Ignition coil HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 903 of 2189

![HONDA CIVIC 1998 6.G Workshop Manual TCM Circuit Diagram (96 - 98 Modelsl

UNDEN. HOOD FUSE]RELAY BOX

UNDER OASHFUSE/RELAY 80X

No. 52 1l5A)

No.4l l80A) No.47 (7.5A)

To t 2v lG1sToP sw T HBR( sw- - rur

A/T GEAR POSITIONINDICATOR

IGNITION HONDA CIVIC 1998 6.G Workshop Manual TCM Circuit Diagram (96 - 98 Modelsl

UNDEN. HOOD FUSE]RELAY BOX

UNDER OASHFUSE/RELAY 80X

No. 52 1l5A)

No.4l l80A) No.47 (7.5A)

To t 2v lG1sToP sw T HBR( sw- - rur

A/T GEAR POSITIONINDICATOR

IGNITION](/img/13/6068/w960_6068-902.png)

TCM Circuit Diagram ('96 - 98 Modelsl

UNDEN. HOOD FUSE]RELAY BOX

UNDER OASHFUSE/RELAY 80X

No. 52 1l5A)

No.4l l80A) No.47 (7.5A)

To t 2v lG1sToP sw T HBR( sw- - rur

A/T GEAR POSITIONINDICATOR

IGNITION COIL

Y

I

i

I

IBI-U

rsl

PARKINGBRAKEswrTcH

V

I

I

I

I

IGRN/REO

,t, I

l

I

IGnN,4,vHT

LT GRN

ELKi BI-U

RED

GRN/BLK

NoTEi if :ro 5V

T :To t2v

cRN ---l F----- GnN

Bru -J F------ 61U

8LK

II

Tl

G401G404

,o IJ'^A'

14-226

Page 925 of 2189

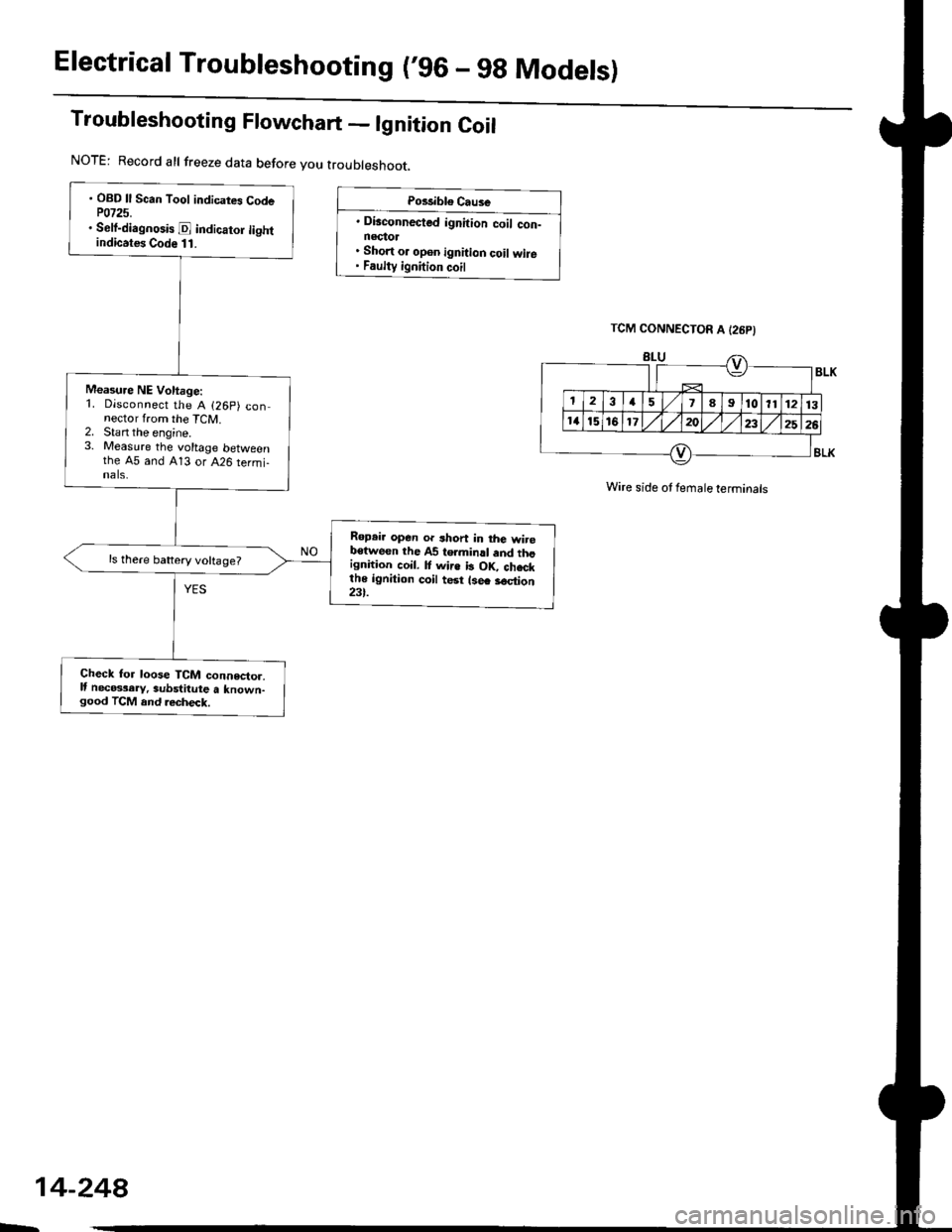

Electrical Troubleshooting ('96 - 9g Models)

Troubleshooting Flowchart - lgnition Coil

NOTE: Record all freeze data before you troubleshoot,

Po3rible Cause

. Dbconnected ignition coil con-nectol. Short o. op6n ignition coil wire' F.ulty ignition coil

Wire side ot female terminals

. OBD ll Scan Tool indicates CodePOl25.. Soll-diagnosis E indicarol lightindicates Code 11.

