Flywheel HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 52 of 2189

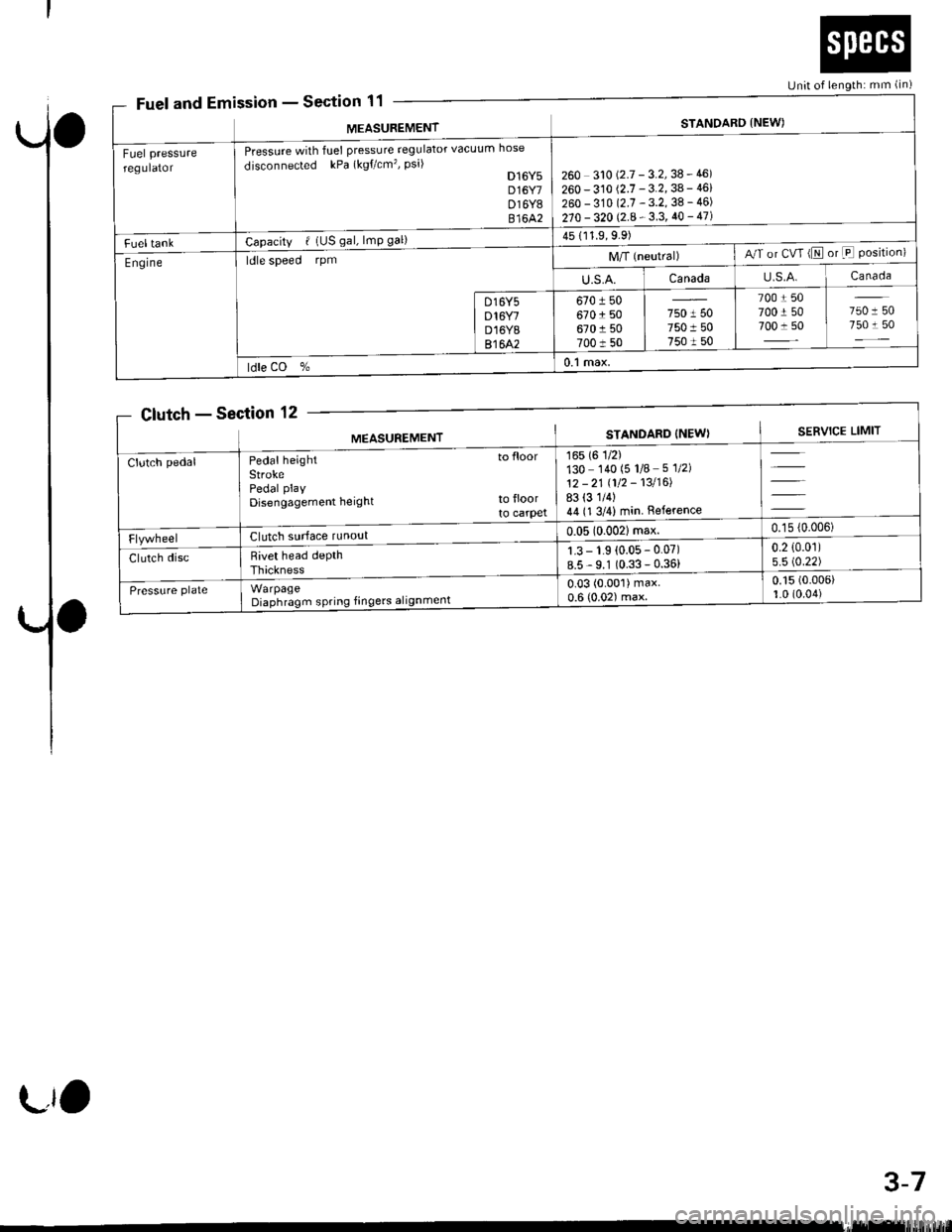

Unit of length: mm (in)

Fuel and Emission - Section

MEASUREMENTSTANOARO (NEW)

260 310 (2.7 - 3.2, 38 - 46)

260 - 310 (2.7 - 3.2, 38 - 46i

260 - 310 (2.7 - 3.2, 38 - 46)

210 - 320 Q.A - 3.3, 40 - 47 1

45 {11.9, 9.9)

M/T (neutral) I A/T or C\.T (lE or fd positioni

Fuel paessure

regulator

Pressure wilh fuel pressure regulator vacuum hose

disconnected kPa (kgvcm'�, Psi)D16Y5D 16Y7D16Y881642

FueltankCapacity I (US gal, lmp gal)

E ngineldle speed rpm

016Y5D16Y7D16Y8816A2

u.s.A.CanadaU,S,A.Canada

670 1 506701 50670150700 t 50

7501 507501 507501 50

700 t 50700 I 507001 50750150750 r 50

ldle CO %0.1 max.

Clutch - Serrtion 12

MEASUREMENTSTANDARD {NEWI I SERVICE LIMIT

Clutch pedalPedal height to floor

StrokePedal play

Disengagement height to floorto carpet

16s (6 1/2)130 140 (5 1/8 5 1/2)

12 -21 t1l2 - 13/16183 (3 1/4)44 (1 3/4) min. Reference

FlywheelClutch surface ruoout

Rivet head depthThickness

0.05 (0.002) max.0.15 (0.006)

Clutch disc1.3- 1.9 (0.05 - 0.07)

8.5 - 9.1 (0.33 - 0.36)

0.2 {0.01)5.5 (0.22)

Pressure plateWarpageDiaphragm spring fingers alignment

0.03 (0.001) max0.6 (0.02) max

0.15 (0.006)

1.0 (0.04)

