front brake HONDA CIVIC 1998 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1134 of 2189

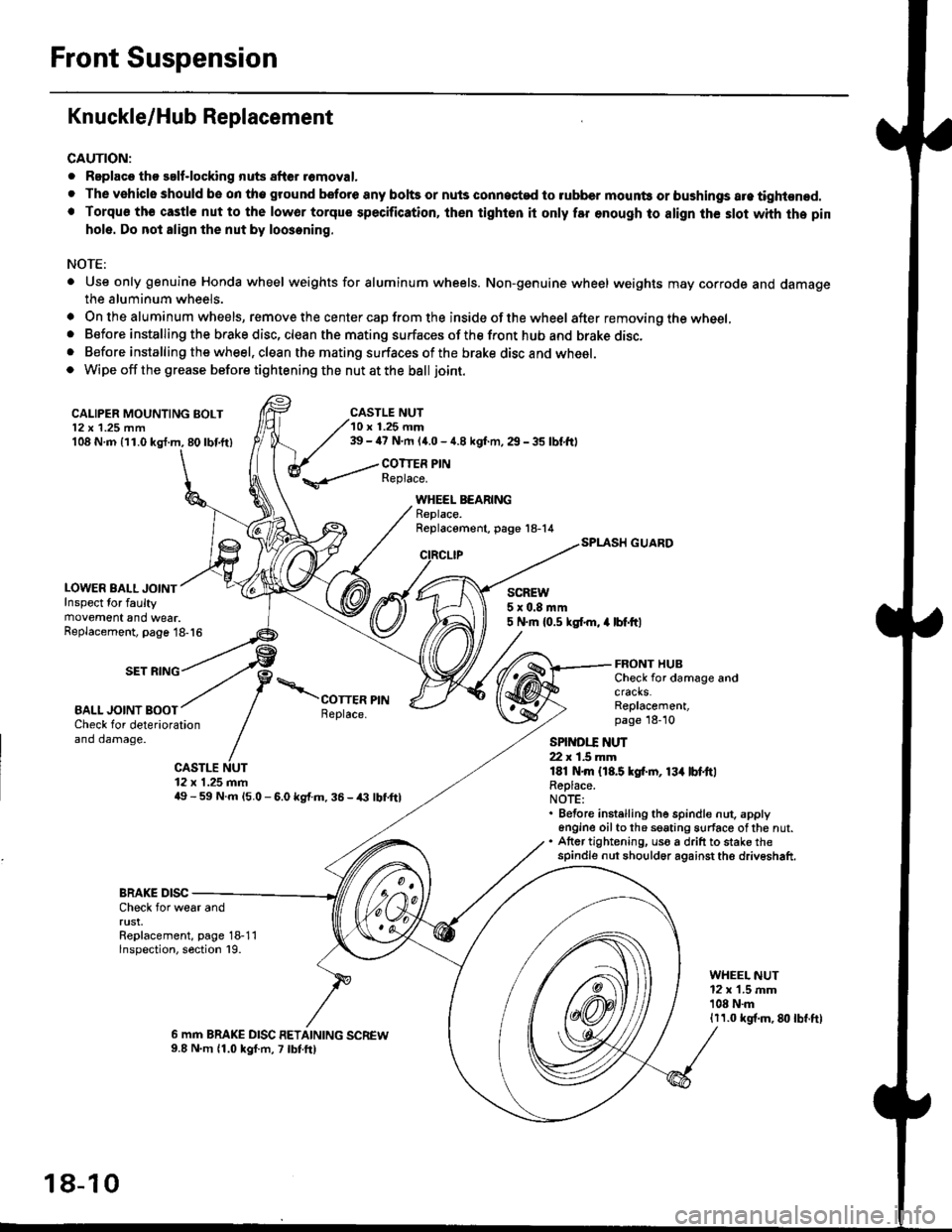

Front Suspension

Knuckle/Hub Replacement

CAUTION:

. Replaco tho salf-locking nuts after romoval.

. The vehiclo should be on tho ground bsfore any bohs or nuls connected to rubber mounb or bushings are tightened.. Torqu€ th€ castle nut to the lowor torque specification, ihen tighton it only far enough to align th€ slot whh the pin

hole. Do not align the nut by loosening.

NOTE:

. Use only genuine Honda wheel weights for aluminum wheels. Non-genuine wheel weights may corrode and damagethe aluminum wheels.

. On the aluminum wheels, remove the center cap from the inside of the wheel after removing the wheel,. Before installing the brake disc, clean the mating surfaces of the front hub and brake disc,. Before installing the wheel, clean the mating surfaces of the brake disc and wheel.o Wipe off the grease before tightening the nut at the ball joint.

CALIPER MOUNTING BOLT12 x 1.25 mm108 N.m {11.0 kgl.m, 80lbf.ft)

LOWER BALL JOINTInspect for faultymovement and wear.

CASTLE NUT10 r 1.25 mm39 - ia7 N.m (4.0 - 4.8 kgf.m, 29 - 35 lbf,ftl

COTTER PINReplace.

WHEEL BEARINGReplace.Replacement, page 18-14

CIRCLIP

SCREW5x0.8mm5 N.m {0.5 ksl.m, 4 lbf.ftlReplacement, page 18-16

SET RING

BALL JOINT BOOT

FRONT HUBCheck for damage andcracks.Replacement,page 18-10Check for deteriorationand damage.

CASTLE NUT12 x 1.25 mm49 - 59 N.m l5.O - 6.0 kg{.m. 36 - /(} lbf,ftl

SPINDI.T ]{UT22 r 1.5 mmlEl N.m {18.5 kgf.rn, 13{ lbl.ttlReplace.NOTE:. Before instelling the spindle nut. apply6n9ine oilto th6 seating surface ofthe nut.. Atter tightening, uso a drift to stake thespindle nut should6r against the driveshaft.

BRAKE DISCCheck for wear andrust.Replacement, page 18-11lnspection, section 19.

