oil HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1192 of 2189

Rear Drum Brake

Brake Shoe Reassembly {cont'dl

Connect the parking brake cable to the parking

brake lever.

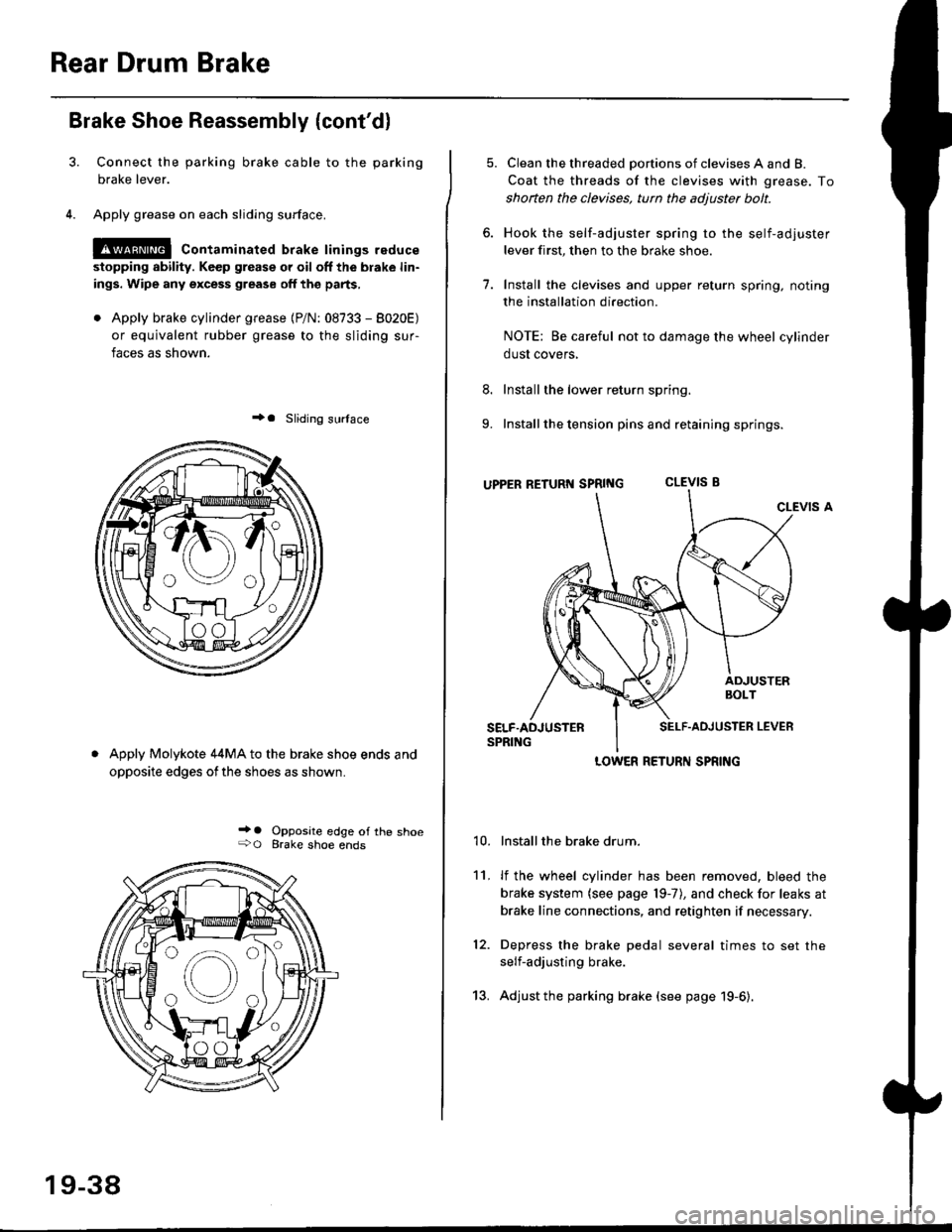

Apply grease on each sliding surface.

!@ contaminated brake linings reduce

stopping ability. Keep grease or oil off the blake lin-

ings. Wipe any excess grease off the parts,

. Apply brake cylinder grease {P/N: 08733 - 8020E)

or equivalent rubber grease to the sliding sur-

faces as shown.

+a Sliding surlace

Apply Molykote 44MA to the brake shoe ends and

opposite edges ofthe shoes as shown.

_' o Opposite edge of the shoe+O Brake shoe ends

19-38

13.

5. Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with grease. To

shoften the clevises, tun the adjuster bolt.

6. Hook the self-adjuster spring to the self-adjuster

lever first, then to the brake shoe

7. Install the clevises and upper return spring. noting

the installation direction.

NOTE: Be careful not to damage the wheel cylinder

dust covers,

8. Install the lower return spring.

9. Install the tension pins and retaining springs.

uppER RETURT{ SpRtNG CLEVIS B

CLEVIS A

Installthe brake drum.

lf the wheel cylinder has been removed, bleed the

brake system (see page 19-7), and check for leaks at

brake line connections, and retighten if necessary.

Depress the brake pedal several times to set the

self-adjusting brake.

Adjust the parking brake (see page 19-6).

't0.

11.

12.

