Lamp HONDA CIVIC 1998 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 494 of 2189

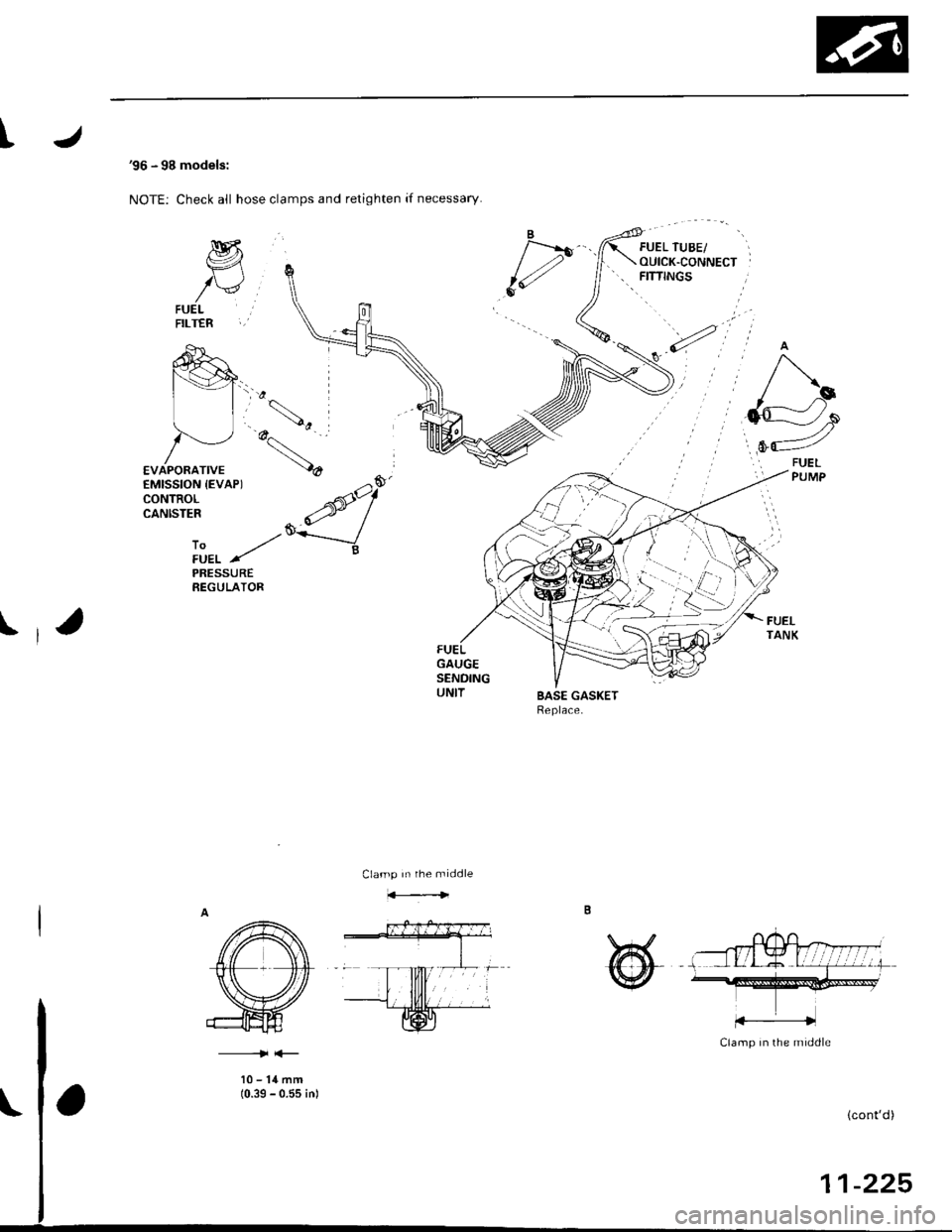

I'96 - 98 models:

NOTE: Check all hose clamps and retighten if necessarY.

M

/vFUELFILTER

PRESSUREREGULATOR

IFUELTANKFUELGAUGESENDINGUNITBASE GASKETReplace.

Clamp In rhe middle

@

Clamp in the middle

10-14mm(0.39 - 0.55 inl

(cont'd)

