description HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 909 of 2189

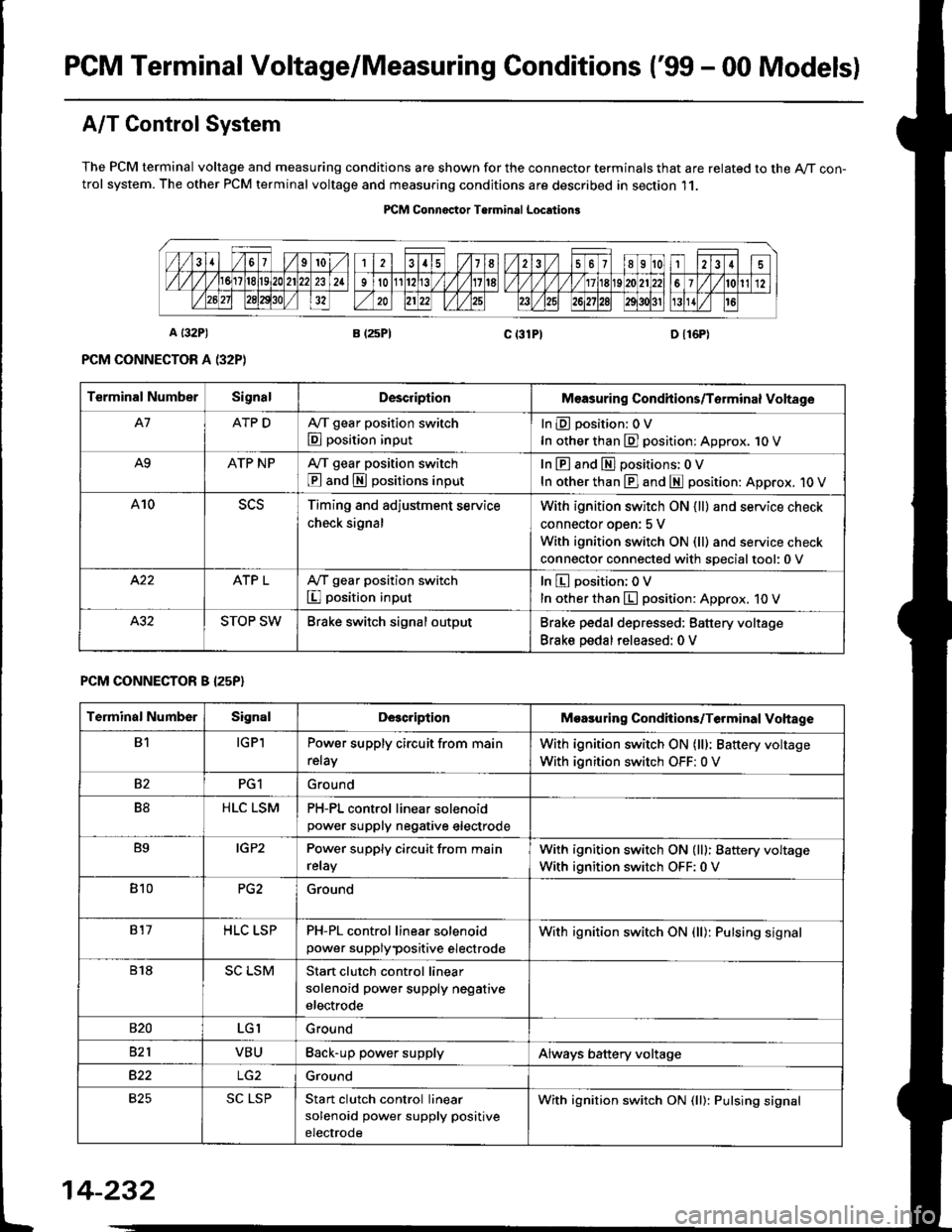

PGM Terminal Voltage/Measuring Conditions ('99 - 00 Modelsl

A/T Control System

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A/T con-trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

PICM Connoctor Terminrl Location3

Terminal NumberSignalDescriplionMeasuring Condhions/Torminal Voltage

A7ATP DA,/T gear position switch

E position input

InEposition:OV

In other than E] position: Approx. 1O V

A9ATP NPA/T gear position switch

@ and S positions input

In E and El positions: 0 V

In other than E] and E position: Approx. 1O V

A10Timing and adjustment service

check signal

With ignition switch ON {ll} and service check

connector oDen: 5 V

With ignition switch ON (ll) and service check

connector connected with soecialtool:0 v

ATP LA,/T gear position switch

I position input

In E position; OV

In other than E position: Approx. 10 V

STOP SWBrake switch signal outputBrake pedal depressed: Battery voltage

Brake pedal released: 0 V

PCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMoasuring Condhions/Terminal Vohage

B1IGPlPower supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF: 0 V

82PG1Ground

B8HLC LSMPH-PL control linear solenoidpower supply neqative electrode

B9IGP2Power supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF:0 V

810PG2Ground

817HLC LSPPH-PL control linear solenoid

power supplypositive electrode

With ignition switch ON {ll): Pulsing signal

818SC LSMStart clutch control linear

solenoid power supply negative

electrode

s20LGIGround

821VBUBack-up power supplyAlways battery voltage

B22Ground

825SC LSPStan clutch control linear

solenoid power supply positive

electrode

With ignition switch ON (ll): Pulsing signal

t

14-232

Page 910 of 2189

![HONDA CIVIC 1999 6.G Workshop Manual \a

PCM CONNECTOR D {16P)

