iat HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 630 of 2189

Transmission Assembly

Removal(cont'd)

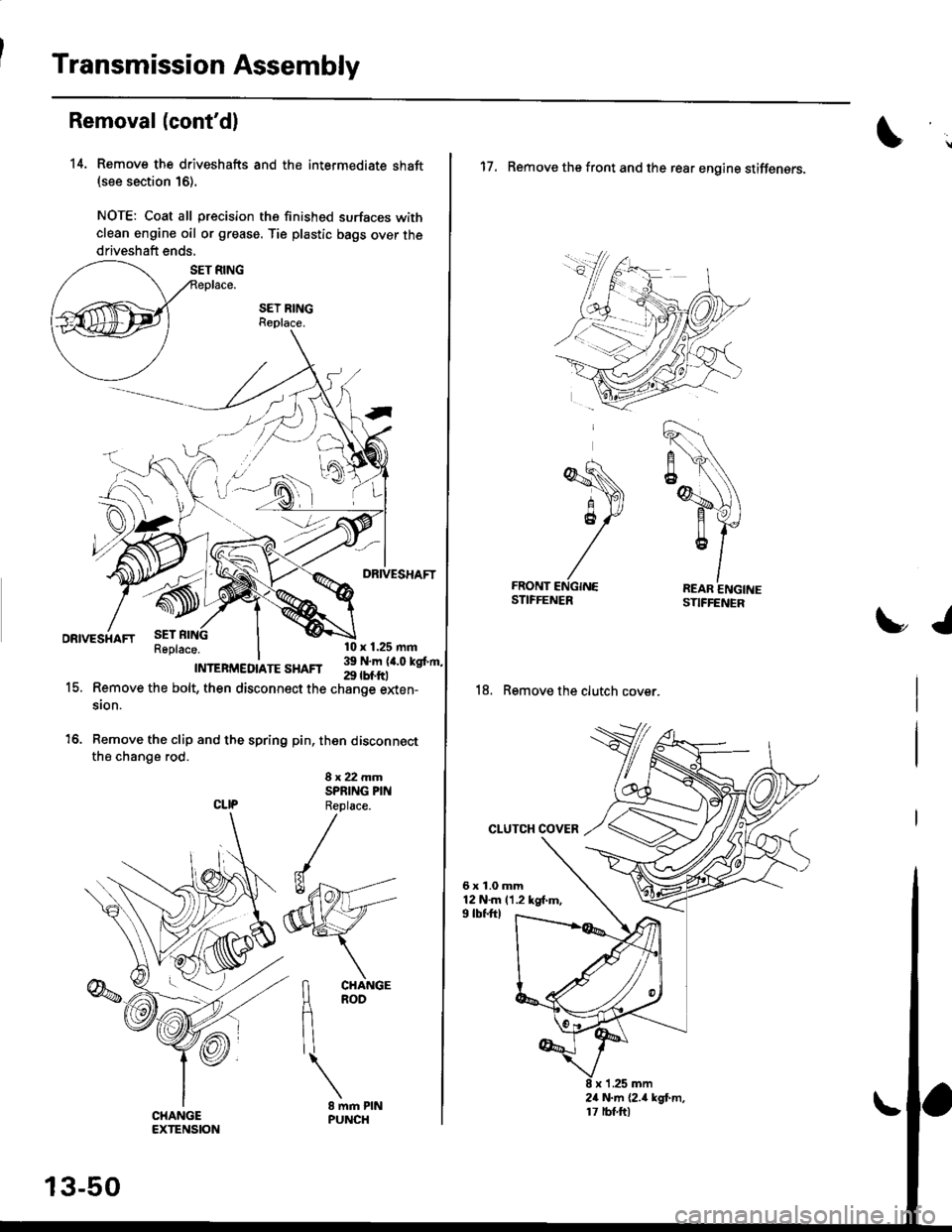

14. Remove the driveshafts and the intermediate shaft(see section 16).

NOTE: Coat all precision the finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends,

Remove the bolt, then disconnect the change elden-

sion.

Remove the clip and the spring pin, then disconnectthe change rod.

8x22mmSPRING PINCLIP Replace.

15.

13-50

17. Remove the front and the rear engine stiffensrs.

18. Remove the clutch cover.

CLUTCH COVER

6x1.0mm12 N.m (1.2 kg{.m,9 tbf.ftl

x 'l .25 mm

tJ

24 N.m {2.4 kgt m,17 rbt ftl

Page 640 of 2189

Change Holder Assembly

Clearance Inspection (cont'd)