11-225

Page 495 of 2189

Fuel Supply System

Fuel Lines (cont'dl

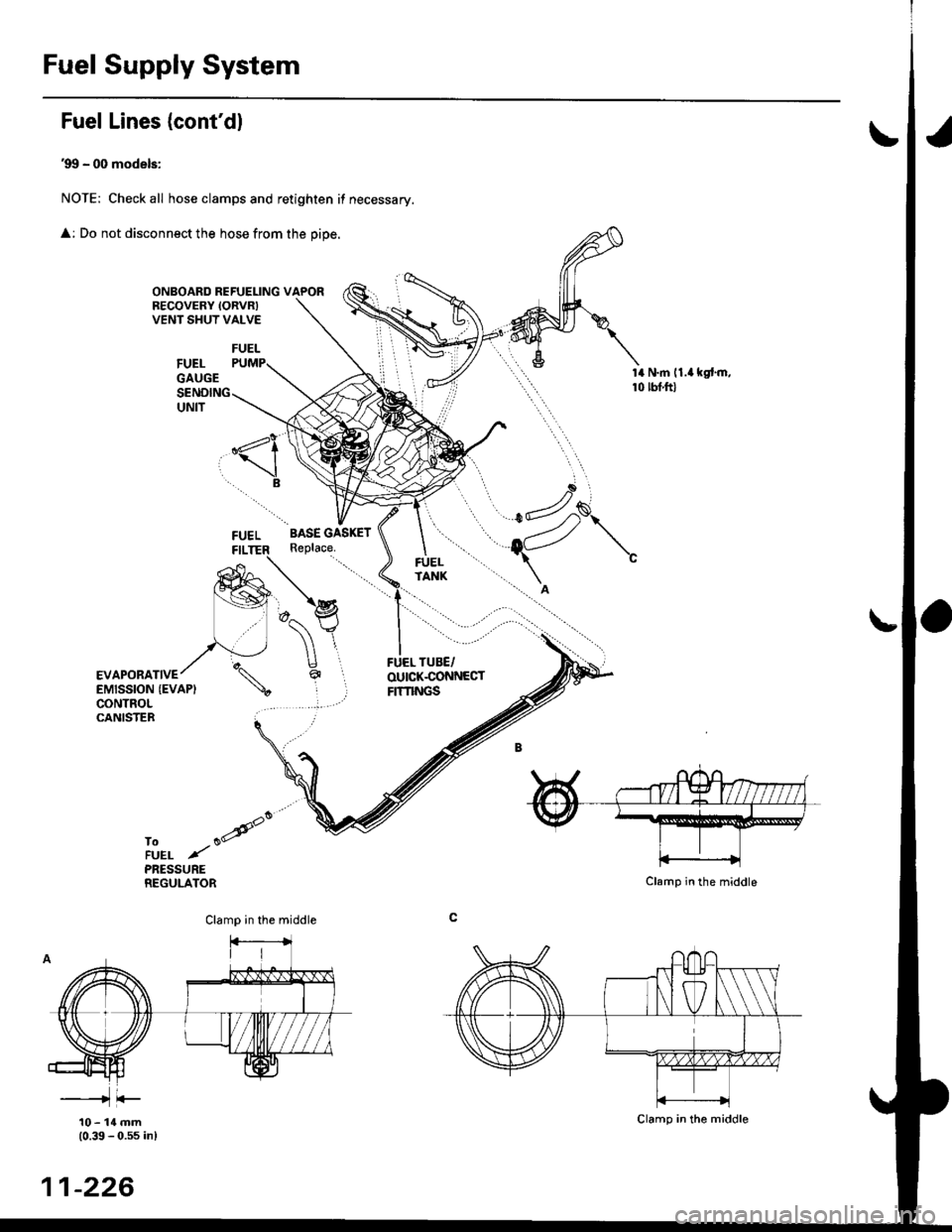

.99 - 00 models:

NOTE: Check all hose clamps and retighten if necessary.

: Do not disconnect the hose from the pipe.

ONBOARD REFUELING VAPORBECOVERY IORVRIVENT SHUT VALVE

B

FUELGAUGElt N.rn l1.a kgt.m,r0 lbt ftl

ftr, n'fo'PRESSUREREGULATOR

Clamp in the middle

Clamp in the middle

11-226

Page 500 of 2189

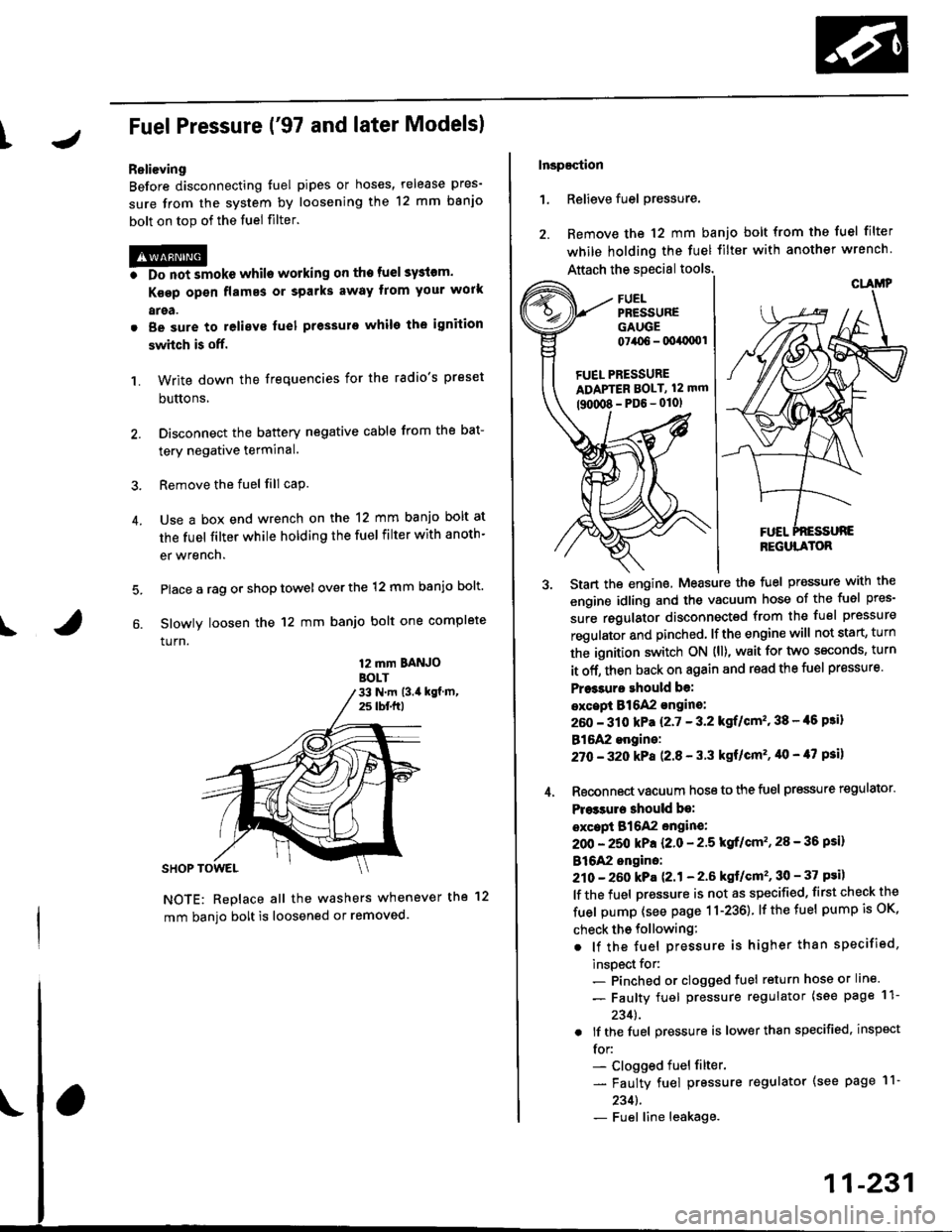

tJFuel Pressure {'97 and later Models)

ReliGving

Before disconnecting tuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on top of the fuel filter.

@o Do not smoke whilo working on the fuel sy3lom.

Ksgp op€n flames or sparks away tlom Your work

arga.

. Be sure to relieve fuel pressule while the ignition

swhch is off.

