engine parts HONDA CIVIC 1998 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 588 of 2189

Transmission Assembly

Removal(cont'd)

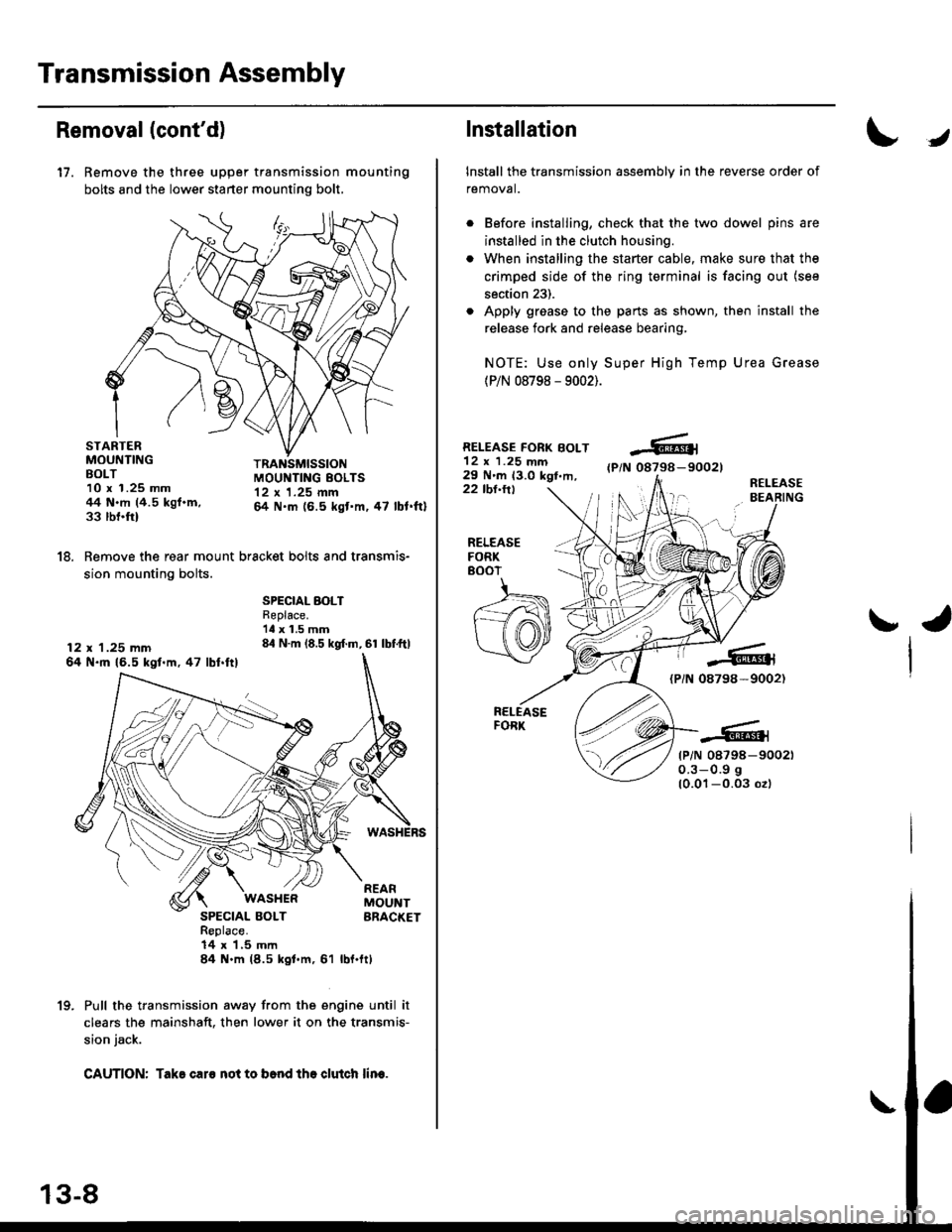

17. Remove the three upper transmission mounting

bolts and the lower starter mounting bolt,

STARTERMOUNTINGBOLT10 x 1.25 mm44 N.m (4.5 kgf.m,33 rbnftl

TRANSMISSIONMOUI{TING EOLTS12 x 1.25 mm& N.m (6.5 kgt'm,47 lbl.ftl

18. Remove the rear mount bracket bolts and transmis-

sion mounting bolts.

12 x 1.25 mm64 N.ft 16.5 kgl.m,47 lbl.ftl

SPECIAL BOLTReplace.'ll x 1.5 mm84 N.m (8.5 kgf.m, 61 lbf.ftl

SPECIAL BOLTReplace.14 x 1,5 mln84 N.m (8.5 kgl.m, 61

WASI{ERREARMOUNTBRACKET

rbl.ftt

Pull the transmission away from the engine until it

clears the mainshaft. then lower it on the transmis-

sion jack.

CAUTION: Take caro not to b6nd tho clutch lin€.

1(|

Installation

Install the transmission assembly in the reverse order of

removal.

Before installing, check that the two dowel pins are

installed in the clutch housing.

When installing the starter cable, make sure that the

crimped side of the ring terminal is facing out (see

section 23).

Apply grease to the parts as shown, then install the

release fork and release bearing,

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

RELEASE FORK BOLT12 x 1.25 mm29 N'm 13.0 kgt,m,(P/N 08798-90021

22 tbl.ttlR€LEASEBEARING

J

RELEASEFORK8()07

ra

{PiN 08798-9002)