WHEEL NUT12 x 1.5 mm'108 N.m1r1.0 kgf.m, 8lt lbf.ft)

6 mm BRAKE DISC RETAINING SCREW9.8 N.m 11.0 kgf.m, 7 lbtft)

18-10

Page 1135 of 2189

)

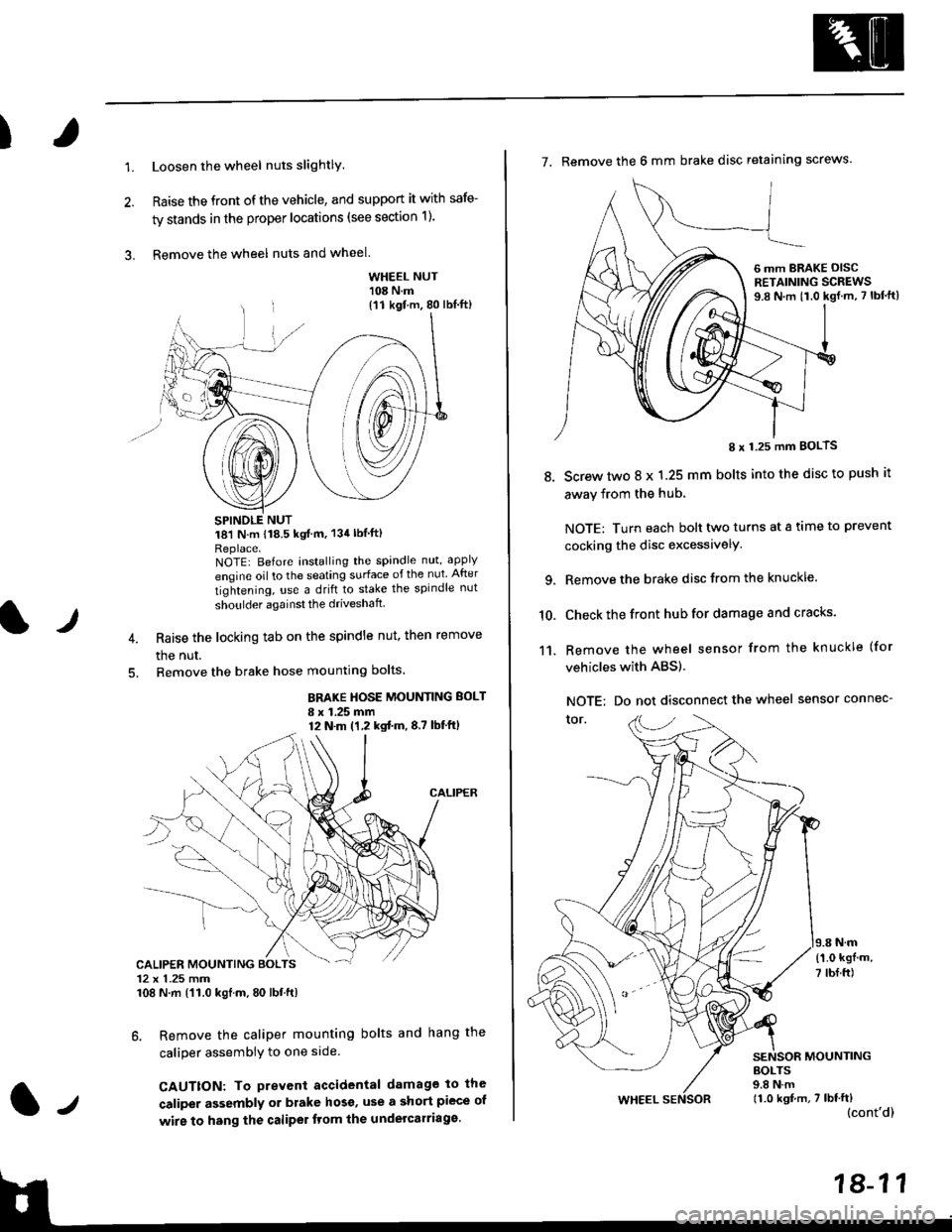

1.Loosen the wheel nuts slightlY.

Raise the front of the vehicle, and support it with safe-

ty stands in the proper locations (see section 1).

Remove the wheel nuts and wheel.3.

l)

WHEEL NUT'108 N.m

18'l N.m 118.5 kgf m, 134lblfti

Replace.NOTEI Before installing the spandle nut, apply

engine oil to the seating surface of the nut After

tightening, use a drift to stake the spindle nut

shoulder againsl the driveshaft

Raise the locking tab on the spindle nut, then remove

the nut.

Remove the brake hose mounting bolts.

BRAKE HOSE MOUNTING BOLT

I x 1.25 mm12 N.m (1,2 kgtm,8,7 lbf'ftl

6. Remove the caliper mounting bolts and hang the

caliper assembiy to one side

CAUTTON: To prevent accidental damage to the

caliper assembly or brake hoso' use a short piece of

wire to hang the caliPer tlom lhe undelcarriage.

{11 kgf m, 80 lbl.ft)

CALIPER MOUNTING BOLTS12 x 1.25 mm108 N.m {'11.0 kgtm, 80 lbt.ft)

7. Remove the 6 mm brake disc retaining screws.

8.

I x 1.25 mm BOLTS

Screw two 8 x 1.25 mm bolts into the disc to push it

away from the hub,

NOTE: Turn each bolt two turns at a tame to prevent

cocking the disc excessivelY.

Remove the brake disc from the knuckle.

Check the front hub for damage and cracks.

Remove the wheel sensor from the knuckle (for

vehicles with ABS).

NOTE: Do not disconnect the wheel sensor connec-

tor.

N.m

6 mm BRAKE OISCRETAINING SCREWS9.8 N.m t1.0 kgf.m, 7 lbf'ft)

{'1.0 kgf m,

7 tbf.ft)

10.

11.