LOWER RETURN SPRING

Page 1202 of 2189

L

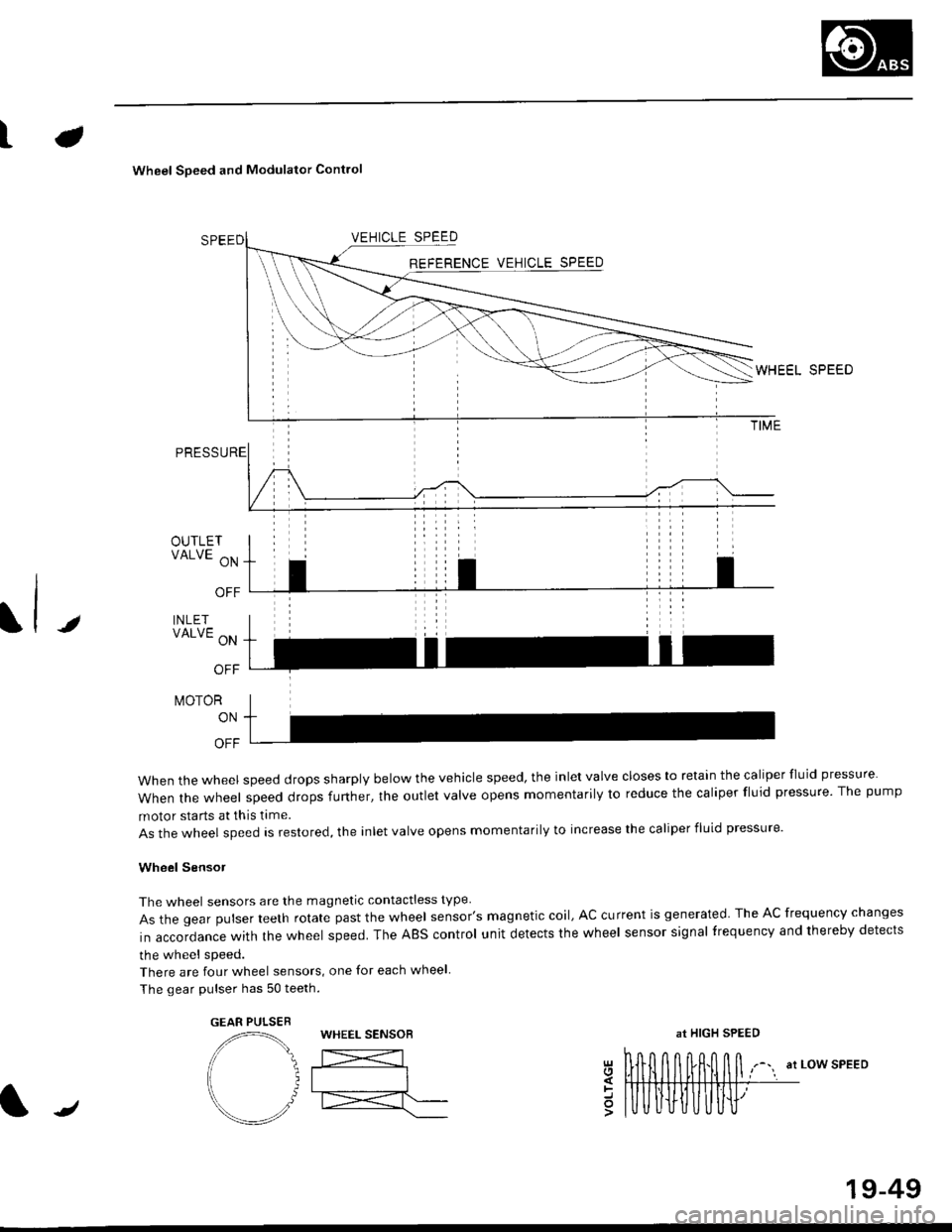

Wheel Soeed and Modulator Contlo

t

OUTLETVALVE ON

OFF

INLETVALVE ON

OFF

t\,40ToR

ON

OFF

when the wheel speed drops sharply below the vehicle speed, the inlet valve closes to retain the caliper fluid pressure

When the wheel speed drops further, the outlet valve opens momentarily to reduce the caliper fluid pressure. The pump

motor starts at this time.

As the wheel speed is restored, the inlet valve opens momentarily to increase the caliper fluid pressure.

Wheel SensoJ

The wheel sensors are the magnetic contactless type

As the gear pulser teeth rotate past the wheel sensor's magnetic coil, AC current is generated The AC frequency changes

in accordance with the wheel speed. The ABS control unit detects the wheel sensor signal frequency and thereby detects

the wheel speed.

There are four wheel sensors, one for each wheel

The gear pulser has 50 teeth.

