service check connector HONDA CIVIC 1998 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 719 of 2189

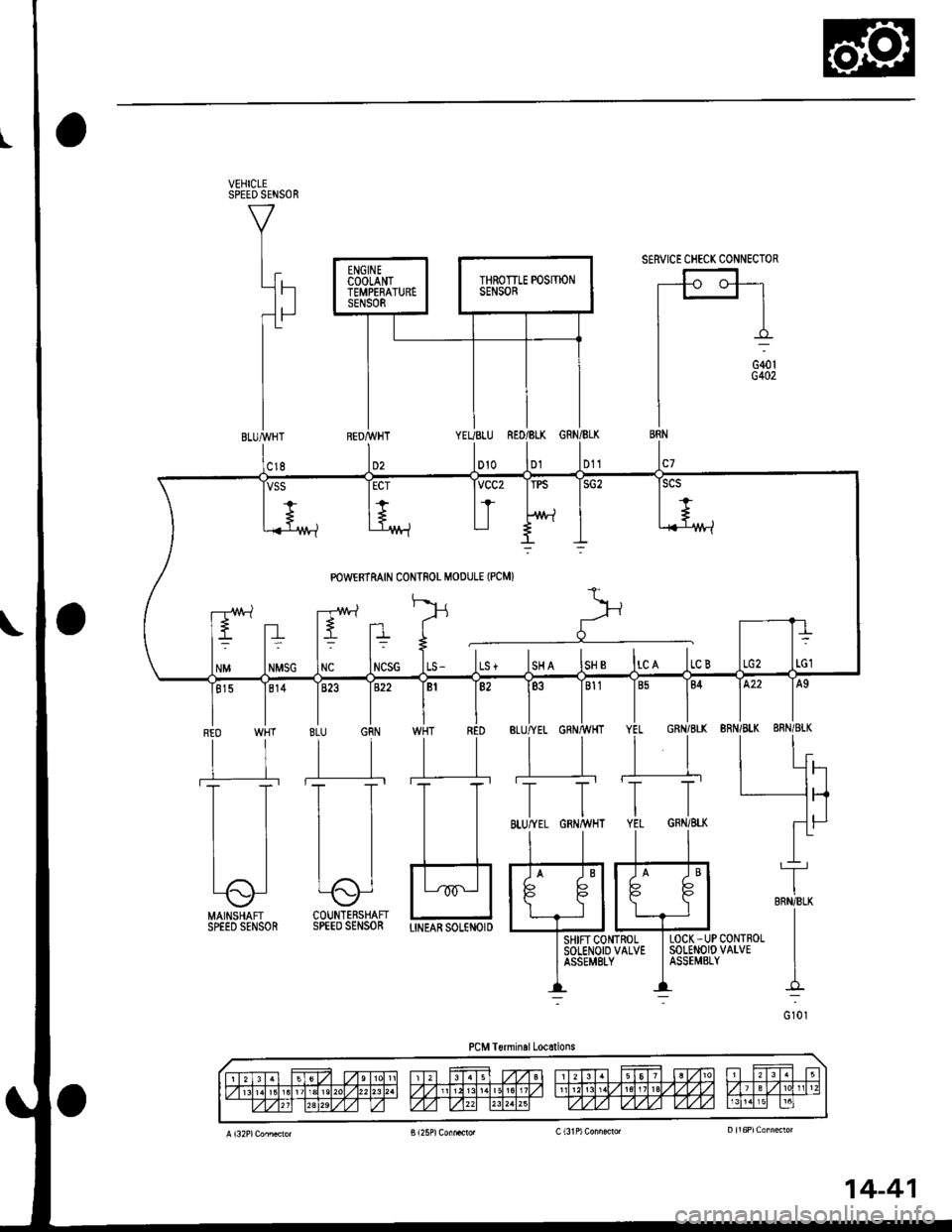

SERVICE CHECK CONNECTOR

LOCK -UP CONTROLSOLENOIO VALVEASSEMELY

RED WHT

tlll'