MOUNTING

WHEEL

BOLTS9.8 N.m11.0 kgf,m, 7 lbf'ft)(cont'd)

Page 1139 of 2189

I

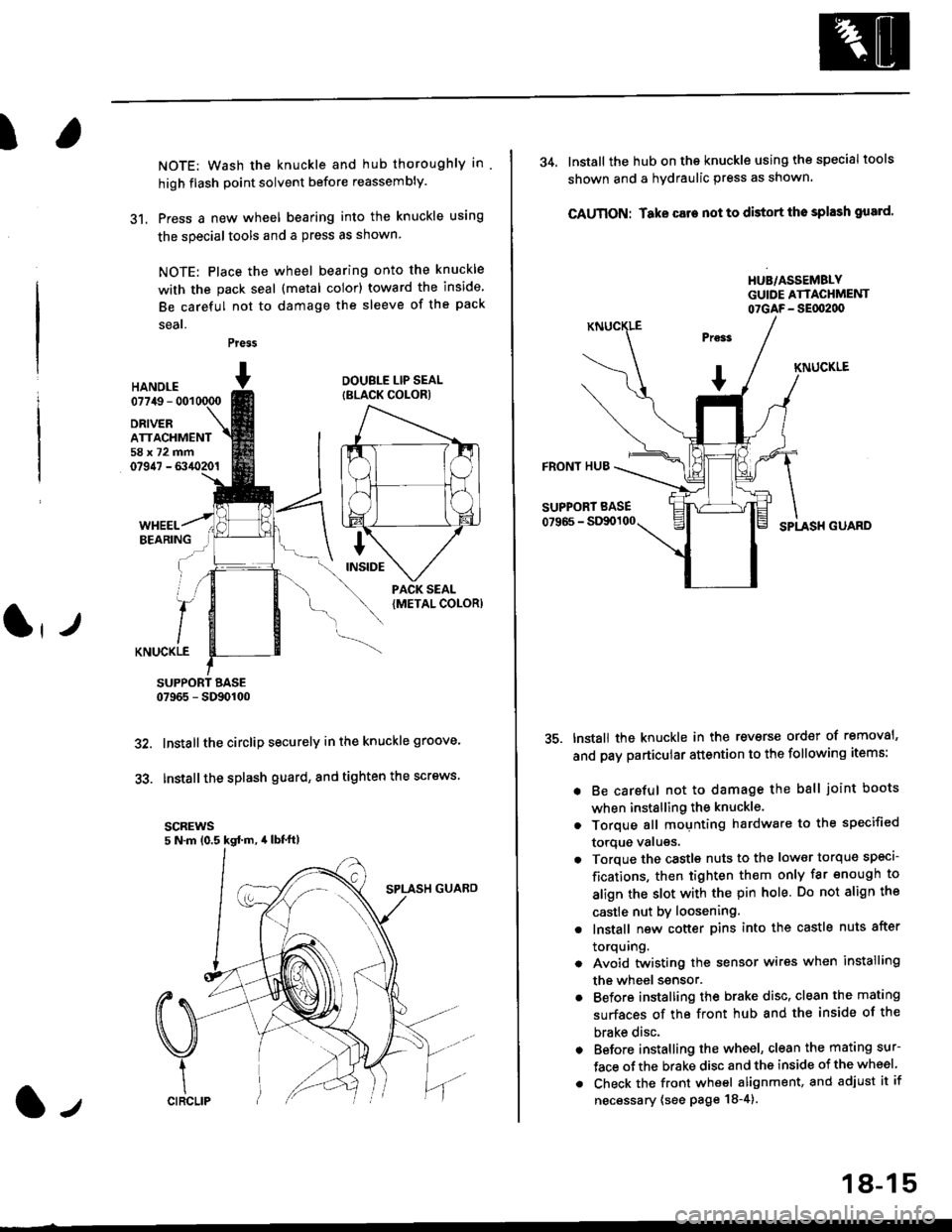

NOTE: Wash the knuckle and hub thoroughly in

high flash point solvent before reassembly.

31. Press a new wheel bearing into the knuckle using

the specialtools and a press as shown

NOTE: Place the wheel bearing onto the knuckle

with the pack seal (metal color) toward the inside

Be careful not to damage the sleeve of the pack

seal.

Press

HANOI.E07749 - 001

DRIVERATTACHMENT58x72mm07947 - 6340201

DOUBLE LIP SEAL

{BLACK COLOR)

KNUCKLE

SUPPORT BASE07965 - SD90100

Installthe circlip securely in the knuckle groove'

Installthe splash guard, and tighten the screws.

scREws5 N.m (0.5 kgd m, 4lbt'ft)

32.

33.

l-,

18-15

34. lnstall the hub on the knuckle using the specialtools

shown and a hydraulic press as shown.

CAUTION: Take care not to distort tho splash gusrd'

HUB/ASSEMBLYGUIDE ATTACHMENT07GAF- SEflt2d)

KNUCKLE

FRONT HUB

SUPPORT BASE

07966 - StXx)100SPLASH GUARD

tnstall the knuckle in the reverse order of removal'

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle.

. Torque all mounting hardware to the specified

torque valugs.

. Torque the castls nuts to the low€r torque specl-

fications, then tighten them only far enough to

align the slot with the pin hole. Do not align the

castle nut by loosening.

. lnstall new cotter pins into the castle nuts after

torquing.

. Avoid twistin0 the sensor wires when installing

the wheel ssnsor.

. Before installing the brake disc, clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the wheel, clean the mating sur-

