23-9 HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 1471 of 2189

l'f .

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1479 of 2189

D

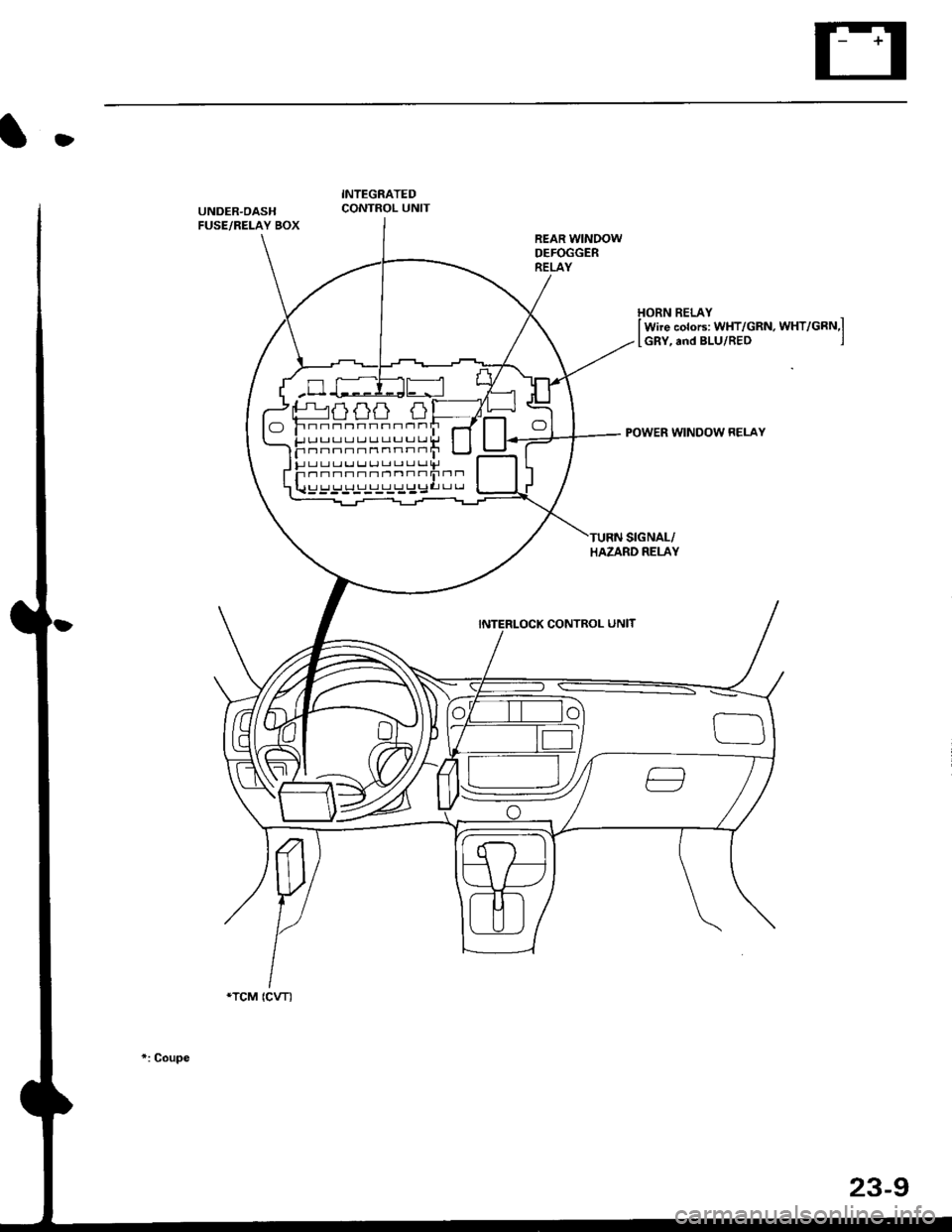

INTEGRATEDCONTROL UNITUNDER.OASHFUSE/RELAY BOX

HORN RELAYI Wire colors: WHT/GRttt, WXf/Cnru,l

[GRY, and BLU/RED ,J

POWER WINDOW RELAY

INTERLOCK CONTROL UNIT

'gtP"tat{}r) (}t /t t ------,)

F;;snHn-nnn"nf-H-n o

F !r rr rr rr r,r Lr Ll u u l,r

Fnnnnnnnrrrr-1F rr rr rJ LJ rJ r-r t-r L-r LJ Lr ||J

u_::;_:_:_:_:_l_;I::

*TCM (CVT)