1. Write down the frequencies for the radio's preset

buttons,

2. Disconnect the battery negative cable from the bat-

tery negative terminal.

3. Remove the fuel fill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with anoth-

er wrench.

Place a rag or shop towel over the 12 mm banio bolt.

Slowly loosen the 12 mm banjo bolt one complete

turn.

4.

I

12 mm BAtt OBOLT33 N.m (3.i1 kgf m,25 tbf.f0

NOTE: Replace all the washers whenever the 12

mm banio bolt is loosened or removed.

Inspaqtion

1. Relieve fuel pressure.

2. Remove the 12 mm banjo bolt from the fuel filter

while holding the fuel Jilter with another wrench

Attach the special tools.

3. Start the enginethe fuel Pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched lfthe engine will not start, turn

the ignition switch ON {ll), wait for two seconds, turn

it off, then back on again and read the fuel pressure'

Pr$3uro ehould be:

excepi 816A2 sngine:

260 - 310 kPa {2'7 - 3.2 kgf/cm" 38 - {6 Fi}

B16A2 engine:

27O -32O kPa P.8 - 3'3 kgf/cm'�, '10 - 47 psi)

4. Reconnect vacuum hoso to the fuel pressure regulator'

Pre33ure 3hould be:

except B16A2 engin€:

2OO - 250 kPa {2.0 - 2'5 kgf/cm'�, 28 - 36 psi)

B16A2 engino:

210 - 260 kPa 121 - 2.6 ksf/cm'�, 30 - 37 psi)

lf the fuel pressure is not as specified, first check the

fuel pump (see page 11-236) lfthetuel pumpisoK,

check tho following:

. lf the fuel pressure is higher than specified,

inspect for:- Pinched or clogged fuel return hose or line.

- Faulty fuel pressure regulator (see page 11-

2341.

. lf the fuel pressure is lower than specified, inspect

for:- Clogged fuel filter.

- Faulty fuel pressure regulator (see page l1-

2341.- Fuel line leakage.

FUEL PRESSUREADAPTER BOLT, 12 mm

tguxt8-PD6-0101

CLAMP

REGULATOR

11-231

Page 503 of 2189

Fuel Supply System

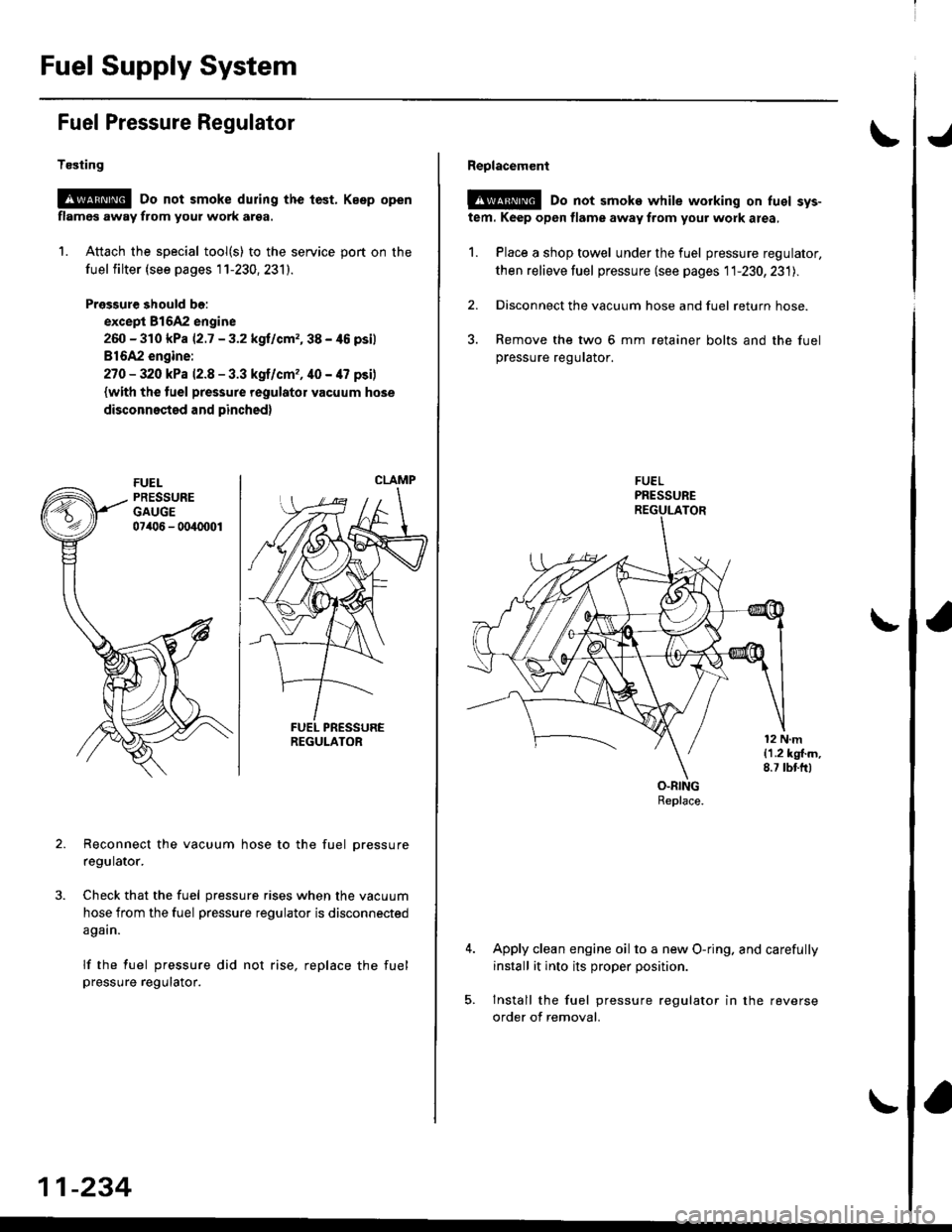

Fuel Pressure Regulator

Te3ting

@ Do not smoke during the tast. Keep open

flamcs away from your work arsa.

1. Attach the special tool(s) to the service port on the

fuel filter (see pages 1 1-230, 231).

