countershaft HONDA CIVIC 1998 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CIVIC, Model: HONDA CIVIC 1998 6.GPages: 2189, PDF Size: 69.39 MB

Page 53 of 2189

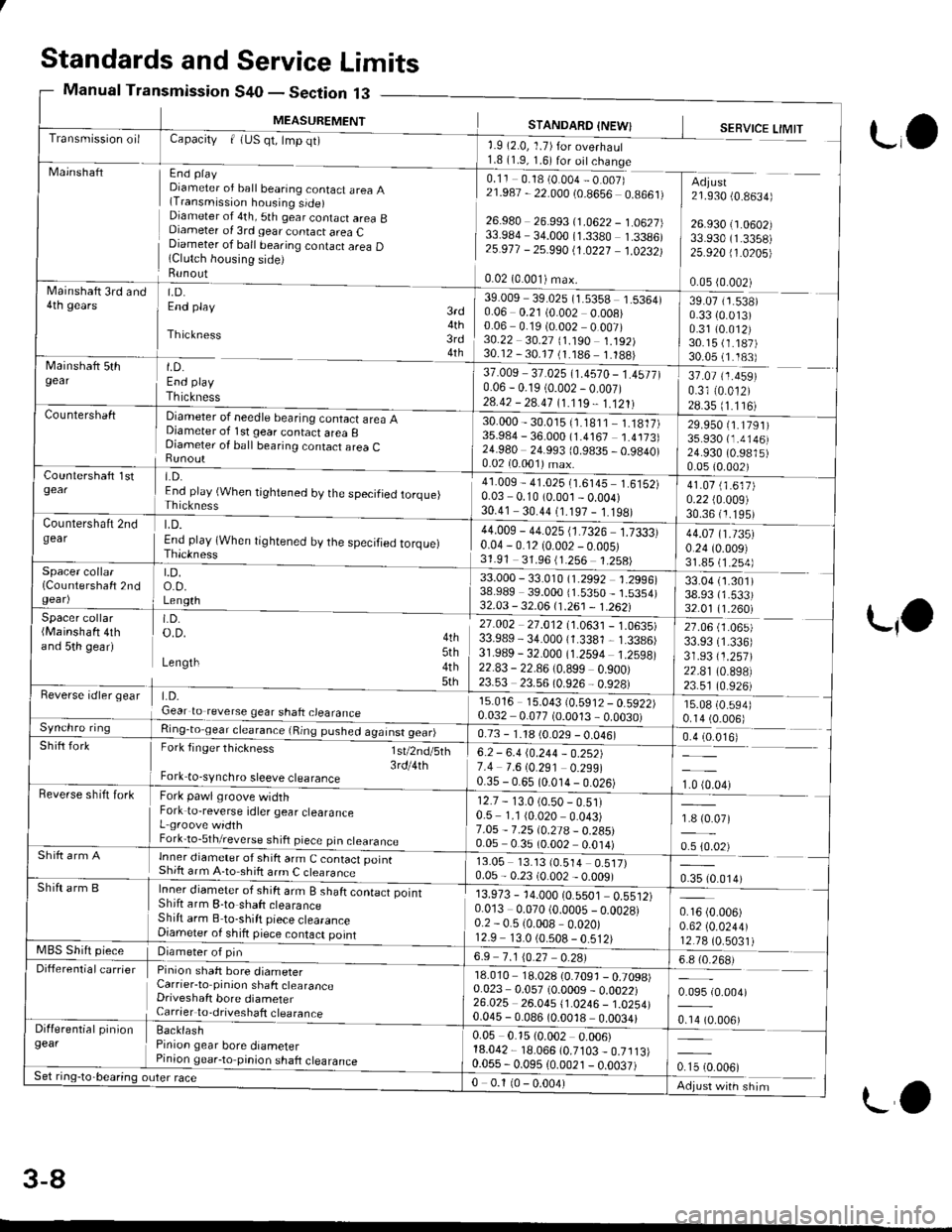

Standards and Service Limits

Manual Transmission S40 - Section 13

MEASUREMENT

Capacity | (US qt, tmp qt)

End playDiameter of ball bearing contact area A(Transmission housing side)Diameter of 4th, 5th gear contact area BDiameter of 3rd gear contact area CDiameter of ball bearing contact area D(Clutch housing side)Bunout

STANDARD INEW}'1.9 (2.0, 1.7)for overhaul1.8 (1.9, 1.6) for oitchange

0.11 0.18 (0.004 _ 0.007)21.987 - 22.000 (0.8656 0.8661)

26.980 26.993 (1.0622 _ 1.0627)33.984 34.000 (1.3380 1.3386)25.917 - 25.99011.0227 1.0232)

0.02 (0.001) max.

SEBVICE LIMIT

ro

MainshaftAdjust21.930 (0.8634)

26.930 ('1.0602i33.930 (1.3358)

25.92011.0205)

0.05 (0.002)

39.07 ('r.538)

0.33 {0.013)0.31 (0.012)

30.15 (1.187)

30.05 (1.183)

37.07 {1.459)0.31 (0.0'12)

28.35 (1.116)

LrO

39.009 39.025 (1.5358 1.5364)0.06 0.21 (0.002 0.008)0.06 0.19 (0.002 0.007)30.22 30.21 (1.190 1.192)30.12 - 30.17 (1.186 1.188)

37.009 37.025 (1.4570 _ 1.4577)0.06 - 0.19 (0.002 - 0.007)28.42 - 2a.47 11.119,1.1211Countershaft Diameter of needle bearing contact area ADjameter of lst gear contact area gDiameter of ball bearing contact area CRunout

30.000- 30.015 {1.181 1 - 1.1817)35.984 - 36.000 (1.4167 1.4173)24.980 24.993 (0.9835 - 0.9840)0.02 (0.001)max.

29.950 (1.1791)3s.930 r.4146)24.930 (0.9815)0.0s (0.002)

End play (When tightened by the specified torque)Thickness

41.009 - 41.025 ('�t.6145 1.6152)0.03 0.10 (0.001 _ 0.004)30.41 30.44 (1.197 - 1 198)

41 .01 11.617J0.22 (0.009)

30.36 (1.195)

gear End ptay (When tightened by the specified torque)44.009 - 44.025 (1.7326 1.7333)0.04 - 0.12 (0.002 - 0 005)31.91 31.96 (1.256 1.258)

44.01 11.t35)0.24 (0.009)

31.85 (1.2s4)

33.04 {1.301)38.93 (1.533)32.01 (1.260)

27.06 (1.065)

33.93 (1.336)

3r.93 {1.257)22.81 (0.898)

23.51 (0.926)

15.08 (0.594)

0.14 (0.006)

0.4 (0.016)

0.16 (0.006)

o.6210.0244112.78 (0.5031)

t.D.o. D.Length

33.000 - 33.010 (1.2992 1.2996)38.989 39.000 11.53s0_ 1.53s4)32.03 - 32.06 tl.261 - 1.2621Spacer collar(Mainshaft 4thand 5th gear)

Beverse rdler gear LD.Gear to reverse gear shaft cjearance

27.002 27.012 (1.0631 _ 1.0635)33.989 - 34.000 (1.3381 - 1.3386)3r.989 - 32.000 (1.2594 1.2598)22.83 - 22.86 (0.899 0.900)23.53 23.56 (0.926 - 0.928)

rs.016 15.043 (0.5912 _ 0.5922)0.032 0.077 (0.0013 _ 0.0030)Ring-to gear clearance {Ring pushed against gear)0.73 - 1.l8 (0 029 - 0.046)Fork finger thickness

Fork to-synchro sleeve clearance

lsv2nd/sth I 6.2 - 6.410.244 - O.ZS2)3rdl4th 7.4 i.6lO 2g1 O 2ggt0.35 - 0.65 (0.014 - 0.026)Beverse shitt fork Fork pawl groove widthFork to-reverse idler gear clearanceL groove widthFork'to-5th/reverse shift piece pin clearance

12.7 - 13.0 (0.50 _ 0.51)0.5 1. t (0.020 0.043)7 .05 - 7 .25 tO.21A - 0.28510.05 0.35 (0.002 0.014)Sh ift a rm A tnner diameter of sh ift arm C contact ffiShift arr14-go "L;L ".m C clearance13.05 13.13 (0.514 0.517)0.05 - 0.23 (0.002 _ 0.009)Inner diameter of shift arm B shaft contact pointShift arm 8-to shaft clearanceShift arm B to-shift piece clearanceDiameter of shift piece contact point

13.973 - 14.000 (0.5501 0.5512)0.013 0.070 (0.0005 _ 0.0028)0.2 - 0.5 {0.008 0.020)12.9 13.0 (0.508 - 0.512)MBS Shift prece Diameter of pin6.9 7 .1 \O.27 0 2A)