EEL SPEED

at LOW SPEEDgl

=o

GEAR PULSEBWHEEL SENSOBat HIGH SPEED

/

19-49

Page 1259 of 2189

tInstallation

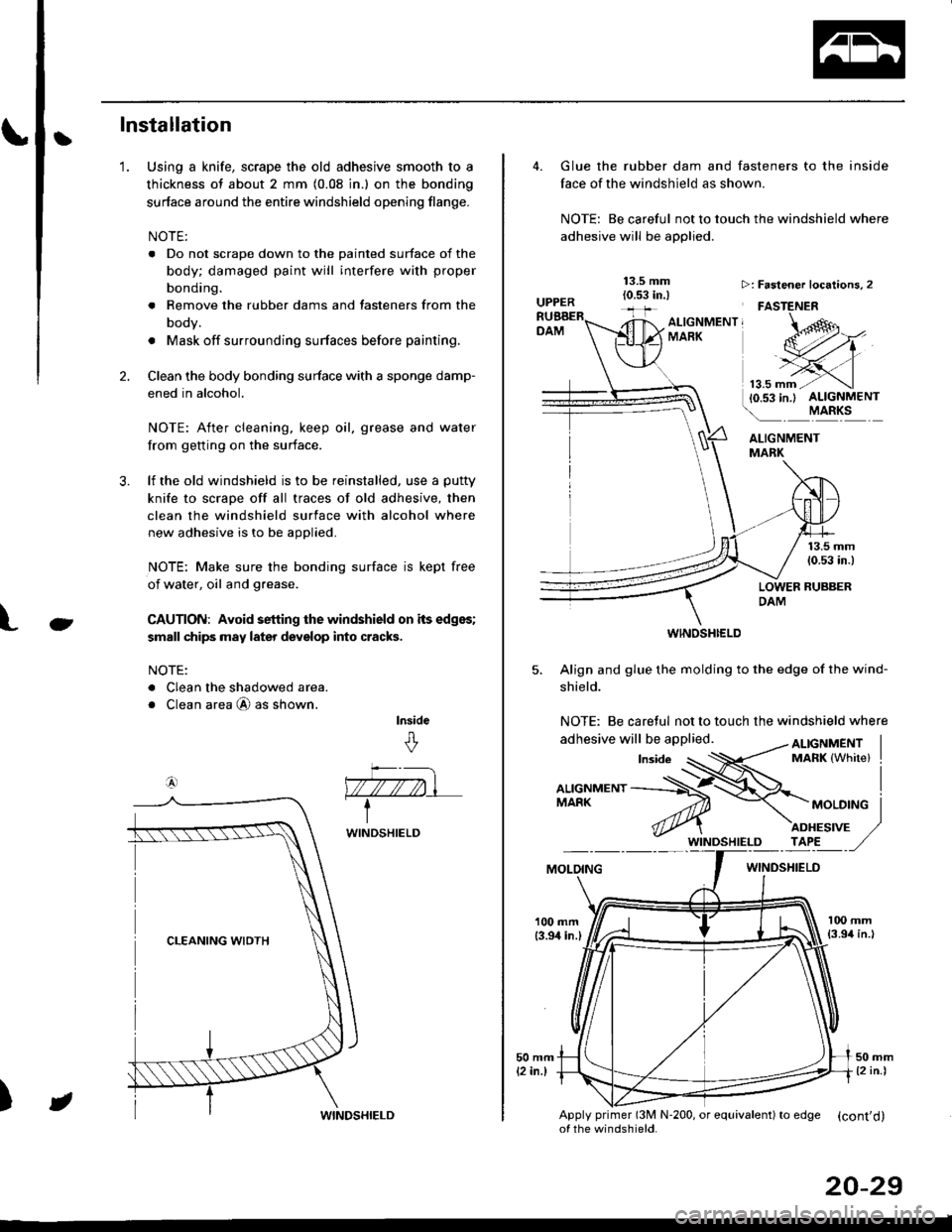

Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surface around the entire windshield opening flange.

NOTE:

. Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding.

. Remove the rubber dams and tasteners from the

body.

. Mask off surrounding surfaces before painting.

Clean the body bonding surface with a sponge damp-

ened in alcohol.

NOTE: After cleaning, keep oil, grease and water

from getting on the surface.

lf the old windshield is to be reinstalled, use a putty

knife to scrape off all traces of old adhesive, then

clean the windshield surface with alcohol where

new adhesive is to be applied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting the windshield on its edges;

small chips may later deyelop into cracks.

NOTE:

. Clean the shadowed area.

o Clean area @ as shown.

lnside

&

'1.

2.

3.

Ct

a4)

)

WINDSHIELD

JWINDSHIELD

20-29

Glue the rubber dam and fasteners to the inside

face of the windshield as shown.

NOTE: Be careful not to touch the windshield where

adhesive will be applied.

ALIGNMENTMABK

13.5 mm(0.53 in.)

LOWER RUBBERDAM

WINOSHI€LD

5. Align and glue the molding to the edge of the wind-

shield.

NOTE: Be caretul not to touch the windshield where

>: Faslener localions, 2

FASTENER

ALTGNMENT, -oMARK

MOLOINGWINDSHIELO

100 mm{3.94 in.l

Apply primer (3M N'200, or equivalent) to edSe (cont'd)of the windshield.

Page 1263 of 2189

Ilnstallation

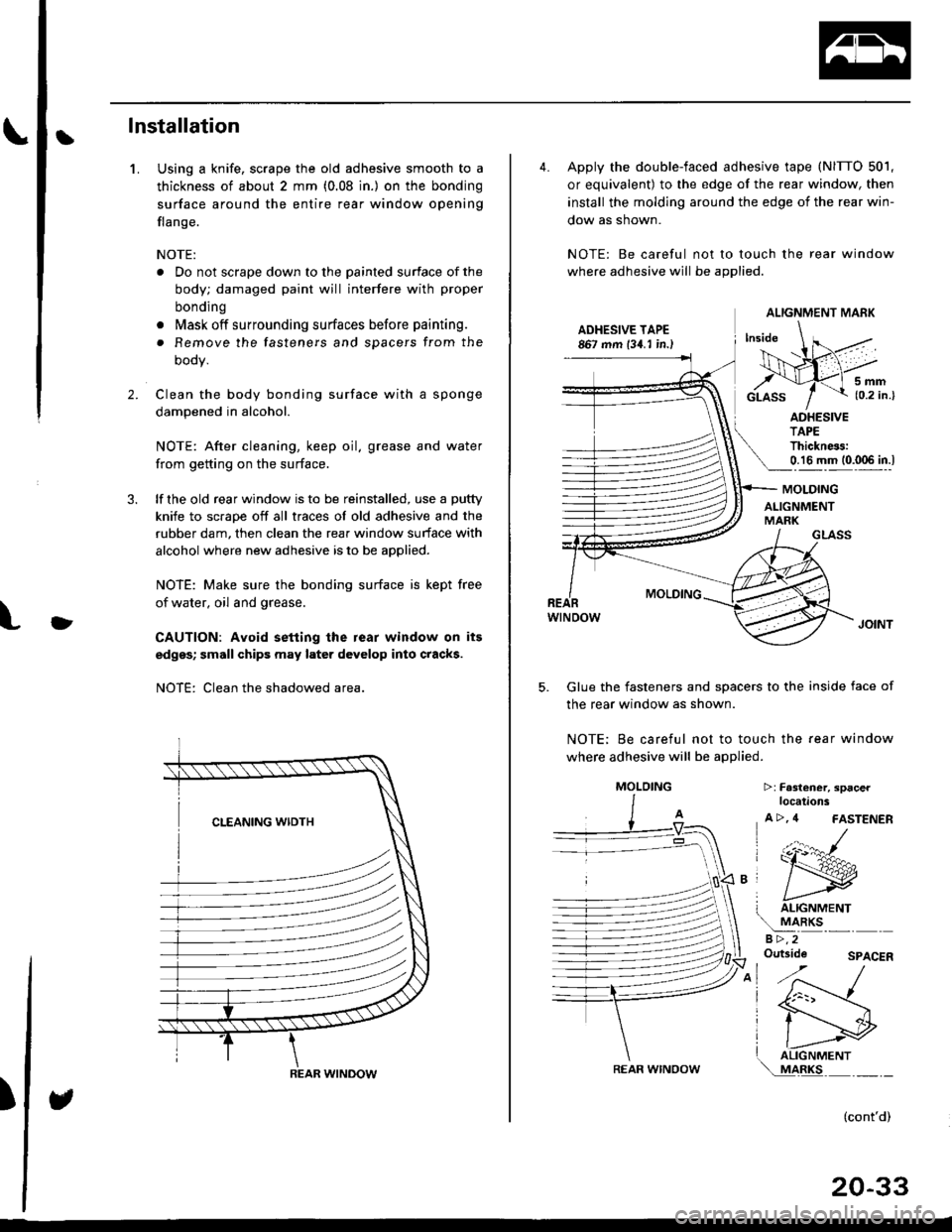

Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surface around the entire rear window opening

flange.