tP/N 08798-900210.3-0.9 g

10.01-0.03 ozl

Page 595 of 2189

Mainshaft Assembly

I

lndex

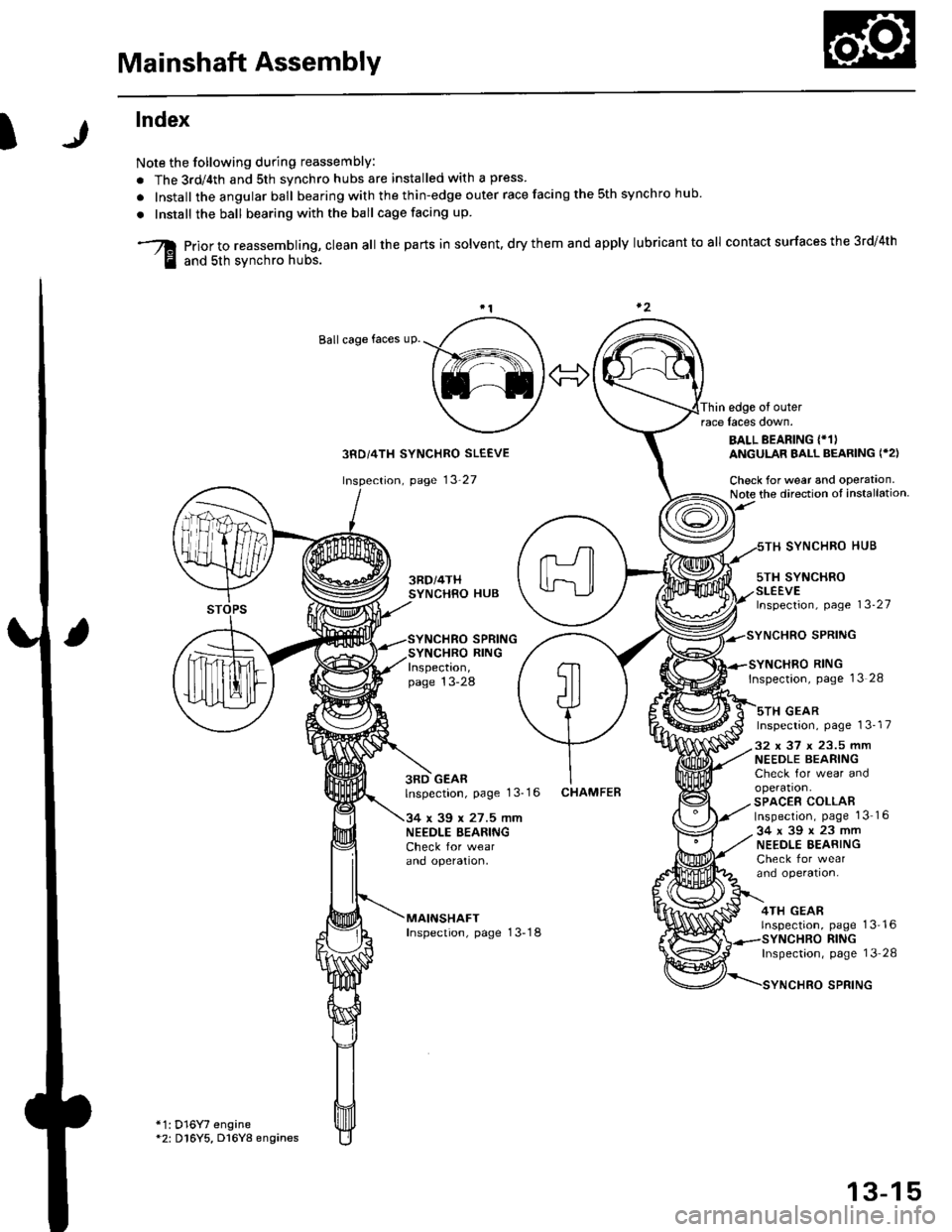

Note the following during reassembly:

. The 3rd/4th and sth svnchro hubs are installed with a press

. Install the angular ball bearing with the thin-edge outer race facing the sth synchro hub

. Install the ball bearing with the ball cage facing up

prior to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces the 3rd/4th

and sth svnchro hubs.

Ballcage faces uP.

Thin edge of outerrace laces down.

3RD/4TH SYNCHRO SLEEVE

page 13'27

SYNCHRO SPRINGSYNCHRO RINGInspection,page 13-28

BALL BEARING {*1)ANGULAR BALL BEARING ('2)

Check for wear and operataon.Note the direction ot installation

5TH SYNCHROSLEEVElnspection, page 13-27

SYNCHRO HUB

SYNCHRO RINGInspection, pase 13 28

sTH GEARInspection, page 13-17

3RD GEARlnspection, page 1 3-1 6

34 x 39 x 27.5 mmNEEDLE BEARINGCheck for wearano opetaflon,

MAINSHAFTInspection, page 13-18

CHAMFEB

32 x 37 x 23.5 mmNEEDLE BEARINGCheck for wear andoperation.SPACER COLLABInspection, page 1316