0.095 (0.004)

0.14 (0.006)

Adjust with shim

Differenlial carrier Pinion shaft bore diameterCarrier-to pinion shaft clearanceDriveshaft bore diameterCarrier to,driveshaft clearance

18.010 18.028 (0.7091 _ 0.7098)0.023 0.057 (0.0009 - 0.0022)26.025 26.04s {1.0246_ 1.0254)0.045 - 0.086 (0.0018 0.0034)BacklashPinion gear bore diameterPinion gear-to pinion shaft clearance

0.05 0.15 (0.002 0.006)18.042 - 18.066 (0.7103 _ 0.7113)0.055 - 0.095 {0.0021 _ o.oo37)

0 0.1 10 - 0.004)

3-8

LO

Page 57 of 2189

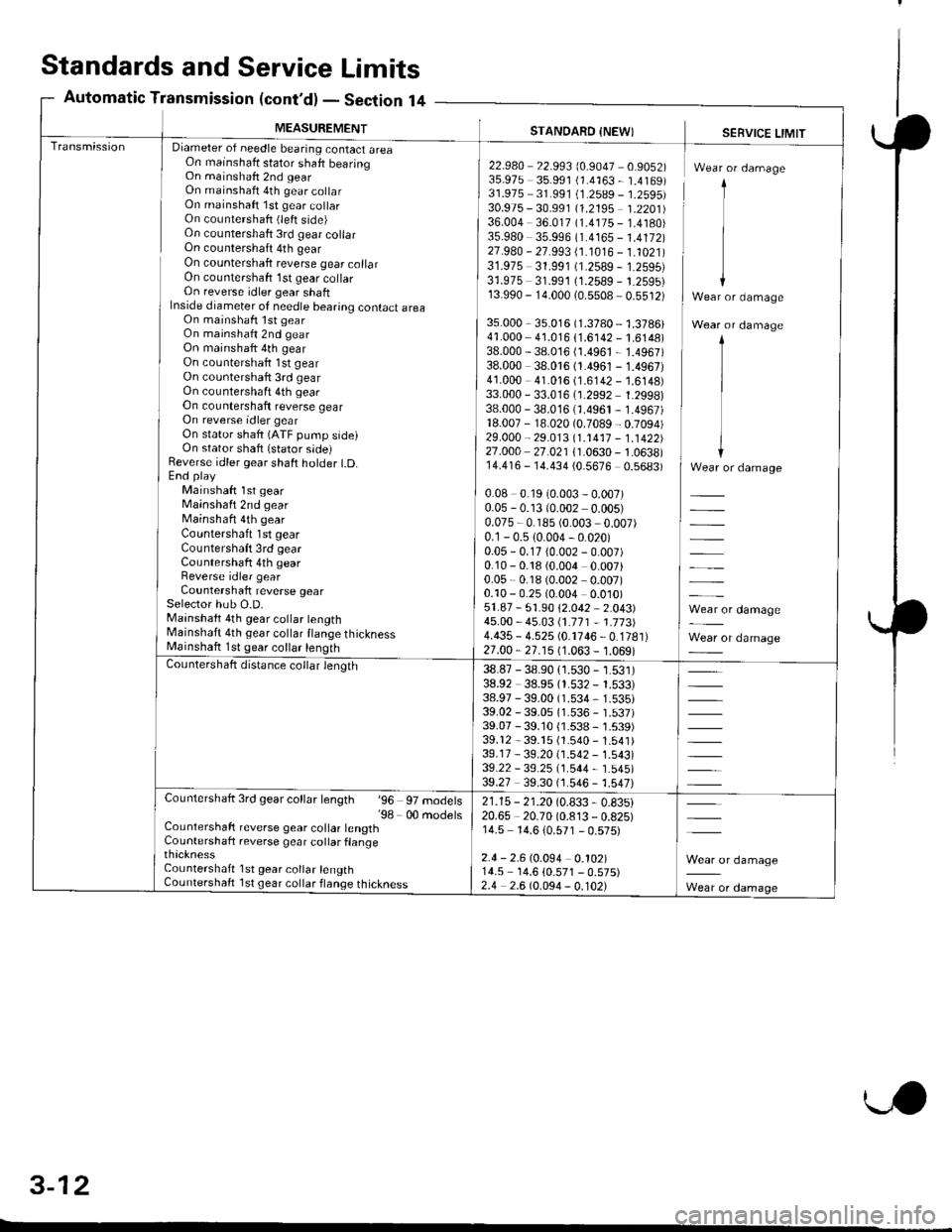

Standards and Service Limits

Automatic Transmission (cont'd) - Section l4

MEASUREMENTSTANOARD {NEW)SERVICE LIMITDiameter of needle bearing contact areaOn mainshaft stator shaft bearingOn mainshaft 2nd gearOn mainshaft 4th gear collarOn mainshaft 1st gear collarOn countershaft (left side)On countershaft 3rd gear collarOn countershaft 4th gearOn countershaft reverse gear collarOn countershaft 1st gear collarOn reverse idler gear shaftInside diameter of needle bearing contact areaOn mainshaft 1st gearOn mainshaft 2nd gearOn mainshaft 4th gearOn countershaft 1st gearOn countershaft 3rd gearOn countershaft 4th gearOn countershaft reverse gearOn reverse idler gearOn stator shaft (ATF pump sideiOn stator shalt (stator side)Reverse idler gear shaft holder l.D.End playMainshaft lst gearMainshaft 2nd gearMainshaft 4th gearCountershaft lst gearCountershaft 3rd gearCountershaft 4th gearReverse idler gearCountershaft reverse gearSelecto. hub O.D.Mainshaft 4th gear collar lengthMarnshaft 4th gear collar Ilange thicknessMainshaft lst gear collar length

22.980 22.993 10.9047 0.9052|j35.975 35.991 (1.4163 - 1.4169)31.975 31.991 (1.2589_,1.2595)30.975 - 30.991 t1.2195 1.2201136.004 36.017 (1.4175 - 1.4180)35.980 35.996 (1.4165 - 1.4172)27.980 - 27.993 (1.1016 - 1.1021)31.975 31.991 (1.2589 - 1.2595)31.97s 31.991 (1.2589 - 1.2595)13.990 - 14.000 {0.5508 - 0.5512)

35.000,3s.016 (1.3780 - 1.3786)41.000 - 41.016 11.6142 - 1.6148)38.000 - 38.0'16 {1.4961 - 1.4967)38.000 38.016 (1.4961 - 1.4967)41.000 41.016 (1.6142 - 1.6148)33.000 - 33.016 (1.2992 1.2998)38.000 - 38.016 (1.4961 - 1.4967)18.007 - 18.020 (0.7089 - 0.7094)29.OO0 -29.O1311.1417 - 1.1422127.O00 27.02111.0630 - 1.0638)'14.416 - 14.434 (0.5676 0.5683)

0.08 0.19 (0.003 - 0.007)0.05 - 0.13 (0.002 0.005)0.075 - 0.185 (0.003 0.007)0.1 - 0.5 {0.004 - 0.020)0.05 - 0.17 {0.002 - 0.007)0.10 - 0.18 (0.004 0.007)0.05 - 0.18 (0.002 0.007)0.10 - 0.25 (0.004 0.010)51.87 - 51.90 {2.042 2.043)45.00 - 45.03 (1.771 - 1.773)4.435 - 4.525 (0.1746 - 0.1781)27.00- 27.15 (1.063 - 1.069)Countershaft distance collar length38.87 - 38.90 {1.530 - 1.531)38.92 38.95 {1.532 - 1.533)38.97 - 39.00 (1.534,1.535i39.02 - 39.05 (1.536 - 1.537)39.07 - 39.10 {1.538 - 1.539)39.r2 - 39.15 (1.540 - 1.541)39.17 - 39.20 (1.542 - 1.543)39.22 - 39.25 (1.544 - '�t.545)

39.27 39.30 (1.546 - 1.547)Countershaft 3rd gear collar length ,96 97 models'98 - 00 modetsCountershaft reverse gear collar lengthCountershaft reverse gear collar flangethacknessCountershaft 1st gear collar lengthCountershaft lst gear collar flange thickness

21.15 - 21.20 (0.833 - 0.835)20.65 20.70 (0.813 - 0.825)14.5 r4.6 {0.571 - 0.575)

2.4 - 2.6 10.094 0.102)14.s - 14.6 (0.571 - 0.575)2.4 2.6 (0.094 - 0.102)