Pressure should bo:

except 81642 engine

260 - 310 kPa |'2.7 - 3.2 kgllcrn2,38 - /t6 psil

816A2 engine:

27O - 320 kPa 12.8 - 3.3 kgf/cm,, 40 - 47 psi)

{with the tuel pressure regulator vacuum hose

disconnested and pinched)

Reconnect the vacuum hose to the fuel pressure

regulator.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnected

again.

lf the fuel pressure did not rise, replace the fuel

pressure regutalor.

CLAMP

REGULATOR

11-234

Reolacement

@@ Do not smoke while working on luel sys-

tem. Keep open flame away from your work area,

1. Place a shop towel under the fuel pressure regulator,

then relieve fuel pressure (see pages 11-230,231l..

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts and the fuel

pressure regurator.

Apply clean engine oil to a new O-ring. and carefully

install it into its proper position.

Install the fuel pressure regulator in the reverse

order of removal.

Page 510 of 2189

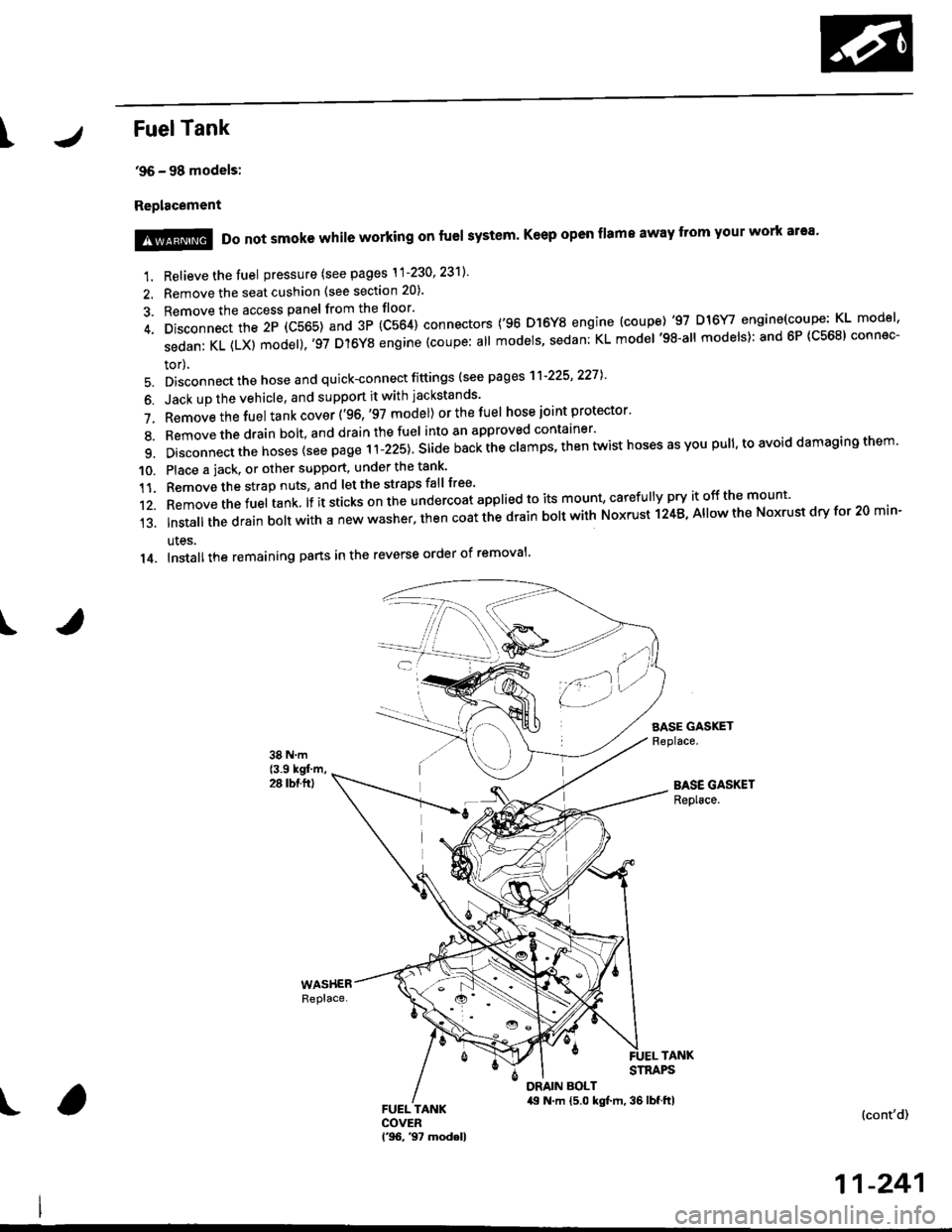

IFuelTank

'96 - 98 models:

Replacement

I

1. Relieve the fuel pressure (see pages \1-230' 23'll'

2. Remove the seat cushion (see section 20).

3. Remove the access panel from the floor'

4. Disconnect the 2P (C565) and 3P (C564) connectors ('96 D]6Y8 engine (coupe) '97 D16Y/ engine(coupe: KL model'

sedanKL(LX)model).'97D'l6YSengine(coupe:allmodels'sedan:KLmodel'98-allmodels):and6P(C568)connec-

tor),

5. Disconnect the hose and quick-connect fittings (see pag es'l'l-225' 2271

6. Jack up the vehicle, and support it with jackstands'

7. Removethefuel tank cover ('96,'97 model) orthefuel hose joint protector'

8. Bemovethedrain bolt,and drainthefuel into an approved container'

9. Disconnect the hoses {see page r i-izst. Sria" nu"i ihe clamps, then twist hoses as you pull, to avoid damaging them'

10. Place a jack. or other support, under the tank'

11. Remove the strap nuts, and let the straps fall free'

12. Removethefuel tank lf it sticks on the undercoat applied to its mount' caref u lly pry it off the mount'

13.|nsta||thedrainbo|twithanewwasher.thencoatthedrainbo|twithNoxrustl24B,A||owtheNoxrustdryfor20min-

ules.

14. Installthe remaining pans in the reverse order of removal'

SASE GASKETReplace.

BASE GASKETReplace.