Lro

3-7

lfllHlllllllllrltllli[

Page 60 of 2189

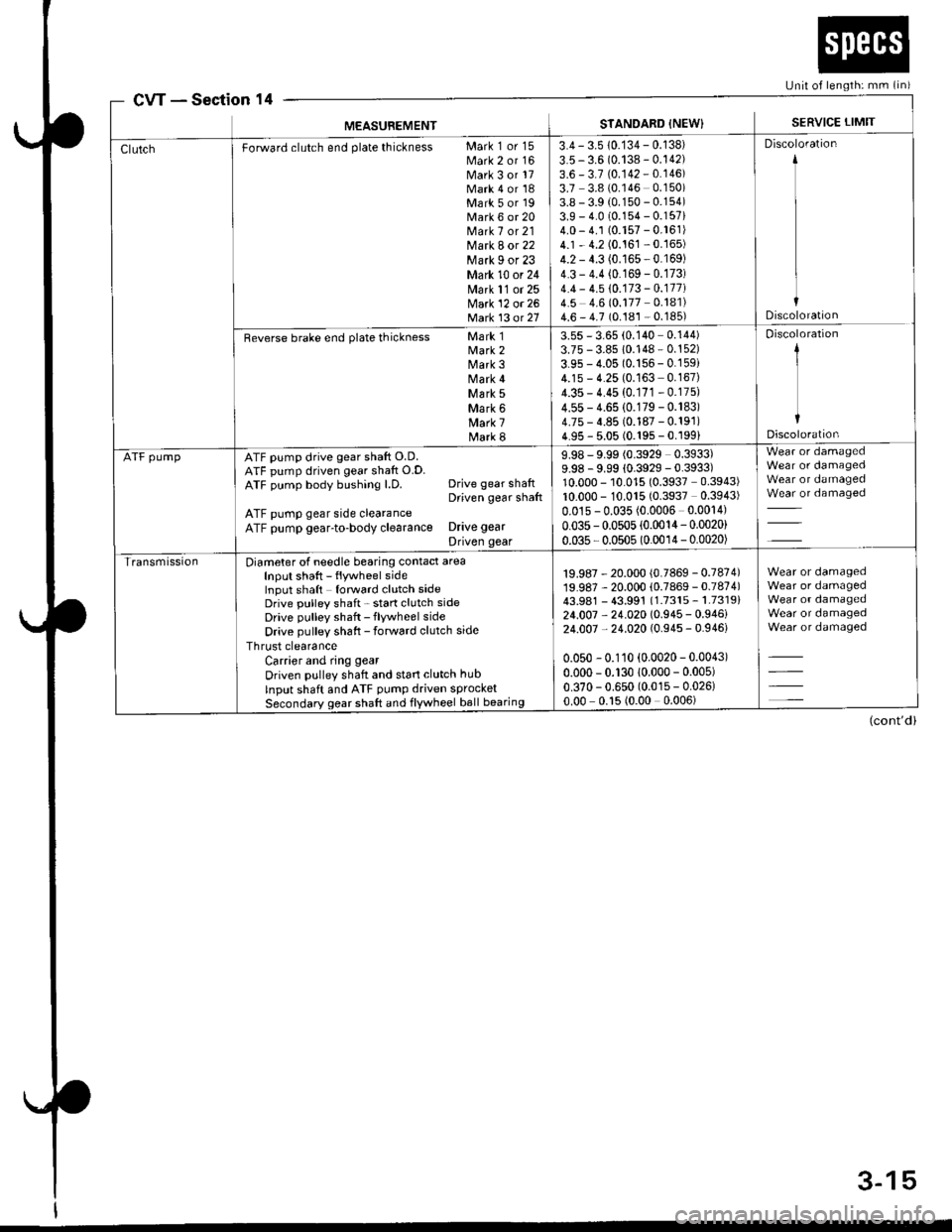

cwSection 14[Jnit of length: mm (in)

MEASUBEMENTSTANDARD {NEW}SERVICE LIMIT

Forward clutch end plate thickness Mark 1 or 15Mark 2 or 16Mark 3 or 17Mark 4 or 18Mark 5 or 19Mark 6 or 20Mark 7 or 21Mark 8 or 22Mark I or 23Mark 10 or 24Mark 11 or 25Mark 12 or 26Matk 13 ot 21

3.4 - 3.5 10.134 - 0.138)

3.5 - 3.6 (0.138 - 0.142)3.6 - 3.7 (0.142 - 0.146)3.7 3.8 (0.146 0.150)3.8 - 3.9 (0.150 - 0.154)3.9 - 4.0 (0.154 - 0.157i4.0 - 4.1 (0.157 - 0.161)4.1 - 4.2 (0.161 - 0.165)4.2 - 4.3 (0.165 - 0.169)4.3 - 4.4 (0.169 - 0.173)4.4 - 4.5 10.173 - 0.177i4.5 4.6 (0.177 0.181)4.6 - 4.7 (0.181 - 0.185)

Discoloration

Discoloration

Reverse brake end plate thickness Mark 1Mark 2Mark 3Mark 4\44 rk 5Mark 6Mark 7Mark 8

3.55 - 3.65 (0.140 0.144)3.75 - 3.85 10.148 - 0.152)

3.95 - 4.05 (0.156 - 0.159i4.15 - 4.25 (0.163 0.167)4.35 - 4.45 (0.171 - 0.175)

4.55 - 4.65 (0.179 - 0.183)4.75 - 4.85 (0.187 - 0.191)4.95 - 5.05 (0.195 - 0.199)

Discoloration

1

IDiscoloration

ATF pumpATF pump drive gear shaft O.D.ATF pump driven gear shaft O.D.ATF pump body bushing l.D. Drive gear shaftDriven gear shaft

ATF pump gear side clearanceATF pump gear-to-body clearance Drive gear

Driven gear

9.98 - 9.99 (0.3929 0.3933)9.98 - 9.99 {0.3929 - 0.3933)10.000 - 10.015 (0.3937 0.3943)10.000 - 10.015 (0.3937 0.3943)

0.01s - 0.035 (0.0006 0.0014)

0.035 - 0.0505 (0.0014- 0.0020)

0.035 - 0.0505 (0.0014 - 0.0020)

Wear or damagedWear or damagedWear or damagedWear or damaged

TransmissionDiameter of needle bearing contact areaInput shaft - flywheel sideInput shaft forward clutch sideDrive pulley shaft - start clutch sideDrive pulley shaft - flywheel side

Drive pulley shaft - forward clutch side

Thrust clearanceCarrier and ring gear

Driven pulley shaft and start clutch hub

Input shaft and ATF pump driven sprocketSecondary gear shaft and flywheel ball bearing

19.987 - 20.000 (0.7869 - 0.7874)19.987 - 20.000 (0.7869 - 0.7874)43.981 - 43.991 (1.7315 - 1.7319)24.007 - 24.020 (0.945 - 0.946)24.007 - 24.020 (0.945 - 0.946)

0.050 - 0.110 (0.0020 - 0.0043)

0.000 - 0.130 10.000 - 0.005)

0.370 - 0.650 (0.015 - 0.026)0.00 0.15 (0.00 0.006)

Wear or damagedWear or damagedWear or damagedWear or damagedWear or damaged

(cont'd)

3-15

Page 61 of 2189

Transmission(cont'd)