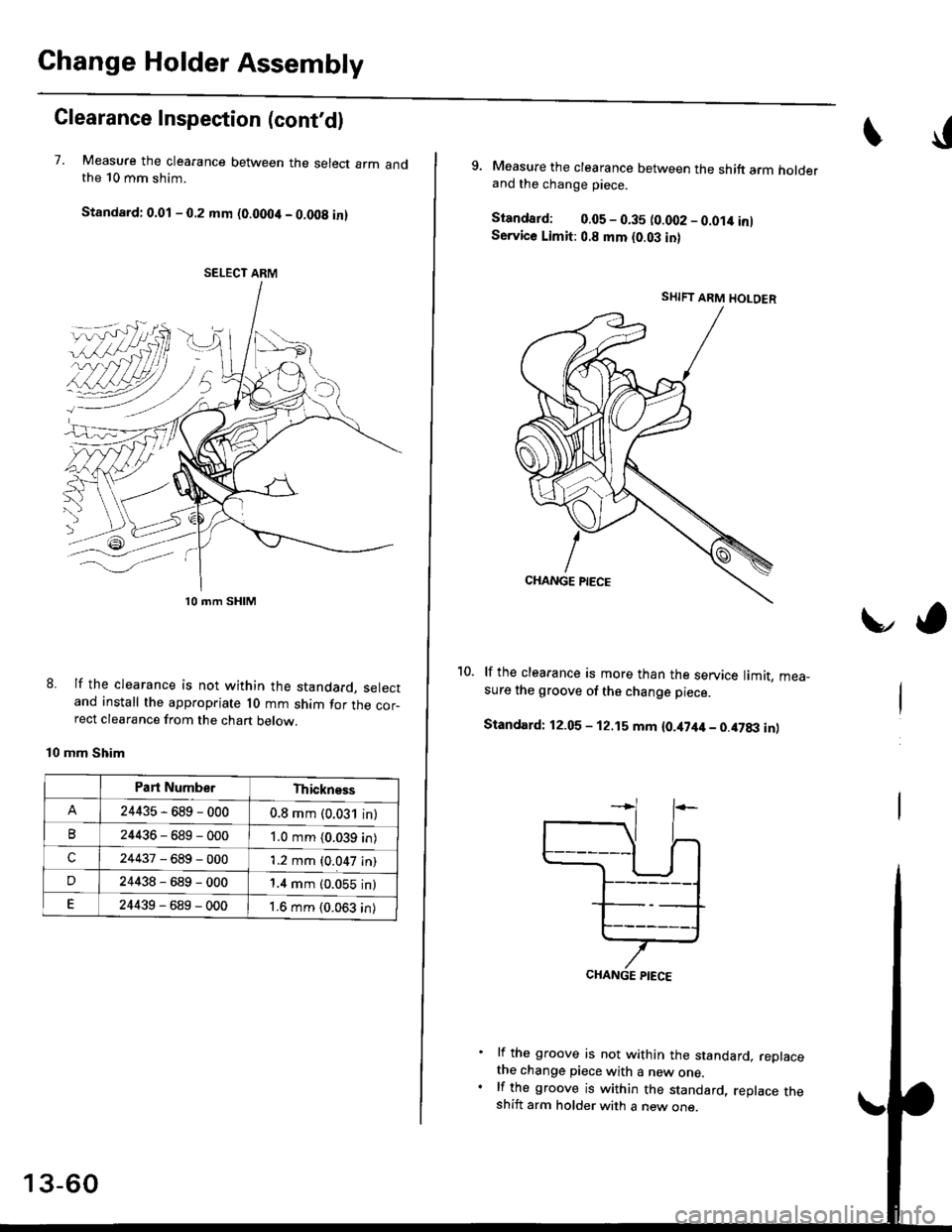

7. Measure the clearance between the select arm andthe 10 mm shim.

Standard: 0.01 - 0.2 mm (0.0004 - 0.008 in)

lf the clearance is not within the standard, selectand install the appropriate l0 mm shim for the cor-rect clearance from the chart below.

mm Shim

8.

SELECT ARM

l0 mm SHIM

Part NumberThickness

24435-689-0000.8 mm (0.031 in)

B24436-589-0001.0 mm (0.039 in)

c24437-689-0001.2 mm (0.047 in)

D24438-689-0001.4 mm (0.055 in)

E24439-689-0001.6 mm {0.063 in)

13-60

I

9. Measure the clearance between the shift arm holderand the change piece.

Standard; 0.05 - 0.35 (0.fi)2 - 0.014 inlService Limit: 0.8 mm (0.03 in)

lf the clearance is more than the service limit. mea_sure the groove of the change piece.

Standard: 12.05 - 12.15 mm {0.i[7it4 - 0.47txt inl

lf the groove is not within the standard, replacethe change piece with a new one.lf the groove is within the standard, replace theshift arm holder with a new one.