!@@ Do not smoke while working on fuel system' Keep open flame away from your work ar'a'

TANKSTRAPS

DRAIN BOLT,19 N.m {5.0 kgt m, 36 lbf.ftl(cont'd)

11-241

Page 511 of 2189

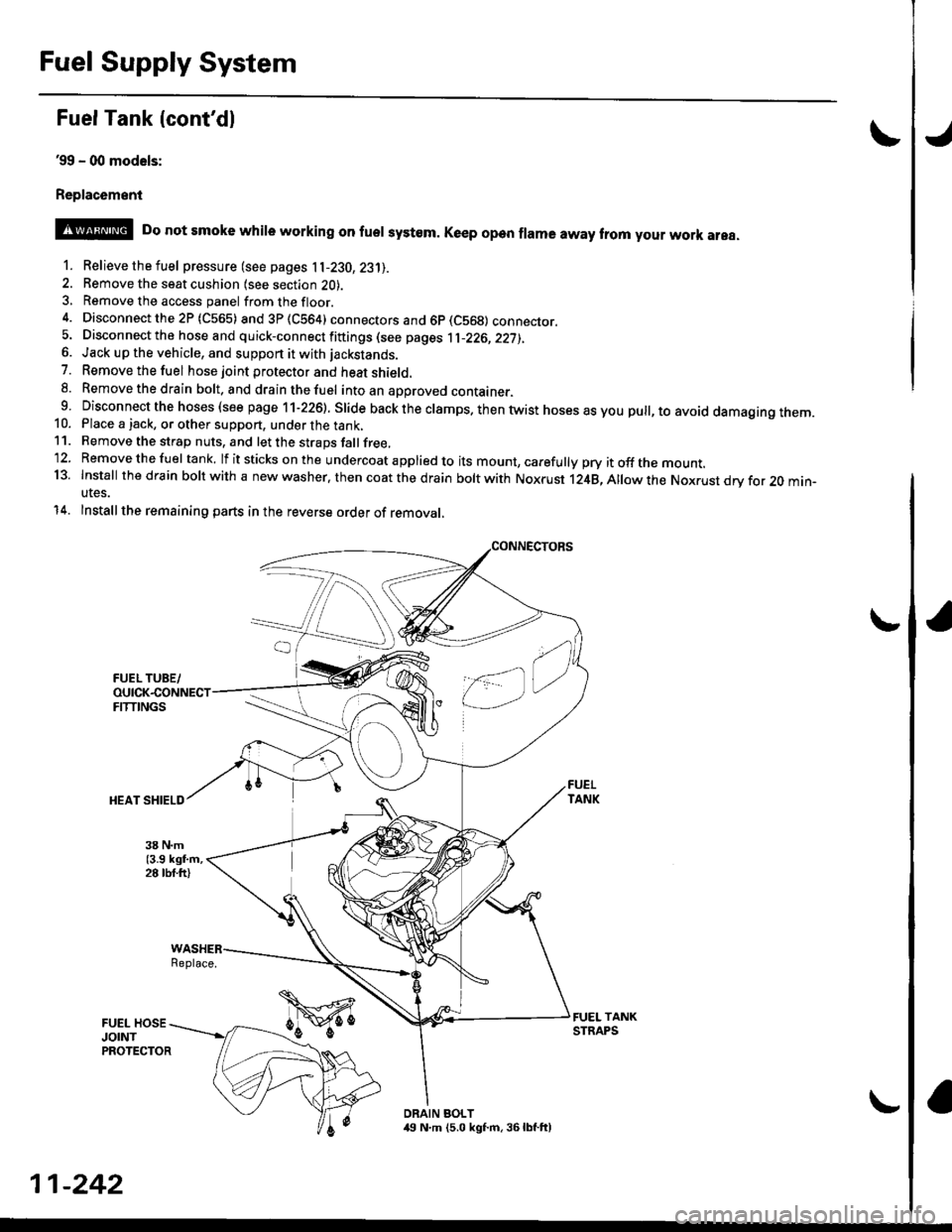

Fuel Supply System

Fuel Tank {cont'dl

39 - (xt models:

Replac6ment

o

@ Do not smoke whire working on fuer system. Ke€p open frama away trom your work area.

1. Relievethefuel pressure (see pages 11-230,23'll.

2. Remove the seat cushion lsee section 2O).3, Remove the access panel fromthefloor.

4. Disconnectthe2P (C565) and3P(CS64) connectors and 6p (C569) connecror.5. Disconnect the hose and quick-connect fiftings (see pages 1l-226,22j),6. Jack up the vehicle, and support it with jackstands.

7. Removethefuel hose joint protector and heat shield.8. Removethedrain bolt. and drainthefuel intoan aporoved container.9 Disconnect the hoses (see page 11-226). Slide back the clamps. then twist hoses as you pull, to avoid damagtng rnem.10. Place a jack, or other support, under the tank,11. Remove the strap nuts, and let the straps fallfree,'12. Removethefuel tank. lf itsticks onthe undercoat applied to its mount, carefully pry itoffthe mount.13. Install thedfain boltwith a new washer. then coat the d rain bolt with Noxrust 124B,Allowthe Nox.ust drv for 20 min-utes.

14. Installthe remaining parts in the reverse order of removal,

Replace.

DRAIN BOLT,19 N.m (5.0 kgf.m, 36lbf.ft)