*: Coupe

23-9

Page 1560 of 2189

lgnition Switch

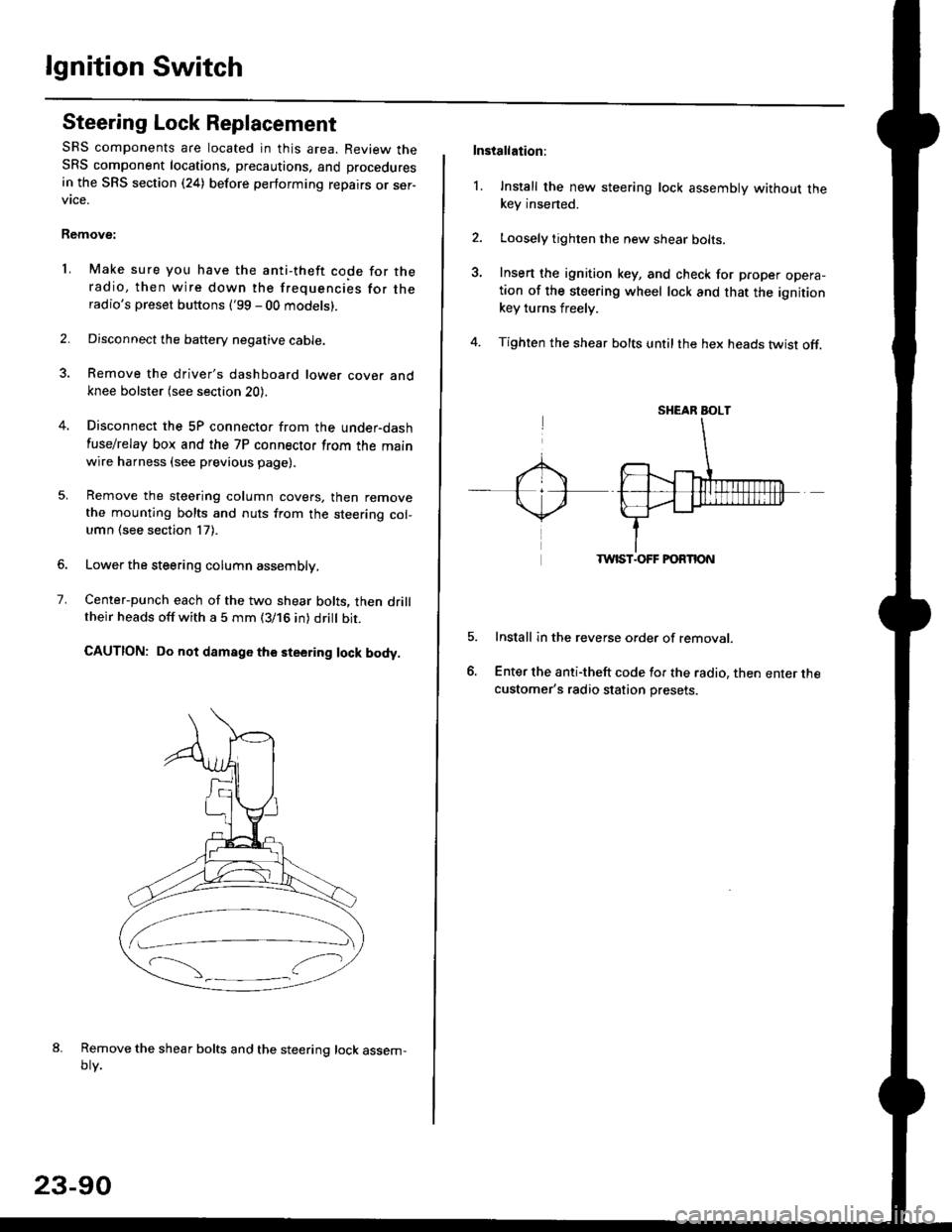

Steering Lock Replacement

SRS components are located in this area. Review theSRS component locations. precautions, and procedures

in the SRS section (24) before performing repairs or ser-vtce.

Remove:

LMake sure you have the anti-theft code for theradio, then wire down the frequencies for theradio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable.

Remove the driver's dashboard lower cover andknee bolster (see section 20).

Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connector from the mainwire harness (see previous page).

Remove the steering column covers, then removethe mounting bolts and nuts from the steering col-umn (see section l7).

Lower the steering column assembly,

Center-punch each of the two shear bolts, then drilltheir heads off with a 5 mm (3/16 in) dritt bit.

CAUTION: Do not damago the steering lock body.

Remove the shear bolts and the steering lock assem,oty.

2.

1.

23-90

Installation:

l. Install the new steering lock assembly without thekey insened.

Loosely tighten the new shear bolts-

Insert the ignition key, and check for proper opera-tion of the steering wheel lock and that the ignitionkey turns freely.

Tighten the shear bolts untilthe hex heads twist off.

TWIST.OFF FORTION

Install in the reverse order of removar.

Enter the anti-theft code for the radio, then enter thecustomer's radio station presets.