vo

SHIFT ARM HOLOER

CHANGE PIECE

Page 791 of 2189

Road Test

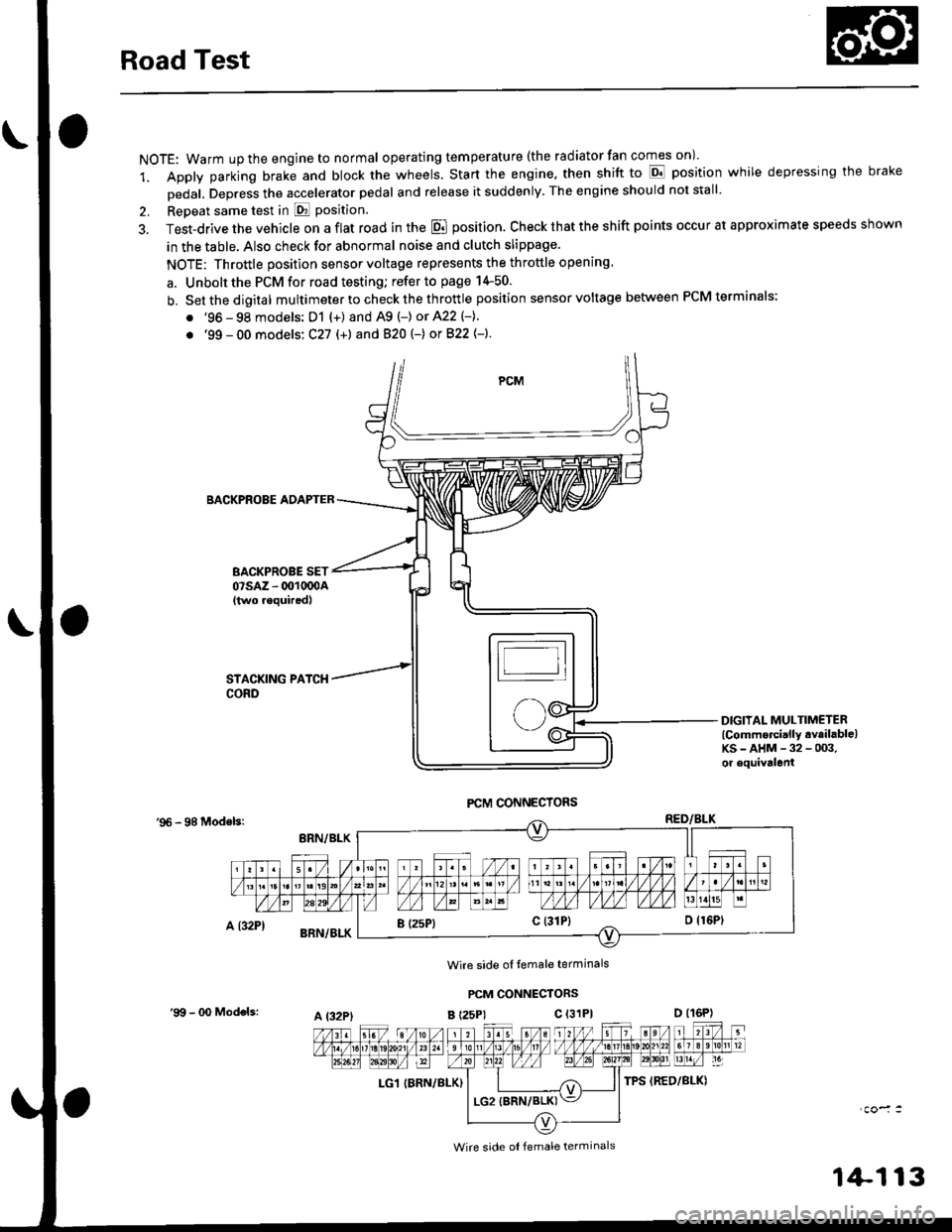

NOTE: Warm up the engine to normal operating tem peratu re (the rad iator fan comes on )'

1. Apply parking brake and block the wheels. Start the engine, then shift to E position while depressing the brake

Dedal, Depress the accelerator pedal and release it suddenly. The engine should not stall'

2. Repeat same test in E Position.

3. Test-drive the vehicle on a flat road in the E position. Check that the shift points occur at approximate speeds shown

in the table. Also check for abnormal noise and clutch slippage.

NOTE: Throttle position sensor voltage represents the throttle opening

a. Unbolt the PCM for road testing; refer to page 14-50.

b. Setthedigital multimeter to check the th rottle position sensor voltage between PCM terminals;

. '96 - 98 models: D1 {+) and A9 (-) or 422 (-}.

. '99 - 00 models: C27 (+) andB20t-) orB22{-}.

BACKPROBE ADAPTER

BACKPROBE SET07sAz - 001oq)A{two requiredl

DIGIIAL MULTIMETERlCommercially available)KS-AHM-32-003,or equivalenl

'96 - 98 Modelsr

Wire side ol temale terminals

PCM CONNECTORS

B t25Pl c (31P)

LG1 IBRN/BLK)

I (25P1c (31P}

A t32PtD (16P)

Wire side ol female terminals

'9!t - 00 Models:

1+113

Page 793 of 2189

Accelerate to about 35 mph (57 km/h) so the transmlssion is in 4th, then shift from Dl position to Z position The

vehicle should immediately begin slowing down from engine braking'

CAUTION: Do not shift from -91 or -Dd position to E position at speeds ov6r 63 mph {100 km/hl; You mav damage

the transmission.

Check for abnormal noise and clutch slippage in the following positions'

E (2nd Gear) Position

ll Accelerate from a stop at full throttle. check that there is no abnormal noise or clutch slippage.

b. Upshifts and downshifts should not occur with the selector in this posirion'

E (Reverse) Position

i"ccelerate from a stop at fullthrottle, and check for abnormal noise and clutch slippage'

Test in B (Park) Position

Park the vehicle on slope (approx. l6'), apply the parking brake' and shift into E position Belease the brake; the veh'

