no. 25 HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 443 of 2189

PGM-FI System

l-Fos3sl

tFos36l

tF1361 l

Fr362-1

tF13sil

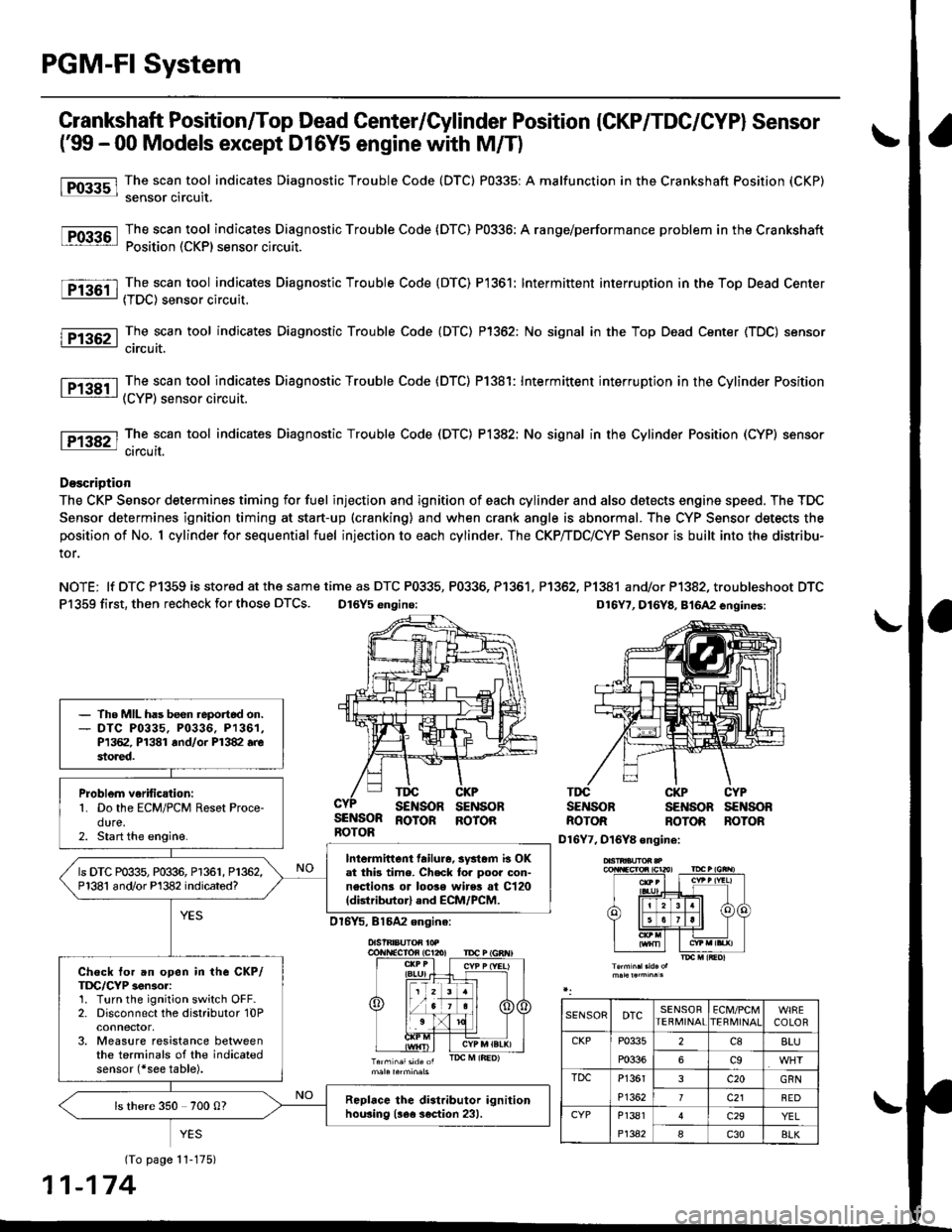

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

f99 - 00 Models except D16Y5 engine with M/T)

The scan tool indicates Diagnostic Trouble Code (DTC) P0335: A malfunction in the Crankshaft Position (CKP)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the Crankshaft

Position (CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1361: Intermittent interruption in the Top Dead Center

{TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1362: No signal in the Top Dead Center (TDC) sensor

circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position(CYP) sensor circuit.

lTiaSt The scan tool indicates Diagnostic Trouble Code (DTC) P1382; No signal in the Cylinder Position (CYP) sensor: circuil.

DoscriDtion

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDC

Sensor determines ignition timing at start-up (cranking) and when crank angle is abnormal. The CYP Sensor detects the

position of No. 1 cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-

tor.

NOTE; lf DTC P1359 is stored at the same time as DTC P0335, P0336, P1361. P1362, P1381 and/or P1382, troubleshoot DTC

P1359 first, then recheck for those DTCS. D16Y5 engino:

SENSORROTOR

TDGSENSORCKPSENSOBTDCSENSOBCKPSENSOBCYPs€NsonBOTORROTORBOTONROTOR ROTOR

D16Y7, D16Y8 ongine:

(To page 11-175)

1-174

- The MIL has been reportod on.- DTC P0335, P0336. P1361,P1362, P1381 rnd/or P1382.restored.

Problem verific{tion:1. Do the ECM/PCM Reset Proce-dure.2. Start the engine.

Intormittcnt failure, systom b OKat thb time. Check to. poor con-nections or loose wires at C120(dktributorl and ECM/PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or Pl382 indicated?

Check tor an open in the CKP/TDC/CYP 3enior:1. Turn the ignition switch OFF.2. Disconnect the distributor 10Pconnector,3. Measure resistance betweenthe terminals of the indicatedsensor (*see table).

