low idle HONDA CIVIC 1998 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 447 of 2189

PGM-FI System

Barometric Pressure (BAROI Sensor

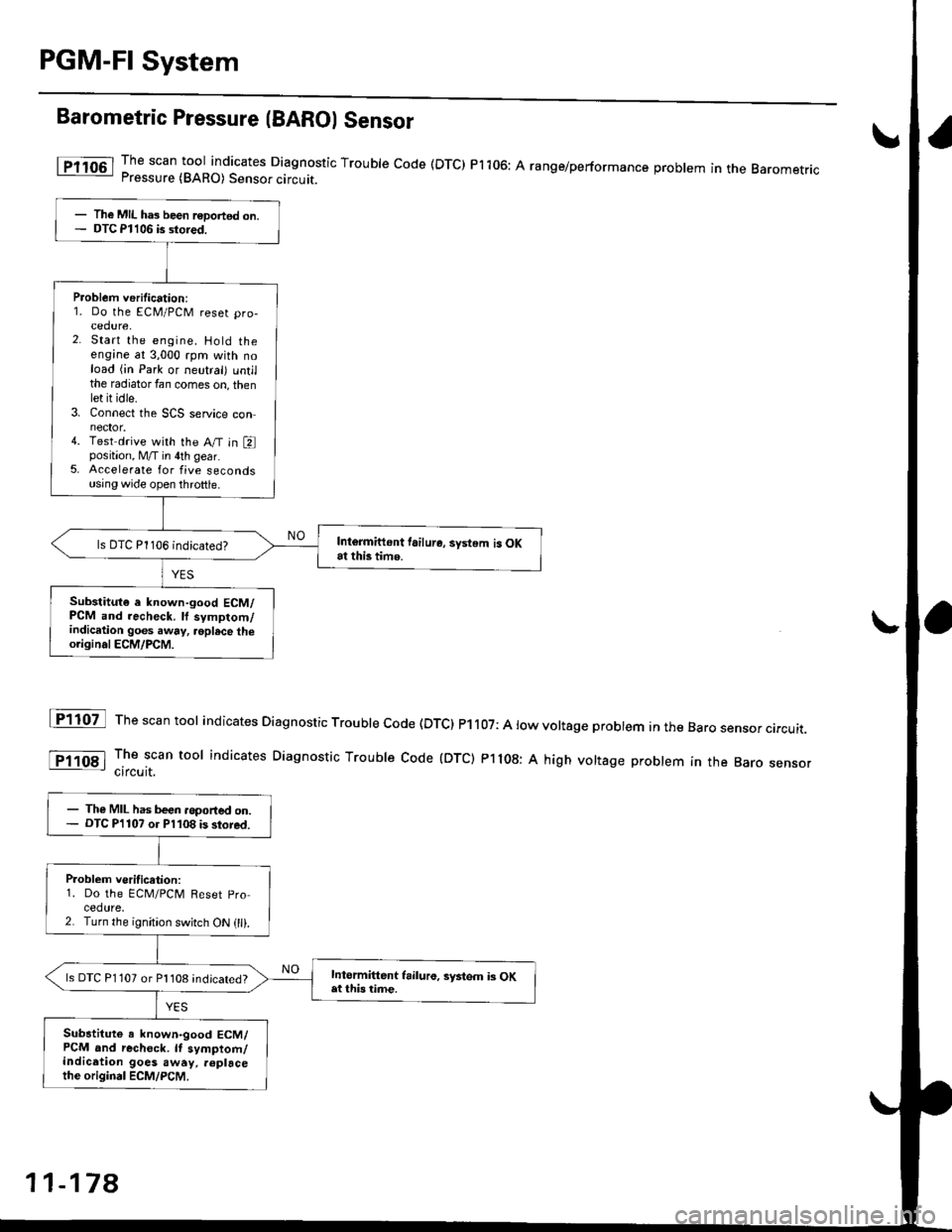

The scan tool indicates Diagnostic Trouble code (DTC) Pi106: A range/performance problem in the BaromerrrcPressure (BARO) Sensor circuit.

The scan tool indicates Diagnostic Trouble code (DTc) P1107: A low voltage probtem in the Baro sensor circurr.

The scan tool indicates Diagnostic Troubre code {DTC) p1108: A high vortage probrem in the Baro sensorcircuit.

fF1lot

tPlloal

The MIL ha3 been r€Dortsd on.DTC Pl106 is stored.

Problem verification:1. Do the ECM/PCM reset pro-cedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.3. Connect the SCS service connector.4. Test drive with the A/T in Eposition, M/T in 4th gear.5. Accelerate for five secondsusing wide open throttle.

Intormittont tailure, system is OKat this time.ls DTC P1106 indicated?

Substitut€ e known-good ECM/PCM and recheck. ll symptom/indication goes .way, .oplsce theo.iginal ECM/PCM.

The MIL has been .oported on.DTC P'l107 o. Pl108 is stored.

P.oblem veritication:1. Do the ECM/PClvl Reset pro

cedure,2. Turn the ignition switch ON (ll).

Intormittent frilure, syitem i3 OKat this time.ls DTC P1 107 or Pl108 indicated?

Substitute a known-good ECM/PCM and rechock. It symptom/indication goes away, .6placethe original ECM/PCM.