cle shou,d nol move

1+115

Page 794 of 2189

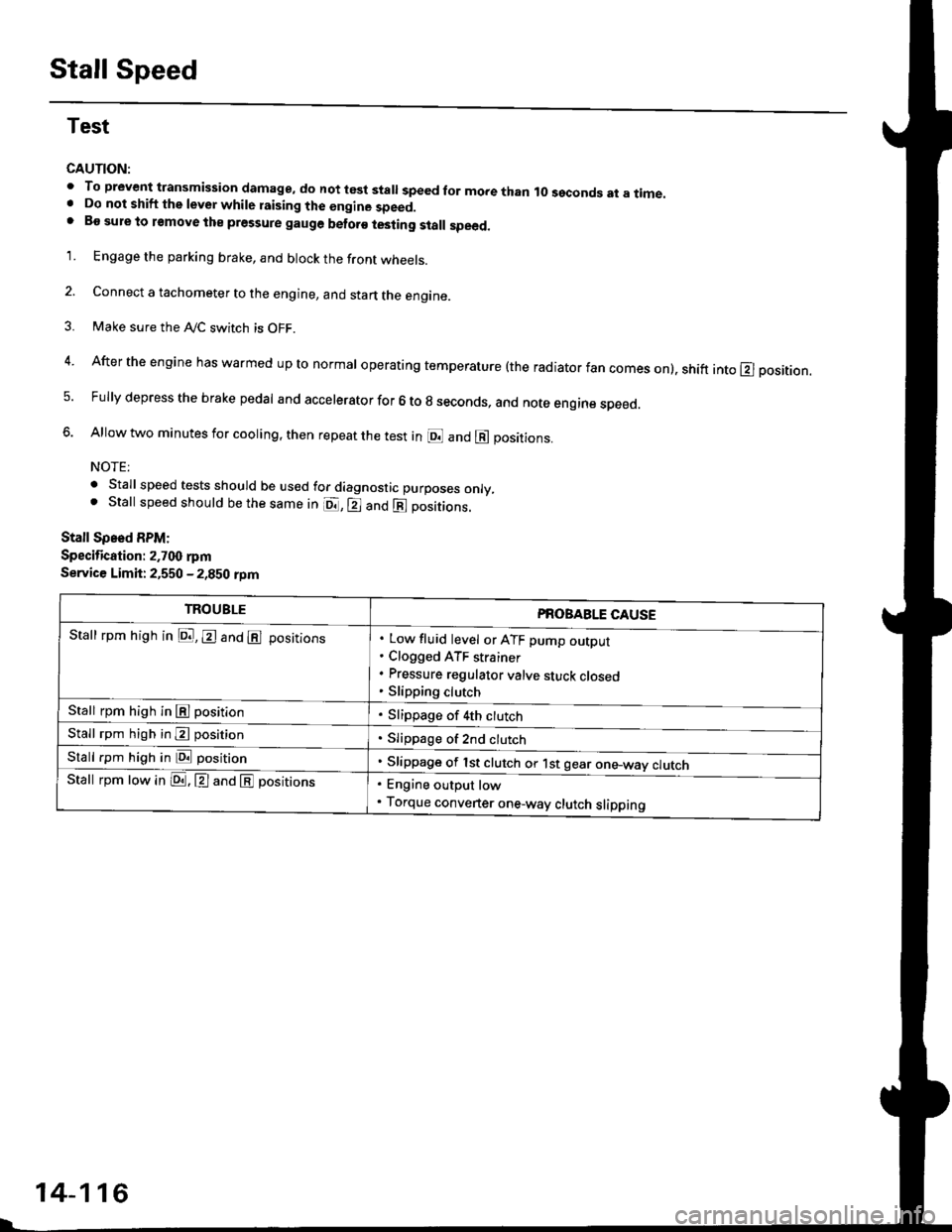

Stall Speed

Test

CAUTION:

. To prev€nt transmission damage, do not t6st stall speed for more than ro sgconds at a time.. Do not shift the levor while raising the engine speed.. Bo sule lo remove the pressure gauge betoro testing stall speed.

'1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the Ay'C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on). shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to g seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in @ and @ positions.

NOTE:

. Stall speed tests should be used for diagnostic purposes only,. Stall speed should be the same in o., E and E positions.

Stall Spsed RPM:

Specification: 2.700 rpm

Service Limit: 2,550 - 2,850 rDm

TROUBLEPROBABLE CAUSE

. Low fluid level or ATF pump outDur. Clogged ATF strainer. Pressure regulator valve sluck closeo. Slipping clutch

. Slippage of 4th ctutch

. Slippage of 2nd clutch

. Slippage of lst clut"tr or. t"t g""io*-*"y "lut"h

Stall rpm high in D., E and E positions

Stall rpm high in El position

Stall rpm high in E posirion

Stall rpm high in E position

Stall rpm low in LDa . El and E positrons. Engine output low. Torque converter one-way clutch slipping