MEASUREMENT

Thrust shim,25 x 31 mm thickness

STANDARD {NEW}

rlz-r-osr-o.o+o oolrr1.09 - 1.12 (0.043 0.044)1.16 1.19 (0.046 - 0.047)1.23 1.26 (0.048 0.050)1.30 - 1.33 (0.051 0.052)1.37 - 1.40 (0.054 0.055)1.44 - 1.47 (0.057 0.058)1.51 1.54 (0.059 0.061)1.58 1.61 (0.062 - 0.063)1.65 - 1.68 (0.065 0.066)1.72 1.75 {0.068 0.069)1.79 1 .a2 t0.O10 - 0.012]}1.055 1.085 (0.0415 0.0427)1.125 - 1.155 (0.0443 0.0454)1.195 - '�I.225 (0.0470 0.0482)1.265 - 1.29s (0.0498 0.0510)1.335 1.365 (0.0526 - 0.0537)1.40s - 1.435 (0.0553 - 0.0565)r.475 1.505 {0.0580 0.0593)1.545 1.575 (0.0608 0.0620)1.615 1.645 (0.0636 - 0.0648)1.685 1.71510.0663 - 0.0675)1.755 - 1.785 {0.0691 0.0703)

SERVICE LIMIT

I Wr"r - d-"-"g"d

ii

11

ir

Cotters thickness2.87 - 2.90 (0.1 13 - 0.114)2.97 - 3.00 (0.117 0.118)3.07 -3.10 \0.121 0.122)3.17 - 3.20 (0.125 0.126)

Wear,or damaged

IWear or damaoedATF pump drive sprocket thrust shim, 22 x 28 mmthickness1.12 1.1510.044 - 0.045)1.37 1.40 (0.054 - 0.055)1.62 - 1.65 (0.064 0.065)1.87 - 1.90 (0.074,0.075)2.12 2.15 (0.083 - 0.08s)2.37 2.40 (0.093 0.094)

Wear or damaged

t

{Wear or damagedSecondary gear shaft thrust shim, 25 x 35 rnmthickness2.80 - 2.85 (0.1'�t0 - 0.112)2.90 2.95 (0.114 - 0.116)3.00 3.05 (0.118 - 0.120)3.10 -3.15 10.122 0.124)3.20 - 3.25 (0.126, 0.128i3.30 - 3.35 (0.130 0.132)3.40 - 3.4s 10.134 0.136)3.50 3.55 (0.138 - 0.140)3.60,3.65 (0.142 0.144)3.70 - 3.75 (0.146 0.148)3.80 - 3.8510.150 0.152)

Wear or damaged

Wear or damaqedInput shaft feed pipe O.D.Drive pulley leed pipeForward clutch feed pipeInput shaft bushing t.D.Drive pulley feed pipe bushingForward clutch feed pipe bushingDriven shaft feed pipe O.D.Start clutch feed pipe (right side cover side)Driven pulley feed pipeStan clutch feed pipe (ftywheet housing side)Driven pulley shaft bushing LD.Stan clutch feed pipe (right side cover sroerDrive pulley feed pipeStart clutch feed pipe (flywheel housing side)Secondary driven gear sealing ring groove widthStart clutch end plate l.D.Input shaft sealing ring groove widthDnve pullev shaft LD. at sealing ring

Park brake conePark brake pawlPark gear

6.97 - 6.98 (0.274 - 0.27s)11.47 - 1'1.48 (0.4516 0.4520)

7.O0O 7.0t510.2156 - 0.2762]l11.500 11.518 (0.4528 0.4535)

6.97 - 6.9A \0.214 0.275:l11.47 - 11.48 (0.4516 _ 0.4520)8.97 8.98 10.353 - 0.354)

7.000 7.015 (0.2756 - 0.2762)1 1.500 - '11.518 (0.4528 - 0.4535)9.000 9.015 10.354 - 0.355)2.50 2.65 (0.098 0.104)88.900,88.935 (3.500 - 3.501)2.00 2.10 10.079 - 0.083)

5*

6.95 (0.274)

11.45 (0.451)

7.030 (0.277)11.533 (0.4s4)

6.95 (0.274)

11.45 (0.451)

8 95 (0.352)

t.030l0.2t7l1r.533 (0.454)

9.03 (0.356)2.655 (0. r05)Wear or damaged2.105 (0.083)Wear or damaqedShifting deviceano parKbrake control