Measure NE Voltrge:1. Disconnect the A {26p) connector from the TCM.2. Start the engine.3. Measure the voltage betweenthe A5 and 413 or A26 termi-nals,

R6p.i. open or short in the wireb€lween the A5 te.minsl and thoignhion coil. It wir€ b OK, checkthe ignition coil test lsoc aoction23t.

ls there battery voltage?

Check for loose TCM connector.It nec$sery. substilute a known-good TCM and .echeck.

Page 1476 of 2189

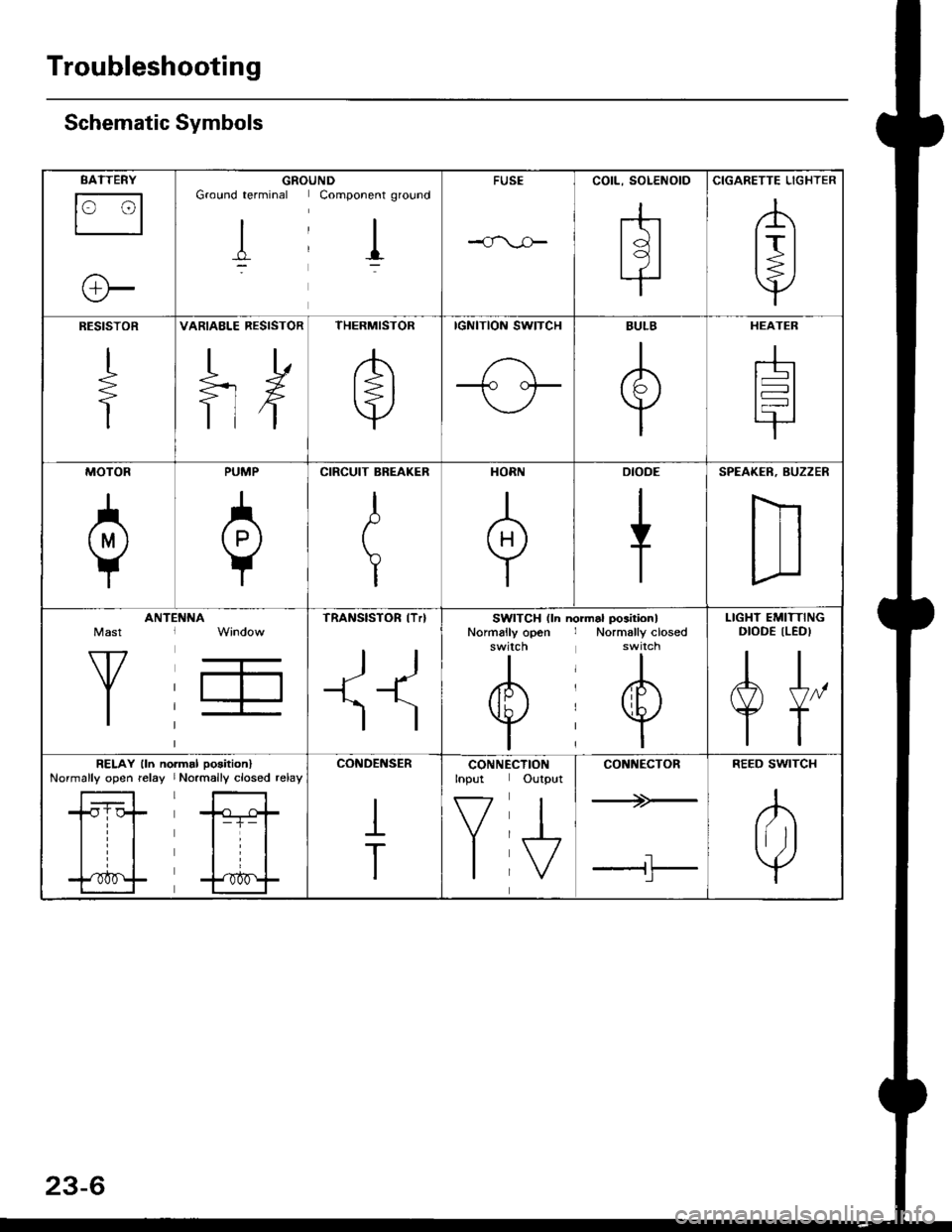

Troubleshooting

Schematic Symbols

BATTERY

E

@

GROGroLrnd terminal

II_d:

UNDComponent ground

II_..'-

FUSE

--cn-.e

COIL, SOLENOID

r{r

tql'|

CIGARETTE LIGHTER

A

lrl

P

RESISTOR

I

f

VARIAELE RESISTOR

ilH

THERMISTOR

c

IGNITION SWITCH

-fo o.t-

BULB

+

HEATEB

At-l

F

MOTOR

0

PUMP

H

CIRCUIT BREAKER

I

r

Yr

T

HORN

+

DIODE

+

SPEAKER, BUZZER

D

Mast

Y

ANTt:f\,NATRANSISTOR lTrl

II

SWITCH (ln niNormally open

I

/F\t tL I\Y/

I

rrdal positionlNormally closed'*i."n

@

I

LIGHT EMITTINGDIODE ILEDI

A+,

TT

RELAY lln noNormally opon relay

| ....--1'rl*r

til

t "t^f

fmal poaitionlNormally closed relay

ffl-+- |

lrl

lrl

fff

CONDENSER

I

T

CONNTInput

V

I

:CTIONOutput

J

CONNECTOR

*>-

'l!

