blue HONDA CIVIC 1998 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 151 of 2189

Cylinder HeadValve Seats

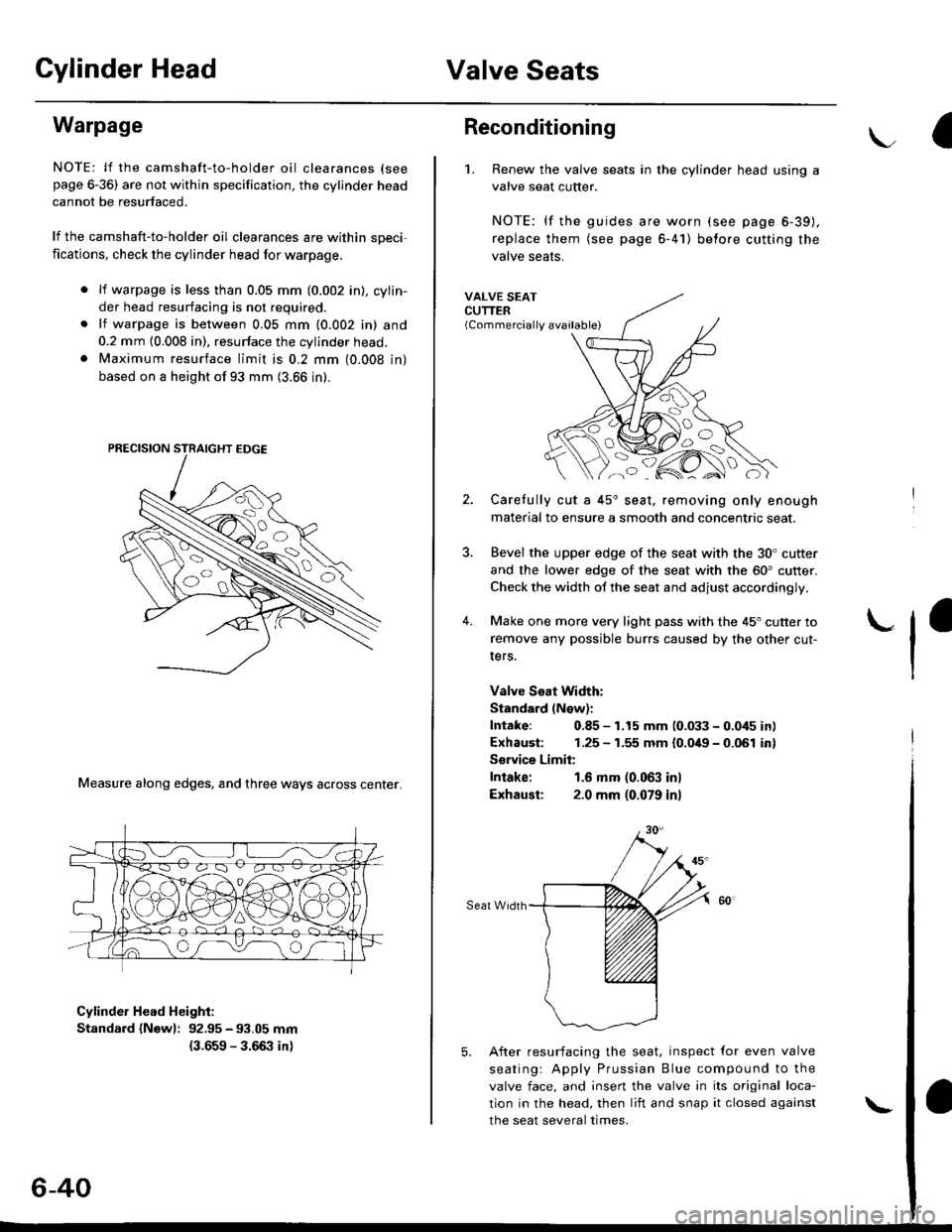

Warpage

NOTE: lf the camshaft-to-holder oil clearances (see

page 6-36) are not within specification, the cylinder head

cannot be resurfaced.

lf the camshaft-to-holder oil clearances are within sDeci,

fications, check the cylinder head lor warpage.

lf warpage is less than 0.05 mm (0.002 in), cylin-

der head resurfacing is not required.

lf warpage is between 0.05 mm (0.002 in) and

0.2 mm {0.008 in), resurface the cylinder head.

Maximum resurface limit is 0,2 mm (0.008 in)

based on a height of 93 mm (3.66 in).

Measure along edges, and three ways across center.

Cylinder Head Height:

Standard {Newl: 92.95 - 93.05 mm

{3.659 - 3.66:} in)

6-40

\

Reconditioning

'1. Renew the valve seats in the cylinder head using a

valve seat cutter.

NOTE: lf the guides are worn (see page 6-39).

replace them (see page 6-41) belore cutting the

valve seats.

VALVE SEATCUTTER(Commercially available)

2.

?

4.

Carefully cut a 45'seat, removing only enough

material to ensure a smooth and concentric seat.

Bevel the upper edge of the seat with the 30. cutter

and the lower edge of the seat with the 60' cutter.

Check the width of the seat and adjust accordingly.

Make one more very light pass with the 45" cutter to

remove any possible burrs caused by the other cut-

Iers.

Valve Seat Width:

Standard (N€w):

Intake: 0.85 - 1.15 mm 10.033 - 0.045 in)

Exhaust: 1.25 - 1.55 mm {0.049 - 0.061 in}

Sorvice Limit:

Intake: 1.6 mm (0.063 inl

Exhausl: 2.0 mm (0.079 in)

Seat Width

5. After resurfacing the seat, inspect for even valve

seatingr Apply Prussian Blue compound to the

valve face, and insert the valve in its original loca-

tion in the head, then liit and snap it closed against

the seat several times.

Page 152 of 2189

Valve Guides

7.

