Transmission HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 665 of 2189

t

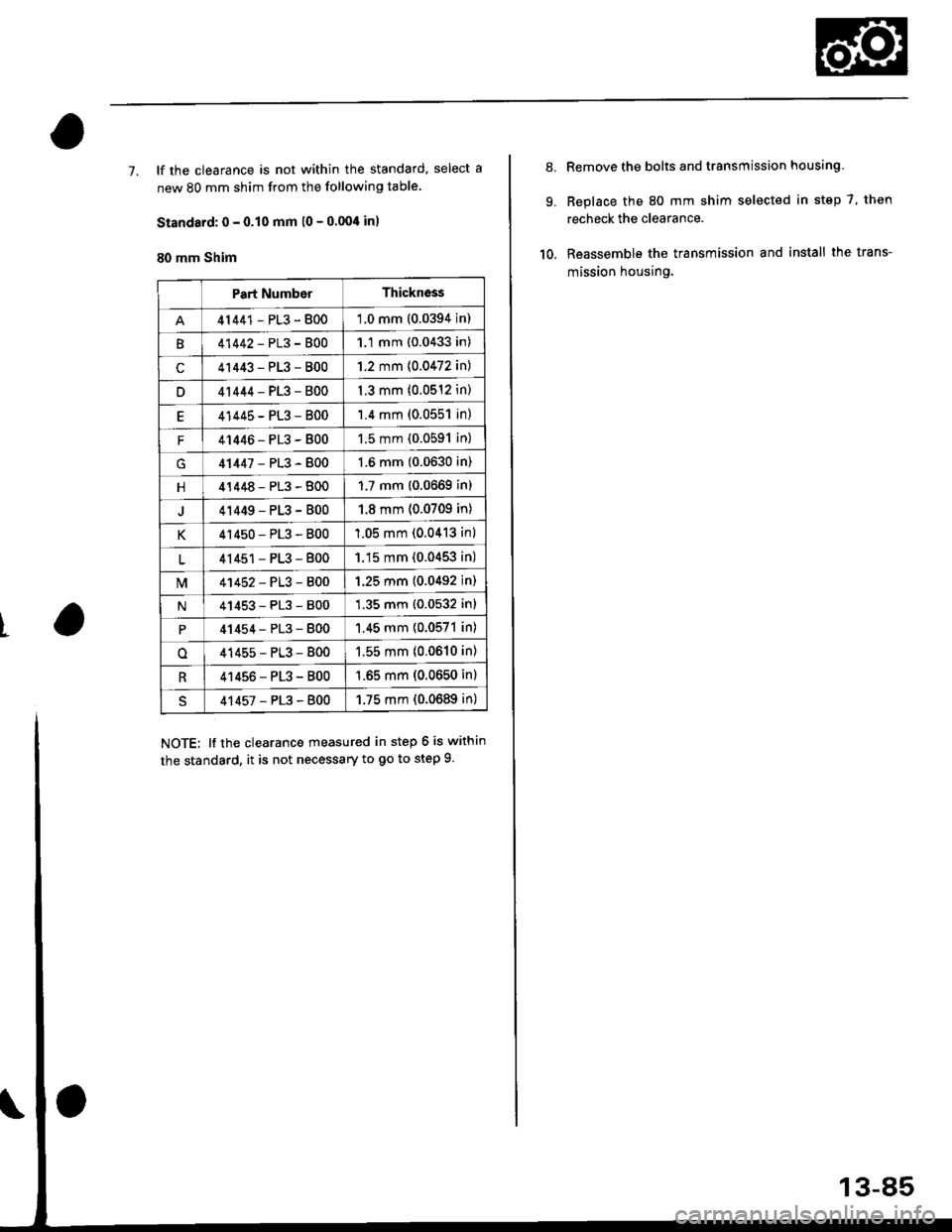

7. lf the clearance is not within the standard, select a

new 80 mm shim from the following table.

Standard: 0 - 0.10 mm (0 - 0.004 inl

80 mm Shim

Part NumberThickn6ss

41441 - PL3 - 800'1.0 mm (0.0394 in)

B41442-PL3-B001.1 mm (0.0433 in)

c41443-PL3-8001.2 mm (0.0472 in)

D41444-PL3-8001.3 mm (0.0512 in)

41445-PL3-8001.4 mm (0.0551 in)

41446-PL3-8001.5 mm (0.0591 in)

41447-PL3-8001.6 mm (0.0630 in)

H41448-PL3-8001.7 mm (0.0669 in)

41449-PL3-8001.8 mm (0.0709 in)

K41450-PL3-B001.05 mm (0.0413 in)

41451 - PL3 - 8001.'15 mm (0.0453 in)

IV41452-PL3-8001.25 mm (0.0492 in)

N41453-PL3-B001.35 mm (0.0532 inl

P41454-PL3-8001.45 mm (0.0571 in)

41455-PL3-8001.55 mm (0.0610 in)

R41456-PL3-8001.65 mm (0.0650 inl

41457-PL3-8001.75 mm (0.0689 in)

NOTE; lf the clearance measured in step 6 is within

the standard, it is not necessary to 9o to step 9.

13-85

8.Remove the bolts and transmission housing.

Beplace the 80 mm shim selected in step 7, then

recheck the clearance.

Reassemble the transmission and install the trans-

mission housing.

10.