14-233

Terminal Numbs]SignalDescriptionMeasuring Conditions/Terminal Voltage

D1VELSecondary gear shaft speed

sensor signal input

Depending on vehicle speed: Pulsing signal

Whe HONDA CIVIC 1999 6.G Workshop Manual \a

PCM CONNECTOR D {16P)

14-233

Terminal Numbs]SignalDescriptionMeasuring Conditions/Terminal Voltage

D1VELSecondary gear shaft speed

sensor signal input

Depending on vehicle speed: Pulsing signal

Whe](/img/13/6068/w960_6068-909.png)

\a

PCM CONNECTOR D {16P)

14-233

Terminal Numbs]SignalDescriptionMeasuring Conditions/Terminal Voltage

D1VELSecondary gear shaft speed

sensor signal input

Depending on vehicle speed: Pulsing signal

When vehicle is stoPPed: APProx. 0 V

02SOL INHlnhibitor solenoid controlWith inhibitor solenoid ON: Battery voltage

With inhibitor solenoid OFF: 0 V

D3SH LSMShift control linear solenoid

power supply negative electrode

D4SH LSPShift control linear solenoid

power supply positive electrode

With ignition switch ON (ll): Pulsing signal

D5VB SOLPower supply for solenoid valvesWith ignition switch ON (ll): Baftery voltage

With ignition switch OFF:0 V

D6ATP RA,/T gear position switch E

position input

InEposition:0V

In other than B position; Approx. 10 V

D]VEL SGSecondary gear shaft sPeed

sensor ground

D8Not used

D9Not used

D10NDNDriven pulley speed sensor signal

anput

In other than E and E position: Pulsing signal

D11NDRDriven pulley speed sensor signal

input

ln other than E and E position: Pulsing signal

D12NDR SGDrive pulley speed sensor ground

D13ATP SA,/T gear position switch E

position input

InE position: 0V

In other than E position: Battery voltage

D14D INDD indicator light controlWhen ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Battery voltage

D15Not used

D16NDN SGDriven pulley speed sensor

grou nd

Page 1035 of 2189

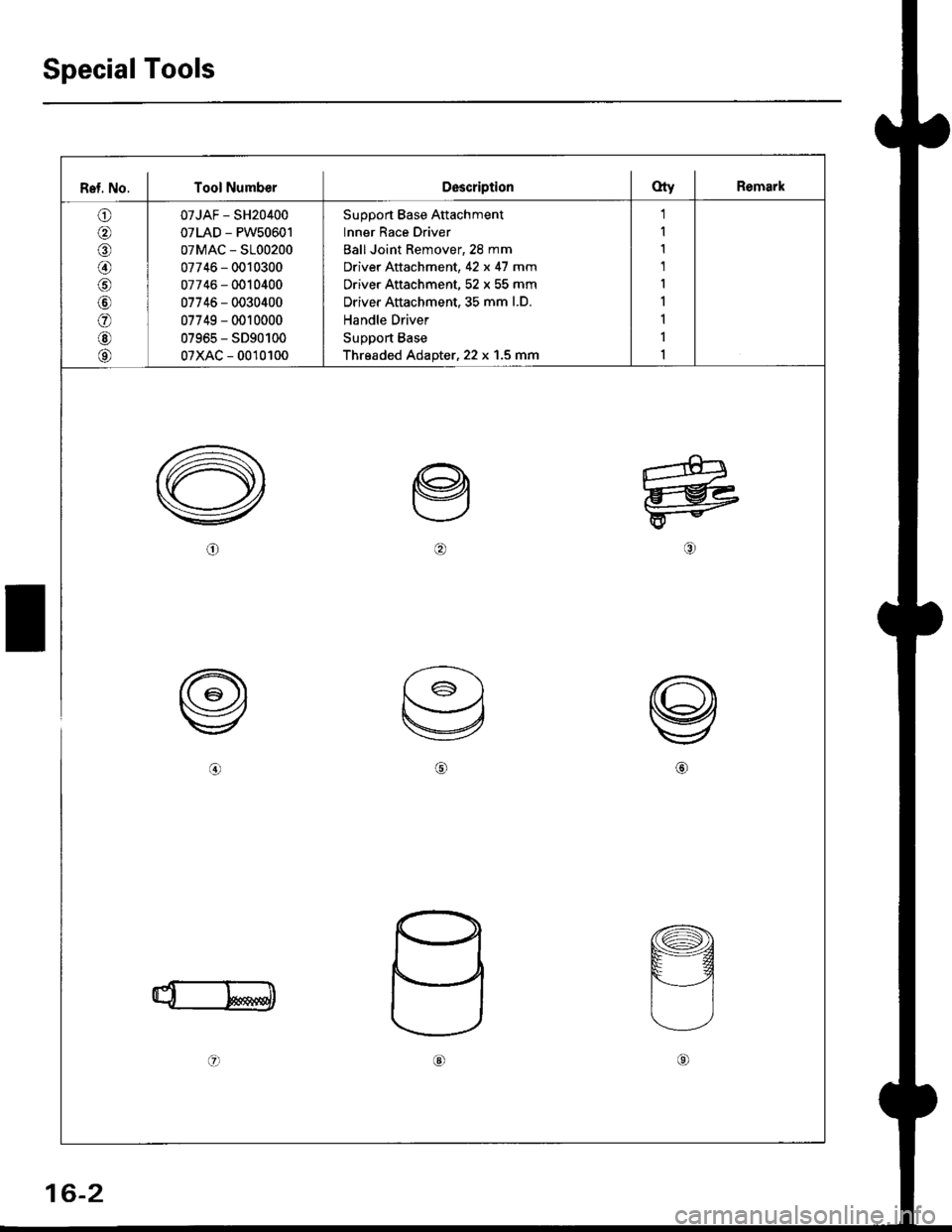

Special Tools

Ref. No. I Tool NumberDescriptionOty I Remark

o

@,a

\9'

o

@

@

07JAF - SH20400

07LAD - PW50601

07MAC - S100200

07746 - 0010300

07746 - 0010400

07746 - 0030400

07749 - 0010000

07965 - SD90100

07xAc - 0010100

Support Base Attachment

Inner Race Driver

Ball Joint Remover, 28 mm

Driver Attachment, 42 x 47 mm

Driver Attachment, 52 x 55 mm

Driver Attachment, 35 mm l.D.