11-242

Page 583 of 2189

MaintenanceBack-up Light Switch

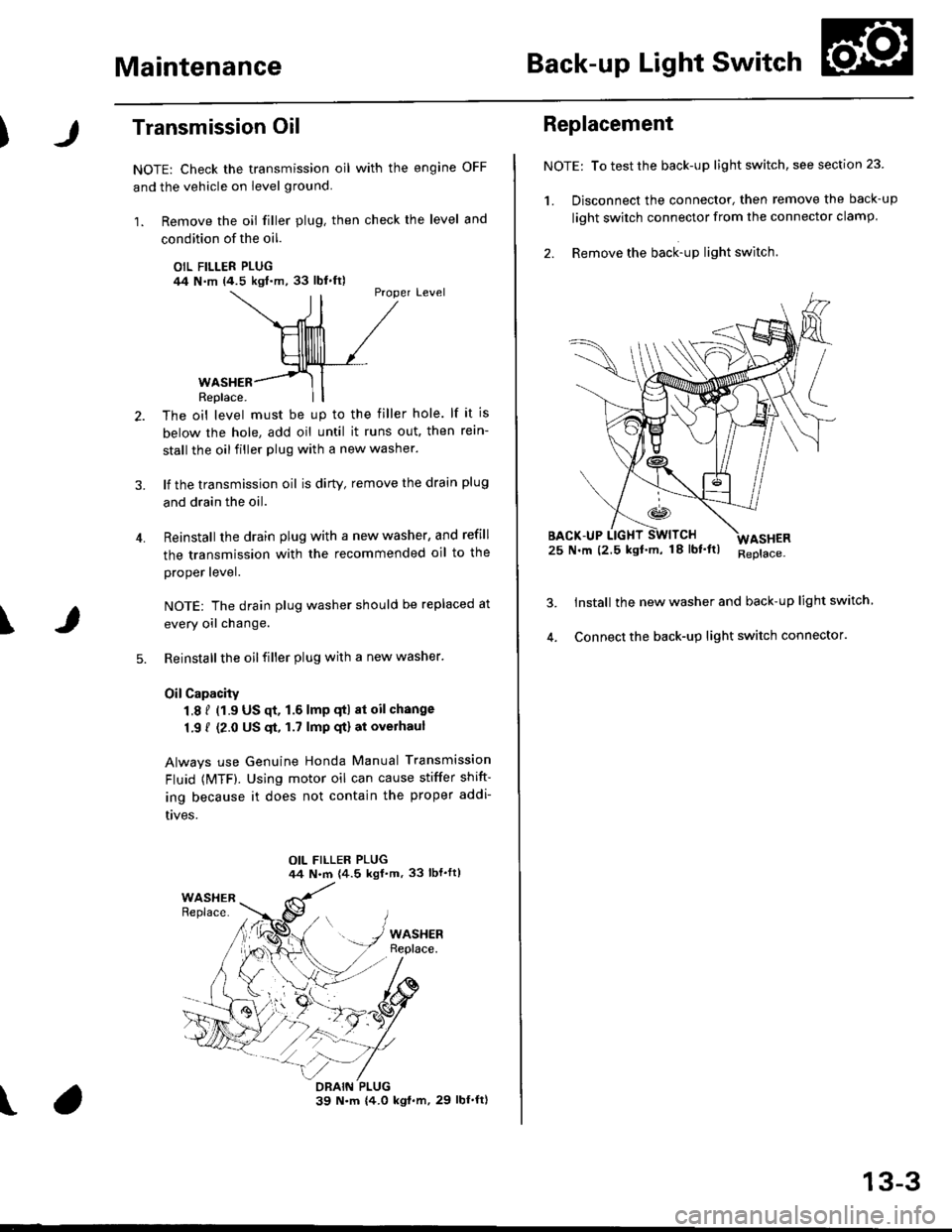

Transmission Oil

NOTE: Check the transmission oil with the engine OFF

and the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

OIL FILLER PLUG/14 N.m (4.5 kgl.m,33 lbl.ft)Proper Level

4.

WASHERReplace.

The oil level must be up to the filler hole. lf it is

below the hole, add oil until it runs out. then rein-

stall the oil filler plug with a new washer.

lf the transmission oil is dirty, remove the drain plug

and drain the oil.

Reinstall the drain plug with a new washer, and refill

the transmission with the recommended oil to the

proper lever.

NOTE: The drain plug washer should be replaced at

every oil change.

Reinstall the oil filler plug with a new washer.

OilCapacity

1.8 f (1.9 US qt. 1.6 lmp qtl at oil change

1.9 { (2.0 US $, 1.7 lmp qt) at overhaul

Always use Genuine Honda Manual Transmission

Fluid {MTF). Using motor oil can cause stiffer shift-

ing because it does not contain the proper addi-

t|ves.

\

\

Replacement

NOTE: To test the back-up light switch, see section 23

1. Disconnect the connector, then remove the back-up

light swirch connector from the connector clamp.

2. Remove the back-up light switch.

25 N.m (2.5 kgf'm, 18lbf'ltl

Install the new washer and back-up light switch

Connect the back-up light switch connector.

