engine stop HONDA CIVIC 1998 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 384 of 2189

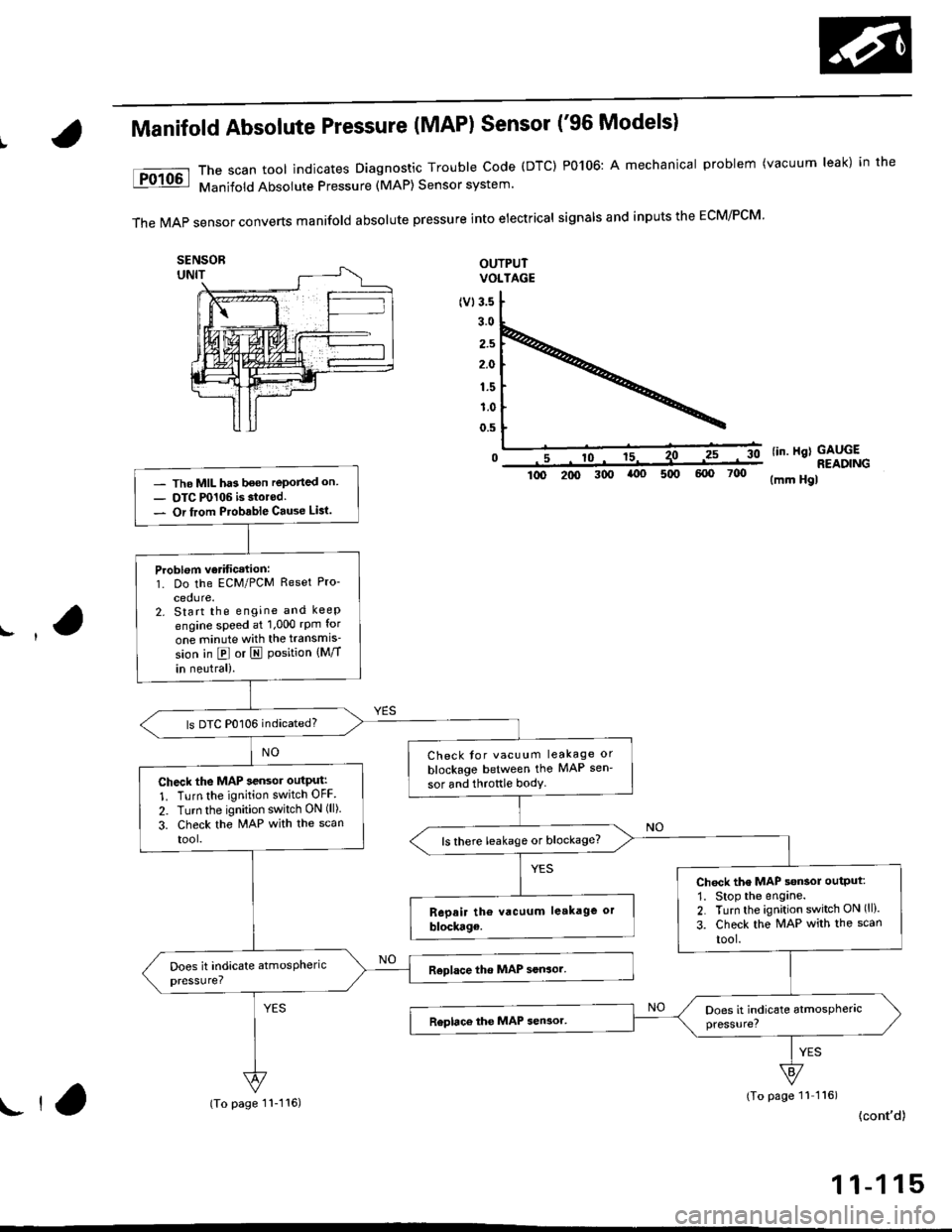

Manifold Absolute Pressure (MAP) Sensor ('96 Models)

The scan tool indicates Diagnostic Trouble Code (DTC) P0106: A mechanical problem (vacuum leak) in the

Manifold Absolute Pressure (MAP) Sensor system'

TheMAPsensorconvertsmanifoIdabsoIutepressureintoeiectricaIsigna|sandinpUtstheEcM/PcM'

OUTPUTVOLTAGE

(v13.5

3.0

2.5

2.0

1.5

1.0

0.5

0lin. Hgl GAUGE

- The MIL has been reported on- OTC P0106 is storod.- Or from Ptobable Cause Lisl.

Problom verificetion:1. Do the ECM/PCM Reset Pro-

cedure.2. Start the engine and keep

engine speed at 1,000 rpm for

one minute with the transmis'

sion in @ or I Position {Mff

in neutral).

ls DTC P0106 indicated?

Check tor vacuum leakage or

blockage between the MAP sen'

sor and throftle bodyCheck the MAP sensor outPut:

1. Turn the ignition switch OFF

2. Turn the ignition switch ON (ll).

3. Check the MAP with the scan

tool.ls there leakage or blockage?

Chock the MAP s€nsol output:

1. Stop the engane.2. Turn the ignition switch ON (ll).

3. Check the MAP with the scan

tool.

READING300(mm Hgl

(To page 11 116)

{cont'd)ll,(To page 11-116)