14-116

Page 795 of 2189

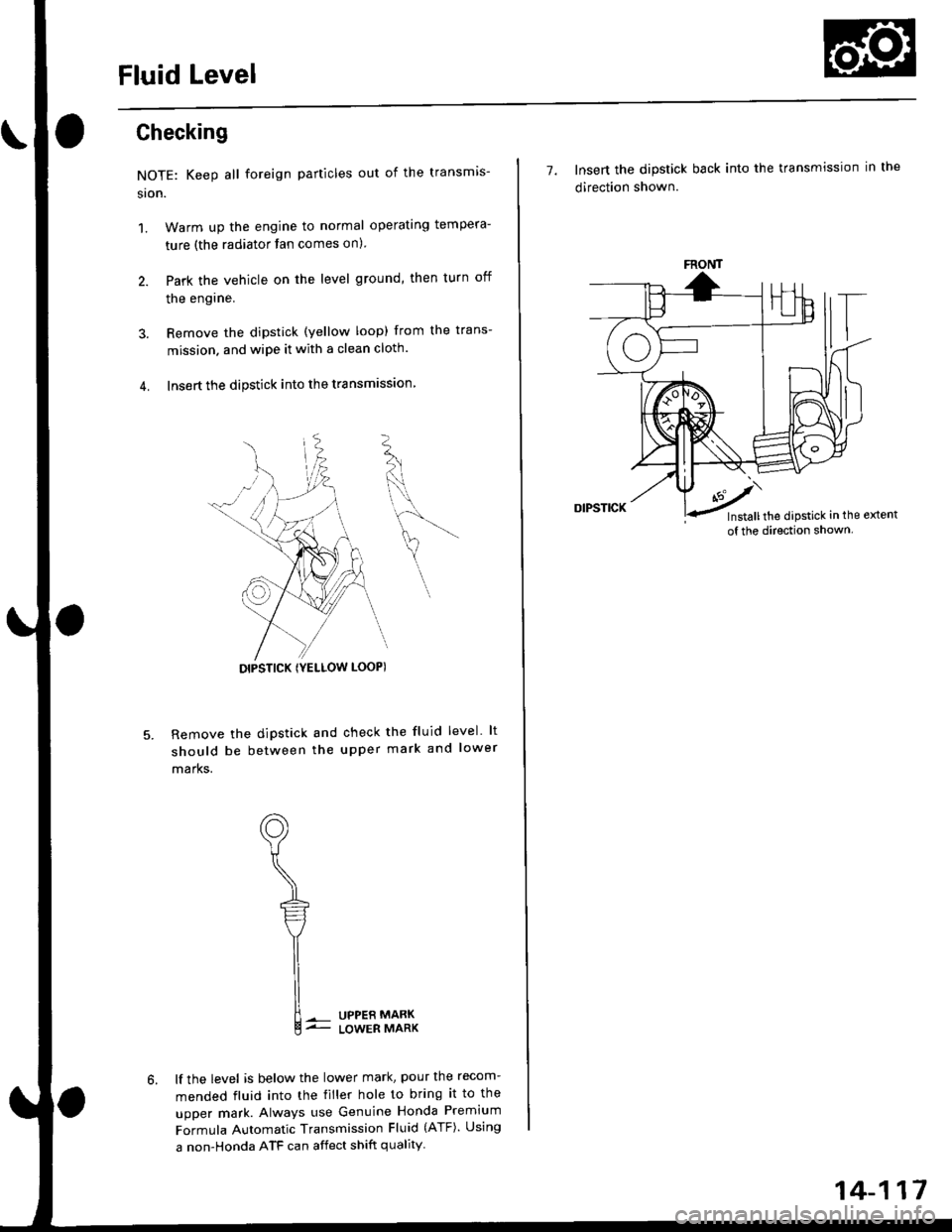

Fluid Level

Ghecking

NOTE: Keep all foreign particles out of the transmis-

sron.

1.Warm up the engine to normal operating tempera-

ture (the radiator fan comes on)

Park the vehicle on the level ground, then turn off

the engrne.

Remove the dipstick (yellow loop) from the trans-

mission. and wipe it with a clean cloth.

Insert the dipstick into the transmrssron

Remove the dipstick and check the fluid level lt

should be between the upper mark and lower

marks.

UPPER MABKLOWER MARK

lf the level is below the lower mark, pour the recom-

mended fluid into the tiller hole to bring it to the

upper mark. Always use Genuine Honda Premium

Formula Automatic Transmission Fluid (ATF). Using

a non-Honda ATF can affect shift quality

K

L

DIPSTICK IYELLOW LOOPI

7. Insert the dipstick back into the transmission in the

direction shown.

FRONT

Installthe dipstick in the extent

of the direction shown.