NOTE:

. Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding

o Mask off surrounding surfaces before painting.

. Remove the fasteners and spacers from the

oooy.

Clean the body bonding surface with a sponge

dampened in alcohol.

NOTE: After cleaning, keep oil. grease and water

from getting on the surface.

lf the old rear window is to be reinstalled, use a putty

knife to scrape off all traces of old adhesive and the

rubber dam, then clean the rear window surface with

alcohol where new adhesive is to be applied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting the rear window on its

edges; small chips may later develop into cracks.

NOTE: Clean the shadowed area.

1.

2.

)

)

REAR WINDOW

4. Apply the double-faced adhesive tape (NITTO 501,

or equivalent) to the edge of the rear window, then

install the molding around the edge of the rear win-

dow as shown.

NOTE: Be careful not to touch the rear window

where adhesive will be applied.

ADHESIVE TAPE867 mm 134. I in.)

5mm{0.2 in.}

ADHESIVETAPEThickness:0.16 mm (0.006 in.l

GLASS

MOLDING

wtNoow

Glue the fasteners and spacers to the inside face of

the rear window as shown.

NOTE; Be careful not to touch the fear window

where adhesive will be applied.

5.

MOLDING

ALIGNMENTMARK

T ALIGNMENT

!

aRKsa >,2Outside

>:Fa3l€ner, spacerlocations

A >, 4 FASTENER

(:r:^#-

ry

I liGrtrrrrertrr\..!44llc-''' - -

SPACER

(cont'd)

20-33

ALIGNMENT MARK

REAR WINOOW

MOLOING

Page 1266 of 2189

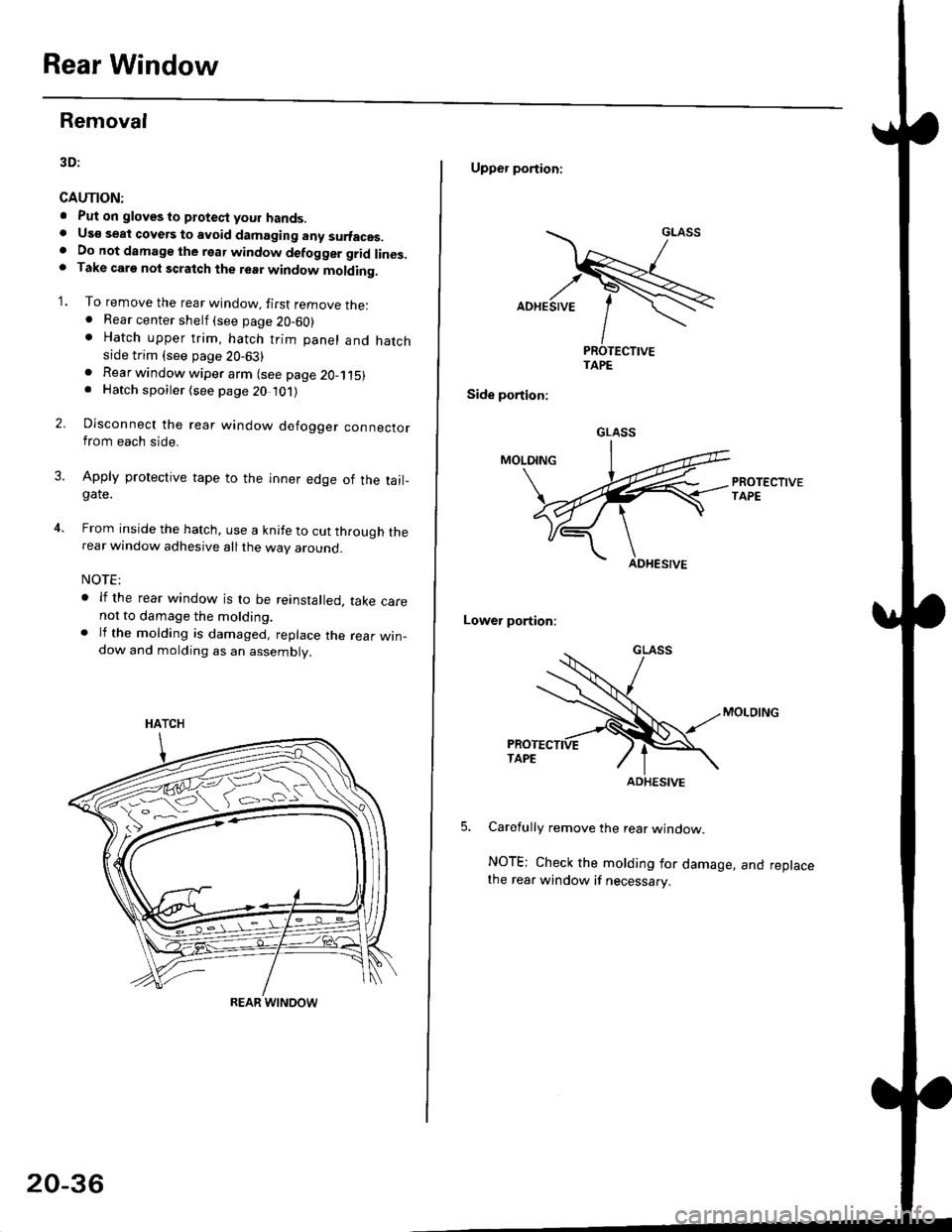

Rear Window

Removal

3D:

CAUTION:

. Put on gloves to ptotect your hands.. Us€ seat cove6 to avoid damaging any surfaces.. Do not damage the rear window defogger grid lines.. Take carg nol scratch the terr window molding.

'1. To remove the rear window, firsr remove the:. Rear center shelf (see page 20-60). Hatch upper trim, hatch trim panel and hatchside trim (see page 20-63)

2.

. Rear window wiper arm (see page 2O-115). Hatch spoiler (see page 20 101)

Disconnect the rear window defogger connectorfrom each side.

Apply protective tape to the inner edge of the tail_gate.

From inside the hatch, use a knife to cut through therear window adhesive all the way around.

NOTE:

. lf the rear window is to be reinstalled, take carenot to damage the molding.. lf the molding is damaged, replace the rear win_dow and molding as an assembly.

HATCH

ffi#

REAR WINOOW

20-36

Upper portioni

TAPE

Side portion:

Lower portion;

Carefully remove the rear window.