1 1-1 15

Page 467 of 2189

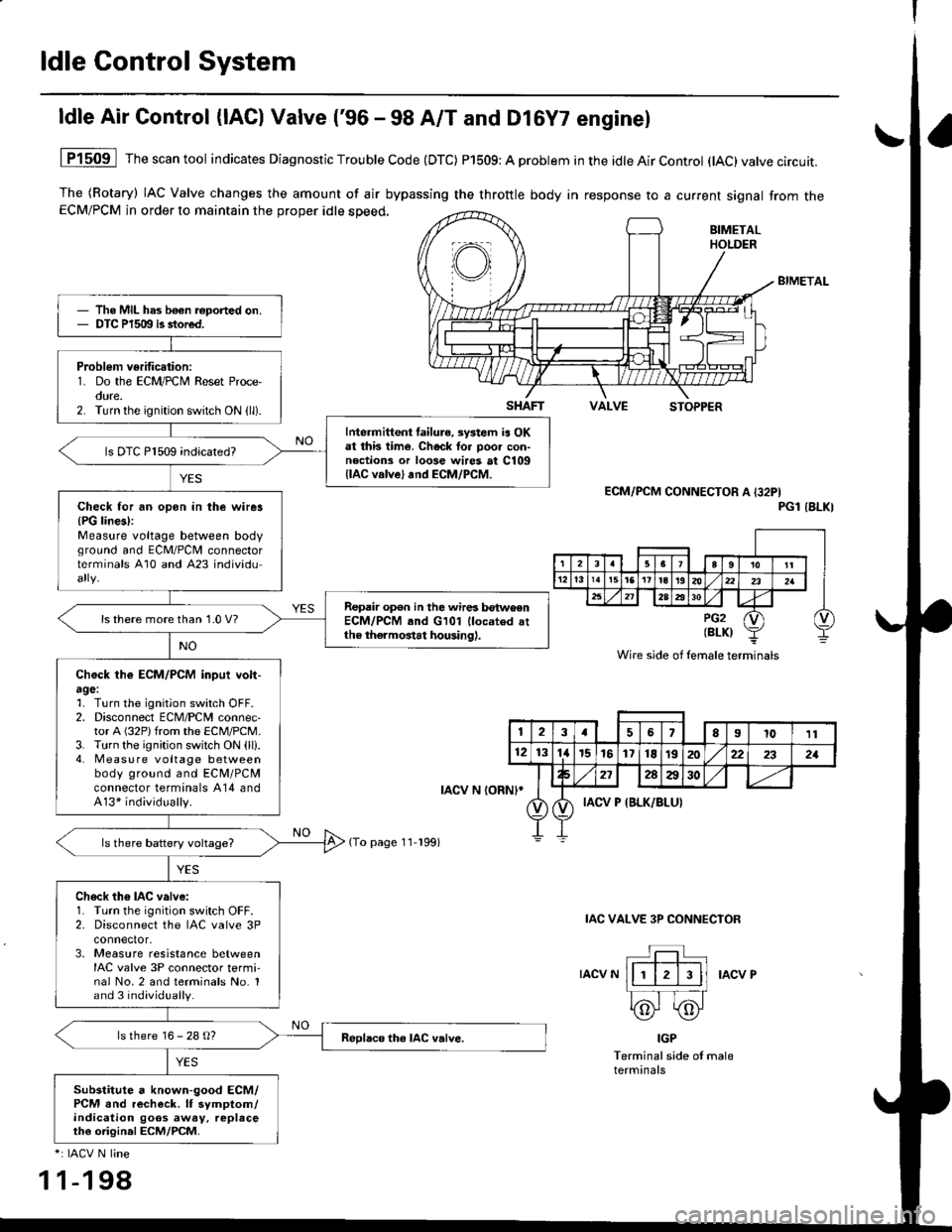

ldle Control System

ldle Air Control (lAC) Valve ('96 - 98 A/T and Dl6Y7 enginel

The (Rotary) IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from theECM/PCM in order to maintain the proper idle speed,

BIMETAL

VALVESTOPPER

1P1509 Thescantool indicates Diagnostic Trouble Code (DTC) P1509: A problem in the idle Air Control (tAC)valve circuit.

ECM/PCM CONNECTOR A I32PIPGl IBLKI

IAC VALVE 3P CONNECIOR

IACV NIACV P

IGP

Terminal side of maleterminals

*: IACV N line

1 1-198

The MIL has b€€n roported on.DTC P1509 is stored.

Problem verification:1. Do the ECM/PCM Reset Proce-oure.2. Turn the ignition switch ON (ll).

Intermittent failura, systom ia OKat this time. Check tor poo. con-noctions or loose wires at C109llAC valve) and ECM/PCM.

ls DTC P1509 indicated?

Check for an opon in the wirer{PG lines):Measure voltage between bodvground and ECM/PCII connectorterminals A10 and A23 individu

Repair op€n in the wires betwoenECM/PCM and G101 llocated attho thermostat housing).

ls there more than 1.0 V?

Chock th€ ECM/PCM inpui volt-agel1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P)from the ECM/PCM.3. Turn the ignition switch ON (ll).4. Measu re voltage betweenbody ground and ECM/PCMconnector terminals A14 andA13* individually.

Ch6ck th6 IAC valve:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 3Pconnector,3, Measure resistance betweenIAC valve 3P connector termi-nal No.2 and terminals No. 1and 3 individually.

ls there 16 - 28 g?

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goos away, replaceth€ origin.l ECM/PCM.

SHAFT

rAcv N loRNl*

(To page 11-199)