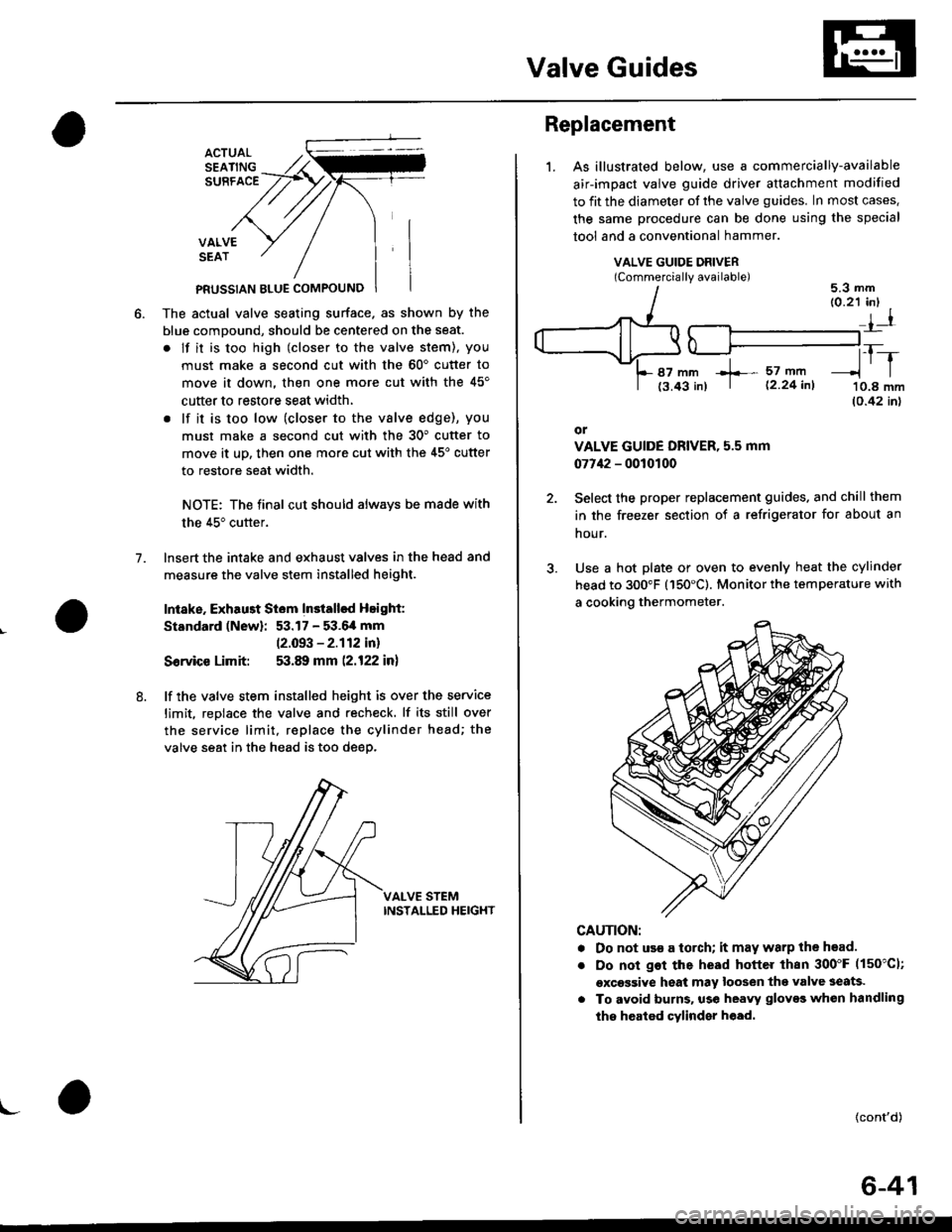

VALVESEAT

PFUSSIAN BTUE COMPOUNO

The actual valve seating surface. as shown by the

blue comDound, should be centered on the seat.

. lf it is too high (closer to the valve stem), you

must make a second cut with the 60'cutter to

move it down, then one more cut with the 45'

cutter to restore seat width,

. lf it is too low (closer to the vslve edge), you

must make a second cut with the 30" cutter to

move it uD, then one more cut with the 45'cutter

to restore seat width.

NOTE: The final cut should always be made with

the 45" cutter.

lnsert the intake and exhaust valves in the head and

measure the valve stem installed height.

Intake. Exhau3t Siem Installsd Height:

Standard (New): 53.17 - 53.6,4 mm

12.093 - 2.112 in)

Sorvice Limit: 53.89 mm (2.122 in)

lf the valve stem installed height is over the service

limit. reDlace the valve and recheck. lf its still over

the service limit, replace the cylinder head; the

valve seat in the head is too deep.

VALVE STEMINSTALLED HEIGHT

8.

\-

Replacement

1.As illustrated below, use a commercially-available

air-impact valve guide driver attachment modified

to fit the diameter of the valve guides. In most cases.

the same procedure can be done using the special

tool and a conventional hammer.

VALVE GUIDE DRIVERlCommerciallv available)5.3 mm

87 mm +- 57 mft

t3.43 in) | 12 24 inl

tr-r'10.8 mm(0.42 inl

or

VALVE GUIDE DRIVER, 5.5 mm

07742 - 0010100

Select the proper replacement guides. and chill them

in the freezer section of a refrigerator for about an

nour.

Use a hot plate or oven to evenly heat the cylinder

head to 300"F (150'C). Monitor the temperature with

a cooking thermometer.

CAUTION:

. Do not use a torch; it may warp the head.

Do not got the head hottel than 300"F (150"C1;

excessive heat may loosen thg valve seats.

To avoid burns. use heayy gloves whon handling

the heated cylinder h€ad.

{cont'd)

