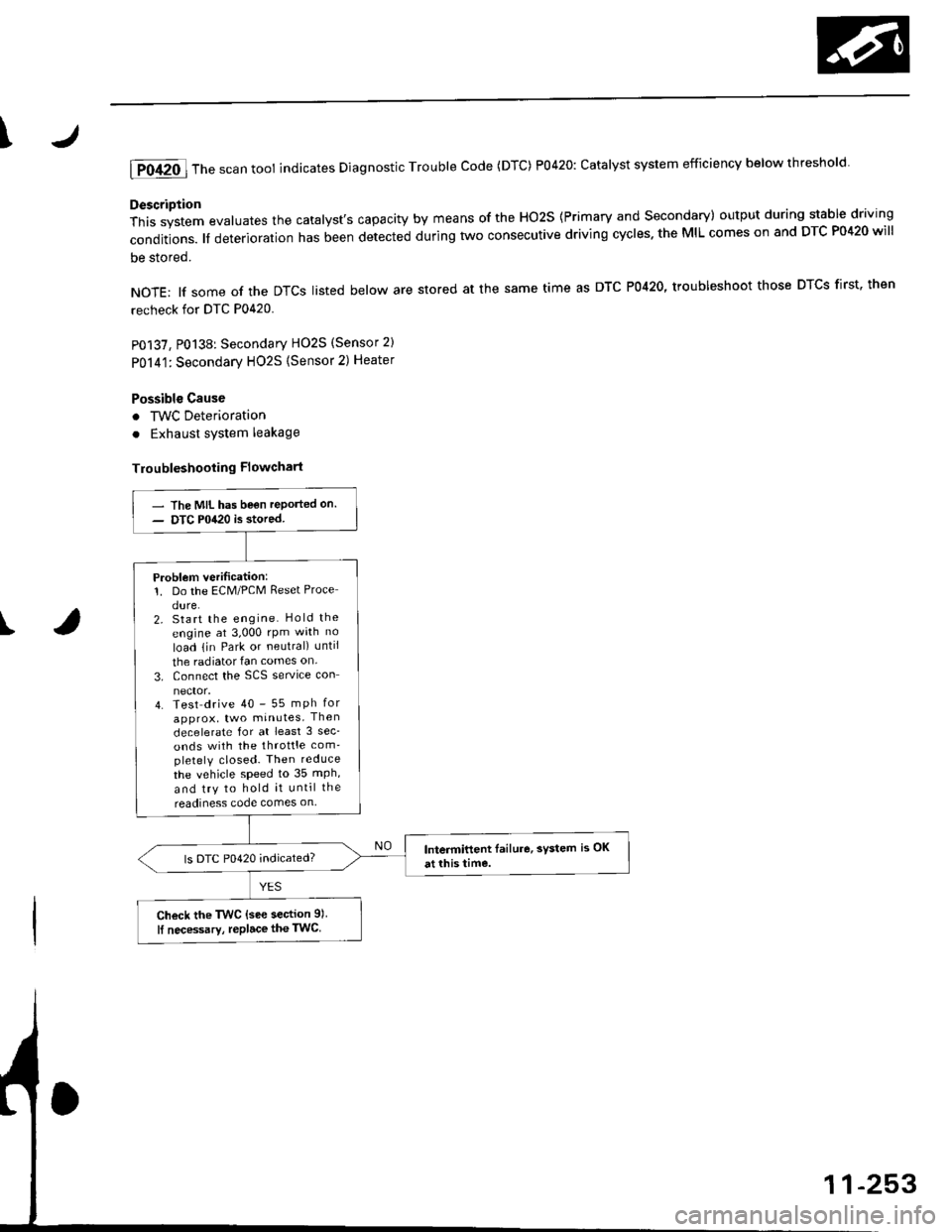

lTo420l Th" """n toot indicates Diagnostic Troubte code (DTc) p0420: catatyst sysrem efficiency below threshold.

Description

This system evaluates the catalyst's capacity by means of the Ho2s {Primary and secondary) output during stable driving

conditions. ll deterioration has been detected during two consecutive driving cycles. the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS tisted below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

recheck for DTC P0420

P0137, P0138: Secondary HO2S (Sensor 2)

Po14'1:Secondary H02S {Sensor 2) Heater

Possibl€ Cause

. TWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

I

The MIL has been reported on.

DTC P0420 is stored

Problem verilication:1. Do the ECM/PCM Reset Proce

dure.2. Start the engine Hold the

engine at 3,000 rpm wath no

load {in Park or neutral) until

the radiator fan comes on.

3. Connect the SCS service con

4. Test drive 40 - 55 mph for

approx, two minutes Then

decelerate for at least 3 sec_

onds with the throttle com'pletely closed- Then reduce

the vehicle speed to 35 mph,

and try to hold it until the

readiness code comes on

Intermittent Iailure, system is OK

at this time.ls DTC P0420 indicated?