34x39x23mmNEEDLE EEARINGCheck for wearand operation,

4TH GEARrnspeclron,

*1: D16Y7 engine*2: D16Y5, D16Y8 engines

page 13'16RINGInspectaon, page 13 28

SPRING

13-15

Page 600 of 2189

Countershaft Assembly

Index

I.r

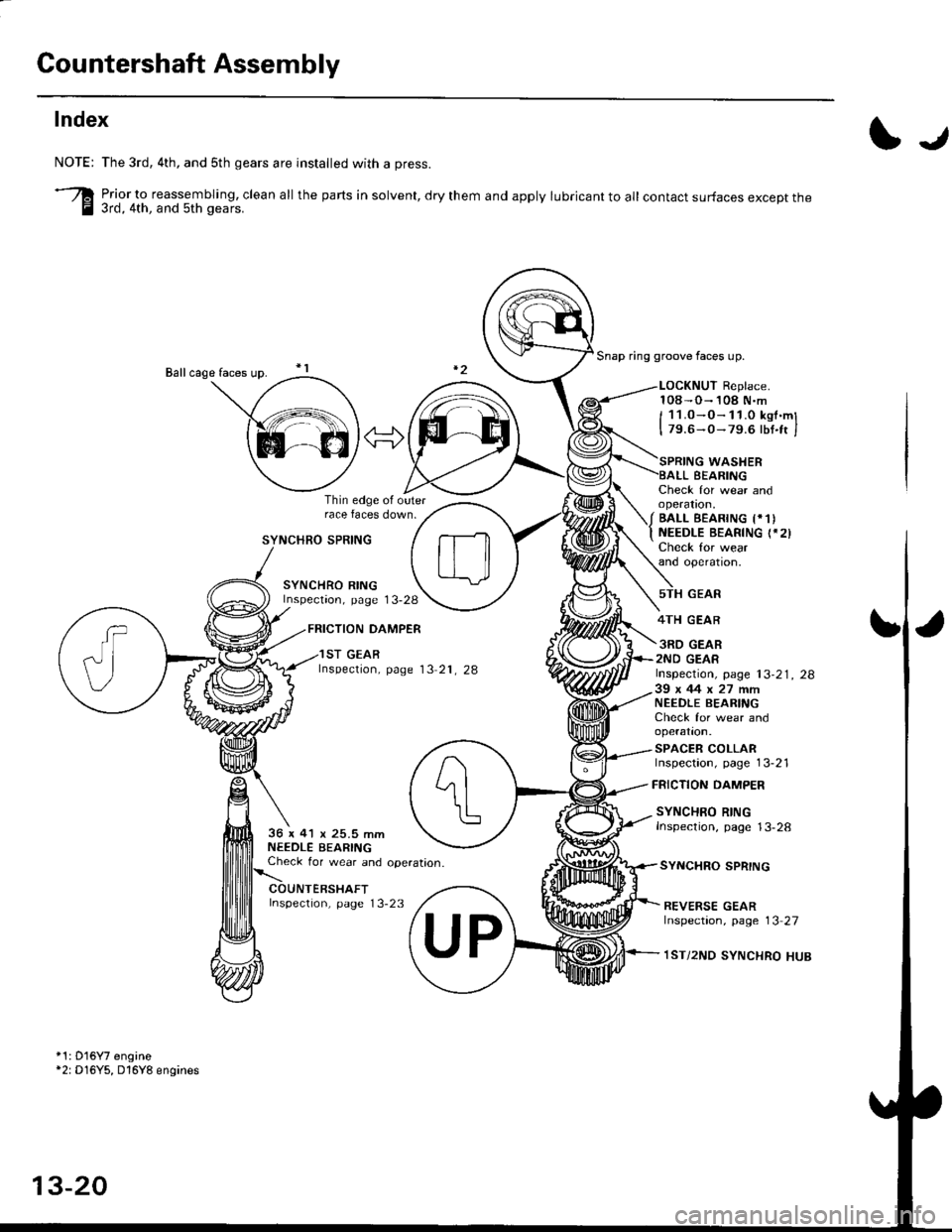

NOTE:

-re

The 3rd, 4th, and sth gears are installed with a press.

Prior_to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces except the3rd, 4th, and 5th gears.

Snap ring groove faces up.

LOCKNUT Replace.108-O- 108 N.m

I 11.0-O-11.0 kst.ml

I 79.6-0- 79.6 lbt.ft I

SYNCHRO SPRING

SYNCHRO RINGInspectaon, page 13-28

FRICTION DAMPER

Thin edge ol outerrace faces down.

Check for wear andoperatron,

/ BALL EEAR|NG t*1)

t NEEDLE BEARTNG (.2)

Check for wearand operatron,

WASHERBEARING

GEAR

4TH GEAR

3RD GEAR2ND GEAR

FRICTION DAMPER

SYNCHRO SPRING

SYNCHRO RINGInspection, page 13-2836 x 41 x 25.5 mmNEEDLE BEARINGCheck for wear and operataon.

Inspection, page 13-23

1ST GEARlnspection, page 13 21, 28lnspection, page 13-21, 2839x44x27m�mNEEDLE BEARIfI'GCheck for wear andoperation.

SPACER COLLARInspection, page 13-21

REVERSE GEARlnspection, page 13 27

1ST/2ND SYNCHRO HUB

*1: D'16Y7 engine*2: D16Y5, D16Y8 engines

13-20

Page 970 of 2189

Start Clutch Control@

T

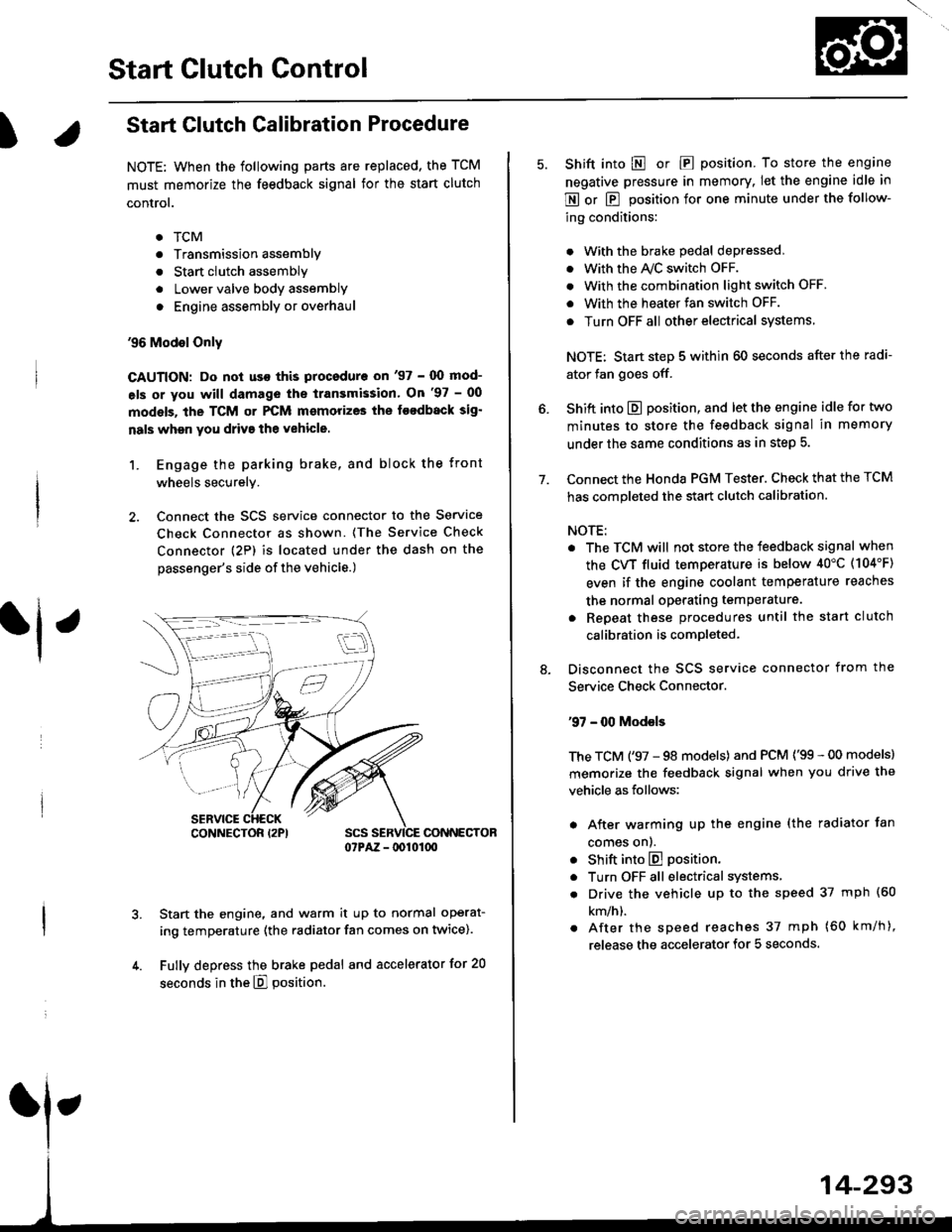

Start Clutch Calibration Procedure

NOTE: When the following parts are replaced, the TCM

must memorize the feedback signal for the start clutch

control.