IT

tl

ll

Lo-l

MAINSHAFTSPEED SENSOR

TBRNiBLK

I

I

I-

G 101

NCSG ILS - ILS + ISH A ISH B ltc A ltc B

SHIF'CONTROLSOTENOID VALVEASSEMEI-Y

PCM Terminel Locations

14-41

Page 721 of 2189

I

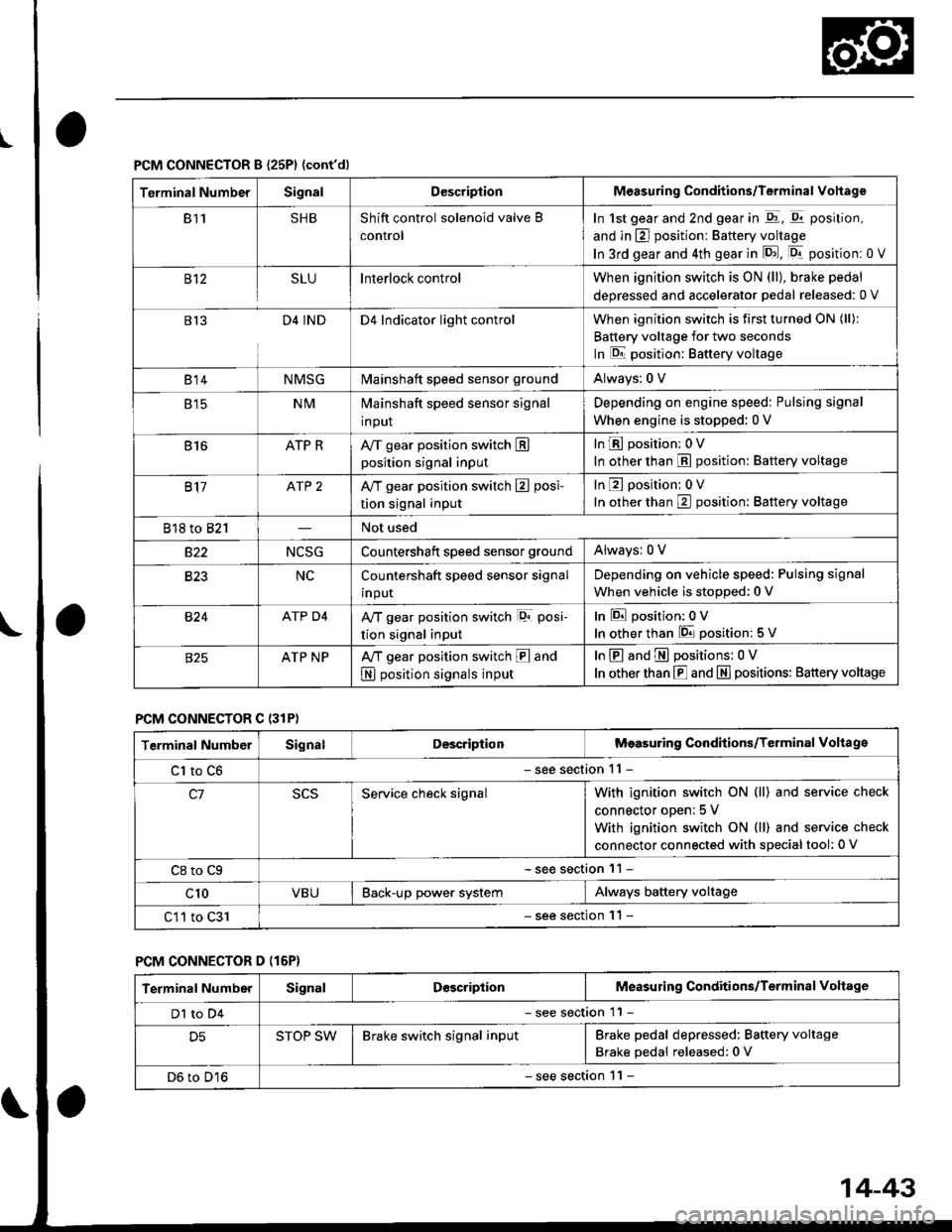

PCM CONNECTOR B {25P1 {cont'dl

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Vohage

811SHBShift control solenoid valve B

control

In 1st gear and 2nd gear in -q1, q11 position,

and in E] position: Battery voltage

In 3rd gear and 4th gear in lD.J, [Dr- position: 0 V

B't2SLUInterlock controlWhen ignition switch is ON (ll), brake pedal

deoressed and accelerator Dedal released: 0 V

813D4 INDD4 Indicator light controlWhen ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Baftery voltage

B't 4NMSGMainshaft speed sensor groundAlways: 0 V

E tcNMMainshaft speed sensor signal

input

Depending on engine speed: Pulsing signal

When engine is stopped: 0 V

816ATP RAy'T gear position switch Eposition signal input

InE position: 0V

In other than E position: Battery voltage

817ATP 2A/T gear position switch E posi-

tion signal input

InE position: 0V

In orher than E position: Battery voltage

818 to 821Not used

s22NCSGCountershatt speed sensor groundAlwaysr 0 V

B�23NCCountershaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stopped: 0 V

B�24ATP D4Ay'T gear position switch lor posi-

tion signal input

InEposition:0V

In other than 6 position: 5 V

ATP NPA,/T gear position switch E and

N position signals input

InE and E positions: 0V

In otherthan E and N] positions: Battery voltage

PCM CONNECTOR C {31P)

