Tachometer HONDA CIVIC 1998 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 797 of 2189

Pressure Testing

@I While testing, be caroful of th€ rotating front wheels.

. Make sure lifts, iacks, and satoty stands are placod properly (see section 1)'

CAUTION:

. Beforo iesting, be sure the transmission fluid is tilled to tho proper level'

. Warm up tho engine before testing'

1. Raise the vehicle (see section 1).

2. Warm up the engine, then stop the engine and connect a tachometer'

3. Connect the oil pressure gauges to each inspection hole.

TOROUE: 18 N.m (1.8 kgf'm, 13 lbnft)

cAUTloN: connact the oil pressuro gauges securely; be suro not to allow dust and other foreign Parlicles to entel

the inspestion holos'

A/T OIL PRESSURE GAUGESET w/PANEL07t06 - 0020400

A/T LOW PRESSURE GAUGE

SET WPANEL07406 - 0070300

A/T OIL PRESSURE HOSEADAPTER07Mru - PY0120(4 requiJedl

A/T OIL PBESSURE HOSE

2210 mmOTMAJ - PY4{)llA

14 roquircdl

Start the engine, and measure the respective ptessure as follows'

a Line Pressure

. 1st Clutch Pressure

. 2nd,3rd and 4th Clutch Pressure

Install a new washer and the sealing bolt in the inspection hole. and tighten to the specified torque'

TOROUE: l8 N.m (1.8 kgf'm,13lbf'ft)

NOTE: Do not reuse old sealing washers; always replace washers'

(cont'd)

14-119

Page 975 of 2189

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not test stall sp€€d for mole than 10 seconds at a time.

. Do not shift the lsver whils raising the engine speod.

. Be sure lo remove the pressure gauge before tosting stall speed.

. Stall speed tssts should be used tor diagnostic purposes only,

1. Engage the parking brake, and block the tront wheels.

2. Connect a tachometer to the engine, and stan the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds, and note engine speed,

6. Allow two minutes for cooling, then repeat the test in E, E, and E positions.

Stall Speed BPM in E poshion:

Specification: 2,500 rpm

Servic€ Limit: 2,350 - 2.650 rpm

Stall Speed RPM in E, E and E positions:

Specitication: 3,000 rpm

Service Limit: 2,800 - 3,100 rpm

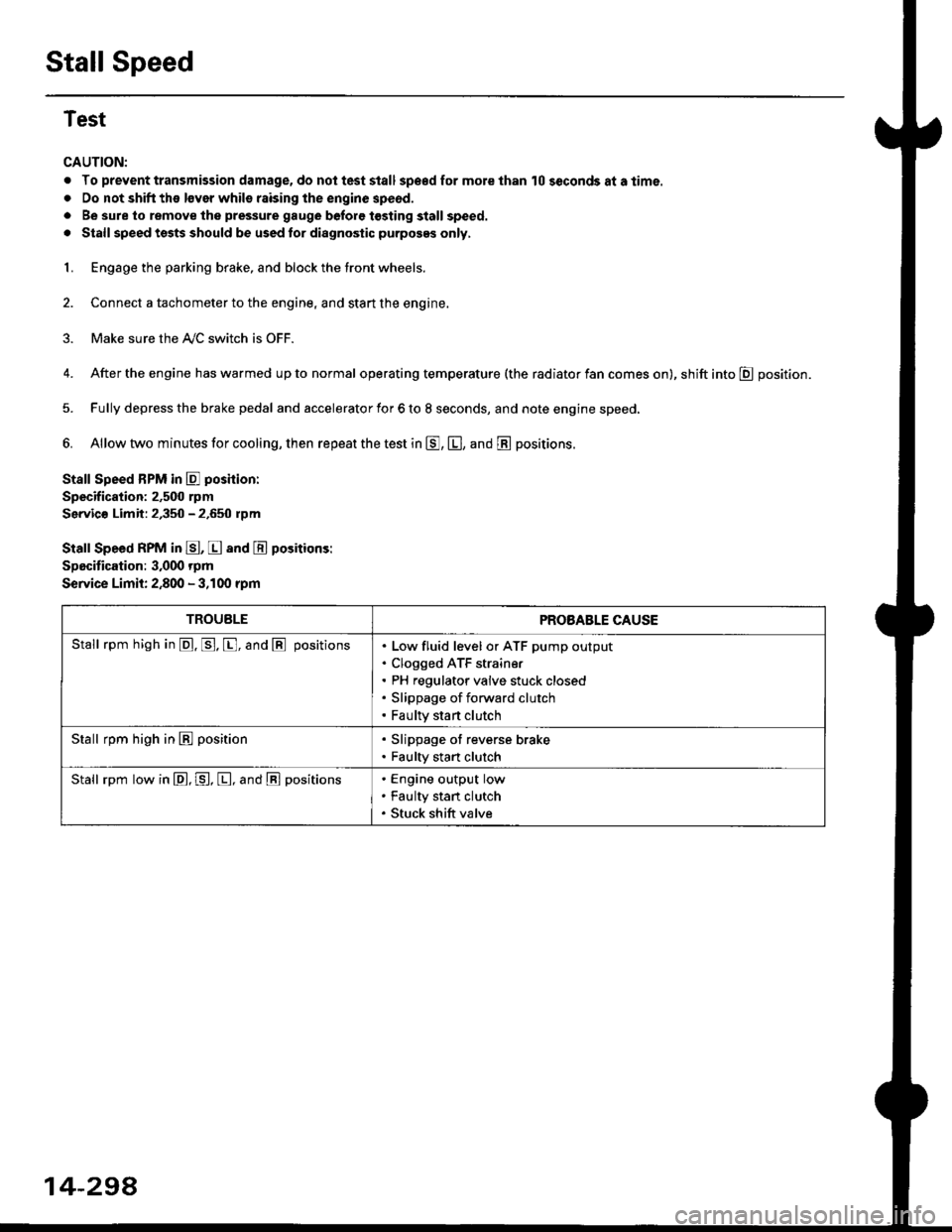

TROUBLEPROBABLE CAUSE

Stall rpm high in @. p. [, and @ positionsLow fluid level or ATF pump output

Clogged ATF strain€r

PH regulator valve stuck closed

Slippage of forward clutch

Faulty start clutch

Stall rpm high in E position. Slippage of reverse brake. Faulty start clutch

Stall rpm low in E, P, [, and @ positionsEngine output low

Faulty stan clutch

Stuck shift valve

14-294

Page 977 of 2189

Pressure Testing

. While testing, be careful of the rot8ling front wheels.