Page 668 of 2189

Mainshaft Thrust Clearance

Adjustment

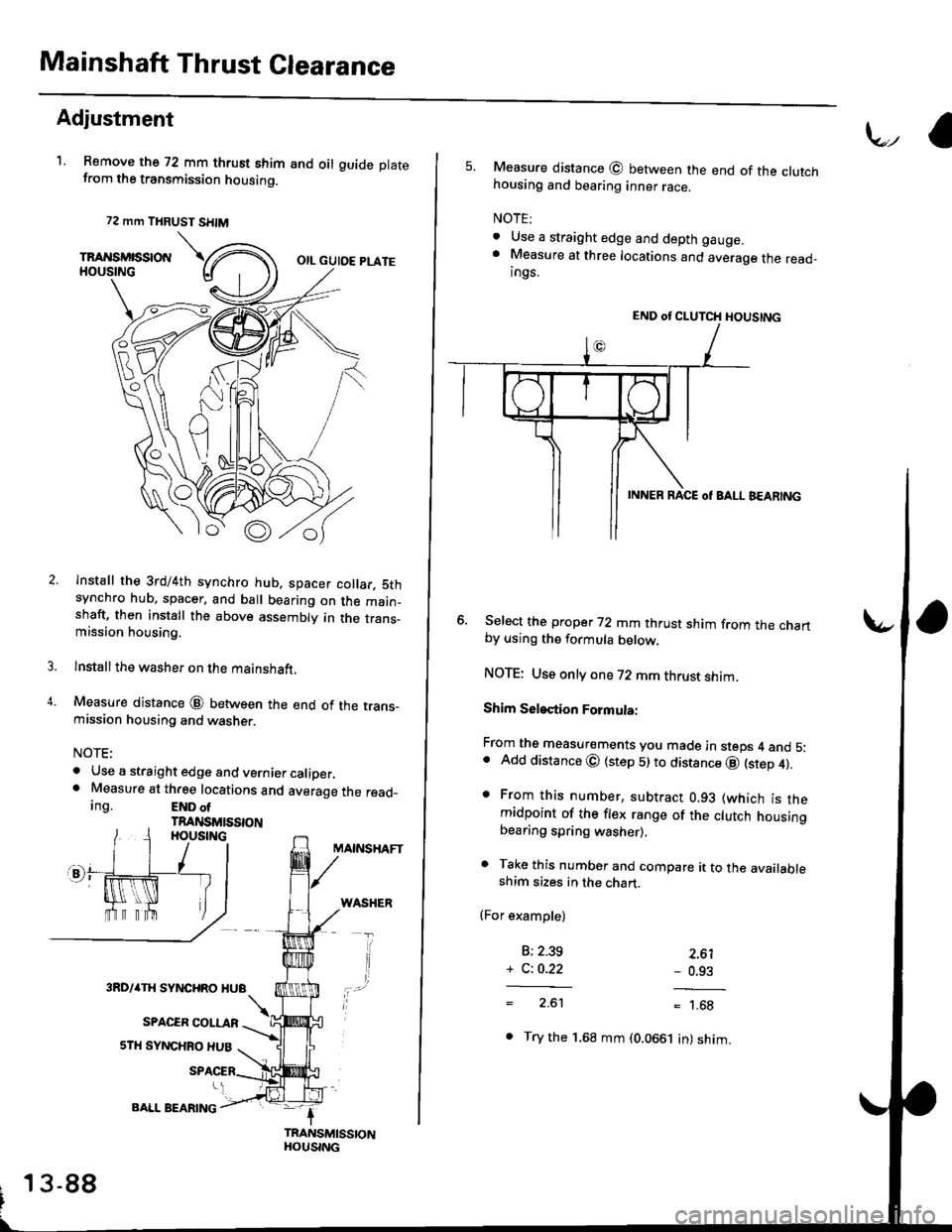

1. Remove the 72 mm thrust shim and oil guide platefrom the transmission housing.

4.

TFANSMISSIONHOUSING

72 mm THRUST SH|M

TRAt{SMtSStONHOUSINGOIL GUIOE PLATE

lnstall the 3rd/4th synchro hub. spacer collar,5thsynchro hub. spacer, and ball bearing on the main_shaft, then install the above assembly in the trans_mission housing.

lnstall the washe[ on the mainshaft,

Measure distance @ between the end of the trans-mission housing and washer.

NOTE;

. Use a straight edge and vernier caliper.. Measure at three locations and average the read_ing.ENO otlnA sMtsstoNHOUSINGMAINSHAFT

3RD/irTH SYNCHRO HUB

SPACCR COLLAR

5TH SYNCHRO HUB

o

B

13-88

AALL BEARING

V.

5. Measure distance @ between the end of the clutchhousing and bearing inner race.

NOTE;

. Use a straight edge and depth gauge.. Measure at three locations and average the read-ings.

Select the prcpet 72 mm thrust shim from the chartby using the formula below.

NOTE: Us€ only one 72 mm thrust sntm.

Shim Selection Formula:

From the measurements you made in steps 4 and 5:. Add distance O lstep 5) to distance @ (step 4).

. From this number, subtract 0.93 (which is themidpoint of the flex range of the clutch housingbearing spring washer).

. Take this number and compare it to the availableshim sizes in the chart.

{For example)

B;2.39

+ C: 0.22- 0.93

2.61 = 1.68

Try the 1.68 mm (0.0661 in) shim.