REED SWITCH

A

tftl

Y

Page 1566 of 2189

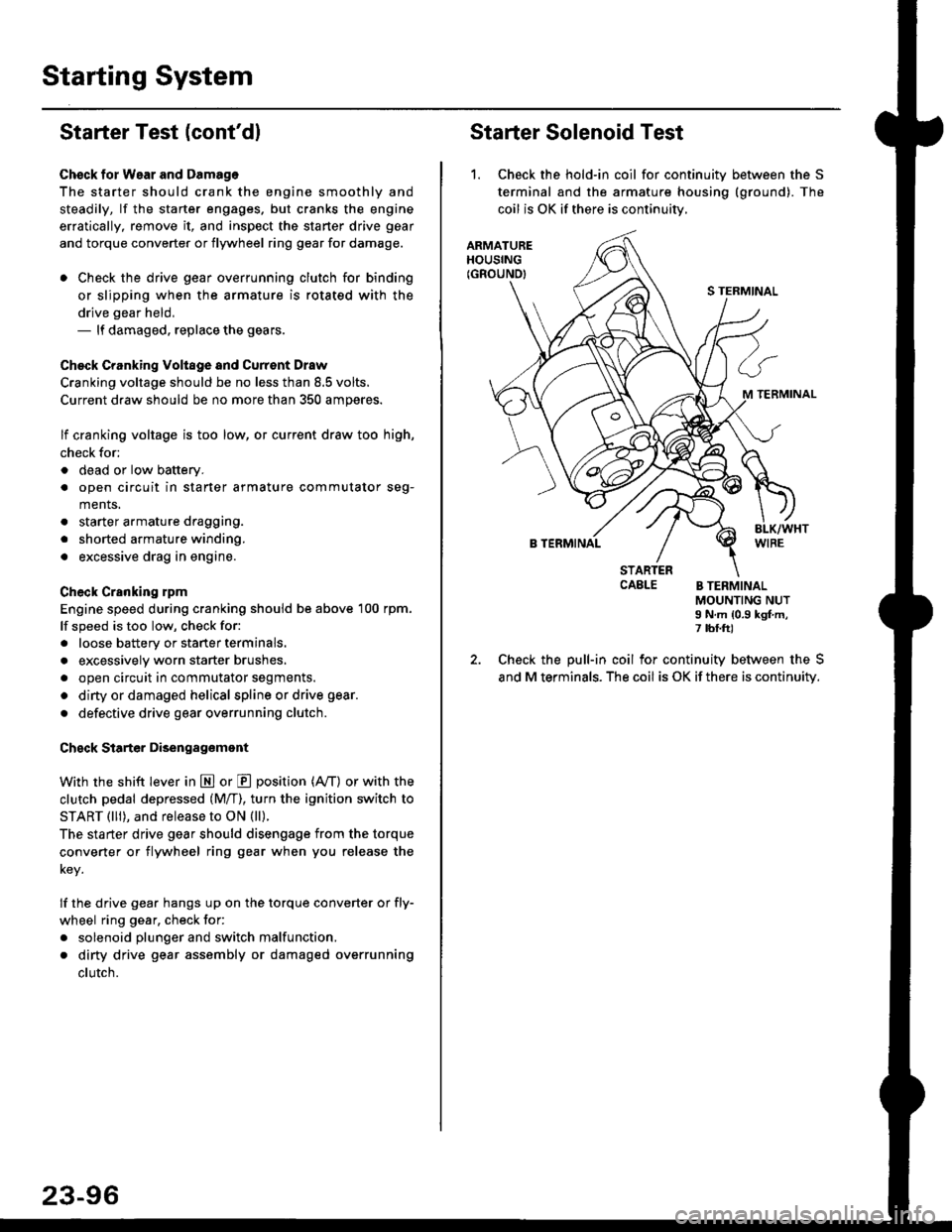

Starting System

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1572 of 2189

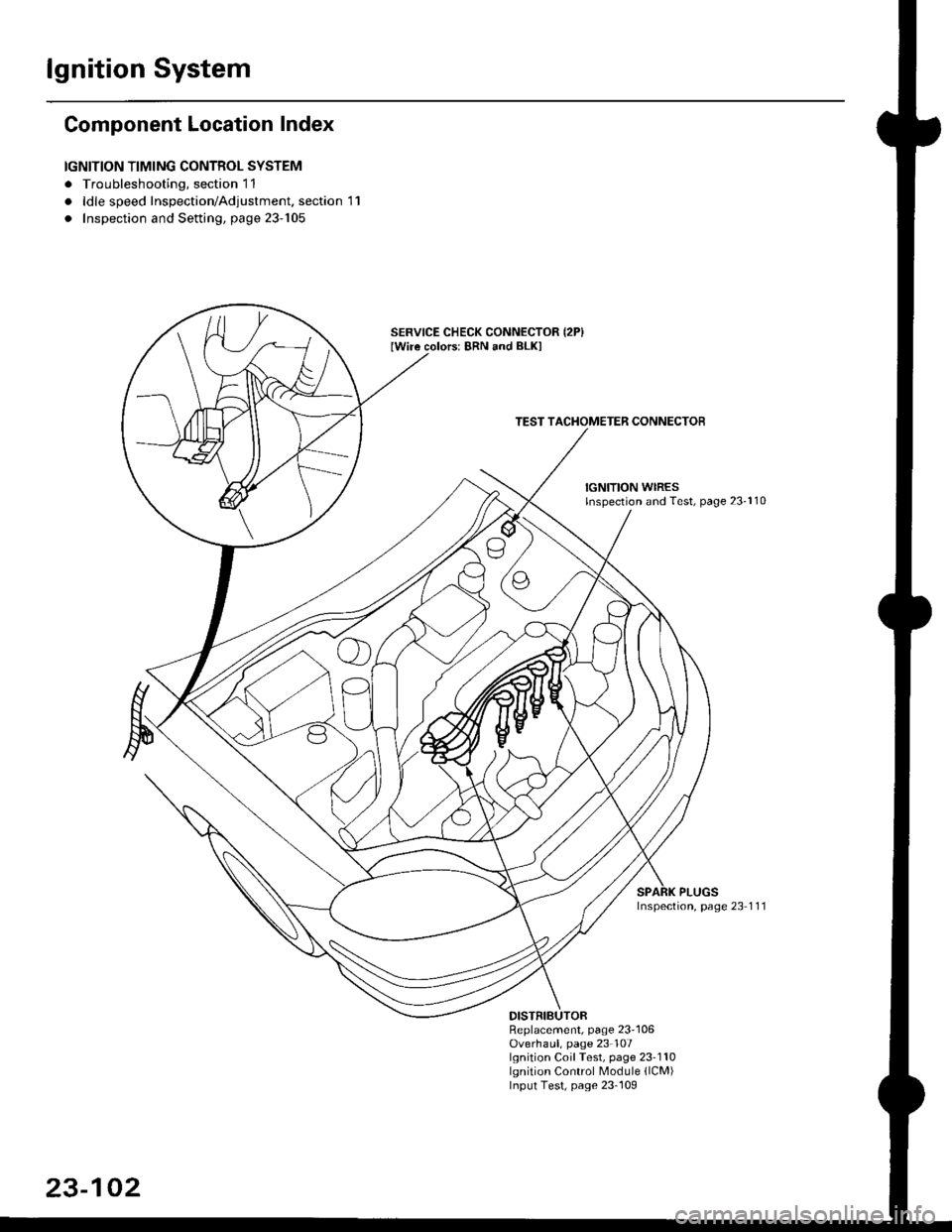

lgnition System

Component Location Index

IGNITION TIMING CONTROL SYSTEM

. Troubleshooting, section 11

. ldle speed Inspection/Adjustment. section 11

. Inspection and Setting, page 23-105