Wear or damage

t a.\

L

Page 58 of 2189

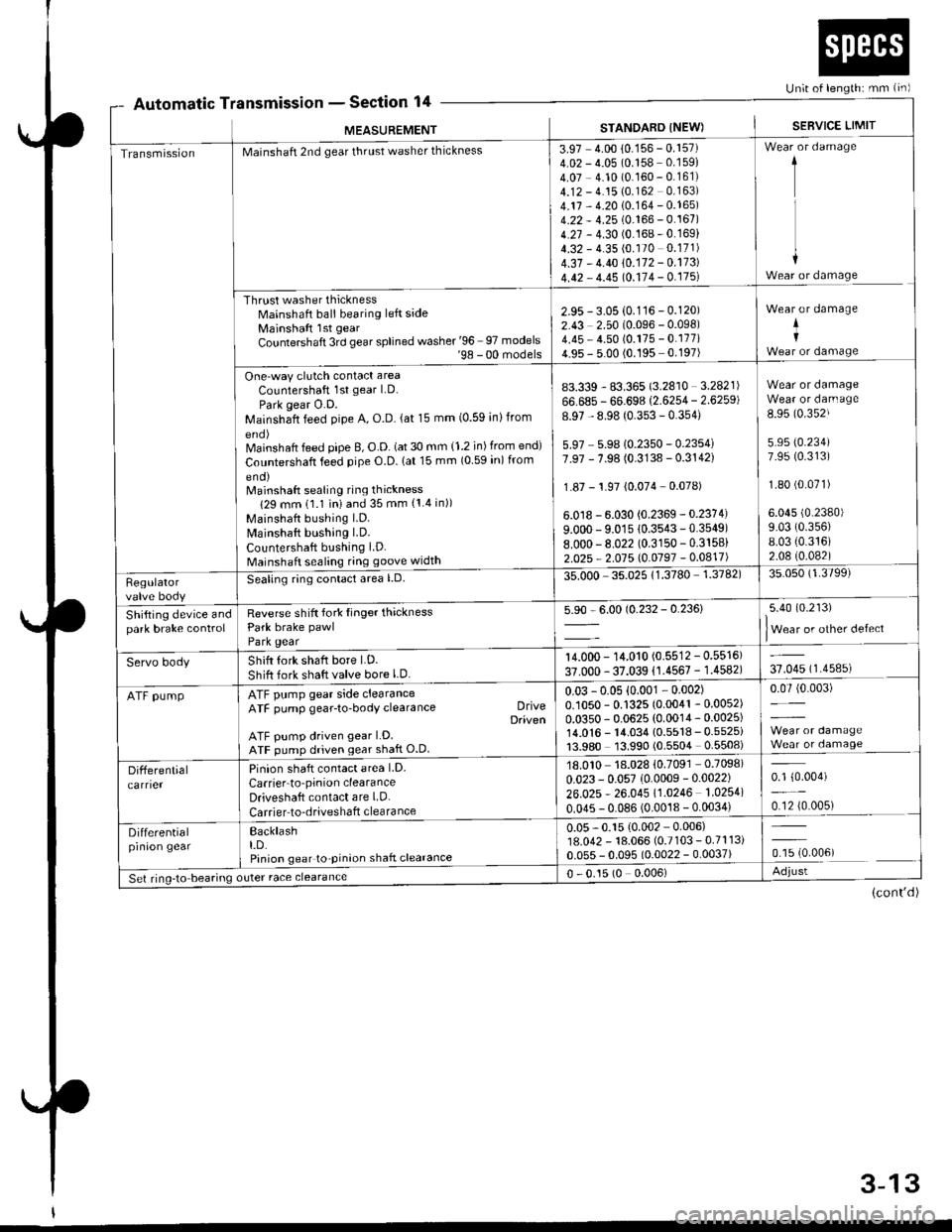

Automatic TnsmtsstonSection 14Un;t of length: mm {in)

r

MEASUREMENT

a

STANDARD INEW)SEBVICE LIMIT

TransmissionMainshaft 2nd gear thrust washer thickness

Thrust washer thicknessMainshaft ball bearing left sideMainshaft lst gear

Countershaft 3rd gear splined washer '96 97 models'98 - 00 models

One-way clutch contact area

Countershaft 1st gear LD.

Park gear O.D.Mainshaft feed pipe A, O.D. (at 15 mm (0.59 inlfrom

Mainshaft feed pipe B, O.D. (at 30 mm {1.2 in) from end)

Countershaft feed pipe O.D. lat 15 mm (0 59 in) from

eno)Mainshaft sealing ring thickness

129 mm 11.1 iniand 35 mm {1.4 in))

Mainshaft bushing l.D.

Mainshaft bushing LD.

Countershaft bushing LD.Mainshaft sealing ring goove width

3.97 4.00 10.156 - 0.157)4.02 - 4.05 (0.158 0.159)

4.07 - 4.10 (0.160 - 0.161)4.12 - 4.15 (0.162 0.163)

4.17 - 4.20 10.164 - 0.165)4.22 - 4.25 (0.166 - 0.167)4.27 - 4.30 (0.168-0.169)

4.32 - 4.35 (0.170 0.171)

4.37 - 4.40 10.172 - 0.173)

4.42 - 4.45 10.114 - 0.175l

1

I

+Wear or damage

2.95 - 3.05 {0.116 - 0.120)2.43 2.50 (0.096 - 0.098)4.45 - 4.50 (0.175 - 0.177i4.95 - 5.00 (0.195 0.197)

Wear or damage

+I

83.339 - 83.365 (3.2810 3.2821)

66.685 - 66.698 (2.6254 - 2.6259)

8.97 - 8.98 (0.353 - 0.354)

5.97 5.9810.2350 - 0.2354i7.97 - 7.98 (0.3138 - 0.3142)

1.87 - 1.97 {0.074 0.078)

6.0 r8 - 6.030 {0.2369 - 0.2374)

9.000 - 9.01s 10.3543-0.3549)8.000-8.022 (0.3150 - 0.3158)

2.025 - 2.015 l0.0197 -0.0417)

Wear or damageWear or darn age

8.95 (0.352J

5.95 (0.234)

7.95 (0.313)

1.80 (0.071)

6.045 (0.2380)

9.03 (0.356)

8.03 {0.316)2.08 (0.082)

Regulatorvalve body

Seating ring conlact area l.D.35.000 35.02511.3780 1.3782)35.050 (1.3799)

Shifting device andpark brake controlReverse shift fork Iinger thicknessPark brake pawl

Park gear

5.90 - 6.00 (0.232 - 0.236)5.40 (0.213)

lWear or other defect

Servo bodyShift fork shaft bore LD.

Shift fork shaft valve bore l.D.

14.000 - 14.010 (0.5512 - 0.5516)

37.000 - 37.039 (1.4567 - 1.4582)37.045 (1.4585)

ATF pumpATF pump gear side clearanceATF pump gear-to-body clearance DriveDaiven

ATF pump driven gear LD.ATF pump driven gear shaft O.D

0.03 -0.05 {0.001 - 0.002)0.1050 - 0.1325 (0.0041 - 0.0052)

0.0350 - 0.0625 (0.0014 - 0.0025)14.0'�|6 - 14.034 {0.5518 - 0.5525i13.980 13.990 (0.5504 0.5508)

0.07 (0.003)

Differentialcarrier

Pinion shaft contact area LD.

Carrier to'pinion clearanceDriveshaft contact are LD.

Carrier to-driveshaft clearance

18.010 18.028 {0.7091 0.7098)

0.023 - 0.057 (0.0009 -0.0022)

26.025 * 26.045 11.0246 1.0254)

0.045 - 0.086 (0.0018 - 0.0034)

0.1 {0.004)

0.12 {0.005)

Differentialprnron gearBacklasht.D.Pinion gear to-pinion shaft clearance

0.05 - 0.15 {0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.7113i0.055 - 0.095 (0.0022 - 0.0037)ffi.oour

Set ring-to bearing outer race clearance0 - 0.15 (0 0.006)Adjust

(cont'd)