sr{€aR SroLT

Page 1561 of 2189

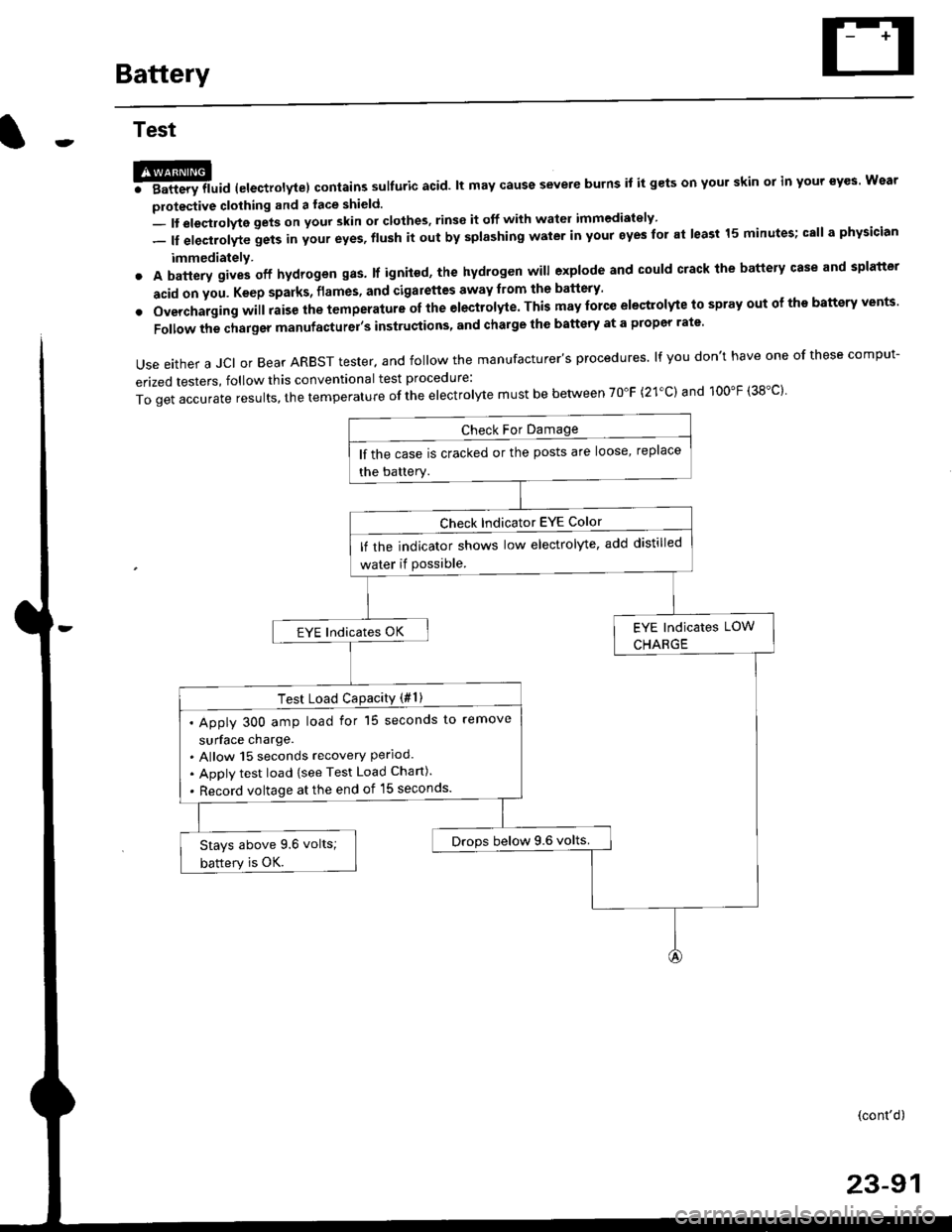

Battery

Test

@l. Battery lluid lelectrolytel contalns sulfuric acid. lt may cause severe burns it it gets on your skin ol in your eyes Wear

protective clothing and a face shield.

- It eleqtlolyte gets on your skin or clothes, rinse it off with watel immediately

- lf electrolyte gets in your eyes, flush it out by splashing water in your eyes for at least 15 minutes; call a physician

immediately.

. A battery gives off hydrogen gas. lf ignited, the hydrogen will explode and could crack the battery case and splatter

acid on you. Keep sparks, flames, and Gigarettes away from the battery'

o Overchaiging will raise the temperature oI the electrolyte. This may force electrolyte to spray out ot ths battery vents'

Follow the charger manufacturel's instrustions, and chalge the battery at a propcr rate.

Use either a JCI or Bear ARBST tester. and follow the manufacturer's procedures. lf you don't have one of these comput-

erized testers, follow this conventional test procedure:

ToqetaccurateresuIts,thetemperatureoftheeIectro|ytemustbebetweenT0"F(21.c)and100"F(38.c}'

lf the case is cracked or the posts are loose, replace

the battery.

lf rhe indicator shows low electrolyte, add distilled

water if Possible.

EYE lndicates OK

Test Load CaPacitY (#l )

. Apply 300 amp load for 15 seconds to remove

surface charge.. Allow 15 seconds recovery Perloo.. Apply test load {see Test Load Chan).

. Record voltage at the end of l5 seconds.

Drops below 9.6 volts.Stays above 9.6 volts;

battery is OK.

(cont'd)