face ofthe brake disc and the inside of the wheel

. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

Page 1140 of 2189

Front Suspension

L

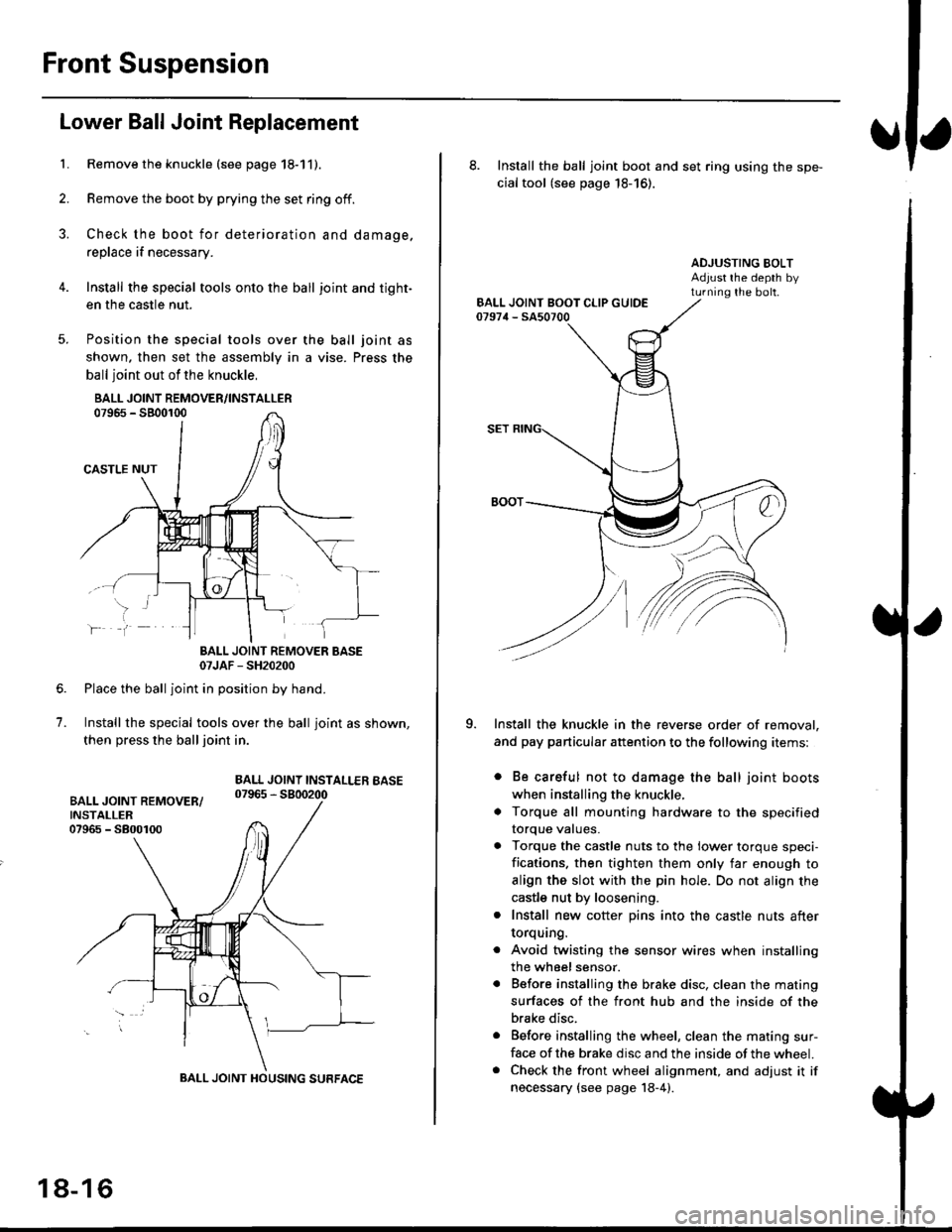

Lower Ball Joint Replacement

Remove the knuckle (see page 18-11).

Remove the boot by prying the set ring off.

Check the boot for deterioration and damage.

replace if necessary.

Install the special tools onto the ball joint and tight-

en the casfle nut.

Position the special tools over

shown. then set the assembly in

ball joint out of the knuckle,

BALL JOINT REMOVER/INSTALLER07965 - SB00r00

CASTLE NUT

the ball joint as

a vise. Press the

lf

7.

BALL JOINT REMOVER BASE07JAF - SH20200

Place the ball joint in position by hand.

Install the special tools over the ball joint as shown,

then press the ball joint in.

BALL JOINT INSTALLEB BASE07965 - 5800200

BALL JOINT HOUSING SURFACE

18-16

8. Install the ball joint boot and set ring using the spe-

cial tool (see page 18-16).

ADJUSTING BOLTAdjust rhe depth byturning the bolt.

Install the knuckle in the reverse order of removal,

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle,

. Torque all mounting hardware to the specified

torque values.

. Torque the castle nuts to the lower torque speci-

fications. then tighten them only far enough to

align the slot with the pin hole. Do not align the

castle nut by loosening.

. Install new cotter pins into the castle nuts after

torquang.

. Avoid twisting the sensor wires when installing

the wheel sensor.

. Before installing the brake disc. clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the wheel, clean the mating sur-

face of the brake disc and the inside of the wheel.. Check the front wheel alignment, and adjust it if

necessary {see page 18-4).

Page 1144 of 2189

Front Damper

Installation (cont'd)