6-41

Page 188 of 2189

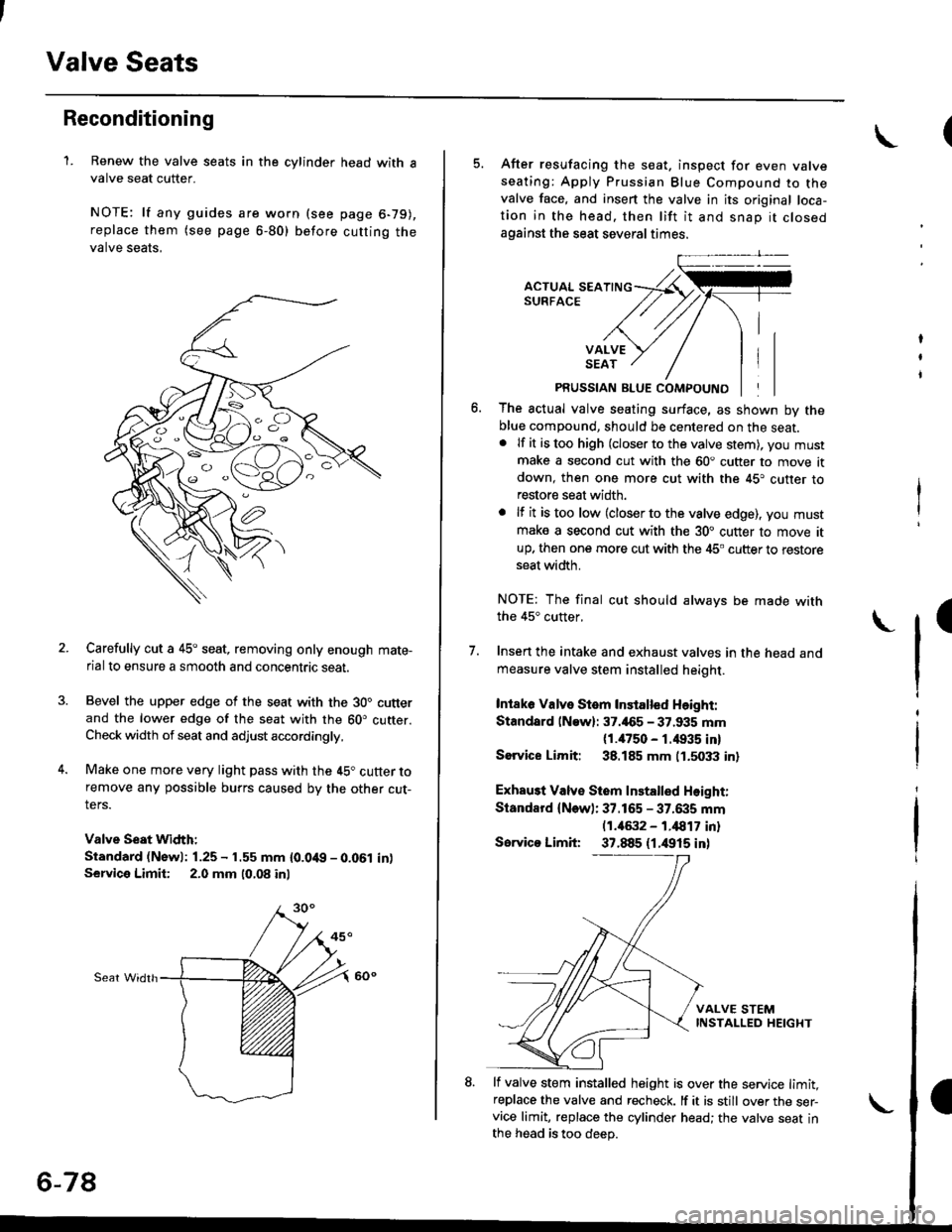

Valve Seats

Reconditioning

1. Renew the valve seats in the cylinder

valve seat cutter.

NOTE: lf any guides are worn (see

replace them (see page 6-80) before

valve seats,

head with a

page 6-79),

cutting the

Carefully cut a 45o seat, removing only enough mate-

rial to ensure a smooth and concentric seat.

Bevel the upper edge of the seat with the 30" cutterand the lower edge of the seat with the 60. cutter.Check width of seat and adjust accordingly,

Make one more very light pass with the 45" cutter toremove any possible burrs caused bv the other cut-

ters.

Valve Seat Width:

Standard (Newl: 1.25 - 1.55 mm {0.0't9 - 0.061 in)Service Limii: 2.0 mm 10,08 inl

Sear Widrh

6-78

5. After resufacing the seat. inspect for even valveseating: Apply Prussian Blue Compound to thevalve face, and insert the valve in its original loca-tion in the head. then lift it and snap it closedagainst the seat several times.

PRUSSIAN BLUE COMPOUND

The actual valve seating surface, as shown by theblue compound, should be centered on the seat.. lf it is too high (closer to the valve stem), you mustmake a second cut with the 60. cutter to move itdown, then one more cut with the 45. cutter torestore seat width.

. lf it is too low (closer to the valve edge), you must

make a second cut with the 30. cutter to move itup. then one more cut with the 45. cutter to restoreseat width.

NOTE: The final cut should always be made withthe 45" cutter,

7. Insen the intake and exhaust valves in the head and

measure valve stem installed heioht.

Intaka Valve Stem Installed Height:

Standsrd lNaw): 37.465 - 37.935 mm(1./P50 - r.4935 inl

Sorvice Limit: 38.185 mm 0.5033 in)

Exhau3t Valv€ Stem Installed Height:

Standard (New): 37.165 - 37.6i|5 mm(1.46:t2 - 1.i1817 inl

Servico Limit 37.885 (1.4915 inl

lf valve stem installed height is over the service limit,replace the valve and recheck. lf it is still over the ser-vice limit, replace the cylinder head; the valve seat inthe h6ad is too deep.