11-178

Page 450 of 2189

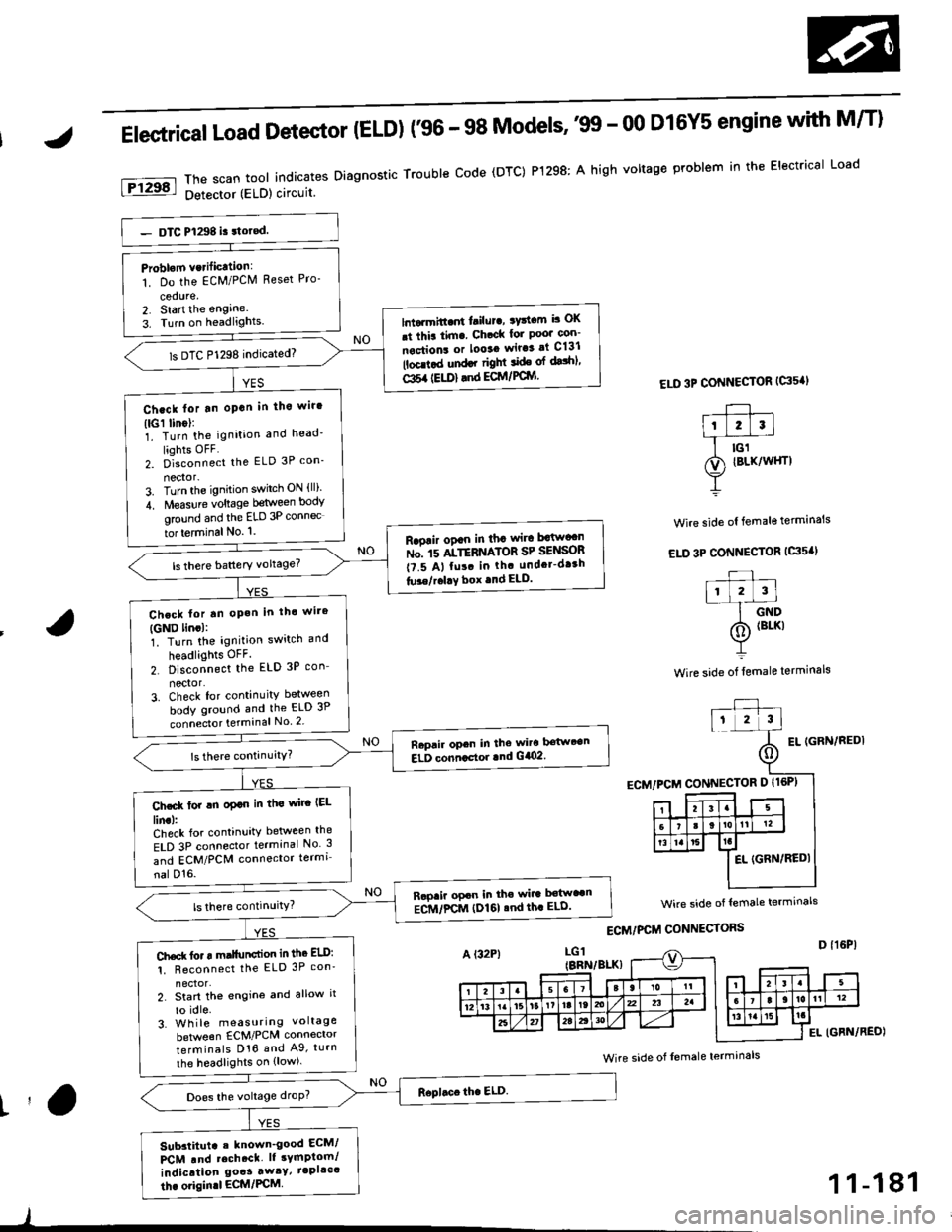

Elestrical Load Detector (ELD) f96 - 98 Models''99 - 00 D16Y5 engine with M/T)

ThescantoolindicatesDiagnosticTroubleCode(DTC)P1298:AhighvoltageproblemintheElectricalLoad

Detector (ELD) circuit

ELD 3P CONNECTOR {G's'I

Wire side ol female terminals

EL IGFN/REDI

Problom vcrificttion:

1. Do the EcM/PClVl Reset Pro-

cedure,2. Start the engine.

3. Turn on headlights.lntarmitt..rt l.ilur., ryttcm b OK

.t thia tim. Ch.ck lor Poo' con-

nections or looaa wir.3 at C131

lbcd.d und.r right ide ol dalhl'

Gl5a {EU)} .nd ECM/PCIYI

ls DTC P1298 indicated)

Ch.ck lor tn oPan in tho wir'

(lGl linol:1. Turn the ignition and head'

liohts OFF2. D]""onn""t the ELD 3P con_

nector-3. Turn the ignition switch ON {ll)'

4. Measure voltage between body

ground and the ELD 3P connec

tor terminal No. '1.

R.oair ogan in tha wira Mw"n

ru". rs ltTEnrlton SP SelSOn

t?.5 A, fu!. in th. undcr-dr3h

tu3e/r.l!Y box .nd ELD.

Chcck lor tn oP.h in thc wire

{GND lincl:1. Turn the ignition switch and

headlights OFF.

2. Disconnect the ELD 3P con_

nector'3. Check for continuity between

body ground and the ELD 3P

connecto. terminal No 2

Raprir opcn in the wira bstwt€n

ELD conncctor lnd G/O2.

Ch.ck lor !n oplo in tha wirc IEL

lin.l:Check for continuity between the

ELD 3P connector terminal No 3

and ECM/PCM connector termi

nal D'16.

Rapaii opcn in the wira b€tw"n

ECM/FCM (I)161 .nd th. ELD'

Ch.d( fo. r m.llunction in thc ELD:

1. Reconnect the ELD 3P con'

2. Start th€ engine and allow it

to idle.3. Wh ile measuring voltage

beNveen ECM/PCM connector

terminals D16 and A9, turn

the headlights on {low).

Does the voltage droP?

Sub3titut. . known_good ECM/

PCM .nd rcch.ct. lt sYmptom/

indication goas away/ iapllc'

thc origin.l ECM/PCM

wire side of lemale termrnals

Wire side of Iemale terminals

t'a

)

