Air HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1172 of 2189

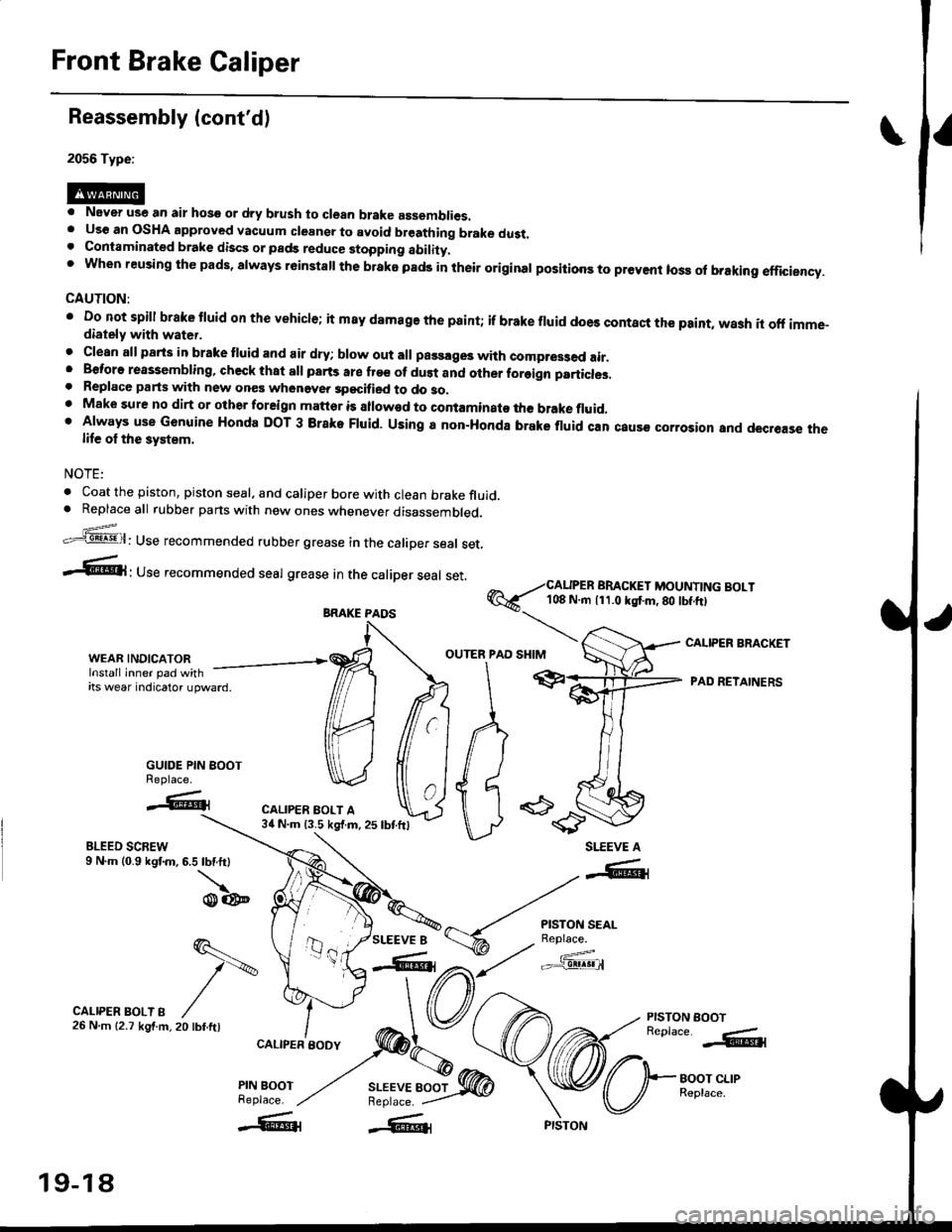

Front Brake Caliper

Reassembly (cont'd)

2056 Type:

. Never use an air hose or dry b.ush to clean brake assemblies.. Uso an OSHA approved vacuum cleansr to avoid breathing brake dust.. Contaminated brake discs or pads reduce stopping ability.t when reusing the pads, always r6instsll the brake pads in their original positioos to prevent loss ol braking efficiency.

CAUTION:

' Do not spill brake tluid or th€ vehicle; it m8y damage the paint; if brake fluid does contact the paint, wash it off imme-diately with water.

. Clean all parts in brake tluid and air dry; blow out all passages with compr63ed air.. Beforo reassembling, check that all parts are fr€e of dust and other foreign particles,. Replace parts with new ones whenevea specified to do so.. Make sure no dirt or other foreign matter is allowad to contaminato the brake fluid,' Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can caus€ corrosior and decrease thelife ol the system.

NOTE:

. Coat the piston, piston seal, and caliper bore with clean brake fluid.. Replaceall rubber parts with new ones whenever disassembled.

.'=5@: Use recommended rubber grease in the caliper seal set,

-6l ' Use recommended seal grease In the caliper seal set.

@6--i#i['i,?li"..;:l]l?Y]li"'"'

I

r""'"rr r"""ip"autr, -/ffr

e"6ft 'ADRETATNERSitswearndcatoru'ward

MffiA pr

GUIDE PIN BOOT ) {I I II ) I I

% caL,PER

\I\d/ tt ' id 6

u -es'---r..'.* ".-,."oo*'J.l, ru,oonW U

**=*t

WEAR,INDICAToR. ,ffi OUTERIPAD

BLEED SCREW9 N.m (0.9 kgf.m, 6.5 lbf.ft)

\o@

CALIPER BRACKET

PISTON EOOTReplace. -.&l

BOOT CLIPReplace.

SLEEVE A

SLEEVE 8

-"-41

r{.i'""Jg*'

a,t/ c'f3!@

q.-

t\

20 tbf.ftl

CALIPER BOLT B26Nm{2.7kgf.m,

CALIPER BODY

PIN BOOTReplace.