(

Page 208 of 2189

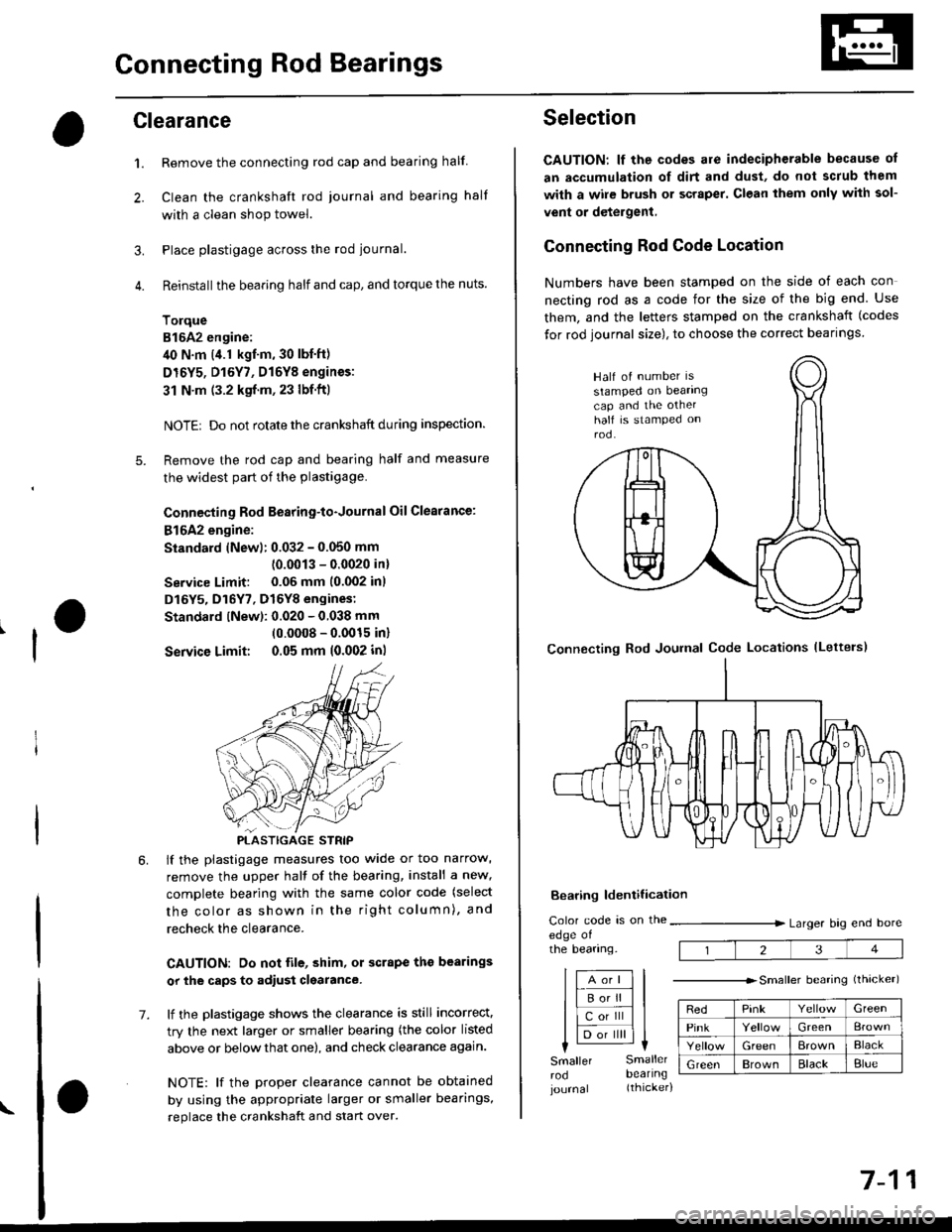

Connecting Rod Bearings

Clearance

Remove the connecting rod cap and bearing half

Clean the crankshaft rod iournal and bearing half

with a clean shop towel.

Place plastigage across the rod journal.

Reinstall the bearing half and cap, and torque the nuts.

Torque

Bl6A2 engine:

40 N.m (4.1 kgl.m, 30 lbf'ft)

Dr6Y5, D16Y7, D16Y8 enginss:

31 N'm (3.2 kgf.m, 23 lbf ftl

NOTE| Do not rotate the crankshaft during inspection.

Remove the rod cap and bearing half and measure

the widest part of the plastigage.

Connecting Rod Bearing-to.Journal Oil Glearance:

816A2 engine:

Standard lNewl: 0.032 - 0.050 mm

10.0013 - 0.0020 in)

Service Limit: 0.06 mm 10.002 inl

D16Y5, D16Y7, D16Y8 engines:

Standard lNew): 0.020 - 0.038 mm

(0.0008 - 0.0015 in)

Service Limit 0.05 mm 10.002 inl

'1.

4.

lf the plastigage measures too wide or too narrow'

remove the upper half of the bearing, install a new,

complete bearing with the same color code (select

the color as shown in the right column), and

recheck the clearance.

CAUTION: Do not lile, shim, or scrape the bearings

or the caps to adiust clgarance.

lf the plastigage shows the clearance is still incorrect.

try the next larger or smaller bearing (the color listed

above or below that one), and check clearance again.

NOTE: lf the Droper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

PLASTIGAGE STRIP

\

7.

7-11

Selection

CAUTION: lf the codes are indecipherable because of

an accumulation of dirt and dust, do not sclub them

with a wile brush or scraper. Clean them only with sol-

vent or detergent,

Connecting Rod Code Location

Numbers have been stamped on the side of each con

necting rod as a code for the size of the big end Use

them, and the letters stamped on the crankshaft (codes

for rod journal size), to choose the correct bearlngs

Half of number ls

stamped on bearingcap and the otherhalf is stamped onrod.

Bearing ldentilication

Color code is on theedge ofthe bearing.

lfA--;T] |

lle"'tt l;llcorlll ll

I lD;;ilril |l-l

Larger brg end bore

Smaller Smallerrod bearlngjournal (thicker)

---------------- Smallerbearing{thrcker)

RedPinkGreen

PinkGreen

GreenErownBlack

GreenBrownBlackBlue

1234

Connecting Rod Journal Code Locations (Lettels)

Page 1475 of 2189

t

Five-step Troubleshooting

2.

1.Verify The Complaint

Turn on all the components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

Analyze The Schematic

Look up the schematic for the problem circuit.

Determine how the circuit is supposed to work by

tracing the current paths from the power feed

through the circuit components to ground. lf several

circuits fail at the same time, the fuse or ground is a

likely cause.

Based on the symptoms and your understanding of

the circult operation, identify one or more possible

causes of the problem.

lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep in mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure first. Try to make

tests at points that are easily accessible.

Fix The Problem

Once the specific problem is identified, make the

repair. Be sure to use proper tools and safe proce-

dures.

Make Sure The Circuit Works

Turn on all components in the repaired circuit in all

modes to make sure you've fixed the entire prob-

lem. lf the problem was a blown fuse, be sure to

test all of the circuits on the fuse, Make sure no new

problems turn up and the original problem does not

recur.

3.

Wire Color Codes

The following abbreviations are used to identify wire

colors in the circuit schematics:

wHT ............................. White

YEL ............................... Yellow

BLK ............,.,...............81ack

BLU .............................. Blue

GRN .............................Green

RED .......................,...... Red

ORN ............................. Orange

PNK .............................. Pink

BRN .............................. Brown

GRY .............................. Gray

PUR .,.................,.,........ Purple

LT BLU ......................... Light Blue

LT GRN ........................ Light Green

The wire insulation has one color or one color with

another color stripe. The second color is the stripe.