SERVICE CHECK CONNECTOR {2P}Iwiie colors: 8RN and BLKI

TEST TACI{OMETER CONNECTOB

IGNITION WIRESlnspection and Test, page 23-110

PLUGSInspection, page 23 1 11

Replacement, page 23'106Overhaul, page 23-107lgnition Coil Test, page 23'110lgnition Control Module llCM)Input Test, page 23-109

23-102

Page 1578 of 2189

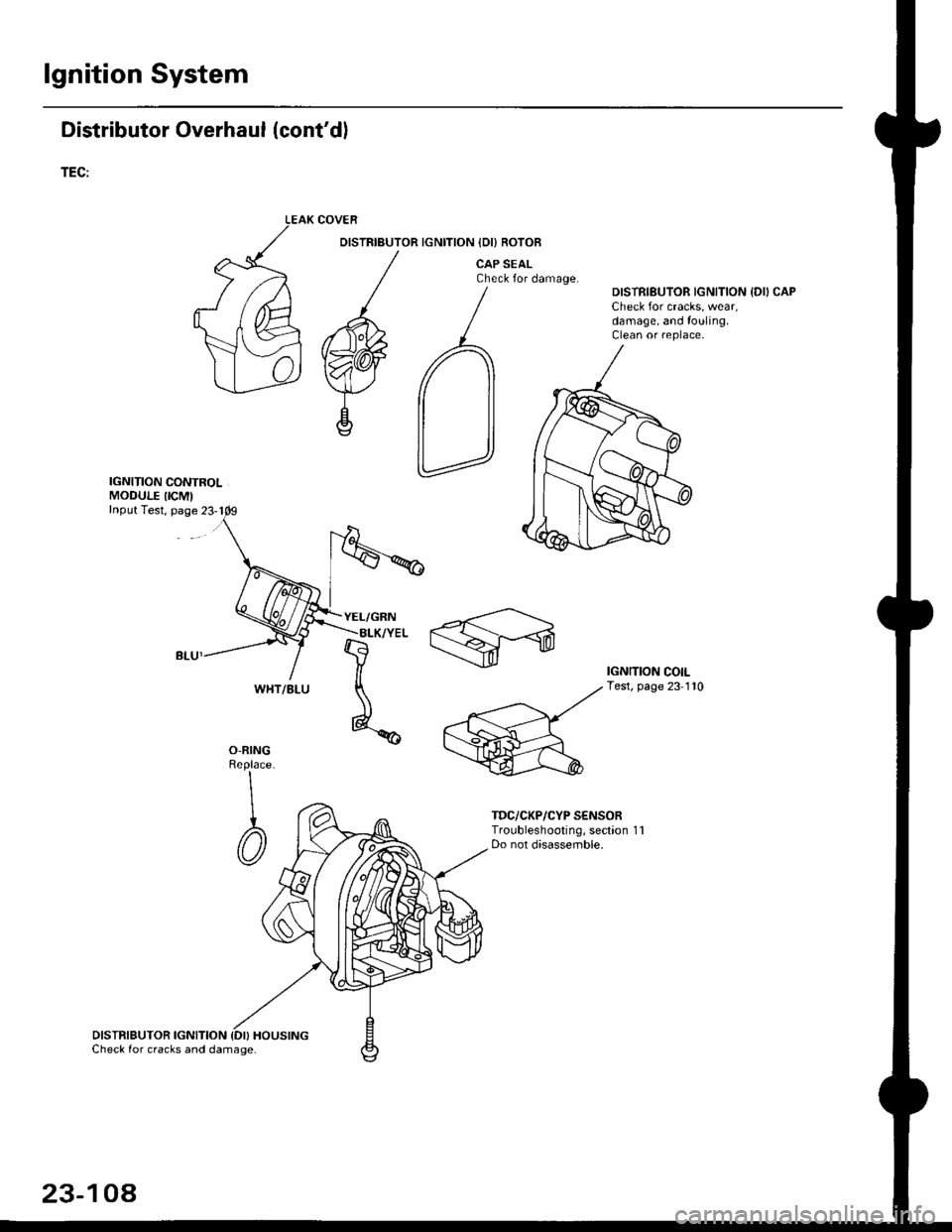

lgnition System

Distributor Overhaul (cont'dl

TEC:

IGNITION CONTROLMODULE IICM'Input Test, page 23-1

DISTRIBUTOR IGNITION {DI} HOUSINGCheck for cracks and damage.

COVER

DISTRIBUTOR IGNITION IDI) ROTOB

CAP SEALCheck for damage.DISTRIBUTOR IGNITION {DII CAPCheck for cracks, wear,damage, and fouling.Clean or replace,

IGNITION COILTest, page 23-110

O-RINGReplace

\

I

@

TDC/CKP/CYP S€NSORTroubleshooting, section 1 1Do not disassemble.

WHT/BLU

23-104

Page 1579 of 2189

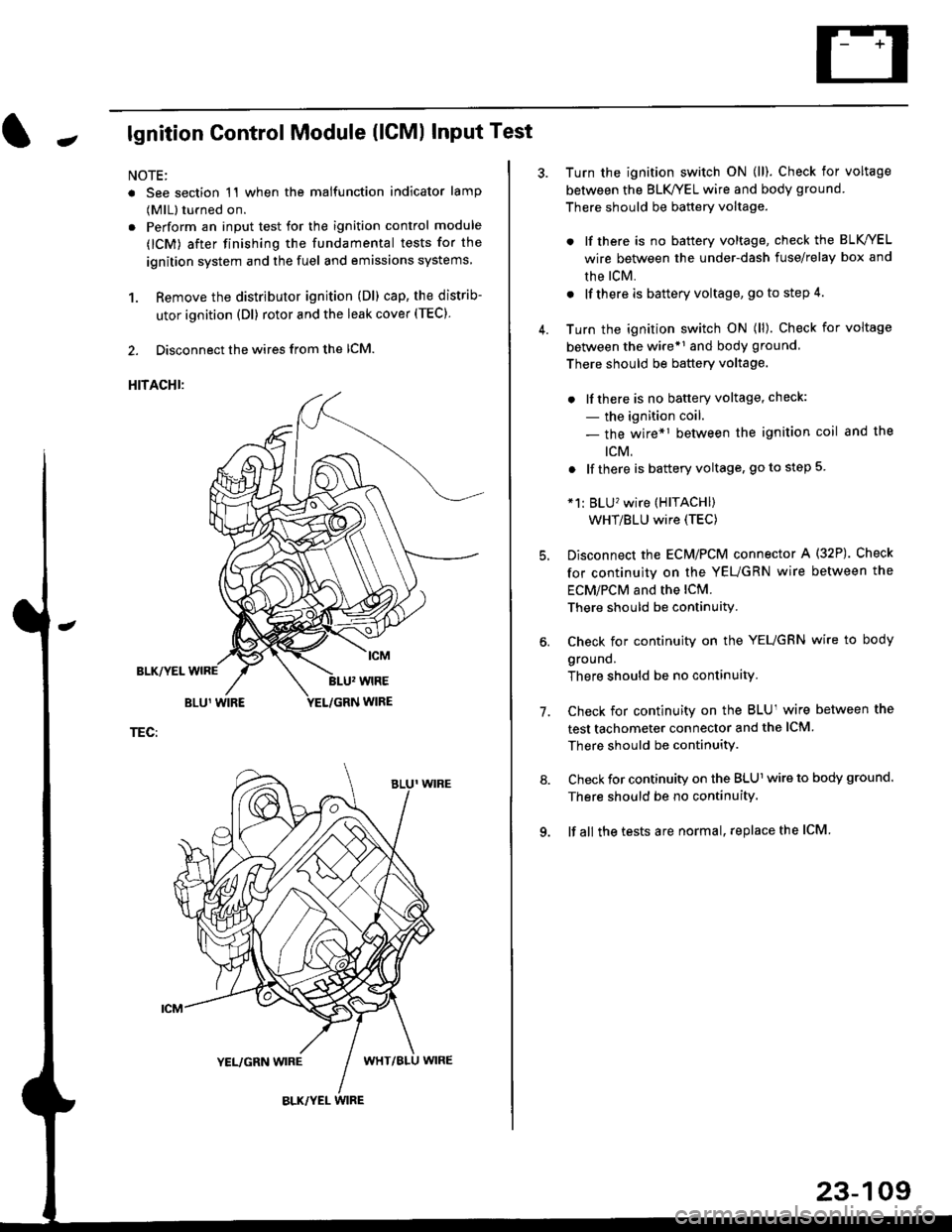

Jlgnition Control Module (lCMl Input Test

NOTE:

. See section 1'l when the malfunction indicator lamp

(MlL) turned on.

. Perform an input test for the ignition control module

(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems

1. Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor and the leak cover (TEC).

2. Disconnect the wires from the lCM.

HITACHI:

BLK/YEL

TEC:

Turn the ignition switch ON (ll). Check for voltage

between the BLK/YEL wire and body ground.

There should be battery voltage.

. lf there is no battery voltage, check the BLK/YEL

wire between the under-dash fuse/relay box and

rhe lcM.