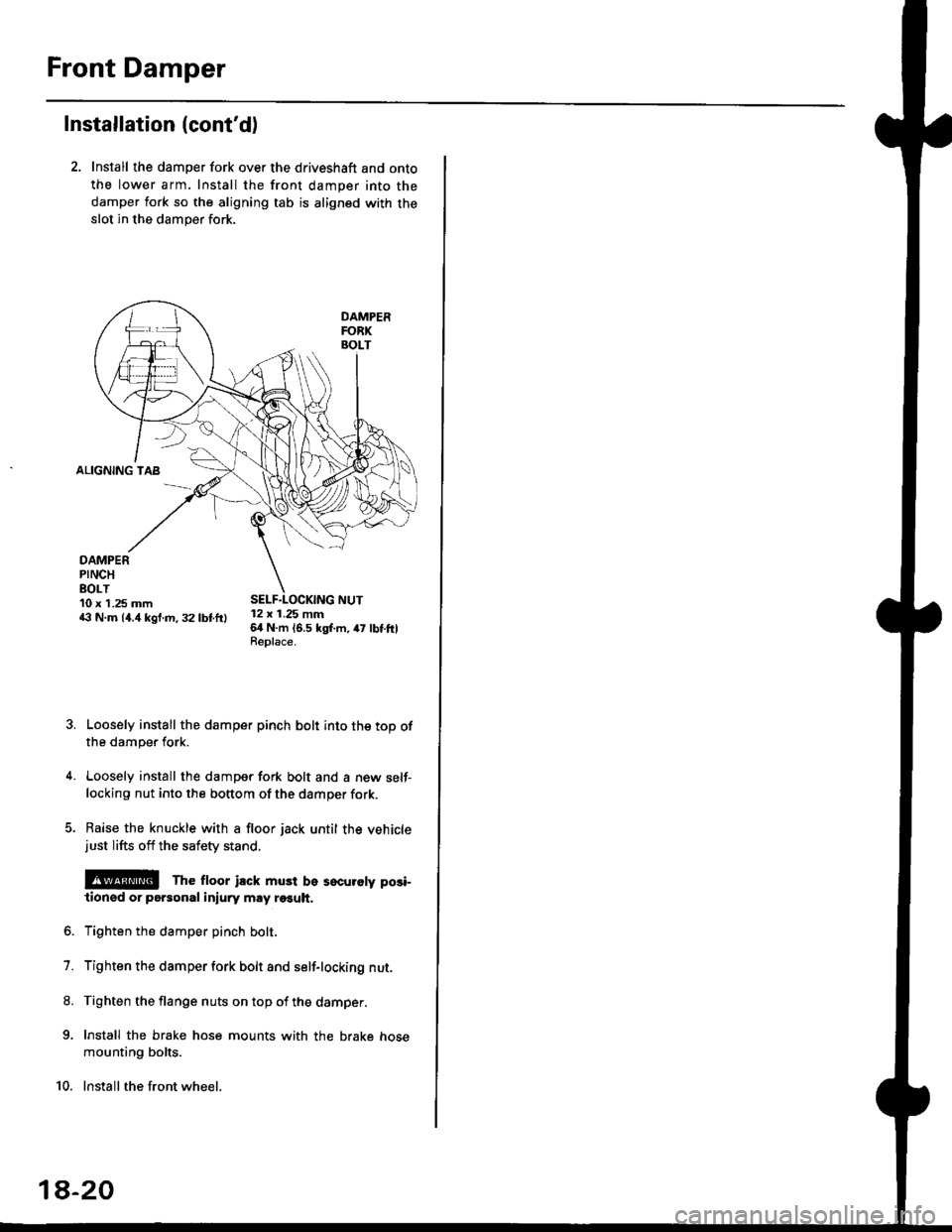

2. Install the damper fork over the driveshaft and onto

the lower arm. Install the front damper into the

damper fork so the aligning tab is aligned with the

slot in the damper fork.

ALIGNING TAB

DAMPERPINCHEOLT10 x 1.25 mm43 N.m 14.4 kgf.m, 32 lbtftl12 x 1.25 mm64 N.m 16.5 kgl.m, 47 lbtftlReplace.

Loosely install the damper pinch bolt into the top ofthe damper fork.

Loosely install the damper fork bolt and a new self-locking nut into the bottom of the damper fork.

Raise the knuckle with a floor jack until the vehiclejust lifts off the safety stand.

@E The ftoor ilck must be sscuroty posi-

lionsd or personal iniury may r€€uh.

Tighten the damper pinch bolt.

Tighten the damper fork bolt and self-locking nut.

Tighten the flange nuts on top of the damper.

Install the brake hose mounts with the brake hose

mounting bolts.

Install the front wheel.

7.

8.

9.

10.

1a-20

Page 1155 of 2189

t

Conventional Brake

Speciaf Tools .............19'2

Component Locations

lndex ................ ...... 19-3

Inspection and Adiustment

Brake System Rubber Parts

and Brake Booster ...........,.,............. 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19-7