Check the TWC {see section 9l

lf necessary, replace the TwC

Page 523 of 2189

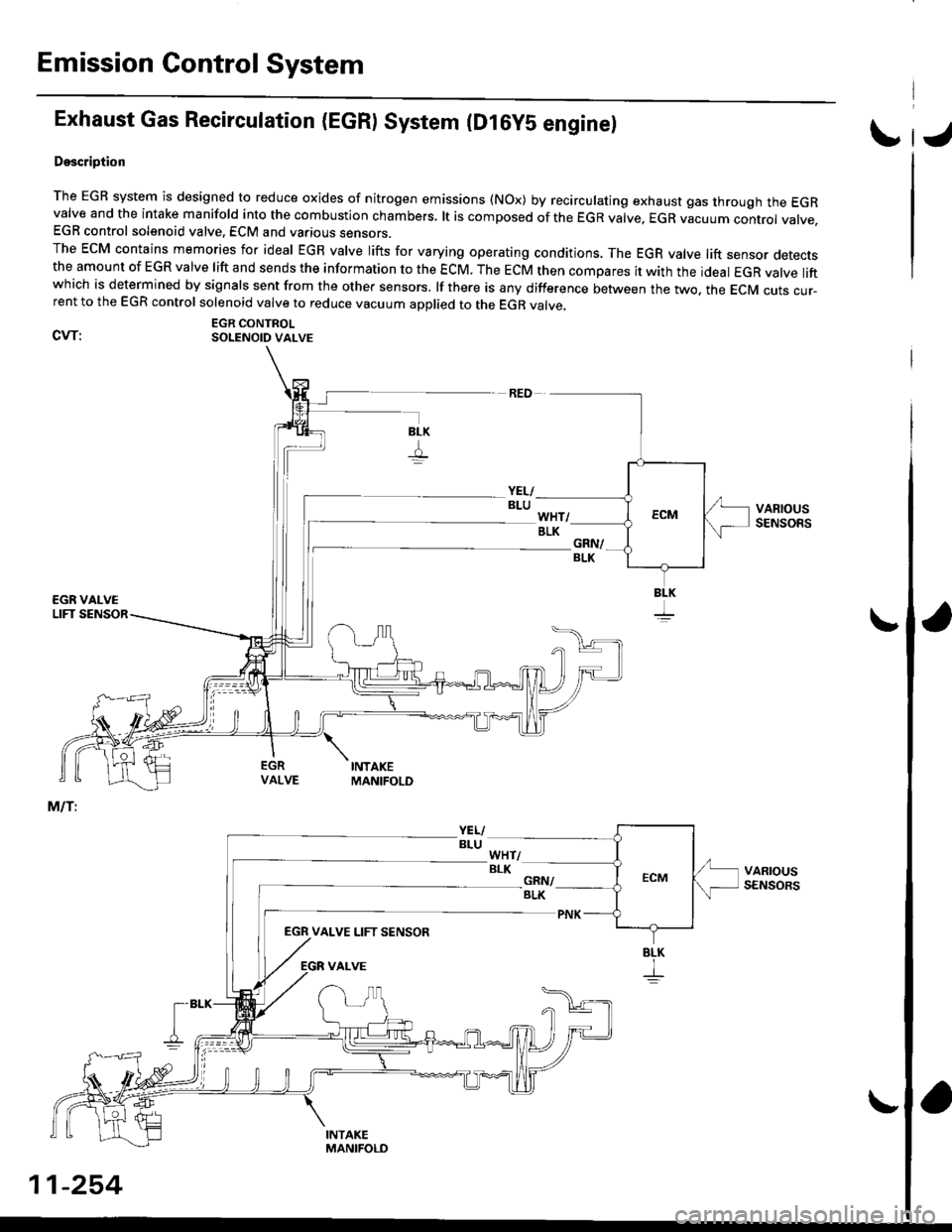

Emission Control System

Exhaust Gas Recirculation (EGR) System (D16yS engine)

Doscription

The EGR system is designed to reduce oxides of nitrogen emissions (NOx) by recirculating exhaust gas through the EGRvalve and the intake manifold into the combustion chambers. lt is composed of the EGR valve. EGR vacuum conrrot vatve.EGR control solenoid valve. ECM and various sensors.The EcM contains memories for ideal EGR valve lifts for varying operating conditions, The EGR valve lift sensor detectsthe amount of EGR valve lift and sends the information to the ECM. The ECM then compares it with the ideat EGR valve liftwhich is determined by signals sent from the other sensors. lf there is any difference between the two. the EcM cuts cur-rent to the EGR control solenoid valve to reduce vacuum applied to the EGR valve.