Handle Driver

Support Base

Threaded Adapter, 22 x 1.5 mm

1

1

1

1

I

I

1

I

1

@e

@

&

w

@

@

c

6

@

'

lo,

c[G)

8-)

ge

l..---,l

G)

16-2

Page 1057 of 2189

l.

t

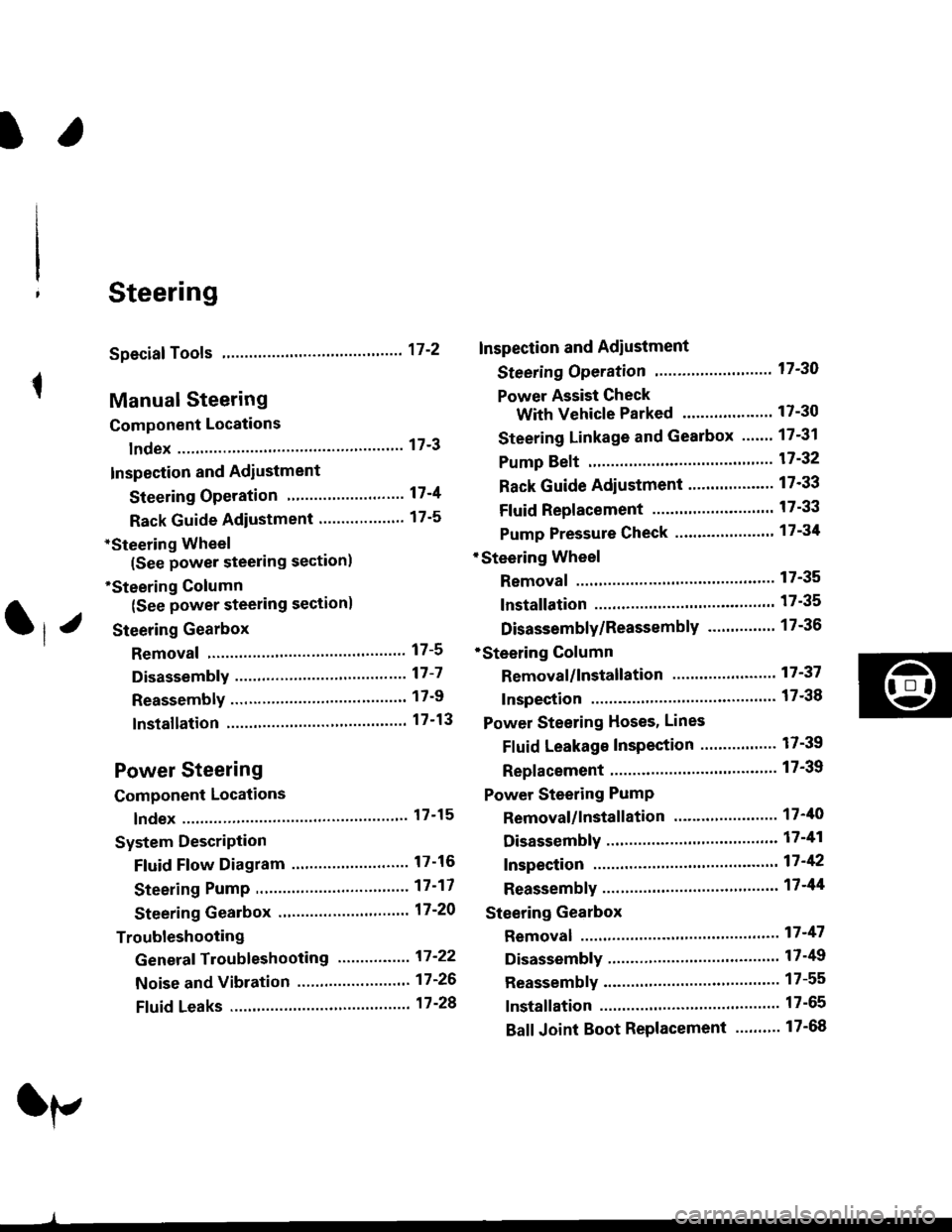

Steering

Speciaf Tools ....."'.....17-2

Manual Steering

Component Locations

lndex ................ ....... 17-3

Inspection and Adiustment

Steering Operation "'......"............... 17-4

Rack Guide Adiustment ................... 17-5

*Steering Wheel

(See power steering section)