. M8k6 suro lifts, iacks, and satety stands are placed properly lsee section 11.

CAUTION:

. Before testing, be sur. the transmb3ion fluid is fillod to the propor lcvel.. Warm up the engin€ to nolmal operating tsmperature bofore testing. While t€sting, be 3ure not to allow dust and other loreign particles to onler into the transmi$ion.

1. Raise the front of the vehicle, and support it with safety stands (see section 1).

2. Set the parking brake. and block both rear wheels securely.

3. Allow the front wheels to rotate freely.

4. Warm up the engine (the radiator fan comes on), then stop arid connect a tachometer.

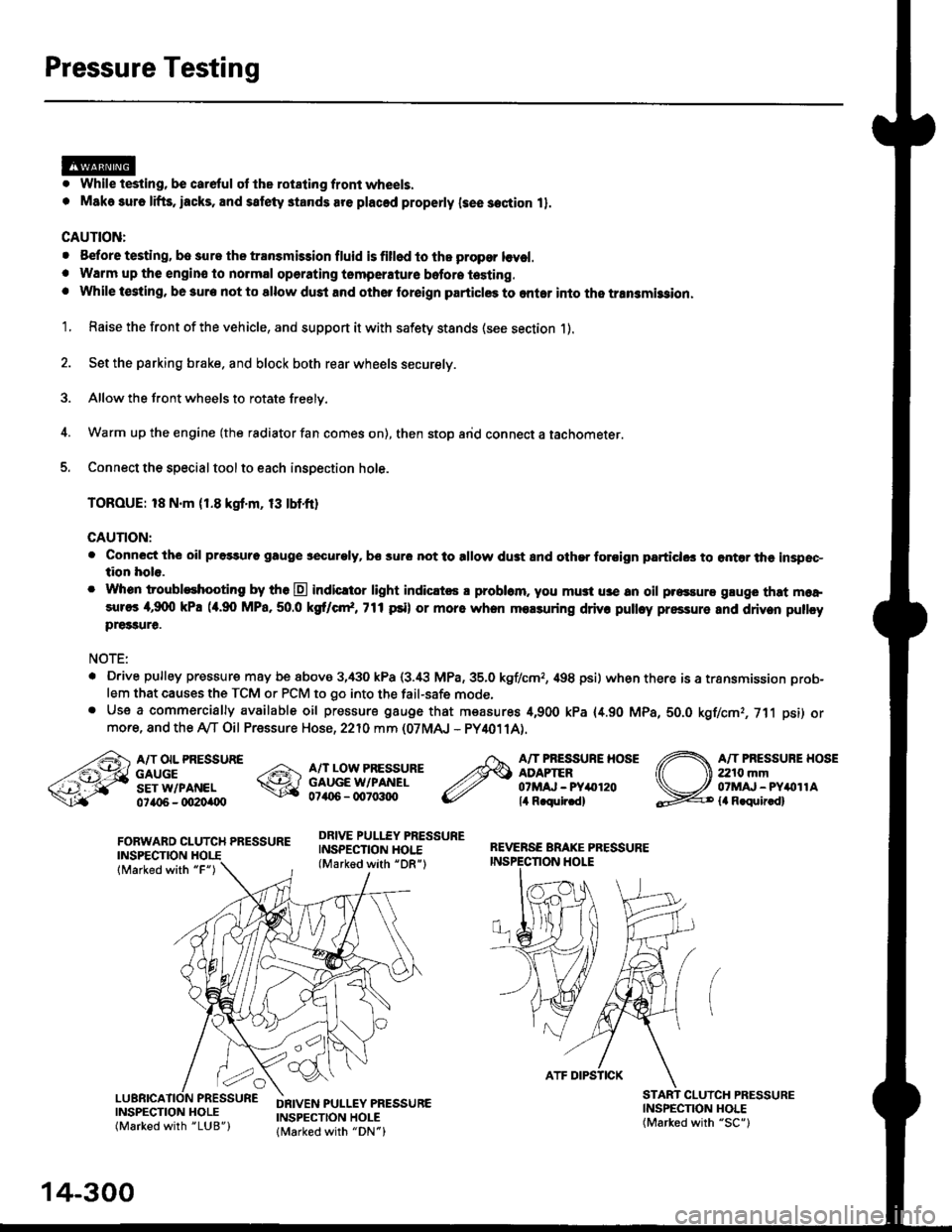

5. Connect the special tool to each inspection hole.

TOROUE: 18 N.m (1.8 kgt'm, 13 tbtfr)

GAUTION:

. Connect the oil pressuro gauge !!€curoly, bs sur6 not to allow dust and other foroign particlG3 to ontar the inspsc-tion hole.

. Whon troubleshooting by tho E indicltor light indic.t6 a problam. you mu3t u3e an oil p.essure gluge that moa,sures 4,9(X) kPa (a.90 MPa,50.0 kS cr*,771psi) or more when molsuring driv. pulley pressure and driven pullcypre33ure.

NOTE:

. D.ive pulley pressure may be above 3,430 kPa (3.i8 MPa,35.0 kgf/cmr, 498 psi) wh€n there is a transmission prob-

lem that causes the TCM or PCM to go into the fail-safe mode,. Use a commercially available oil pressure gauge that measures 4,900 kPa {4.90 MPa, 5O.O kgf/cmr, 711 psi) ormore, and the Ay'T Oil Pressure Hose, 2210 mm (07MAJ - PY4011A).