14-117

Page 796 of 2189

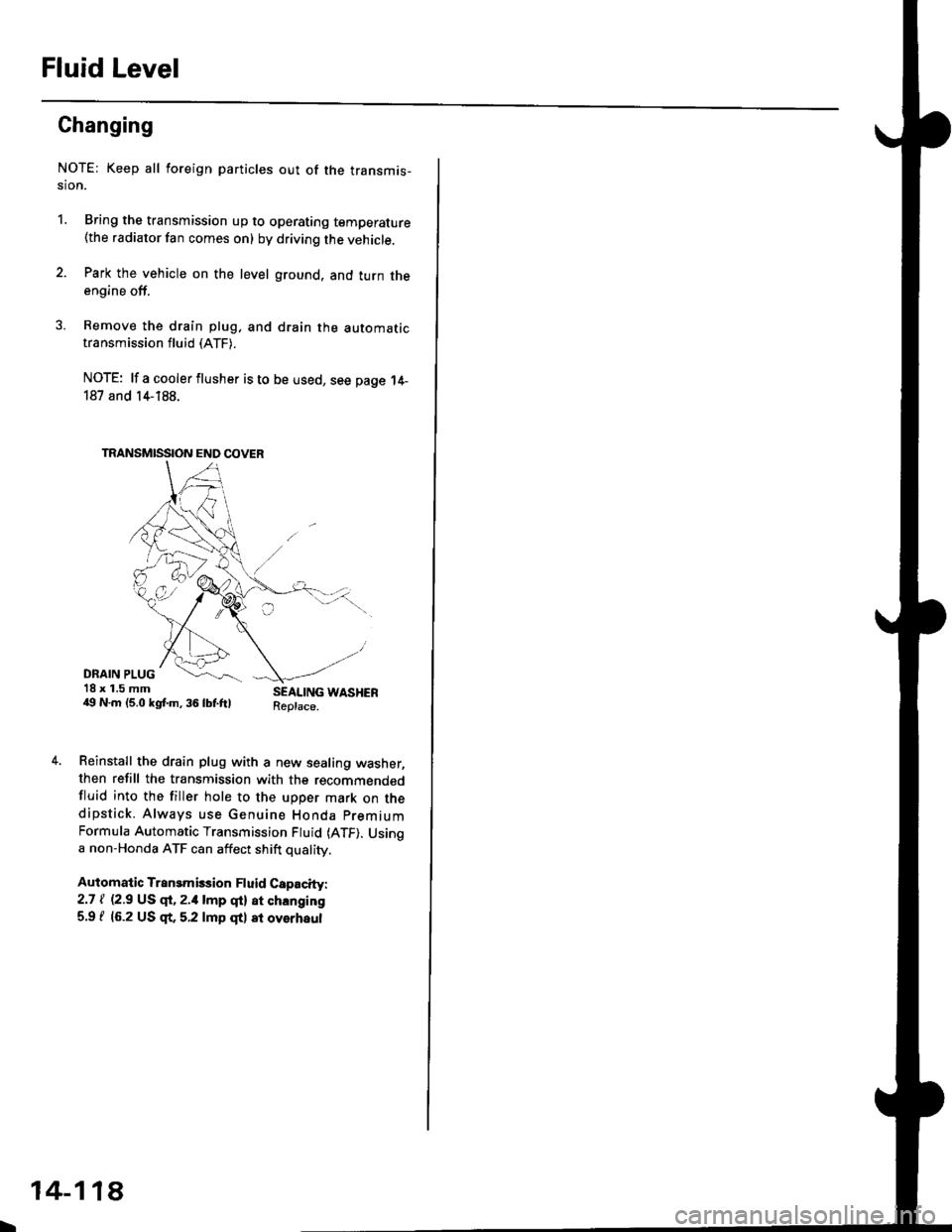

Fluid Level

Changing

NOT€: Keep all foreign particles out of the transmis-sion.

'1.Bring the transmission up to operating temperature(the radiator fan comes on) by driving the vehicle.

Park the vehicle on the level ground, and turn theengine off.

Remove the drain plug. and drain the automatictransmission fluid (ATF).

NOTE: lf a cooler flusher is to be used, see page 14-187 and 14-188.

TRANSMISgION END OOVER

DNAIN PLUG18 x 1.5 mm49 N.m (5.0 kgtm, 36lbf.ftlSEALING WASHERReplace.

Reinstall the drain plug with a new sealing washer,then refill the transmission with the recommended

fluid into the filler hole to the upper mark on thedipstick. Always use Genuine Honda premium

Formula Automatic Transmission Fluid (ATF). Usinga non-Honda ATF can aftect shift quality.

Automatic Transmission Fluid Capacity:

2.7 | |'2.9 US ql,2.a lmp qtl at Ghlnging

5.9 f 16.2 US qt. 5.2 lmp qt) at overhaul

I

14-11A

Page 853 of 2189

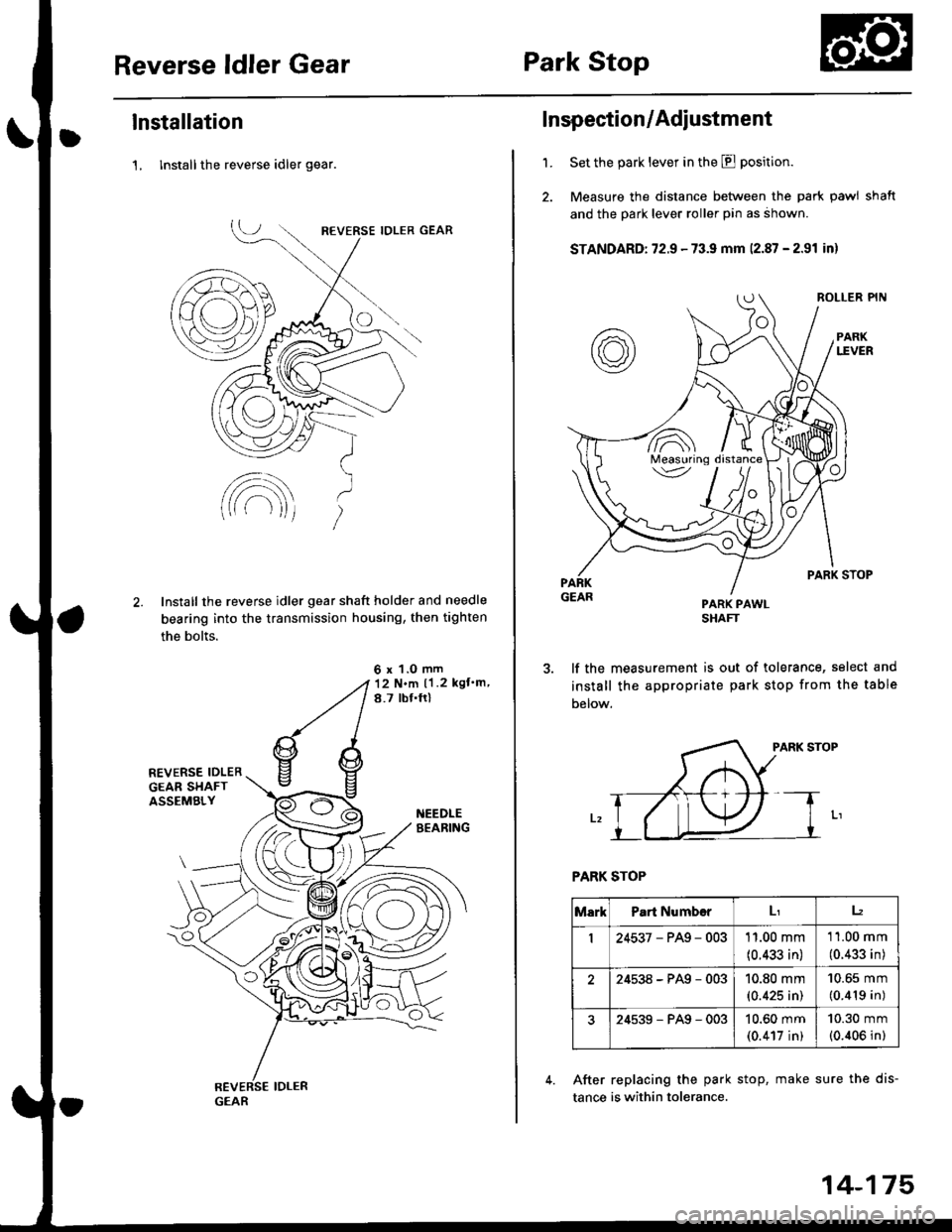

Reverse ldler GearPark Stop

lnstallation

1, lnstall the reverse idler gear.

Install the reverse idler gear shaft holder and needle

bearing into the transmission housing, then tighten

the bolts.

6 x 1.0 mm12 N.m ll .2 kgf'm,

8.7 tbf.ftl

GEAR

'1.

Inspection/Adiustment

Set the park lever in the E position.

Measure the distance between the park pawl shaft

and the park lever roller pin as ahown.

STANDARD: 72.9 - 73.9 mm 12.87 - 2.91 inl

PARK PAWLSHAFT

lf the measurement is out of tolerance, select and

install the appropriate park stop from the table

Delow.

PARK STOP

PARK STOP

After replacing the park stop, make sure the dis-

tance is within tolerance.

/A\Measuring\v

MarkPart Numb€rLr12

I24537-PAg-00311.00 mm

(0.433 in)

11.00 mm

(0.433 in)

24538-PAg-00310.80 mm(0.425 in)

10.65 mm

(0.419 in)

24539-PAg-00310.60 mm(0.417 in)

10.30 mm(0.406 in)

14-175

Page 871 of 2189

Continuously Variable Transmission (CVTI

Special Tools ................ 14-194

Description .................... 14-195

Clutches/Reverse Brake/Planetary

Gear/Pulleys .......... 14-198

power Flow ..............,..... 14-200

Electronic Control SYstem(,96 - 98 Modets) ......14-203

Electronic Control System

('99 - oo Models) " 14-205

Hydraulic Control '....... 14-208

Hydraulic Flow .'..-.....'... '14-212

Park Mechanism .....-...'.' 14-222

Eleqtrical Systom

Component Locations'96 - 98 Models """"""' 14-224,99 - 00 Modets ............. 14-225

TCM Circuit Diagram ('96 - 98 Models) ............. 14-226

TCM Terminal Voltage/Measuring Condiiions ('96 - 98 Models) '.... 14-228

PcM Circuit Oiaqram{A/T Control System: '99 - 00 Models} ...--.... 14-230

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)

A/4 Control System .'.'...14-232

Troubleshooting Procedures ... . .... .....',........."' '14-234

Symptom-to-ComPonent Chart

Electrical System - '96 - 98 Models ......'..... '14-234

Electrical System -'99 - 00 Models ..'....-..-. '11-210

Electrical Troubleshooting

Troubleshooting Flowcharts('96 - 98 Models) """'11-242

Troubleshooting Flowchart

('99 - 0O Modets) ...... 14-265

Linear Solenoids/lnhibitor Solenoid

Test ......................... . ...... 14-29f

Drive Pulley/Driven Pulley/Secondary Gear

Shaft Speed Sensors

Replacement .........'...... .14-292

Start Clutch Control

Start Clutch Calibration Procedure ....... ....,. 14-293

Hydraulic SYstem

Symptom-to-ComPonent Chart

Hydraulic System '.'.......14-294

Road Test ............................ 14-296

Stall Speed

Test......................... ...... 14-294

Fluid Level

Checking/Changing ....... 14-299

Pressure Testing ................. 14-300

Lower Valve BodY AssemblY

Replacement ..........,... 14-302

ATF Filter

Removal/lnstallation ..... 14-303

Transmission

Transmission

Removal ........... . 14-304

lllustrated Index

Transmission/Lower Valve BodY

Assembly ................. 14-308

Transmission Housing/Flywheel Housing ... 14-310

End Cover/f ntermediate Housing ..........'.'.... 14-312

Transmission Housing/Lower Valve Body Assembly

Removal ..........'.... .. " 14-314

Transmission Housing/Flywhesl Housing

Removal ................. ........ 1+316

End Cover/lntermediate Housing

14-318Removal .........,...............