23-91

Page 1562 of 2189

Battery

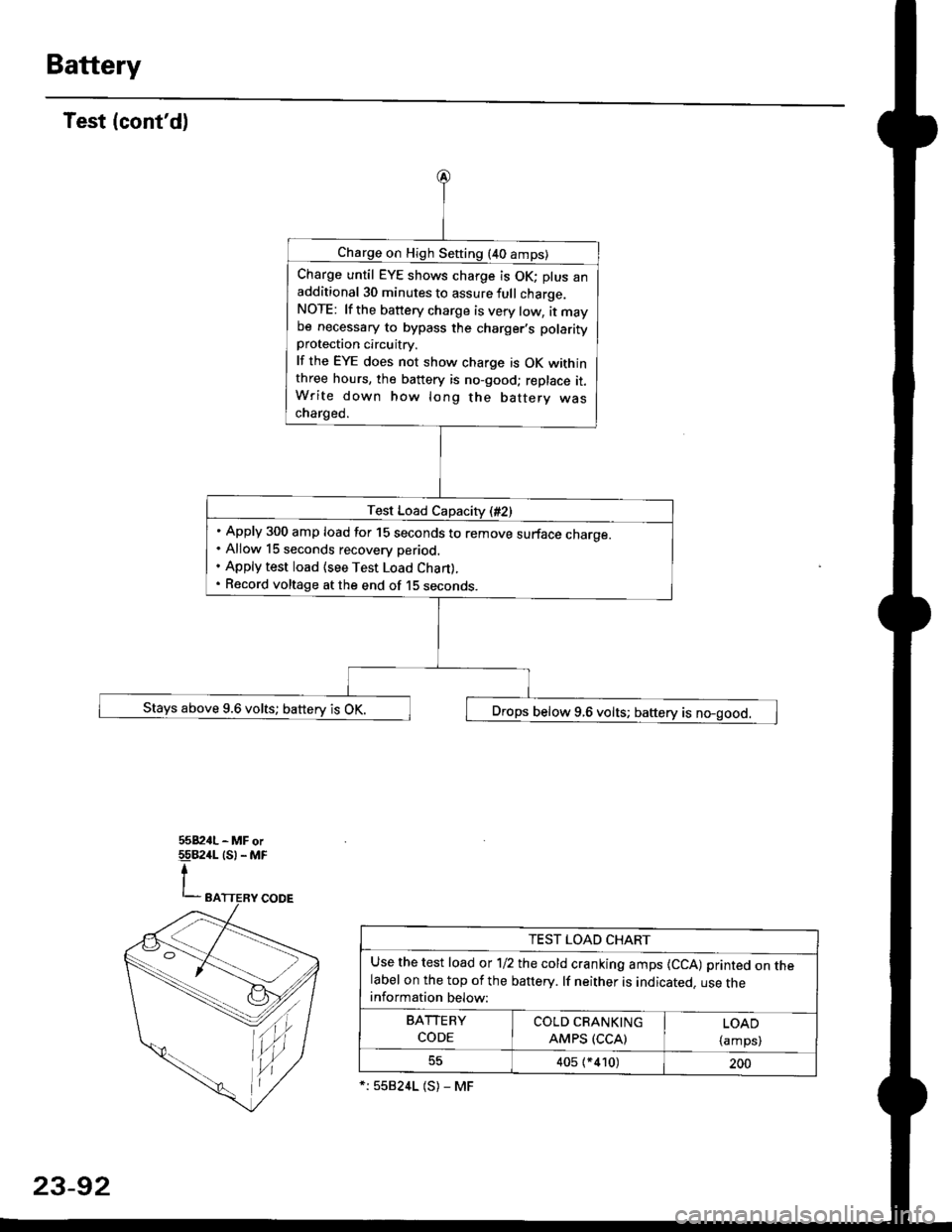

Test (cont'd)

Charge on High Sefting (40 amps)

Charge until EYE shows charge is OK; plus anadditional 30 minutes to assure full charge.NOTE: lf the battery charge is very tow, it maybe necessary to bypass the charger,s polarityprotection circuitry.

lf the EYE does not show charge is OK withinthree hours, the battery is no-good; replace it.Write down how long the battery wascharged.

Test Load Capacity (#2)

Apply 300 amp load for 15 seconds to remove surface charoe.Allow 15 seconds recovery period.

Apply test load {see Test Load Chan).

Record voltage at the end of 15 seconos.

Stays above 9.6 volts; battery is OK. ,] Drops below 9.6 volts; baftery is no-good.

tu,

TEST LOAD CHART

Use the test load or 1/2 the cold cranking amps {CCA) printed on thelabel on the top of the banery. lf neither is indicated. use theinformation below:

BArrERy coLb@

coDE I AMps (ccAl | {amps)