BRAKE PAOS

19-18

Page 1178 of 2189

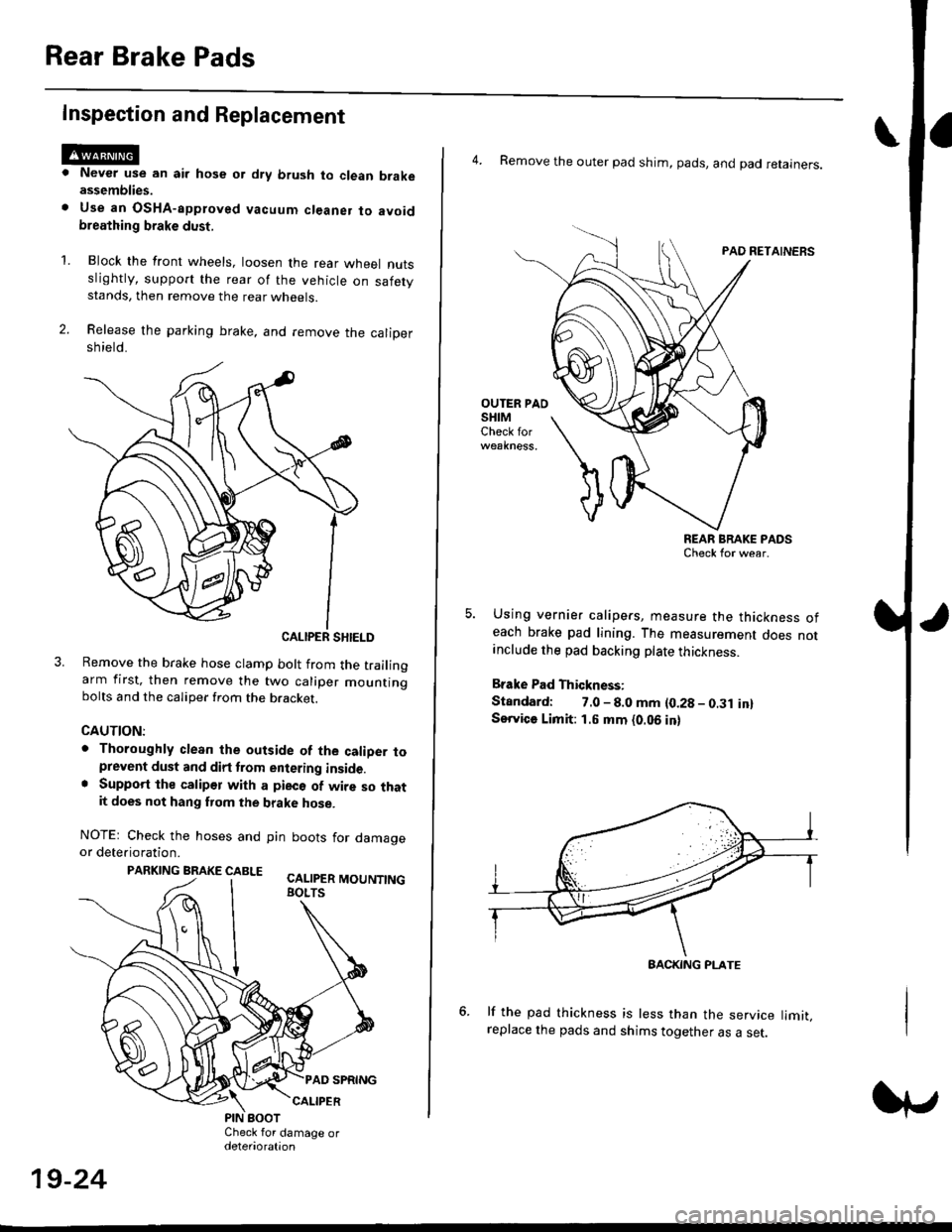

Rear Brake Pads

Inspection and Replacement

Never use an air hose or dry brush to clean brakeassemblies.

Use an OsHA-apptoved vacuum cl€aner to avoidbreathing brake dust,

Block the front wheels, loosen the rear wneet nutsslightly, support the rear of the vehicle on safetystands, then remove the rear wheels.

Release the parking brake, and remove the calioersh ield.

CALIPER SHIELD

Remove the brake hose clamp bolt from the trailingarm first, then remove the two caliper mountingbolts and the caliper from the bracket.

CAUTION:

. Thoroughly clean the outside of the caliDer toprevent dust and dirt trom entering inside.. Support the calipor with a pieco of wire so thatit does not hang fuom the brake hose.

NOTEr Check the hoses and pin boots for damageor deterioration.

PARKING BRAKE CABLE ^.. ._-_ ---.

'L

19-24

4. Remove the outer pad shim, pads, and pad retainers.

PAO RETAINERS

OUTER PAOSHIMCheck for

REAR BRAKE PADSCheck for wear.

Using vernier calipers, measure the thickness ofeach brake pad lining. The measurement does notanclude the pad backing plate thickness.

Brake Pad Thickness:

Standard: 7.0 - 8.0 mm {0.28 - 0.31 in}Service Limit: 1.5 mm {0.06 in}

lf the pad thickness is less than the service limit,replace the pads and shims together as a set.