Wire side of lemale terminals

123a56El011

121314r5161718t9202:22321

272AA30

IACV P {BLK/BLUI

Page 469 of 2189

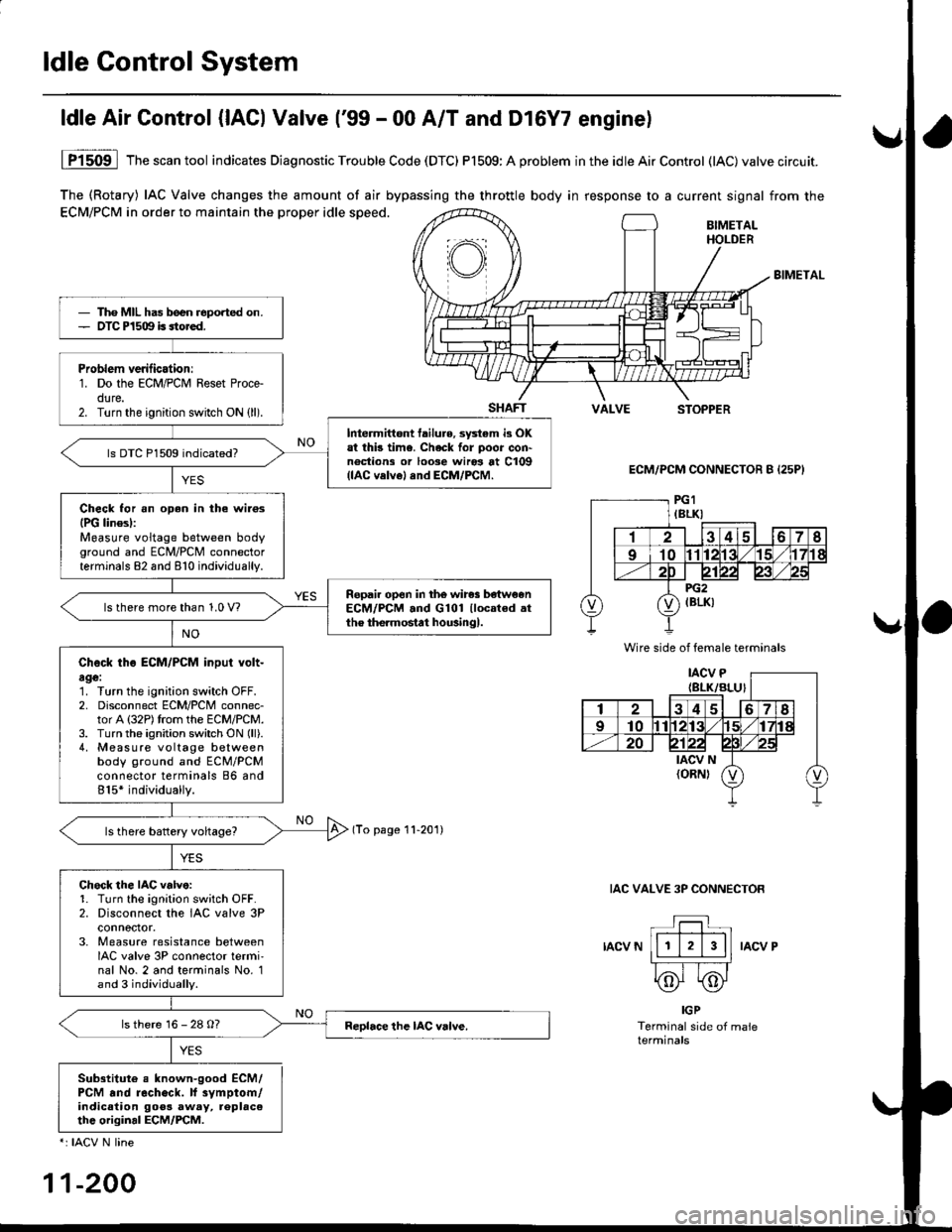

ldle Gontrol System

The (Rotary) IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the

ECM/PCM in order to maintain the proper idle speed.BIMETALHOLDER

BIMETAL

SHAFTVALVESTOPPER

ECM/PCM CONNECTOR B {25P}

(To page 11-201)

IAC VALVE 3P CONNECTOR

IACV NIACV P

ldle Air Control {lACl Valve ('99 - 00 A/T and Dl6Y7 enginel

YES

1P1509 lThescantool indicates Diagnostic Trouble Code (DTC) P1509:A problem inthe idleAirControl (lAC)valve circuit.

IGP

Terminal side of maleterminals

Sub3titute e known-good ECM/PCM .nd recheck. lf 3vmptom/indicalion goos away, replac6thc original ECM/PCM.

*: IACV N line

11-200

Tho MIL has b€en reported on.OTC P1509 is sto.ed.

Problem verilicationr1. Do the ECM/PCM Reset Proce-dure.2. Turn the ignition switch ON (ll).

Intermittont tailure, sy3tem i3 OKat thb time. Check for poor con'noctions or loose wiros at C109(lAC velvel and ECM/PCM.

ls DTC P1509 indicated?

Check for an oDen in the wilosIPG linesl:Measure voltage between bodyground and ECM/PCM connectorterminals 82 and 810 individually.

Ropail open in the wires be'tw€enECM/PCM .nd G101 llocated .tthe the.mostat housingl.ls there more than 1.0 V?

Check tho ECM/PCM input volt-age:1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P)trom the ECM/PCM.3. Turn the ignition switch ON (ll).

4, Measure voltage betweenbody ground and ECM/PCMconnector terminals 86 and815* individually.

Chock the IAC v.lve:1. Turn the ignition sw;tch OFF.2. Disconnect the IAC valve 3Pconnoctor.3. Measure resistance betweenIAC valve 3P connector termi'nal No. 2 and terminals No. 1and 3 individually.

ls there 16 - 28 O?