INNER RACE ot EALL BEARING

Page 669 of 2189

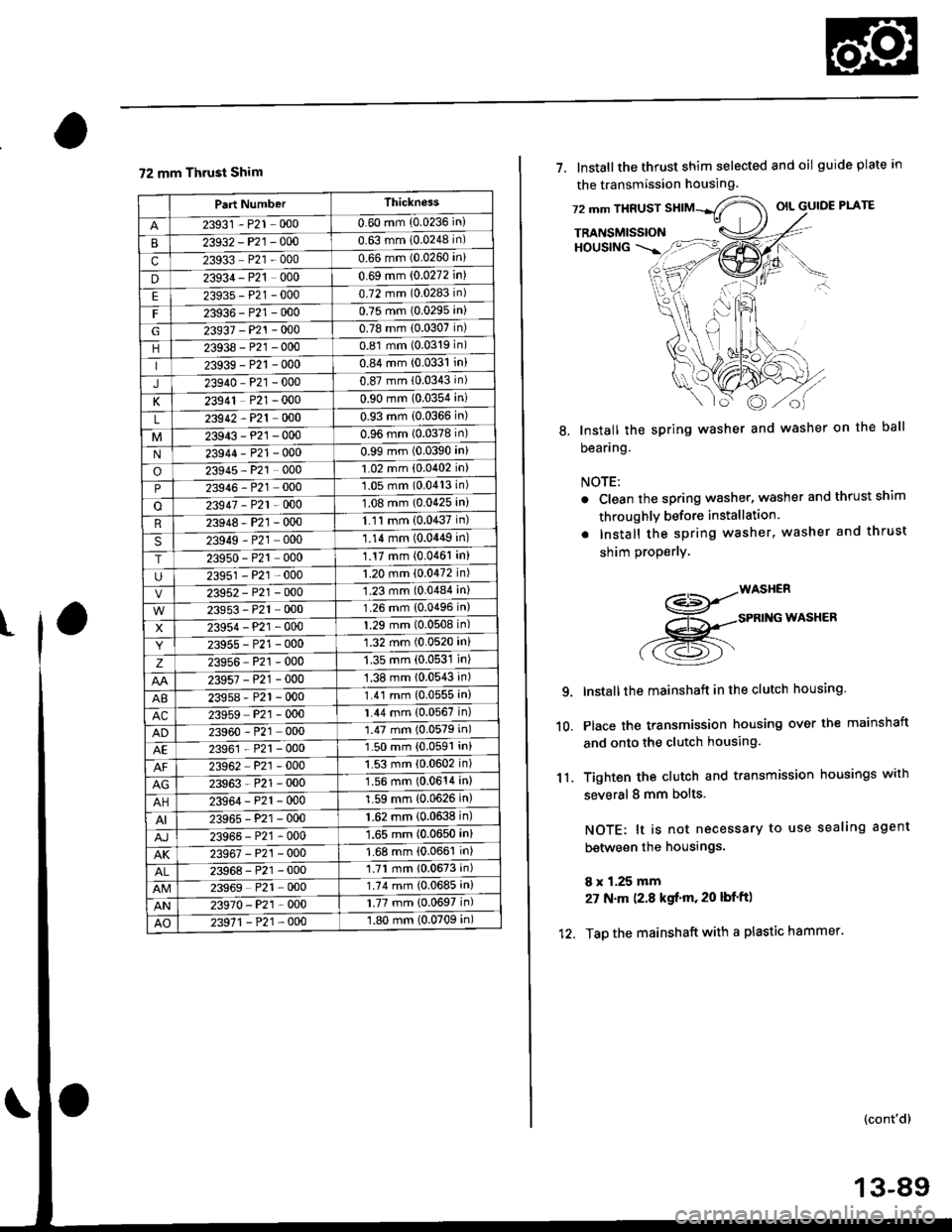

72 mm Thrust Shim

t

Part NumberThickness

23931 - P21 0000.60 mm {0.0236 in}

23932-P21 -0000.63 mm 10.0248 in)

c23933 P21 - 0000.66 mm (0.0260 in)

D23934 - P21 0000.69 mm (0.0272 in)

E2393s-P21-0000.72 mm (0.0283 in)

F23936-P21 -0000.75 mm (0.0295 in)

G23937 -P21-O000.78 mm (0.0307 in)

23938-P21 -0000.81 mm (0.0319 in)

23939-P21 -0000.84 mm (0.0331 in)

J23940-P21 -0000.87 mm (0.0343 in)

K23941 P21 - 0000.90 mm (0.0354 ini

L23942 - P21 0000.93 mm (0.0366 in)

23943-P21 -0000.96 mm 10.0378 in)

N23944 - P21 -0000.99 mm (0.0390 in)

o23945 - P21 0001.02 mm (0.0402 in)

P23946 - P21 0001.05 mm (0.0413 in)

o23947 - P2l 0001.08 mm (0.0425 in)

R23948-P21 -0001.'1 'l mm (0.0437 in)

S23949 - P21 0001.14 mm (0.0449 in)

T23950 - P21 0001.17 mm (0.0461 in)

23951 - P21 -0001.20 mm (0.0472 in)

23952 - P21 -0001.23 mm (0.0484 in)

23953-P21 -0001.26 mm (0.0496 in)

X23954-P21 -0001.29 mm (0.0508 in)

23955 - P21 -0001.32 mm (0.0520 in)

z23956-P21 -0001.35 mm (0.0531 in)

23957-P21 -0001.38 mm 10.0543 in)

AB23958 - P21 -0001.41 mm (0.0555 in)

AC23959 P21 - 0001.44 mm {0.0567 in)

23960 - P21 0001.47 mm (0.0579 in)

AE23961 - P21 -0001.50 mm {0.0591 in)

23962 P21 - 0001.53 mm {0.0602 in)

AG23963-P21 -0001.56 mm (0.0611in)

AH23964-P21 -0001.59 mm {0.0626 in)

23965-P21 -000'1.62 mm {0.0638 in)

23965-P21 - 0001.65 mm (0.0650 in)

AK23967-P21 -0001.68 mm {0.0661 in)

23968 - P21 -0001.71 mm 10.0673 in)

23969 P21 - 0001.74 mm {0.0685 in)

AN23970-P21 -0001.77 mm {0.0697 in)

AO23971 - P21 -0001.80 mm (0.0709 in)

7. lnstallthe thrust shim selected and oil guide plate in

the transmission housing.

72 mm THRUSTOIL GUIDE PLATE

TRANSMISSIONHOUSING

8. Install the spring washer and washer on the ball

beaflng.

NOTE:

. Clean the spring washer, washer and thrust shim

throughly before installation.

. Install the spring washer, washer and thrust

shim properlY.

-WASH€R-<]>-.-'

x -sPRtNG WASHER

-.-sK((9r'

lnstallthe mainshaft in the clutch housing.

Place the transmission housing over the mainshaft

and onto the clutch housing.

Tighten the clutch and transmission housings with

several 8 mm bolts.

NOTE: lt is not necessary to use sealing agent

between the housings.

8 x 1.25 mm

27 N.m (2.8 kgf.m. 20 lbf'ft)

Tap the mainshaft with a plastic hammer.

(cont'd)

9.

10.

'I l.

12.

13-89

Page 670 of 2189

Mainshaft Thrust Clearance

Adjustment (cont'd)