BACKING PI-ATE

Page 1181 of 2189

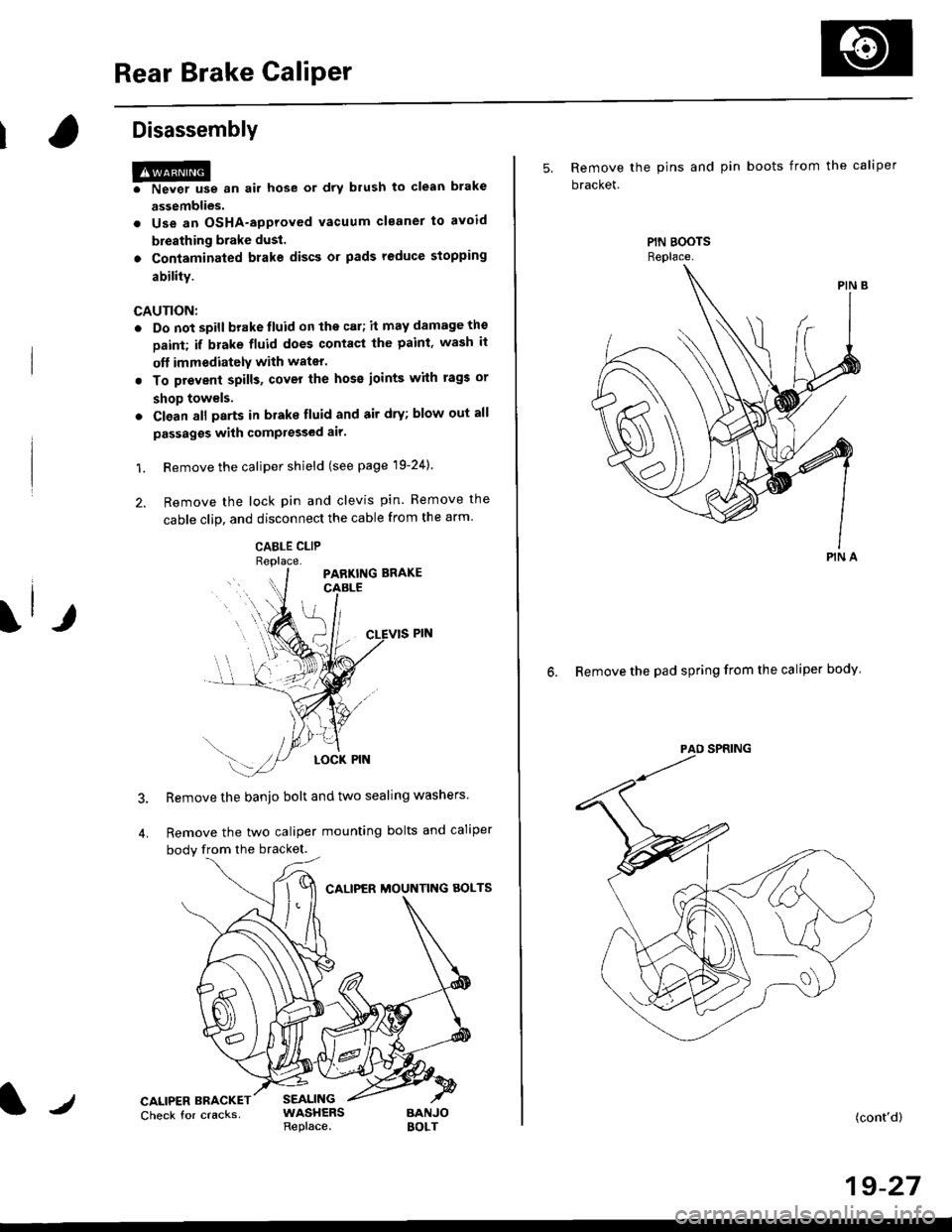

Rear Brake Caliper

Disassembly

@f l',lever use an air hose or dry brush to clean

assemblies.

. Use an OsHA-approved vacuum cleaner to

brake

avoid

breathing brake dust.

. Contaminated brake discs or pads reduce stopping

ability.

CAUTION:

. Do not spill brake tluid on the cal; h may damage the

paint; if brake fluid does contact the paint, wash ii

ofl immediatelY with water.

. To prevent spills, cover the hose ioints whh rags or

shop tow€ls.

. Clean all parts in brake fluid and air dry; blow out all

passagss with complessed air.

1. Remove the caliper shield (see page 19-24).

2. Remove the lock pin and clevis pin. Remove the

cable clip, and disconnect the cable from the arm

CABLE CLIP

Remove the banjo bolt and two sealing washers

Remove the two caliper mounting bolts and caliper

body from the bracket.

CALIPER MOUNTNG AOLTS

CALIPER BRACKETCheck for cracksSEALINGWASHERSReplace.BANJOBOLT

5, Remove the pins and pin boots from the caliper

bracket.

6. Remove the pad spring from the caliper body

PIN A

(cont'd)