405 (*410)200

*:558241 (S) - MF

23-92

Page 1563 of 2189

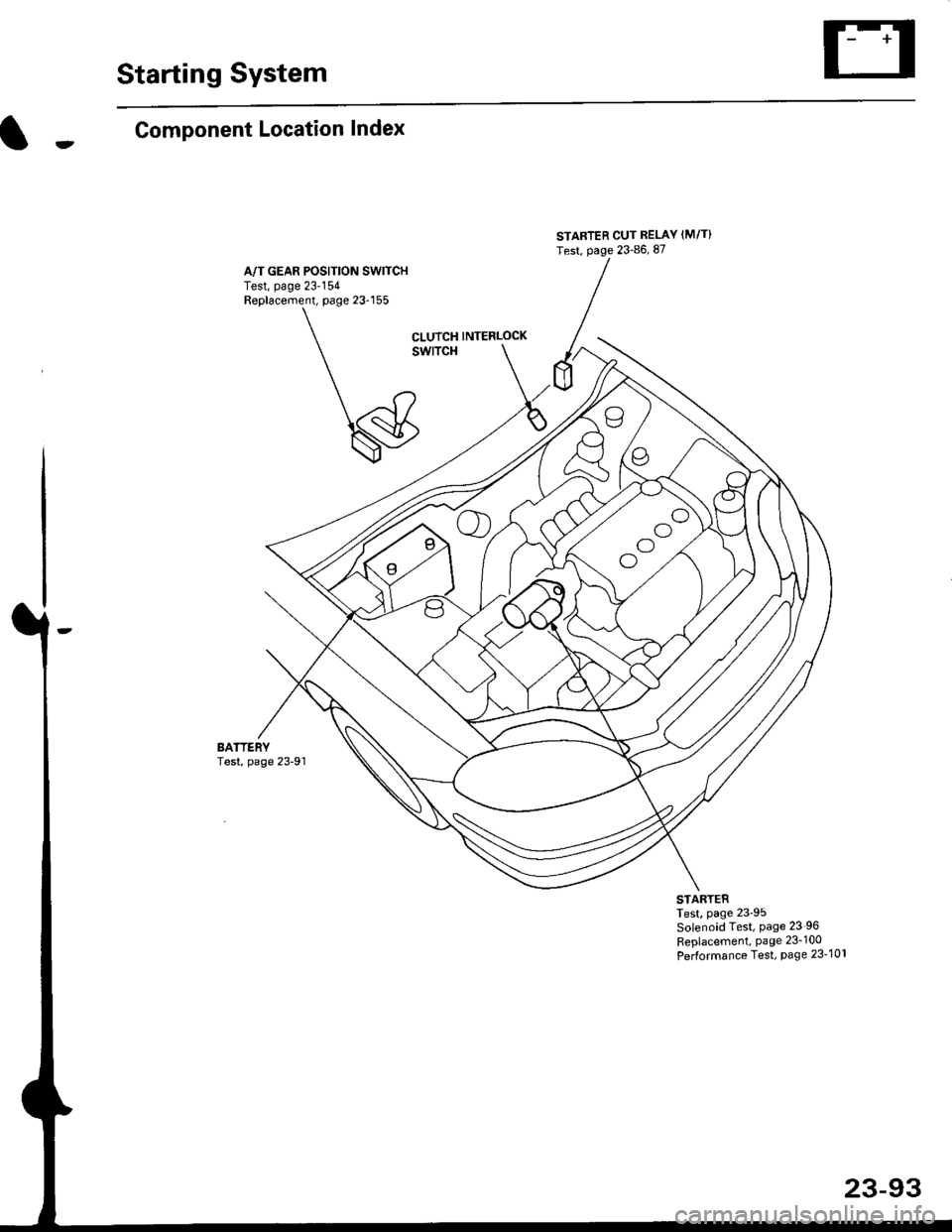

Starting System

Component Location Index

A/T GEAR POSITION SW|TCHTest, page 23'154Replacement, page 23-155

STARTER CUT RELAY (M/T}

Test, page 23-86, 87

oo

ool

CLUTCH INTERLOCK

swlTcH

BATTERYTest, page 23-91

STARTERTest, page 23'95Solenoid Test, Page 23 96

Replacement, Page 23-100

Performance Test, Page 23-101

23-93

Page 1564 of 2189

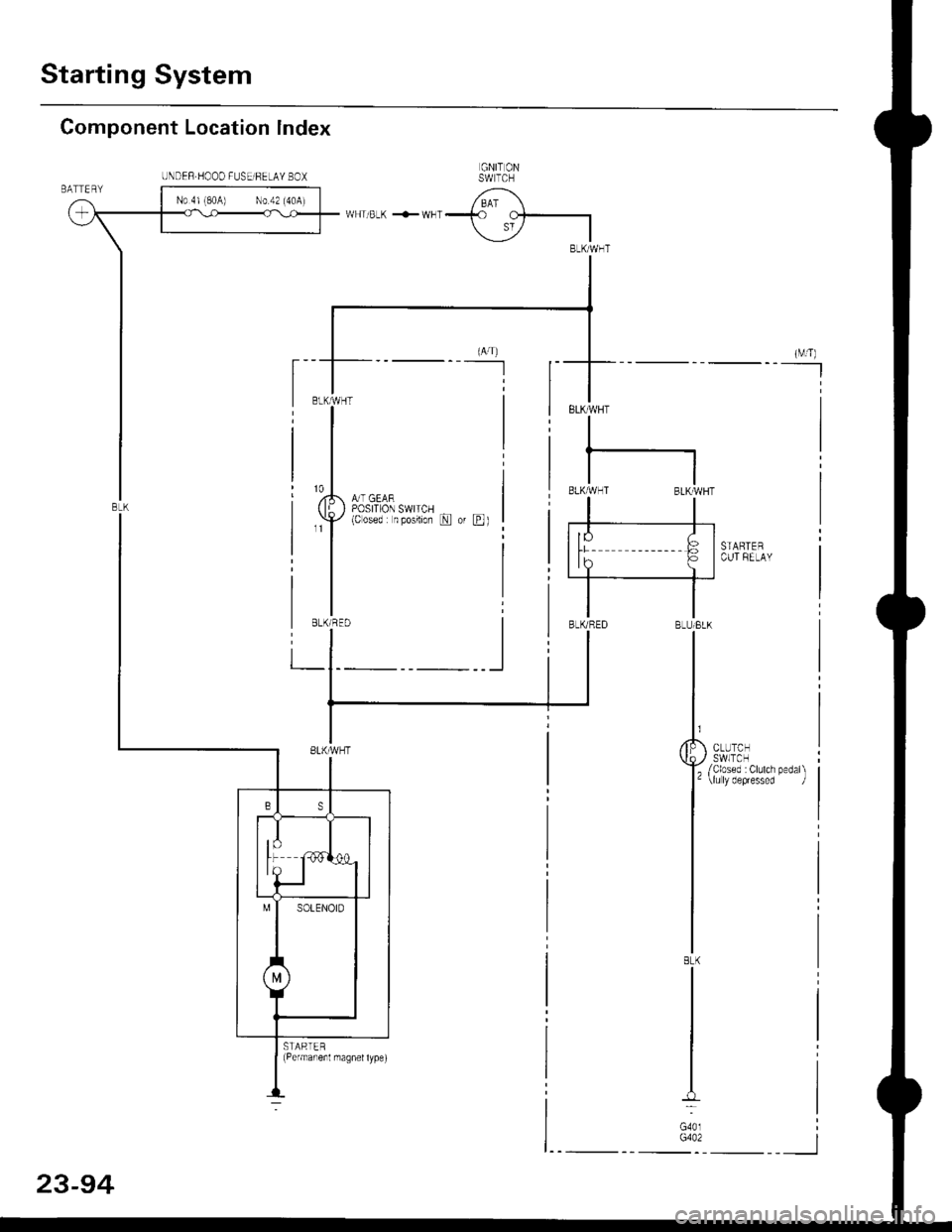

Starting System

Component Location lndex

GNIT ONSW TCH

t,U,-*€,-l

&T GEARPOSITION SWITCH(Cosed n posilion N or E)

ELKMHT

I

tl81X,4{HT BLKIWHT

STARTERCUT FELAY

STAPTER(Permaneit nragnel type)

N0 4l (80A) N0 42 (40A)

UNDEF.HOOO FUSEiFELAY BOX