*Steering Column

(See power steering sectionl

Steering Gearbox

Removal ................. 17-5

Disassembly ......."" 17-7

ReassemblY ..'......... 17-9

lnstallation ............. 17-13

Power Steering

Component Locations

lndex "......."..... """' 17-15

System DescriPtion

Fluid Flow Diagram .........""............. 17'16

Steering Pump ............'... "........"'...-- 17 -17

Steering Gearbox .".................'...'.'.' 17-20

Troubleshooting

Generaf Troubleshooting ..........--.... 17'22

Noise and Vibration ......................... 17 -26

Ffuid Leaks .............17-28

Inspection and Adiustment

Steering Operation'......."'........'...... 1 7-30

Power Assist Check

With Vehicle Parked .."................ 17-30

Steering Linkage and Gearbox ....." 17-31

Pump Beft ...--.""".. 17-32

Rack Guide Adiustment .'.......'.......'. 17'33

Fluid Replacement .....'.."................. 17-33

Pump Pressure Check .............'....-. " 17 -34

'Steering Wheel

Removal .."'........'... 17-35

lnstallation ............. 17-35

Disassembly/Reassembly ......'.....'.' 17-36

*Steering Column

Removal/lnstallation ....'........... ---.... 17'37

lnspection .............. 17'38

Power Steering Hoses, Lines

Fluid Leakage Inspeetion ............'.... 17-39

Replacement ......".. 17-39

Power Steering PumP

Removal/lnstallation .'.'..'..'............. 17-40

Disassembly ".........17-41

fnspection .......---'." 17'42

Reassembly ..'.........17-44

Steering Gearbox

Removal ....'........."' 17'47

DisassemblY ..........' 17-49

Reassembly '........... 17-55

lnstallation ............. 17-65

Ball Joint Boot Replacement .......'.. 17-68

Ir/

lp

Page 1058 of 2189

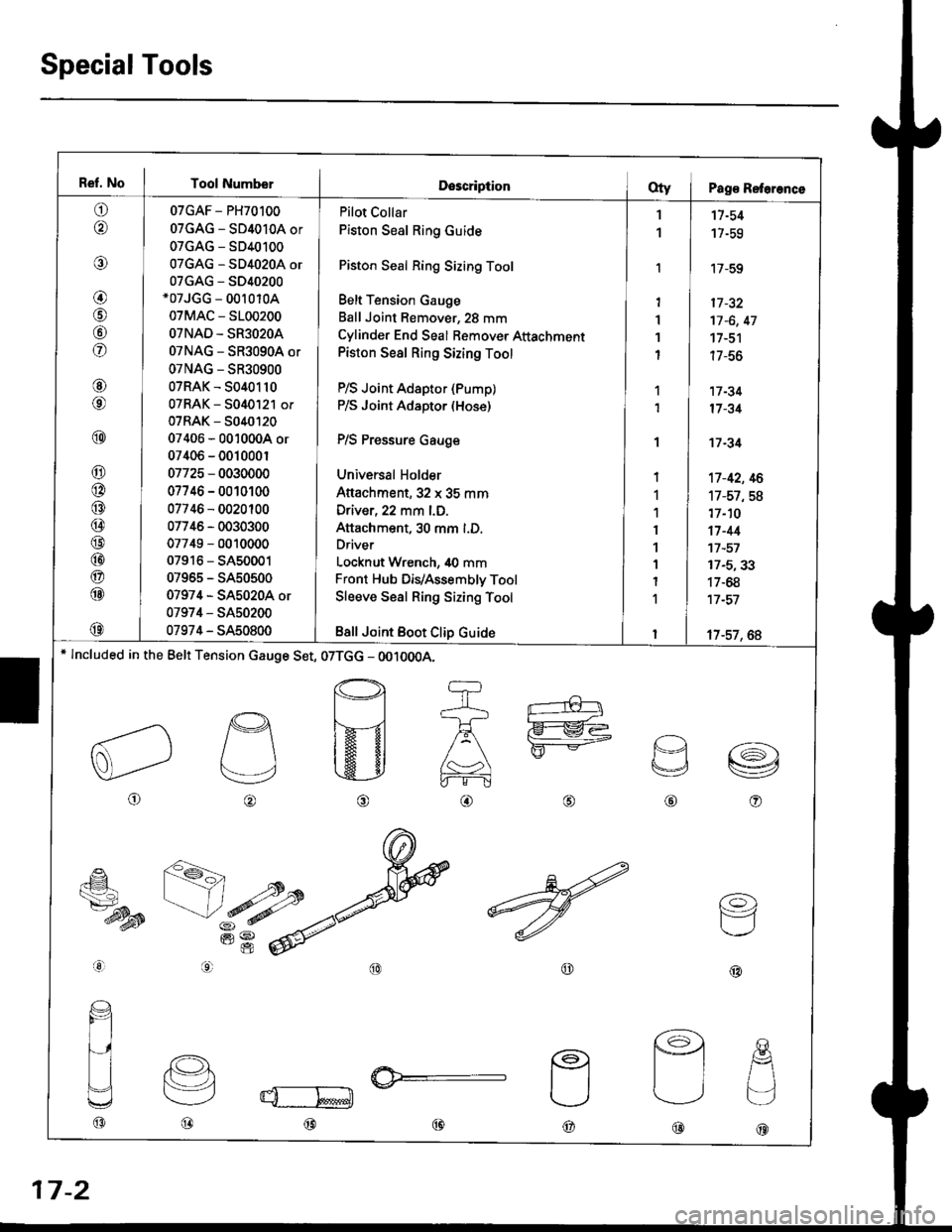

Ref. No I Tool NumberDescriptionOty I Pag€ Reterence

o

@

@

@

@

fof

@

@

@

@

@

@

@

@

@

@

@

@

@

07GAF - PH70100

07GAG - SD4010A or

07GAG - SD40100

07GAG - SD4020A or

07GAG - S040200*07JGG - 00r 010A

07MAC - 5100200

OTNAD - SR3O2OA

07NAG - SR3090A or

07NAG - SR30900

07RAK - 5040110

07RAK - 5040121 or

07RAK - 5040t20

07406 - 0010004 or

07406 - 001000r

07725 - 0030000

07746 - 0010100

07746 - 0020100

07746 - 0030300

07749 - 0010000

07916 - SA50001

07965 - SA50500

07974 - SA5020A or

07974 - SA50200

07974 - SA50800

Pilot Collar

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover, 28 mm

Cylinder End Seal Bemover Attachment

Piston Seal Ring Sizing Tool

P/S Joint Adaptor (Pump)

P/S Joint Adaptor (Hose)

P/S Pressure Gauge

Universal Holder

Attachment,32 x 35 mm

Driver, 22 mm l.D.