EGR CONTROLCVT: SOLENoID vALvE

EGN VALVE LIFT SENSOR

BLK

I

I

11-254

Page 525 of 2189

Emission Control System

Exhaust Gas Recirculation (EGR) System (D16Y5 engine with GWI (cont'dl

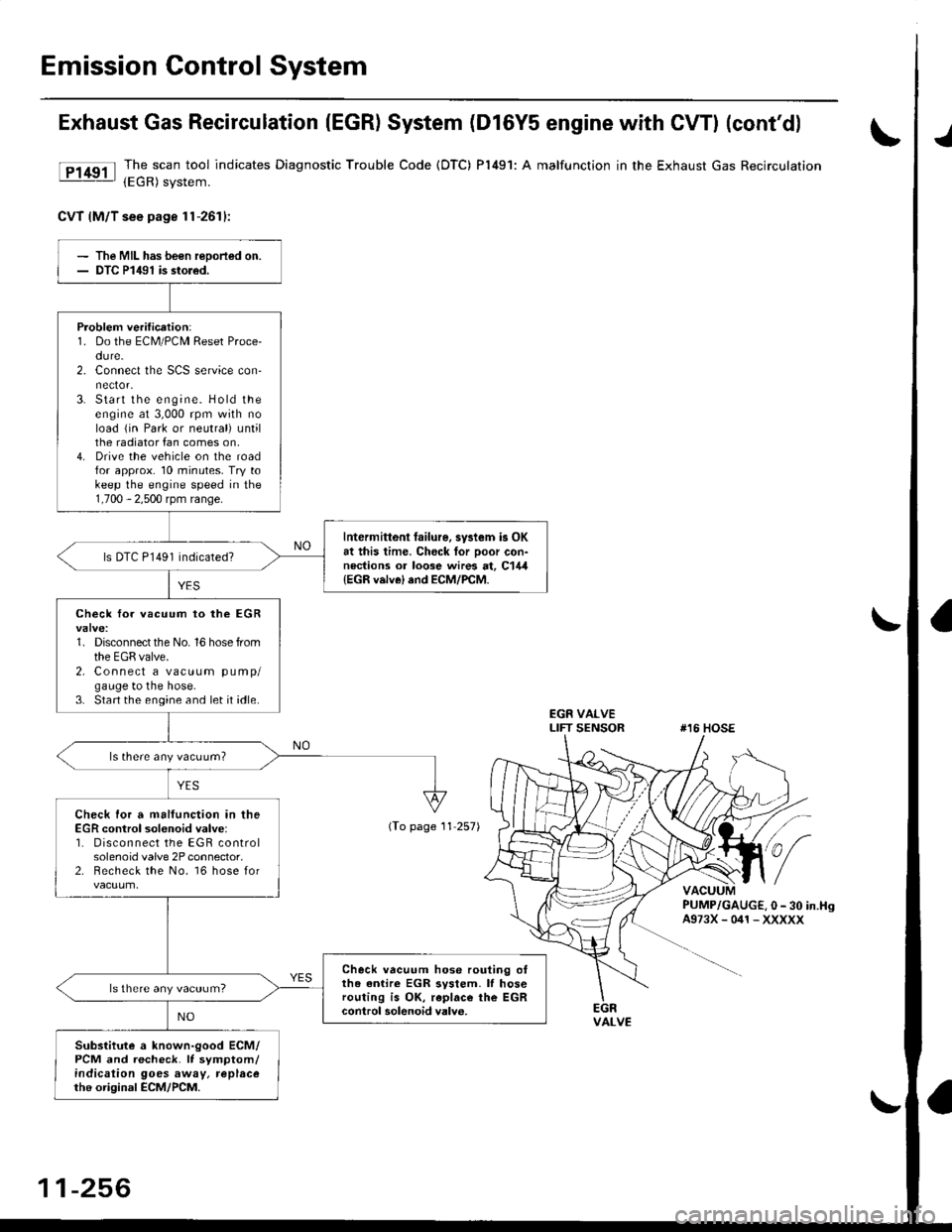

lTl49il T_he scan tool indicates Diagnostic Trouble Code (OTC) P1491: A malfunction in the Exhaust Gas Recirculation- lEgh) svstem.

CvT lM/T see page 1l-2611:

J

EGR VALVELIFT SENSOR#16 HOSE

PUMP/GAUGE,0- 30 in.HsA973X-041-XXXXX

EGRVALVE

The MIL has been reoorted on.DTC P1491 is stoled.

Problem verification:1. Do the ECM/PCM Reset Proce-du re.2. Connect the SCS service con'

3. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral) untilthe radiator fan comes on,4. Drive the vehicle on the roadfor approx. 10 minutes. Try tokeep the engine speed in the1,700 - 2,500 rpm range.

Intermittonl failure, system is OKat this time. Check for Door con-nections or loose wires at, C144{EGR velve} and ECM/PCM.

ls DTC P l49l indicated?

Check fo. vacuum to ihe EGR

1. Disconnect the No. 16 hose fromthe EGR valve.2. Connect a vacuum pump/gauge to the hose.3. Start the engine and let it idle.

ls there any vacuum?

Check tor a malfunction in theEGR control solenoid valve:'1. Disconnect the EGR controlsolenoid valve 2P connector,2. Becheck the No. 16 hose for

Check vacuum hose routing o,the entire EGR svstem. lf hoserouting is OK, replac€ the EGRcontrol solenoidvalv6.

ls there any vacuum?

Substitute a known-good ECM/PCM and recheck. It symptom/indicalion goes away, replacethe original ECM/PCM.