3-13

Page 358 of 2189

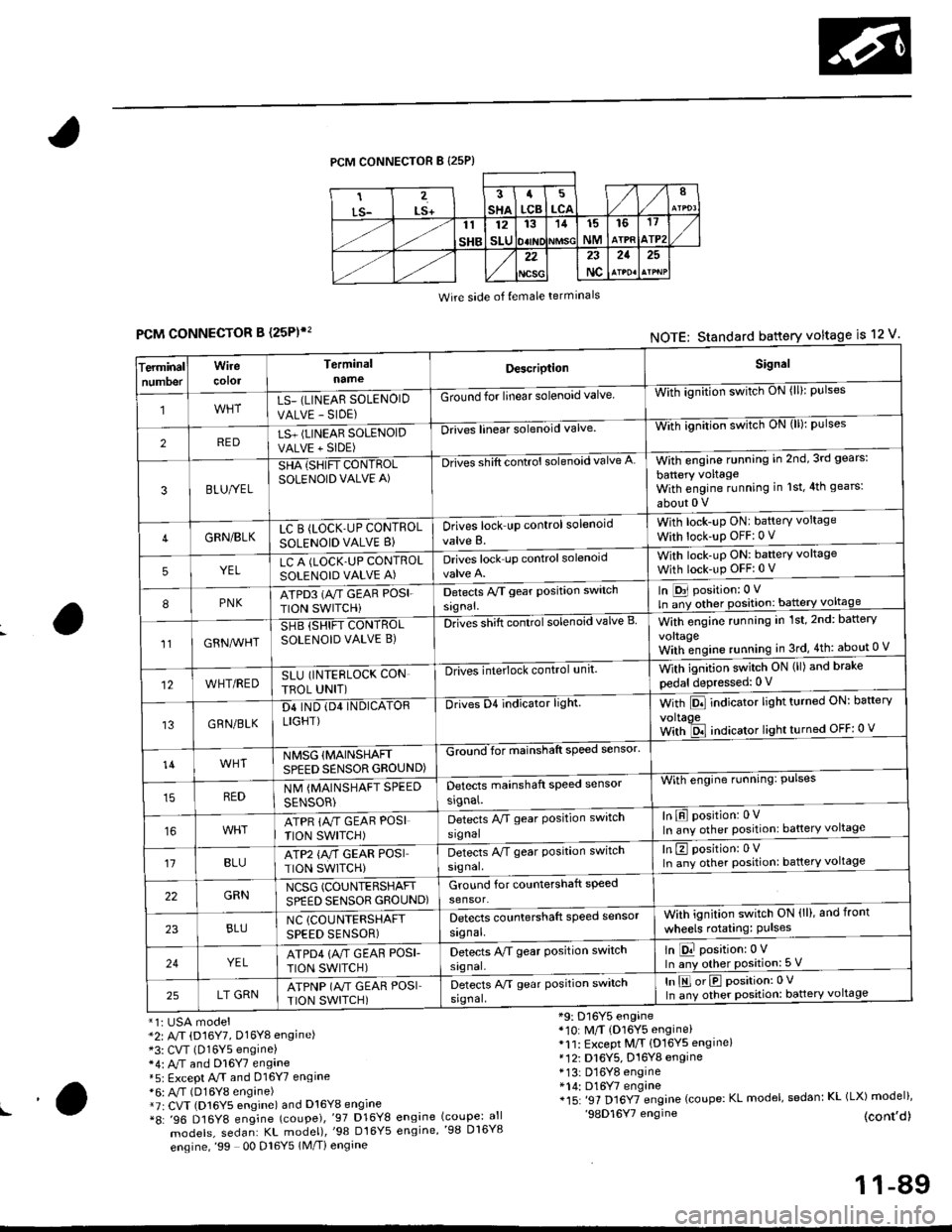

PCM CONNECTOR B {25P)

Wire side of {emale terminals

CONNECTOR B (25P)',

*1i USA model*2: A/T (D16Y7, Dl6Yg engine)*3: CVT (D16Y5 engine)*4: M and Dl6Y7 engane*5: Except A.rT and 016Y7 engine*6: A,/T (D16Y8 engine)*7r CVT (D16Y5 engine) and D16Y8 engine*8: '96 D16Y8 engine (coupe),'97 D16Y8

models, sedan: KL model),'98 Dt6Y5

engine,'99 00 Dl6Y5 1M/Ti engine

*9: D16Y5 engine*10: M/T (D16Y5 engine)*11: Except M/T {D16YS engine}*12i D16Y5, D16Y8 engine* 13: D16Y8 engine*14: D16Y7 engine*15: '97 Dl6YTengine (coupe: KL model, sedan: KL (LX) model)''98D16Y7 engine (cont,d)engine (coupe: allengine,'98 D16Y8

FCMNOTE: Standard battery voltage is 12 v'

erminalTnumoer

Wirecotol

TerminalnameDescriptionSignal

1LS_ (LINEAR SOLENOID

VALVE - SIDE)

Ground for linear solenoid valveWii-ignnion switctr oN {ll}: pulses

2REDLS+ (LINEAR SOLENOIDVALVE + SIDE)

-Drii6l linear solenoid valveWith ignilion switch uN (lll: pulses

3BLU/YEL

SHA {SHIFT CONTROLSOLENOID VALVE A)

-Drives shift control solenoid valve AWith engine running in 2nd,3rd gears:

battery voltageWith engine running in 1st,4th gears:

about 0 V

4GRN/BLKLC B (LOCK'UP CONTROL

SOLENOID VALVE B}Drives lock up control solenoid

valve B.

With lock-up ONI battery voltage

With lock-up OFF:0 v

5YELLC A (LOCK.UP CONTROLSOLENOID VALVE A)Drives lock up controlsolenoidWith lock-uP ON: baftery voltage

With lock-up OFFi 0 V

8PNKATPD3 (NT GEAR POSI.

TION SWITCHi

Detects Py'T gear Position switch

signal.

In [D31 position: 0 V

ln ;y other position: battery voltage

1lGRN^lr'HT

SHB (SHIFT CONTROLSOLENOID VALVE B)DnGs shift conttol solenoid valve BWith engine running in 1st,2nd: battery

vo|taqeWith;ngine running in 3rd,4th: about 0 V

12WHT/REDSLU (INTERLOCK CON

TBOL UNIT)

-DlivEilite'lock control,rnit.With ignition switch ON (ll) and brake

pedal depressed: 0 V

13GRN/BLK

D4 IND (D4 INDICATORLIGHT)

Drives D4 indicator light.With Pll indicator lrght turneo urr: oarterv

voltaoeWith ld indicator light turned OFF: 0 v

14WHTNMSG {MAINSHAFTSPEED SENSOR GROUND)

GZiiI'for mainshaft speed sensol

With engine running: Pulses

In E position: 0VIn any other position: battery voltage

REDNM {MAINSHAFT SPEED

SENSOR)

Detects mainshaft speed sensor

srgnal.

ATPR {M GEAR POSI

TION SWITCH)

Detects M gear Position switch

signal

't1BLUATP2 {A/T GEAR POSITION SWITCH)

Detects A/T gear Position switch

signal.

In E position: 0VIn any other position: battery voltage

22GRNNCSG (COUNTERSHAFT

SPEED SENSOR GROUND)Ground for countershaft speed

sensor.

23BLUNC (COUNTERSHAFT

SPEED SENSOR)

Detects countershaft speed sensor

signal.

Vvith ignition switch ON (ll), and front

wheels rotating: Pulses

24YELATPD4 {M GEAF POSI-

TION SWITCH)

Detects M gear Position switch

signal.

ln E position:0 VIn any other position: 5 V

25LT GRNATPNP (A"/T GEAR POSITION SWITCH)