1 1-181

Page 451 of 2189

PGM-FI System

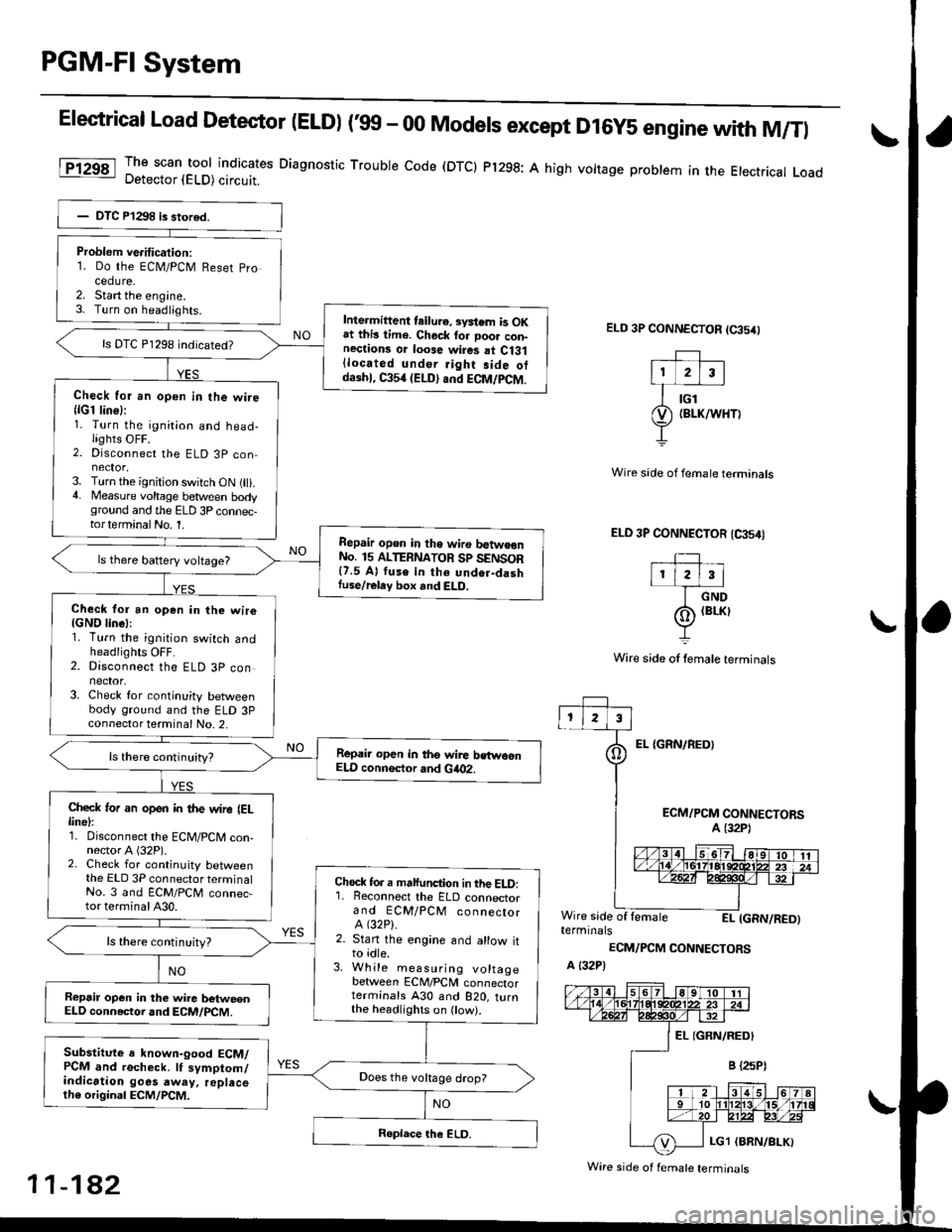

Elestrical Load Detector (ELDI ('99 - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble code (DTCI Pl298: A high vottage problem in the Etectrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR (65/0

EL {GRN/REOI

Wire side of fernale terminals

ELD 3P CONNECTOR (CA54I

TIr l2l3l

I crvo

(o) (BrKr

Y

Wire side of lemale terminals

ECM/PCM CONNECTORSA (32P1

Wire side of lemaleEI- IGRN/RED)terminals

ECM/PCM CONNECTORS

A {32P)

Problem ve.itication:1. Do the ECN4/PCM Reset pro

cedure.2. Start the engine.3- Turn on headiights.Inte.mittent teilu.e, svstem is OKat this lime. Chock for Door con-nections or loose wires at Ci31{located under Jight side otdaihl, C354 (ELD) and ECM/PCM.

ls DTC P1298 indicated?

Check for an open in the wire{lG1 line}:1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P con

3. Turn the ignition switch ON (ll).4. Measure voltage between bodyground and the ELD 3P connec-torterminalNo. 1.

Repair opon in tho wiro batwe€nNo. 15 ALTERNATOR Sp SENSOR{7.5 A} fuse in th6 undor-dashIuse/reley box and ELD.

ls there battery voltage?

Check for an open in the wiro{GND linel:1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P connector.3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2,

Repair open in the wire bstwoenELD connsctor and Gia02.

Check ,or an open in the wire IELlinel:1. Disconnect the ECM/PCM con-nector A (32P).2. Check for continuity betweenthe ELD 3P connector terminalNo. 3 and ECM/PCM connec-tor terminal A30.

Chock fo. a malfunction in the ELD:'1. Reconnect the ELD connectorand ECM/PCM connectorA (32P).

2. Stan the engine and allow itto idle.3. While measuring voltagebetween ECM/PCM connectorterminals A30 and B2O, turnthe headlighrs on ow).

ls there continuity?

Repsir op€n in the wire betweenELD connector and ECM/PCM.

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away. replacelh6 original ECM/PCM.

Does the vokage drop?