-

__l

23-94

Page 1565 of 2189

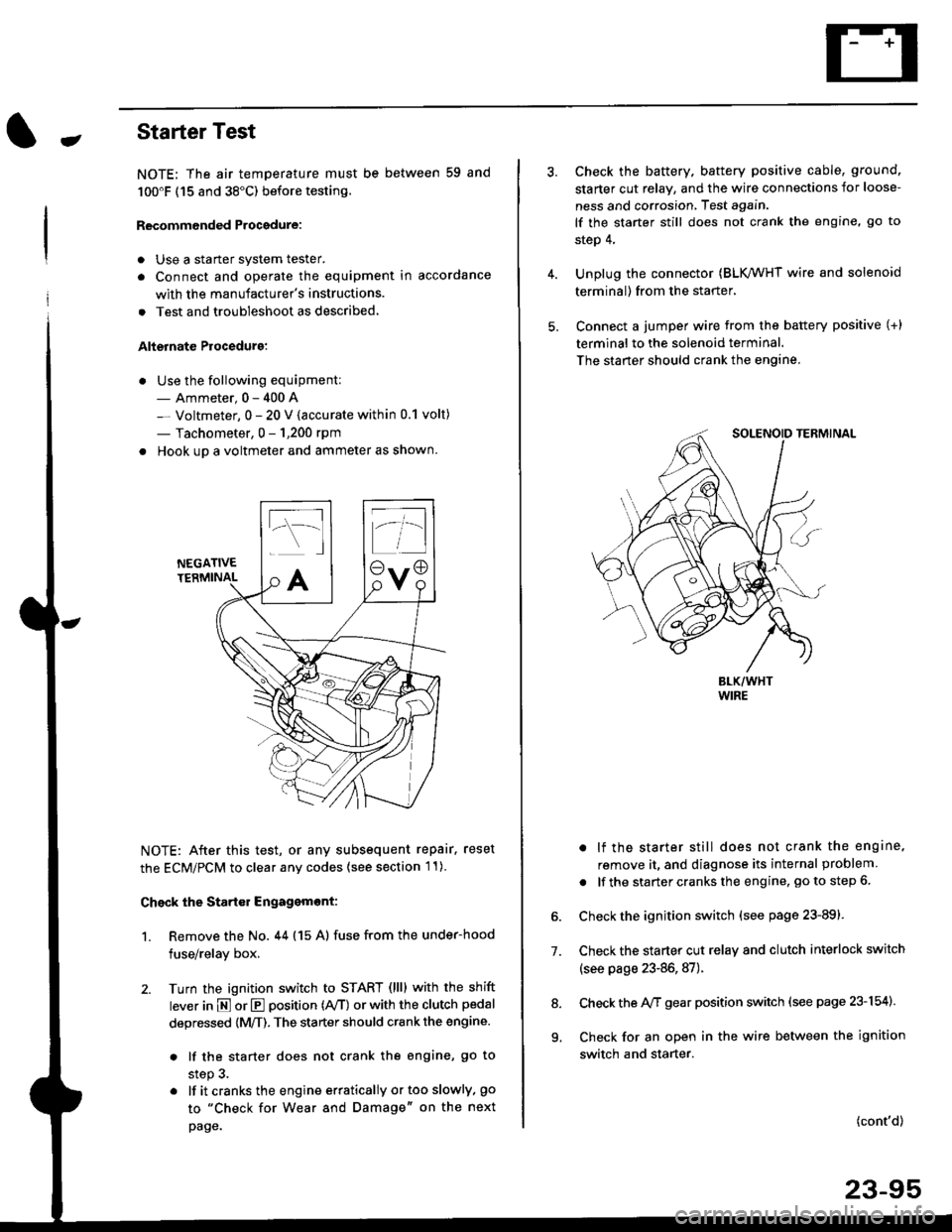

-Starter Test

NOTE; The air temoerature must be between 59 and

100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described,

Alternate Procedurg:

. Use the following equipment:- Ammeter, 0 - 400 A

- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

- Tachometer, 0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NEGATIVETERMINAL

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section l1)

Check the Start€r Engagemont:

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

2. Turn the ignition switch to START (llll with the shift

lever in E or E position (rVT) or with the clutch pedal

depressed {M/T). The starter should crank the engine.