Attachment, 30 mm l.D.

Driver

Locknut Wrench, 40 mm

Front Hub DiVAssembly Tool

Sleeve Seal Ring Sizing Tool

Bsll Joint Boot Clip Guide

1

1

'I

1'I

1

I

1

1

I

1

1

I

1

1

I

1

I

11-54

17-59

'17-59

17 -32

17 -6, 47

17-51

| /-ao

17 -34

17 -31

't7 -34

't7-42, 16

17-57,58

17-10

17-44't7 -57

17-5,33

17-68

17 -57

17-57, 6A* lncluded in the Belt Tension cauge Set, 07TGG - OO10OOA.

o

p

v

@o

€_

ts7-dysB

aal

@@

(o)

F=1

@@@

@@@

17-2

Page 1072 of 2189

System Description

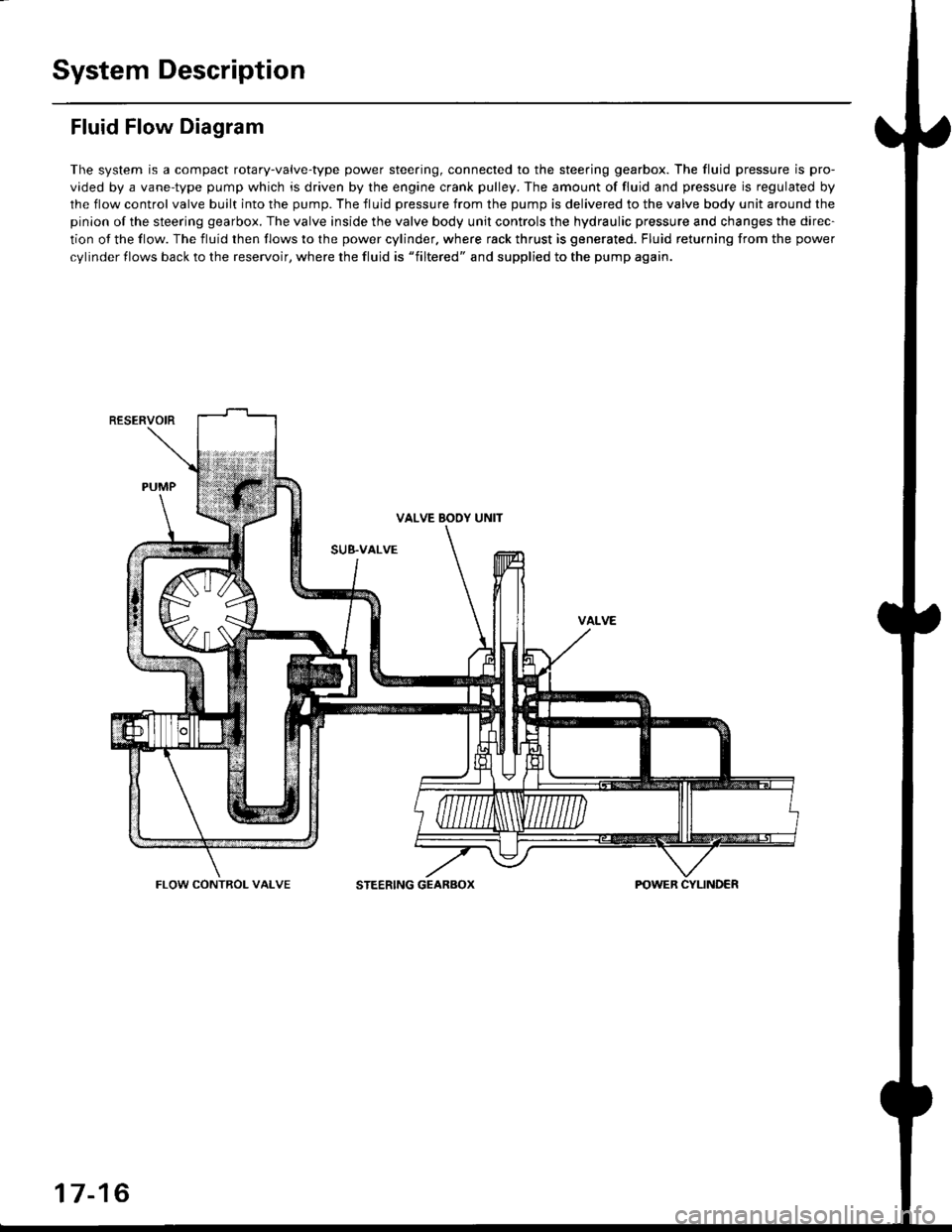

Fluid Flow Diagram

The system is a compact rotary-valve-type power steering, connected to the steering gearbox. The fluid pressure is pro-

vided by a vane-type pump which is driven by the engine crank pulley. The amount of fluid and pressure is regulated by

the flow control valve built into the pump. The fluid pressure from the pump is delivered to the valve body unit around the

pinion of the steering gearbox. The valve inside the valve body unit controls the hydraulic pressure and changes the direc-

tion of the flow. The fluid then flows to the power cylinder. where rack thrust is generated. Fluid returning from the power

cylinder flows back to the reservoir, where the fluid is "filtered" and supplied to the pump again.