19-27

Page 1185 of 2189

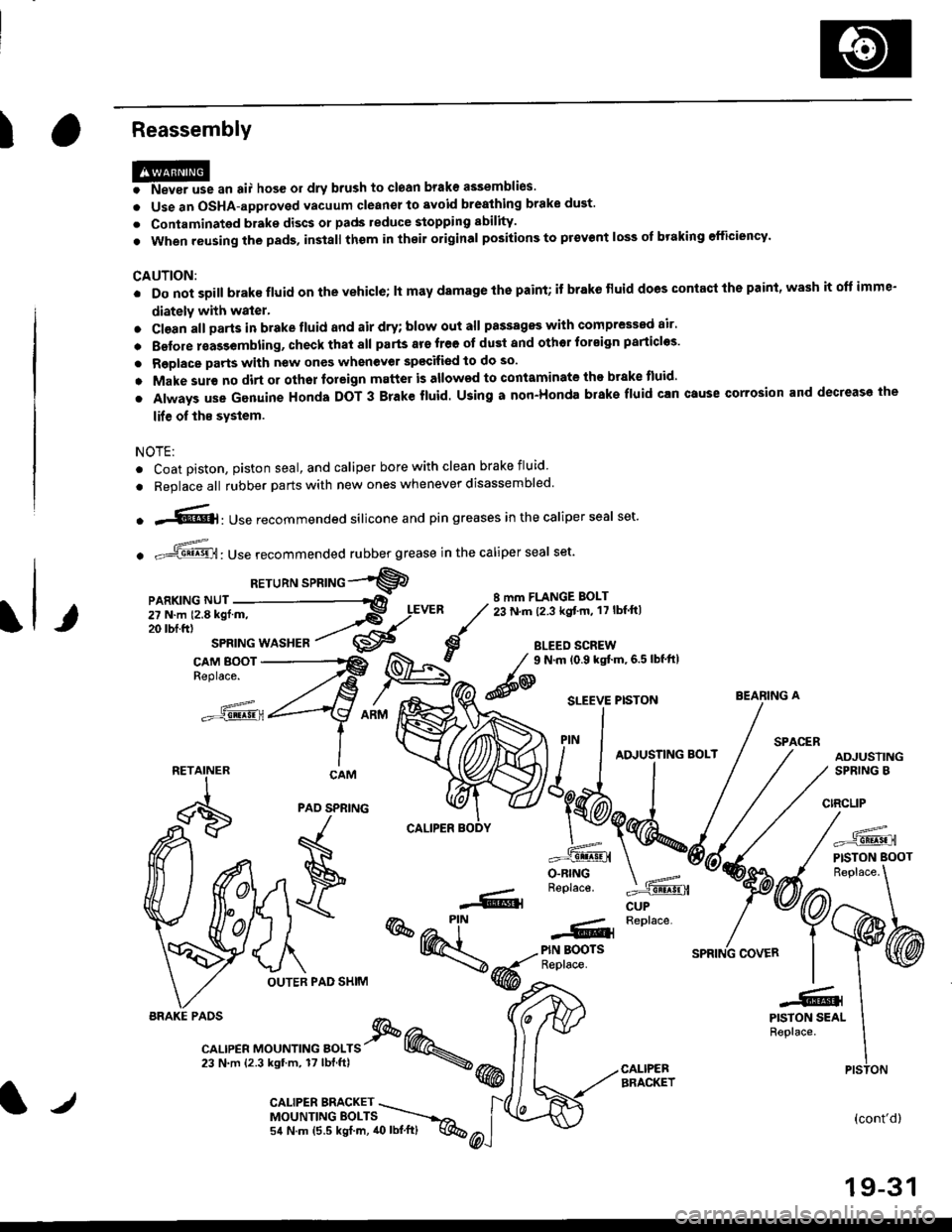

IReassembly

HP* "n ",, hos6 or drv brush to ctoan brake assemblies.

o Use an OSHA-approved vacuum cleanel to avoid brealhing brake dust'

. Contaminated brake discs or pads reduce stopping sbility.

. When reusing the pads, in3tall thom in thoil original positions to prevent loss of braking efficiency'

CAUTION:

. Do not soill brake fluid on the vehicle; lt may damage lhe paint; if brake fluid does contacl the paint' wash it oft imme-

diately with water.

. Cl€an all Darts in brake fluid and air dry; blow out all passagss with comPressed air'

. Belore rsas3embling, check that all parts ars free ot du3t and othor tor€ign particles'

. Replace parts with new ones whenever spscifiod to do so.

o Make sur€ no dirt or othor foreign matter is allowed to contaminate the brake tluid'

. Always use Genuine Honda DOT 3 Brake fluid. Using a non-Honda brake fluid can Gtuse corrosion and decrease the

lif€ of ths system.

NOTE:

. Coat piston, piston seal, and caliper bore with clean brake fluid

. Replace all rubber parts with new ones whenever disassembled.

o .-'{@]: Use recommended silicone and pin greases in the caliper seal set.

. -ffi,Use recommended rubber grease in the caliper seal set.

RETuRN sPRTNG -"'9

8 mm FLANGE BOLT23 N.m (2.3 kgt'm, 17 lbf ftl

BLEED SCREW

@

9 N.m (0.9 kgtm,6.5lbf'ft|

CUP

=^.

PISTON BOOT

(cont'd)

19-31

BEARING A

PAO SPNING

F

\

OUTER PAD SHIM

r--- Replace..ffiPIN BOOTSReplace.

-61

@@-t-.

"l-r,r., "or"'*o " orr" I @.,23 N.m {2.3 kgtm, 17lbf.ftl \@

PISTON SEALReplace.

CALIPEBBRACKET

iiilji:ll;;