NOTE; Check the molding for damage, and replacethe rear window if necessary.

GLASS

ADHESIVE

Page 1267 of 2189

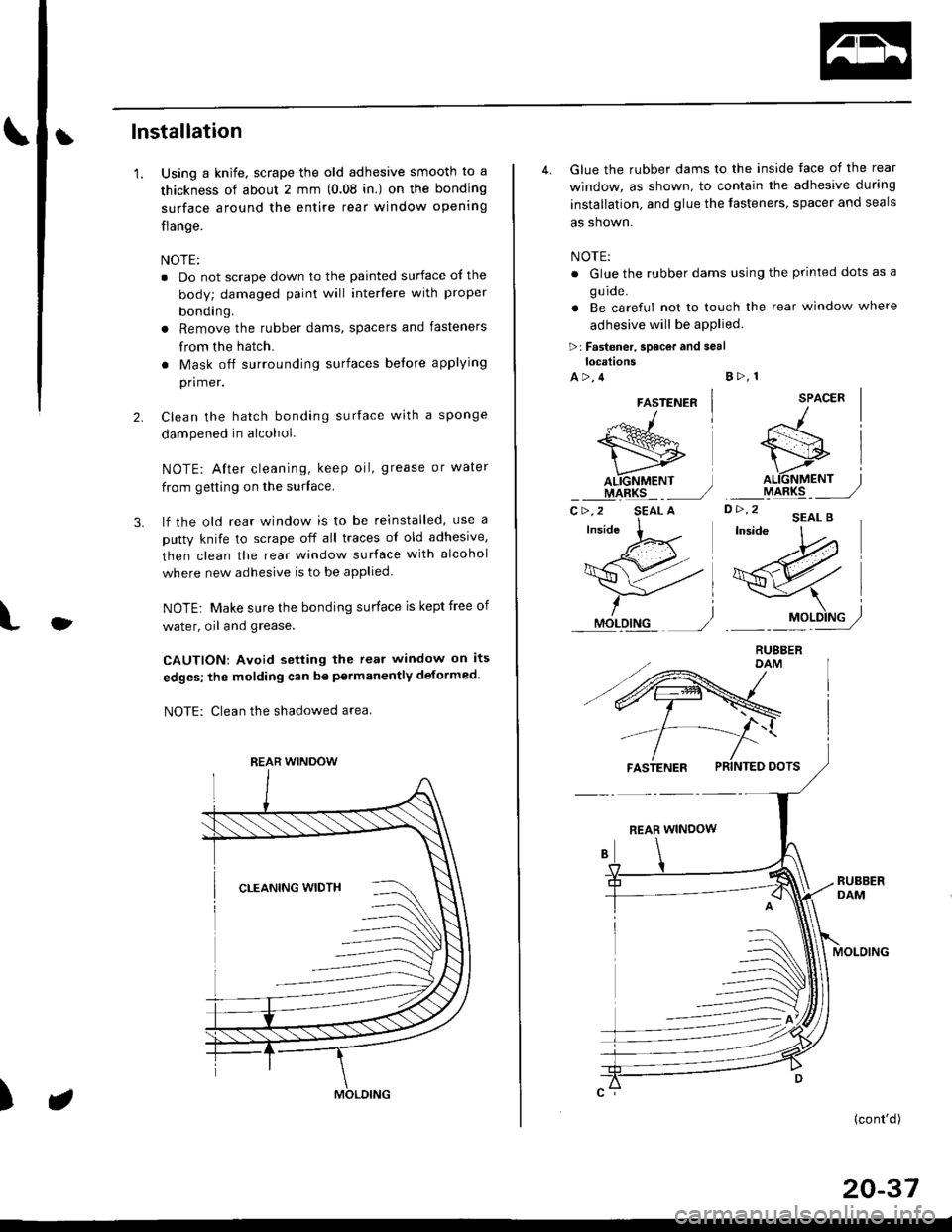

tlnstallation

'1.

3.

Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surface around the entire rear window opening

flange.

NOTE:

. Do not scrape down to the painted surface ol the

body; damaged paint will interfere with proper

bonding.

a Remove the rubber dams, spacers and fasteners

from the hatch.

. Mask off surrounding surfaces before applying

primer.

Clean the hatch bonding surface with a sponge

dampened in alcohol.

NOTE: After cleaning, keep oil, grease or water

from getting on the surface.

lf the old rear window is to be reinstalled, use a

putty knife to scrape off all traces of old adhesive,

then clean the rear window surface with alcohol

where new adhesive is to be applied.

NOTE; Make sure the bonding surface is kept free of

water, oil and grease.

CAUTION: Avoid setting the rear window on its

edges; the molding can be permanently deformed.

NOTE: Clean the shadowed area

2.

O

)

REAR WINDOW

4. Glue the rubber dams to the inside face of the rear

window, as shown, to contain the adhesive during

installation, and glue the fasteners, spacer and seals

as shown.

NOTE:

. Glue the rubber dams using the printed dots as a

g u ide.

. Be careful not to touch the rear window where

adhesive will be aPPlied

>r Fastener, spacor and seallocations

A>,4B>, 1

SPACER

D> '2 'EAL B'W

/l

si

o.\6fif,", j

ryt48rq _ _ ,,/

-\l

19Pry/

FASTENER PRINTED DOTS

REAR WINDOW

MOLOING

(cont'd)