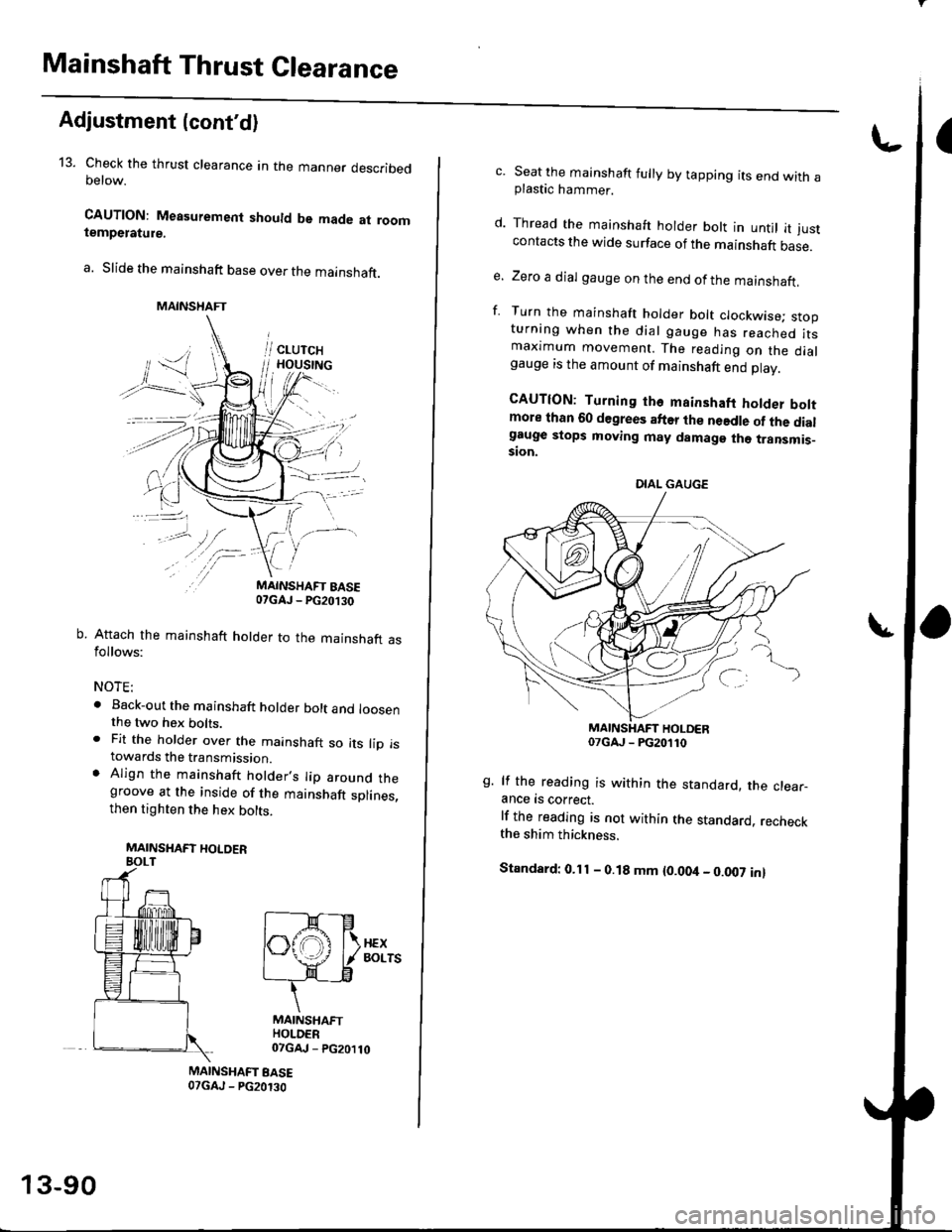

13. Check the thrust clearance in the manner describedoetow.

CAUTION: Measuremenl should be made at roomtempetature.

a. Slide the mainshaft base over the mainshaft.

MAINSHAFT EASE07GAJ - PG20.130

b. Attach the mainshaft holder to the mainshaft asfollows:

NOTE:

. Back-out the mainshaft holder bolt and loosenthe two hex bolts.. Fit the holder over the mainshaft so its lip istowards the transmission.. AIign the mainshaft holder.s Iip around thegroove at the inside of the mainshaft splines,then tighten the hex bolts.

MAINSHAFT HOLOERBOLT

MAINSHAFT

[--F-e

l6fffi l

rx| - \-/ I/ Borrs

ff

MAINSHAFTHOLDER07GAJ - PG20110

MAINSHAFT BASE07GAJ - PG20130

13-90

c. Seat the mainshaft fully by tapping its end with aplastic hammer.

d. Thread the mainshaft holder bolt in untjl it justcontacts the wide surface of the mainshaft base.

e. Zero a dial gauge on the end ofthe mainshaft.

f. Turn the mainshaft holder bolt clockwise; stooturning when the dial gauge has reached itsmaxtmum movement. The reading on the dialgauge rs the amount of mainshaft end Dlav.

CAUTION: Turning tho mainshaft holder boltmore than 60 degrees after the needle of the dialg€uge stops moving may damage the transmis_ston.

07cAJ _ PG20110

g. lf the reading is within the standard, the clear-ance is correct.

lf the reading is not within the standard. recheckthe shim thickness.