WHT/BLK

23-5

Page 1678 of 2189

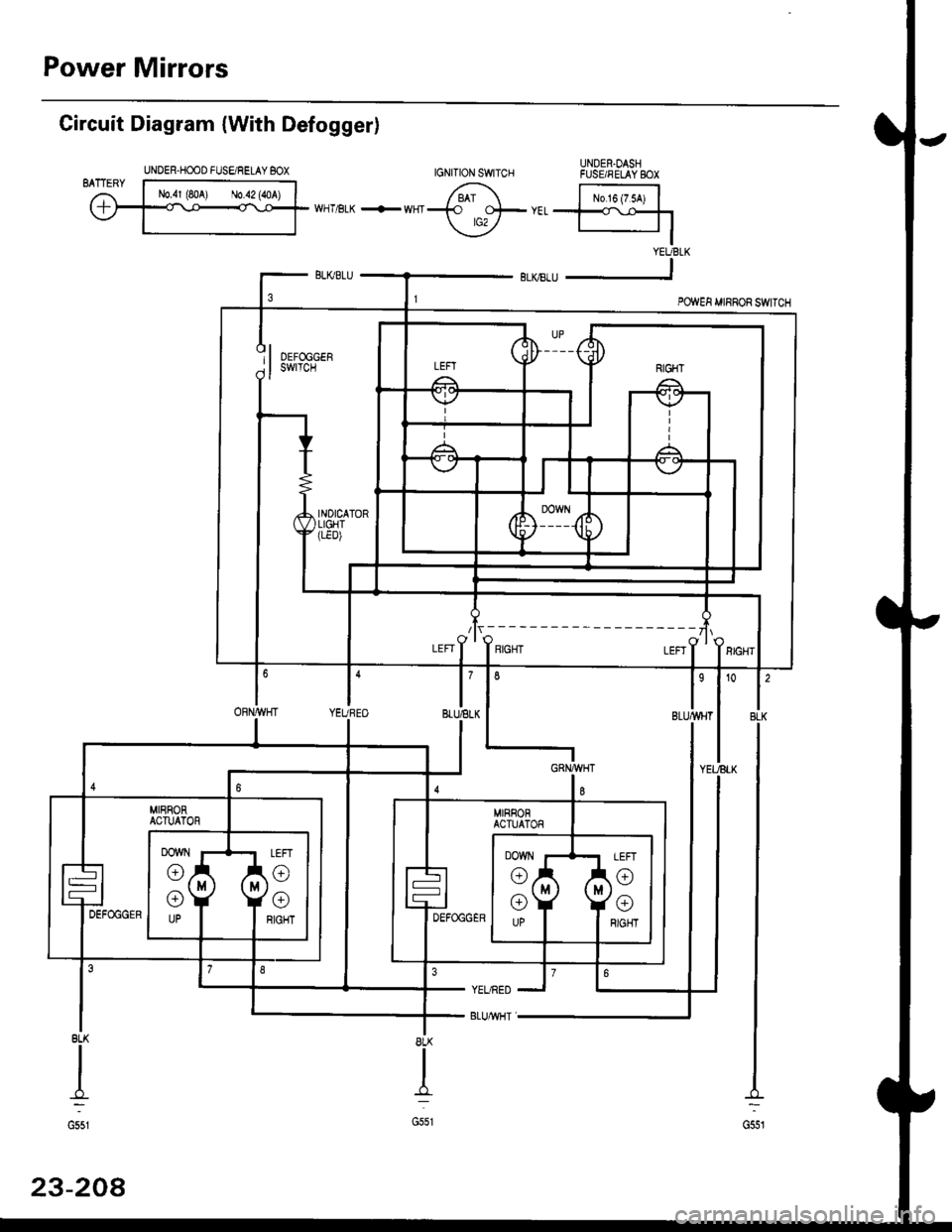

Power Mirrors

UNDER.OASHFUSE/FELAY BOX

Circuit Diagram {With Defogger)

BLK

G551

8LK

I

G551

YEURED

BLUMHT

8LK

II

-f,:

G551

23-208

UNDER-HOOD FUSE/RELAY BOX

/lr,---------- ---zlr

I'BLUELKl'YEUBEO

6

ORN/WHT

Page 1825 of 2189

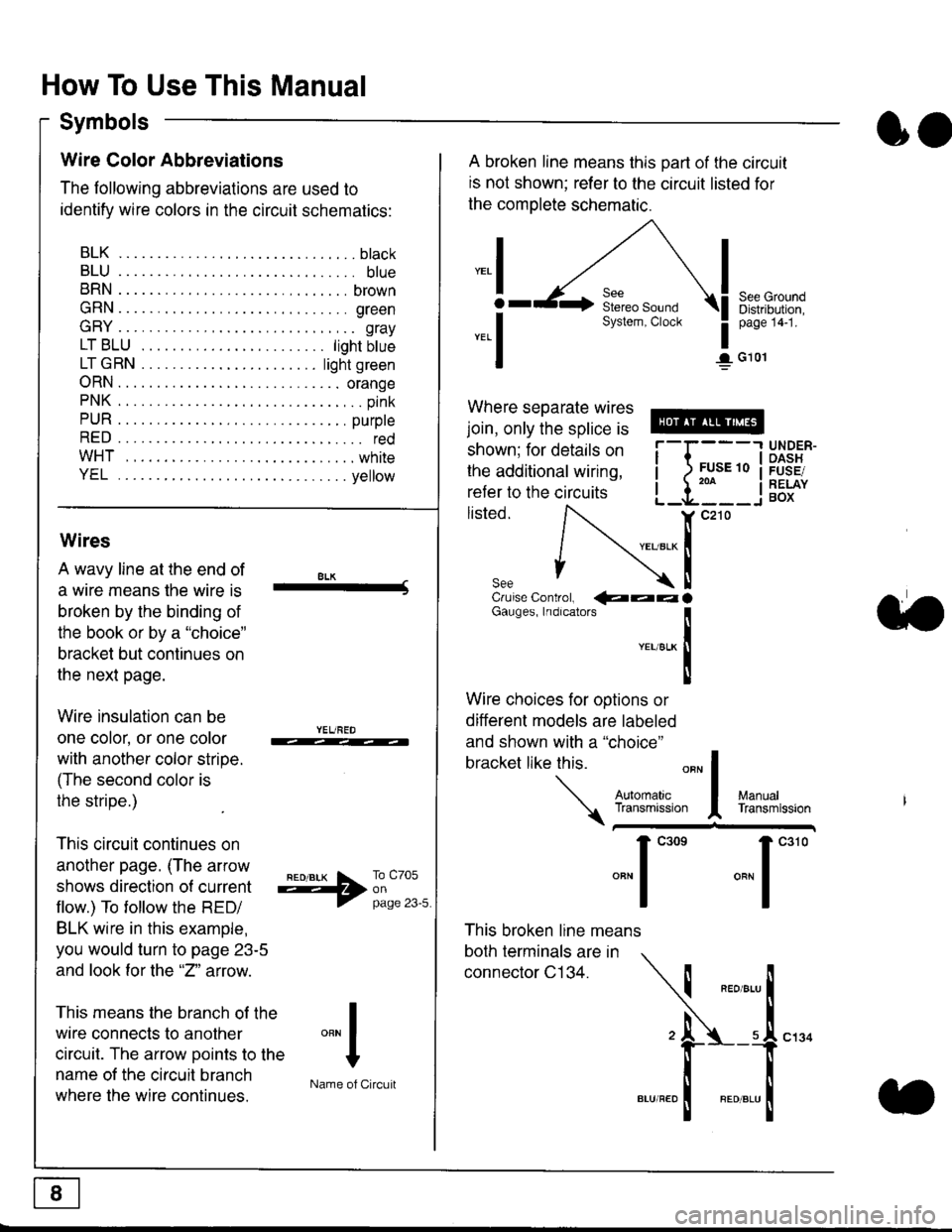

How To Use This Manual

Symbols

oo

Wire Color Abbreviations

The following abbreviations are used to

identify wire colors in the circuit schematics:

BLK.... .........b|ack

BLU.... ......... blue

BRN.... ,....... brown

GRN.... ........ green

GRY.... ......,.. gray

LTBLU . .....lightbtue

LTGRN. ....lightgreen

ORN.... ....... orange

PNK .... .......,.. pink

PUR .... ........ purple

RED .... .......... red

WHT... .........white

YEL .... ........ yellow

A broken line means this part of the circuit

is not shown; refer to the circuit listed for

the complete schematic.