20-37

FASTENER

"-*^1

wAL.IGNMENT ]IIARKS _ _,/C>,2 SEAL A

Page 1271 of 2189

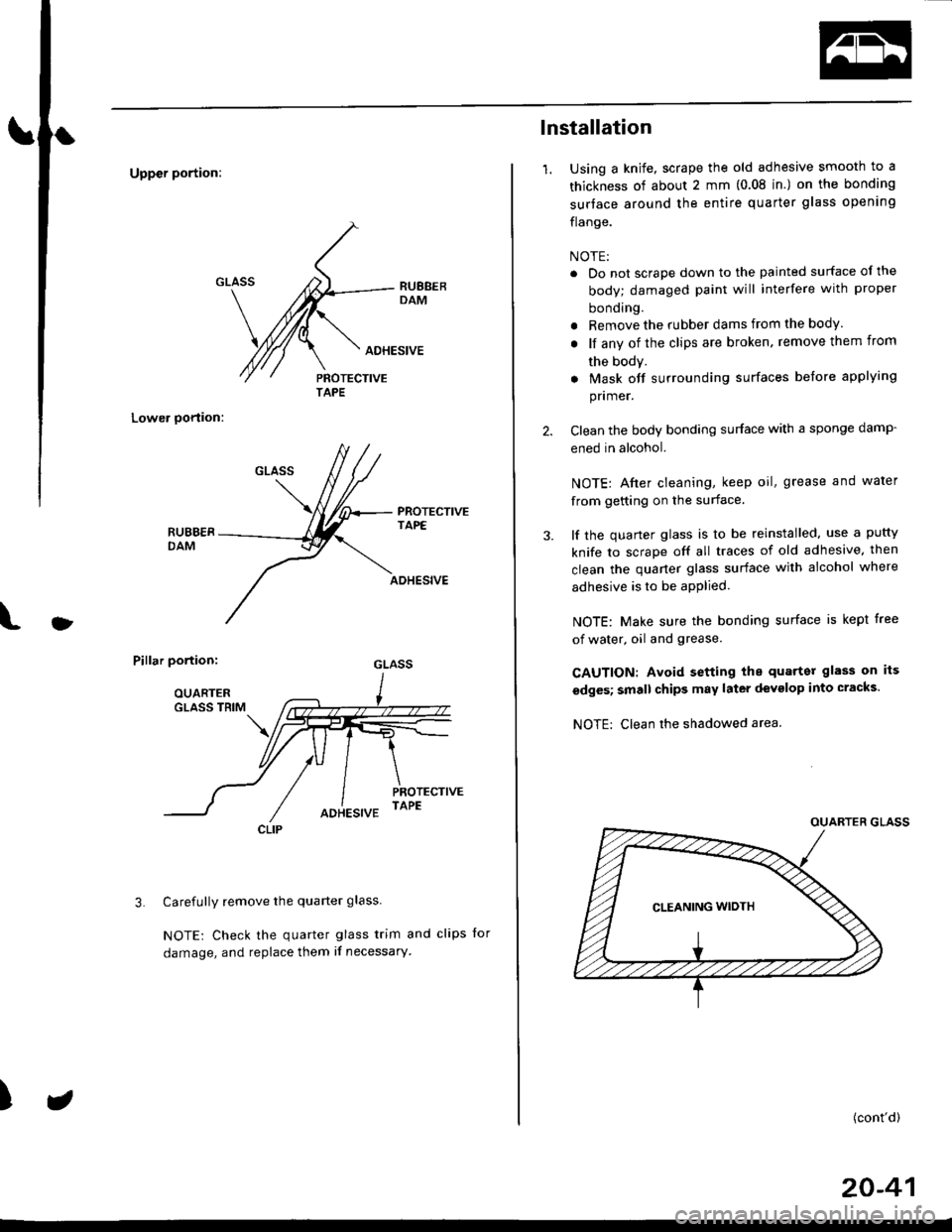

Uppcr portion:

Lower oortion:

PROTECTIVETAPE

l

ADHESIVE

Pillar portion:

Carefully remove the quarter glass

NOTE: Check the quarter glass trim and clips for

damage, and replace them if necessary'

3.

)

AOHESIVE

TAPE

CLIP

lnstallation

1.Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surtace around the entire quarter glass opening

flange.

NOTE:

. Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding.

r Remove the rubber dams from the body.

. lf any of the clips are broken, remove them from

the body.

. Mask off surrounding surfaces before applying

pnmer.

Clean the body bonding surface with a sponge damp-

ened in alcohol.

NOTE: Afier cleaning, keep oil, grease and water

from getting on the surface.

lf the quarter glass is to be reinstalled, use a putty

knife to scrape off all traces of old adhesive. then

clean the quaner glass surface with alcohol where

adhesive is to be apPlied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting the quarter glass on its

edges; small chips may later devglop into cracks.

NOTE: Clean rhe shadowed area.

(cont'd)