RESERVOIR

VALVE BOOY UNIT

SUB.VALVE

FLOW CONTROL VALVESTEERING GEARBOX

17-16

Page 1074 of 2189

System Description

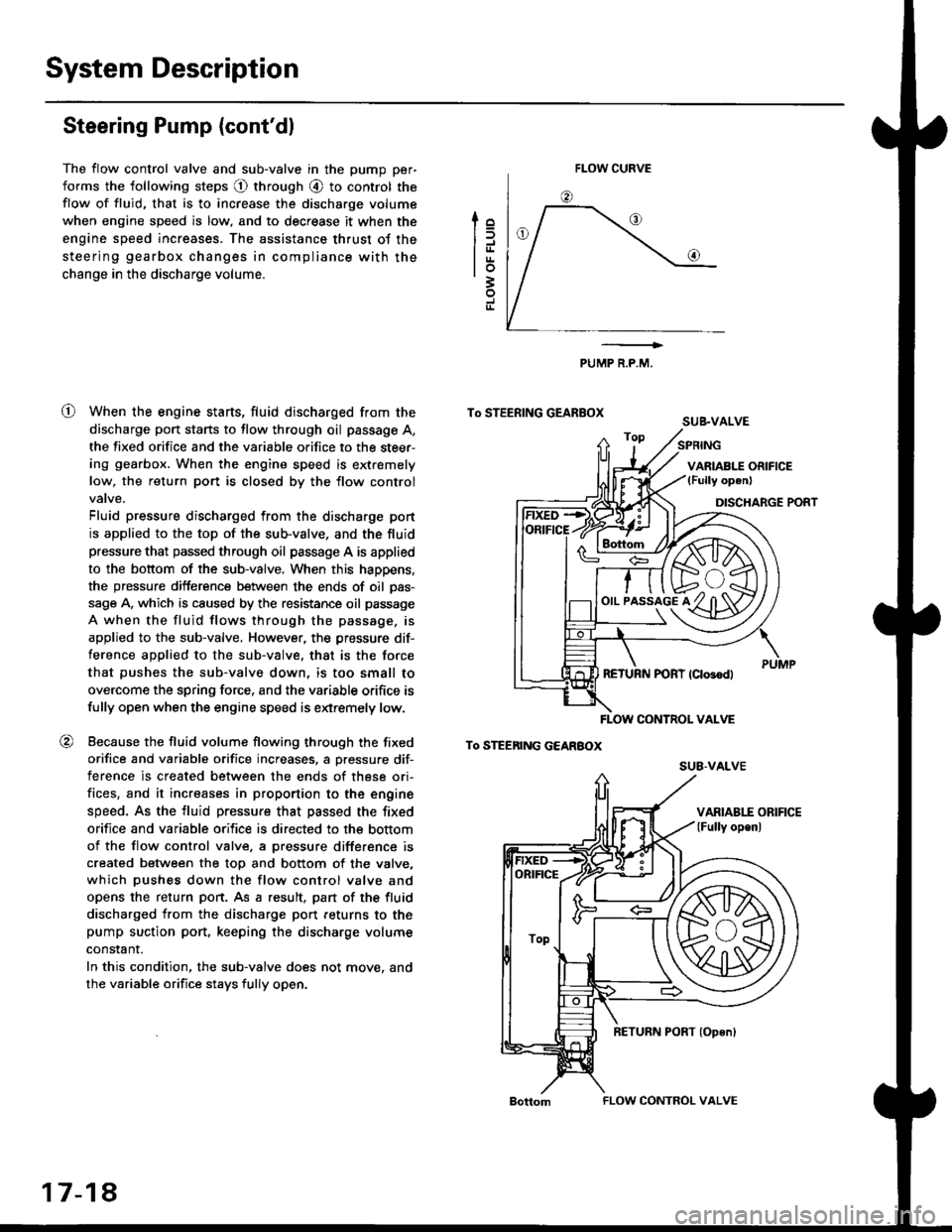

Steering Pump (cont'dl

The flow control valve and sub-valve in the pump per-

forms the following steps @ through @ to control the

flow of fluid, that is to increase the discharge volume

when engine speed is low, and to decrease it when the

engine speed increases. The assistance thrust of the

steering gearbox changes in compliance with the

change in the discharge volume.

When the engine starts, fluid discharged from the

discharge port starts to flow through oil passage A,

the fixed orifice and the variable orifice to the steer-

ing gearbox. When the engine speed is extremely

low, the return port is closed by the flow control

Fluid pressure discharged from the discharge port

is applied to the top of the sub-valve, and the fluid

pressure that passed through oil passage A is applied

to the bottom of the sub-valve. When this happens,

the pressure difference between the ends of oil pas-

sage A, which is caused by the resistance oil passage

A when the fluid flows through the passage. is

applied to the sub-valve, However, the pressure dif-

ference applied to the sub-valve. that is the force

that pushes the sub-valve down, is too small to

overcome the spring force, and the variable orifice is

fully open when the engine speed is extremely low.

Because the fluid volume flowing through the fixed

orifice and variable orifice increases, a pressure dif-

terence is created between the ends of these ori-

fices, and it increases in proportion to the engine

speed. As the fluid pressure that passed the fixed

orifice and variable orifice is directed to the bottom

of the flow control valve. a pressure difference is

created between the top and bottom of the valve,

which pushes down the flow control valve and

opens the return port. As a result, pan of the fluid

discharged from the discharge port feturns to the

pump suction port, keeping the discharge volume

constant.