FORWARD CLUTCH PRESSUREINSPECTION

lMarked with "F")

REVERSE BRAKE PRESSUREINSPECTION I.IOLE

A/T OIL PRESSUREGAUGESET W/PANEL0ta{r6 - oO2Oi|(Xt

A/T LOW PRESSUREGAUGE W/PANEL0706 - qt7o:t{ro

DRIVE PULLEY PRESSUREINSPECTION HOI.E(Marked with "DR")

A/T PRESSURE HOSEADAPTER07MAJ - PYar'120lil R.qulr.d)

A/T PRESSUBE HOSE2210 mm07MAJ - PYitollAla R.quir.d)

(

INSPECNON HOLE(Marked with "SC")

CLUICH PRESSURE

INSPECTION HOLE(Marked with "LUB")

DRIVEN PULLEY PRESSUREINSPECTION HOLElMarked with "DN")

14-300

ATF DIPSTICK

Page 1500 of 2189

Connector ldentification and Wire Harness Routing

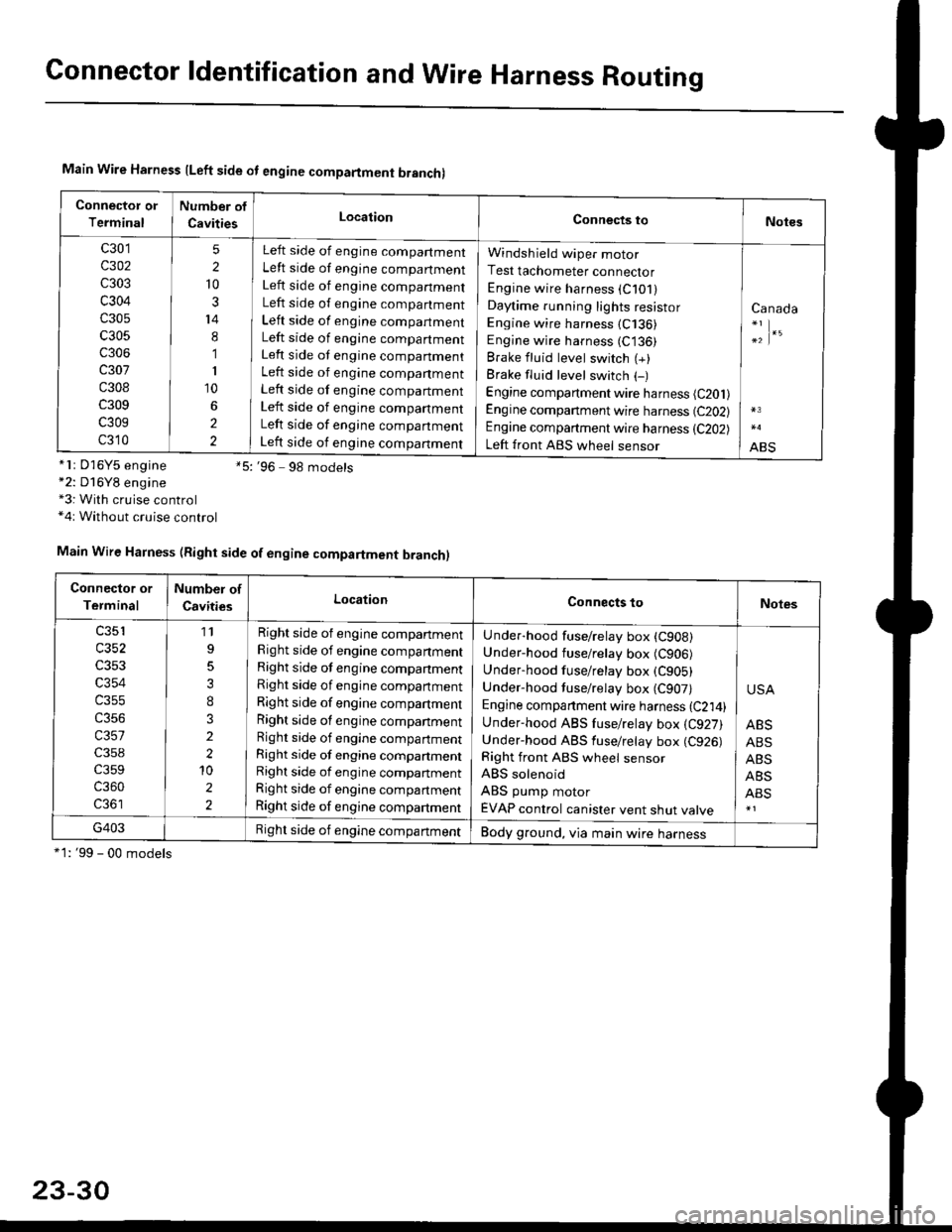

Main Wire Harness lLeft side ot engine compartment branchl

Connector or

Terminal

Number of

CavitiesLocationConnects toNotes

c301

c302

c303

c304

c305

c305

c306

c307

c308

c309

c309

c310

5

2

10

3

14

8

1

I

10

2

2

Left side of engine compartment

Left side of engine compartment

Left side of engine companment

Left side of engine compartment

Left side of engine compartment

Left side of engine compartment

Left side ot engine companment

Left side of engine companment

Left side of engine compartment

Left side of engine companment

Left side of engine companment

Left side of engine companment

Windsh ield wiper motor

Test tachometer connector

Engine wire harness (C101)

Daytime running lights resistor

Engine wire harness (C136)

Engine wire harness (C136)

Brake fluid level switch (+)

Brake fluid level switch (-)

Engine compartment wire harness (C201)

Engine companment wire harness (C202)

Engine compartment wire harness (C202)

Left front ABS wheel sensor

Canada

;|.'