Wire side of f€male terminals

11-182

Page 460 of 2189

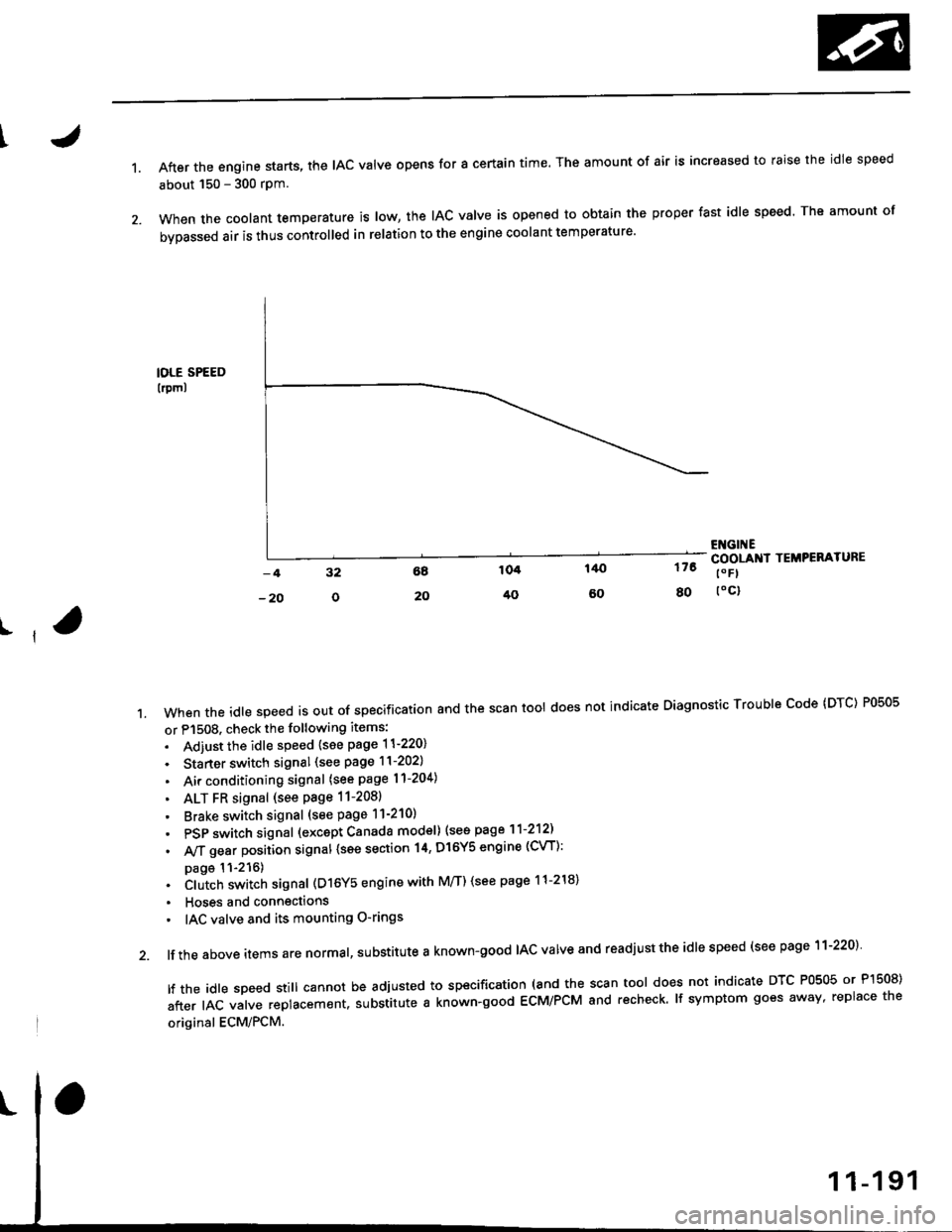

1.After the engine starts, the lAc valve opens for a certain time. The amount of air is increased to raise the idle speed

about 150 - 300 rpm.

When the coolant temperature is tow, the IAC valve is opened to obtain the proper fast idle speed. The amount of

bypassed air is thus controlled in relation to the engine coolant temperature'

IOLE SPEED

lrpml

176

80

ENGI ECOOLANI TEMPERATURE

t" Fl

toc)

ll

't.Whentheid|espeedisoutofspeciiicationandthescantoo|doesnotindicateDiagnosticTroub|ecode(DTc)P0505

or P1508. check the following items:

. Adiust the idle speed {see page 11-220}

. Starter switch signal (see page 11-202)

. Air conditioning signal (see page l1-204)

. ALT FR signal (see Page 11-2081

' Brake switch signal (see page 11-210)

. PSP switch signal (excapt Canada model) (see page 11-212)

. A,/T gear position signal {see section 14, Dl6Y5 engine (CVT):

page 11-216). Clutch switch signal (D16Y5 engine with M/T) (see page 11-218)

. Hoses and connections

' IAC valve and its mounting O-rings

lf the above items are normal, substitute a known-good IAC valve and readjust the idle speed (see page 11-220)

|ftheid|espeedsti||cannotbeadjustedtospecification(andthescantoo|doesnotindicateDTcP0505orP]50S)

after IAC valve replacement. substitute a known-good ECM/PCM and recheck. lf symptom goes away, replace the

original ECM/PCM.