In this condition, the sub-valve does not move. and

the variable orifice stays fully open.

lo

trrtrrlo3

J

o

PUMP R.P.M.

To STEERING GEARBOXSUB.VALVE

To STEEnING GEARBOX

FLOW CURVE

!rs+/f/ffih\

o,,-i^"l^tKzYt)91y ul3Yl

FLOW CONTNOL VALVE

su8-vALvE

ORIFICE

ToP

17-18

FLOW CONTROL VALVE

Page 1076 of 2189

System Description

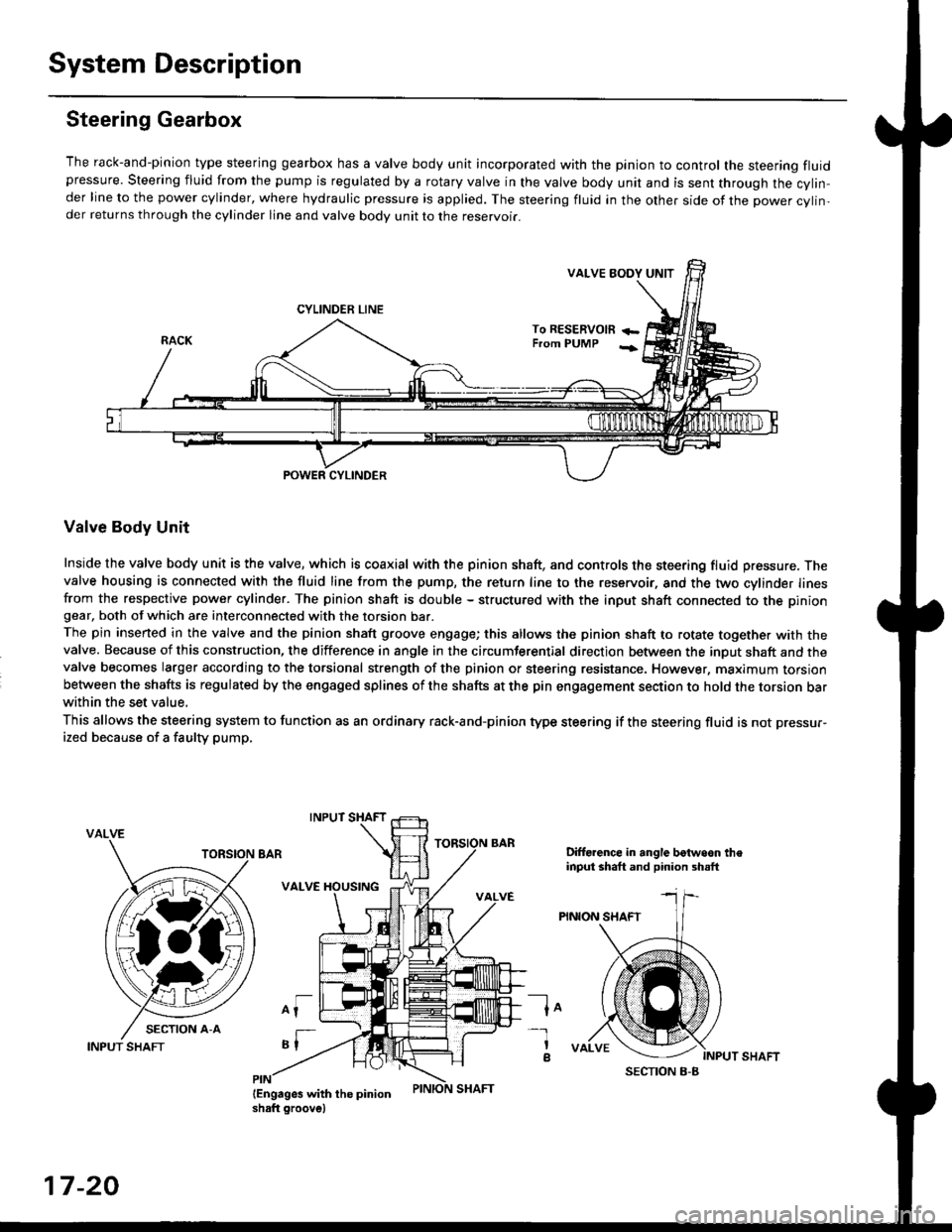

Steering Gearbox

The rack-and-pinion type steering gearbox has a valve body unit incorporated with the pinion to control the steering fluidpressure. Steering fluid from the pump is regulated by a rotary valve in the valve body unit and is sent through the cylin,der line to the power cylinder, where hydraulic pressure is applied. The steering fluid in the other side of the power cylin,der returns through the cylinder line and valve body unit to the reservoii.

VALVE EODY UNIT

CYLINDER LINE

To RESERVOm +-From PUMP -;

POWER CYLINDER

Valve Body Unit

Inside the valve body unit is the valve, which is coaxial with the pinion shaft, and controls the steering fluid pressure. Thevalve housing is connected with the fluid line from the pump, the return line to the reservoir, and the two cylinder linesfrom the respective power cylinder. The pinion shaft is double - structured with the input shaft connected to the piniongear, both of which are interconnected with the torsion bar.