ABS*lr D'16Y5 engine *5:'96 9g models*2: D16Y8 engine*3: With cruise control*4r Without cruise control

*1: '99 - 00 models

Main Wire Harness (Right side of engine compartment branch)

Connector or

Terminal

Number of

CavitiesLocationConnects toNotes

c353

c354

c355

c356

c357

c359

c360

11

3

I

3

2

2'10

2

2

Right side of engine compartment

Right side of engine companment

Right side of engine companment

Right side of engine compartment

Right side of engine compartment

Right side of engine companment

Right side of engine compartment

Right side of engine compartmentRight side of engine compartment

Right side of engine compartment

Right side of engine compartment

Under-hood fuse/relay box (CgoB)

Under-hood fuse/relay box (C906)

Underhood fuse/retay box (C905)

Under-hood tuse/relay box (C907)

Engine companment wire harness {C214)Under-hood ABS fuse/relay box {C927)Under-hood ABS fuse/retay box (C926)

Right front ABS wheel sensor

ABS solenoid

ABS pump motor

EVAP control canister vent shut valve

USA

ABS

ABS

ABS

ABS

ABS

G403Right side of engine compartmentBody ground, via main wire harness

23-30

Page 1565 of 2189

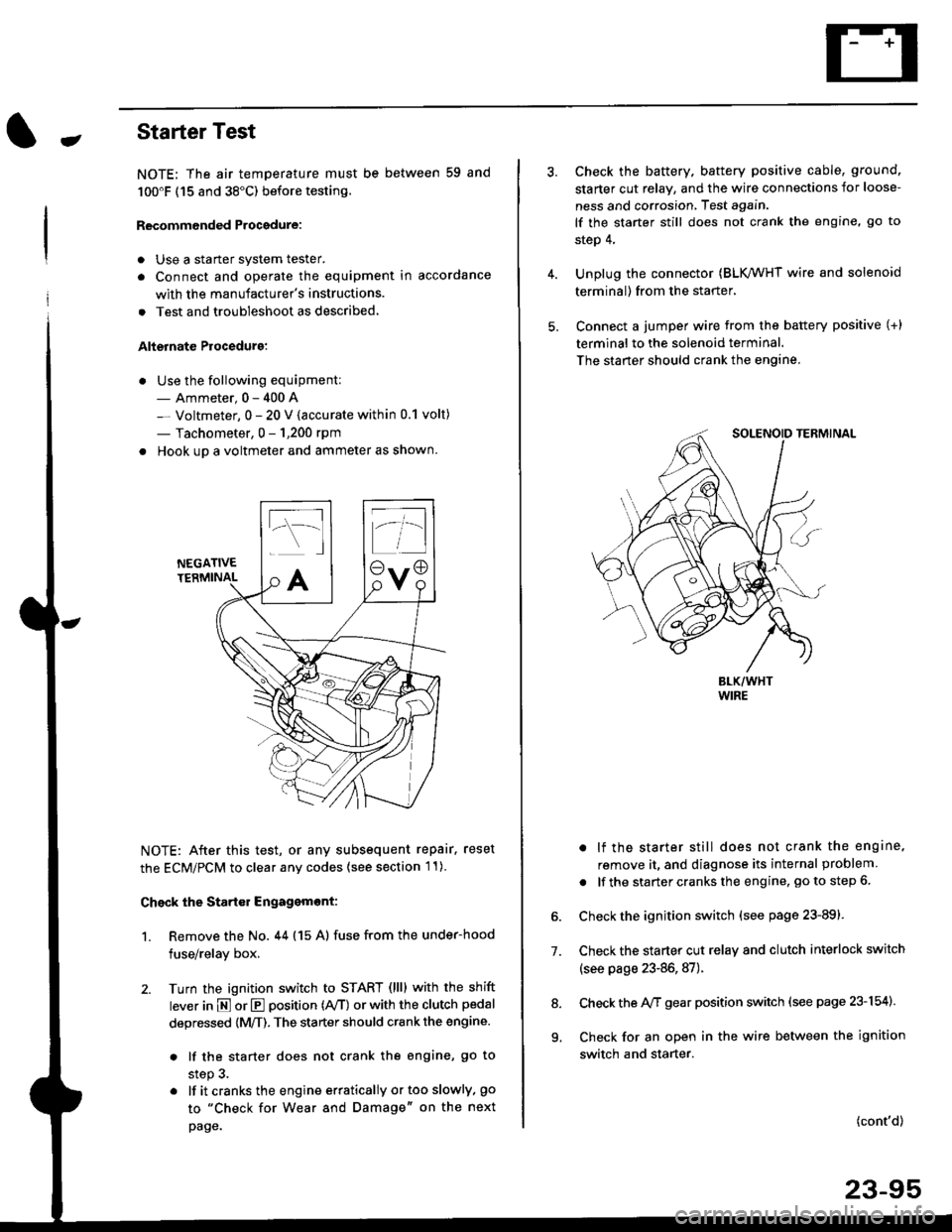

-Starter Test

NOTE; The air temoerature must be between 59 and

100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described,

Alternate Procedurg:

. Use the following equipment:- Ammeter, 0 - 400 A

- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

- Tachometer, 0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NEGATIVETERMINAL

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section l1)

Check the Start€r Engagemont:

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

2. Turn the ignition switch to START (llll with the shift

lever in E or E position (rVT) or with the clutch pedal

depressed {M/T). The starter should crank the engine.

. lf the starter does not crank the engine, go to

step 3.

. lf itcranksthe engineerraticallyortooslowly, go

to "Check for Wear and Damage" on the next

page.

Check the battery. battery positive cable, ground,

starter cut relay, and the wire connections for loose-

ness and corrosion, Test again.

lf the starter still does not crank the engine, go to

step 4,

Unplug the connector (BLK,/WHT wire and solenoid

terminal) from the starter,

Connect a jumper wire from the battery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem

. lf the startercranksthe engine, goto step 6.

Check the ignition switch (see page 23-891.

Check the starter cut relay and clutch interlock switch

(see page 23-86,87).

Check the A/f gear position switch (see page 23-154).

Check for an open in the wire between the ignition

switch and starter.

7.

(cont'd)

23-95

9.