ASHER

13-3

Page 585 of 2189

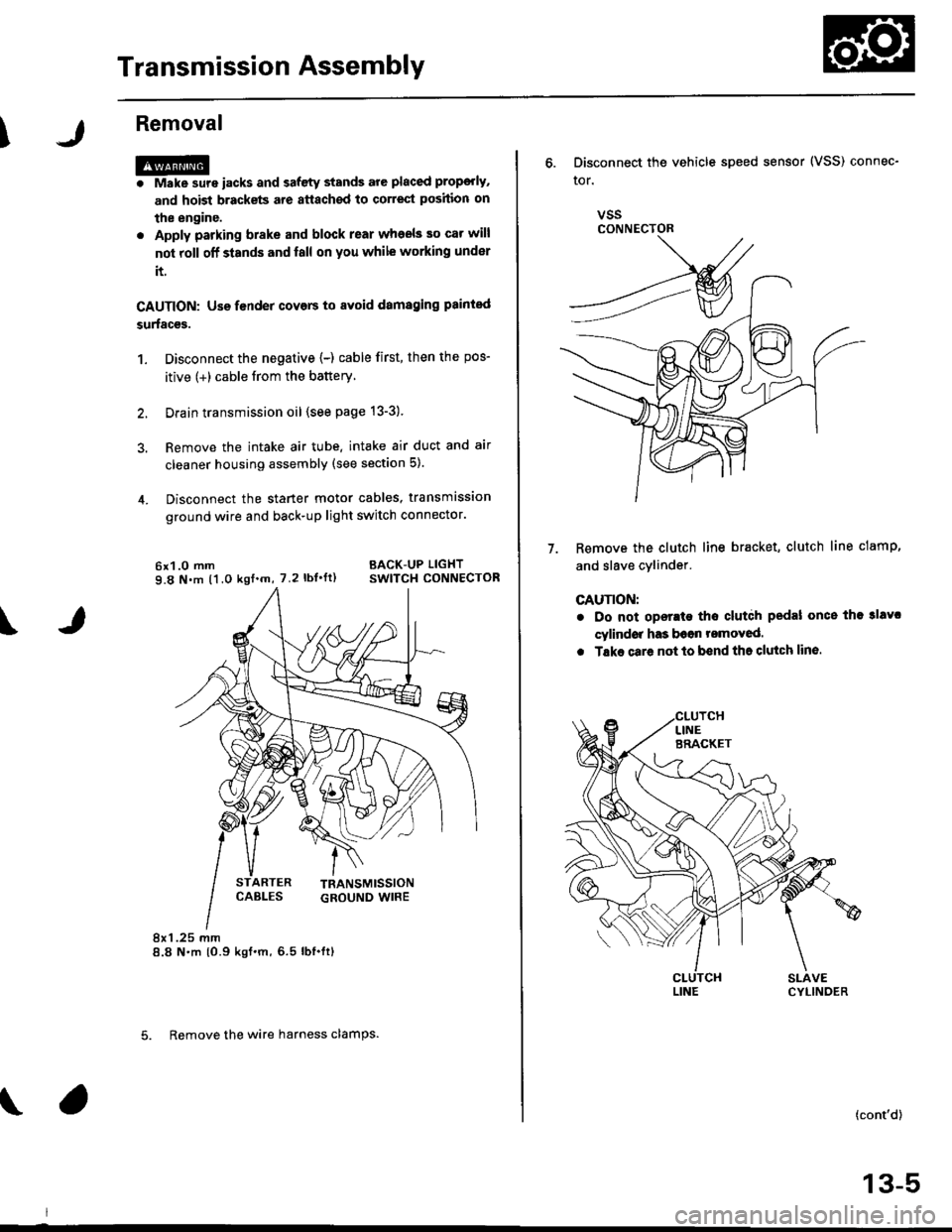

Transmission Assembly

I

Removal

@. Make sure iacks and safety stands are placed prop€dy,

and hoist brackets are atlach€d to correct position on

the enginc.

. Apply parking brake and block rear whosls so car will

nol roll olf stands and lall on you while working under

it.

CAUTION: Use fender covers to svoid damaging painted

surfaces.

1. Disconnect the negative {-) cable first, then the pos-

itive (+) cable from the battery'

Drain transmission oil {see page 13-3).

Remove the intake air tube. intake air duct and air

cleaner housing assembly (see section 5).

Disconnect the starter motor cables, transmission

ground wire and back-up light switch connector.

6x1.0 mm BACK-UP LIGHT

9.8 N.m (1.0 ksf.m, 7.2 lbI.ft) swlTcH CoNNECTOR

8x 1 .25 mm8.8 N.m {0.9 kgt.m,6.5 lbf.ftl

\

ARTER

5. Remove the wire harness clamps.

vssCONNECTOR

6. Disconnect the vehicle speed sensor (VSS) connec-

ror.

Remove the clutch line bracket, clutch line clamp,

and slave cvlinder.

CAUTION:

. Do not opsr.te tho clutdh pedal once the 3lavc

cylindor has b6on romoved.

. Tske care not to bend tha clutch lin6.

7.

(cont'd)

13-5

Page 602 of 2189

Countershaft Assembly

Disassembly

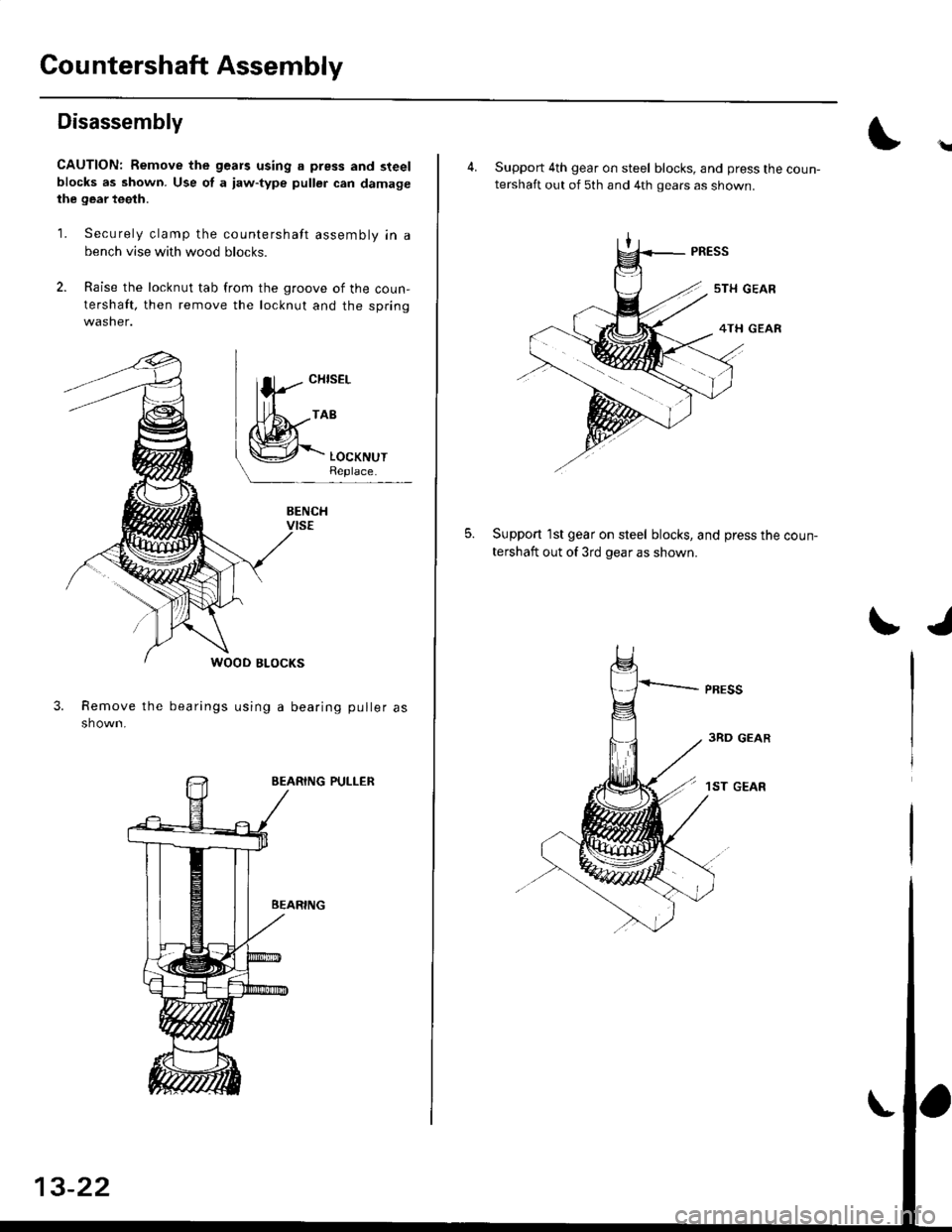

CAUTION: Remove the gears using a press and steelblocks as shown. Use of a iaw-type puller can damagethe gear teeth.