Page 461 of 2189

ldle Control System

ldle ControlSystem

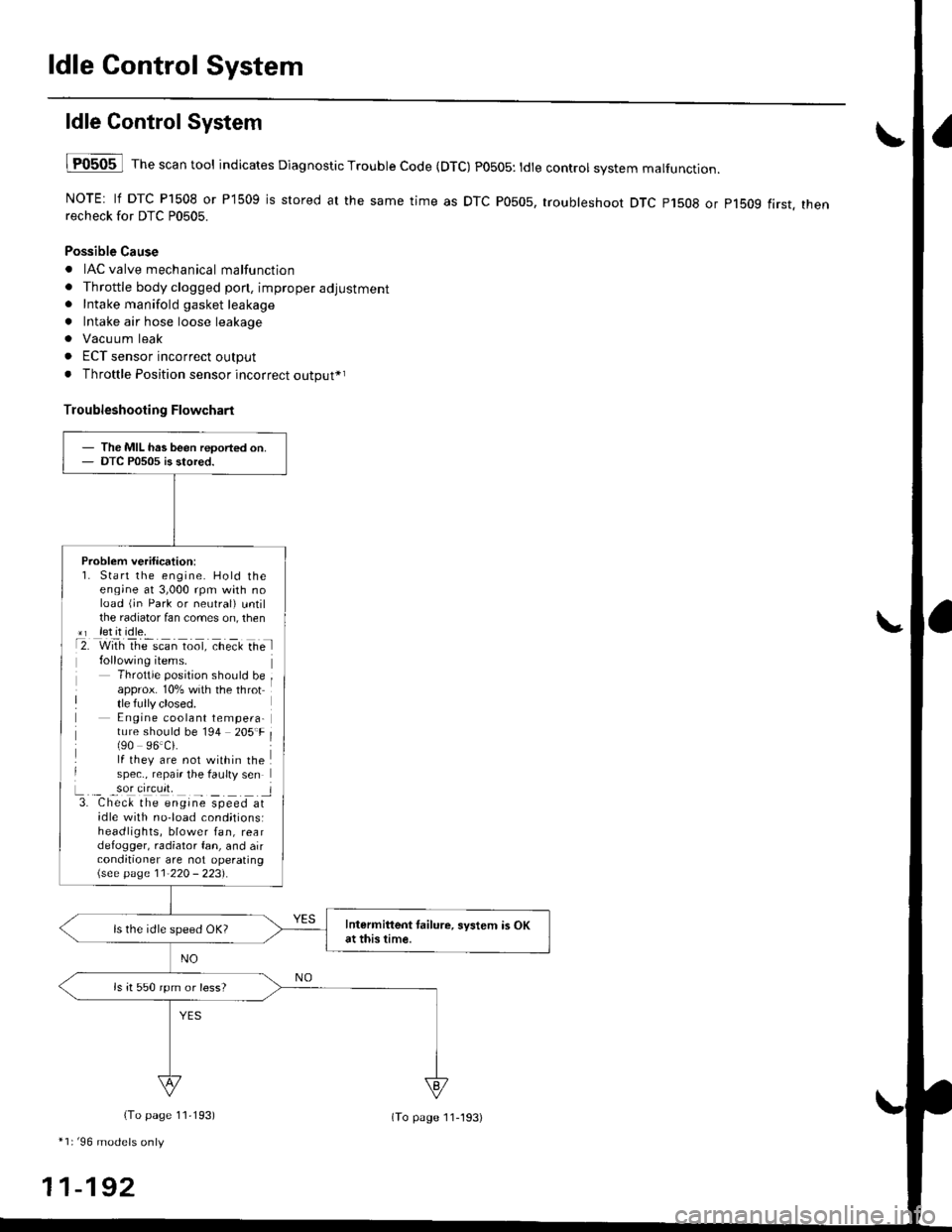

lF0505 l Th" """n tool indicates Diagnostic Trouble Code (DTC) PO5O5: tdte controt system malfunction.

NOTE: lf DTC P1508 or P1509 is stored at the same time as DTC P0505, troubleshoot DTC p1508 or p1bog first. thenrecheck for DTC P0505.

Possible Cause

. IAC valve mechanical malfunction

. Throttle body clogged pon, improper adjustment. Intake manifold gasket leakage

. Intake air hose loose leakage

. Vacu um leak

. ECT sensor incorrect output

. Throttle Position sensor incorrect output*r

Troubleshooting Flowchart

The MIL has been reoorted on.DTC P0505 is stored.

Problem verification:1. Start the engine. Hold theeng;ne at 3,000 rpm with noload (jn Park or neutral) untilthe radiator fan comes on, then*r let it idle.t2. with rhe scan toot, ct'eit Ge l

Throttle position should beapprox. 10% with the throttle fully closed.E ngine coolant tempera-ture should be 194 205'F(90 96.Ci.lf they are not within thespec., repair the faulty sen

L._ _9oI9[cr]41 l3. Chec& the engine speed atidle with no-load cond;tionsiheadlights, blower fan, reardefogger, radiator fan, and airconditioner are not operating\see page l1-22O - 223).

Intermittent tailure, system is OKat this time.ls the idle speed OK?

ls it 550 rpm or less?

(To page 11,193)

*1r'96 models only

11-192

(To page ll-193)

Page 462 of 2189

I

L

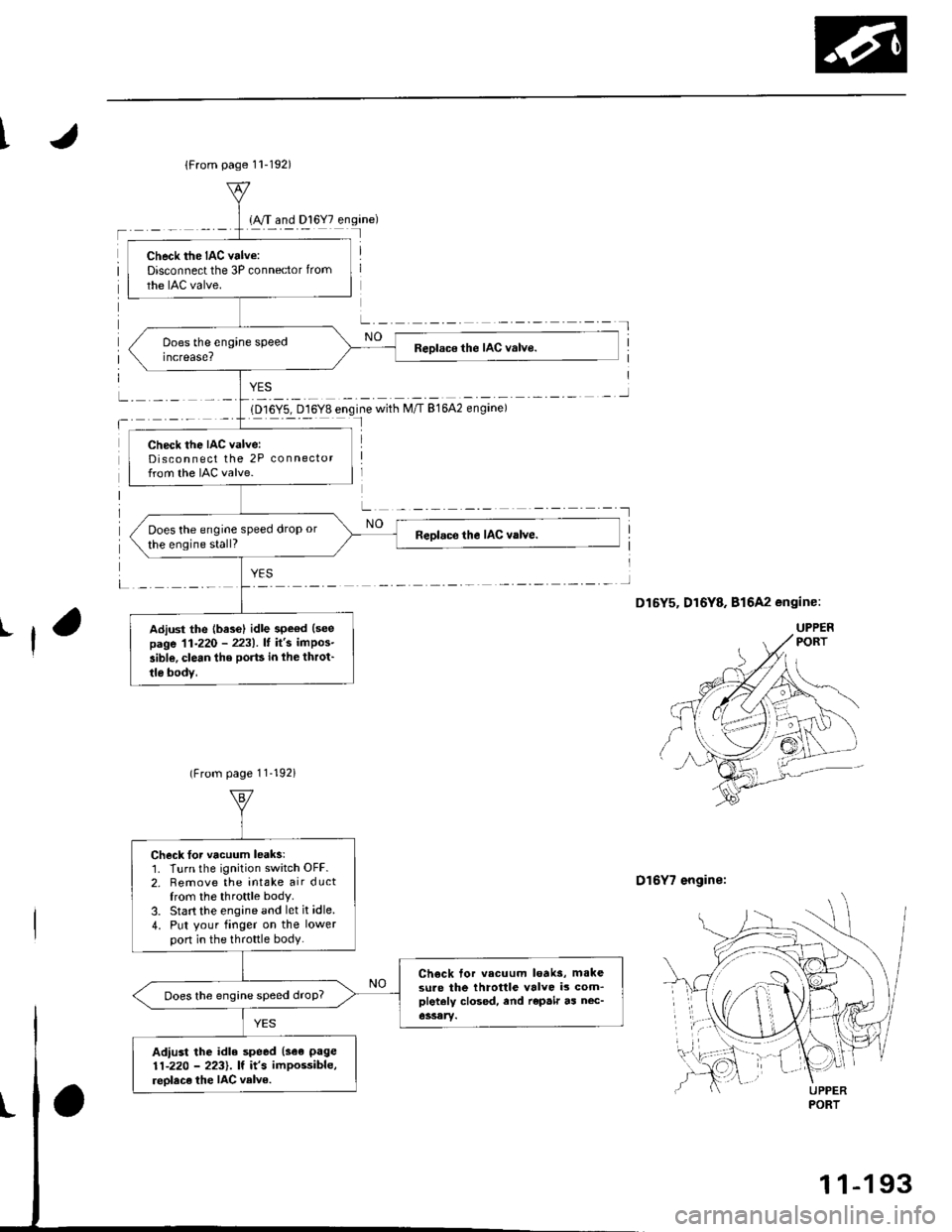

1D16Y5, D16Y8 engine with M/T 81642 engine)I

D16Y7 engine:

{From page 11-192)

Check the IAC valve:Disconnect the 3P connector from

the IAC valve.