Manual Valve Body

Disassembly/lnspection/Reassemblv .'.'.'..... 1 4-320

Forward Clutch

lltustrated Index ........................................ 14-321

Disassemblv .................. 14-322

Reassemblv , ,, . ',','......14-324

Secondary Gear Shaft

25 x 35 mm Thrust Shim Selection ..'.'....-... 14-324

Differential

lllustrated lndex ...,.....................,.,...-.-.-...'... 14-329

Backlash Inspection .-....14-329

Bearing Replacement ......'........'....'... ....'... 14-330

Differential Carrier Replacement ........'........ 14-330

Oil Seal Removal ........... 14-331

Oil Seal Installation/Side Clearance ....... . . 14-331

Flywheel Housing Input Shaft Oil Seal

Replacement .....,.... ...'.'.. 14-333

Transmission Housing Bearings

Driven Pulley Shaft Bearing

Replacenient ...................'. . ...................'.. 14-334

Secondary Gear Shaft Bearing

Reolacbment ...................... . .......... . ........ 14-335

Flywheel Housing Beating

Secondary Gear Shaft BearingReo1acement..................,........................... 14-335

Ring Gear Bearing

Replacement......... ........ 14-336

Control Shaft Assembly

Removal/lnstallation ....................'........... 14-336

Transmission

Reassembly .................. 14-338

Flywheel/Drive Plate .. . ...... . ...... ... . ....-.....'.'...14-341

Transmission

lnstalation ..................... 14-348

Cooler Flushing .'......... 14-352

shift cable

Removal/lnstallation....'........." """ 14-354

Adjustment .......'........ 14-355

Shift Lever ........................,. 14'356

Shift Indicator Panel

Adjustment ................ 14-357

ATF Cooler/Hoses

lnsta llation ......,,...... .... 14-357

Page 873 of 2189

Description

The Continuously Variable Transmission (CVT) is an electronically controlled automatic transmission with drive and driv

en Oullevs, and a steel belt. The CVT provides non stage speeds forward and one reverse. The entire unit is positioned in

line with the engine.

Transmission

Around the outside of the flywheel is a ring gear which meshes with the starter pinion when the engine is being staned.

The transmission has four parallel shafts: the input shaft, the drive pulley shaft. the driven pulley shaft, and the secondary

gear shaft. The input shaft is in line with the engine crankshaft. The drive pulley shaft and the driven pulley shaft consist of

movable and fixed face pulleys. Both pulleys are linked by the steel belt.

The input shaft includes the sun gear. The drive pulley shaft includes the forward clutch which mounts the carrier assem-

bly on the forward clutch drum. The carrier assembly includes the pinion gears which mesh with the sun gear and the ring

gear. The ring gear has a hub-mounted reverse brake disc.

The driven pulley shaft includes the start clutch and the secondary drive gear which is integral with the park gear' The sec-

ondary gear shaft is positioned between the secondary drive gear and the final driven gear. The secondary gear shaft

includes the secondary driven gear which serves to change the rotation direction. because the drive pulley shaft and the

driven oullev shaft rotate the same direction. When certain combinations of planetary gears in the transmission are

engaged by the clutches and the reverse brake, power is transmitted from the drive pulley shaft to the driven pulley shaft

to provide E, E, E, and El.

Electronic Control'96 - 98 Models:

The electronic control system consists of the Transmission Control Module (TCM), sensors, three linear solenoids, and a

inhibitor solenoid. Shifting is electronically controlled under all conditions'

The TCM is located below the dashboard, behind the kick panel on the driver's side.'99 - 00 Models:

The electronic control svstem consists of a Powertrain Control Module (PCM), sensors, three linear solenoids and an

inhibitor solenoid. Shifting is electronically controlled under all conditions. A Grade Logic Control System to control shift-

ing in E position while the vehicle is ascending or descending a slope.

The PCM is located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the Pressure Low (PL) reguiator valve body, the shift valve

body, the start clutch control valve body, and the secondary valve body. They are positioned on the lower part of the

transmission housing.

The main valve body contains the Pressure High (PH) control valve, the lubrication valve, and the pitot regulator valve.

The secondary valve body contains the PH regulator valve, the clutch reducing valve, the start clutch valve accumulator,

and the shift inhibitor valve. The PL regulator valve body contains the PL regulator valve and the PH-PL control valve

which is ioined to the PH,PL control linear solenoid. The inhibitor solenoid valve is bolted on the PL regulator valve body.

The shift valve body contains the shift valve and the shift control valve. which is joined to the shift control linear solenoid.

The start clutch control valve body contains the start clutch control valve, which is joined to the start clutch control linear

solenoid. The linear solenoids and the inhibitor solenoid are controlled by the TCM or PCM. The manual valve body which

contains the manual valve and the reverse inhibitor valve, is bolted on the intermediate housing.

The ATF pump assembly is located on the transmission housing, and is linked with the input shaft by the sprockets and

the sprocket chain. The pulleys and the clutch receive fluid from their respective feed pipes, and the reverse brake receives

fluid from internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which linear solenoid the TCM or PCM will activate.

Activating the shift control linear solenoid changes the shift control valve pressure, causing the shift valve to move. This

pressurizes the drive pulley pressure to the drive pulley and the driven pulley pressure to the driven pulley and changes

their effective pulley ratio. Activating the start clutch control linear solenoid moves the start clutch control valve. The start

clutch control valve uncovers the port, providing pressure to the start clutch to engage it(cont'd)

14-195

,!