. lf there is battery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the wire*r and body ground

There should be battery voltage.

. lfthere is no battery voltage, check:

- the ignition coil.

- the wire*1 between the ignition coil and the

tcM.

. lf there is battery voltage, go to step 5

*1: BLU'�wire (HITACHI)

WHT/BLU wire (TEC)

Disconnect the EcM/PCM connector A (32P). Check

for continuity on the YEUGRN wire between the

ECM/PCM and the lCM.

There should be continuity.

Check for continuity on the YEUGRN wire to body

ground.

There should be no continuity.

Check for continuity on the BLUl wire between the

test tachometer connector and the ICM

There should be continuitY.

Check for continuity on the BLUl wire to body ground.

There should be no continuity.

lf all the tests are normal, replace the ICM

7.

23-109

Page 1580 of 2189

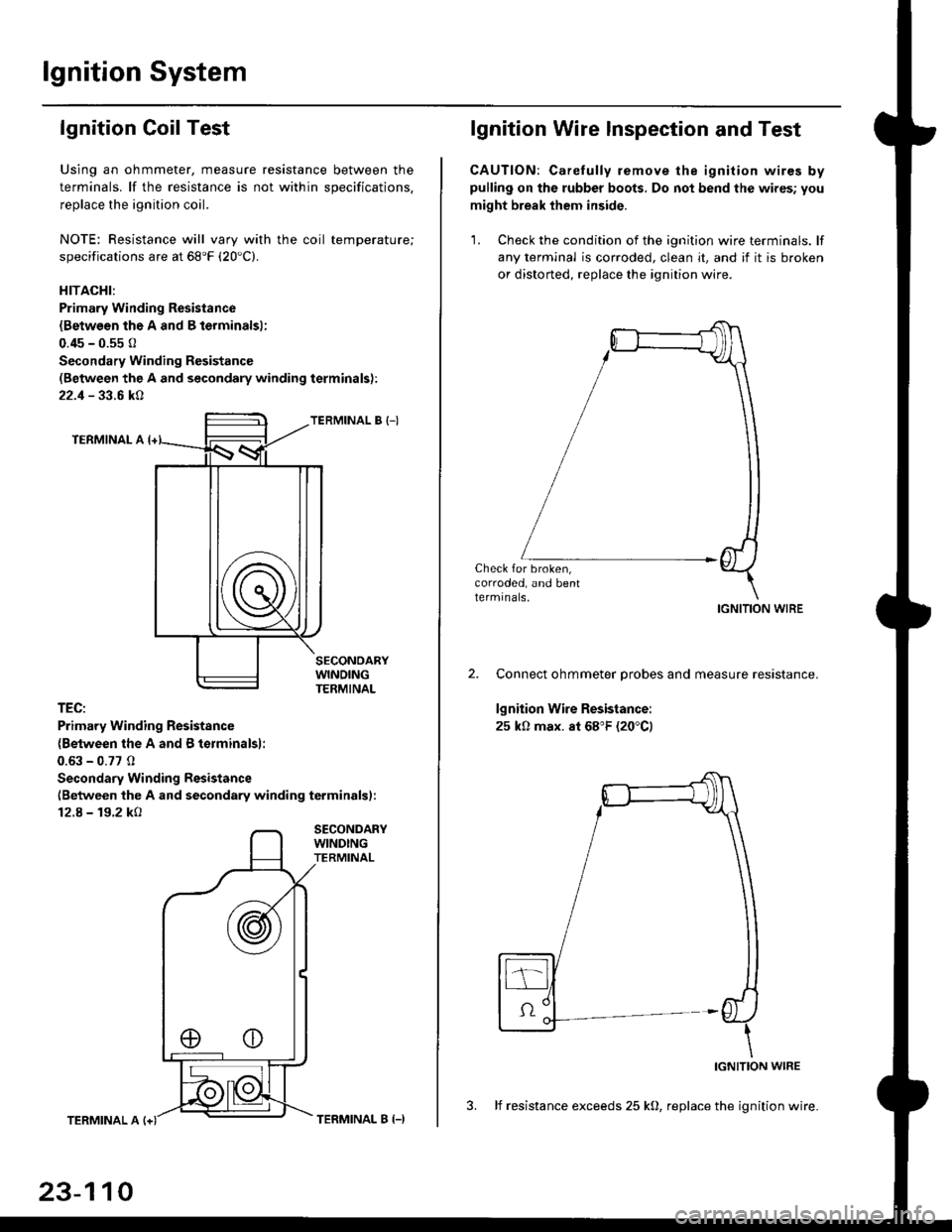

lgnition System

lgnition Coil Test

Using an ohmmeter, measure resistance between the

terminals. lf the resistance is not within soecifications.

replace the ignition coil.

NOTE: Resistance will vary with the coil temperature;

specifications are at 68'F (20'C).

HITACHI:

Primary Winding Resistance

{Betwesn the A and B lerminalsl;

0.45 - 0.55 0

Secondary Winding Resistanc€

(Between the A and secondary winding terminals):

22.1 - 33.6 kA

TERMINAL B {-)

TERMINAL A

TEC:

Primary Winding Resistsnce

{Between the A and B terminalsl:

0.63 - 0.77 0

Secondary Winding Resistance

(Between the A and secondary winding terminals):

12.8 - 19.2 kO

SECONDARYWINDINGTERMINAL

TERMINAL A

23-110

TERMINAL B (-)

lgnition Wire lnspection and Test

CAUTION: Carelully remove the ignition wires bypulling on the rubber boots, Do not bend the wires; you

might break them inside.

'1. Check the condition of the ignition wire terminals. lf

any terminal is corroded, clean it, and if it is broken

or distorted, replace the ignition wire.