Check the IAC valve:Disconnect the 2P connectorfrom the IAC valve.

Does the engine speed drop or

the engine stall?

Adiust the {base} idle speod (see

page 11-220 - 2231.It it's impos-

aible, clean the ports in lhe throt'

tle bodv,

(From page 11-192i

Check Ior vacuum leaks:1. Turn the ignition switch OFF.2. Remove the intake air ductfrom the throttle body.

3. Start the engine and let it idle.

4. Put your finger on the lowerpon in the th.ottle body.

Ch€ck tor vecuum loaks, m.kesure the throttle valve is com_pletaly closed, end repair as nec-Does the engine speed droP?

Adiust the idle speed (see page

11-220 - 2231. lf it's impossible,

reolace the IAC velve.UPPERPORT

1 1-1 93

Page 489 of 2189

ldle Control System

ldle Speed Setting

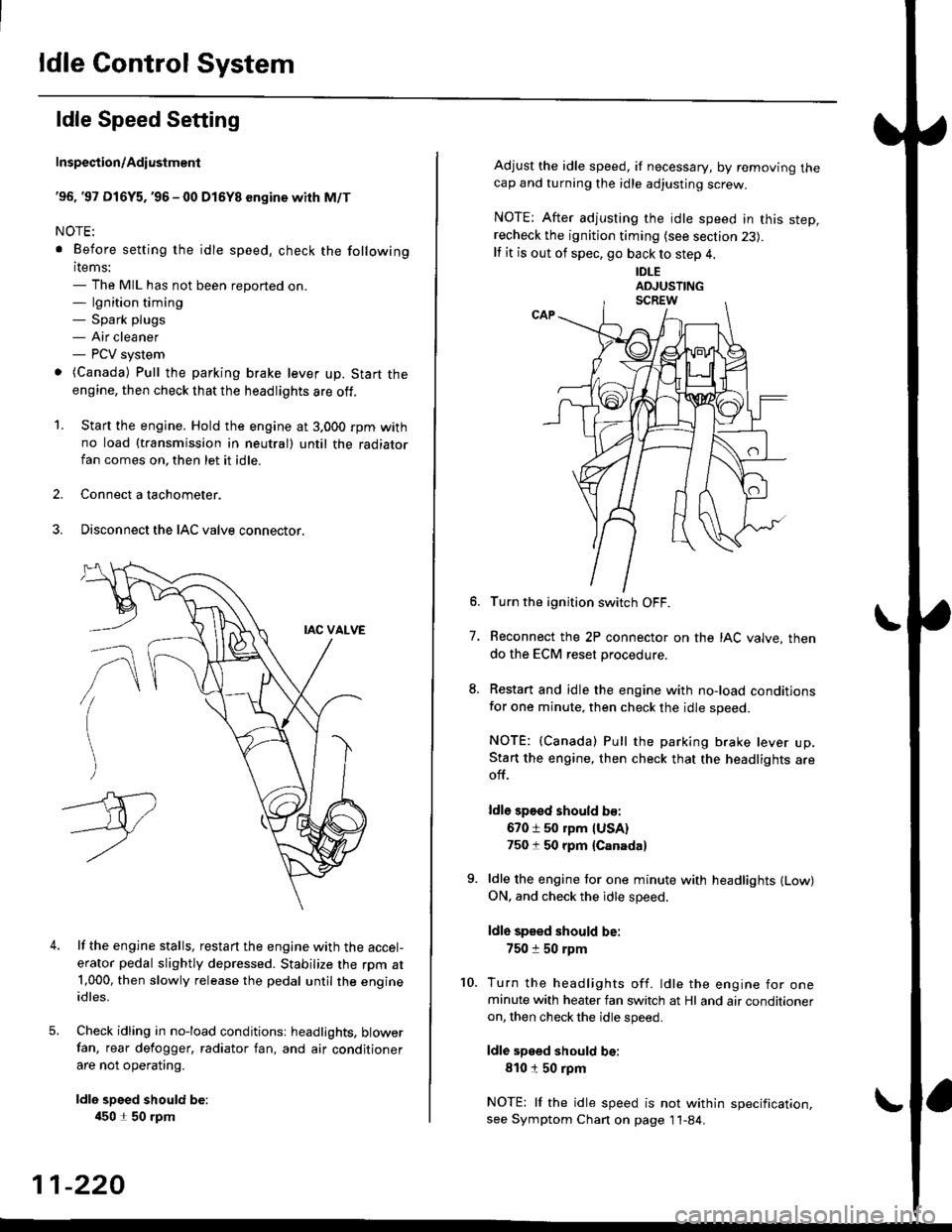

Inspection/Adiustmenl

'96, '97 Dl6Y5. '96 - 00 Dl5Y8 sngine with M/T

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

o (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3.000 rpm withno load (taansmission in neutral) until the radiatorfan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the IAC valve connector.

4.lf the engine stalls, restart the engine with the accel-

erator pedal slightly depressed. Stabilize the rpm at1,000, then slowly release the pedal until the engineidles.

Check idling in no-load conditionsr headlights. blowerfan. rear defogger, radiator fan, and air conditioner

are not operating.

ldle spsed should be:

450 1 50 rpm

11-220

Adjust the idle speed, if necessary, by removing thecap and turning the idle adjusting screw.

NOTE; After adjusting the idle speed in this step,recheck the ignition timing (see section 23).

lf it is out of spec, go back to step 4.

IDLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the IAC valve, then

do the ECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

ldle sp€sd should b€:

670 i 50 rpm IUSA)750 t 50 rpm {Canada}

9. ldle the engine tor one minute with headlights {Low)ON. and check the idle speed.

ldle speed should be:

750 :r 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air conditioneron, then check the idle speed.

ldle speed should be:

810150 rpm

NOTE: lf the idle speed is not within specification,see Symptom Chan on page 11-84.