1. Securely clamp the countershaft assembly in a

bench vise with wood blocks.

2. Raise the locknut tab from the groove of the coun-

tershaft, then remove the locknut and the springwasher.

3.Remove the bearings using a bearing puller as

shown.

EEARING PULLER

\

4. Support 4th gear on steel blocks, and press the coun-tershaft out of 5th and 4th gears as shown.

Support 1st gear on steel blocks, and press the coun-

tershaft out of 3rd gear as shown.

5.

I./

3RD GEAR

1ST GEAR

Page 604 of 2189

Countershaft Assembly

Reassembly (cont'd)

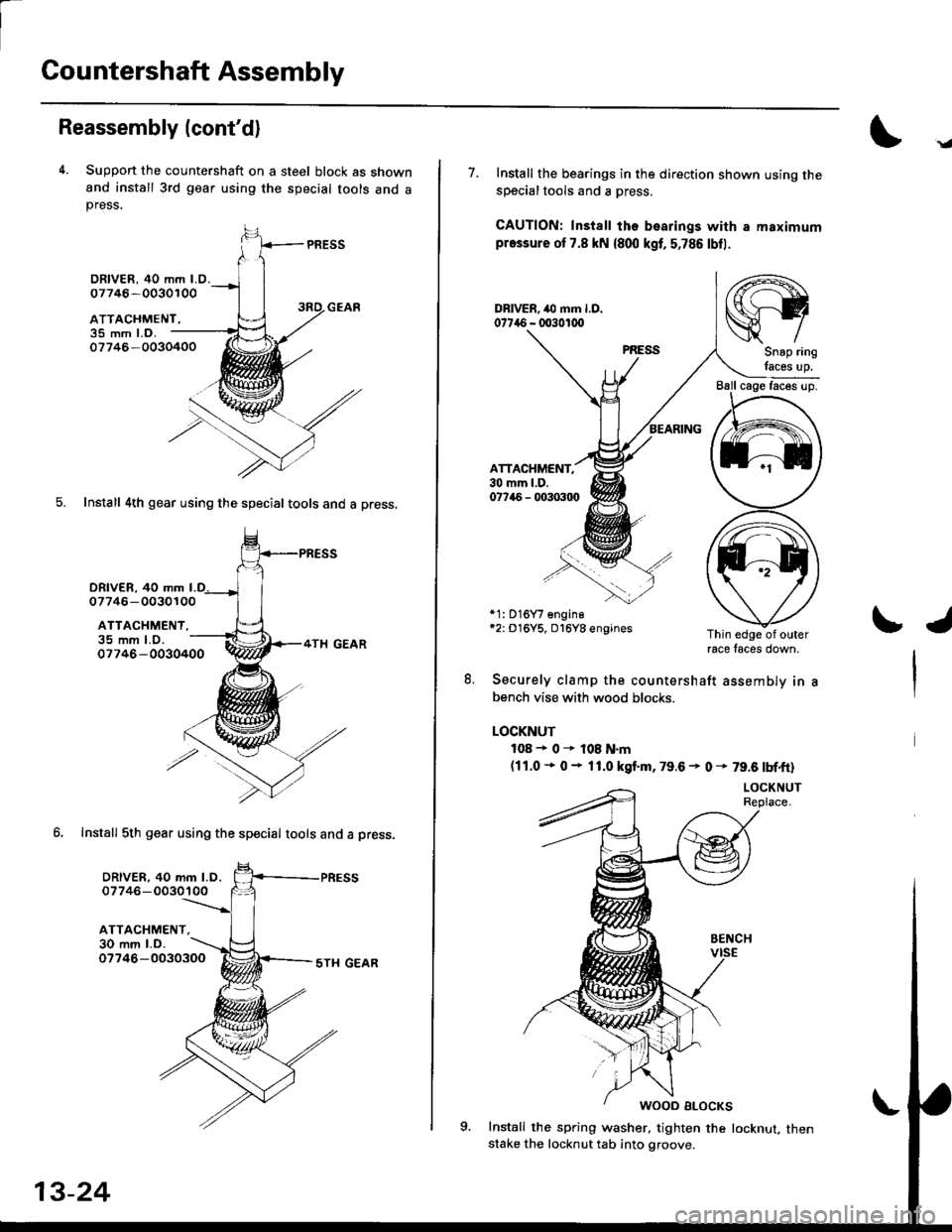

4. Suppon the countershaft on a steel block as shownand install 3rd gear using the special tools and apress.

PRESS

35 mm l.o.07746-0030400

5. Install 4th gear using the special tools and a press.

DRlvER. 40 mm

DRIVER, 40 mm LO.07746 -0030100

ATTACHMENT,

07746- 0030100

ATTACHMENT,

DRIVER, 40 mm l.D.07746-0030100

ATTACHMENT,30 mm l.D.

35 mm LO.07746-0030400

6. Install 5th gear using the special tools and a Dress.

07746-00303005TI{ GEAR

.g

7. Install the bearings in the direction shown using thesDecialtools and a oress.

CAUTION: Install ths bearings with a maximumpressure ot 7.8 kN {800 kgt, 5,786 lbfl.

ATTACHMENT,30 mm l.D.07745 - q'303tl)

*1: 016Y7 engine*2: D16Y5, D16Y8 enginesThin edge of outerrace faces down,

8. Securely clamp the countershaft assemblv in

bench vise with wood blocks.

LOCKNUT

108+0r108N.m(11.0 * 0 - 11.0 kgt m. 79.6 - 0 * 79.6 tbf.ft)

Install the spring washer, tighten the locknut, thenstake the locknut tab into groove.

/rt-\

srySnap ring

lacss up.

\J