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

Cl to C6- see section 11 -

c1Service check signalWith ignition switch ON (ll) and service check

connector oDen; 5 V

With ignition switch ON (ll) and service check

connector connected with sDecial tool: 0 V

C8 to Cg- see section 11 -

c10VBUBack-up power systemAlways battery voltage

C11 to C31- see section '11 -

PCM CONNECTOR D (16P}

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

Dl to D4- see section 11 -

D5STOP SWBrake switch signal inputBrake pedal depressed: Battery voltage

Brake pedal released: 0 V

D6 to D16- see section 1 l -

14-43

Page 724 of 2189

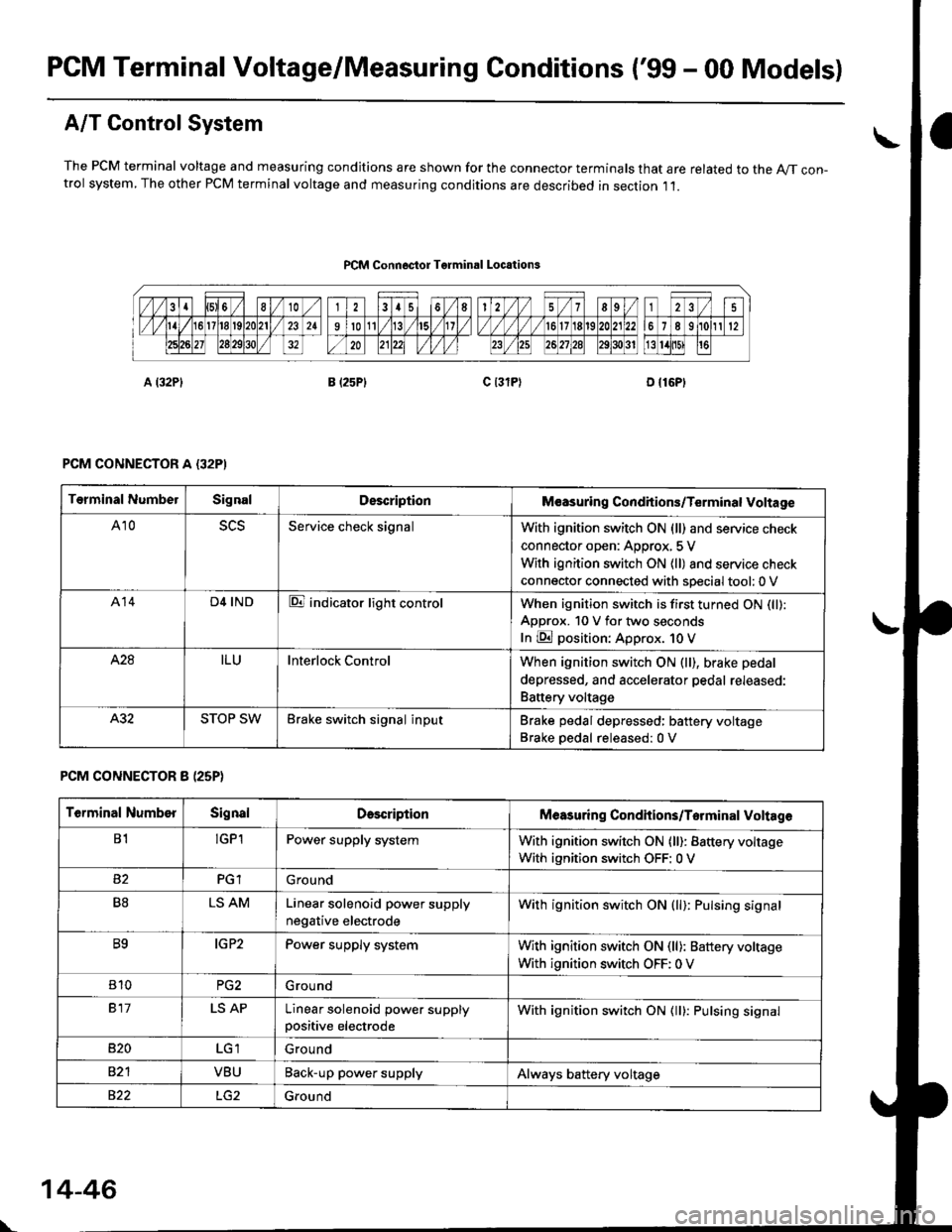

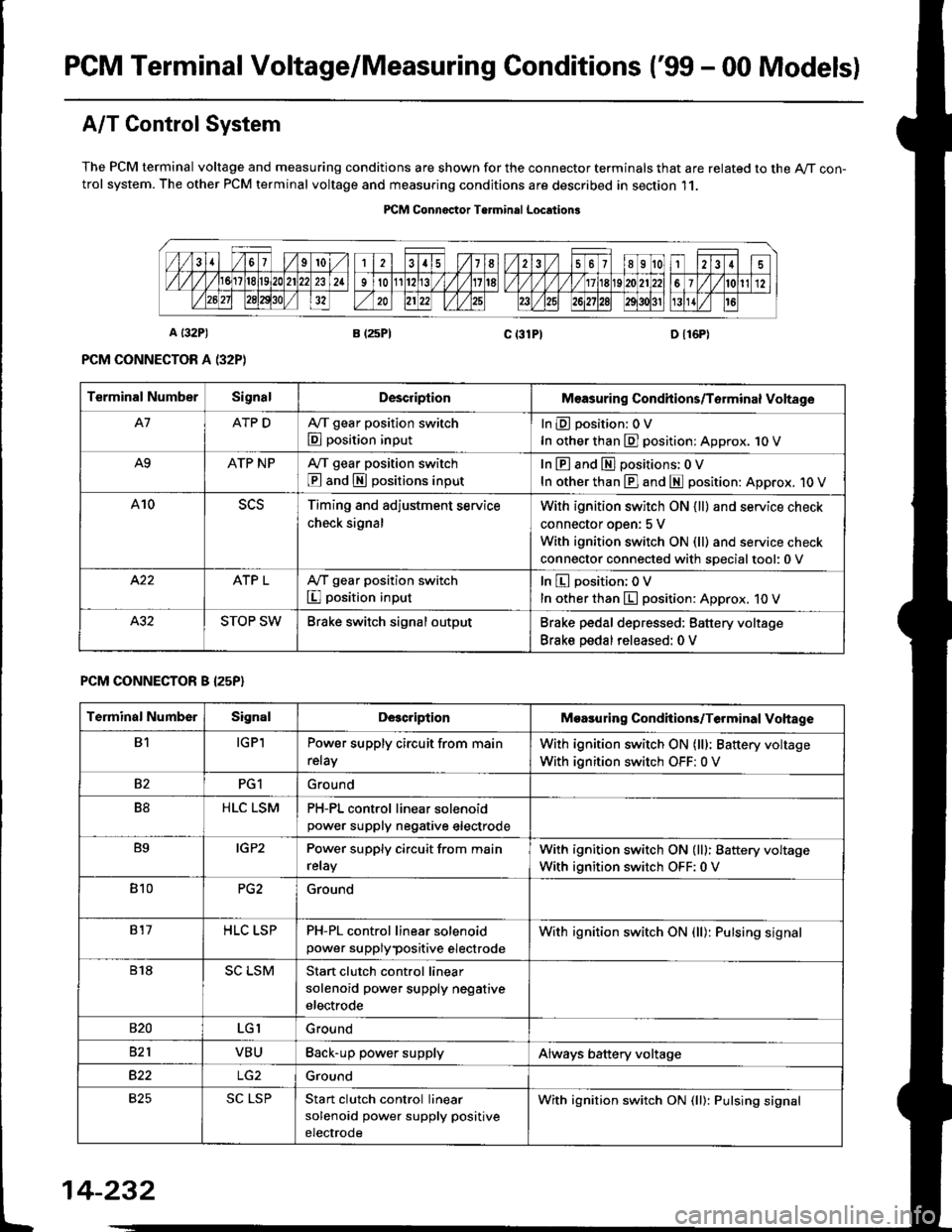

PCM Terminal Voltage/Measuring Conditions ('99 - 00 Models)

A/T Control System

The PCM terminal voltage and measuring condjtions are shown for the connector terminals that are related to the A//T con-trol system, The other PCM terminal voltage and measuring conditions are described in section ,11.

PCM Connoctor Tgrminrl Locations

PCM CONNECTOR A {32PI

PCM CONNECTOR 8 (25P}

Terminal NumbelSignalDescriptionM€asuring Conditions/Terminal Voltage

A105L5Service check signalWith ignition switch ON (ll) and service check

connector open: Approx, 5 V

With ignition switch ON (ll) and service check

connector connected with sDecial tool: 0 V

A14D4 INDE indicator light controlWhen ignition switch is first turned ON (ll):

ApDrox. 10 V for two seconds

In E position: Approx. 1O V

428ILUInterlock ControlWhen ignition switch ON (ll), brake pedal

depressed, and accelerator pedal rereaseo:

Battery voltage

A.32STOP SWBrake switch signal inputBrake pedal depressed: battery voltage

Brake oedal released:0 V

Terminal NumberSignalDescdptionMeasuring Condhions/Torminal Voltag6

B1!GP1Power supply systemWith ignition switch ON (ll): Battery voltage

With ignition switch OFF: 0 V

PGlGround

B8LS AMLinear solenoid power supply

negative electrode

With ignition switch ON (ll): Pulsing signal

B9IG P2Power supply systemWith ignition switch ON (ll): Baftery voltage

With ignition switch OFF: 0 V

810PG2G rou nd

917LS APLinear solenoid power supplypositive electrode

With ignition switch ON (ll): Pulsing signal

B�20Ground

VBUBack-up power supplyAlways battery voltage

822Ground

\

14-46

Page 727 of 2189

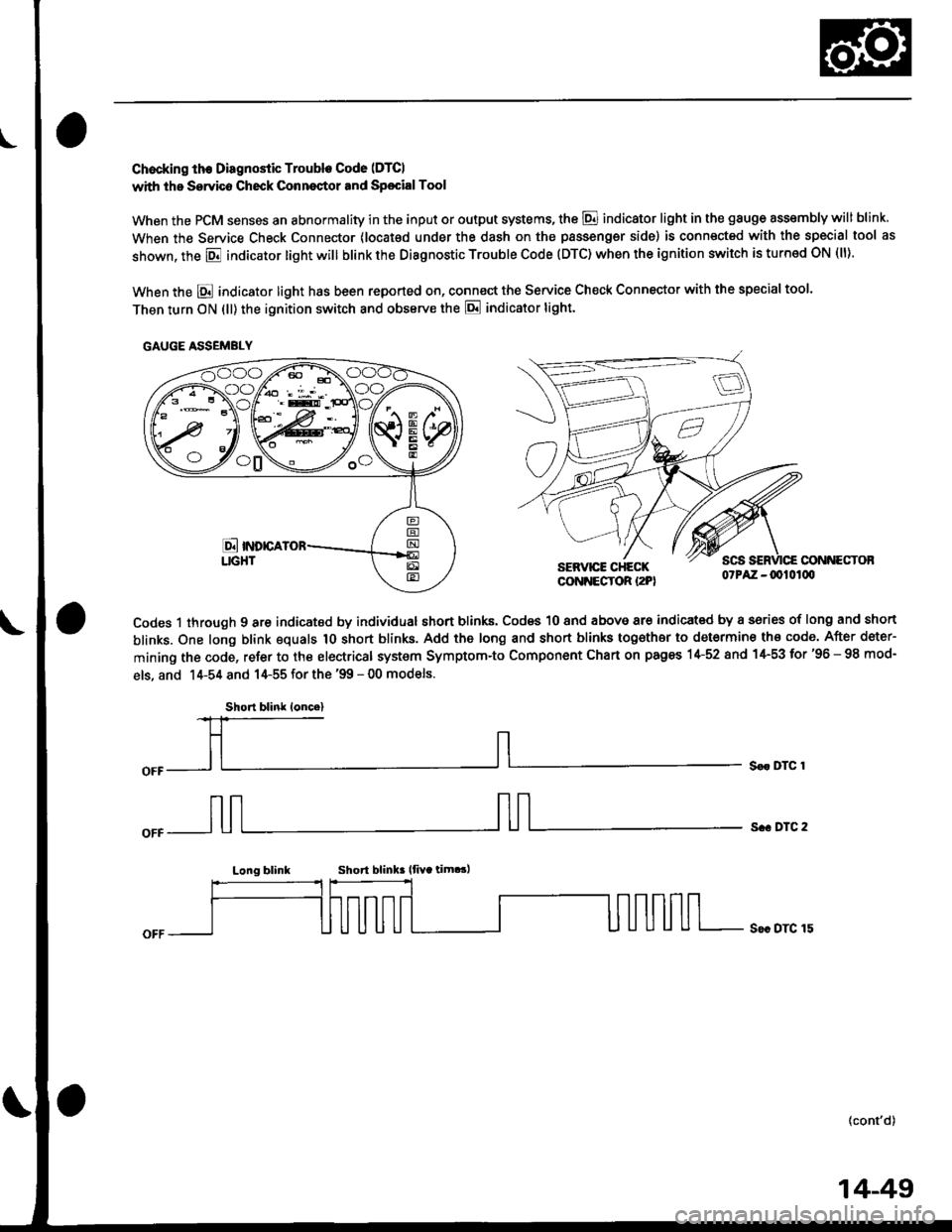

Chocking th€ Diagnostic Trouble Code (DTCI

with the Servico Check Conneqtor and Sp€cialTool

When the PCM senses an abnormality in the input or output systems, the @ indicator light in the gauge assembly will blink

When the Service Check Connector (locat€d under the dash on the passengsr side) is connected with the special tool as

shown, the E indicator light will blink the Diagnostic Trouble Code (DTC) when the ignition switch is turned ON (ll).

When the E indicator light has been reported on, connect the Service Check Connector with the special too'.

Then turn ON (ll) the ignition switch and obssrve the E indicator tight.

CONNECTOBSERVICE CHECKCONNECTOR I2PI07PAZ -0010100

Codes 1 through 9 are indicated by individual short blinks, Codes 10 and above are indicat€d by a sories of long and short

blinks. One long blink equals 1O short blinks. Add the long and short blinks together to determine th€ code. After deter-

mining the code, refer to the electrical system Symptom-to Component Chart on pages 1+52 and 1+53 for'96 - 98 mod-

els, and 14-54 and 14-55 for the '99 - 00 models.

S€r DTC 1

s.. DTC 2

Long blinkShort blink lfiYa tim.!,

S€c DTC 15

(cont'd)