Standard: 0.11 - O.18 mm {0.004 - 0.007 in}

DIAL GAUGE

Page 671 of 2189

Transmission

ReassemblY

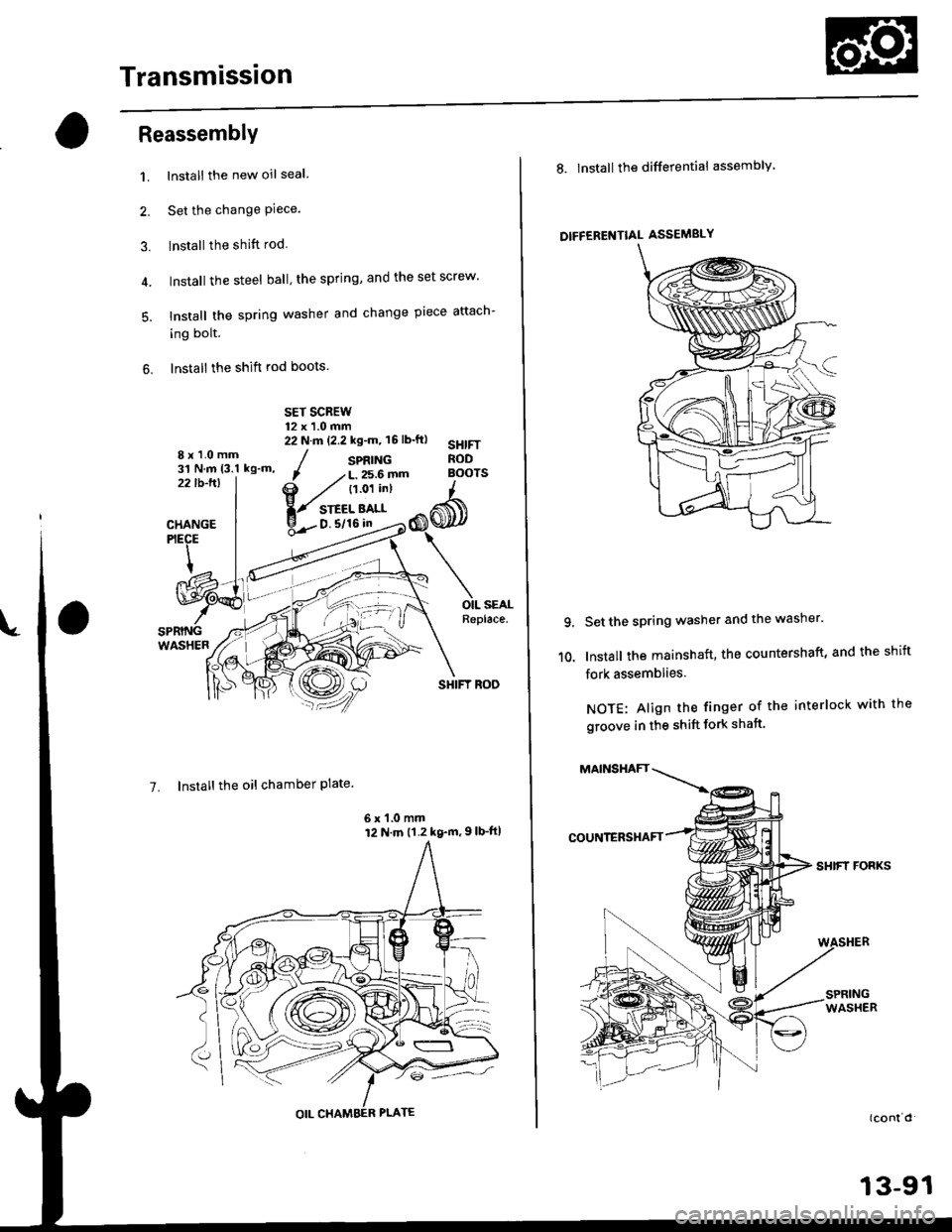

1. Install the new oil seal

2. Set the change Piece.

3. Install the shift rod

4. Install the steel ball' the spring, and the set screw'

5. Install the spring washer and change piece attach-

ing bolt.

6. Install the shift rod boots.

8x1.0mm31 N.m 13.1 kg-m,22lb-ltl

CHANGEPIECE

@:4OIL SEALReplace.SPRINGWASHER

7. Install the oil chamber Plate'

6 x '1.0 mm12 N.m (1.2 kg-m,9lb-ft|

SPRING

, /L.256fim B()(

@ / t't o'ti"l I

{zw"y-6@

q

10.

Set the spring washer and the washer'

lnstall the mainshaft, the countershaft, and the shift

fork assemblies.

NOTE: Align the finger of the interlock with the

groove in the shift fork shaft.

SHIFT FORKS

13-91

Page 672 of 2189

Transmission

Reassembly (cont'd)

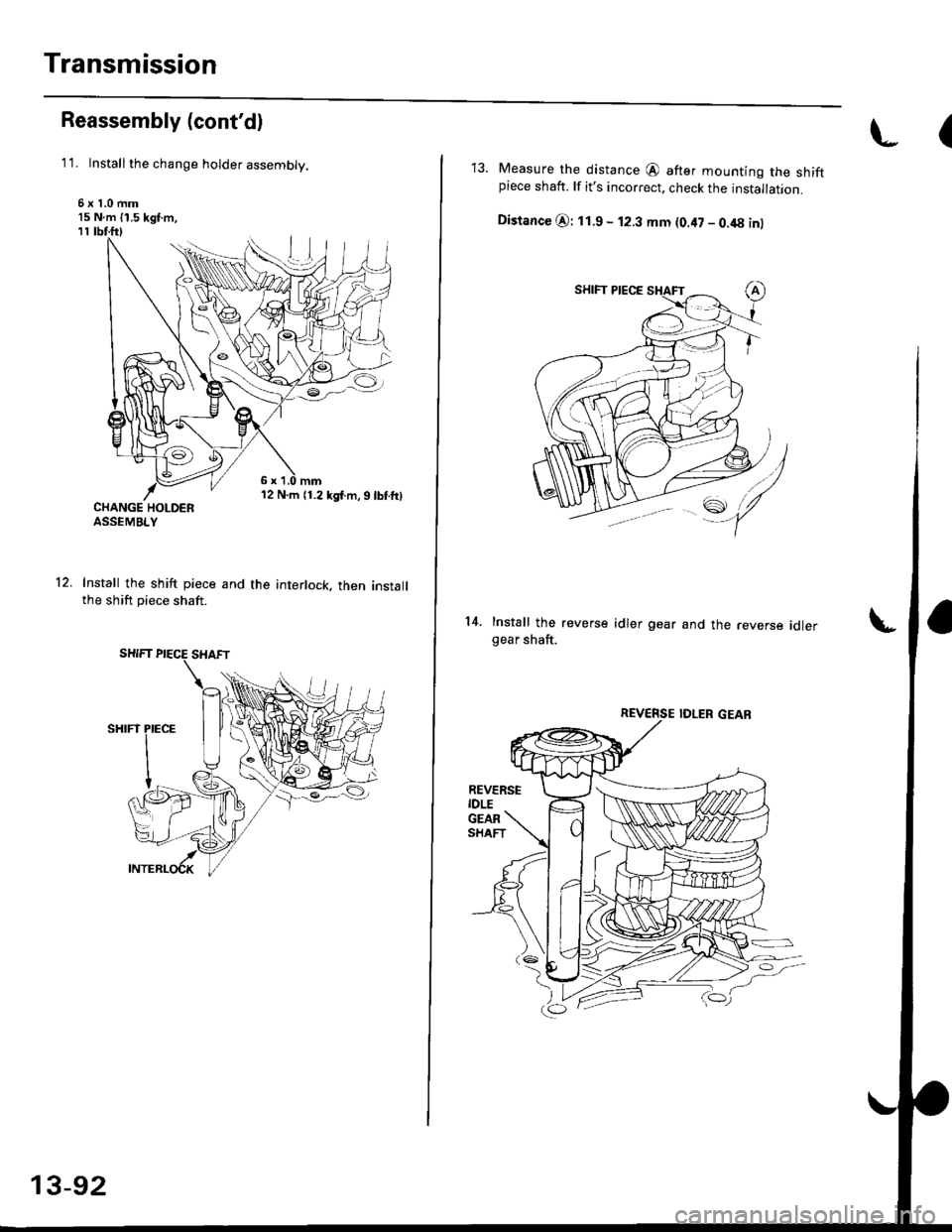

11. Installthe change holder assembly.

6x1.0mm15 N.m {1.5 kgf.m,

12 N.m {1.2 kgf.m,9lbtftlCHANGE HOLDERASSEMBLY

Install the shift piece and the interlock. then installthe shift piece shaft.