20-41

Page 1276 of 2189

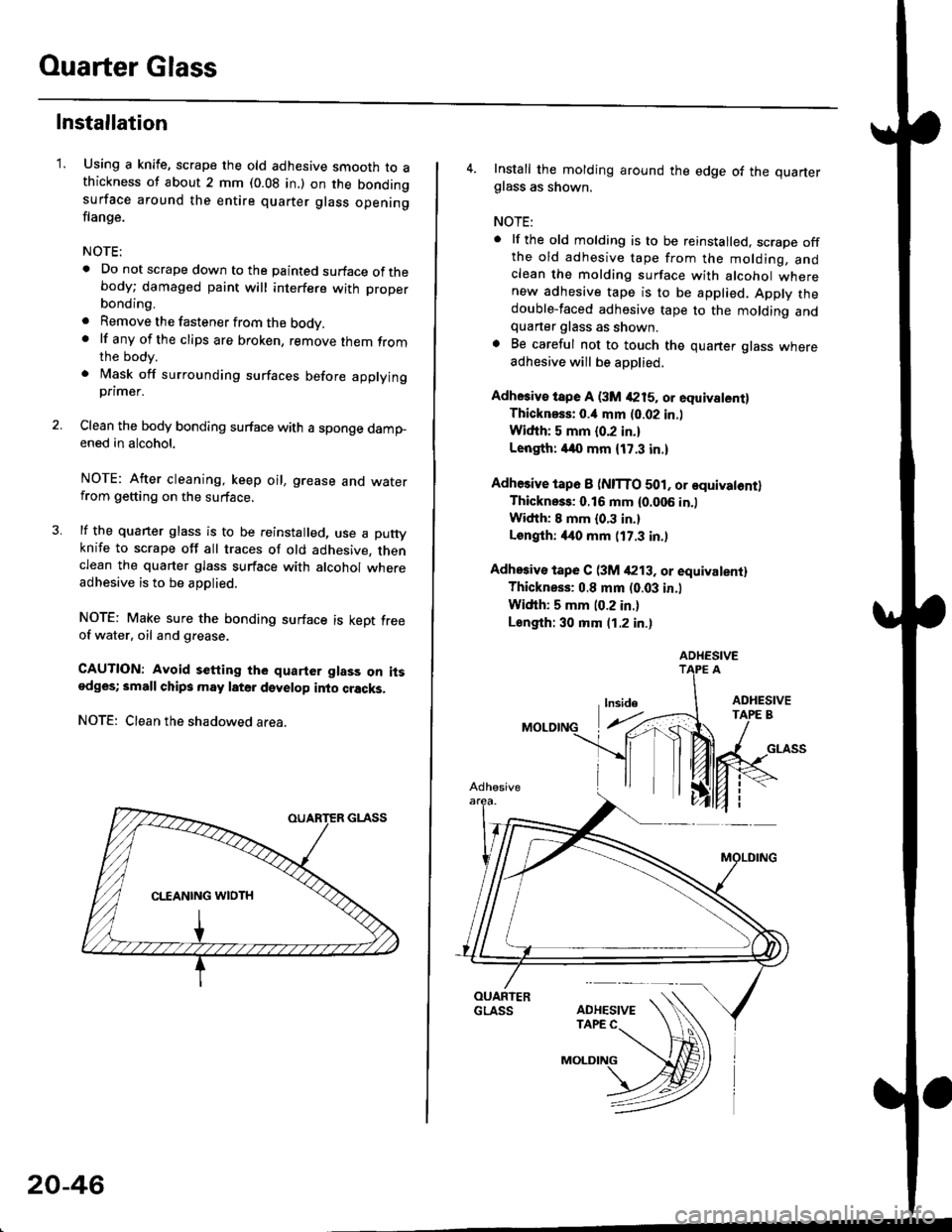

Ouarter Glass

1.

Installation

Using a knife, scrape the old adhesive smooth to athickness of about 2 mm (0.08 in.) on the bondingsurface around the entire quarter glass openingflange.

NOTE:

. Do not scrape down to the painted surface of thebody; damaged paint will interfere with proper

a

a

bonding.

Remove the fastener from the body.lf any of the clips are broken, remove lhem fromthe body.

Mask off surrounding surfaces before applyingpnmer.

Clean the body bonding surface with a sponge dampened in alcohol.

NOTE: After cleaning, keep oil, grease and waterfrom getting on the surface.

lf the quarter glass is to be reinstalled, use a puttyknife to scrape off all traces of old adhesive. thenclean the quarter glass surface with alcohol whereadhesive is to be applied.

NOTE: Make sure the bonding surface is kept freeof water. oil and grease.

CAUTION: Avoid setting the quarter glass on itsodges; small chips may later develop into cracks,

NOTE: Clean the shadowed area.

20-46

4. Install the molding around the edge of the quarterglass as shown.

NOTE:

. lf the old molding is to be reinstalled, scrape offthe old adhesive tape from the molding, andclean the molding surface with alcohol wherenew adhesive tape is to be applied. Apply thedouble-faced adhesive tape to the molding andquarter glass as shown.. Be careful not to touch the quarter glass whereadhesive will be aoDlied.

Adhesiv€ tspe A (3M 4215, or equivalent)Thicknsss: o.il mm (0.02 in.l

Widih: 5 mm {0.2 in.}

Length: /140 mm {17.3 in.)

Adhesive tap6 I (NITTO 501, or equivatontlThickness: 0.16 mm {0.006 in.)

Width: I mm {0.3 in.}

Longlh: 4it0 mm (17.3 in.)

Adhosiv€ tape C (3M /P13. or equivalentl

Thickness: 0.8 mm (0.03 in.l

Width: 5 mm (0.2 in.)

Length: 30 mm (1.2 in.)