Wire side of female terminals

Page 491 of 2189

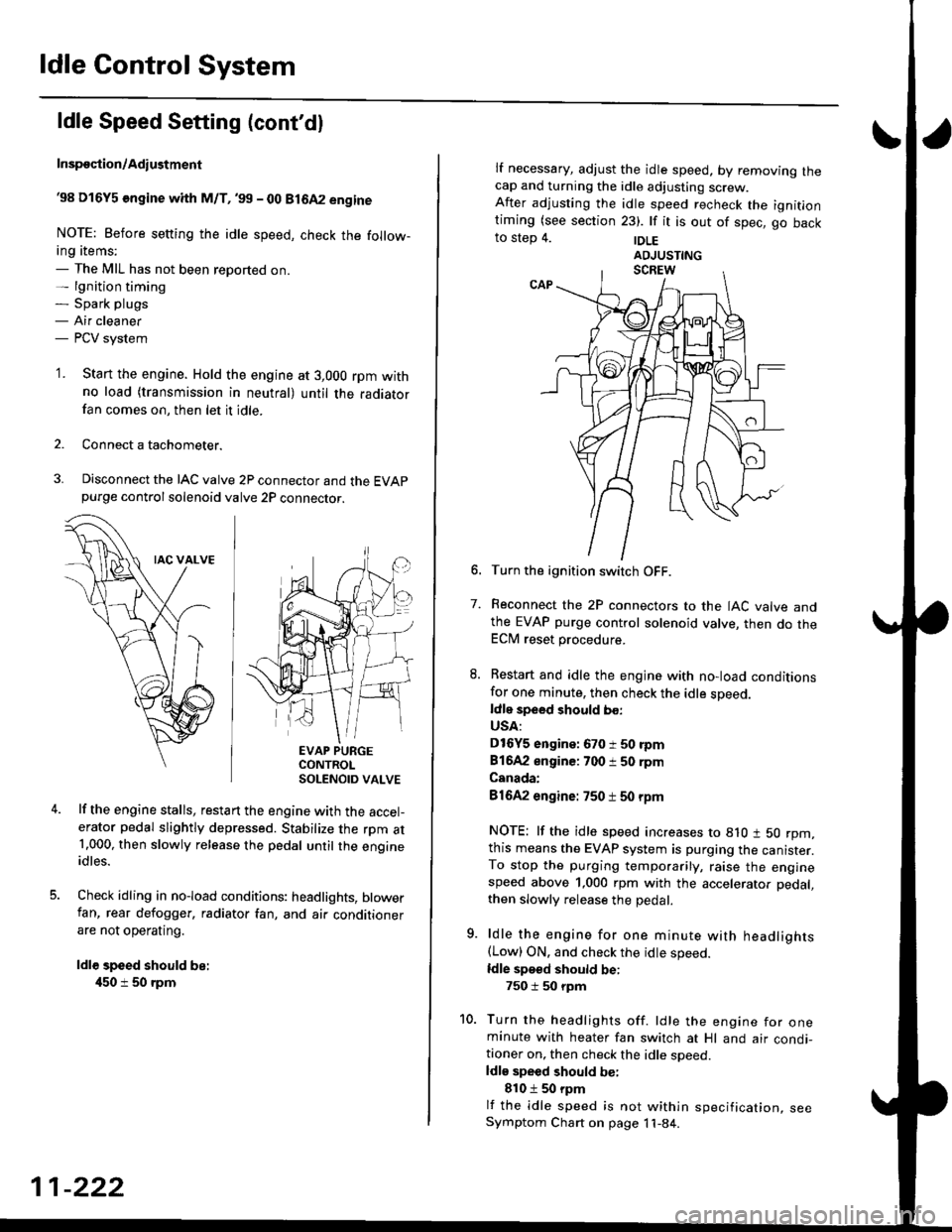

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

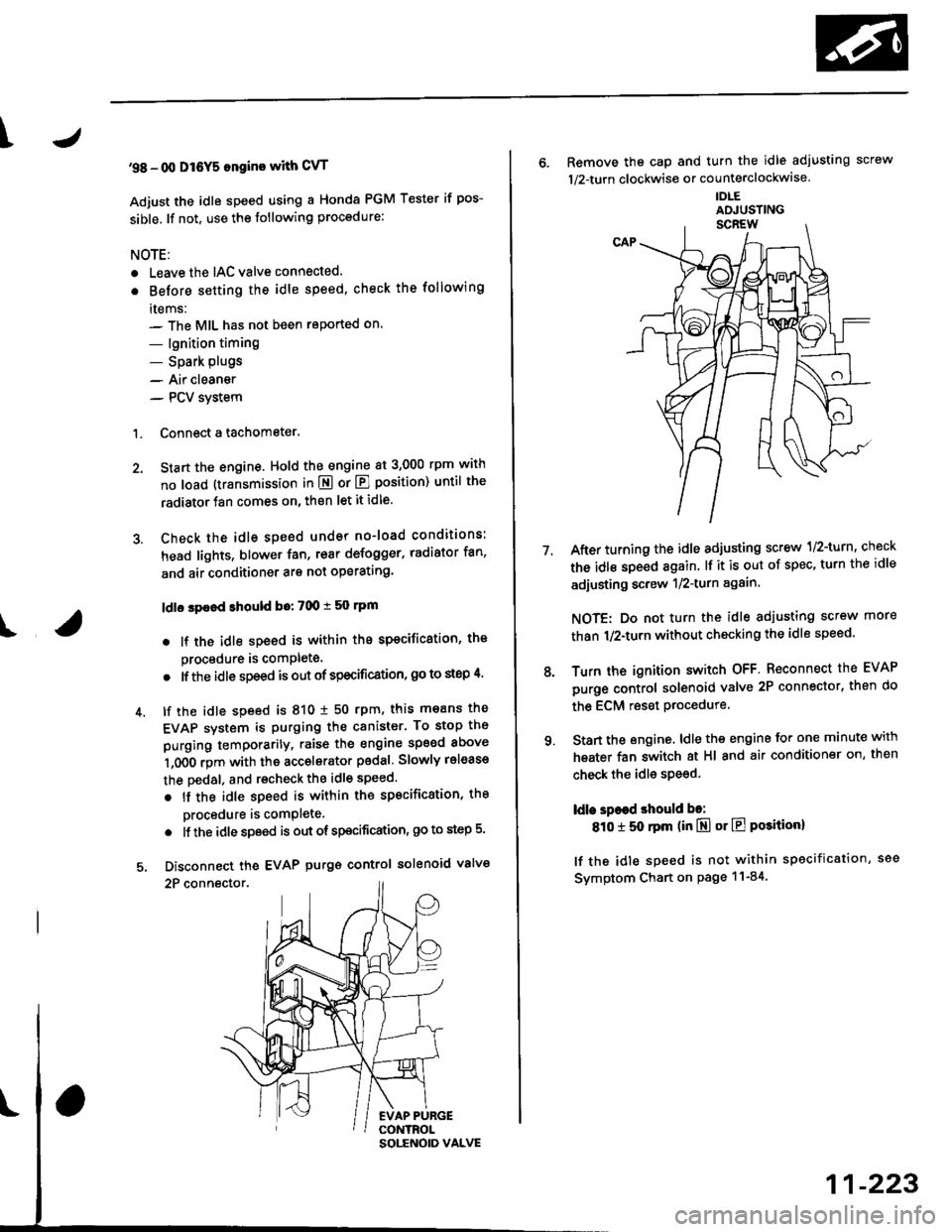

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223

Page 516 of 2189

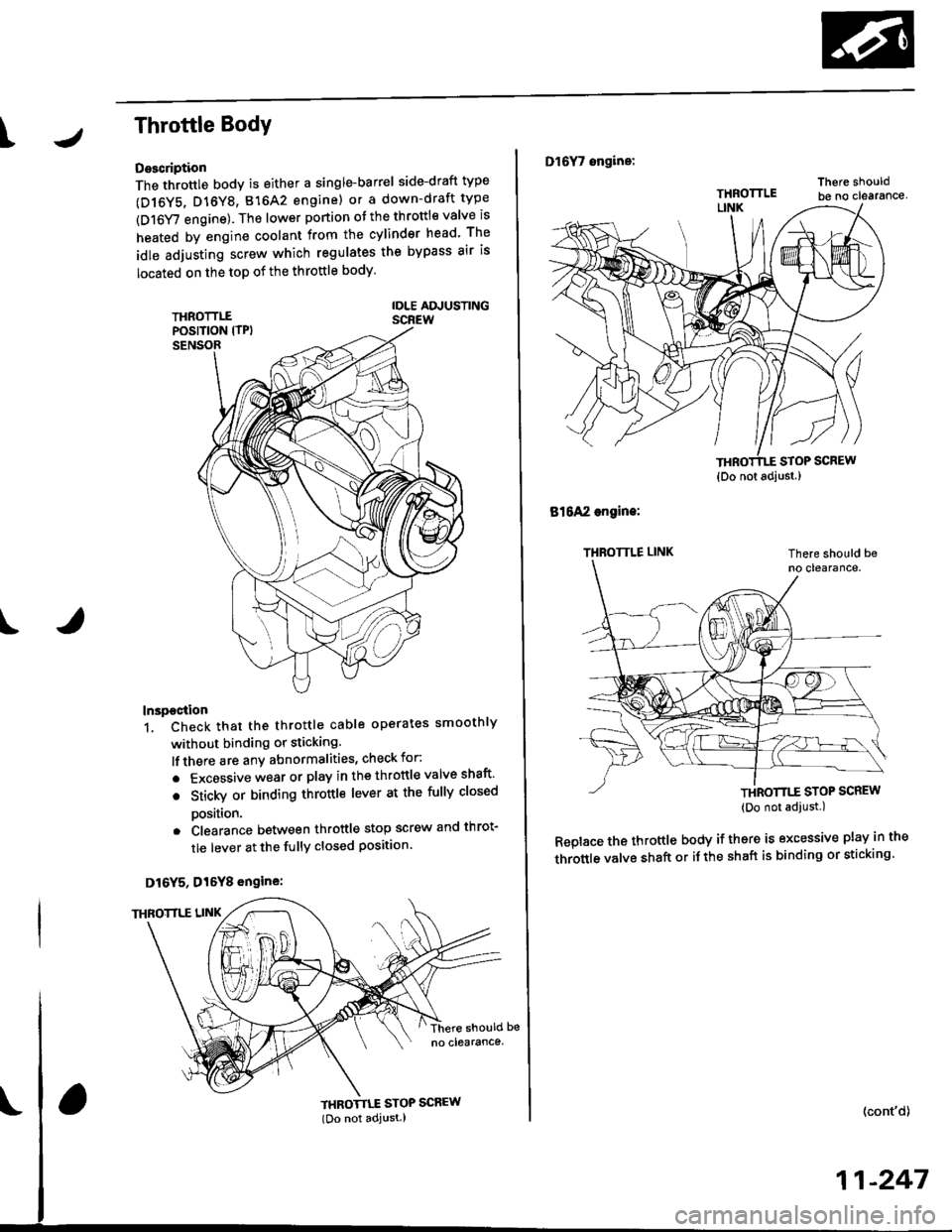

IThrottle BodY

Description

The throttle bodY is either a single-barrel side-draft type

(D16Y5, D16Y8, 816A2 engine) or a down-draft type

(D16Y/ engine). The lower portion ot the throttle valve is

heated by engine coolant from the cylinder head' The

idle adjusting screw which regulates the bypass air is

located on the top of the throttle body

THROTTLEPOS|T|ON lTPlSENSOR

IDLE AD.'USTINGSCREW

t

In3pection

1. Check that the throttle cable operates smoothly

without binding or sticking.

lf there are any abnormalities, check for:

. Excessive wear or play in the throttle valve shaft'

. StickY or binding throttle lever at the fully closed

Position.. Clearance between throttle stop screw and throt-

tle lever at the fully closed position'

D16Y5, Dl6Y8 engine:

THROTTLE STOP SCREW

{Do not adjust.)

Dl6Y7 ongine:

816A2 engins:

THROTTLE LINK

STOP SCREW

THROTTTE STOP SCREW(Do not adjust.)

Replace the throftle body if thsre is excessive play in the

throttle valve shaft or iJ the shaft is binding or sticking'

(cont'd)

11-247

{Do not adjust.)