(To page 11 257)

11-256

Page 527 of 2189

Emission Gontrol System

Exhaust Gas Recirculation (EGRI System (Dl6Y5 engine with CW) (cont'dl

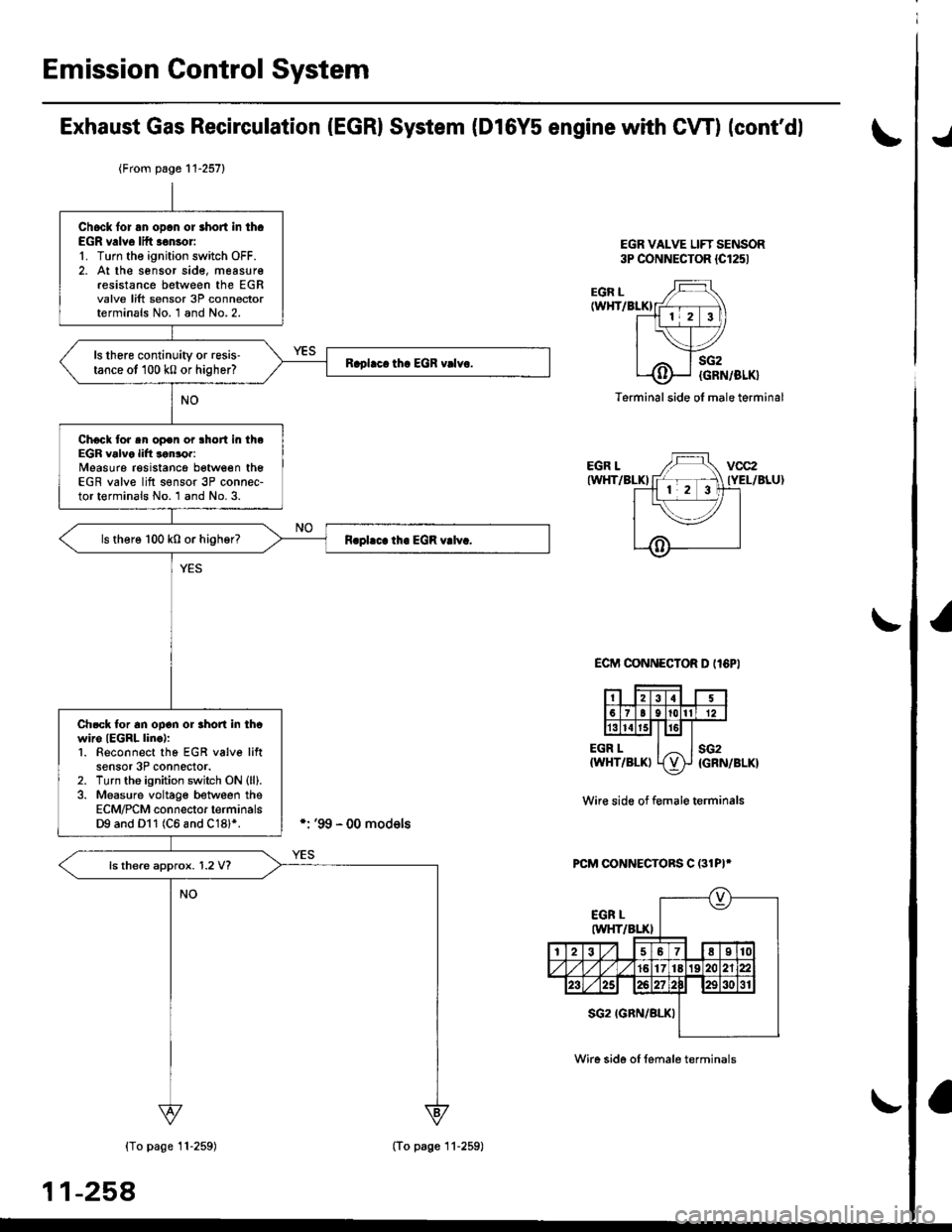

EGR VALVE LIFT SENSOR3P CONNECTOR {Cl251

./

EGR L(WHT/BLKI

EGR LIWHT/BLKI

EGR L{WHT/BLKI

sG2

{GRN/BLK}

sG2{GRN/BLK}

Terminal side ol male terminal

ECIT'I CONNECTOR D II6PI

Wir€ side of f€male terminals

PCM CONNECTORS C (31PI*

{To page 11-259)

11-258

{From page 11-257}

Chock lor an opcn or short in th.EGR v.lve lift .€nsor'1. Turn the ignition switch OFF.2. At the sensor sid€, measur€resistance between the EGRvalve lift sensor 3P connectorterminals No. 1 and No.2.

ls there continuity or resis'tance ot 100 k0 or higher?

Chock tor sn op€n or lhort in theEGR valve lift lonror:Measure resistancg between theEGR valve lift s€nsor 3P connec-tor terminals No. 1 and No. 3.

ls there 100 k0 or higher?

Ch.ck tor an ooon or rhon in thcwiro IEGRL linc):1. Beconnect tho EGR v6lve liftsensor 3P connector.2. Turn tho ignition switch ON (ll).

3. Measure voltage between theECM/PCM connector terminalsD9 and Dl1 (C6 and C18l*.

ls there approx. 1.2 V?