Wear or other defectWear or other defectWear or other defect

Standardsand Service Limits

CW {cont'd)Section 14

rl

w

3-16

ro

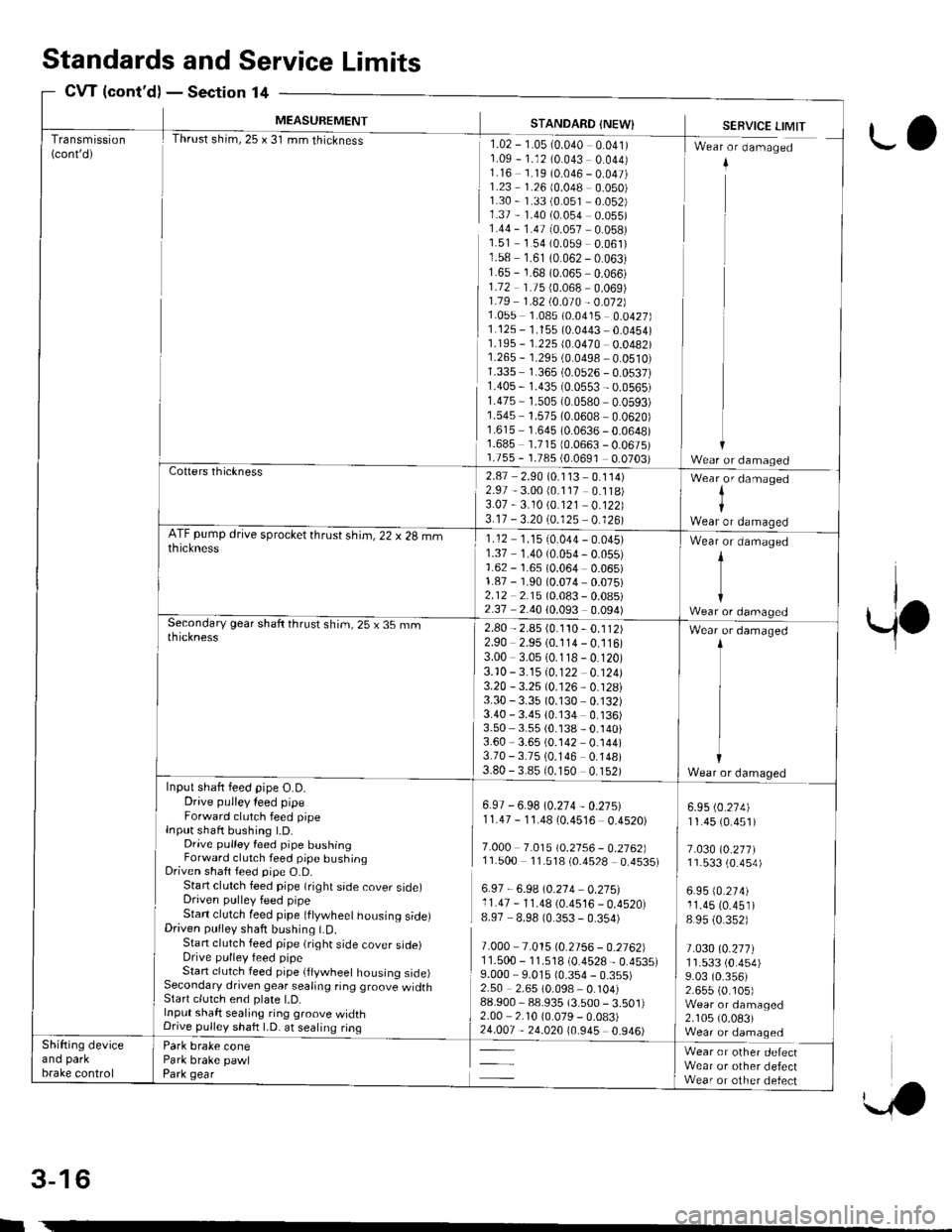

Page 198 of 2189

Engine Block

Speciaf Tools ..........." 7-2

lllustlated Index ...................."..'.......... 7-3

Flywheel and Drive Plate

Repf acement """'.' 7-7

Connecting Rod and Crankshaft

End Play ..........."....7-8

Main Bearings

Clearance ............... 7-9

Selection ................7-10

Connecting Rod Bearings

clearance ....'.......... 7-11

Selection ................ 7-11

Pistons and Crankshaft

Removaf ................. 7 -12

Crankshaft

Inspection ."".........7-14

Pistons

Inspection ......"'.....7-15

fnstaffation .............7-23

Cylinder Block

lnspec'tion ..............7-16

Bore Honing ..........7-17

Piston Pins

Removal ...,...........'.7-17

lnstallation .............7-18

Inspection .'............7-19

Connecting Rods

Selection ................7-18

Piston Rings

End Gap ..........".."' 7'2O

Repfacement .........7-2O

Ring-to-Groove Clearance ...........'.'. 7 -21

Afignment .......""'.. 7'21

Crankshaft Oil Seal

fnstaffation .............7-22

Crankshaft

fnstaffation ..-.-..'.".' 7'23

Oil Pan

lnstallation .............7-26

Oil Seals

fnstaffation ....""""' 7-29

r-f

Page 200 of 2189

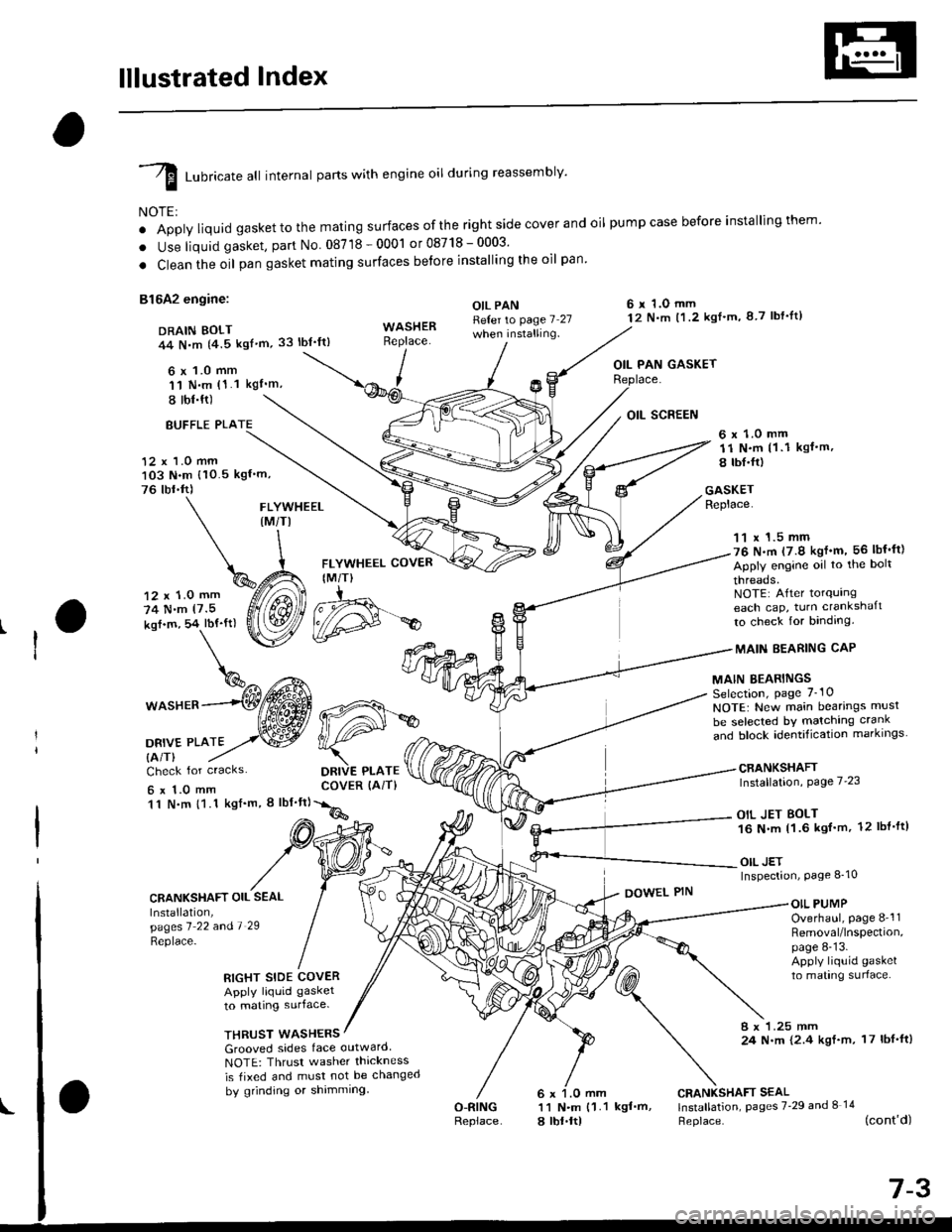

lllustrated Index

I runricate att internal parts with engine oil during reassembly'