. lf the starter does not crank the engine, go to

step 3.

. lf itcranksthe engineerraticallyortooslowly, go

to "Check for Wear and Damage" on the next

page.

Check the battery. battery positive cable, ground,

starter cut relay, and the wire connections for loose-

ness and corrosion, Test again.

lf the starter still does not crank the engine, go to

step 4,

Unplug the connector (BLK,/WHT wire and solenoid

terminal) from the starter,

Connect a jumper wire from the battery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem

. lf the startercranksthe engine, goto step 6.

Check the ignition switch (see page 23-891.

Check the starter cut relay and clutch interlock switch

(see page 23-86,87).

Check the A/f gear position switch (see page 23-154).

Check for an open in the wire between the ignition

switch and starter.

7.

(cont'd)

23-95

9.

Page 1567 of 2189

JArmature Inspection and Test

1.Inspect the armature for wear or damage due to con-

tact with the permanent magnet or field winding.

. lf there is wear or damage. replace the armature.

Inspect for damage.

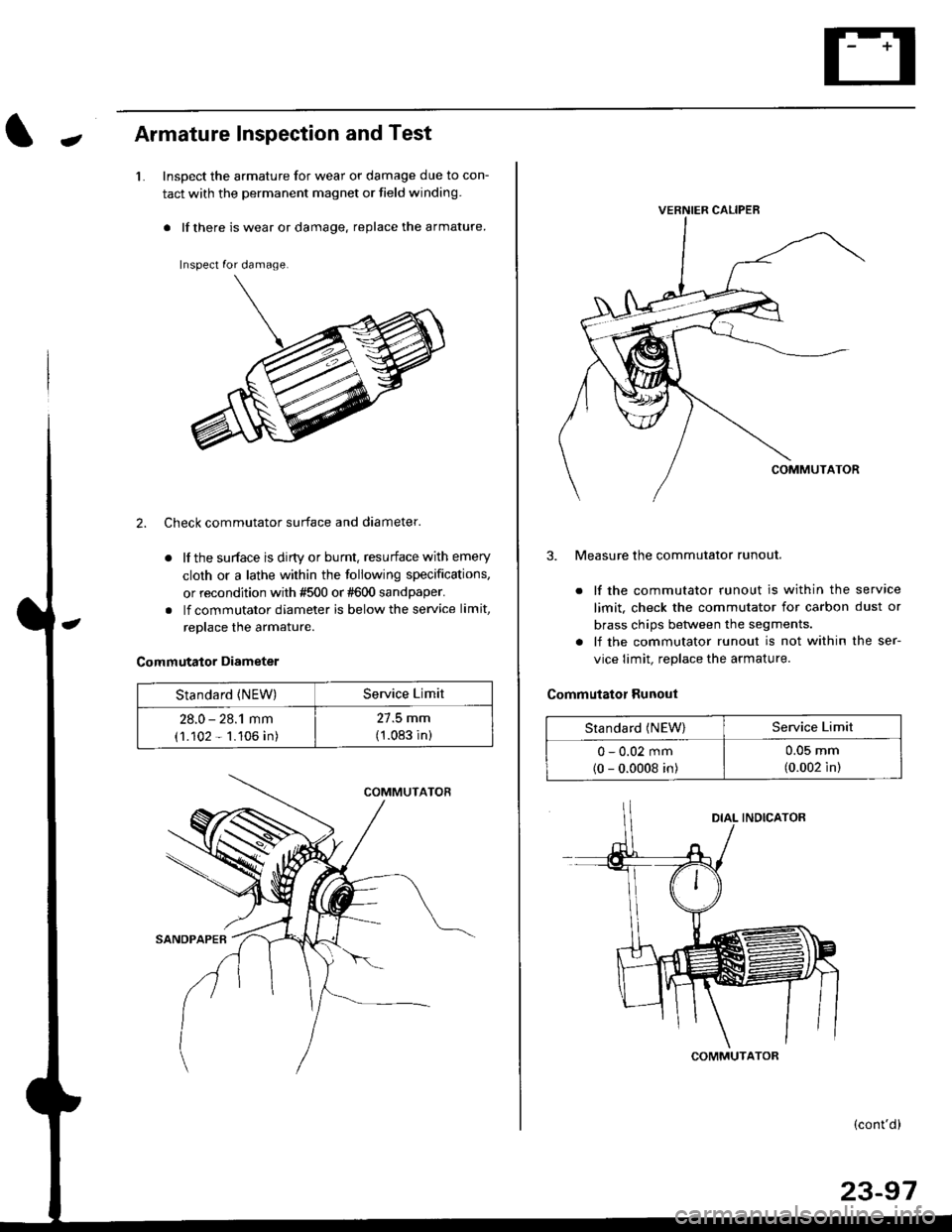

2. Check commutator surface and diameter.

. lf the surface is dirty or burnt. resurface with emery

cloth or a lathe within the following specifications,

or recondition with #500 or #600 sandpaper.