GAUGE ASSEMBLY

Short blink loncel

14-49

Page 729 of 2189

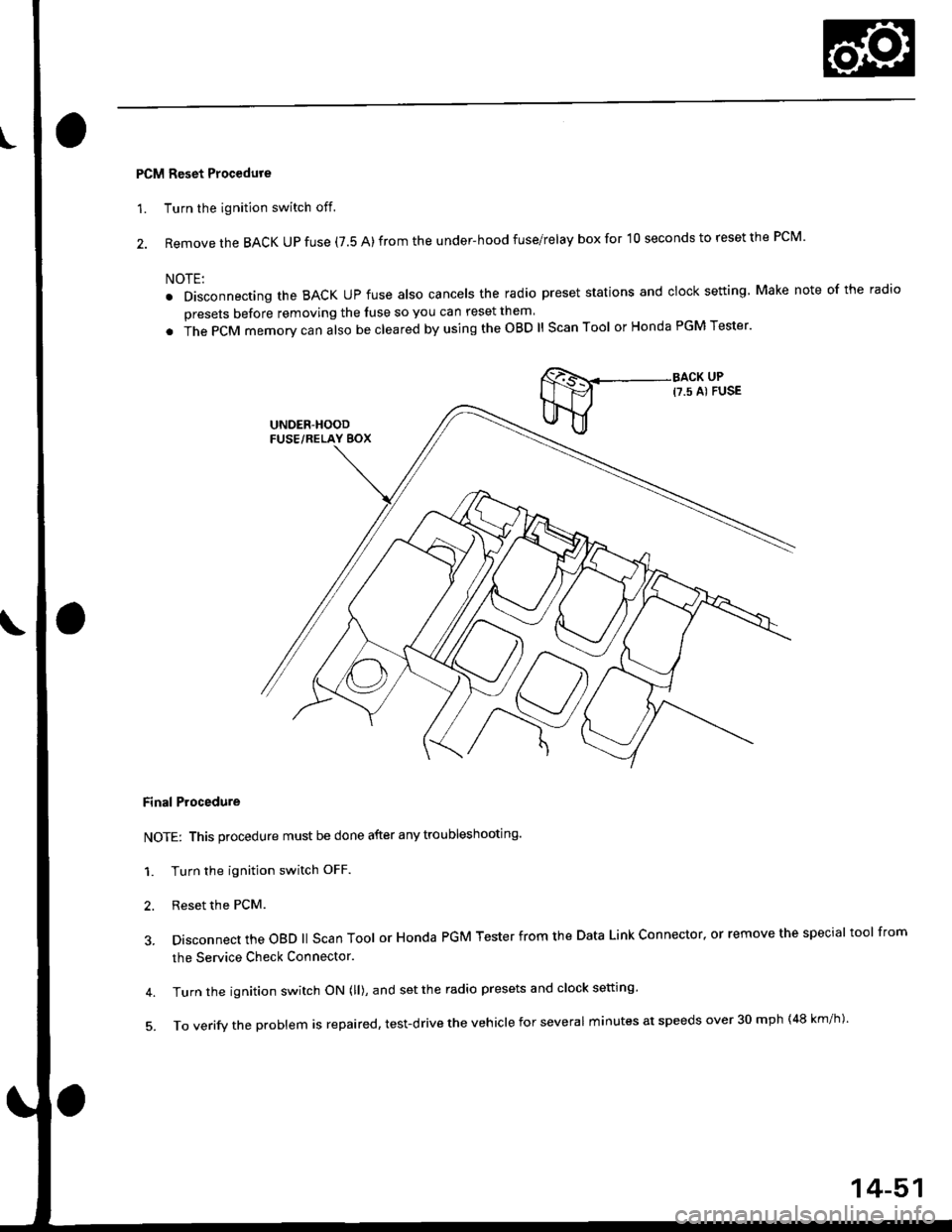

PCM Reset Procedure

1. Turn the ignition switch off.

2. Remove the BACK UP fuse (7.5 A) from the under-hood fuse/relay box for '10 seconds to reset the PCM'

NOTE:

. Disconnecting the BACK UP fuse also cancels the radio preset stations and clock setting Make note of the radio

presets before removing the luse so you can reset them

. in" gCfU memory can also be cleared by using the OBD ll Scan Tool or Honda PGM Tester'

Final Procedure

NOTE: This procedure must be done after any troubleshooting.

1. Turn the ignition switch OFF.

2. Reset the PcM.

3. Disconnect the oBD ll scan Tool or Honda PGM Tester from the Data Link connector, or remove the special tool from

the Service Check Connector.

4. Turn the ignition switch ON (ll), and set the radio presets and clock setting'

5'ToVerifytheprob|emisrepaired,test.drivetheVehic|eforseveralminutesatspeedsover30mph(48km/h).

14-51

Page 754 of 2189

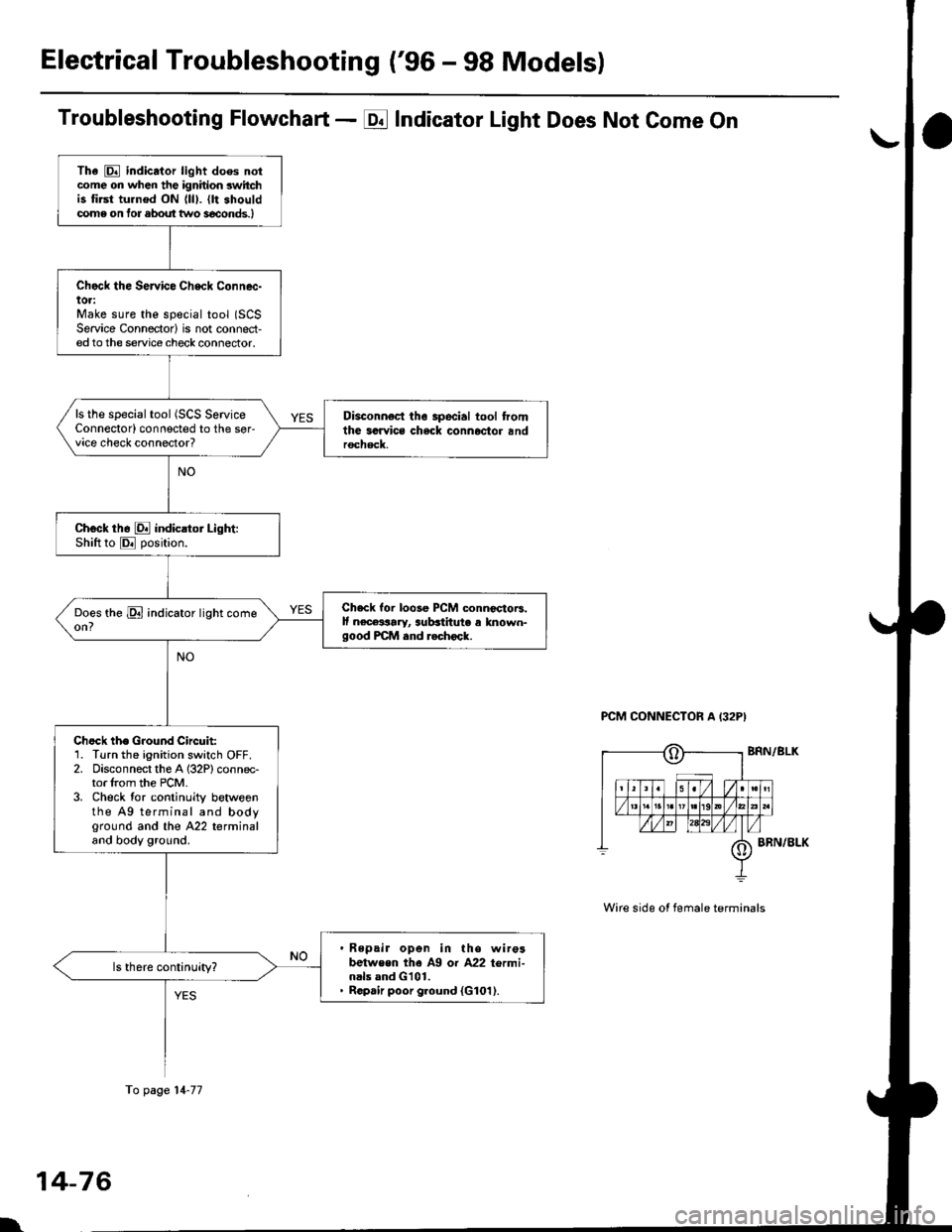

Electrical Troubleshooting ('96 - 98 Models)

Troubleshooting Flowchart - E Indicator Light Does Not Gome On

PCM CONNECTOR A I32PI

Wire side of female terminals

Tha E indicator light does nolcome on when the ignition swhchis first turned ON (lll. {lt shouldcome on tol about two s€conds.l

Chock the SeJvico Check Connec-tor:Make sure the special tool (SCS

Seryice Conneclor) is not connect-ed to the service check connector.

ls the special tool (SCS ServiceConnector) connected to the service check connector?