. TCM

. Transmissionassembly

. Stan clutch assembly

. Lower valve bodv assembly

. Engine assembly or overhaul

'96 Model Only

CAUTION: Do not uso this procsdure on'97 - (X) mod-

els or you will damage the transmission. On '97 - 00

models, the TCM or PCM memorizes ths loodback sig'

nals when you drive the vehicle.

1. Engage the parking brake, and block the front

wheels securely.

2. Connect the SCS service connector to the Service

Check Connector as shown. (The Service Check

connector (2P) is located under the dash on the

passenger's side of the vehicle.)

CONNECTOR07PAZ - lDl01(xt

Start the engine, and warm it up to normal operat-

ing temperature (the radiator fan comes on twice).

Fully depress the brake pedal and accelerator for 20

seconds in the E] position.

rl ,

CONNECTOR I2PI

14-293

7.

Shift into E o|. E position. To store the engine

negative pressure in memory. Iet the engine idle in

E or E position for one minute under the follow-

ing conditions:

. With the brake pedal depressed,

. with the y'\/c switch oFF.

. With the combination light switch OFF.

. With the heater fan switch OFF.

. Turn OFF all other electrical systems

NOTE: Start step 5 within 60 seconds after the radi-

ator fan goes off.

Shift into E position, and let the engine idle for two

minutes to store the feedback signal in memory

under the same conditions as in step 5.

Connect the Honda PGM Tester. Check that the TCM

has completed the start clutch calibration.

NOTE:

. The TCM will not store the feedback signal when

the CVT fluid temperature is below 40"C (104'F)

even if the engine coolant temperature reaches

the normal operating temperature.

. Repeat these procedures until the start clutch

calibration is completed-

Disconnect the SCS service connector from the

Service Check Connector.

'97 - 00 Models

The TCM ('97 - 98 models) and PCM ('99 - 00 models)

memorize the feedback signal when you drive the

vehicle as follows:

. After warming up the engine (the radiator fan

comes onl.

. Shift into E position.

. Turn OFF all electrical systems,

. Drive the vehicle up to the speed 37 mph (60

km/h).

. After the speed reaches 37 mph (60 km/h),

release the accelerator for 5 seconds.

Page 1029 of 2189

![HONDA CIVIC 1998 6.G Owners Manual l.

17.Make sure the transmission is in the E] position.

Fill the transmission with cvT Fluid, and run the

engine for 30 seconds or until approximately 0 95 {

(1.0 US qt.,0.8 lmp qt.) is discharged.

Re HONDA CIVIC 1998 6.G Owners Manual l.

17.Make sure the transmission is in the E] position.

Fill the transmission with cvT Fluid, and run the

engine for 30 seconds or until approximately 0 95 {

(1.0 US qt.,0.8 lmp qt.) is discharged.

Re](/img/13/6068/w960_6068-1028.png)

l.

17.Make sure the transmission is in the E] position.

Fill the transmission with cvT Fluid, and run the

engine for 30 seconds or until approximately 0 95 {

(1.0 US qt.,0.8 lmp qt.) is discharged.

Remove the drain hose, and reconnect the cooler

return hose to the transmission (see page 14-355)

Refill the transmission with CVT Fluid to the proper

level (see page 14-299).

18.

'19.

.l ,

TOOL MAINTENANCE

1. Empty and rinse after each use. Fill the can with water

and pressurize the can. Flush the discharge line to

ensure that the unit is clean.

2, lf discharge liquid does not foam, the orifice may be

blocked.

3. To clean, disconnect the plumbing from the tank at

the large couPling nut.

FILTER

\

\- 0--D

i

I

O.RING

Remove the in-line tilter from the discharge side and

clean if necessary'

The fluid orifice is located behind the filter. Clean it

with the pick stored in the bottom of the tank han-

dle. or blow it clean with air. Securely reassemble

all parts.