Page 517 of 2189

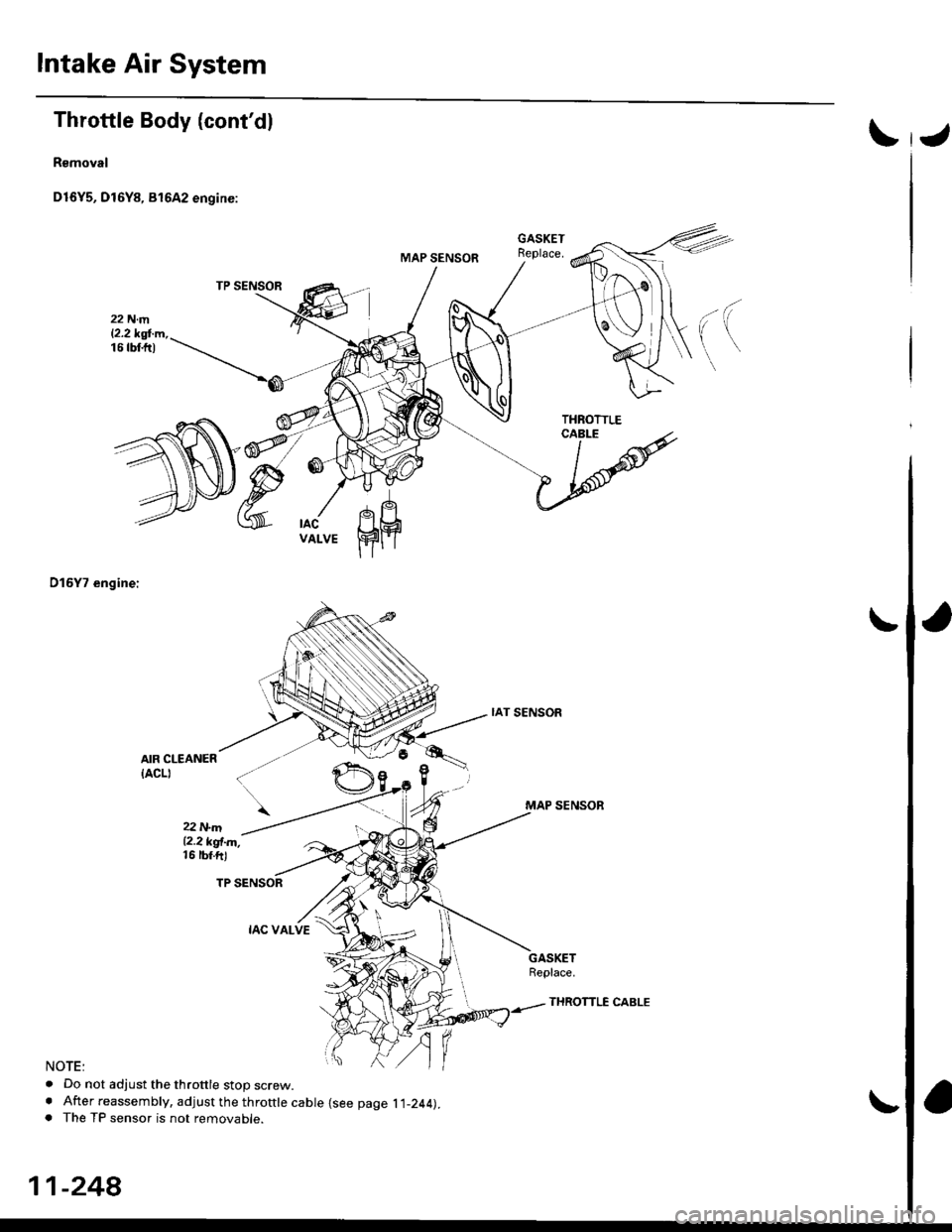

Intake Air System

J

Throttle Body (cont'dl

Removal

D16Y5, Dl6Y8, 81642 engine:

D15Y7 engine:

AIR CLEANER

{ACLI

22 N.m12.2 kgl.m,16 rbf.ftl

NOTE:

. Do not adjust the throttle stop screw.. After reassembly, adjust the throttle cable {see page l l-244).. The TP sensor is not removable.

IAT SENSOR

MAP SENSOR

GASKETReplace.

11-248

THROTTLE CABLE

Page 521 of 2189

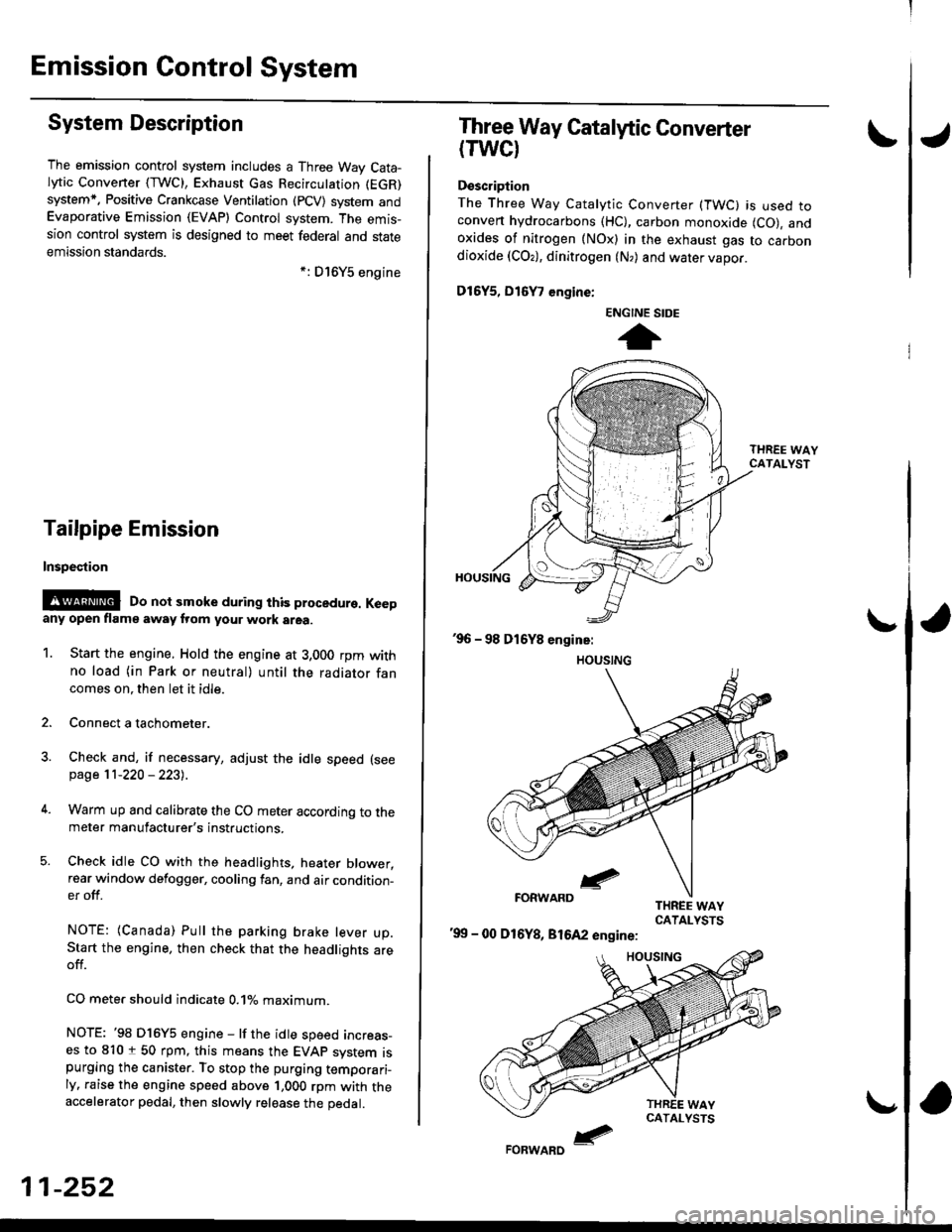

Emission Gontrol System

System Description

The emission control system includes a Three Way Cata-lytic Convener (TWC), Exhaust Gas Recirculation (EGR)

system,. Positive Crankcase Ventilation (pCV) system andEvaporative Emission (EVAP) Control system. The emis-sion control system is designed to meet federal and stateemission standards.*: D16Y5 engine

Tailpipe Emission

Inspestion

@@ Do not smoke during ihis procedure. Keepany open flame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm withno load (in Park or neutral) until the radiator fancomes on. then let it idle.