Page 1573 of 2189

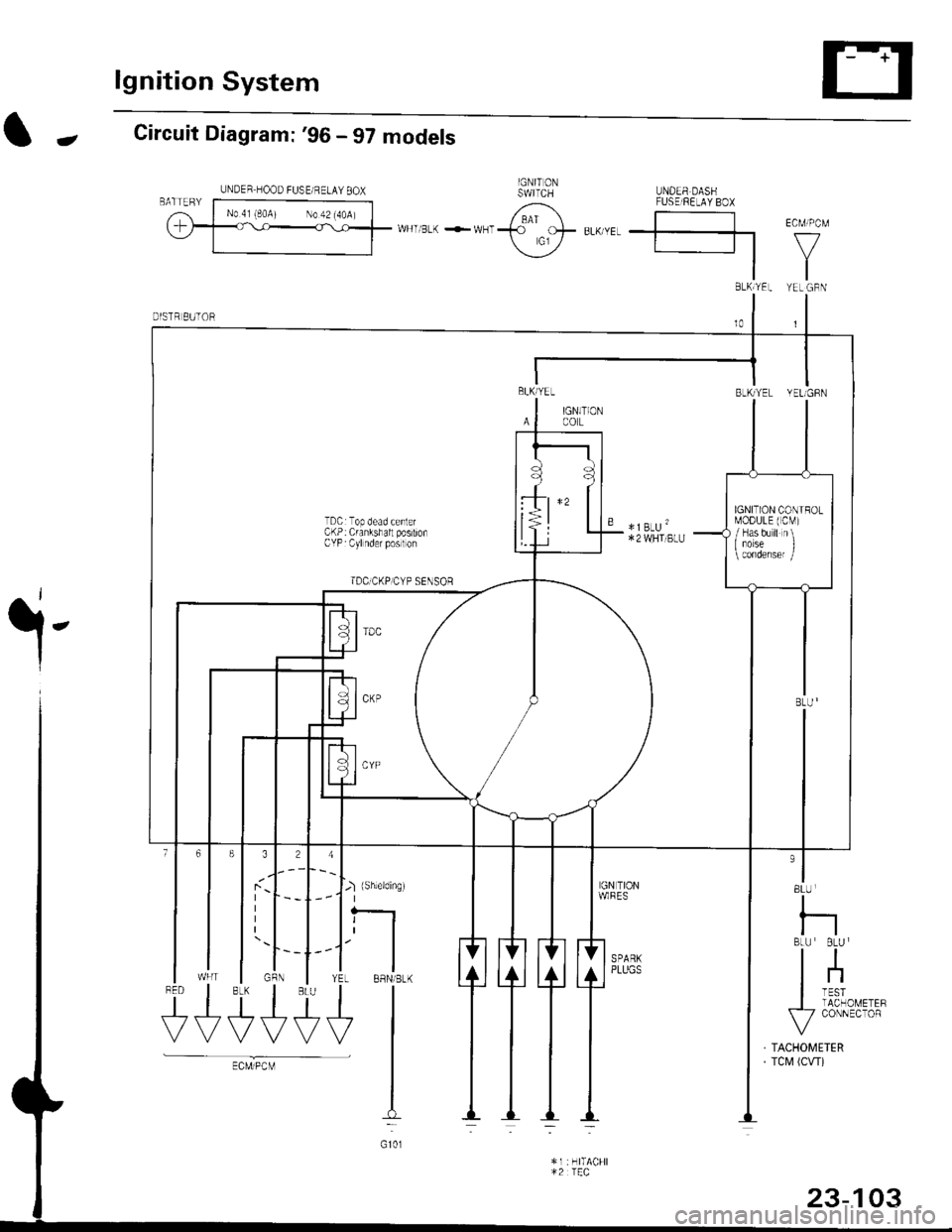

lgnition System

-Circuit Diagram: '96 - 97 models

.i-

8LU

I

nBLU BLU I

tl

lnI TESTI TACHOMETEF\-7 CONNECTOR

TACHOMETERTCM (CW)

J-) {sh,eldinsr't I

tfYEL BBN/BLK

+l

I:

G101

$t+++

UNDER HOOD FUSE/ RELAY 8OX

BLh TEL YEL GBN

BLKlYEL

IAl

BLK/YEL YELIGFN

IGN]TIONCOL

TDCrTop dead cenlerCKP: Crankshall postionCYP Cylnder poslon

TDC]CKP]CYP SENSoR

" *]BLU'*2 WHI BLU

IGNITION CONIROLMODULE (CM)