__X.,,..".^

BRAKE PAOS

PISTON

l/CALIPER BMCKET \MOUNTINGEOLTS ----.-,o,

54 N.m (5.5 kgf.m, 40lbl.ft) q%

Page 1189 of 2189

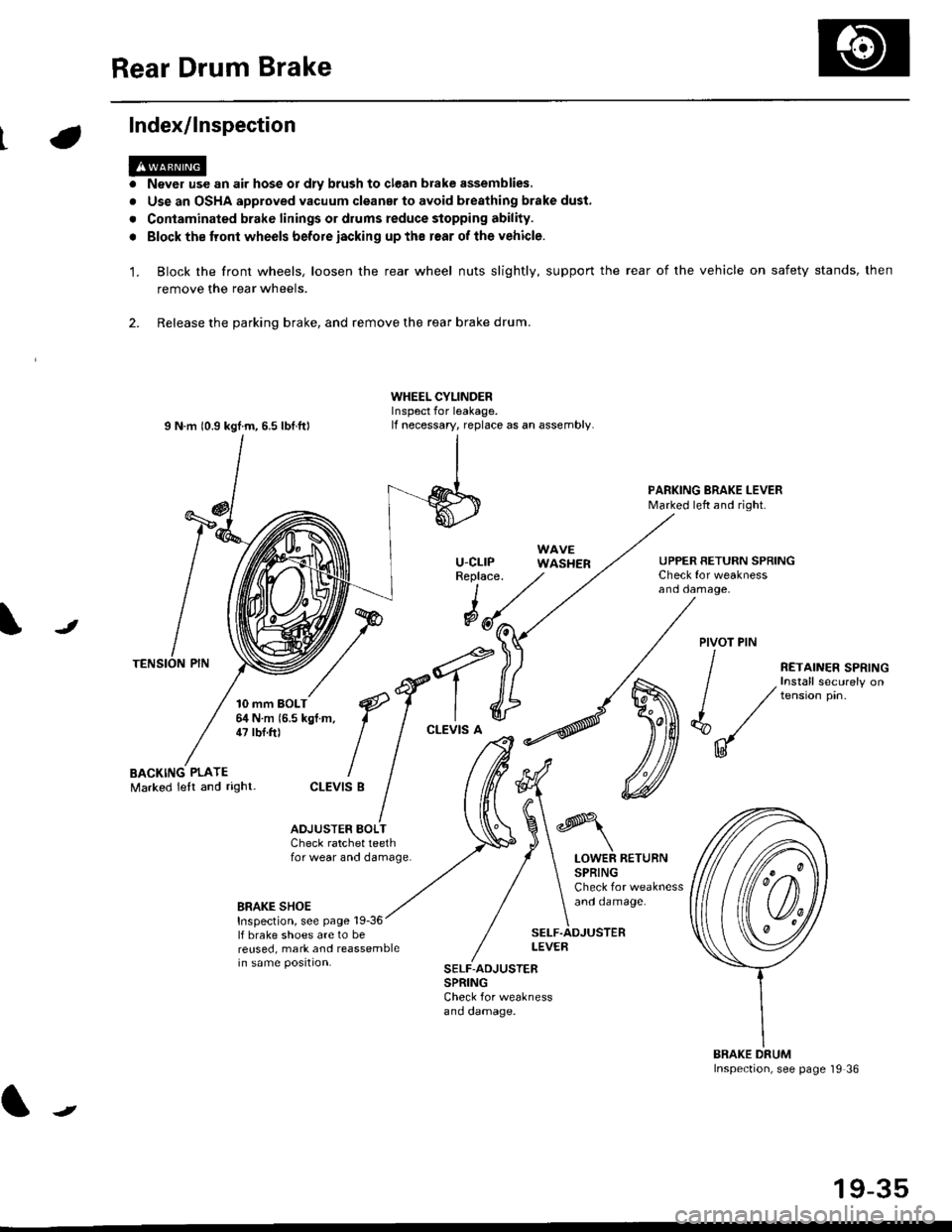

Rear Drum Brake

Index/lnspection

'1.

a

a

Never use an air hose or dly brush to clean brake assemblies,

Use an OSHA approved vacuum cleanar to avoid breathing brake dust,

Contaminated brake linings or drums reduce stopping ability.

Block the tront wheels before iacking up ths r€ar of lhe vehicle.

Block the front wheels, loosen the rear wheel nuts slightly, support the rear of the vehicle on safety stands, then

remove the rear wheels.

2. Release the parking brake, and remove the rear brake drum.

I N m 10.9 kgtm, 6.5 lbf.ftl

TENSION PIN

10 mm BOLT6,1N m 15.5 kgf m,47 tbf.ft)

WHEEL CYLINDERInspect for leakage.lf necessary, replace as an assembly.

u-cLrPReplace.

WAVEWASHER

PARKING BRAKE LEVERMarked left and right.

Check for weaknessano oamage,

UPPER RETURN SPRING

I

@JPIVOT PIN

BACKING PLATEMarked lelt and right-

/

€f-l.^

I I

*'t")

ctEv'sB

/ (t

/ ,.ro,".r r.*,"n

/ , Install securely on

| / tension pin.

d"/

IU

ADJUSTER BOI-TCheck ratchet teethfor wear and damage.LOWER RETURNSPRINGCheck for weaknessand oamage.BRAKE SHOEInspection, see page 19-36lf brake shoes are to bereused, mark and reassemblein same position.

SELF.ADJUSTERLEVEB

SELF-ADJUSTERSPRINGCheck for weaknessano oamage.

BRAKE DRUMInspection, see page '19 36

t

19-35

Page 1208 of 2189

tJ

t\

Kickback

1. The motor operates when the ABS is functioning, and the fluid in the reservoir is forced out to the master cylinder

causing kickback at the brake pedal.

2. TheABScontrol unit operates the solenoid valve when the brake pedal is released afterthe initial diagnosis Youmay

hear the faint solenoid valve operation sound at this time. but it is normal.

Pump Motor

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the faint operation sound

at this time. but it is normal.

Brake Fluid Replacament/Air Blsading

1. Brake fluid replacement and air bleeding procedures are the same as for conventional brakes

Troubleshooting

1. The troubleshooting flowcharts explain the procedures on the assumption that the cause of the problem is still pre-

sent and the ABS indicator light is still on.

Note that troubleshooting following the flowchart when the ABS indicator light does not come on can result in incor-

rect judgment.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

self,diagnosis is made at various times such as the initial diagnosis, except ABS control. during ABS control, during

acceleraiion, during the specified vehicle speed, etc. Therefore, the symptom cannot be checked unless the check

conditions match with the problem conditions

3. When the ABS indicator light does not come on during the test drive, but the troubleshooting is performed based on

the DTC, check for the loose connectors. poor contact of the terminals, etc, before troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the car. Be sure that the ABS indicator light does not come on.

5. The connector illustrations show the female connectors with a single outline and the male connectors with a double

ouflrne.

6. The connector terminal cavities containing female terminals are always numbered by looking at the connector from

the wire side. and the cavities containing male terminals are always numbered by looking at the connector from the

terminal side.

r'