2. Connect a tachometer.

Check and, if necessary, adjust the idle speed (see

page 11-220 - 223).

Warm up and calibrate the CO meter according to themeter manufacturer's instructions.

Check idle CO with the headlights, heater blower,rear window defogger, cooling fan, and air condition-er off.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

CO mete. should indicate 0.1% maximum.

NOTE: '98 Dl6Y5 engine - lf the idle speed incress-es to 8101 50 rpm, this means the EVAp system ispurging the canister. To stop the purging temporari-ly. raise the engine speed above 1,000 rpm with theaccelerator pedal, then slowly release the pedal.

11-252

eFORWARD -

Three Way Catalytic Converter

(TWCI

Doscription

The Three Way Catalytic Converter (TWC) is used toconven hydrocarbons (HC), carbon monoxide (CO), andoxides of nitrogen (NOx) in the exhaust gas to carbondioxide (COr), dinitrogen (N,) and water vapor.

D15Y5, D16

, engine:

'99 - 00 D16Y8, 81642 engine:

ENGINE SIDE

t

Page 584 of 2189

Troubleshooting

Reverse Gear Noise Reduction System

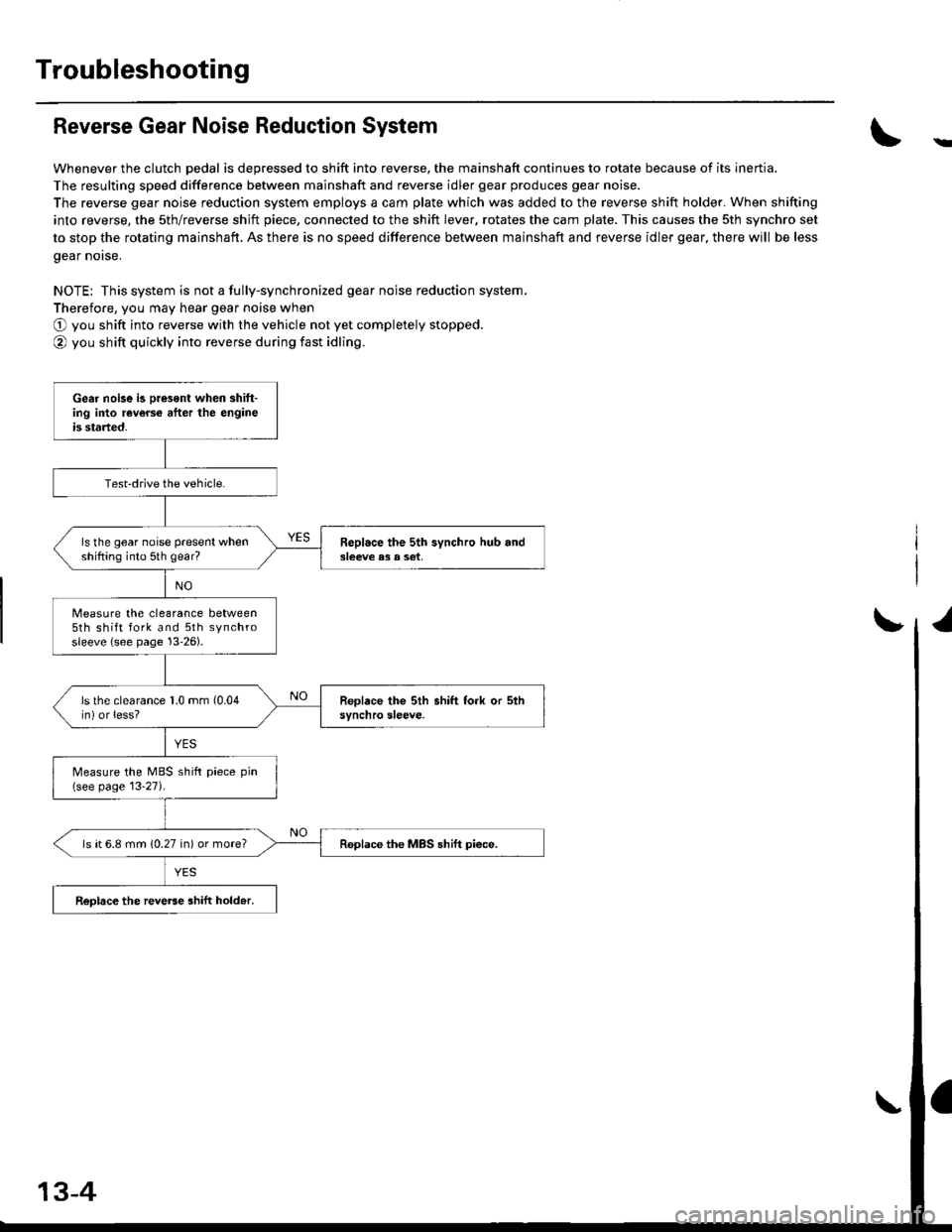

Whenever the clutch pedal is depressed to shift into reverse, the mainshaft continues to rotate because of its inertia.

The resulting speed difference between mainshaft and reverse idler gear produces gear noise.

The reverse gear noise reduction system employs a cam plate which was added to the reverse shift holder. When shifting

into reverse, the sth/reverse shjft piece, connected to the shift lever, rotates the cam plate. This causes the sth synchro set

to stop the rotating mainshaft. As there is no speed difference between mainshaft and reverse idler gear, there will be less

gear norse.

NOTE: This system is not a fully-synchronized gear noise reduction system.

Therefore, you may hear gear noise when

O you shift into reverse with the vehicle not yet completely stopped.

@ you shift quickly into reverse during fast idling.

-

Gear noise is oresent when shift-ing into reverce after the engineis started.

Test-drive the vehicle.

ls the gear noise present whenshifting into 5th gear?Beplace the 5th synchro hub and3leeve e3 a set,

Measure the clearance between5th shift fork and 5th synchrosleeve {see page 13'26).

ls the clearance 1.0 mm (0.04

in) or less?

Measure the MBS shift piece pin(see page 13-27).

ls ( 6.8 mm (0.27 in) or more?Replace the MBS shift piece.

ReDlace the reve6e ahift hold.r.