Detects A/T gear Position switch

srgnal,

In E orE position:0 V

In any other position: battery voltage

!a

11-89

Page 373 of 2189

PGM-FI System

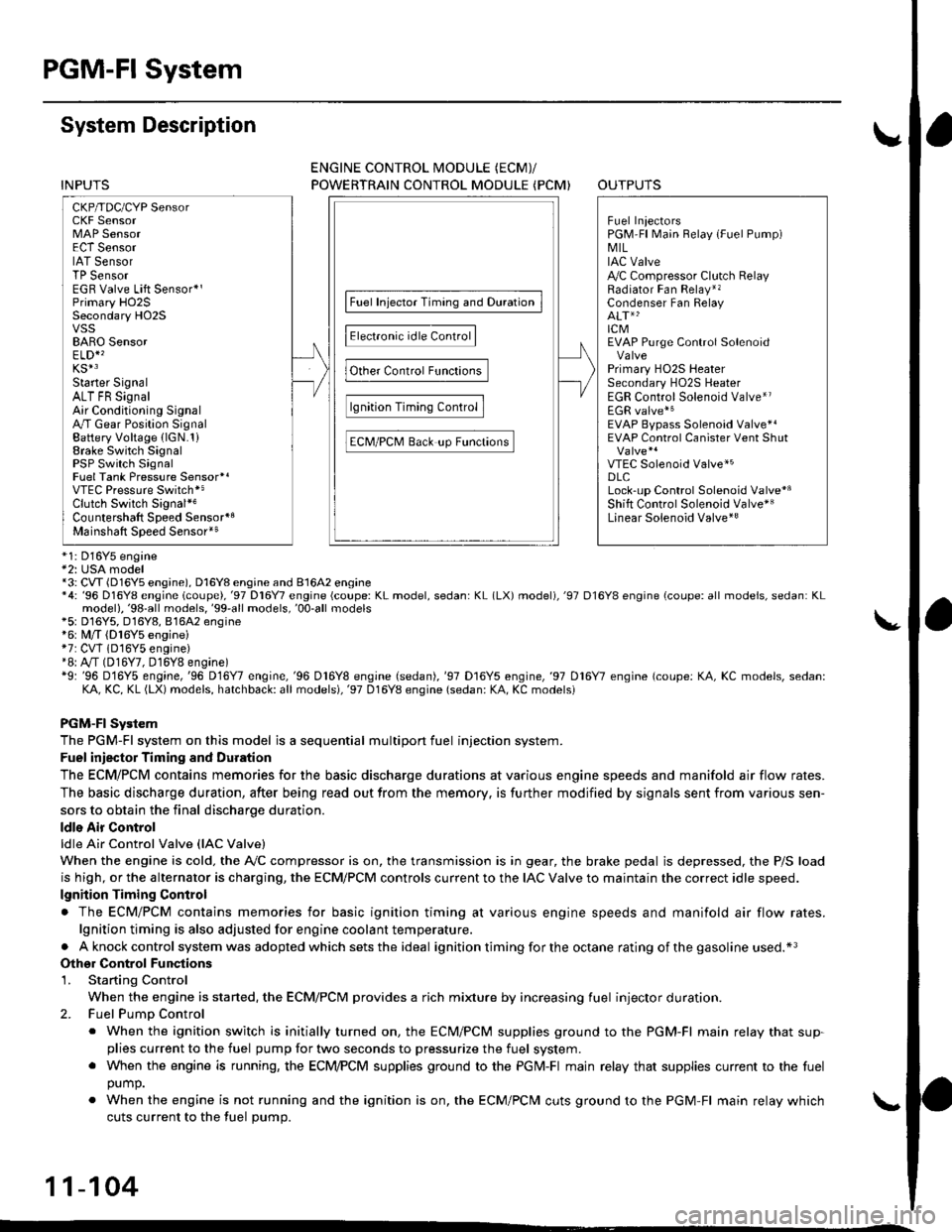

System Description

CKP/TDC/CYP Sensor

MAP Sensor

IAT SensorTP SensorEGR Valve Lift Sensor*'Primary H02SSecondary HO2SVSSBARO SensorELD*'KS€Starter SignalALT FR SignalAir Conditioning SignalA/T Gear Position SignalBattery Voltage {lGN.1}Erake Switch SignalPSP Switch SignalFuel Tank Pressure Sensor*iVTEC Pressure Switch*5Clutch Switch Signal*6Countershaft Speed SensornBMainshaft Speed Sensorrs

-\

----t /

F;ilrr j"-----fi-tri-'r.;l

Fb"t."'i" d" c;;il

F,h"'c;;tr*".io";-l

@."r.l"sc;;ll

EaM/PcM B""k-p F"""till

r\

-:/

Fuel IniectorsPGM-Fl Main Belay {Fuel Pump)MILIAC Valve!y'C Compressor Clutch RelayRadiator Fan Relay*,Condenser Fan RelayALT*'lcMEVAP Purge Control Solenoid

Primary HO2S HeaterSecondary H02S HeaterEGR Control Solenoid Valve*rEGR valve*6EVAP Bypass Solenoid Valve*'EVAP Control Canister Vent Shut

VTEC Solenoid Valve*5DLCLock-up Control Solenoid Valve*aShift Control Solenoid Valve*3Linear Solenoid Valve*3

*1: Dl6Y5 engine*2: USA model*3: CW (D16Y5 ensine), D16Y8 engine and 81642 ensine*4: '96 D16Y8 engine lcoupe),'97 Dl6Y7 engine (coupe: KL model, sedan: KL (LX) model),'97 D16Y8 engine {coupe: all models, sedan: KLmodel),'98-all models,'99'all models,'00-all models+5: D16Y5, D16Y8,816A2 engine*6: M/T (D16Y5 enginei*7: CVT 1D'l6Y5 engine)+8: A/T (D16Y7, D16Y8 engine)*9: '96 D16Y5 engine,'96 D16Y7 engine,'96 Dl6Y8 engine (sedan),'97 D16Y5 engine,'97 Dl6Y7 engine (coupe: KA, KC models, sedan:KA, KC, KL (LX) models, hatchback: all models),'97 D16Y8 engine (sedan: KA, KC modelsi

PGM-FI Sy3lem

The PGM-Fl system on this model is a sequential multipon fuel injection system.

Fuel iniector Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold air flow rates.

The basic discharge duration, after being read out from the memory. is further modified by signals sent from various sen-

sors to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve llAC Valve)

When the engine is cold. the A,/C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

. The ECM/PCM contains memories for basic ignition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. Aknockcontrol system was adopted which sets the ideal ignition timing for the octane rating ofthegasoline used.*3

Othgr Control Funqtions

1. Starting Control

When the engine is started, the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on, the ECM/PCM supplies ground to the PGM-Fl main relay that sup-plies current to the fuel pump for two seconds to pressurize the fuel system.. When the engine is running, the ECI\4PCM supplies ground to the PGM-FI majn relay that supplies current to the fuel

oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

11-104

INPUTS

ENGINE CONTROL MODULE (ECMY

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

Page 581 of 2189

\

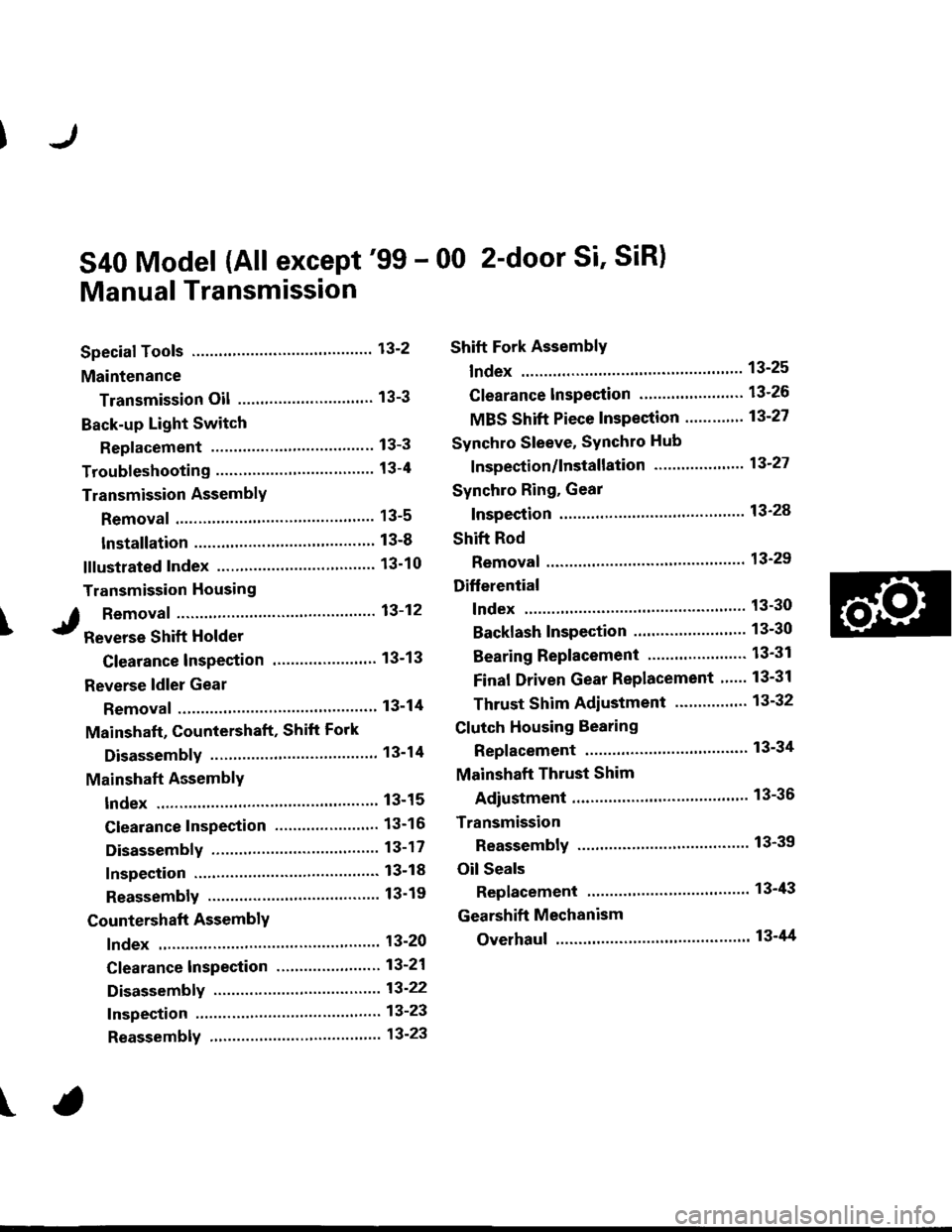

S40 Model (All except'99 - 00 2-door Si' SiR)