19-55

Page 1213 of 2189

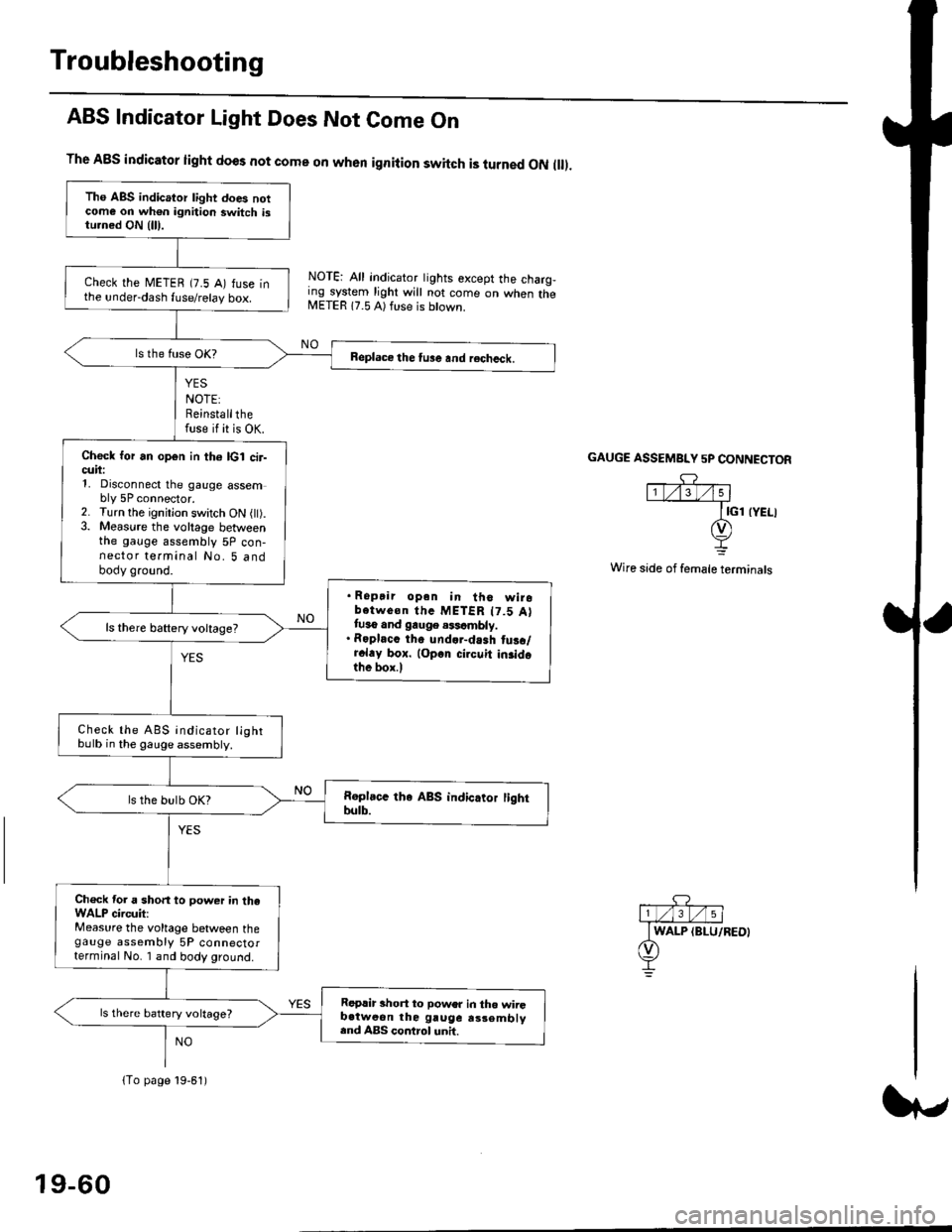

Troubleshooting

ABS Indicator Light Does Not Come On

YES

NOTE:Reinstallthefuse if it is OK.

The A8S indicator light does not come on when ignition switch is turned ON ll.

NOTE: All indicator tights except the charg,ing system light will not come on when theMETER 17.5 A) ft se is btown.

NO

GAUGE ASSEMBI"Y 5P CONNECTOR

Wire side of female terminals

Tho ABS indicator light does notcome on wh€n ignition switch istu.ned ON {lll.

check the METEB (7.5 A) fuse inthe under-dash fuse/relay box.

Beplace the tu3e and recheck.

Check for an open in th6 lcl cir-cuii:1, Disconnect the gauge assembly 5P connector.2. Turn the ignitjon switch ON l).3. Measure the voltage betweenthe gauge assembly 5P con-nector terminal No. 5 andbody ground.

. Ropair opan in tho wirobotwe€n thc METER t7.5 Attuso and gauge .$cmbly.. Roplacc th. und.r-dash tus./r.l.y box. lop.r cirouit in3idothe box.l

ls there baftery voltage?

Check the ABS indicator lightbulb in the gauge assembly.

ls the bulb OK?

Ch€ck tor a short to power in theWALP circuit:Measure the voltage between thegauge assembly 5P connectorterminal No. I and body ground.

Replir short to power in tho wiiGb.tweon the gruge rs3embly.nd ABS control unh.

ls there battery voltage?

lTo page 19-61)

19-60

Page 1214 of 2189

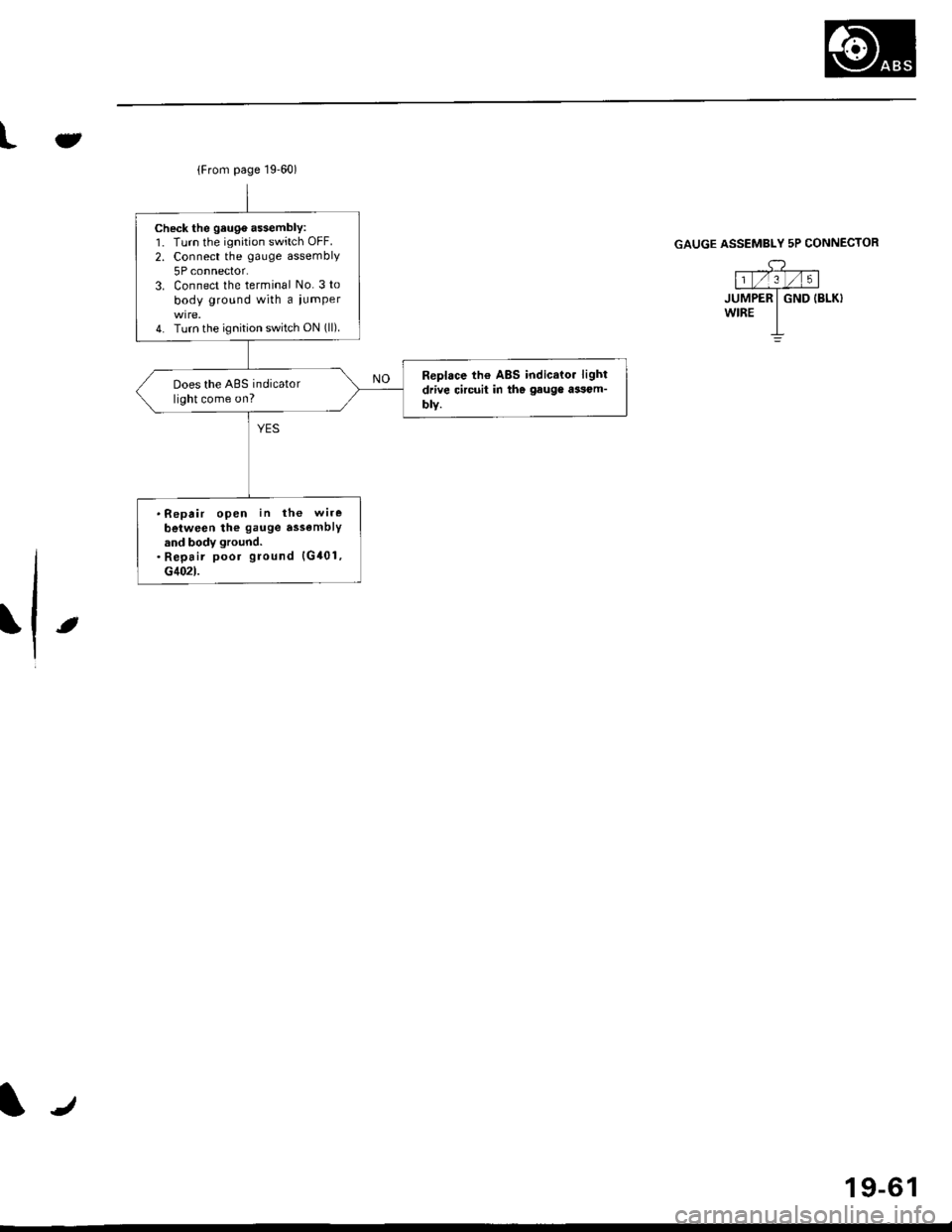

{From page 19.60)

Check the geuge a$embly:1. Turn the ignition switch OFF.