"ral

o

-.1

See GroundDistribution,page 141.

I G101

Where separate wires

join, only the splice is

shown; for details on

the additional wiring,

refer to the circuits

listed.ili::i

{[

UNDER-OASHFUSE/RELAYBOX

Wires

A wavy line at the end of

a wire means lhe wire is

broken by the binding of

the book or by a "choice"

bracket but continues on

the next page.

Wire insulation can be

one color, or one color

with another color stripe.

(The second color is

the stripe.)

This circuit continues on

another page. (The arrow

shows direction o{ current

flow.) To tollow the RED/

BLK wire in this example,

you would turn to page 23-5

and look for the "2" anow.

This means the branch of the

wire connects to another

circuit. The arrow Doints to the

name of the circuit branch

where the wire continues.

8LK-Cruise Control, €�aaaGauges, Indrcalors

!YEUsLK

Ttl

Wire choices for options or

different models are labeled

and shown with a "choice"

bracket like this.

This broken line means

both terminals are in

connector C134.

a.

+##l:i""lManuallransmission

ryil;::,

.""1

""'

"""1".'0

I

""^l

:-lName of Circuit

Page 2109 of 2189

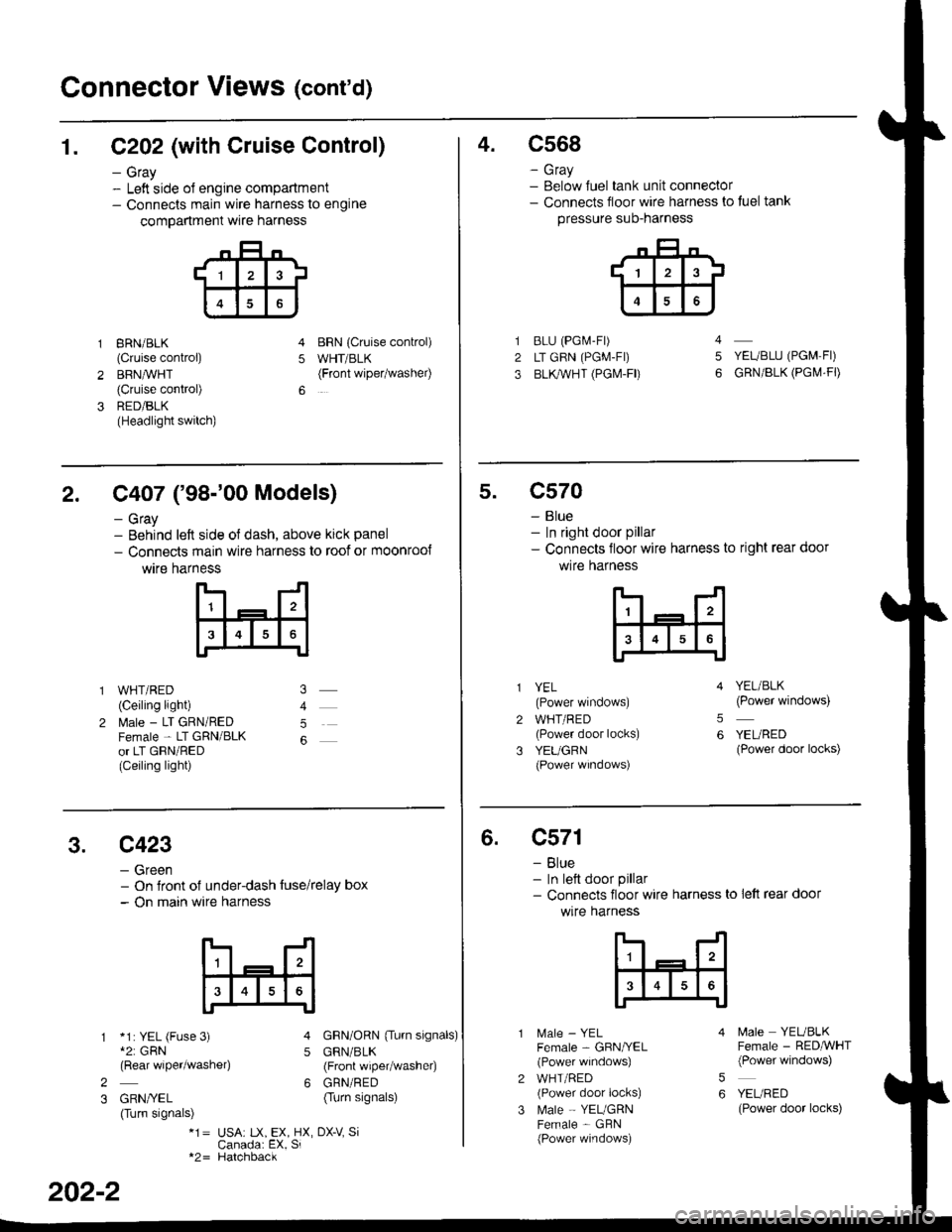

Connector Views (cont'd)

1. C202 (with Cruise Control)

- Gray- Left side ol engine compartment- Connects main wire harness to engine

compartment wre harness

gRN/BLK

(Cruise control)

BRN,ryVHT(Cruise control)

RED/BLK(Headlight switch)

BRN {Cruise conkol)

WHT/BLK(Front wipetwashel)5

4.c568

- Gray- Below Juel tank unit connector- Connects floor wire harness to tuel tank

pressure suo-narness

BLU (PGi.4-Fr)

LT GRN (PGM-FI)

BLl(WHT (PGI\4-FD

YEUBLU (PGM,FI)

GRN/BLK (PGI\,4.FD

4

5

2. C407 ('98-'00 Models)

- Gray- Behind left side ol dash, above kick panel

- Connects main wire harness to roof or moonroo{

wtre harness

WHT/RED(Ceiling light)

l\4ale - LT GRN/REDFemale - LT GRN/BLKor LT GRN/RED(Ceiling light)

5

5.c570

- Blue- In right door pillar- Connects floor wire harness to right rear door

wlre hafness

2

3

YEL(Power windows)

WHT/RED(Power door locks)

YEUGRN(Power wrndows)

YEL/BLK(Power windows)

YEURED(Power door locks)

5

6

3.c423

- Green- On Jront of under-dash tuse/relay box- On main wire harness

*1: YEL (Fuse 3)*2: GRN(Rear wiper/washe4

GRN/YEL(Turn signals)

GRN/ORN {Tu.n signals)