/ Has b'r ll n\I iorse I

rUSE FE-AV BO}

*u r-. .-*---{<9ot # u,,."r. | |

\j/ El v

tl

23-103

Page 1579 of 2189

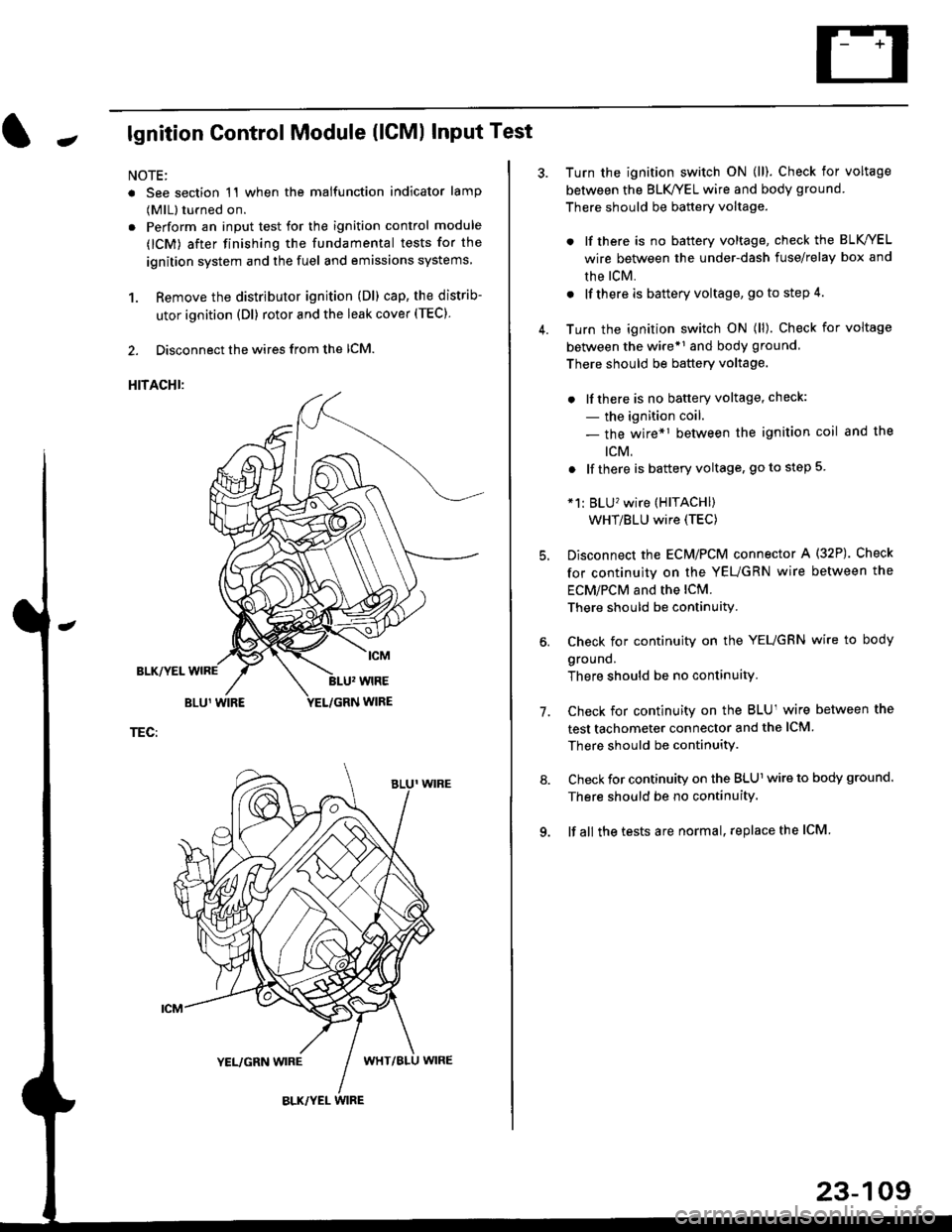

Jlgnition Control Module (lCMl Input Test

NOTE:

. See section 1'l when the malfunction indicator lamp

(MlL) turned on.

. Perform an input test for the ignition control module

(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems

1. Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor and the leak cover (TEC).

2. Disconnect the wires from the lCM.

HITACHI:

BLK/YEL

TEC:

Turn the ignition switch ON (ll). Check for voltage

between the BLK/YEL wire and body ground.

There should be battery voltage.

. lf there is no battery voltage, check the BLK/YEL

wire between the under-dash fuse/relay box and

rhe lcM.

. lf there is battery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the wire*r and body ground

There should be battery voltage.

. lfthere is no battery voltage, check:

- the ignition coil.

- the wire*1 between the ignition coil and the

tcM.

. lf there is battery voltage, go to step 5

*1: BLU'�wire (HITACHI)

WHT/BLU wire (TEC)

Disconnect the EcM/PCM connector A (32P). Check

for continuity on the YEUGRN wire between the

ECM/PCM and the lCM.

There should be continuity.

Check for continuity on the YEUGRN wire to body

ground.

There should be no continuity.

Check for continuity on the BLUl wire between the

test tachometer connector and the ICM

There should be continuitY.

Check for continuity on the BLUl wire to body ground.

There should be no continuity.

lf all the tests are normal, replace the ICM

7.