(To page 11-259)

Wire side of female terminals

Page 529 of 2189

Emission Control System

Exhaust Gas Recirculation (EGR) System (Dl6Y5 engine with CW) (cont'dl

tJ

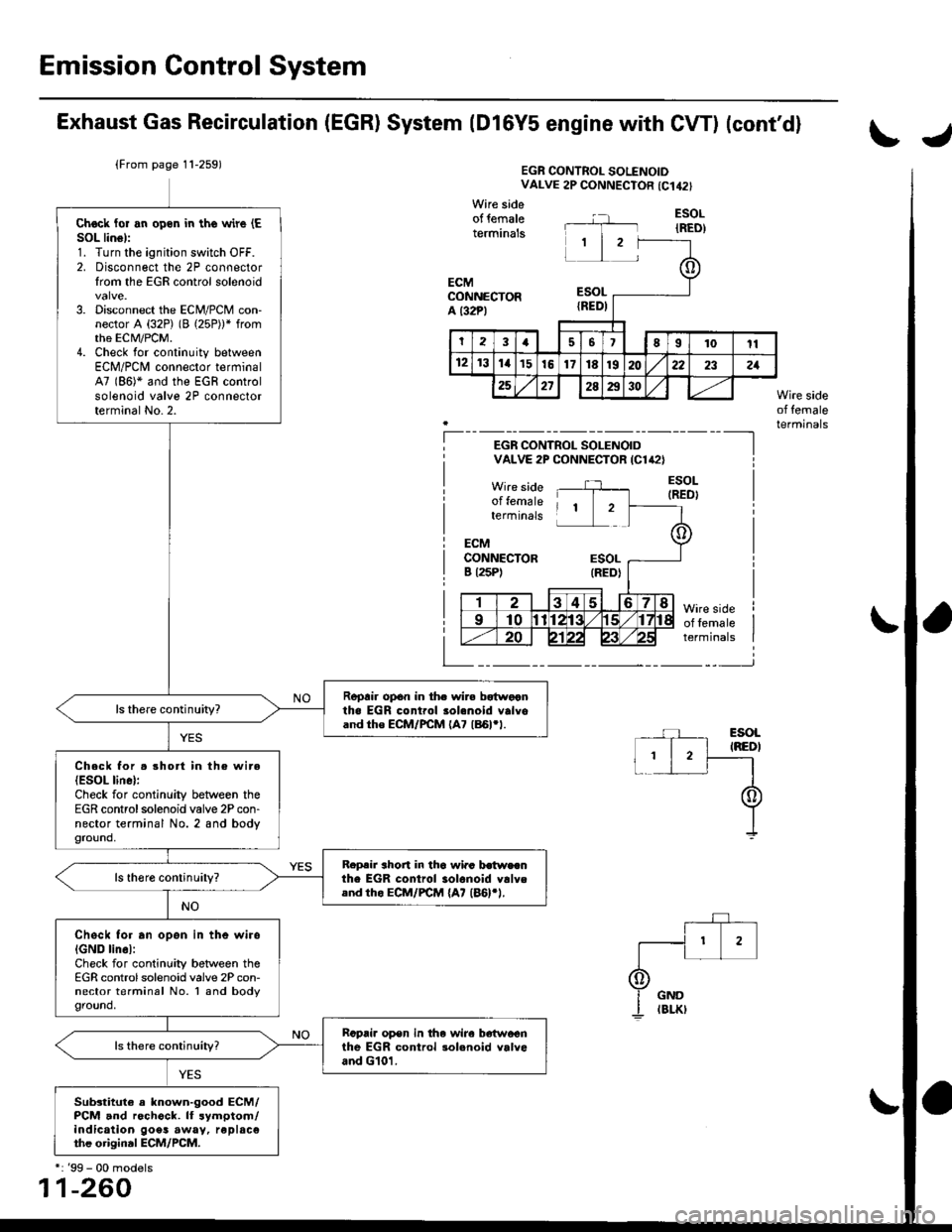

(From page 11-259)EGR CONTROL SOLENOIDVALVE 2P CONNECTOR {C142}

Wire sideof lemaleterminals

ECMCONNECTORa t32Pl

Chock lor an open in the wire (E

SOL linsl:1. Turn the ignition switch OFF.2. Disconnect the 2P connectorIrom the EGR control solenoid

3. Disconnect the ECN4/PCM con-nector A (32P) (B (25P))* fromthe EcM/PCM.4. Check tor continuity betweenECM/PCl, connector terminal47 (86)* and the EGR controlsolenoid valve 2P connectorterminal No.2.

Repair opon in th. wir. bstwocntha EGR control 3ol€noid valvoand tho ECM/PCM (A7 186l'1.

ls there continuity?

Check for . rhort in the wire(ESOL linel:Check for continuity between theEGR controlsolenoid valve 2P con-nector terminal No. 2 and bodyground,

R.p.ir ahort in tha wi.c b.twecnthe EGR control iolonoid vllyeand th. ECM/FCM {A7 (46}rl.

Check for an opon in the wiroIGND linel:Check for continuity between theEGR controlsolenoid vaive 2P con-nector terminal No. I and bodyground,

Rcpai. op€n in the wir6 b6'twoenthe EGR control rol.noid valveand G101.

Sub3titule a known-good ECM/PCM and rechock. lf symptom/indication goes away, replac€the original ECM/PCM.