Check for broken,corroded, and bentlermrnals.IGNITION WIRE

Connect ohmmeter probes and measure resistance.

lgnition Wire Resistance:

25 k0 max. at 68"F (20"C)

IGNITION WIRE

3. lf resistance exceeds 25 kO, replace the ignition wire.

Page 1581 of 2189

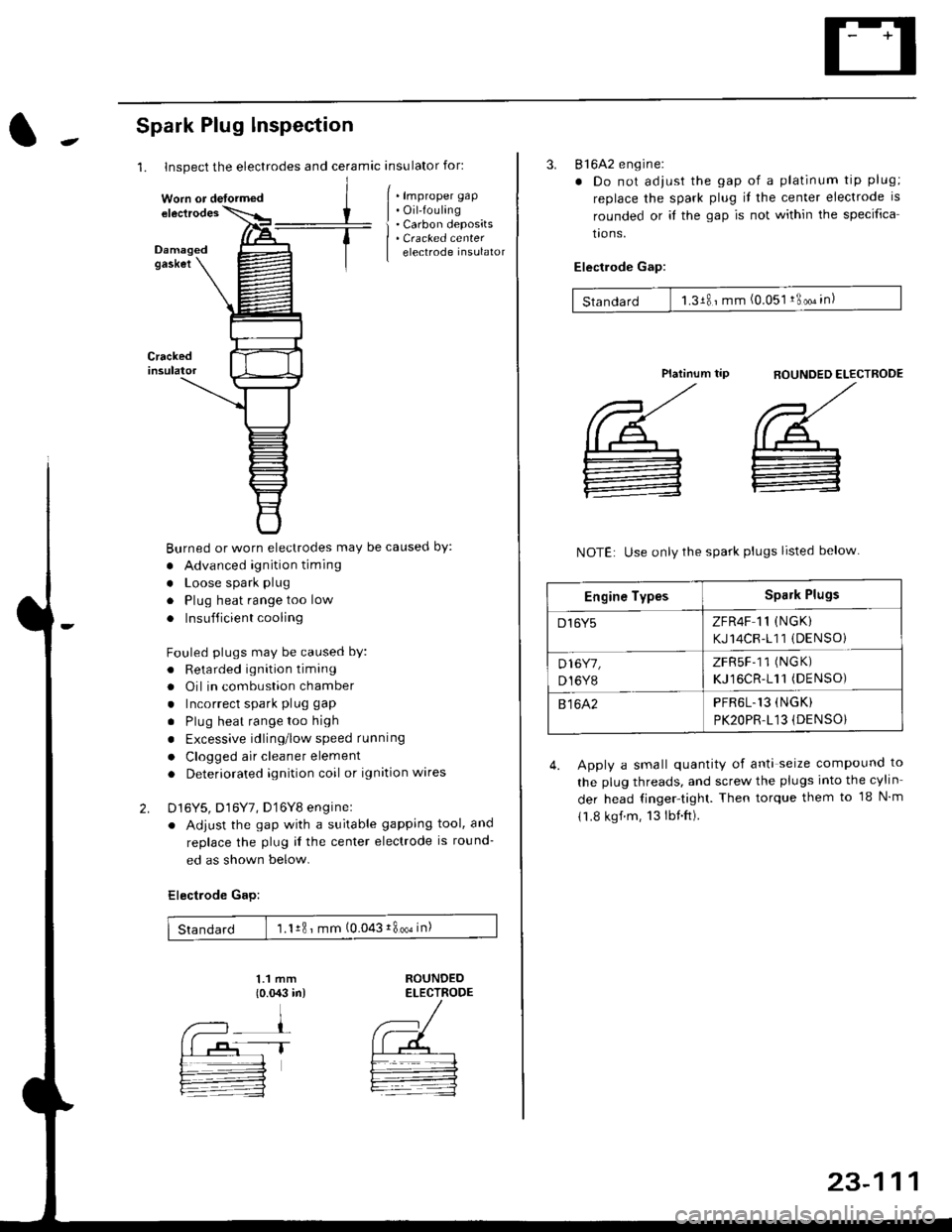

1. Inspect the electrodes and ceramic insulator for:

Spark Plug lnspection

Crackedinsulator

2.

[ . t.p,op", grp

| . Oil-fouling

i . Carbon deposits

| . Cracked center

I electrode insulator

Burned or worn electrodes may be causecl by:

. Advanced ignition timing

. Loose spark plug

. Plug heat range too low

. Insufficient cooling

Fouled plugs may be caused bY:

. Retarded ignition timang

. Oil in combustion chamber

. Incorrect spark plug gap

. Plug heat rangetoo high

. Excessive idling/low speed running

. Clogged air cleaner element

. Deteriorated ignition coil or ignition wares

D16Y5, D16Y7, D'16Y8 enginel

. Adjust the gap with a suitable gapping tool, and

replace the plug il the center electrode is round-

ed as shown below.

Electrode Gap:

1.1 mm

{o.{X:l in)ROUNDEDELECTRODE

Standard 1.1r8 ' mm (0.043i800oin)

Worn or detormed

1T

23-111

3. 816A2 engine:

. Do not adjust the gap of a platinum tip plug;

replace the spark plug il the center electrode is

rounded or it the gap is not within the specifica

tro ns.

Electlode Gap:

Standard 1.3181mm (0.051 !3oo" in)

flOUNDED ELECTROOE

',/

@_

:

Platinum tip

NOTE: Use only the spark plugs listed below

4. Apply a small quantity of anti seize compound to

the plug threads, and screw the plugs into the cylin

der head finger-tight. Then torque them to 18 N m

11.8 kgf.m, 13lbnft).