Front Brake Pads

Inspection and Replacement .......... 19-8

Front Erake Disc

Disc Runout Inspection ................... 19-12

Disc Thickness and Parallelism

Inspection .......... 19-12

Front Brake Caliper

Disassembly .......... 19'13

Reassembly ........... 19-16

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-21

Pushrod Clearance Adiustment ...... 19-22

Brake Booster Inspection ................ 19-23

Rear Brake Pads

Inspection and Replacement ,,........ 19-24

Rear Brake Disc

Disc Runout lnspection ................... 19-26

Disc Thickness and Parallelism

Inspection .......... 19-26

Rear Brake Caliper

Disassembly ...........19-27

Reassembly ........." 19-31

Rear Drum Brake

Index/lnspection .............................. 19-35

Inspection ....,.,....... 19-36

Brake Shoe Disassembly ..............." 19-37

Brake Shoe Reassembly ...............'.. 19-37

Brake Hoses/Lines

Inspection/Torque Specifications ..... 19-39

Hose Replacement ........................... 19-40

Parking Brake Cable

lnspection and Replacement ........,. 19-41

l-l

Page 1157 of 2189

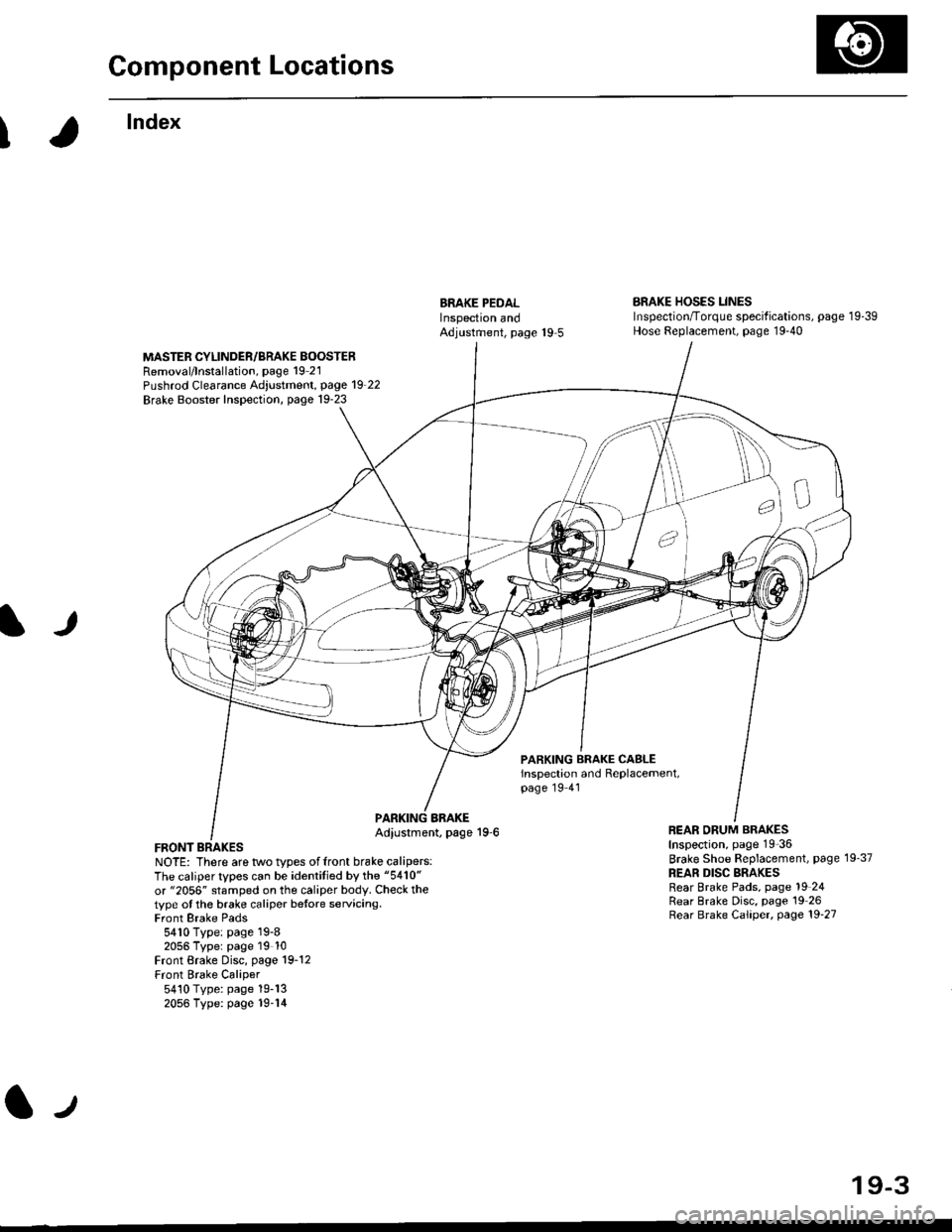

Component Locations

I

lndex

ERAKE PEDALInspectron andAdjustment, page 19 5

BRAKE HOSES LINESInspection/Torque specif ications, page 1 9-39Hose Replacement, page 19-40

MASTER CYLINDER/BRAKE BOOSTERRemoval/lnstallation, page 19 21Pushrod Clearance Adjustment, page 19_22

Brake Booster Inspection, page 19-23

lJ

PARKING BRAKE CASLEinspection and Replacement,page 19 41

FRONT BRAKESNOTE: There are two types offront brake calipers:The caliper types can be identitied by the "5410"

or "2056" stamped on the caliper body. Check thetype ot the brake caliper betore servicing.Front Brake Pads5410 Type: page 19-82056 Typer page 19 10Front Brake Disc, page 19-12Front Brake Caliper5410 Type: page 19-132056 Type: page 19-14

BBAKEAdiustment, page 19-6REAR ORUM BRAKESInspection, page 19-36

Brake Shoe Beplacement, page 19'37

REAR DISC BRAKESRear Brake Pads, page 19 24Rear Brake Disc, page 19 26Rear Brake Caliper, page 19'27