ESOL

IRED)

ESOLIRED)

Wire sideof femaleterminals--_-]

I

EGR CONTROL SOLENOIDVALVE 2P CONNECTOR ICl'2}

Wire sideof femaleilterminals

ECMCONNECTORB l25P)ESOL(REDI

Wire sideof femalerermtnats

*: '99 - 00 models

11-260

Page 530 of 2189

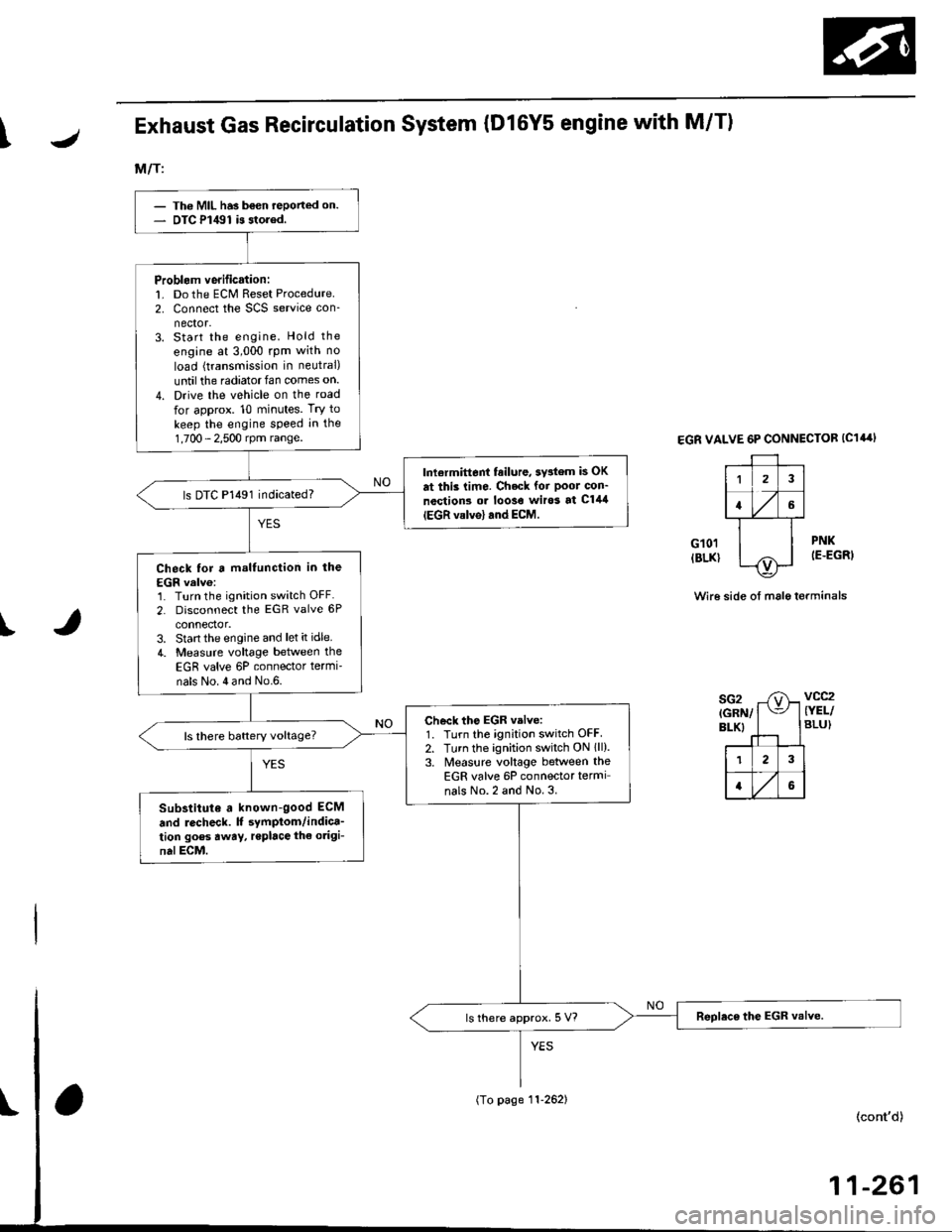

\JExhaust Gas Recirculation System (D16Y5 engine with M/T)

M/T:

EGR VALVE 6P CONNECTOB (C14'rl

G10lIBLK}

1

a

PNK

IE.EGRI

Wi16 side of male terminals

I

sG2{GRN/BLK}

vcc2{YEL/BLU)

- Th6 MIL ha3 b€on reponed on.- DTC Pl,{tl is 3tored.

Prcblem verification:1. Do the ECM Reset Procedure.

2. Connect the SCS service con_nector.3. Start the engine. Hold the

engine at 3,000 rpm with no

load (transmission in neutral)

untilthe radiator fan comes on.

4. Drive the vehicle on the road

for approx. 10 minutes. Try to

keep the engine speed in the

1,700 - 2,500 rpm range.

lnlermittont tailure, svalem is OK

at thi3 tim6. Check foi Poor con'

nections or looso wiro3 at Cl/K

IEGR valvsl and ECM.

ls DTC P1491 indicated?

Check tor a malfunction in the

EGR valv6:1. Turn the ignition switch OFF.

2. Disconnect the EGR valve 6P

connector.3. Stanthe engine and let it idle

4. Measure voltage between the

EGR valve 6P connector termi'

nals No.4and No.6.