COUPLINGNUT

II

-@q

\ORIFICE

FILLER CAP

14-353

Page 1043 of 2189

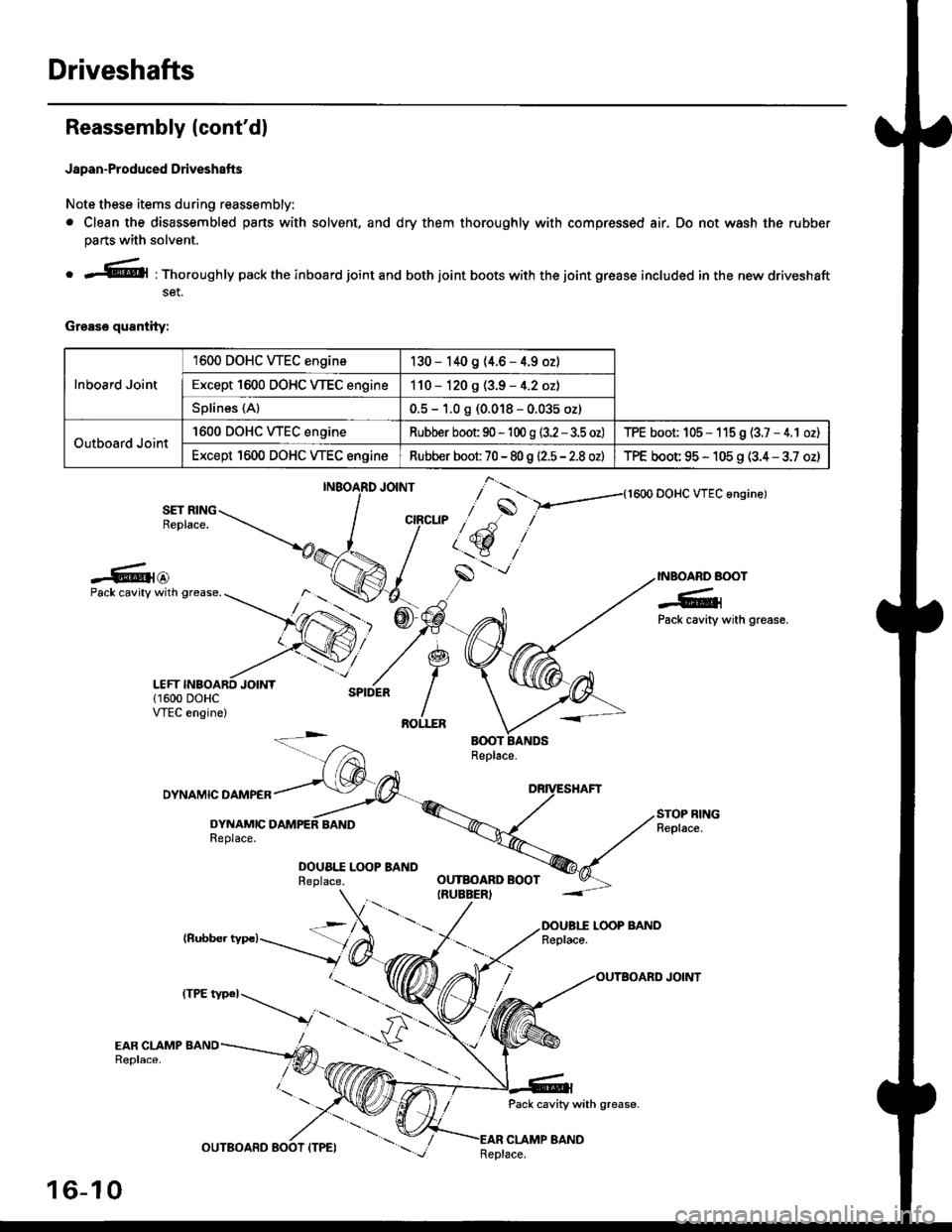

Driveshafts

Reassembly (cont'dl

Japan-Produced Driveshafts

Note these items during reassembly.

. Clean the disassembled pans with solvent, and dry them thoroughly with compressed air. Do not wash the rubber

parts with solvent.

o r@l : Thoroughly pack the inboard joint and both joint boots with the joint grease included in the new driveshaft

set.

Grease quantity:

Inboard Joint

1600 DOHC WEC engine130 - 140 9 (4.6 - 4.9 oz)

Except 1600 DOHC VTEC engine110 - 120 g (3.9 - 4.2 oz)

Splines (Al0.5 - 1.0 g (0.018 - 0.035 oz)

Outboard Joint

'1600 DOHC WEC engineRubber boot 90 - 'l 00 g (3.2 - 3.5 oz)TPE boot; 105 - 115 9 (3.7 - 4.1 oz)

Except 1600 DOHC VTEC engineRubber boot 70 - 80 g |'2.5 - 2.8 ozlTPE boot 95 - 105 g (3.4 - 3.7 oz)

{1600 DOHC VTEC angine)

SET RINGReplace.

-6{@INBOARD BOOT

-6;Pack cavity with grease.

Pack cavity with grease.

DYNAMIC DAMPER

DYNAMICReplace.

DOUA|.I Lq)P BANDReplace.

(Rubber typc)LOOP BANDReplace.

Pack cavity with grease-

CLAMP BAND

],*"u, ,"^S

/ t'.t$ ,''

,/s

-'-

OUTBOARD BOOTIRUEBER)

16-10

tttt t*' -----_.r...-

._

Replace.

Page 1081 of 2189

/

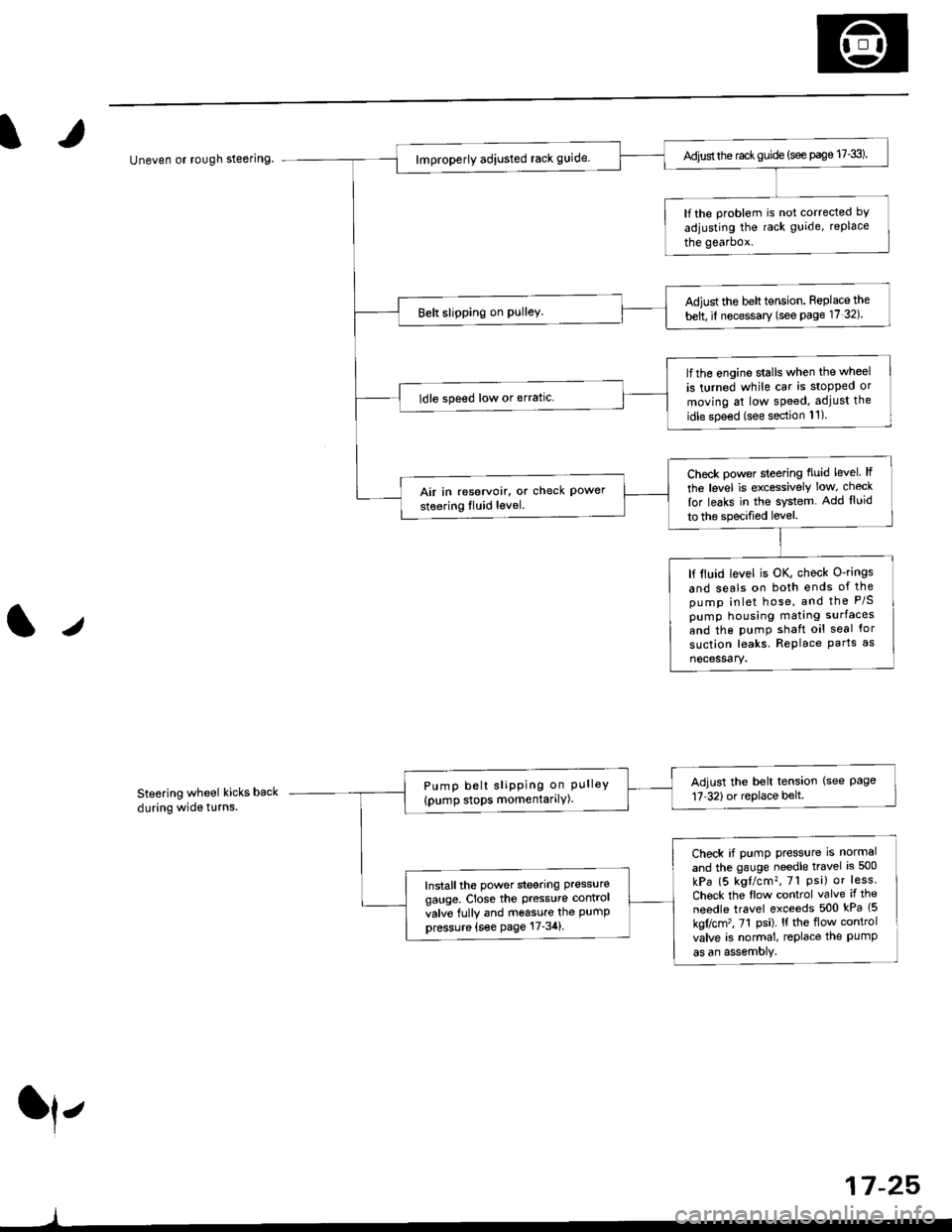

Uneven or rough steering

Steering wheel kicks back

during wide t!rns.

ll,

)

Adjust the rac* guide (see page 17-3).

lf the problem is not corrected bY

adjusting the rack guide, replace

the gearbox.