12.

13-92

(

13. Measure the distance @ after mounting the shiftpiece shaft. lf it's incorrect. check the installation.

Distance @: 11.9 - 12.3 mm {0./t7 - 0.48 inl

14. Install the .everse idler gear and the reverse idlergear shaft.

REVERSE IDLER GEAR

REVERSEIDLE

Page 673 of 2189

tl

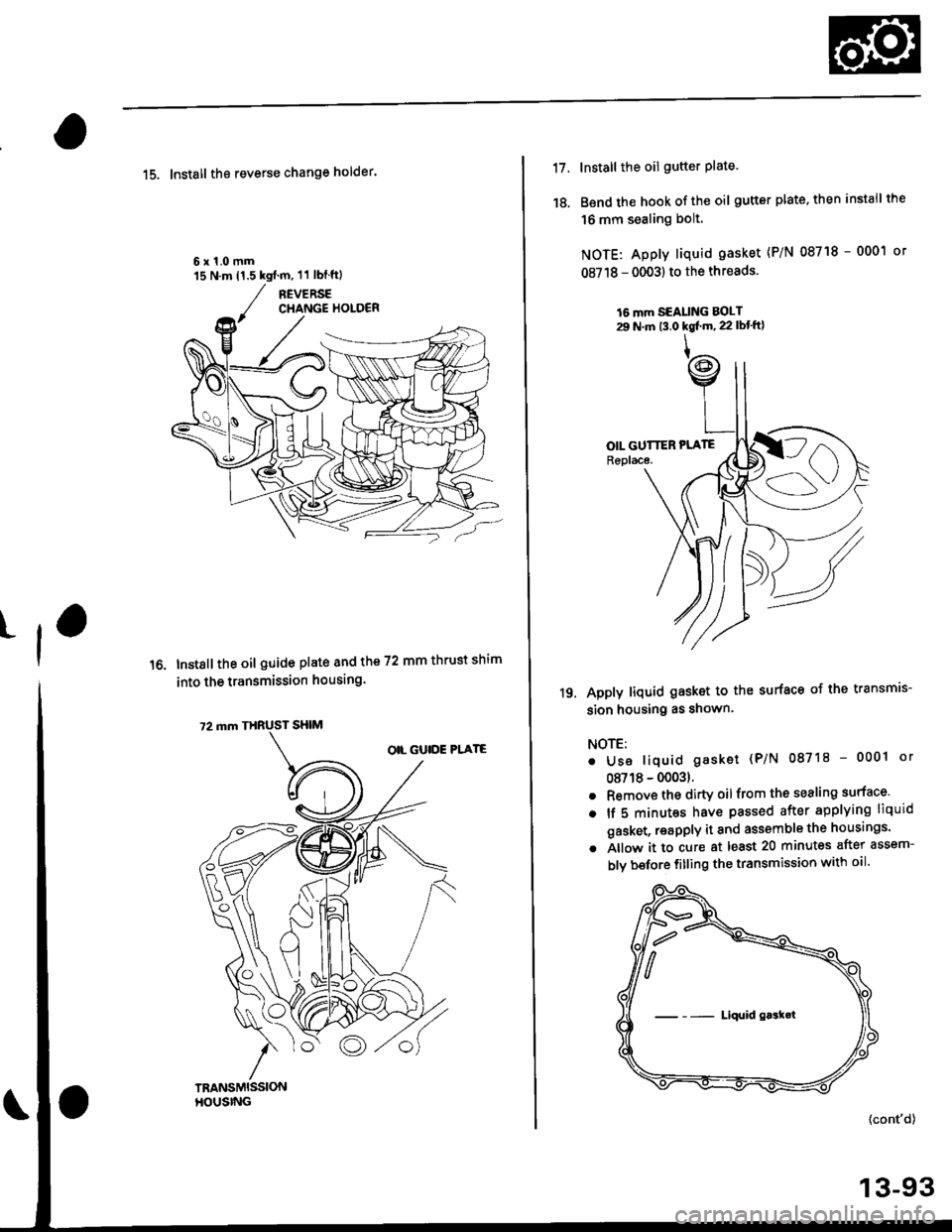

15. Install the reverse change holder.

6x1.0mm'15 N.m 11.5 kgim, 11 lblftl

Instsll the oil guide plate and the 72 mm thrust shim

into the transmission housing.

17.

18.

Install the oil gutter plate.

Bend the hook of the oil gutter plate, then install the

16 mm sealing bolt.

NOTE: Apply liquid gasket {P/N 08718 - 0001 or

08718 - 0003) to the threads.

16 mm SEALING BOLT29 N.m t3.0 kgl'm, 22 lbt'ft}

Apply liquid gasket to the surface of the transmis-

sion housing as shown'

NOTE:

. Use liquid gasket (P/N 087'18 - 0001 or

08718 - 00031.

. Remove the dirty oilfrom the sealing surface'

. lf 5 minut€s have passed after applying liquid

gasket, reapply it and assemble the housings'

. Allow it to cure at least 20 minutes after assem-

blv bsfore fitling the transmission with oil'

19.

(cont'd)