Check the EGR valve:1. Turn the ignition switch OFF2. Turn the ignition switch ON lll).3. Measure voltage between theEGR valve 6P connector termi

nals No.2 and No.3.

ls there battery voltage?

Substitute a known-good ECM

and recheck. It symptom/indica_tion goes away, replace th€ origi-

nal ECM.

ls there approx.5V?

(To page 11-262)

Page 531 of 2189

Emission Control System

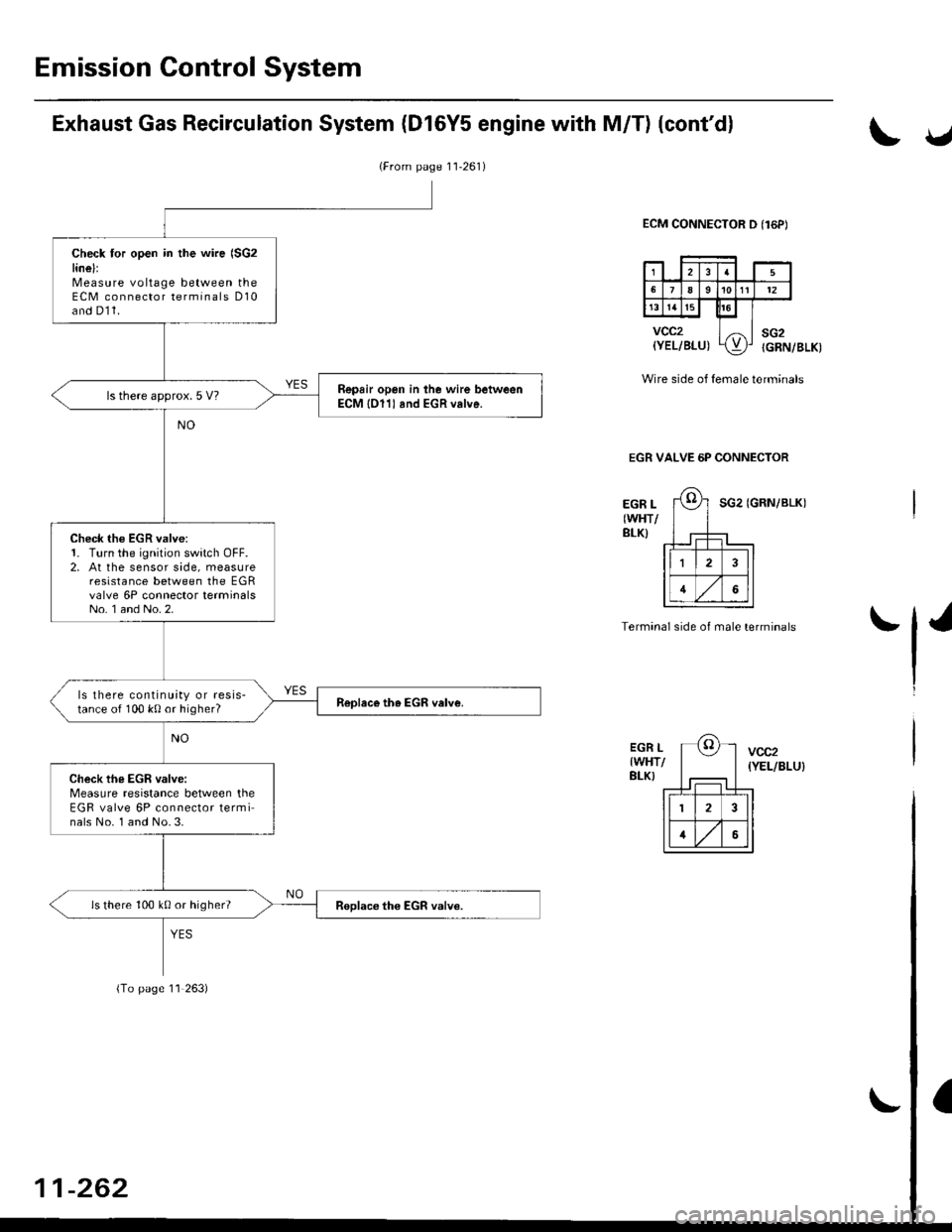

(From page 11-261)

Check tor open in the wire (SG2

linel:Measure voltage between theECM connector terminals D10and D11.

Repsir open in lhe wire beiweenECM lOllland EGR valve.ls there approx. 5 V?

Check the EGR valve:1. Turn the ignition switch OFF.2, At the sensor side, measureresistance between the EGRvalve 6P connector terminalsNo. 1 and No. 2.

ls there continuity or resis-tance of 100 k0 or higher?

Check the EGR valve:Measure resistance between theEGR valve 6P connector terminals No. 1 and No.3.

ls there 100 k0 or higher?