GRN/BLK(Front wiper/washer)

GRN/RED(Turn signals)

5

62

3

*1= USA: tX, EX, HX, DX-V SiCanada: EX, Si*2= Hatchback

202-2

6.c571

- Blue- In lett door pillar- Connects floor wire harness to lett rear door

wlre harness

MaIe _ YELFemale - GBN/YEL(Power windows)

WHT/RED(Power door locks)

Male - YEUGRNFemale - GBN(Power windows)

5

6

N4ale YEUBLKFemale - RED,ryVHT(Power windows)

YEURED(Power door locks)

Page 2110 of 2189

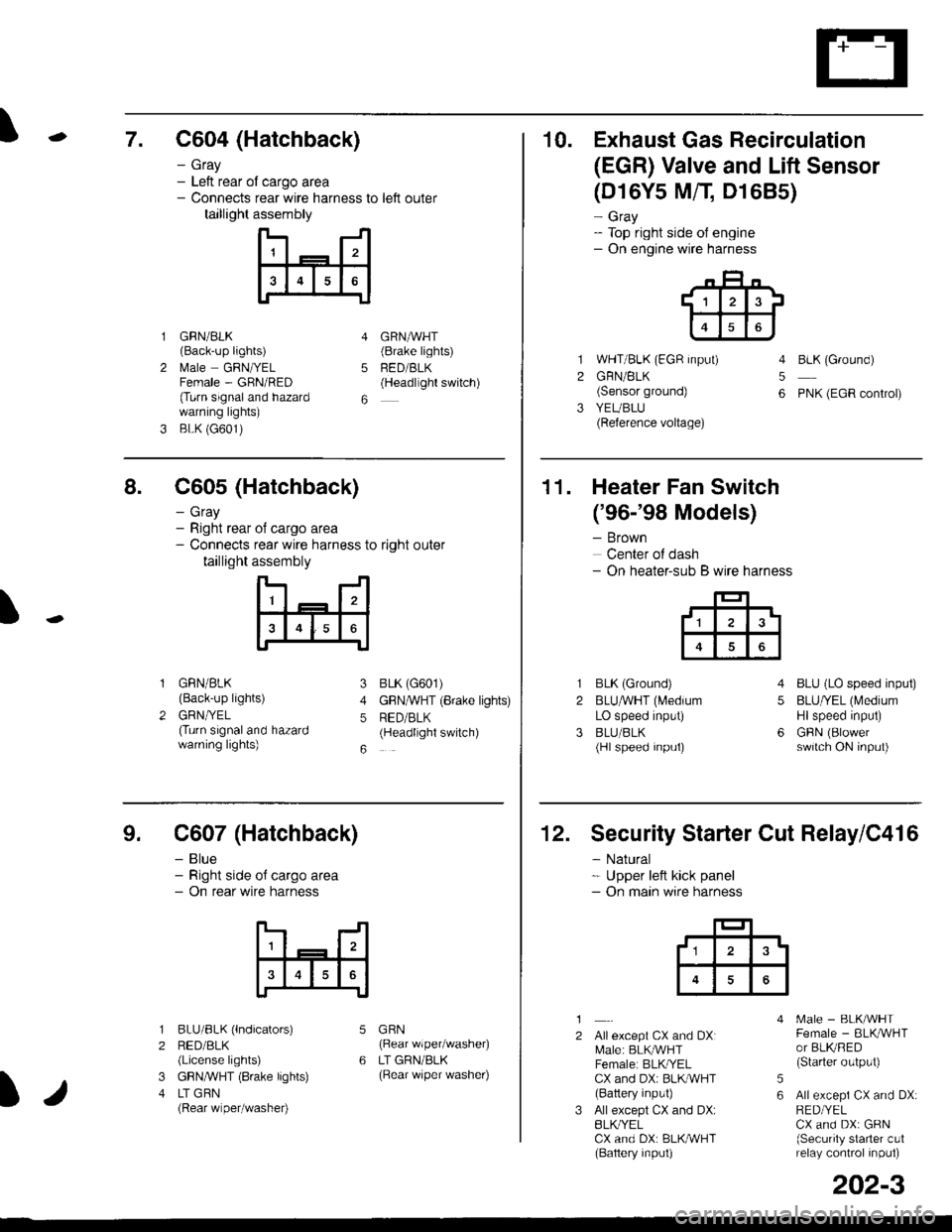

\7. C604 (Hatchback)

GRN/BLK(Back-up lights)

l\4ale GRNIYELFemale - GRN/RED(Turn signaland hazardwarning lights)

BLK (G601)

- Gray- Left rear ol cargo area- Connects rear wire harness to left outer

taillight assembly

4

5

6

1

2

GRNAVHT(Brake lights)

FED/BLK(Headllght switch)

10. Exhaust Gas Recirculation

(EGR) Valve and Lift Sensor

1

2

3

(D16Y5 MfI D1685)

- Gray- Top right side of engine- On engine wire harness

WHT/BLK (EGR input)

GRN/BLK(Sensor ground)

YEUBLU(Reference voltage)

4

5

6

BLK (Ground)

PNK (EGR control)

of cargo area

rear wire harness to right outer

assembly

n- -n

a t | _ a2a

l3I4t5tttl

IJ

I

8. C605 (Hatchback)

- Gray- Right rear- Connects

taillight

GRN/BLK(Back-up lights)

GRNTYEL(Turn signaland hazardwarning lights)

3

4

5

6

1

2

BLK (G601)

GFNAVHT (Brake lights)

RED/BLK(Headlight switch)

11. Heater Fan Switch

('96-'98 Models)

- Brown

Center of dash- On heater-sub B wire harness

BLK (Ground)

BLUAVHT (L4edium

LO speed input)

BLU/BLK(Hl speed input)

4

5

6

1

2

3

BLU (LO speed input)

BLU/YEL (Medium

Hlspeed input)

GFIN (Blowerswitch ON input)

9. C607 (Hatchback)

- Blue- Right side o{ cargo area- On rear wire harness

BLU/BLK (lndicators)

RED/BLK(License lights)

GBN,ryVHT (8rake lights)

LT GBN(Rear wiper/washe0

5

6

1

2

3

4

GRN(Rear wiper/washer)

LT GRN/BLK(Rear \/iper washer)

)/

202-3

12. Security Starter Cut Relay/C416

- Natural* Upper left kick panel- On main wire harness

1

2Allexcept CX and DXI[,4ale: BLK,^r'r'HTFemale: BLKI/ELCX and DXi BLI(WHT(Battery input)

All except CX and DX:BLK^/ELCX and DX: BLK/WHT(Baftery input)

[.4ale - BLK/WHTFemale - BLKAVHTor BLKRED(Starter output)