Adiust the belt tension. Feplace the

belt, il necessary (see Page 17 32).

lfthe engine stalls when the wheel

is turned while car is stopped or

moving at low speed, adjust the

idle spe€d (see section 11)

ldle speed low or erratic.

Check power sleering fluid level lf

the level is excessively low, check

lor leaks in the system. Add lluid

to the specified level.

Air in reservoir, or check Powersteering Iluid level.

lf ltuid level is OK, check O-rings

and seals on both ends of thepump inlet hose, and the P/Spump housing mating surfaces

and the pumP shaft oil seal for

suction leaks. RePlace Parts as

nocessary.

Adjust the belt tension (see Page17 32)or replace belt.Pump belt sliPPing on PLrlleY(pump stops momentarilY)

Check if pump press{rre is normal

and the gauge needle travel is 500

kPa (5 kgl/cm?, 7l Psi) or less.

Chock the flow control valve if the

needle travel exceeds 500 kPa (5

kgflcm'�, 71 Psi). l{ the flow control

valve is normal, replace the PumPas an assemoly.

Install the power steering pressure

gauge, Close the Pressure contrcl

valve fully and m6ssure the PumPpressure {s€e page 17-34}.

17 -25,

Page 1089 of 2189

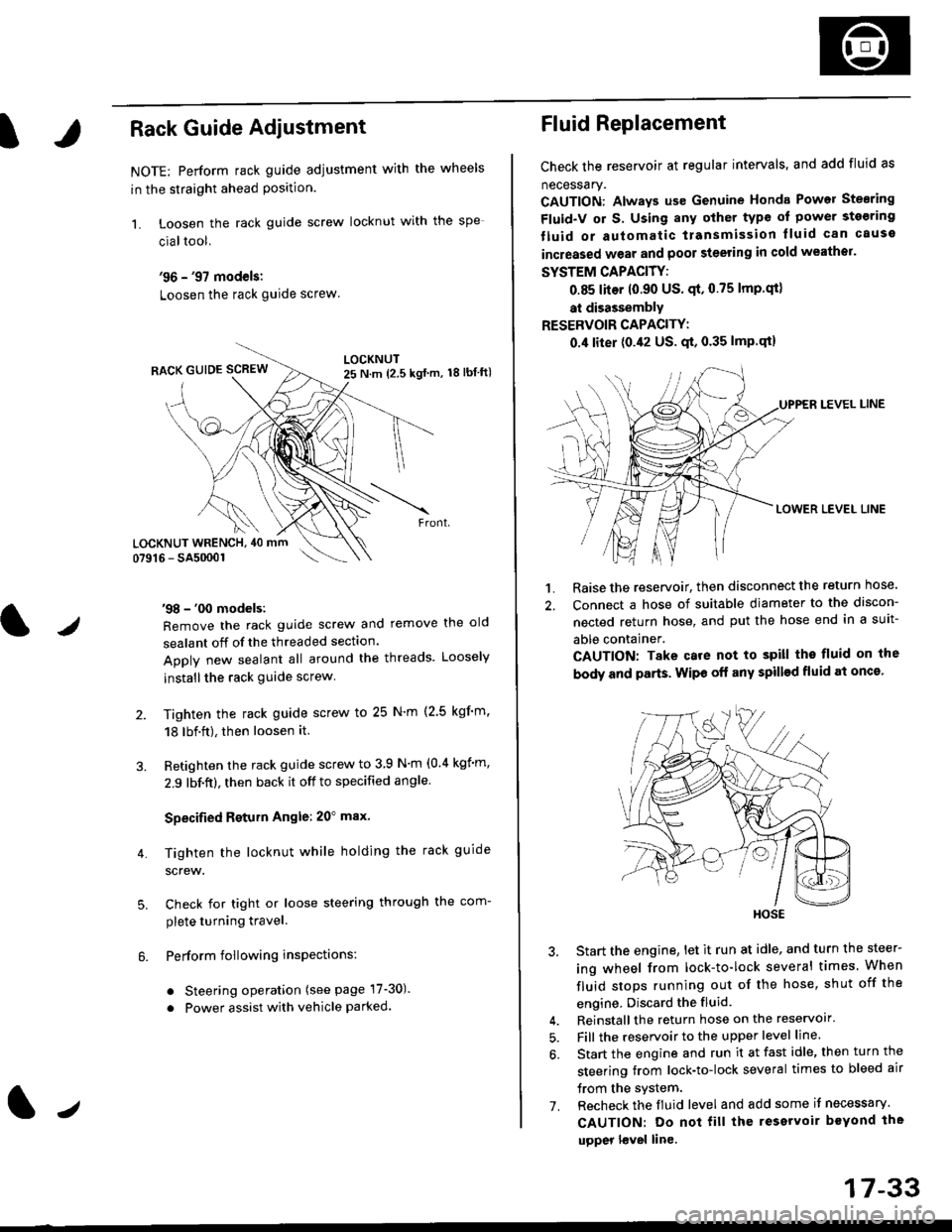

IRack Guide Adjustment

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead Position.

1. Loosen the rack guide screw locknut with the

cialtool.

'96 - '97 models:

Loosen the rack guide screw

'98 - '00 models:

Remove the rack guide screw and remove the old

sealant off of the threaded section.

Apply new sealant all around the threads. Loosely

installthe rack guide screw

Tighten the rack guide screw to 25 N'm (2.5 kgf'm.

18 lbf.ft), then loosen it.