The pin inserted in the valve and the pinion shaft groove engage; this allows the pinion shaft to rotate together with thevalve. Because of this construction, the difference in angle in the circumferential direction between the input shaft and thevalve becomes larger according to the torsional strength of the pinion or steering resistance. However, maximum torsionbetween the shafts is regulated by the engaged splines of the shafts at the pin engagement section to hold the torsion barwithin the set value,

This allows the steering system to function as an ordinary rack-and-pinion type steering if the steering fluid is not pressur-

ized because of a faulty pump,

VALVE

Difforence in angle botwoon theinput shaft and pinion shsft

PINION SHAFT

lo

INPUT SHAFT

-l

a

17-20

INPUT SHAFT

Page 1126 of 2189

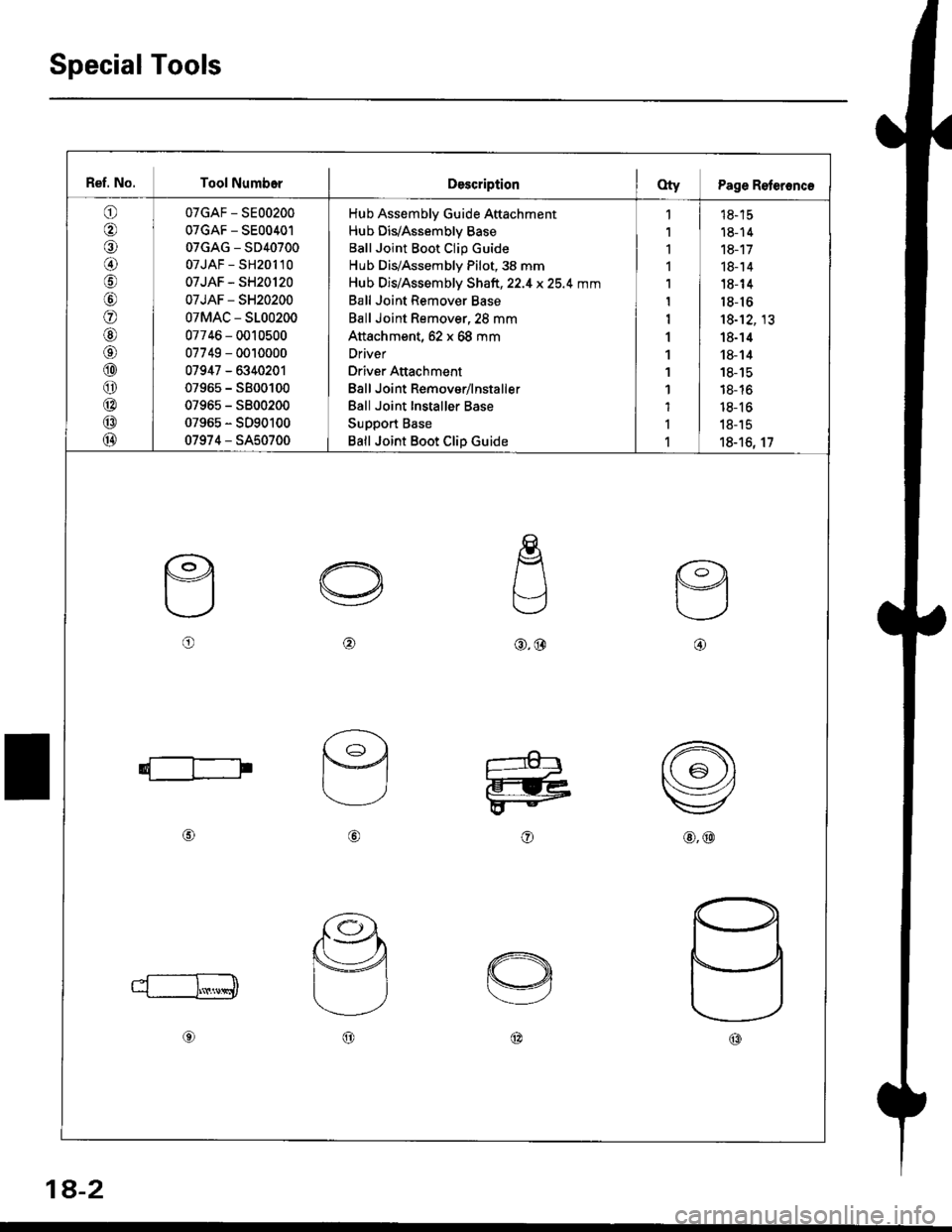

Special Tools

Ref. No. Tool NumborDescriptionOty Page Reteronc€

o

€)

@

\9

o

@aa\

@

o

@

@

@

07GAF - SE00200

07GAF - SE00401

07GAG - SD40700

07JAF - SH201 l0

07JAF - SH20120

07JAF - SH20200

07MAC - S100200

07746 - 0010500

07749 - 0010000

07947 - 6340201

07965 - SB00100

07965 - 5800200

07965 - SD90100

07974 - SA50700

Hub Assembly Guide Attachment

Hub DivAssembly Base

Ball Joint Boot Clip Guide

Hub Dis/Assembly Pilot, 38 mm

Hub Dis/Assembly Shaft,22.4 x25.4 mm

Ball Joint Remover Base

Ball Joint Remover,2S mm

Attachment, 62 x 68 mm

Driver

Driver Attachment

Eall Joint Remover/lnstaller

Ball Joint Installer Base

Support Base

Ball Joint Boot Clip Guide

,|

1

1

1

1

1

1

1

1

1

1

1

I

1

td- tc

18- 14

18-17

18- 14

18- 14

18-16

18-12, 13

18-14

18- 14

18- 15

18- 16

18- 16

18-15

18-16, 17

o@@.@@

@

o@

1a-2

Page 1197 of 2189

Special Tools

Ret. No. I Tool Number I Description I O,V I page Reference

(!) I 07PM- 0010100 I SCS Service Connector t I 19_s6

19-44