2. Connect the gauge assembly

5P connector.3. Connect the terminal No. 3 to

body ground with a iumper

4. Turn the ignition switch ON (ll).

Replace th€ ABS indicato. light

drive circuit in the gauge ai3om-

blY.

Does the ABS indicatorlight come on?

.Repair open in the wire

beiween the gauge assemblYand body ground.. Repair poor ground {G401,G402t.

Jt

GAUGE ASSEMBLY 5P CONNECTOR

,c? "l1t/'.lt/t5 |

JUMPER I GND IBLK}wrRE I-L

t

19-61

Page 1215 of 2189

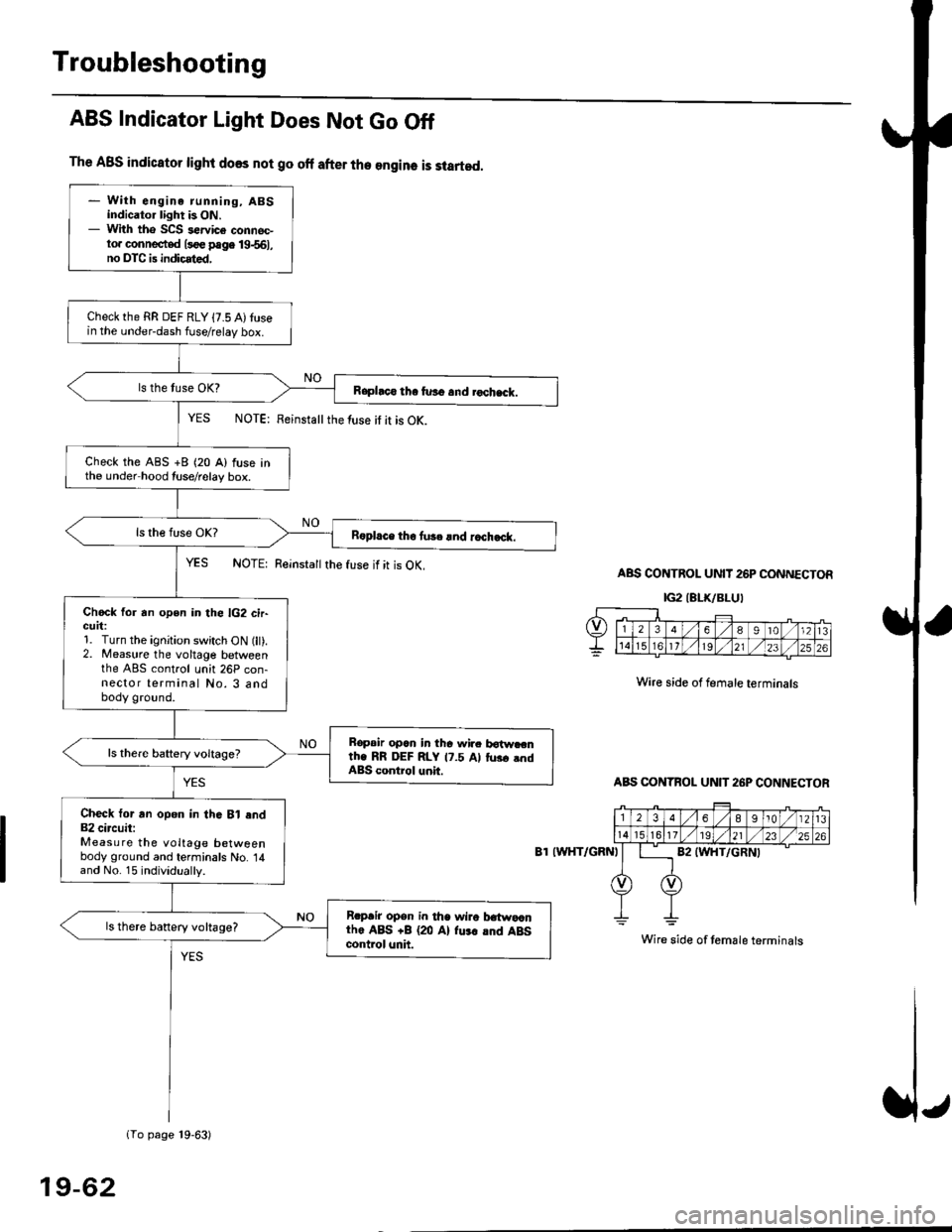

Troubleshooting

The ABS indicator light does not go off after the engine is started.

- With engine running, ABSindicator light is ON.- With tho SCS sewice connec-to. connected l3oe page 19-561,no DTC is indicated,

Checkthe RR DEF RLY {7.5 A)tusein the under-dash fuse/relay box.

Raphco tha furo and rochack.

Check the ABS +B (20 A) fuse inthe under hood tuse/relay box.

R6pl.ce tho tu3c lnd r.ch.ck.

Chock for an open in the lG2 cir-GUrt:1. Turn the ignition switch ON (lt).2. Measure the voltage betweenthe ABS control unh 26P con-nector terminal No. 3 andbody ground.

Bopair opcn in tha wir. botw.cnth. RR DEF RLY 17.5 Al tus. .ndABS control unit.

Check tor an opon in thG Bl end82 circuit:Measure the voltage betweenbody ground and terminals No. 14and No. 15 individually.

Rrpair opsn in tha wiro t atwa,anthe ABS +B (20 Al fu.r .nd ABScontrol unh.

ls there banery voltage?