Retighten the rack guide screw to 3 9 N'm (0.4 kgim,

2.9 lbf.ft), then back it off to specified angle.

Specified Return Angle: 20" max.

Tighten the locknut while holding the rack guide

screw.

Check for tight or loose steering through the com-

plete turning travel.

Perform following insPections:

. Steering operation (see page 17-30).

. Power assist with vehicle parked.

4.

LOCKNUT WRENCH, 40 mm

lr

17-33

Fluid Replacement

Check the reservoir at regular intervals, and add fluid as

necessary.

CAUTION: Always us€ Genuine Honda Power Stearing

Fluid-V or S. Using any other type of power sto€ring

tluid or automatic transmission lluid can cause

increased wear and poor steering in cold weathor.

SYSTEM CAPACITY:

0.85 liter 10.90 US' qt,0.75 lmp'qt)

at disassembly

RESERVOIR CAPACITY:

0.4 liter (0.42 US. qt, 0.35 lmP.qt)

LEVEL LINE

LOWER LEVEL LINE

1. Raise the reservoir, then disconnect the return nose.

2. Connect a hose of suitable diameter to the discon-

nected return hose, and put the hose end in a suit-

able container.

CAUTION: Take care not to spill tho fluid on the

body and parts. Wipe off any spill€d fluid at oncs'

3. Start the engine, let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times When

fluid stops running out of the hose, shut off the

engine, Discard the fluid.

4. Reinstall the return hose on the reservoir'

5. Fill the reservoir to the upper level line.

6. Start the engine and run it at fast idle, then turn the

steering trom lock-to-lock several times to bleed air

trom the system.

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not fill the reservoir beYond the

upper l€vel line.

HOSE

Page 1090 of 2189

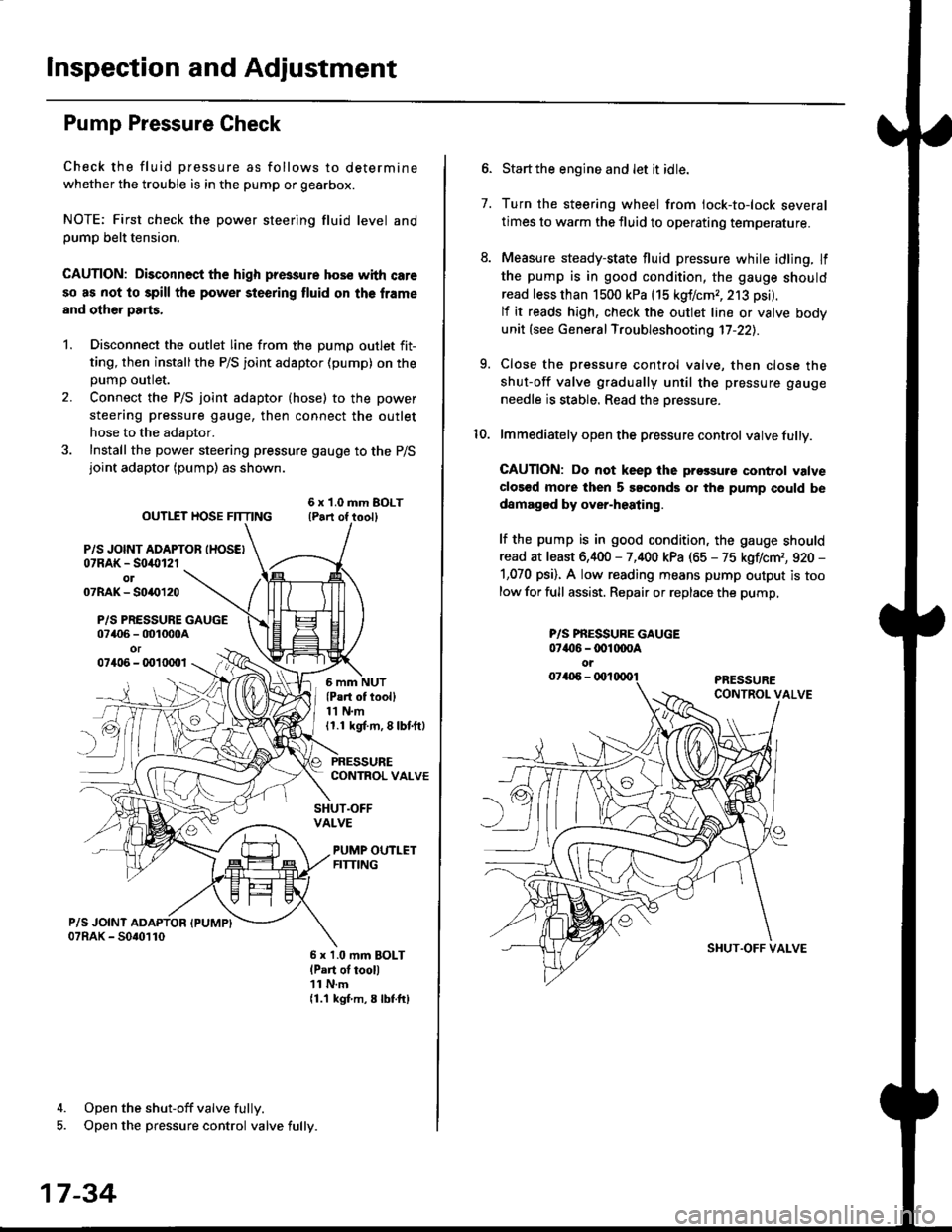

lnspection and Adjustment

Pump Pressure Check

Check the fluid pressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE: First check the power steering fluid level andpump belt tension.

CAUTION: Disconnect the high pr$sure hos€ with care

so as not lo spill the power sieering tluid on tha frame

and other parts.

1. Disconnect the outlet line from the Dumo outlet fit-

ting, then installthe P/S joint adaptor (pump) on the

Dumo outlet.

2. Connect the P/S joint adaptor (hose) to the power

steering pressure gauge, then connect the outlet

hose to the adaptor.

3. Install the power steering pressure gauge to the P/Sjoint adaptor (pump) as shown.

ourlEr HosE FnrNo ,t"ll lrilu"ott

P/S JOINT ADAPTOB IHOSEI07RAK - S0i10l2rol07RAK- 50{{)120

P/S PRESSURE GAUGE07406 - 001000Aor07406 - 0010001

4. Open the shut-off valve fully.

5. Open the pressure control valve fully.

17-34

(Pa.t of tooll11 N.m11.1 kgt m, 8 lbf.ftl

PRESSURECONTROL VALVE

SHUT.OFFVALVE

PUMP OUTLETFITTING

6 x 1.0 mm BOLTlPart of tool)11 N.m11.1 kgf m, 8 lbtftl

7.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling. If

the pump is in good condition, the gauge should

read less than 1500 kPa (15 kgf/cmr, 213 psi).

lf it reads high, check the outlet line or valve body

unit (see General Troubleshooting 17-22).