lJ

19-3

Page 1160 of 2189

Inspection and Adjustment

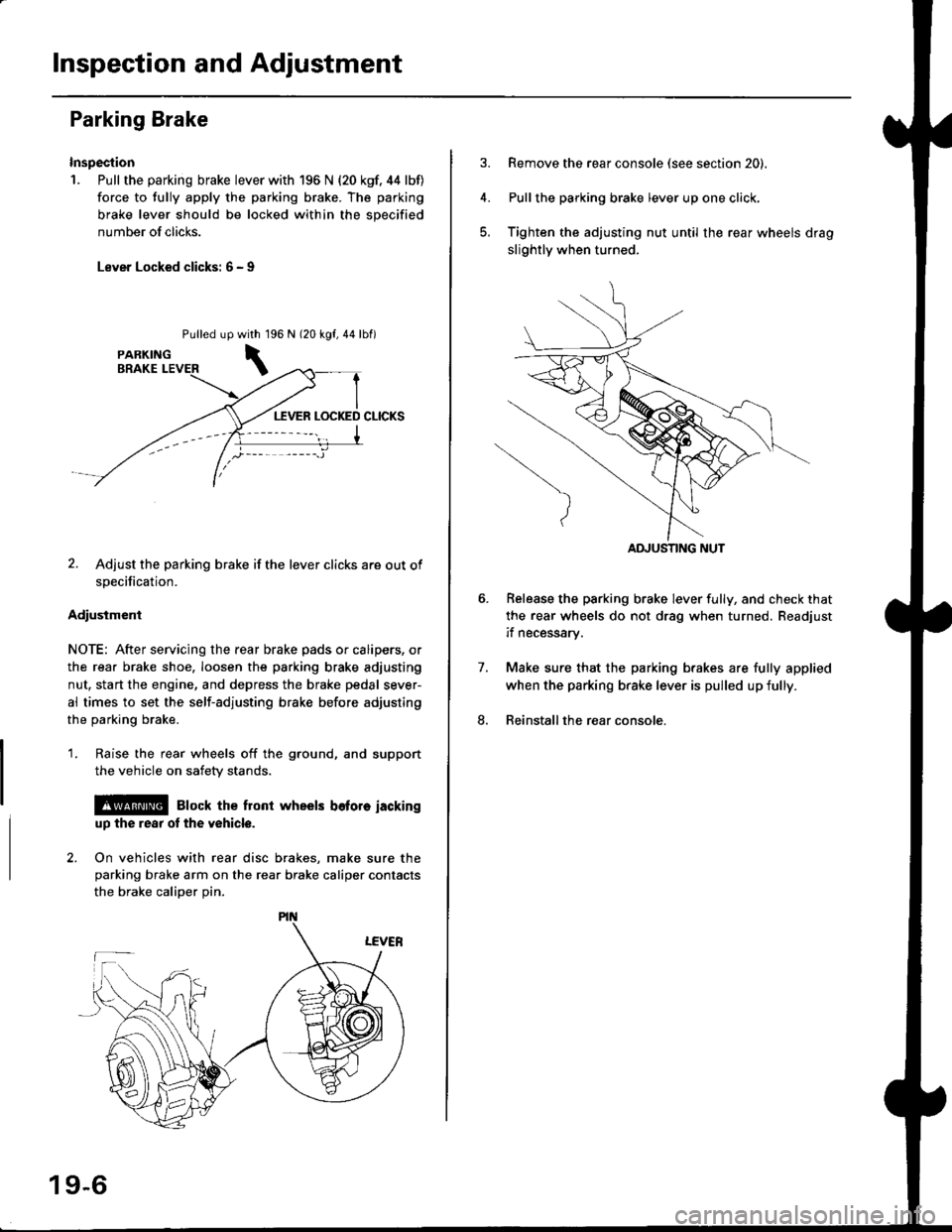

Parking Brake

Inspection

1. Pull the parking brake lever with 196 N {20 kgf. 44 lbf)

force to fully apply the parking brake. The parking

brake lever should be locked within the sDecified

number of clicks.

Lever Locked clicks: 6 - I

Pulled up96 N 120 kgf,44lbf)

2. Adjust the parking brake if the lever clicks are out of

specification.

Adiusiment

NOTE: After servicing the rear brake pads or calipers, or

the rear brake shoe, loosen the parking brake adjusting

nut, start the engine, and depress the brake pedal sever-

al times to set the self-adjusting brake before adjusting

the parking brake.

1. Raise the rear wheels off the ground, and support

the vehicle on safety stands.

l@ Elock the front wheels bofore iackinguD the rear ot the v6hicle.

2. On vehicles with rear disc brakes, make sure theparking brake arm on the rear brake caliper contacts

the brake calioer Din.

with 1

\

19-6

Remove the rear console (see section 20).

Pullthe parking brake lever up one click,

Tighten the adjusting nut until the rear wheels drag

slightly when turned.

Belease the parking brake lever fully, and check that

the rear wheels do not drag when turned. Readjust

if necessarv.

Make sure that the parking brakes are fully applied

when the parking brake lever is pulled up fully.

Reinstall the rear console.

7.

8.

ADJUSTING NUT

Page 1161 of 2189

I

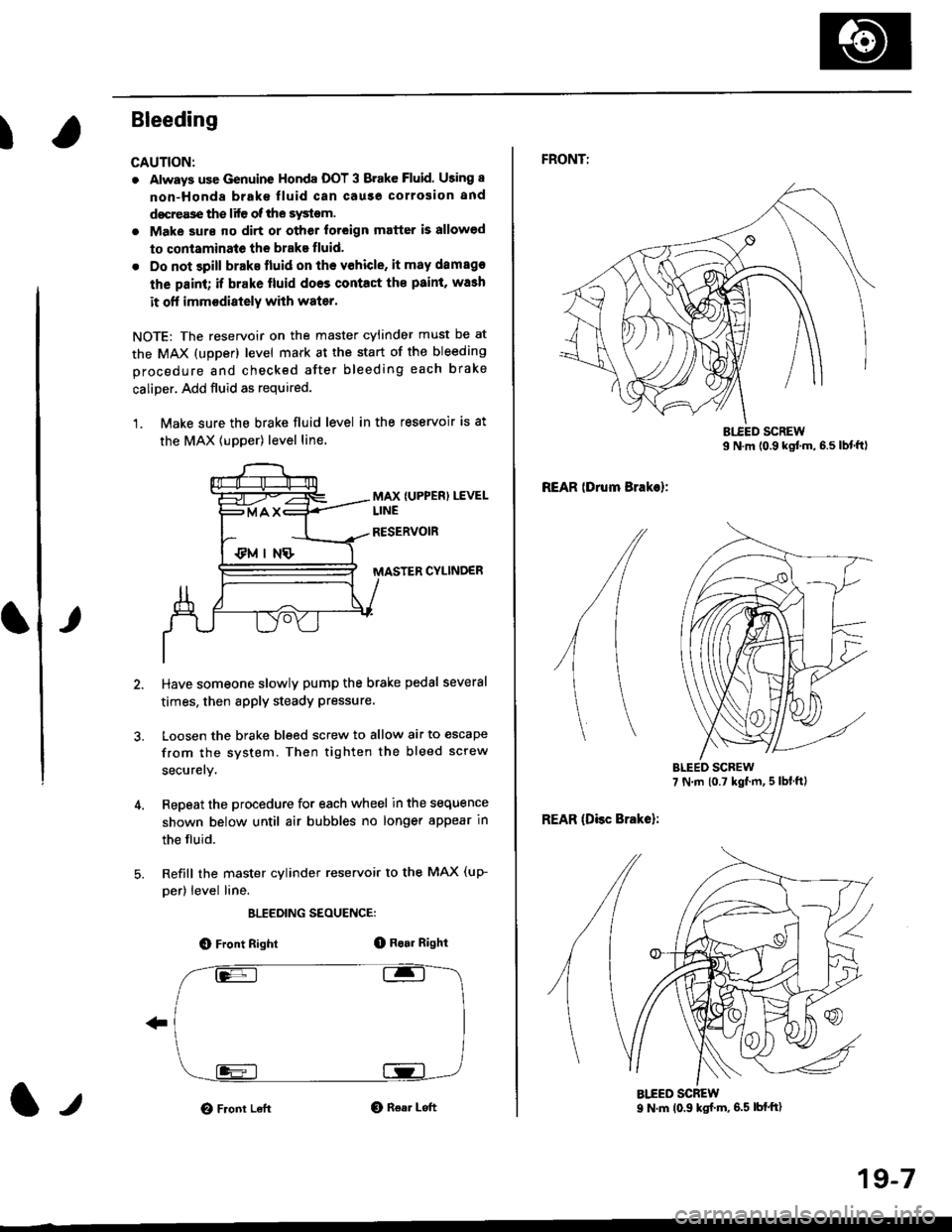

Bleeding

CAUTION:

. Always use Genuine Honda DOT 3 Brake Fluid. Using 8

non-Honda brak€ fluid can cause corrosion and

docrea3e the life of the system.