Page 490 of 2189

t

t

I

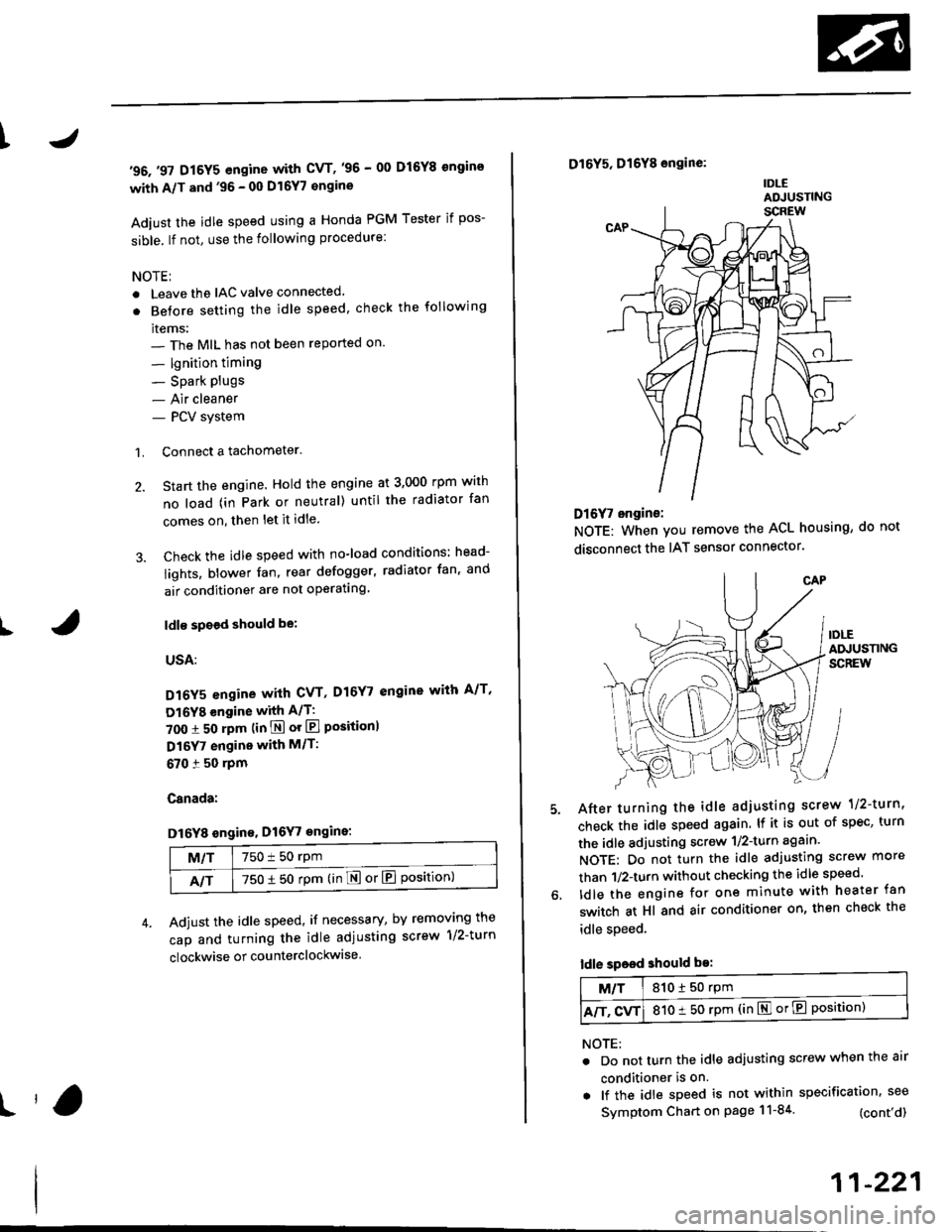

'96.'97 D16Y5 engine with CVT,'96 - 00 D16Y8 ongins

with A/T and'96 - 00 Dl6Y7 €ngine

Adiust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTEI

. Leave the IAC valve connected

. Betore setting the idle speed. check the following

items:- The MIL has not been reported on'

- lgnition timing

- Spark Plugs- Air cleaner- PCV system

1. Connect a tachometer.

2. Start the engine. Hold the engine at 3,000 rpm wirh

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

3. Check the idle speed with no-load conditions: head-

iights, blower fan, rear defogger, radiator fan, and

air conditioner are not operatlng

ldl€ spoed should be:

USA:

D16Y5 engine with CVT, D16Y7 engine with A/T'

Dl6YB engine with A/T:

700 :r 50 rpm (in E or El Positionl

D16Y7 engine with M/T:

670 i 50 rpm

Canada:

Dl6Y8 sngin€, Dl6Y7 engins:

M/T750 t 50 rpm

NT750 1 50 rpm (in E or El Position)

Adjust the idle speed, if necessary, by removing the

cap and turning the idle adiusting screw 1/2-turn

clockwise or counterclockwise

D16Y5, D16Y8 engine:

IDLEADJUSTING

Dl6f, ongine:

NOTE: When you remove the ACL housing, do not

disconnect the IAT sensor connector

After turning the idle adjusting scrow 1/2-turn'

check the idle speed again. lf it is out of spec, turn

the idle adjusting screw 1/2-turn agaan'

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed'

ldle the engine for one minute with heater fan

switch at Hl and air conditioner on, then check the

idle speed.

ldle speed should be:

M/T810150 rpm

A/T. CvT810 t 50 rpm (in El or E Position)

NOTE:

. Do not turn the idle adjusting screw when the air

conditioner is on.

. lf the idle speed is not within specification. see

Symptom Chart on page 11-84 (cont'd)