NOTE:

o Apply liquid gaskettothe mating surfaces ofthe right side cover and oil pumpcase before installingthem'

. Use liquid gasket, part No 08718-0001 or08718-0003'

. Clean the oil pan gasket mating surfaces betore installing the oil pan

81642 engine:

DRAIN BOLT44 N,m {4.5 kgf'm,33 lbt'ft)

6 x 1.0 mm'11 N.m (1.1 kgI'm,

I tbl.ft)

OIL PANReter to page 7 27when installing.

6 r 1.O mm12 N.m t1.2 kgl'm, 8 7 lbf'lt)

OIL PAN GASKET

BUFFLE PLA

12 x 1.0 mm103 N.m {10.5 kgf'm,

76 tbr.ft)

6 x 1.0 mm11 N.m (1 .1 kgf.m,

8 tbI.fr)

GASKETReplace.FLYWHEEL(M/TI

12 x 1.0 mm

74 N.m (7.5

kof.m, 54 lbf'ft)

1^c{Eb\%^ t*^

*o"rr^--(Wffi

oa*,trto2,.w

FLYWHEEL COVER

IM/T)

DRIVE PLATECOVER (AiT)

11 x 1.5 mm76 N.m (7.9 kgf'm, 56 lbf'ft)

Apply engine oil to the bolt

threads.NOTE: After torqurngeach cap, turn crankshaft

to check for binding.

MAIN EEARING CAP

MAIN BEARINGSSelection, page 7_10

NOTE: New main bearings musl

be selected bY matching crank

and block identification markrngs

CRANKSHAFTInstallation, Page 7'23

OIL JET BOLT16 N.m 11.6 kgf'm, 12 lbl'ft)

OIL JETInspection, Page 8_10

Check for cracks

6x1.0mm11 N.m {1.1 kgf'm, I lbf'ft}

CRANKSHAFT OIL SEAL

Installation,pagesl 22 andl 29

Replace-

DOWEL PINOIL PUMPOverhaul, page 8-'l1Removal/lnspection,page 8-13.Apply liquid gasket

to mating surlace.RIGHT SIDE COVERApply liquid gasket

to mating surface.

THRUST WASHERS8 x 1.25 mm24 N.m {2.4 kgf.m, 17 lbf'ft)Grooved sides face outward

NOTE: Thrusr washer thickness

is tixed and must not be changed

by grinding or shimming

O-RINGReplace

CRANKSHAFT SEAL11 N.m {1.1 kgf'm, lnstallation, pages 7'29 and I 14

a lbt.ltl Heplace. (cont'd)

d#*

Page 201 of 2189

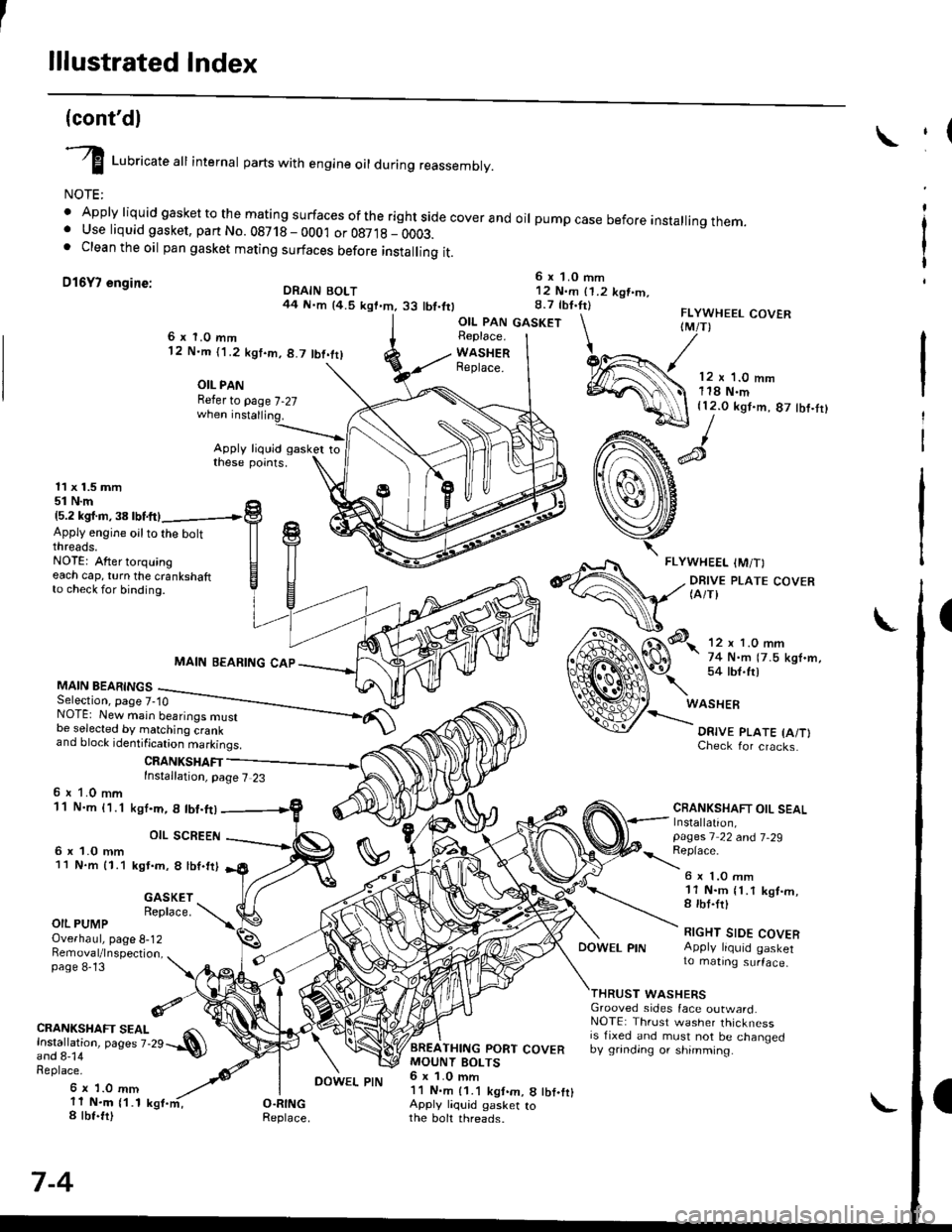

lllustrated Index

(cont'dl

I Luoricate att internal parts with engine oil during reassembly.