13-4

Page 682 of 2189

Description

(cont'dl

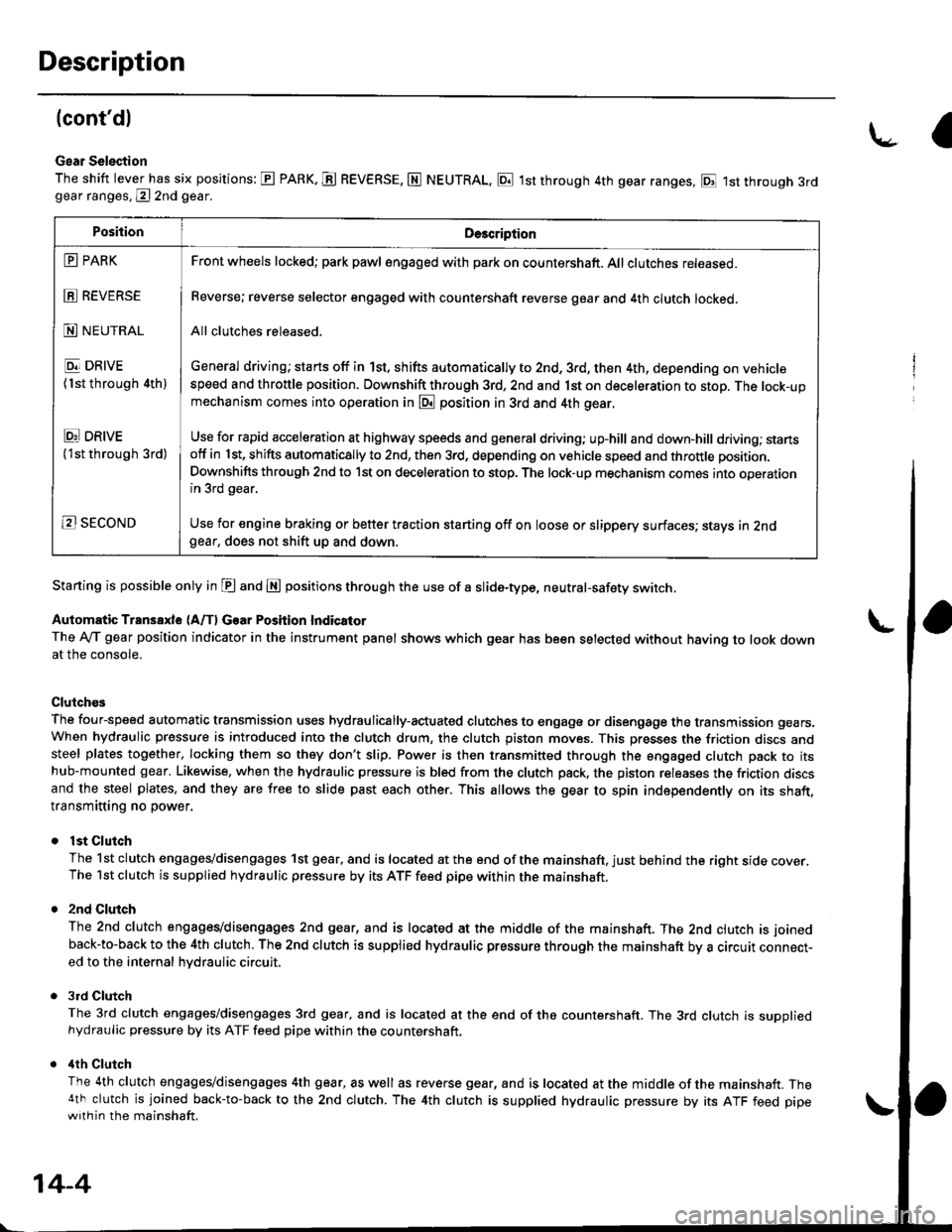

Gear Selection

The shift lever has six positions: E PARK. E REVERSE, N NEUTRAL, E 1st through 4th gear ranges, E 1st through 3rdgear ranges, @ 2nd gear.

Starting is possible only in E and E positions through the use of a slide-type, neutral-safety switch.

Automatic Transaxle (A/f, Gear Position Indicator

The Ay'T gear position indicator in the instrument panel shows which gear has been selected without having to look downat the console.

Clutch€s

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission gears.When hydraulic pressure is introduced into the clutch drum, the clutch piston moves. This presses the friction discs andsteel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch pack to itshub-mounted gear. Likewise, when the hydraulic pressure is bled from the clutch pack, the piston releases the friction discsand the steel plates, and they are free to slide past each other. This allows the gear to spin independently on its shaft,transmitting no power.

lst Clutch

The 1st clutch engages/disengages 1st gear, and is located at the end of the mainshaft, just behind the right sroe cover.The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

2nd Clulch

The 2nd clutch engagegdisengages 2nd gear, and is located at the middle of the mainshaft. The 2nd clutch is joined

back-to-back to the 4th clutch. The 2nd clutch is supplied hydraulic pressure through the mainshaft by a circutr connect-ed to the internal hvdraulic circuit,

3rd Clutch

The 3rd clutch engages/disengages 3rd gear, and is located at the end of the countershaft. The 3rd clutch is suooliedhydraulic pressure by its ATF feed pipe within the countershaft.

ilth Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the middle of the mainshaft. The4th clutch is joined back-to-back to the 2nd clutch. The 4th clutch is supplied hydraulic pressure by its ATF feed pipewith in the mainshaft.

\-a

PositionDe3cription

E PARK

E REVERSE

N NEUTRAL

E DRIVE

{1st through 4th)

Ei DRtvE('lst through 3rd)

B SECOND

Front wheels locked; park pawl engaged with pa* on countershaft. All clutches released.

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

All clutches released.

General driving; starts off in 1st, shifts automatically to 2nd, 3rd, then 4th, depending on vehiclespeed and throttle position. Downshift through 3rd, 2nd and 1st on deceleration to stop. The lock-upmechanism comes into operation in @ position in 3rd and 4th gear.

Use for rapid acceleration at highway speeds and general driving; up-hill and down,hill dfiving; stansotf in 1st, shifts automatically to 2nd, then 3rd, depending on vehicle speed and throttle position.

Downshifts through 2nd to lst on deceleration to stop. The lock-up mechanism comes into operationin 3rd gear,

Use for engine braking or better traction starting off on loose or slippery surfaces; stays in 2ndgear, does not shift up and down.

14-4