13-93

--- Liqui.l gask€t

Page 674 of 2189

Transmission

Reassembly (cont'dl

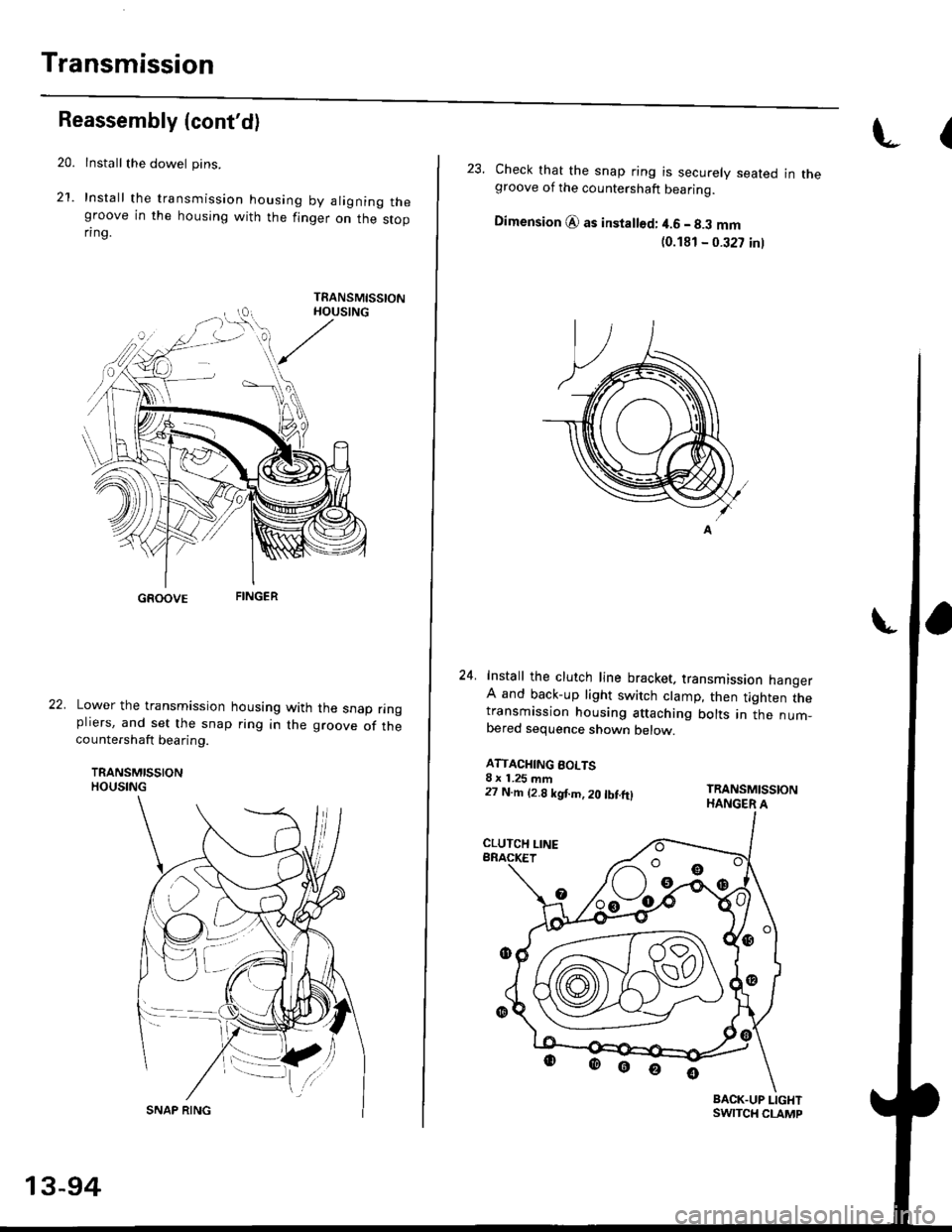

Install the dowel pins.

Install the transmission housing by aligning thegroove in the housing with the finger on the stopfl ng.

GROOVE

21.

Lower the transmission housing with the snap ringpliers, and set the snap ring in the groove of thecountershaft bearing.

TRANSMISSIONHOUSING

13-94

(

23. Check that the snap ring is securely seated in thegroove of the countershaft bearing.

Dimension 6) as instalt6d: 4.6 - 8.3 mm(0.181 - 0.327 inl

24.Install the clutch line bracket, transmission hangerA and back-up light switch ctamp, then tighten thetransmission housing attaching bolts in the num_bered sequence shown below.