. Make surs ||o dirt or other foteign matter is allowed

to contaminate the brake fluid,

. Do not spill brake lluid on the vehicle, it may damago

the paint; if brake lluid doos contac{ the paint, wash

it ofl imm€diately with water.

NOTE: The reservoir on the master cylinder must be at

the MAX (upper) level mark at the start of the bleeding

procedure and checked after bleeding each brake

caliper. Add fluid as required.

1. Make sure the brake fluid level in the reservoir is at

the MAX lupper) level line.

MAX {UPPER) LEVEL

CYLINDER

Have someone slowly pump the brake pedsl several

times, then apply steady Pressure.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the fluid.

Refill the master cylinder reservoir to the MAX (up-

per) level line.

ELEEDING SEOUENCE:

O Front Right(D Bo.r Right

O Front LeftO Rear Left1,,

19-7

FRONTT

REAR lDrum Brakel:

REAR (Disc Brake):

AIEED SCREW9 N.m (0.9 ksf m, 6.5 lbf'ft)

Page 1162 of 2189

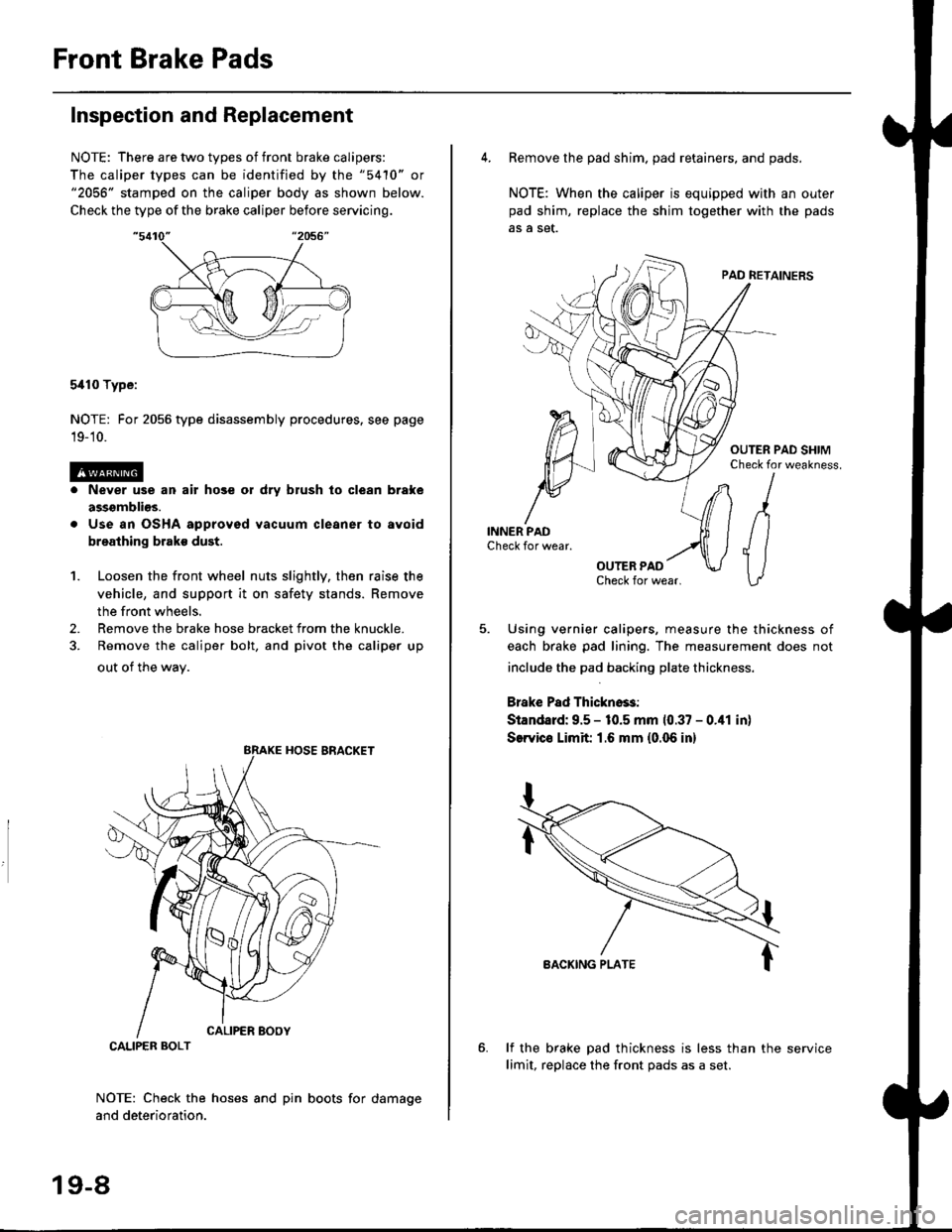

Front Brake Pads

Inspection and Replacement

NOTE: There are two types of front brake calipers:

The caliper types can be identified by the "5410" or"2056" stamped on the caliper body as shown below.

Check the type of the brake caliper before servicing.

5i110 Type:

NOTE: For 2056 type disassembly procedures. see page

19-'10.

Never use an air hose or dry brush lo clean brake

assgmblios.

Use an OSHA approved vacuum cleaner to avoid

breathing brake dust.

Loosen the front wheel nuts slightly, then raise the

vehicle, and support it on safety stands. Remove

the front wheels.

Remove the brake hose bracket from the knuckle.

Remove the caliper bolt, and pivot the caliper up

out of the wav.

1.

2.

NOTE: Check the hoses and pin boots for damage

and deterioration.

CALIPER BOLT

19-8

4. Remove the pad shim. pad retainers, and pads.

NOTE: When the caliper is equipped with an outer

pad shim, replace the shim together with the pads

5. Using vernier calipers, measure the thickness of

each brake pad lining. The measurement does not

include the pad backing plate thickness.

Brake Pad Thickno$:

Standard: 9.5 - 10.5 mm 10.37 - 0.41 in)

SerYico Limit 1.6 mm {0.06 in}

lf the brake pad thickness is less than the service

limit, replace the front Dads as a set.