Engine TypesSpark Plugs

D16Y5ZFR4F 11 (NGK)

KJ14CR-111 (DENSOi

D16Y7,

D,I6Y8

ZFRSF-11 (NGK)

KJ16CR-111(DENSO)

81642PFR6L.13 (NGK)

PK2OPR.L13 (DENSO}

Page 1612 of 2189

Fuel Gauge

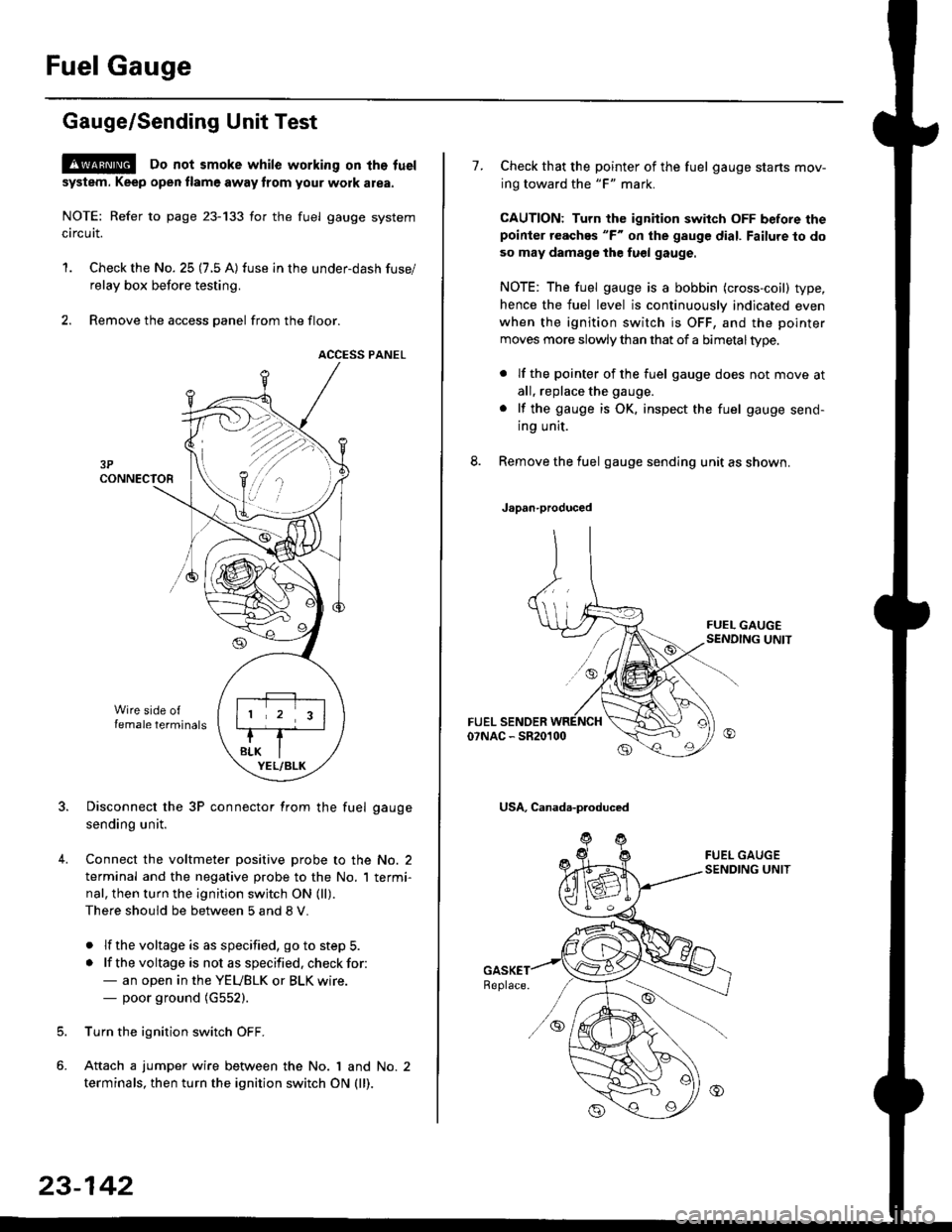

Gauge/Sending Unit Test

!@ Do not smoke while working on tho fuel

system. Keep open tlame away trom your wotk atea.

NOTE: Refer to page 23-133 for the fuel gauge system

circuit.

'1. Check the No. 25 (7.5 A) fuse in the under-dash fuse/

relay box before testing.

2. Remove the access panel from the floor.

ACCESS PANEL

Disconnect the 3P connector from the fuel gauge

sending unit.

Connect the voltmeter positive probe to the No. 2

terminal and the negative probe to the No. I termi-

nal, then turn the ignition switch ON (ll).

There should be between 5 and 8 V.

. lf the voltage is as specified, go to step 5.

. lf the voltage is not as specified. check for:- an open in the YEUBLK or BLK wire.- poor ground (G552).

Turn the ignition switch OFF.

Attach a jumper wire between the No. 1 and No. 2

terminals, then turn the ignition switch ON (ll).

)\

23-142

1.Check that the pointer of the fuel gauge starts mov-

ing toward the "F" mark.

CAUTION: Turn the ignition switch OFF before thepoinier reaches "F" on ihe gauge dial. Failure to do

so may damage the fuel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type,

hence the fuel level is continuously indicated even

when the ignition switch is OFF, and the pointer

moves more slowly than that of a bimetaltype.

. lf the pointer of the fuel gauge does not move at

all, replace the gauge.

. lf the gauge is OK. inspect the fuel gauge send-

ing unit.

Remove the fuel gauge sending unit as shown.

Japan-produced

USA, Canada-produced