11-221

Page 491 of 2189

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

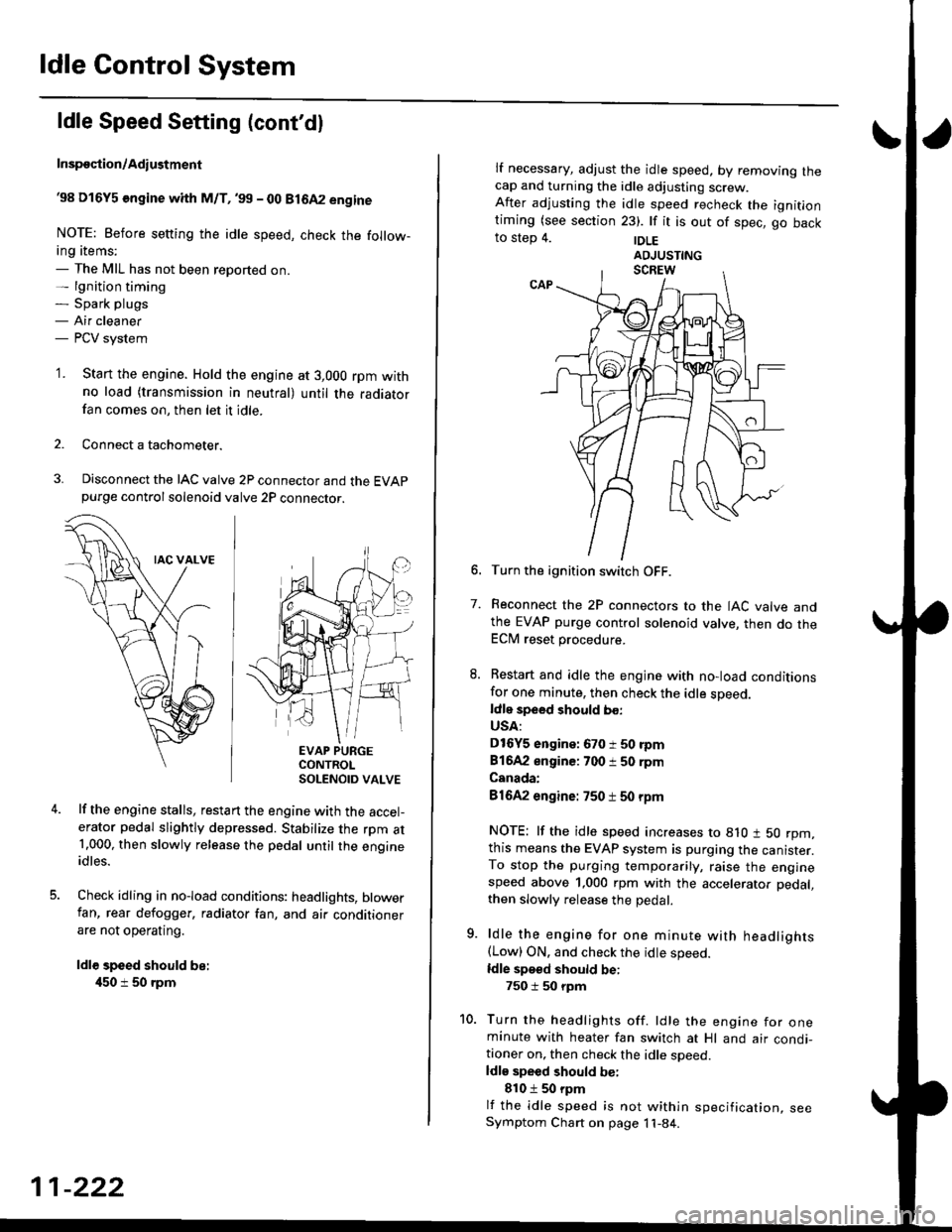

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

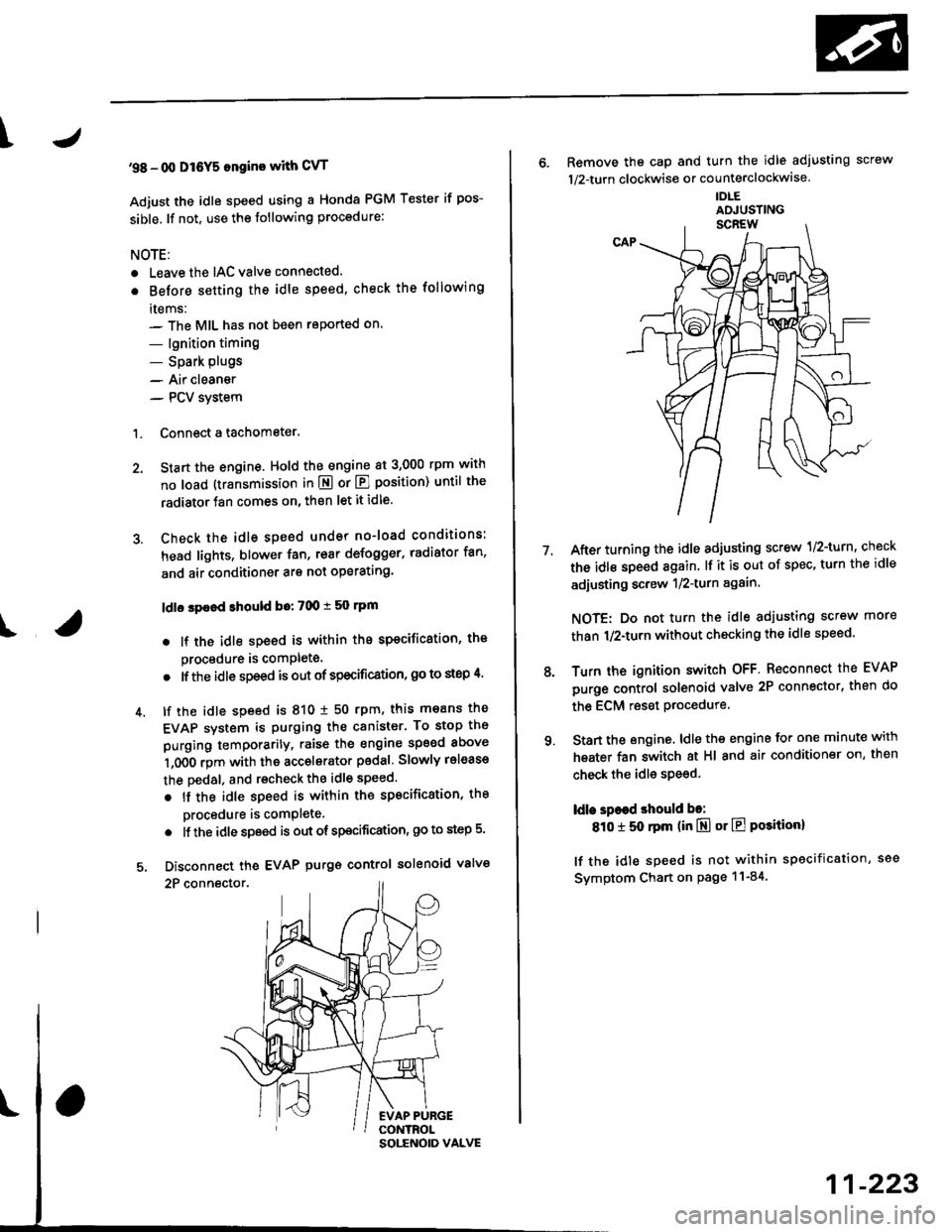

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223