NOTE:

' Apply liquid gasket to the mating surfaces ofthe rightside coverand oil pumpcase before installingthem.. Use liquid gasket, part No. 08718 - 0001 or 087,18 _ OOO3.. Clean the oil pan gasket mating surfaces before installing it.

D16Y7 engine:6 x 1.0 mm12 N.m (1.2 kgt.m.8.7 tbf.tr)DRAIN BOLT44 N.m {4.5 kgt.m.33 tbt.ttl

,(

I

I

OIL PAN GASKETFLYWHEEL COVERIM/T)6x 1.0 mm12 N.m ('l .2 kgt.m, 8.7 tbt.trl

OIL PANRefer to page 7-27

Apply liquid gasker tothese points.

Replace.

WASHERReplace.12 x '1.0 mm118 N.m{12.0 kgt.m, 87 tbf.tr}

11 x 1.5 mm51 N.m15.2 kgl.m,38lbtftl

Apply engine oilto the boltthreads.NOTE: After torquingeach cap, turn the crankshaftto check for binding.

MAIN BEARINGSSelection, page 7-10

MAIN BEARING CAP

CRANKSHAFTInstallation, page 7 23

NOTE: New main bearings mustbe selected by matching crankand block identification markings.

6 r 1.0 mm11 N.m {1.1

6 x 1.0 mm11 N.m 11.1

ksI.m, 8 lbt.ft)

OIL SCREEN

kgt.m, 8 lbf.trl

Check for cracks.

CRANKSHAFT OIL SEALInstallation,pages 1 22 a^d 7-29

\:eprace'

GASKETReplace.

6 x 1.O mm11 N.m {1.1 kgt.m,8 rbt.frl

RIGHT SIDE COVERApply liquid gasker1o matrng surface,

OIL PUMPOverhaul, page 8-12Bemoval/lnspection,page 8-13

DOWEL PIN

WASHERSGrooved sides face outward.NOTE: Thrust washer thicknessis fixed and must not be changedby grinding or shimming.

CRANKSHAFT SEAL

l.j"Ji:l"^ pages z.2e --.S)

Replace.

6 x 1.0 mm11 N.m {1.18 tbt.fr)

7-4

BREATHING PORT COVERMOUNT BOLTS6 x 1.0 mm11 N.m {1.1 kgt.m, 8 tbf.fr}Apply liquid gasker tothe boh threads.

DOWEL PIN

Page 202 of 2189

D16Y5, D16Y8 engines:

DRAIN BOLT39 N.m 14.0 kgt'm,

Apply liquid gasket to

these points.

OIL PANRefer to page 7-25

when installing.WASHERReplace.

29 lbl.tt)

\

\^

6 x 1.0 mm q%

P

I

FLYWHEEL COVER(M/T}

12 x 1.0 mm118 N.m(12.0 kgt.m, 87 lbt'ft)

FLYWHEEL (M/TI

t2 N.m 11.2 kgf'm,

8.7 lbl.ftl

11 x 1.5 mm

51 N.m(5.2 kgf'm, 38 lbf ftl

Apply engine oiltothe bolt

threads.NOTE: Aftertorquingeach cap, turn crankshaft

to check for binding.

MAINBEARING

MAIN BEARINGSSelection, page 7-10NOTE: New main bearings must

be selected by matching crank

"nJ lr."i io"irriti"",ion-markings. --------*-i6{\

CRANKSHAFTInstallation, page 7-23

6 r 1.0 mm11 N.m (1 1 kgf'm, I lbf'ttl

OII PAN GASKETReplace.

DRIVE PLATE COVER

{A/T or CVT)

12 r 1.0 mm

74 N.m

17.5 kgl.m, 54 lbf'ft)

DBIVE PLATE {A/T or CVTI

Check for cracks

6 x 1.O mm11 N.m {1.1 kgl'm,

8 tbl.ftl

CRANKSHAFT OIL SEAL

lnstallation,pages 7'?1 and '1 '28

Replace.

RIGHT SIDE COVER

Apply liquid gasket

to mating surface.

OIL SCREEN

GASKETReplace.

OIL PUMPOverhaul, page 8_12Removal/lnspection,page 8-13Apply liquid gasket

to mating surface.

DOWEL PIN

WASHEFS

Grooved sides tace outward

NOTE: Thrust washer thickness

is fixed and must not be changed

bV grinding or shimming.

CRANKSHAFT SEALInstallation, pages 7 29

and 8-14Replace.

BREATHING PORT COVER

MOUNT BOLTS6 x 1.O mm11 f{..n (1.1 kgf'm, 8 lbf'fl)

Apply liquid gasket to

the bolt threads.

O.RINGReplace.

6 x 1.0 mm

11 N.m (1 1 kgl'm,

8 tbr.ftl

(cont'd)