1To page 19-63)

ABS Indicator Light Does Not Go Off

YES NOTE: Feinstattthe luse it it is OK.

YES NOTE: Reinsta

the fuse if it is OK.ABS CONTROL UNIT 26P CONNECTOR

IG2IELK/BLUI

Wire side of female terminals

ABS CONTBOL UN]T 26P CONNECTOR

8T IWHT/GRNI

Wire side of temale terminals

19-62

Page 1216 of 2189

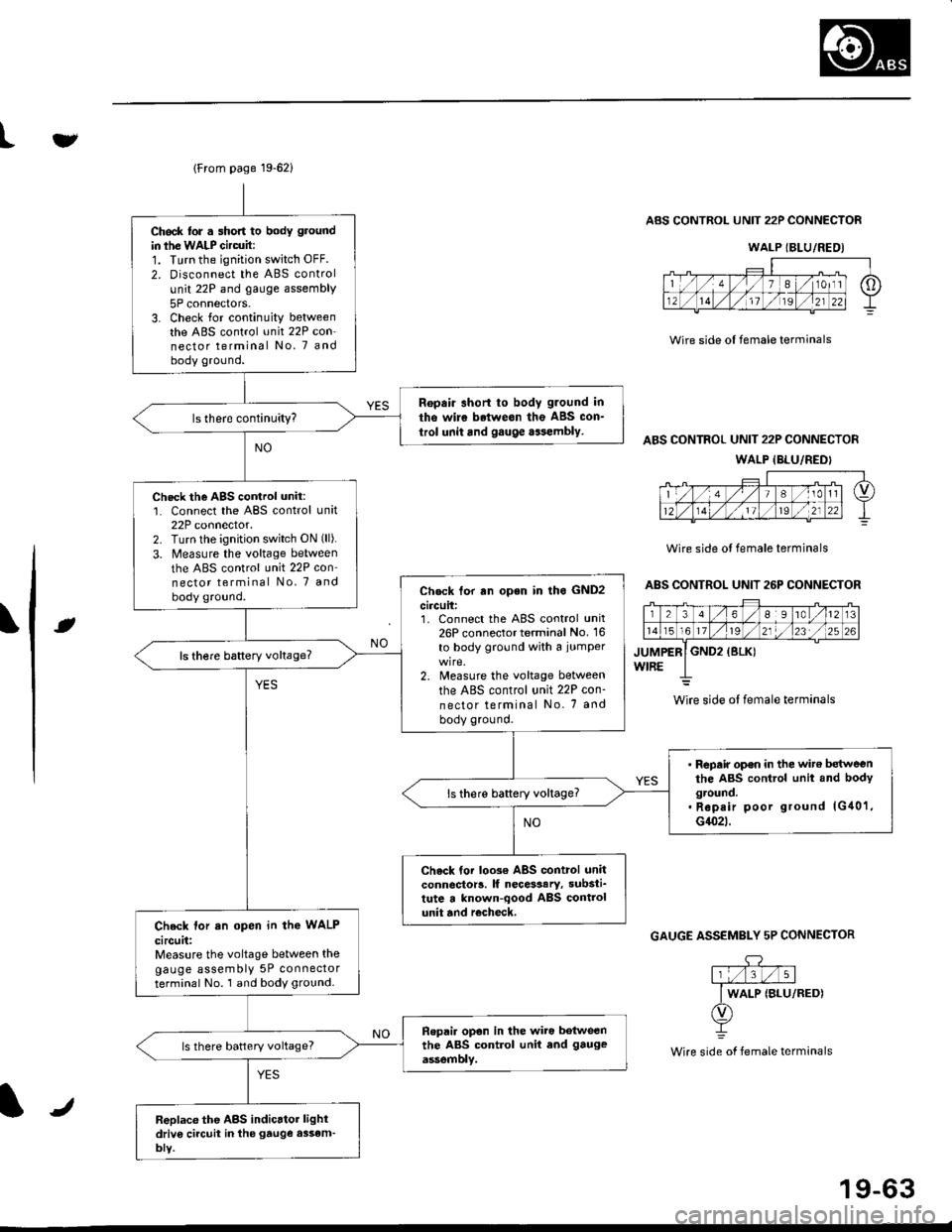

lFrom page 19-621

Ch6ck lor . short to body ground

in ihe WALP Gircuit:1. Turn the ignition switch OFF.

2. Disconnect the ABS control

unit 22P and gauge assembly

5P connectors.3. Check for continuity betweenthe ABS control unit 22P con-nector terminal No. 7 andbody ground.

Ropair short to body g.ound in

tho wire betweon the ABS con_

trol unit and gauge aasembly.

Check the AgS cortrol unit:1. Connect the ABS control unit22P connector.2. Turn lhe ignition switch ON (ll).

3. Measure the voltage between

the ABS control unit 22P con'nector terminal No, 7 and

body ground.Check tor rn open in lho GND2

circuit:1. Connect the ABS control unit26P connector terminal No. 16

to body ground with a iumper

2. Measure the voltage between

the ABS control unit 22P con-

nector terminal No. 7 and

body ground.

ls there baftery voltage?

' Repair op€n in the wit€ betweenthe ABS control unit and bodyground.. Rep.ir poor ground lG40'1,G1(}2t.

ls there battery voltage?

Check tor loo3€ ABS control unitconnector!. lf necesaary, substi_tute a known-qood ABS controlunit and r€check,Check lor an open in the WALP

circuit:Measure the voltage between thegauge assembly 5P connectorterminal No. 1 and body ground.

Ropai. opon in the wiro botweenthe ABS control unit end gauge

assemblv.ls there battery voltage?

Replace the ABS indicrtor lightdriv6 ci.cuit in the gtuge assem-bly.

tv

Wire side ol female terminals

ABS CONTROL UNIT 22P CONNECTOR

ABS CONTROL UNIT 22P CONNECTOR

WALP {BLU/REDI

Wire side ol female terminals

ABS CONTROL UNIT 26P CONNECTOR

rt

GAUGE ASSEMBLY 5P CONNECTOR

.DY

Wire side of female terminals

WALP {BLU/REDI

wire side ol female terminals

J

19-63