Manual Transmission

Special Tools ..'.......... 13-2

Maintenance

Transmission Oil .............................. 13-3

Back-up Light Switch

Replacement ......... 13-3

Troubleshooting '....... 13-4

Transmission AssemblY

Removal ................. 13-5

lnstallation ............. 13-8

lllustrated Index ...............'........."........ 13-10

Transmission Housing

I Removaf .."""""""' 13-12

J R"rr"r"" Shift Holder

Clearance lnspection ....................... 13-13

Reverse ldler Gear

Removal ....'.........." 13-14

Mainshaft, Countershaft, Shift Fork

Disassembly ......'... 13-14

Mainshaft AcsemblY

Index ............... ....... 13-15

Clearance Inspection ..'.................... 13-16

Disassembly .......... 13-17

Inspection ....'......... 13-18

Reassembly ........... 13-19

Countershaft AssemblY

lndex ................ ...... 13-20

Clearance lnspection ."..........'......." 13-21

Disassembly ..."""' 13-22

Inspection .............. 13-23

Reassembly ..'.""... 13-23

Shift Fork AssemblY

lndex ............... ."'... 13-25

Clearance lnspection ."......."........'.. 13'26

MBS Shift Piece Inspection ....-.....'.. 13'27

Synchro Sleeve, Synchro Hub

f nspection/lnstallation .......'...... ".... 13'27

Synchro Ring, Gear

Inspection '....'..".... 13'28

Shift Rod

Removal .'......".""" 13'29

Differential

lndex ......."'...... .'."' 13-30

Backlash Inspection ..........."......."... 13-30

Bearing Beplacement'.............'.".... 13'31

Final Driven Gear Replacement '..... 13-31

Thrust Shim Adiustment ..."........... 13-32

Clutch Housing Bearing

Replacement .......'. 13-34

Mainshaft Thrust Shim

Adiustment '....'..".. 13-36

Transmission

Reassembly ........... 13-39

Oil Seals

Replacement ......... 13-43

Gearshift Mechanism

Overhaul ................ 13-44

\

Page 591 of 2189

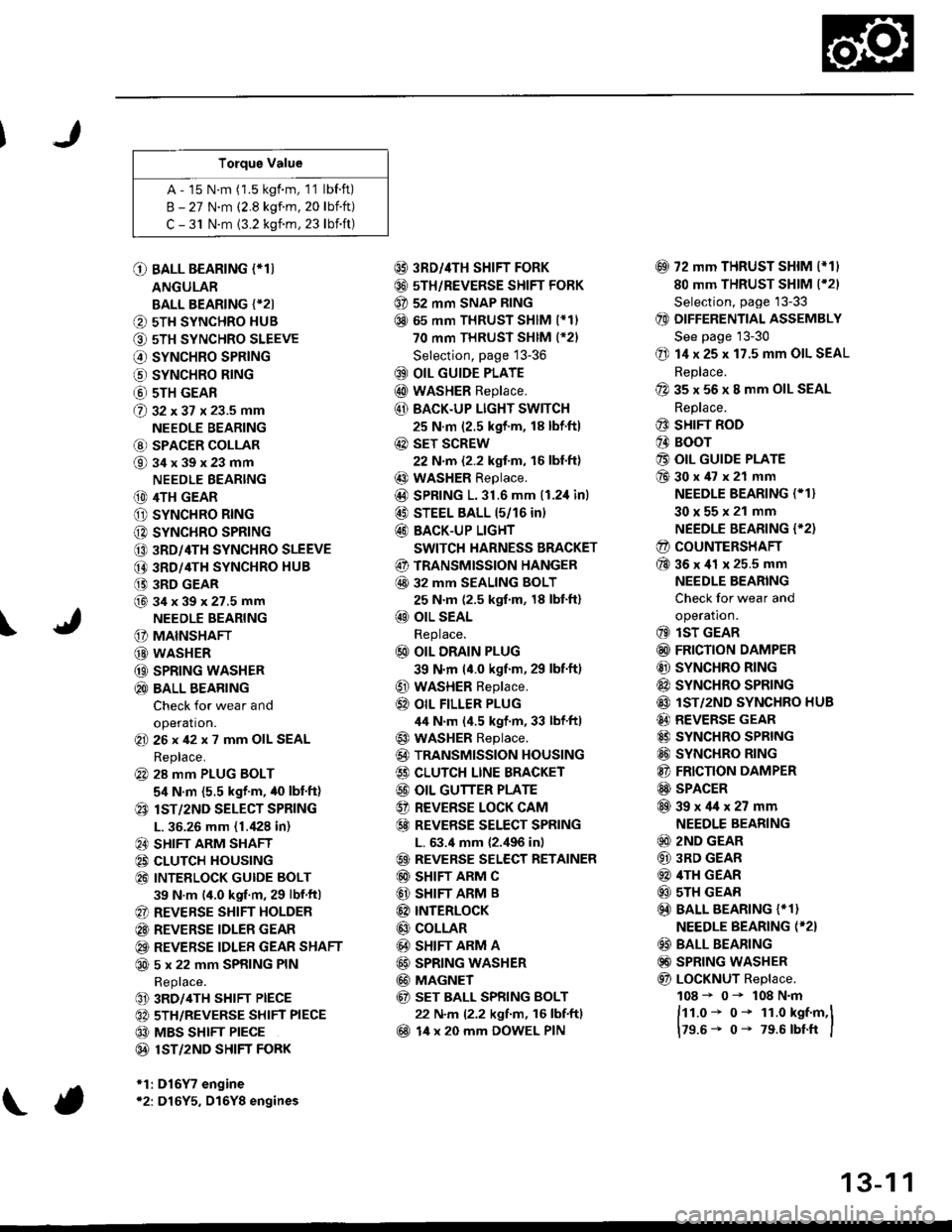

Torque Value

A - 15 N.m (1.5 kgf.m, 1'1 lbf.ft)

B - 27 N.m (2.8 kgf.m. 20 lbift)

C - 31 N.m {3.2 kgnm, 23 lbift)

\

O BALL BEARING (*T)

ANGULAR

BALL BEARING {*2I

O 5TH SYNCHRO HUB

O 5TH SYNCHRO SLEEVE

€) SYNCHRO SPRING

o SYNCHRO B|NG

@ 5TH GEAR

@ gz xgt x 23.5 mm

NEEDLE BEARING

@ SPACER COLLAR

@34x39x23mm

NEEDLE BEARING

(D 4TH GEAR

O SYNCHRO RING

C) SYNCHRO SPRING

CO 3RD/4TH SYNCHRO SLEEVE

@ 3RD/4TH SYNCHRO HUB

(} 3RD GEAR

@34x39x27.5mmNEEDLE BEARING

G) MAINSHAFT

G) WASHER

@ SPRING WASHER

@ BALL BEARING

Check for wear and

operation.(E 26x42x7 mm OIL SEAL

Replace.

@ 28 mm PLUG BOLT

5,1 N.m {5.5 kgf'm, /t0 lbt'ft)

@ lsT/zND SELECT SPRING

L. 36.26 mm (1./P8 in)

@ SHIFT ARM SHAFT

@ CLUTCH HOUSING

@ INTEELOCK GUIDE BOLT

39 N.m (4.0 kgf.m, 29 lbf.ftl

@ REVERSE SHIFT HOLDER

@ REVERSE IDLER GEAR

@ REVERSE IDLER GEAR SHAFT

@ 5 x 22 mm SPRING PIN

Replace.

@ 3RD/4TH SHIFT PIECE

@ 5TH/REVERSE SHIFT PIECE

@ MBS SHIFT PIECE

@ 1ST/2ND SHIFI FORK

*1:D16Y7 engine*2: D16Y5, D16Y8 engines

@ 3RD//|TH SHIFT FORK

@ 5TH/REVERSE SHIFT FORK

@ 52 mm SNAP RING

@ 65 mm THRUST SHIM (*11

70 mm THRUST SHIM (*21

Selection, page 13-36

@ OIL GUIDE PLATE

@ wASHER Replace.