23-109

Page 1599 of 2189

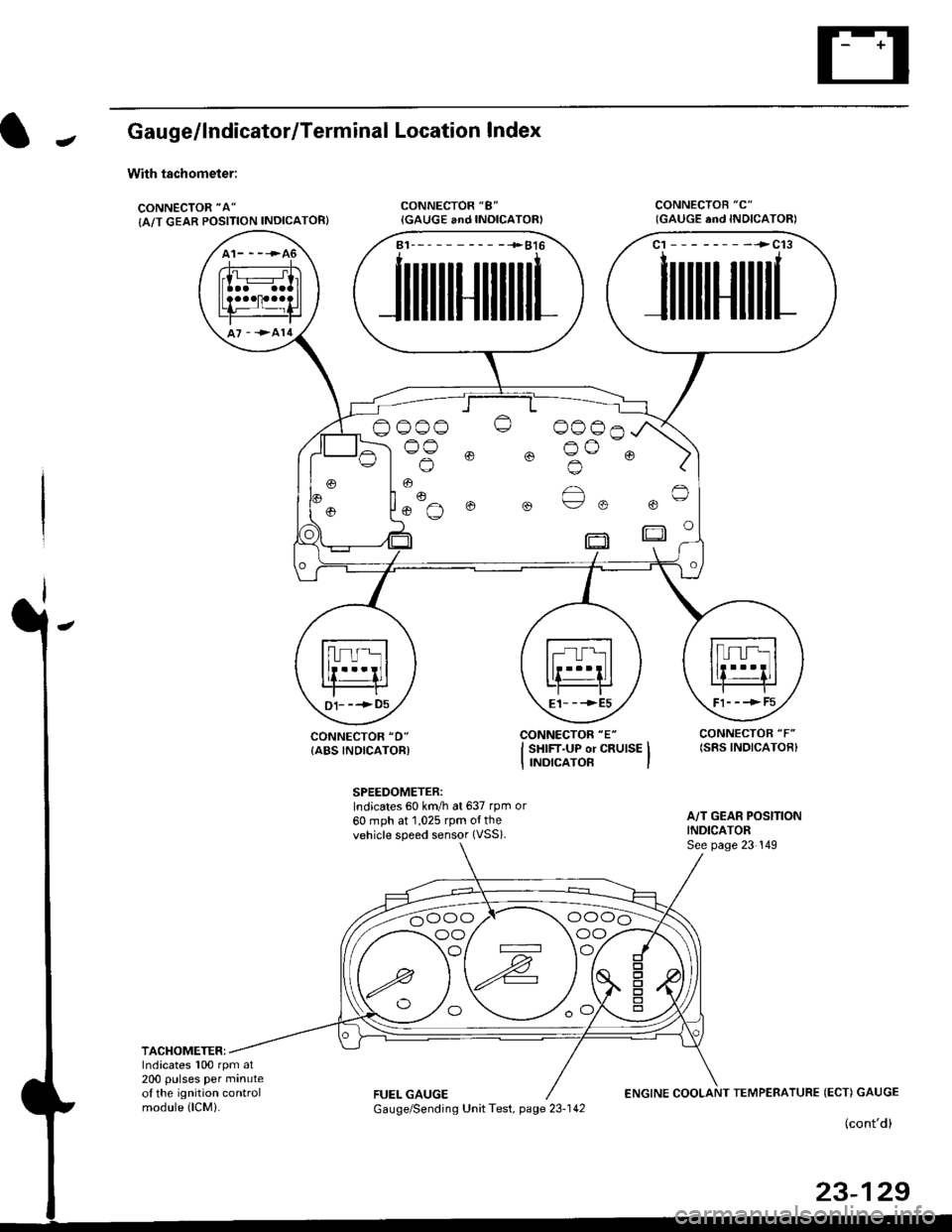

JGau ge/lndicator/Terminal

With tachometer;

CONNECTOR "A"

{A/T GEAR POSITION INDICATOR}

Location lndex

CONNECTOR "8"

{GAUGE and INOICATOR)CONNECTOB "C"

CONNECTOR "D"

{ABS INDICATORI

SPEEDOMETER:Indicates 60 km/h at 637 rpm or

60 mph at 1,025 rpm o{thevehicle speed sensor (VSS).

A/T GEAR POSITIONINDICATORSee page 23 149

TACHOMETER:Indicates 100 rpm at200 pulses per minuteol the ignition controlmodule (lCMi.FUEL GAUGEENGINE COOLANT TEMPERATURE (ECT) GAUGE

(cont'd)

23-129

(GAUGE end INDICATORI

A1-----------+816

JlltlllulllllrL

c1 --------->c13

1ililil{ilrL

oooo o 0006^

)og @ @ o^o @ )'l |. o

Fl- - -> F5E1_ _ -->E5D1- --+05

oo/ \oo

Gauge/Sending Unit Test, page 23-142

Page 1600 of 2189

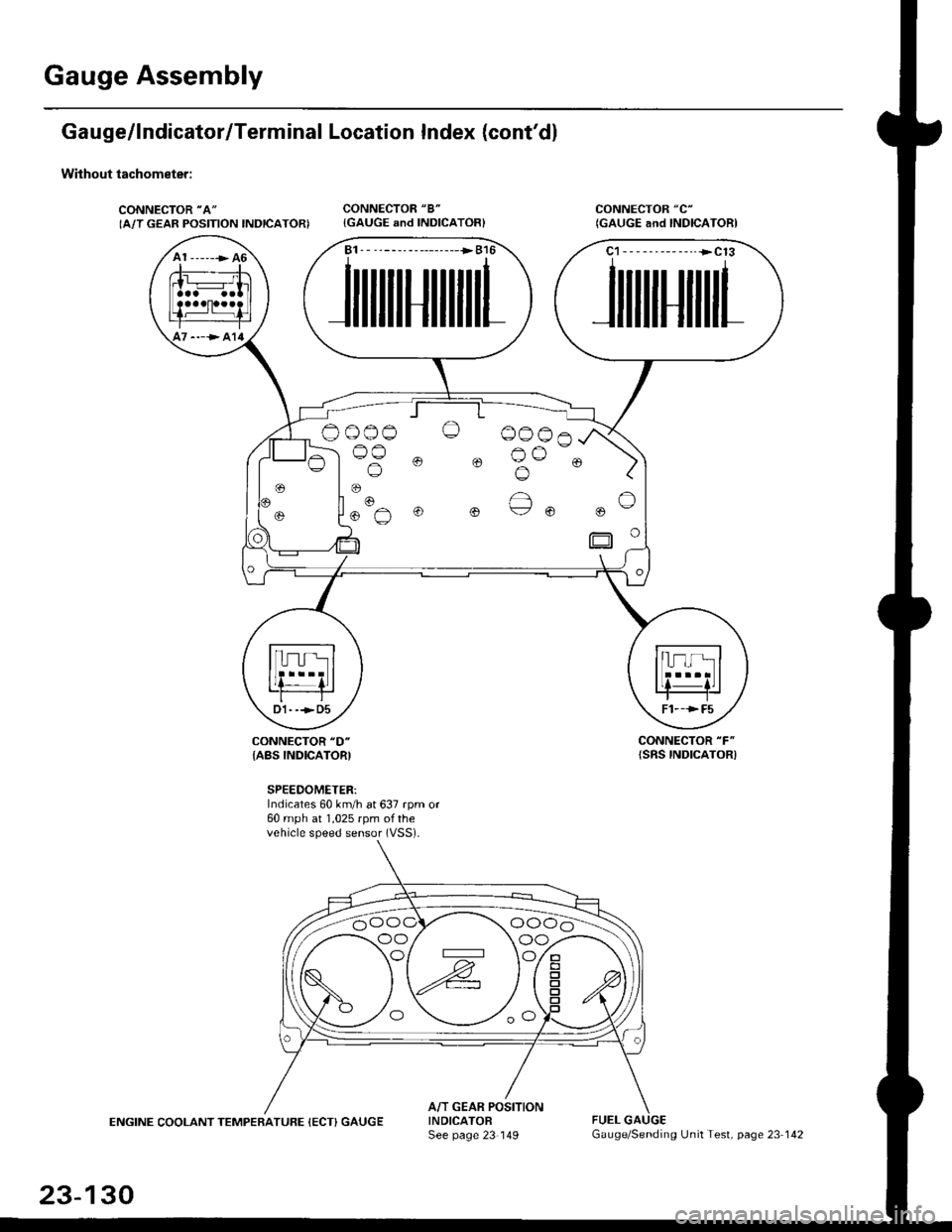

Gauge Assembly

Gauge/lndicator/Terminal Location Index (cont'd)

Without tachometer:

CONNECTOR "A"

IA/T GEAR POSITION INDICATORICONNECTOR "8"

{GAUGE and INDICATOR}CONNECTOR "C"

(GAUGE and INDICAIORI

CONNECTOR "F"

{SRS INDICATOR)CONNECTOR "D"

{ABS INDICATORI

SPEEDOMETER:Indicates 60 km/h at 637 rpm or60 mph at 1,025 rpm ofthevehicle speed sensor (VSS).