7-5

\

OOWEL PIN

Page 204 of 2189

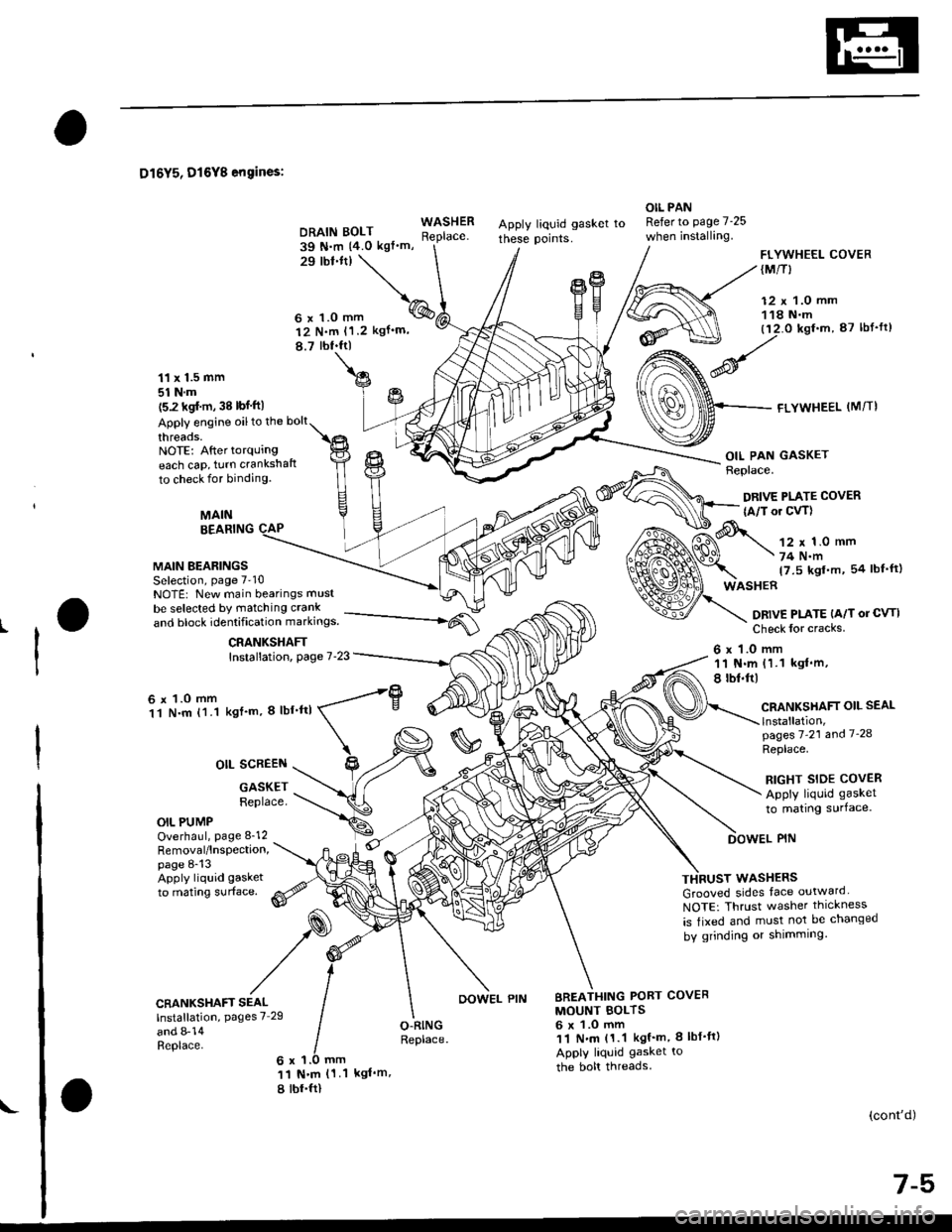

Flywheel and Drive Plate

Replacement

Manual Transmission:

816A2 engine:

Remove the eight flywheel bolts, then separate the fly-

wheel from the crankshaft flange. After installation'

tiohten the bolts in the sequence shown

RING GEAR HOLDER "-i

OTLAB PVOOlOO

D16Y5, D16Y7, D16Y8 engines:

Remove the six flywheel bolts, then separate the flywheel

from the crankshaft flange. After installation, tighten the

bolts in a crisscross Pattern.

RING GEABInspect ring gear

teeth lor wear or

damage.

RING GEARInspect ring gear

teeth lor wear orteetn lor wea( or /danase. ,///.'

12 x 1.0 mm103 N.m(10.5 kgf.m, 76 lbf.tt)

12 x 1.o mm1 18 N,m(12.0 kgI.m, 87 lbf.ftl

L

rurS;u'.\

$..3s'

Automatic Transmission:

Remove the six drive plate bolts, then separate the drive

olate from the crankshaft flange. Atter installation, tighten

the bolts in a crisscross Pattern.