@ BACK.UP LIGHT SWITCH

25 N.m (2.5 kgf'm, 18 lbf'ft)

@ sET SCREW

22 N.m {2.2 kgf.m, 16 lbl.ft}

@ WASHER Replace.

@D SPRING 1.31.6 mm (1.2,1inl

@ STEEL BALL 15/16 in)

@ BACK-UP LIGHT

SWITCH HARNESS BRACKET

@ TRANSMISSION HANGER

@ 32 MM SEALING BOLT

25 N.m (2.5 kgf.m, 18 lbt'ft)

@ OIL SEAL

Replace.

@ OIL DRAIN PLUG

39 N.m (4.0 kgf.m, 29 lbf.ft)

@ WASHER Replace.

@} OIL FILLER PLUG

44 N.m (4.5 kgf.m, 33 lbf'ftl

@ WASHER Replace.

@) TRANSMISSION HOUSING

€) CLUTCH LINE BRACKET

@ OIL GUTTER PLATE

@ REVERSE LOCK CAM

@ REVEBSE SELECT SPRING

L. 63.4 mm {2.,196 in)

@ REVERSE SELECT RETAINER

@ SHIFT ARM C

@ SHIFT ARM B

@ INTERLoCK

@ COLLAR

@ SHIFT ARM A

@ SPRING WASHER

@ MAGNET

@ sET BALL SPRING BOLT

22 N.m (2.2 kgf.m, 16 lbf.ftl

@ 14 x 20 mm DOWEL PIN

@ 72 mm THRUST SHIM l*11

80 mm THRUST SHIM (*21

Selection, page '13-33

@ DIFFERENTIAL ASSEMBLY

See page 13-30

@ 14 x 25 x 17.5 mm OIL SEAL

Replace.

@ 35 x 56 x 8 mm OIL SEAL

Replace.

@ SHIFT ROD

@ BOOr

@ OIL GUIDE PLATE

@30x47x21 mm

NEEDLE BEARING (* 1}

30x55x21 mm

NEEDLE BEARING {'2)

@ COUNTERSHAFT

@36x41 x 25.5 mm

NEEDLE BEARING

Check for wear and

operatron.

@ lsT GEAR

@ FRICTION DAMPER

@ SYNCHRO RING

@ SYNCHRO SPRTNG

@ lST/2ND SYNCHRO HUB

@ REVERSE GEAR

@ SYNCHRO SPRING

@ SYNCHRO RING

@ FRICTION DAMPER

@ SPACER

@39x4lx27mm

NEEDLE BEARING

@ 2ND GEAR

@ 3RD GEAR

@ 4TH GEAR

@ sTH GEAR

@) BALL BEARING {* 1}

NEEDLE BEARING (*2}

@ BALL BEARING

@) SPRING WASHER

@ LoCKNUT Replace.

108 - 0- 108 N.m

ftt.o* o- 1r.o kst.m,l

179.6- 0- 79.6 rbtft I

13-1 1

Page 592 of 2189

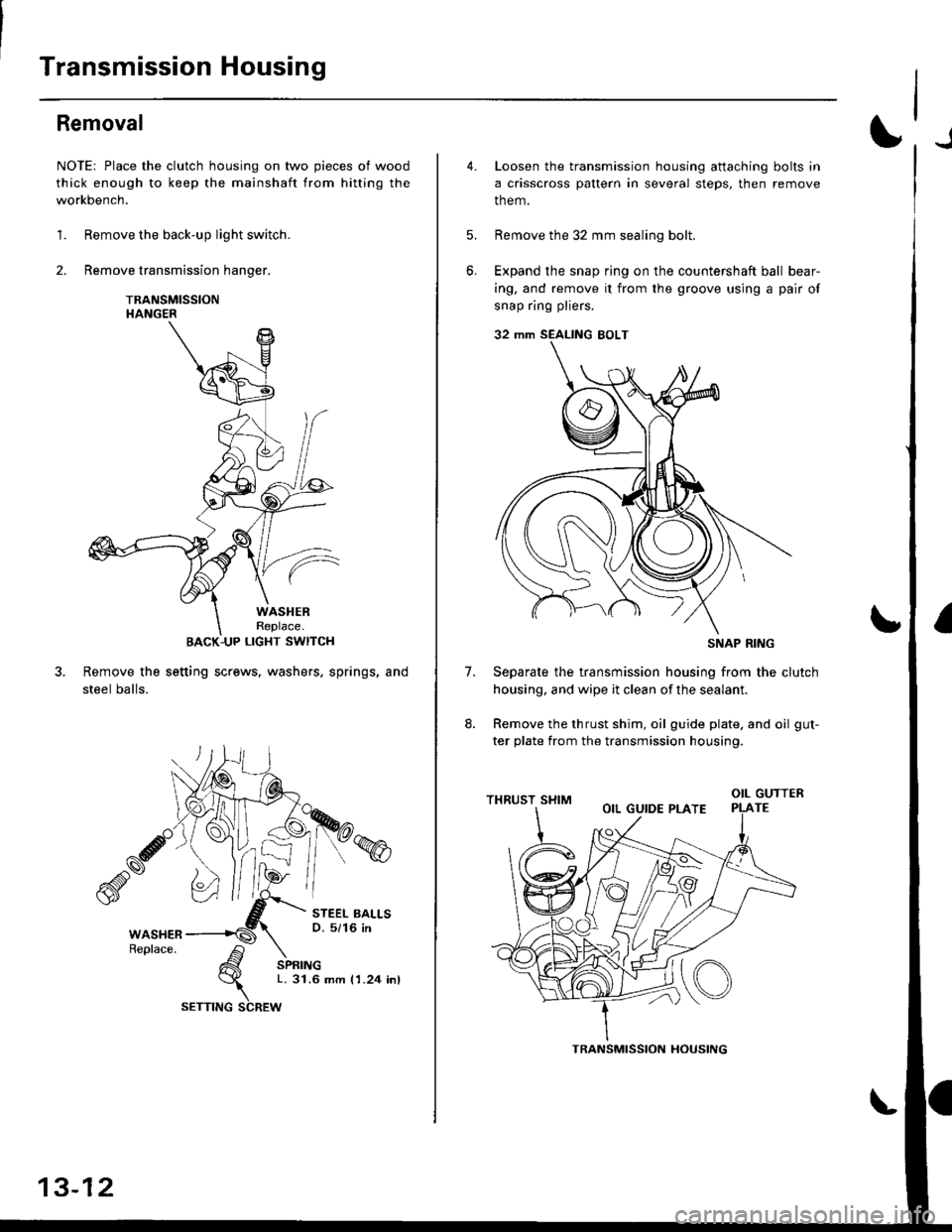

Transmission Housing

Removal

NOTE: Place the clutch housing on two pieces of wood

thick enough to keep the mainshaft from hitting the

workbench.

1. Remove the back-up light switch.

2. Remove transmission hanger.

TRANSMISSIONHANGER

BACK-UP LIGHT SWITCH

Remove the setting screws. washers. springs, and

steel balls.

STEEL BALLSO. 5/16 in

SPRINGL. 31.6 mm I 1.24 inl

13-12

SETTING SCREW

TRANSMISSION HOUSING

6.

4.Loosen the transmission housing attaching bolts in

a crisscross pattern in several steps, then remove

them.

Remove the 32 mm sealing bolt.

Expand the snap ring on the countershaft ball bear-

ing, and remove it from the groove using a pair of

snap ring pliers.

32 mm SEALING EOLT

Separate the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the thrust shim, oil guide plate. and oil gut-

ter plate from the transmission housing.