Close the pressure control valve, then close the

shut-off valve gradually until the pressure gauge

needle is stable. Read the oressure.

lmmediately open the pressure control valve fully.

GAUTION: Do not keep lhe prossure control valve

clos€d more then 5 soconds or the pump could be

damagod by over-heating.

lf the pump is in good condition, the gauge should

read at least 6,400 - 7,400 kPa (65 - 75 kgflcm,, 920 -

1,070 psi). A low reading means pump output is too

low for full assist. Repair or replace the pump,

9.

P/S PBESSURE GAUGE07{16 -@1@OA

oi

SI{UT.OFF VALVE

Page 1096 of 2189

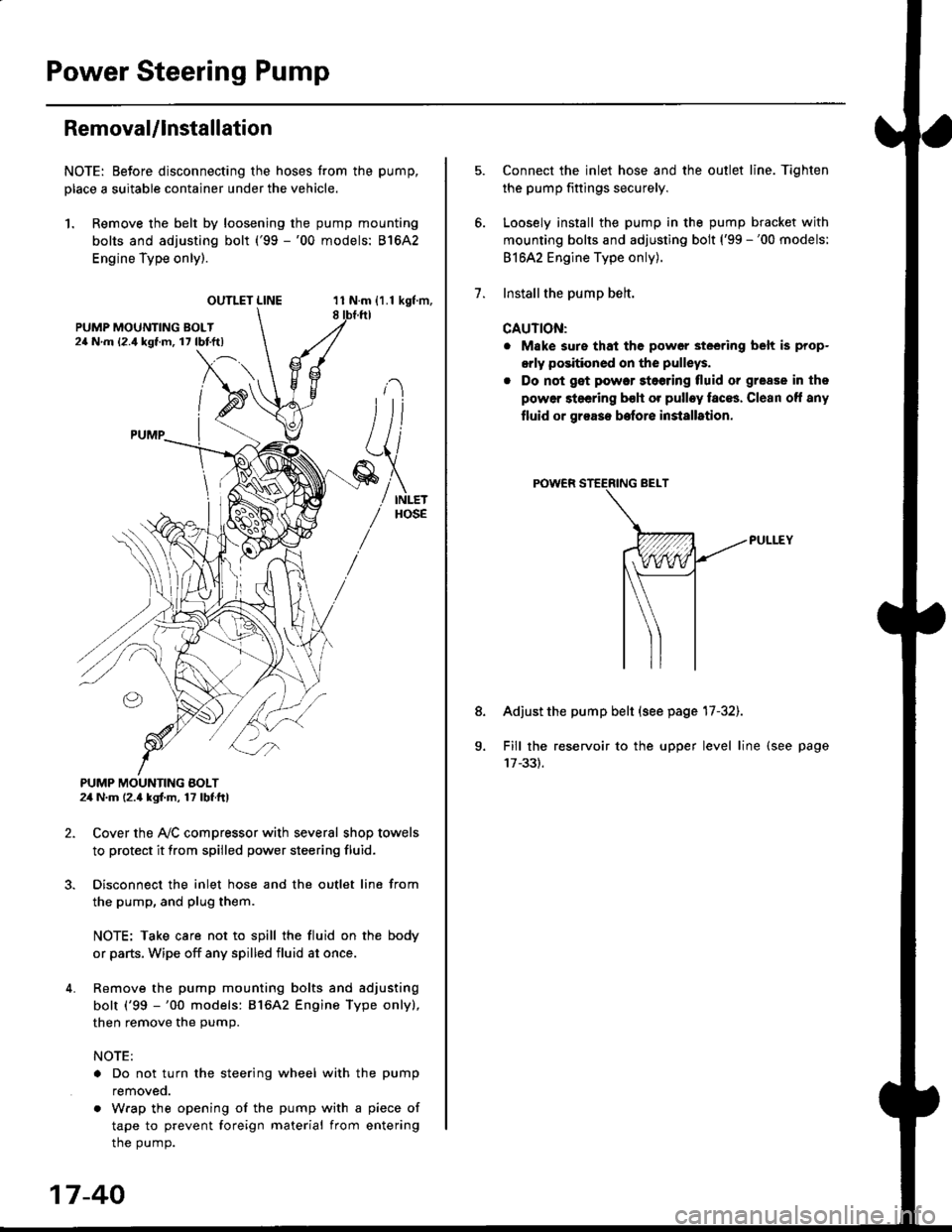

Power Steering Pump

RemovaUlnstallation

NOTE: Eefore disconnecting the hoses from the pump,

Dlace a suitable container under the vehicle.

1. Remove the belt by loosening the pump mounting

bolts and adjusting bolt ('99 -'00 models: 81642

Engine Type only).

OUTLET LINE11 N.m {1.1 kgf'm,8

L

PUMP MOUNTING BOLT24 N.m (2.4 kgl.m, 17 lbf ft)

2. Cover the Ay'C compressor with several shop towels

to protect it from spilled power steering fluid.

3. Disconnect the inlet hose and the outlet line from

the pump, and plug them.

NOTE: Take care not to spill the fluid on the body

or parts, Wipe off any spilled fluid at once.

4. Remove the pump mounting bolts and adjusting

bolt ('99 -'00 models: 816A2 Engine Type only),

then remove the pump.

NOTE:

. Do not turn the steering wheel with the pump

removeo.

. Wrap the opening of the pump with a piece of

tape to prevent foreign material from entering

the pump.

17-40

1.

8.

Connect the inlet hose and the outlet line. Tiqhten

the pump fittings securely.

Loosely install the pump in the pump bracket with

mounting bolts and adjusting bolt ('99 -'00 models:

81642 Engine Type only).

Installthe pump belt.

CAUTION:

. Make sure that the power steering belt is prop-

orly positioned on the pulleys.

. Do not get power stoering tluid or grease in the

power steering bsh or pulley faces. Clean off any

fluid or grease before installrtion.

Adjust the pump belt (see page 17-32).

Fill the reservoir to the upper level line (see page