ENGINE COOLANT TEMPERATUFE (ECT) GAUGEA/T GEAR POSITIONINDICATOFSee page 23 149FUEL

A1 ------> 46

----> al4

B1. - --------------->B16

JilililHililil1

C1-- - --------..+C13

JililHililL

Oo_o-o O 0006

lus 0 0 Bu-. )

oo/ \oo

23-130

Gauge/Sending Unit Test, page 23 142

Page 1606 of 2189

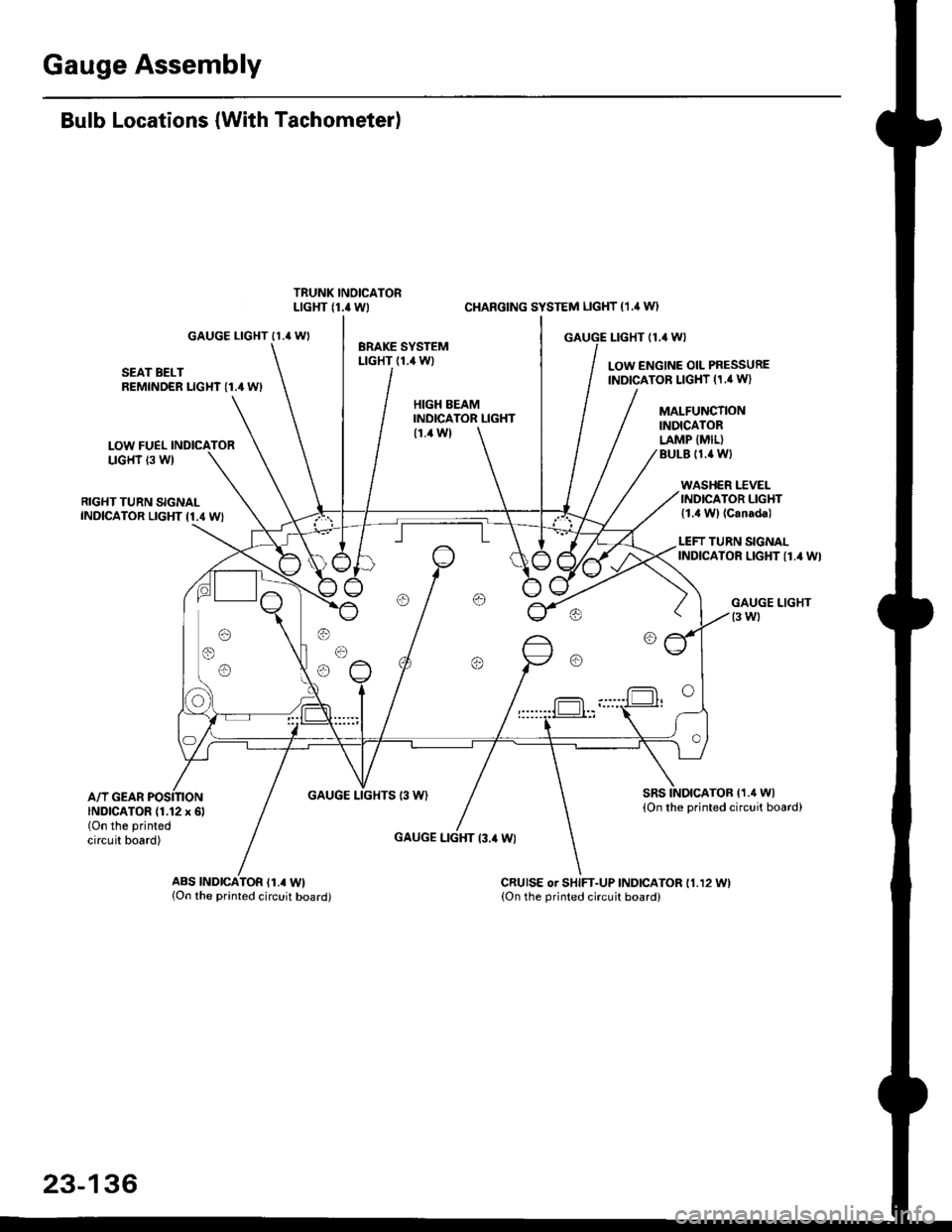

Gauge Assembly

Bulb Locations (With Tachometer)

GAUGE LIGHT II.' WI

SEAT BELTREMINDER LIGHT I1.4 WI

LOW FUELLIGHT 13 W)

RIGHT TURN SIGNALINDICATOR LIGHT I1.4 WI

A/T GEARGAUGE LIGHTS 13 W)

CI{ARGING SYSTEM LIGHT (1.,1W)

GAUGE I-IGHT {1,4 WI

LOW ENGINE OIL PRESSUREINDICATOR LIGHT (1,' W}

HIGH EEAMINDICATOR LIGHT(1.4 W)

GAUGE LIGHT l3.il Wl

MALFUNCTIONINDICATORLAMP {MIL}BULE (1.{ Wl

WASHER I.'C VELINDICATOR LIGHT{1.4 Wl (Canada)

LEFT TURN SIGNALINDICATOR LIGHT {1.4 WI

sRsTOB (1.4 Wl

{On the printed circuit board)INDICATOR (1.12 x 6l(On the printed

circuit board)

ABS |ND|CATOR (1.. Wl{On the printed circuit board)CRUISE or SHIFT-UP INDICATOR 11.12 11.{On the orinted circuit board)

23-136