ADHESIVE

Page 1331 of 2189

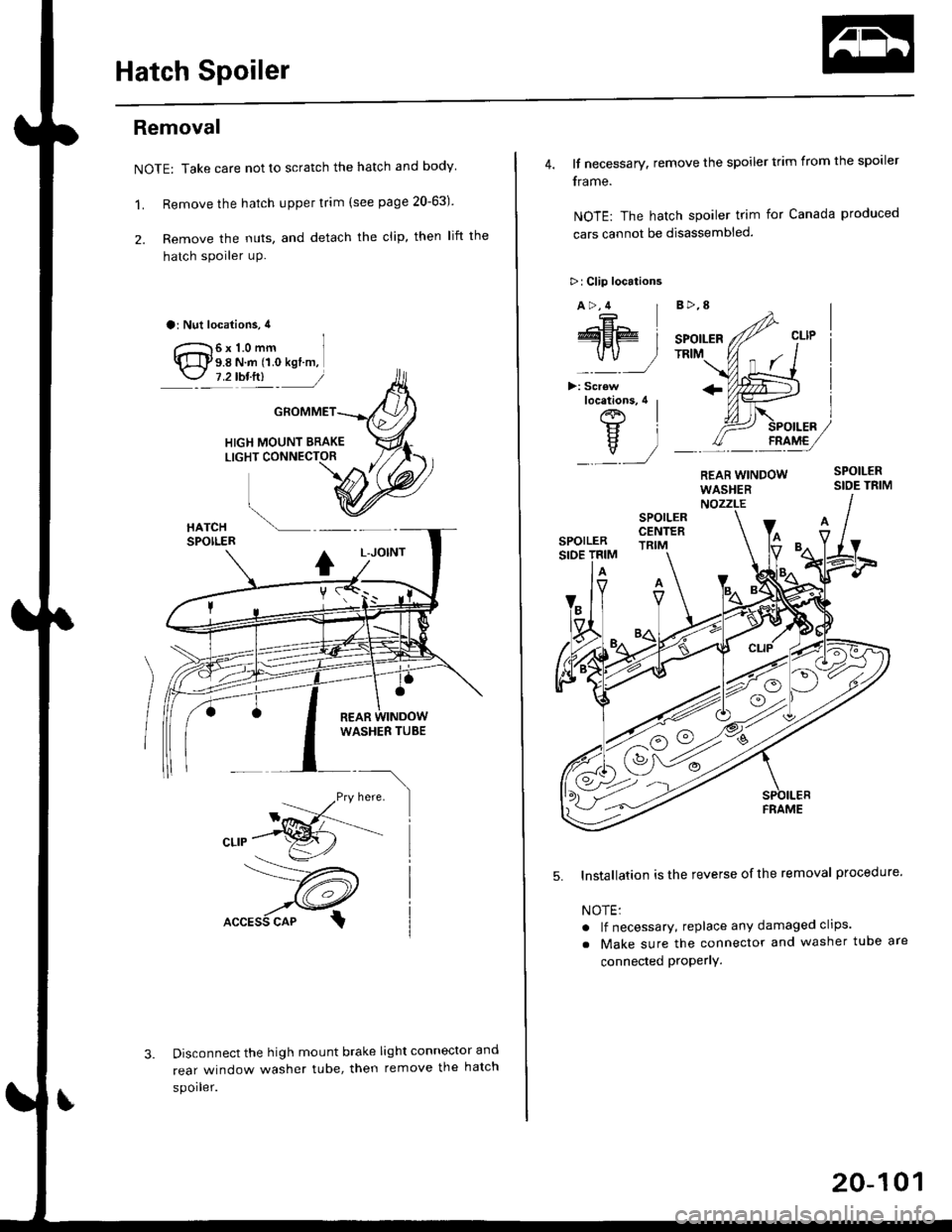

Hatch Spoiler

Removal

NOTE: Take care not to scratch the hatch and body

1. Remove the hatch upper trim (see page 20-63)

2. Remove the nuts, and detach the clip, then lift the

hatch spoiler uP.

a: Nut locations, 4

1 2lbt.ftl _ j/

GROMMET

HIGH MOUNT BRAKELIGHT CONNECTOR

Disconnect the high mount brake light connector and

rear window washer tube, then remove the hatch

spoiler.

------,*;)

4. lf necessary. remove the spoiler trim from the spoiler

frame.

NOTE: The hatch spoiler trim for Canada produced

cars cannot be disassembled.

>: Clip locations

A>,4

>: Scr€w

5. Installation is the reverse of the removal procedure'

NOTEi

. lf necessary, replace any damaged clips.

a Make sure the connector and washer tube are

connected ProPerlY.

20-101

Page 1333 of 2189

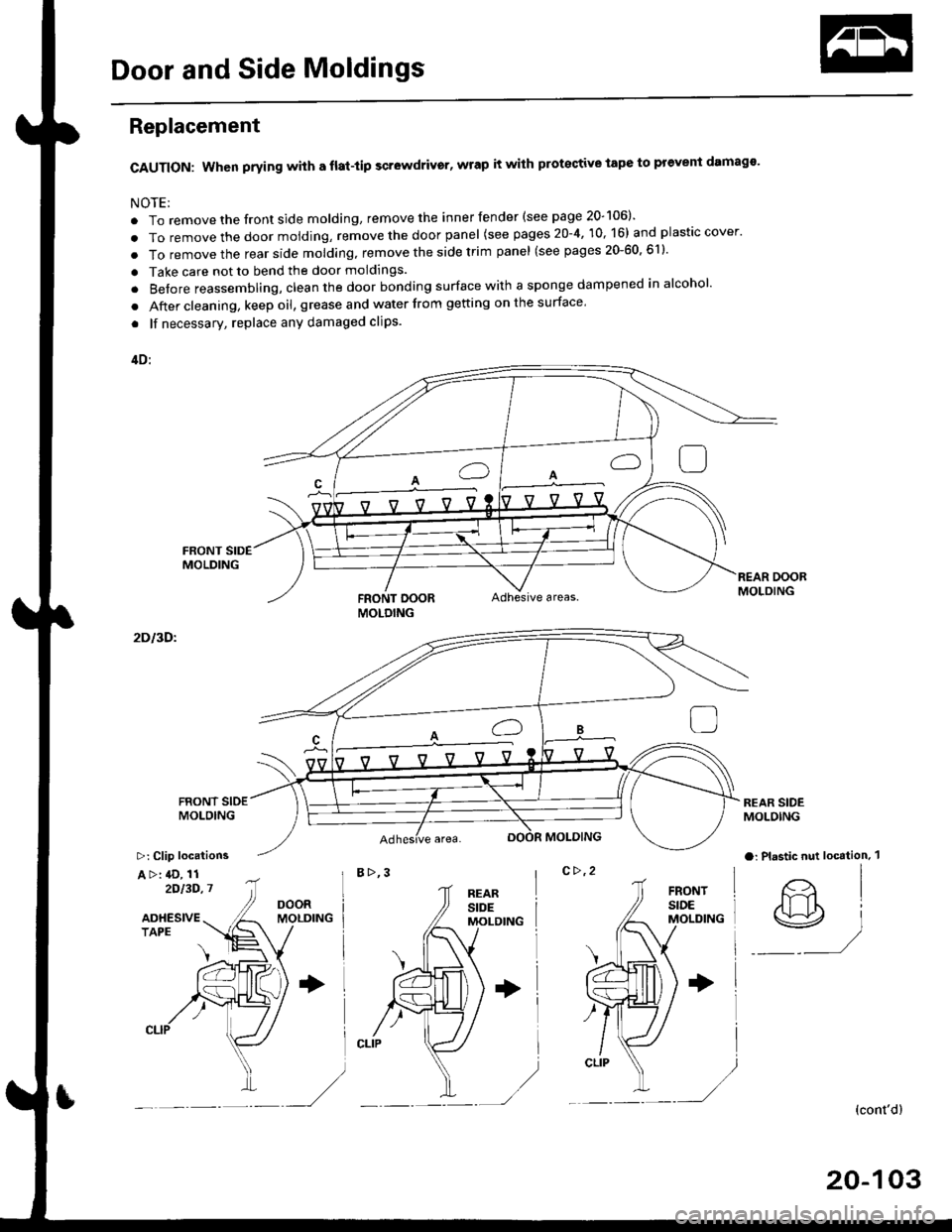

Door and Side Moldings

Replacement

CAUTION: When prying with a flat-tip scr6wdrivgr, wrap it with protective tape to prevent damags'

NOTE;

. To remove the front side molding, remove the inner fender (see page 20-106)'

. To remove the door moiding, remove the door panel (see pages 20-4, 10, 16) and plastic cover.

. To removethe rearside molding, remove the side trim panel (see pages 20-60,611'

. Take care not to bend the door moldings.

. Before reassembling, clean the door bonding surface with a sponge dampened in alcohol'

. After cleaning, keep oil, grease and water from getting on the surface'

. lf necessary, replace any damaged clips.

4D:

FRONT DOORAdhesive areas.

2Dl3Dl

B>,3c>,2

REAR SIDEMOLOING

a: Plastic nut loc€tion. 1

@)

(cont'dl

20-103

MOLDING

>: Clip locations

A >: 4D, 112')13D,7