ATTACHING BOLTS8 x 1.25 mmTRANSMISSIONHANGER A27 N m 12.8 kgtm, 20 tbt.trl

BACK.UP LIGHTSWITCH CLAMP

lar---'o o

"W

Page 675 of 2189

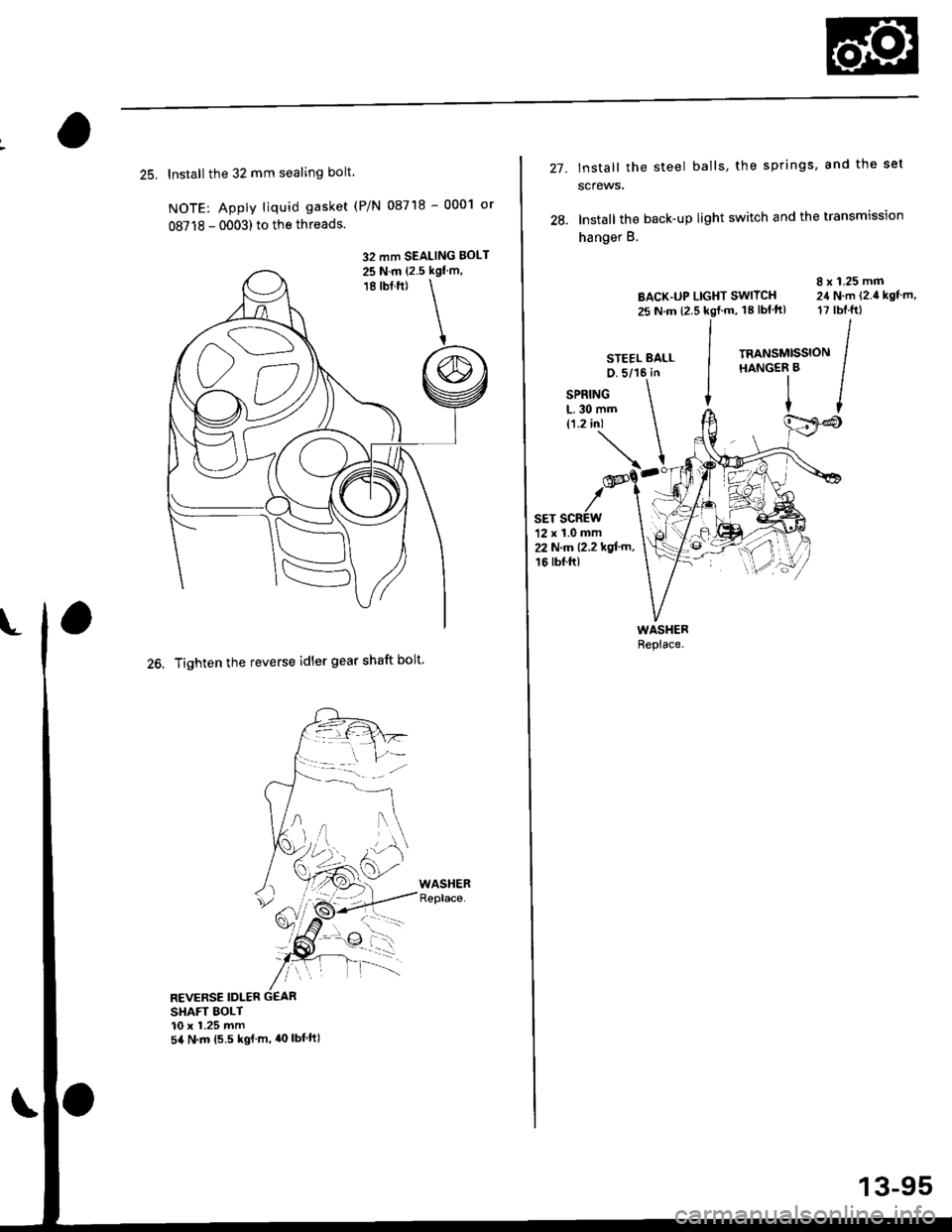

25. Install the 32 mm sealing bolt

NOTE: Apply liquid gasket (P/N 08718 - 0001 or

08718 - 0003) to the threads.

26. Tighten the reverse idler gear shaft bolt'

REVERSE IDLER G€AR

SHAFT BOLT10 x 1.25 mm5a N.rn t5.5 kgl m, {0 lbtftl

32 mm SEALING BOLT

25 N.m {2.5 kgl'm,

lnstall the steel balls, the springs, and the set

screws.

Install the back-up light switch and the transmission

hanger B.

BACK.UP LIGHT SWITCH

25 N.m 12.5 kgt m, 18 lblttl

TRANSMISSIONHANGER B

8x2117

1.25 mmN.m (2.4 kgf m,lbf.ftt

II

I

I

EALL

\\

\

\

SET SCREW'12 x 1.0 mm

22 N.m (2.2 kgf'm,16 tbt.trl

13-95

Page 676 of 2189

Oil Seals

Replacement

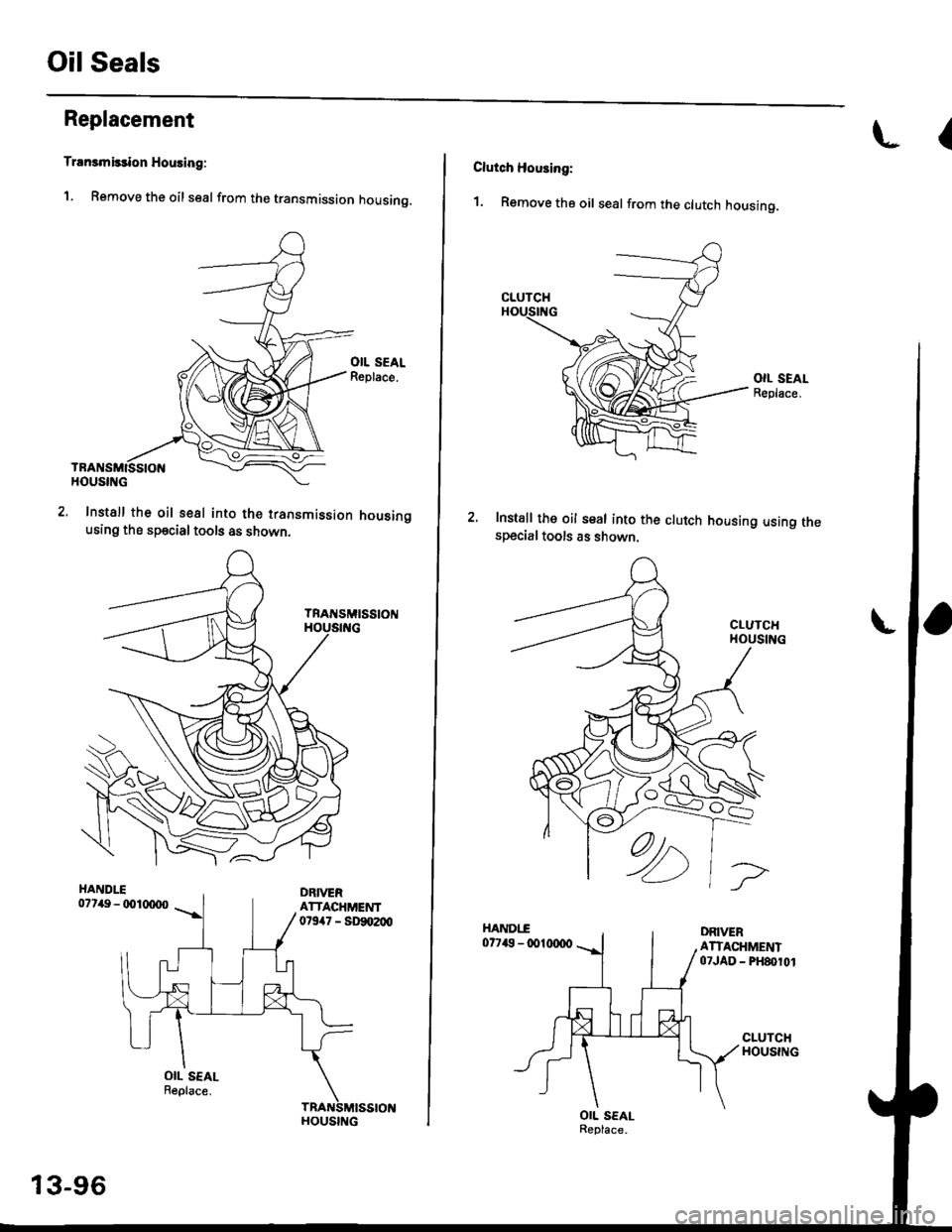

Trrn3mirdon Housing:

1. Remove the oil seal from the transmission housing.

Install the oil seal into the transmission housingusing the sp€cial tools as shown,

HANDLE07149 - d)l(xxto

OIL SEALReplace.

HOUSING

13-96

OIL SEALReplace.

{

Clutch Housing:

1. Remove the oil seal from the clutch housing.

OIL SEALReplace.

Install the oil seal into the clutch housing using thespecialtools as shown.

HANDTI0t?a9 - 001o(xto