All excepi CX and DX:RED/YELCX and DX: GRN(Security starter c!1relay control inpul)

5

6

tl3'

Page 2115 of 2189

Connector Views (cont'd)

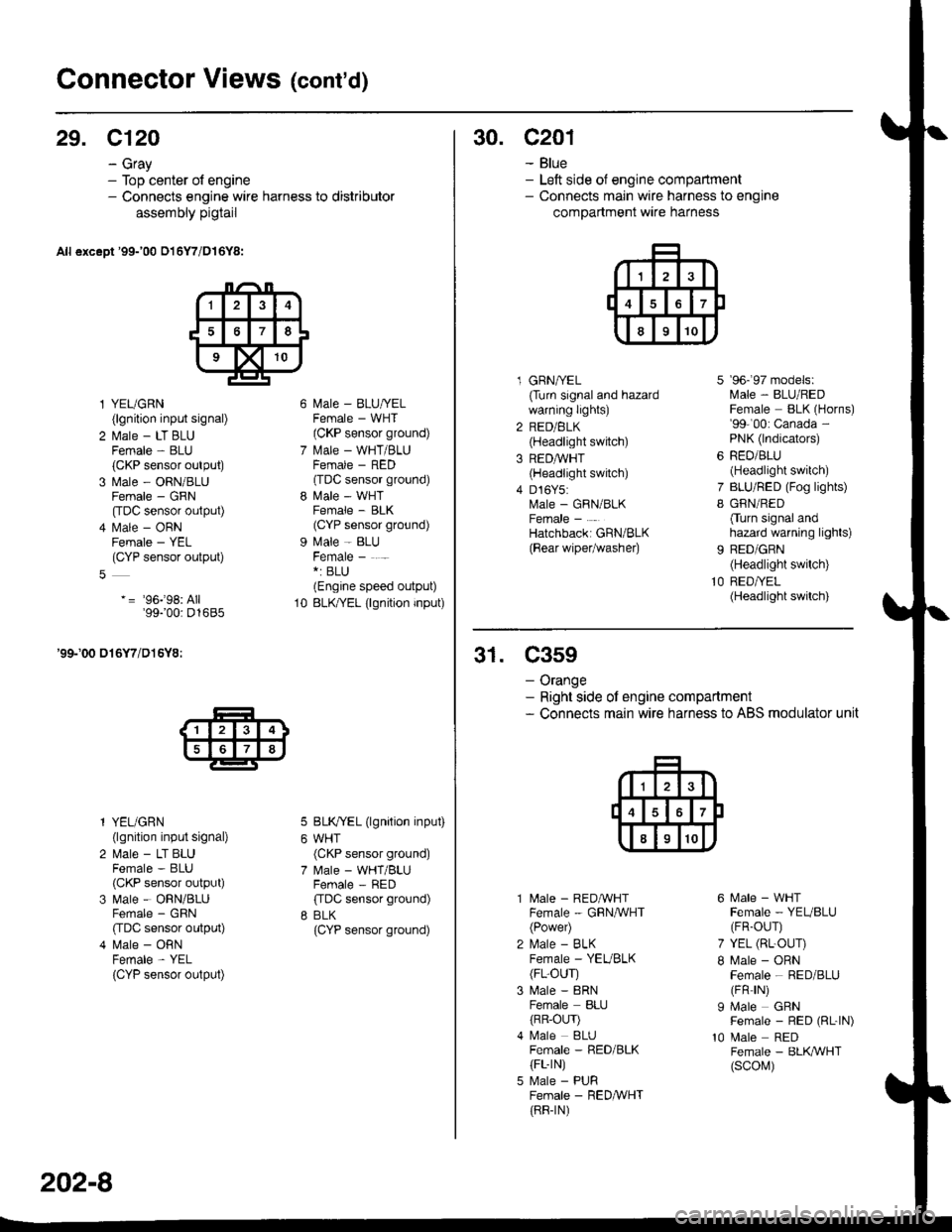

29. C120

- Gray- Top center of engine- Connects engine wire harness to distributor

assembly pigtail

All except '99-'00 016Y7/D16Y8:

l YEUGRN(lgnition input signal)

2 l\.4ale - LT BLUFemale - BLU(CKP sensor output)

3 Male - ORN/BLUFemale - GRN

[tDC sensor output)

4 l\.4ale - ORNFemale - YEL(CYP sensor output)

-= '96j98: All'99100: D1685

'99-'00 016Y7/D16Y8:

l YEUGRN(lgnition input signal)

2 Male - LT BLUFemale - BLU(CKP sensor output)

3 Male - ORN/BLUFemale - GRN

CIDC sensor output)

4 Male - ORNFemale - YEL

{CYP sensor output)

l\4ale - BLU/YELFemale - WHT(CKP sensor ground)

l\.4ale - WHT/BLUFCMAIE _ HtsL'(TDC sensor ground)

l\4ale - WHTFemale - BLK(CYP sensor ground)

Male - BLUFemale - . -*: BLU(Engine speed output)

BLK/YEL (lgnition input)

BLK/YEL (lgnition input)

WHT(CKP sensor ground)

Male - WHT/BLUFemale - RED

ffDC sensor ground)

BLK(CYP sensor ground)

10

202-8

30. c201

- Blue- Left side of engine compartment- Connects main wire harness to engine

compartment wire harness

l GRNA/EL(Turn signal and hazardwarning lights)

2 RED/BLK(Headlight switch)

3 REDAVHT(Headlight switch)

4 D16Y5:Male - GRN/BLKFemale -

Hatchbacki GRN/BLK

{Bear wipetwashe0

7

I

9b- 9/ mooets:lvlale - BLU/REDFemale BLK (Horns)'99-'00: Canada -

PNK (lndicators)

RED/BLU(Headlight switch)

BLU/RED (Fog lights)

GRN/RED

Cturn signal andhazard warning lights)

BED/GRN(Headlight switch)

RED/YEL(Headlight switch)

31. C359

- Orange- Right side ot engine compartment- Connects main wire harness to ABS modulator unit

10

l\4ale - REDAVHTFemale - GRNA/VHT(Power)

l\,4ale - BLKFemale - YEVBLK(FL-OUr)

Male - 8RNFemale BLIJ

{RR-OLrr)l\4ale BLUFemale - RED/BLK(FL-rN)

Male - PURFemale - RED&VHT(RR-rN)

6 Male - WHTFemale - YEUBLU(FR-OUr)

7 YEL (RL-OUr)

I Male - ORNFemale - RED/BLU(FR rN)

I Male GRNFemale - RED (RL-|N)

10 Male REDFemale - BLK,ryVHT(scol\,1)