t7.5 kgl.m, 54 lbl'ltl

12 x 1.0 mm74 N.m

7-7

Page 226 of 2189

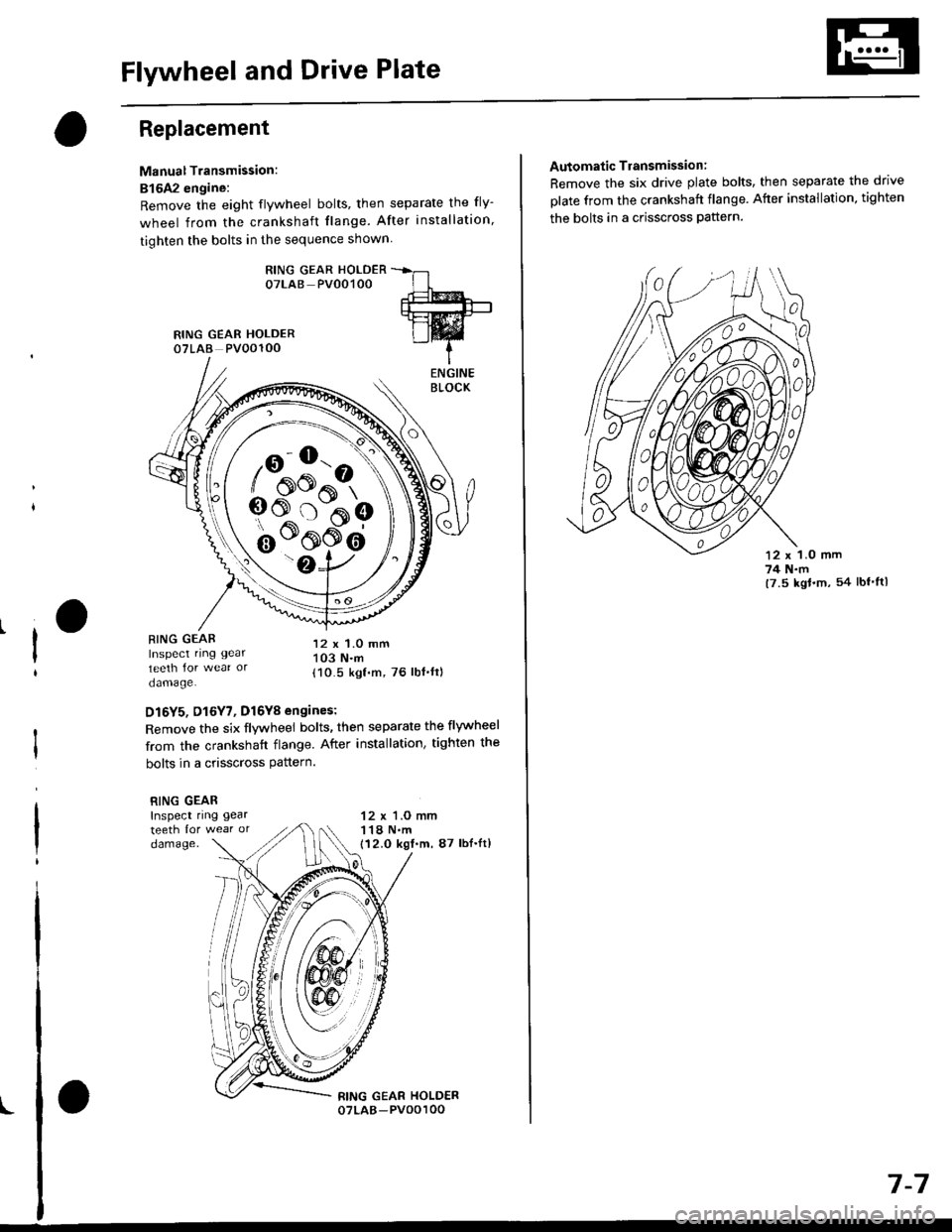

Oil Seals

lnstallation

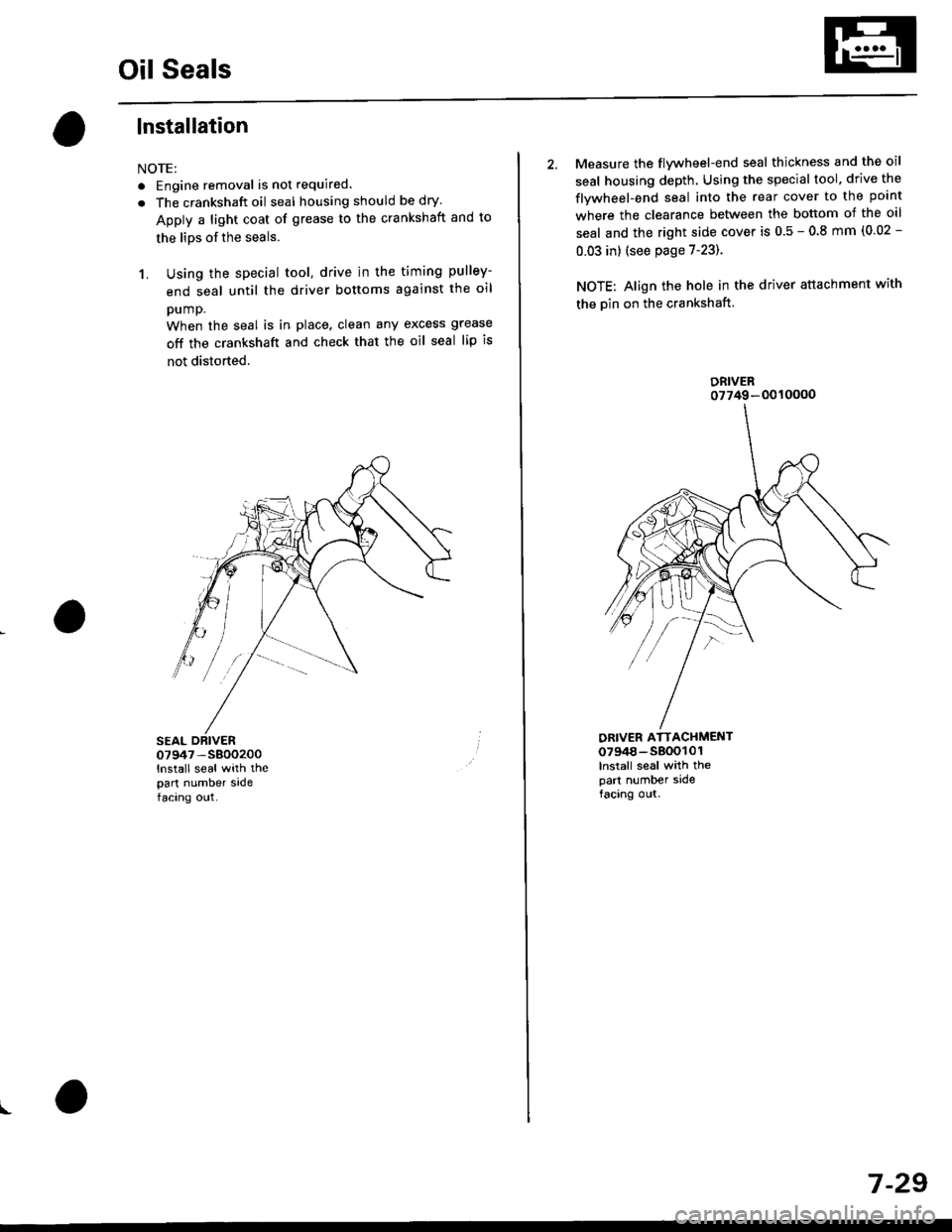

NOTE:

. Engine removal is not required.

. The crankshaft oil seal housing should be dry.

Apply a light coat of grease to the crankshaft and to

the lips of the seals.

1. Using the special tool, drive in the timing pulley-

end seal until the driver bottoms against the oil

pump.

When the seal is in place, clean any excess grease

off the crankshaft and check that the oil seal lip is

not distorted.

07947 -S800200

lnstall seal with thepart number sadefacing out.

I

2. Measure the flvwheel-end seal thickness and the oil

seal housing depth. Using the special tool. drive the

flywheel-end seal into the rear cover to the point

where the clearance between the bottom of the oil

seal and the right side cover is 0.5 - 0.8 mm (0.02 -

0.03 in) (see page 7-23).

NOTE: Align the hole in the driver attachment with

the Din on the crankshaft.

DRIVER ATTACHMENT0794a-s800101lnslall seal with thepart number sidefacing out.

DRIVER07749-0010000

7 -29

Page 568 of 2189

J

t

Clutch

Speciaf Tools .......... ...........12-2

f lfustrated Index .......... ......12-3

clutch Pedal

Adjustment .................... 12'4

Clutch Master Cylinder

Removal/lnstallation ..... 12-5

Slave Cylinder

Removal/lnstallation .....12'6

Pressure Plate

Removal/lnspection ...... 12-7

Clutch Disc

Removal/lnspection ...... 12-8

Flywheel

Inspection ....................... 12-9

Replacement ....................................... 12-9

Clutch Disc, Pressure Plate

lnstallation ..................... 12-10

Release Bearing

Removal/lnspection ......12-11

f nstalfation .................,... 12-12

\