. lf commutator diameter is below the service limit,

replace the armature.

Commutator Diameter

Standard {NEW)Service Limit

28.0 - 28.1 mm

(1.102 - 1.106 in)

27.5 mm

(1.083 in)

VERNIER CALIPEB

3. Measure the commutator runout.

. lf the commutator runout is within the service

limit, check the commutator for carbon dust or

brass chips betlveen the segments.

. lf the commutator runout is not within the ser-

vice limit, replace the armature.

Commutator Runout

Standard (NEW)Service Limit

0 - 0.02 mm(0 - 0.0008 in)

u-u!r mm

(0.002 in)

COMMUTATOR

(cont'd)

23-97

Page 1568 of 2189

Starting System

Armature Inspection and Test (cont'dl

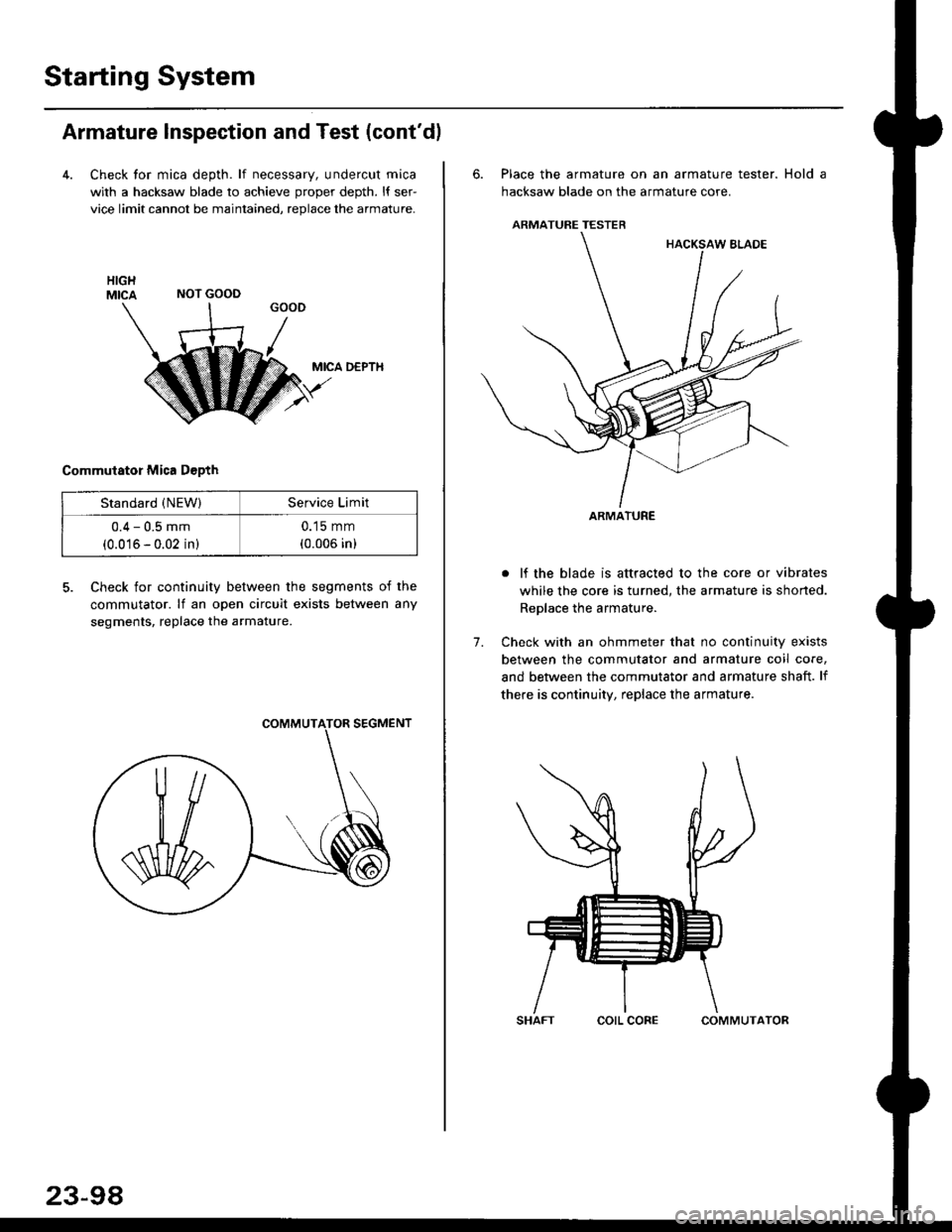

4. Check tor mica depth. lf necessary, undercut mica

with a hacksaw blade to achieve proper depth. l{ ser-

vice limit cannot be maintained, replace the armature.

MICA D€PTH

Commutator Mica D€pth

5. Check for continuity between the segments of the

commutator. lf an open circuit exists between any

segments, replace the armature.

NOT GOOD

Standard (NEW)Service Limit

0.4 - 0.5 mm

(0.016 - 0.02 in)

0.15 mm

(0.006 in)

23-98

corL coFECOMMUTATOR

6. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

ARMATURE TESTER

. lf the blade is attracted to the core or vibrates

while the core is turned, the armature is shorted.

Replace the armature.

7. Check with an ohmmeter that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. lf

there is continuity, replace the armature.

ARMATURE