(o

7.

otLGUTTERTE

SNAP RING

Page 594 of 2189

Reverse ldler Gear

Mainshaft, Cou ntershaft,

Shift Fork

Removal

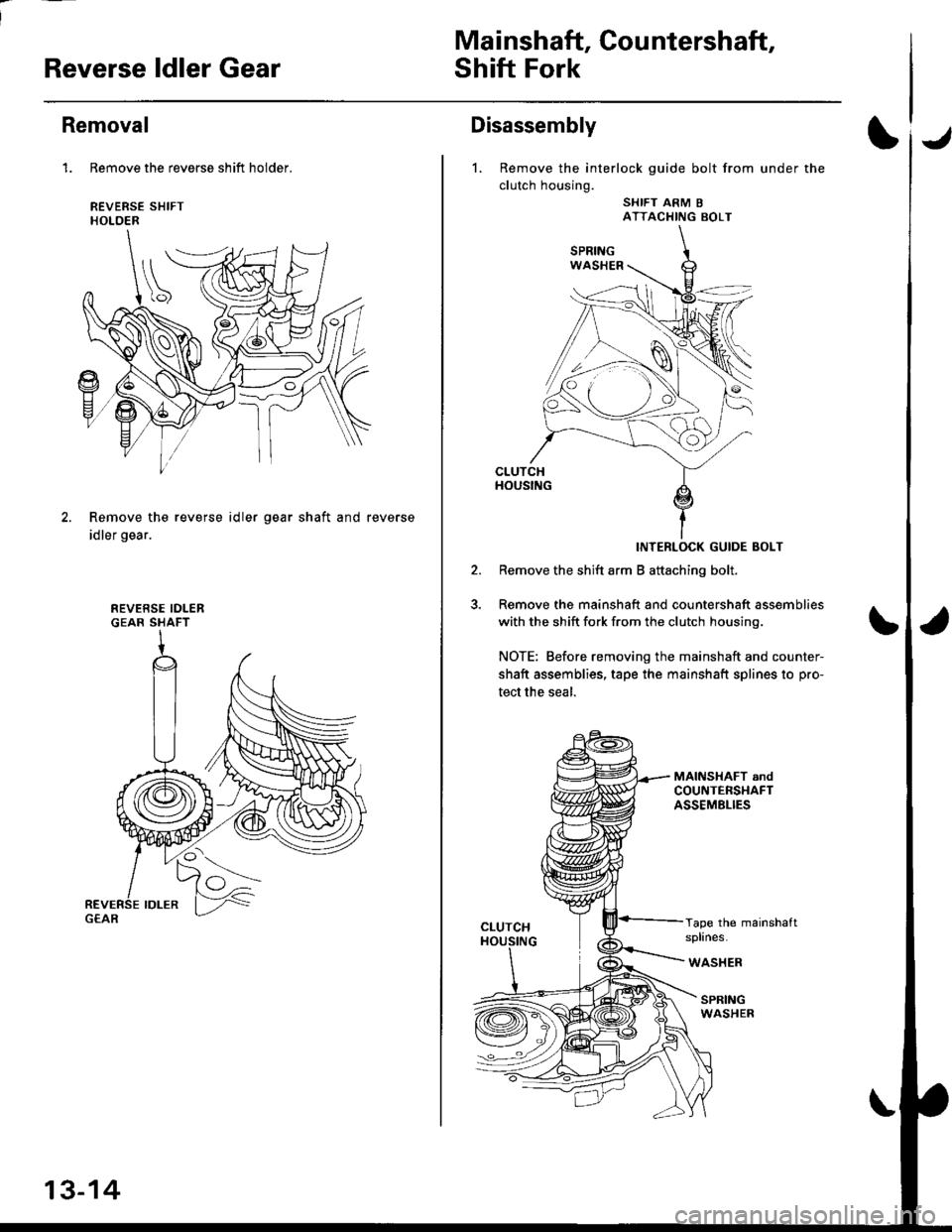

1. Remove the reverse shift holder.

REVERSE SHIFTHOLOER

Remove the reverse id ler

idler gear.

gear shaft and reverse

REVERSE IDLERGEAR SHAFT

13-14

Disassembly

1. Remove the interlock guide bolt from under the

clutch housing.

SHIFT ARM 8ATTACHING BOLT

CLUTCHHOUSING

INTERLOCK GUIDE BOLT

Remove the shift arm B attaching bolt.

Remove the mainshaft and countershaft assemblies

with the shift fork from the clutch housinq.

NOTE: Before removing the mainshaft and counter-

shaft assemblies, tape the mainshaft splines to pro-

tect the seal.

Tape the mainshaftsplines.

WASHER

SPRINGWASHER

Page 600 of 2189

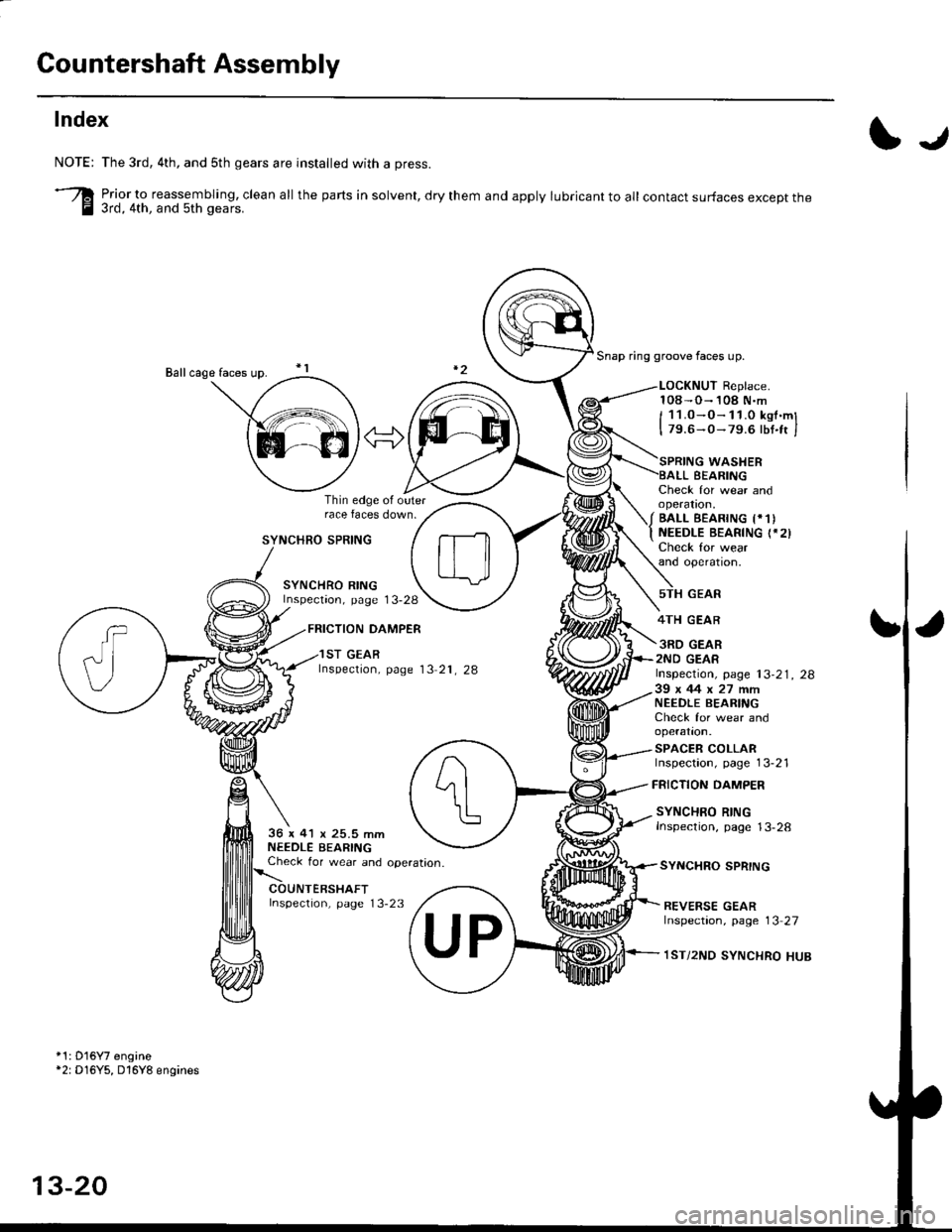

Countershaft Assembly

Index

I.r

NOTE:

-re

The 3rd, 4th, and sth gears are installed with a press.

Prior_to reassembling, clean all the parts in solvent, dry them and apply lubricant to all contact surfaces except the3rd, 4th, and 5th gears.

Snap ring groove faces up.

LOCKNUT Replace.108-O- 108 N.m

I 11.0-O-11.0 kst.ml

I 79.6-0- 79.6 lbt.ft I

SYNCHRO SPRING

SYNCHRO RINGInspectaon, page 13-28

FRICTION DAMPER

Thin edge ol outerrace faces down.

Check for wear andoperatron,

/ BALL EEAR|NG t*1)

t NEEDLE BEARTNG (.2)

Check for wearand operatron,

WASHERBEARING

GEAR

4TH GEAR

3RD GEAR2ND GEAR

FRICTION DAMPER

SYNCHRO SPRING

SYNCHRO RINGInspection, page 13-2836 x 41 x 25.5 mmNEEDLE BEARINGCheck for wear and operataon.

Inspection, page 13-23

1ST GEARlnspection, page 13 21, 28lnspection, page 13-21, 2839x44x27m�mNEEDLE BEARIfI'GCheck for wear andoperation.

SPACER COLLARInspection, page 13-21

REVERSE GEARlnspection, page 13 27

1ST/2ND SYNCHRO HUB

*1: D'16Y7 engine*2: D16Y5, D16Y8 engines

13-20