Disconnect the special tool tromthc sarvice check connoctor androcheck.

Check th6 E indicator Light:Shift to lD.l oosition.

Check tor loose PCM connecto6.ll nece3sary, sub.titute a known-good FCM and r.chock.

Check the Ground Circuit:'1. Turn the ignition switch OFF.2. Disconnecr the A {32P}connec-tor lrom the PCM.3. Check for continuity betweenthe A9 terminal and bodyground and the A22 terminaland body ground.

Repair op6n in tho wirgsbetween tho A9 ot M2 tormi-nals and G101.Rcpair poor glound {G101).

To page 14-77

l.

14-76

Page 780 of 2189

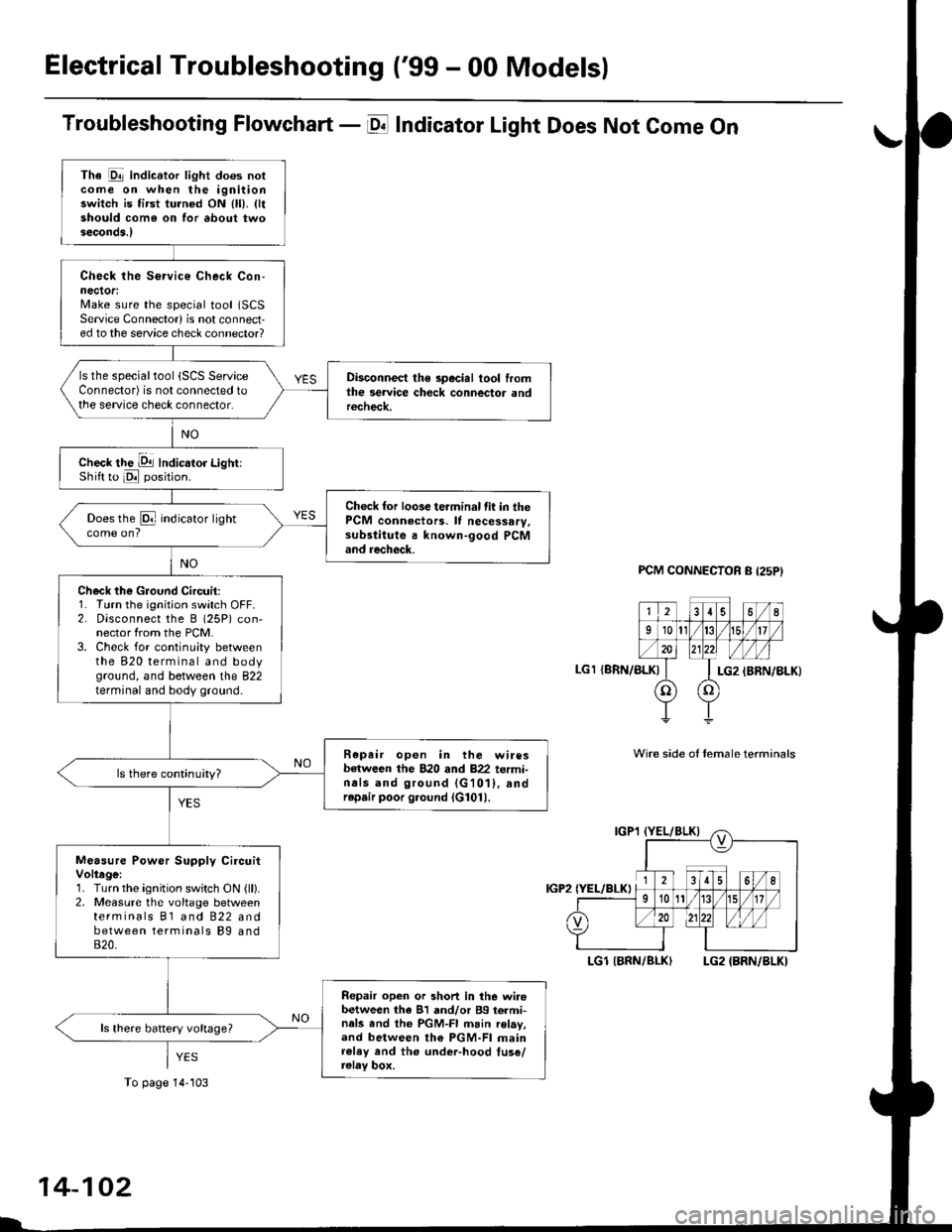

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - E Indicator Light Does Not Come On

FCM CONNECTOR B (25P}

LGl {8RN/ALKI{BRN/8LK}

Wire side ol temale terminals

LGl IBNN/BLK} LG2 {BRN/BLK)

i2t5 6q

910t7

LG2

o) (o

The Pll indicator light does notcome on when the ignitionswitch is fi.st turned ON (ll). lltshould come on for about twoseconda.l

Check the Service Check Con-nector:Make sure the special tool (SCS

Service Connector) is not connect-ed to the service check connector?

ls the specialtool {SCS ServiceConnector) is not connected tothe seNice check connector.

Disconnect the special tool fromthe service check connector andr6check.

Check the Dll lndicator LightiShift to d position.

Check for loose terminal fit in thePCM connecto13. It necessary.sub3titute a known-good PCMand recheck.

Does the @ indicator lightcome on?

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the B (25P) con-nector from the PCM.3. Check for continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Repair open in the wiresbetween the B20 rnd 822 termi-nals and ground (G101), andrep.ir poor ground (G1011.

Measure Power Supply CircuitVoltage:1. Turn the ignition switch ON {ll}.2. Measure the voltage betweenterminals B1 and 822 andbetween terminals Bg and820.