Exhaust Gas Recirculation System (D16Y5 engine with M/T) (cont'dl

ECM CONNECTOR D {16P)

vcc2(YEL/BLU)

\v

sG2IGRN/BLK)

Wire side of female term;nals

EGR VALVE 6P CONNECTOR

EGR L(WHT/

BLK}

SG2 (GRN/BLK)

Termanal side of male terminals'l'

EGR L{WHT/BLK}

vcc2

{YEL/BLU}

(To pase 11 263)

1-262

Page 533 of 2189

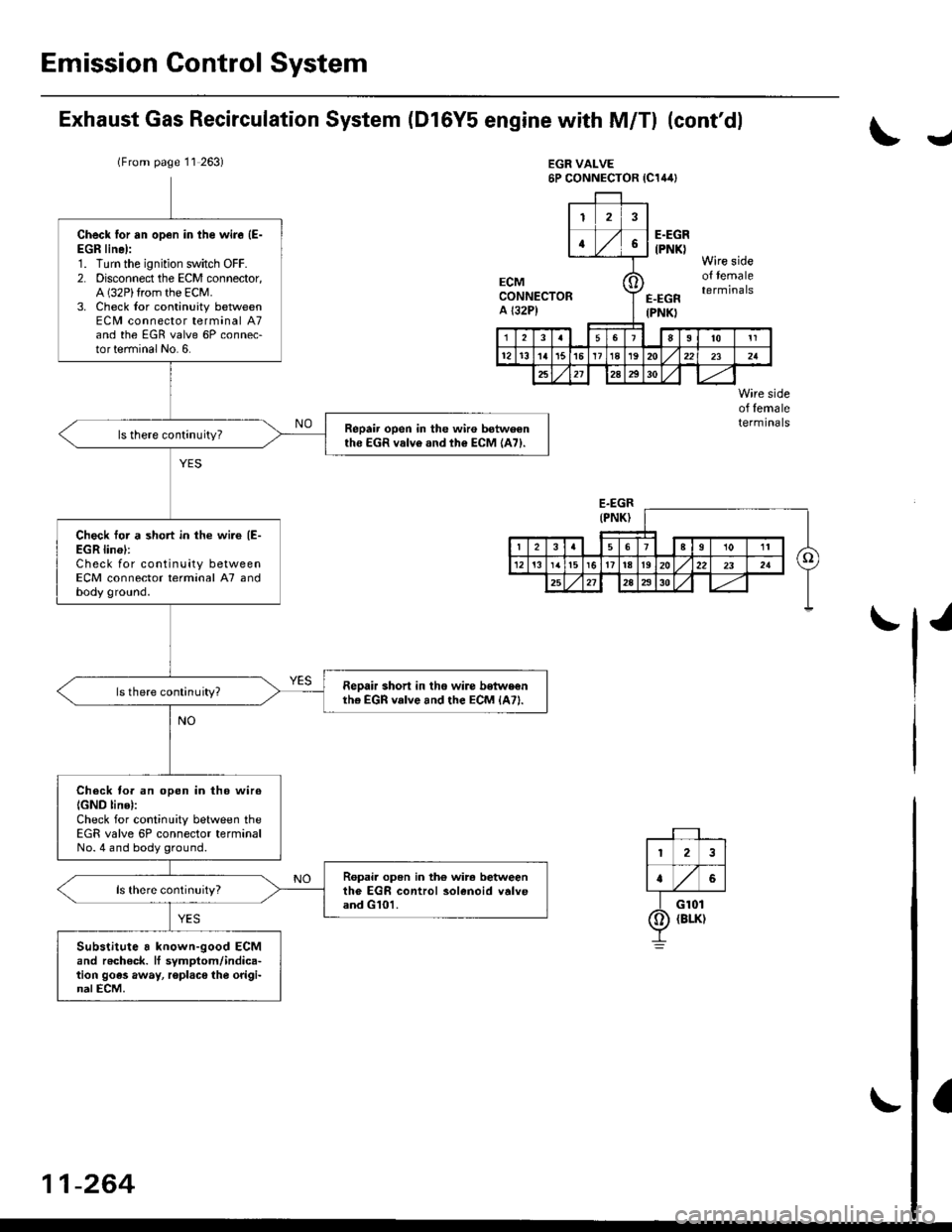

Emission Gontrol System

Exhaust Gas Recirculation System (Dl6Y5 engine with M/Tl (cont'dl

lFrom page 11 263)EGR VALVE6P CONNECTOR {C144}

J

Wire sideof femaletermtnals

J

Check lor an op€n in the wire (E-

EGR line):1. Turn the ignition switch OFF.2. Disconnect the ECM connector,A (32P)trom the ECM.3. Check lor continuity betweenECM connector terminal A7and the EGR valve 6P connec-torterminal No. 6.

Repair open in the wiro botweenthe EGR valv6.nd th€ ECM {A71.

Check tor a short in the wire {E-EGR lin6l:Check for continuity betweenECM connector terminal A7 andbody ground.

Reoair shorl in tho wiro belwe€nthe EGn vake rnd the ECM lA7l.ls there continuity?

Check fo. an open in tho wiro

IGND line):Check for continuity between theEGR valve 6P connector terminalNo.4 and body ground.

R6pai. open in th€ wir. betweenth6 EGF control solenoid v6lveand G101.

Substitute 8 known-good ECMand recheck. It symptom/indica-tion goes away, roplace the origi-nalECM.

CONNECTORA l32P)

2

a

I G101

Q) raur

-264