Repair open or short in the wi.obetween th6 81 and/or 89 termi-nals and the PGM-FI main relav,and between th€ PGM-FI mainr€ley rnd the under-hood tus€/relay box.

To page 14''103

14-102

Page 906 of 2189

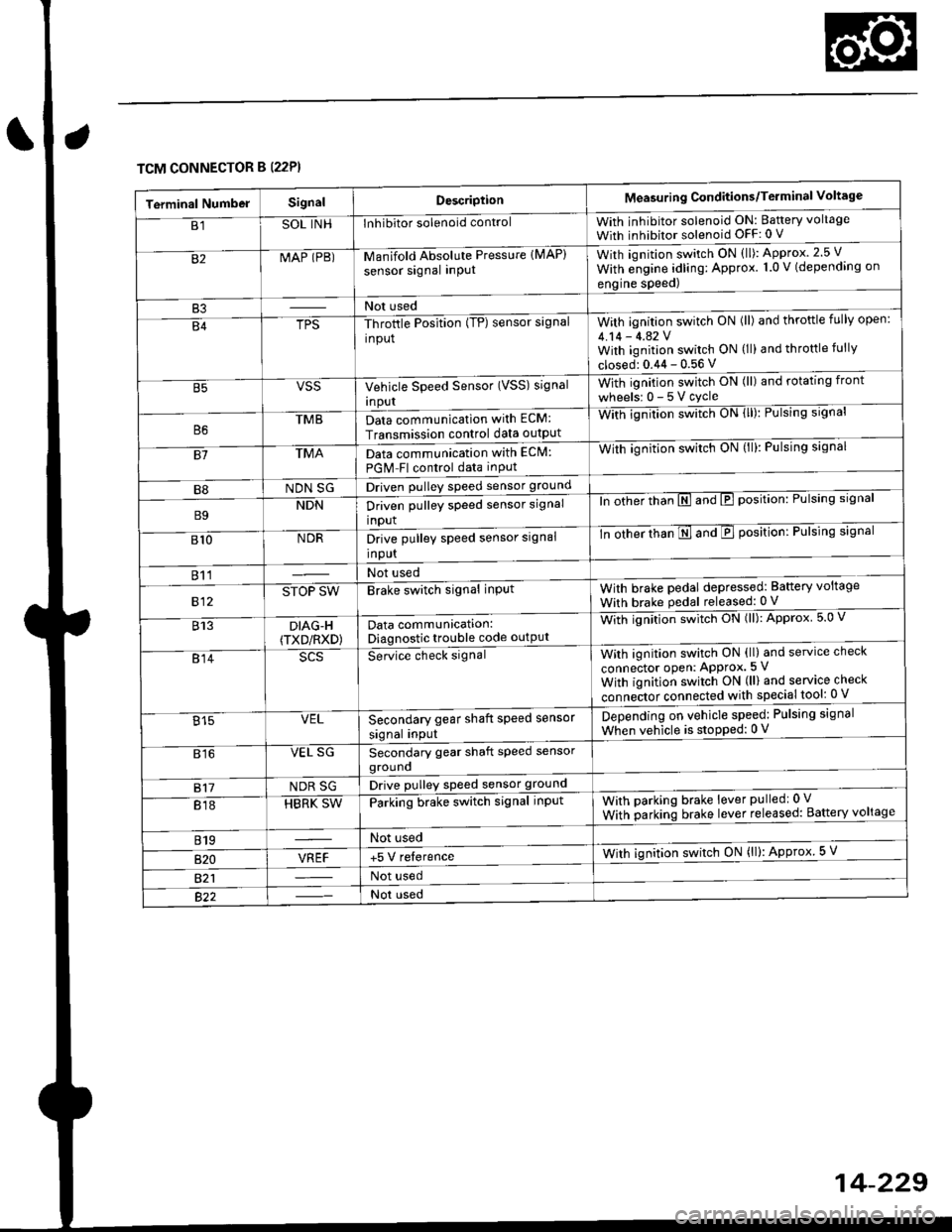

TCM CONNECTOR B (22P}

Terminal NumbelSignalDescriptionMeasuring Conditions/Terminal Voltage

B1SOL INHInhibitor solenoid controlWith inhibitor solenoid ON: Baftery voltage

With inhibitor solenoid OFF: 0 V

82MAP (PB)-M an if old Absol r-rte Pressure IMAP)

sensor signal inPUtWith iqnition switch ON (ll): Approx.2.5 V

With e;gine adling: Approx. 1.0 V (depending on

engine speed)

B3Not used

B4TPS-Throttle Position (TP) sensor signal

input

With ignition switch ON (ll) and throftle fully open:

4.14 - 4.42 VWith ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

VSSVehicle Speed Sensor (VSS) signal

Inpur

With ignition switch ON (ll) and rotating front

wheelsr 0-5Vcycle

TMBData communication with ECM:

Transmission control data outpUt

With ignilion swltch UN lll): rulslng slgnar

81TMAData communication with EClvl:

PGM Fl control data inPut

With ignition swltch uN {ll,: l-ulslng slgnal

B8NDN SGDriven pulley speed sensor ground

B9NDNDriven pulley speed sensor signal

input

ln other thTnE and E position: Pulsing signal

810NDRDrive pulley speed sensor signal

Input

-tn ottrer ttran E ana E position: Pulsing signal

811Not used

812STOP SWBrake switch signal inPutWith brake pedal depressed: Battery voltage

With brake pedal released: 0 V

813DIAG-H(TXD/RXD)Data communication:Diagnostic trouble code outPut

Wittr ignitio.r s*itct' ON (ll): Approx 5.0 V

814Se-ice ctrect signatWith ignition switch ON (ll) and service check

connector oPen: APProx.5 V

With iqnition switch ON (ll) and service check

"onn"itot. connect"d with special tool: 0 V

Secondary gear shaft speed sensor

signal input

Depending on vehicle speed: Pulsing signal

When vehicle is stoPped: 0 V815VEL

816VEL SGSecondary gear shaft speed sensorgrouno

817NDR SGDrive pulley speed sensor ground

818HBRK SWParking brake switch signal inPutWith parking brake lever pulledr 0 V

With parking brake lever released: Battery voltage

819Not used

B�20VREF+5 V relerenceWith ignition switch ON (ll): Approx 5 V

821Not used

Not used

Page 909 of 2189

PGM Terminal Voltage/Measuring Conditions ('99 - 00 Modelsl

A/T Control System

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A/T con-trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

PICM Connoctor Terminrl Location3

Terminal NumberSignalDescriplionMeasuring Condhions/Torminal Voltage

A7ATP DA,/T gear position switch

E position input

InEposition:OV

In other than E] position: Approx. 1O V

A9ATP NPA/T gear position switch

@ and S positions input

In E and El positions: 0 V

In other than E] and E position: Approx. 1O V

A10Timing and adjustment service

check signal

With ignition switch ON {ll} and service check

connector oDen: 5 V

With ignition switch ON (ll) and service check

connector connected with soecialtool:0 v

ATP LA,/T gear position switch

I position input

In E position; OV

In other than E position: Approx. 10 V

STOP SWBrake switch signal outputBrake pedal depressed: Battery voltage

Brake pedal released: 0 V

PCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMoasuring Condhions/Terminal Vohage

B1IGPlPower supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF: 0 V

82PG1Ground

B8HLC LSMPH-PL control linear solenoidpower supply neqative electrode

B9IGP2Power supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF:0 V

810PG2Ground

817HLC LSPPH-PL control linear solenoid

power supplypositive electrode

With ignition switch ON {ll): Pulsing signal

818SC LSMStart clutch control linear

solenoid power supply negative

electrode

s20LGIGround

821VBUBack-up power supplyAlways battery voltage

B22Ground

825SC LSPStan clutch control linear

solenoid power supply positive

electrode

With ignition switch ON (ll): Pulsing signal

t

14-232

Page 912 of 2189

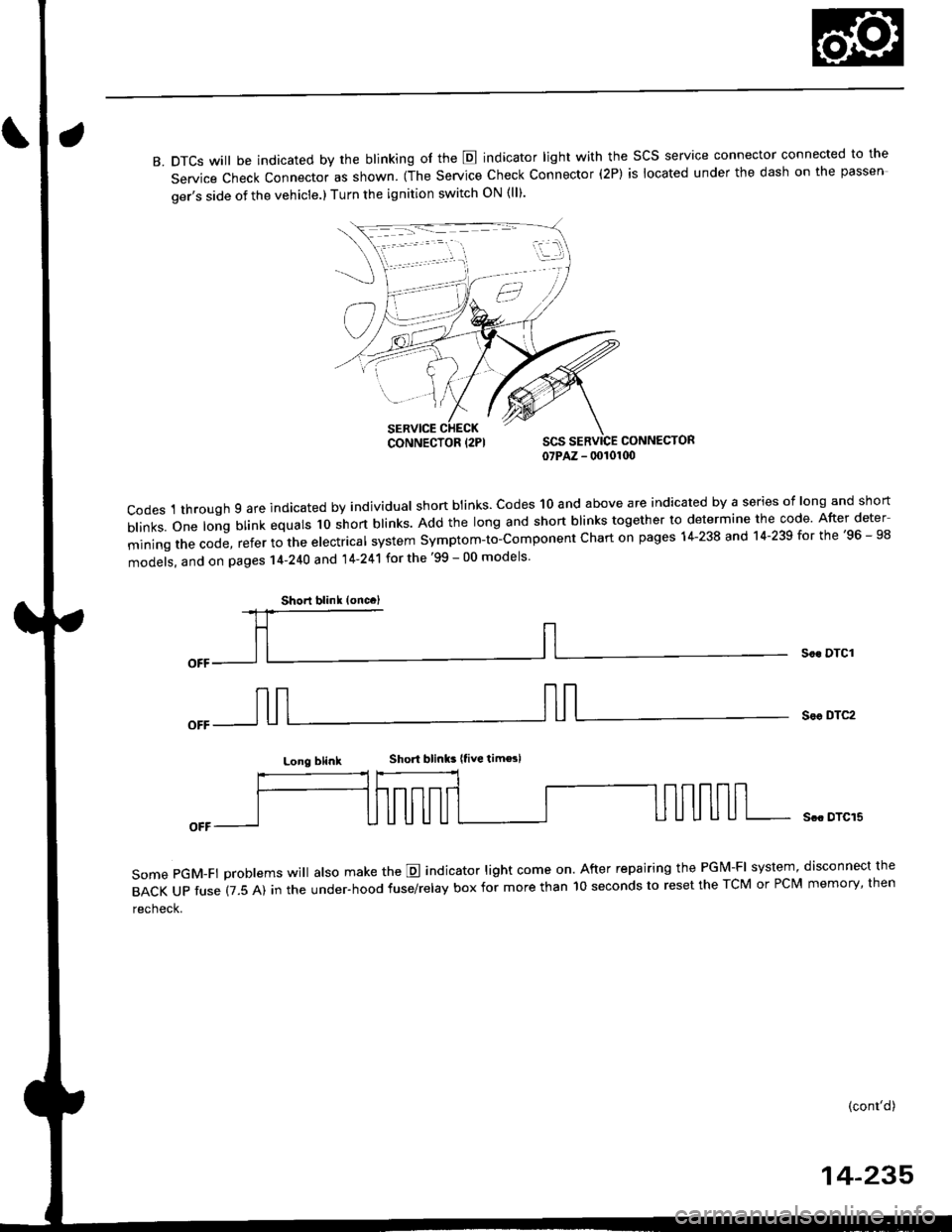

B. DTCS will be indicated by the blinking of the E indicator light with the SCS service connector connected to the

Service Check Connector as shown. (The Service Check Connector (2P) is located under the dash on the passen

ger's side of the vehicle.) Turn the ignition switch ON (ll).

CONNECTOR07PAZ - 00101(x)

codes 1 through 9 are indicated by individual shon btinks. codes 10 and above are indicated by a series of long and short

b|inks.one|ongblinkequa|sloshortb|inks.Addthe|ongandshortb|inkstogethertodeterminethecode.Afterdeter

miningthecode,refertothee|ectrica|systemsymptom-to-componentchartonpagesl4-238and14.239forthe,96_98

models, and on pages 14-240 and 14'241 for the '99 - 00 models

Soc DTCI

Sor DTC2

Long blinkShort blinks |tive tim€sl

some pGM-Ft problems wi

atso make the E indicator light come on. After repairing the PGM-FI system, disconnect the

BACKUPfuse(7.5A)intheUnder.hoodfuse/re|ayboxformorethanl0secondstoresettheTcMorPcMmemory,then

recheck.

Scc DTCI5

(cont'd)

14-235

iii:j

,,,/

CONNECTOR {2PI

Shorl blink (oncc)