Replrce the distributor ignitionhou3ing (!ee section 231.ls there 350 700 0?

SENSORDTCSENSORTEBMINAIECM/PCMTERI\,4INAICOLOR

CKPP0335

P0336

2c88LU

6c9

TDCP1361

P1362

3c20GRN

7c21BED

CYPP1381

P1342

c29YEL

Ic30BLK

Page 448 of 2189

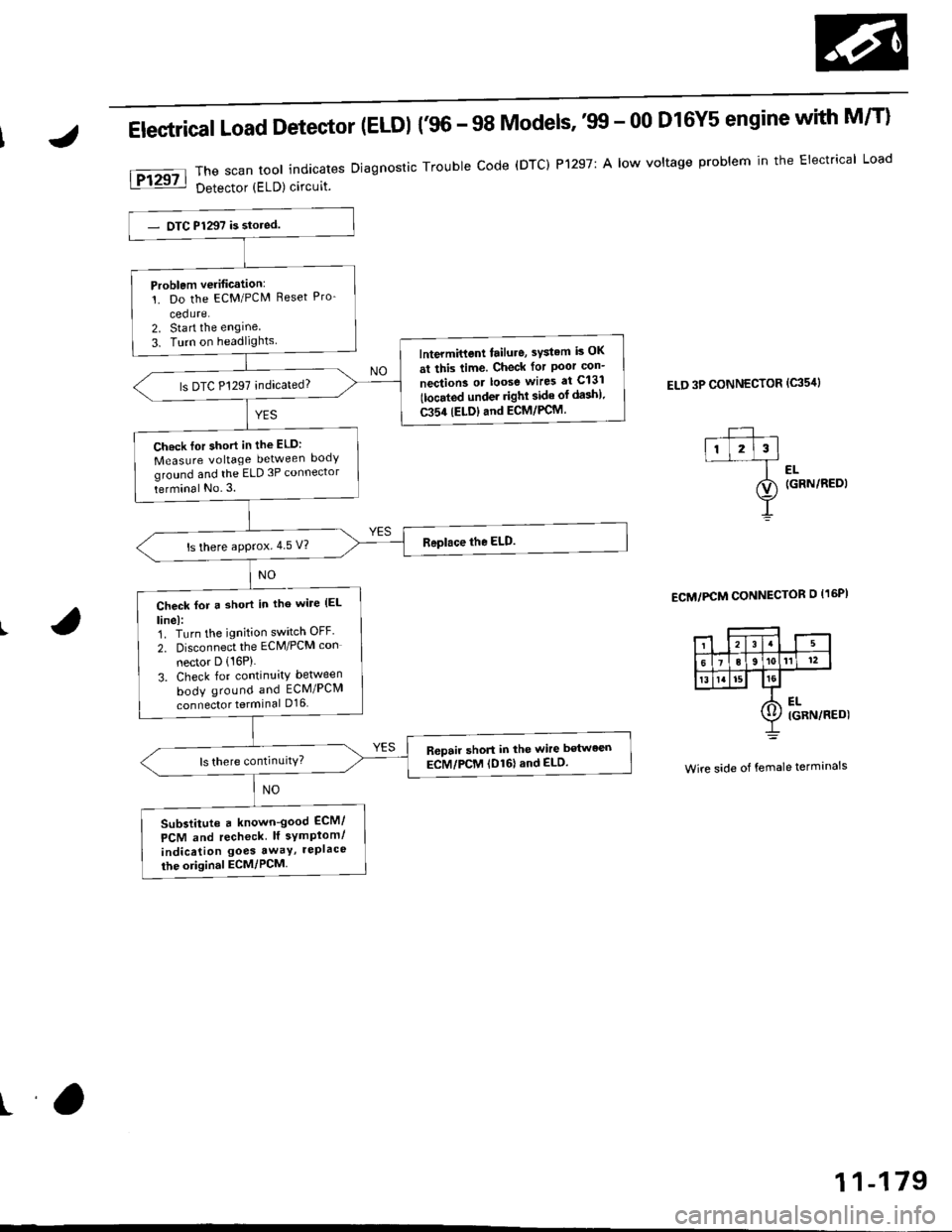

Electrical Load Detector (ELDI {'96 - 98 Models,'tn - 00 D16Y5 engine with M/T}

The scan tool indicates Diagnostic Trouble code (DTC) P1297: A low voltage problem in the Electrical Load

Detector (ELD) circuit.

ELD 3P CONNECTOR (c35'rl

l-- ,ll l2l3l--f ..

ao (GRN/REDI

Y

ECM/PCM CONNECTOR O I16PI

Wire side of female terminals

Problem verification:'!. Do the ECM/PCM Reset Pro-

cedure.2. Sta rt the engine

3. Turn on headlightslntermittent tailure, sYstem is OK

at this time. Check for Poor con-

nection3 or loose wires at C131

tlocated under righl side of da3h).

C354 (ELDIand ECM/PCM.

ls DTC P1297 indicated?

Ch.ck lor short in the ELD:

Measure voltage between body

ground and the ELD 3P connector

terminal No.3.

ls there approx.4 5 V?

Check for a short in tho wile (EL

linel:1. Turn the ignition switch OFF'

2. Disconnect the ECM/PCM con

nector D (16P)

3. Check for continuity between

body ground and ECM/PCM

connector terminal D16

R6pair short in the wire between

ECM/PCM (D161and ELD.

Substitute a known-good ECM/

PCM and recheck lf symplom/

indication goes awaY, rePlace

the original ECM/PCM

ra

11-179

Page 449 of 2189

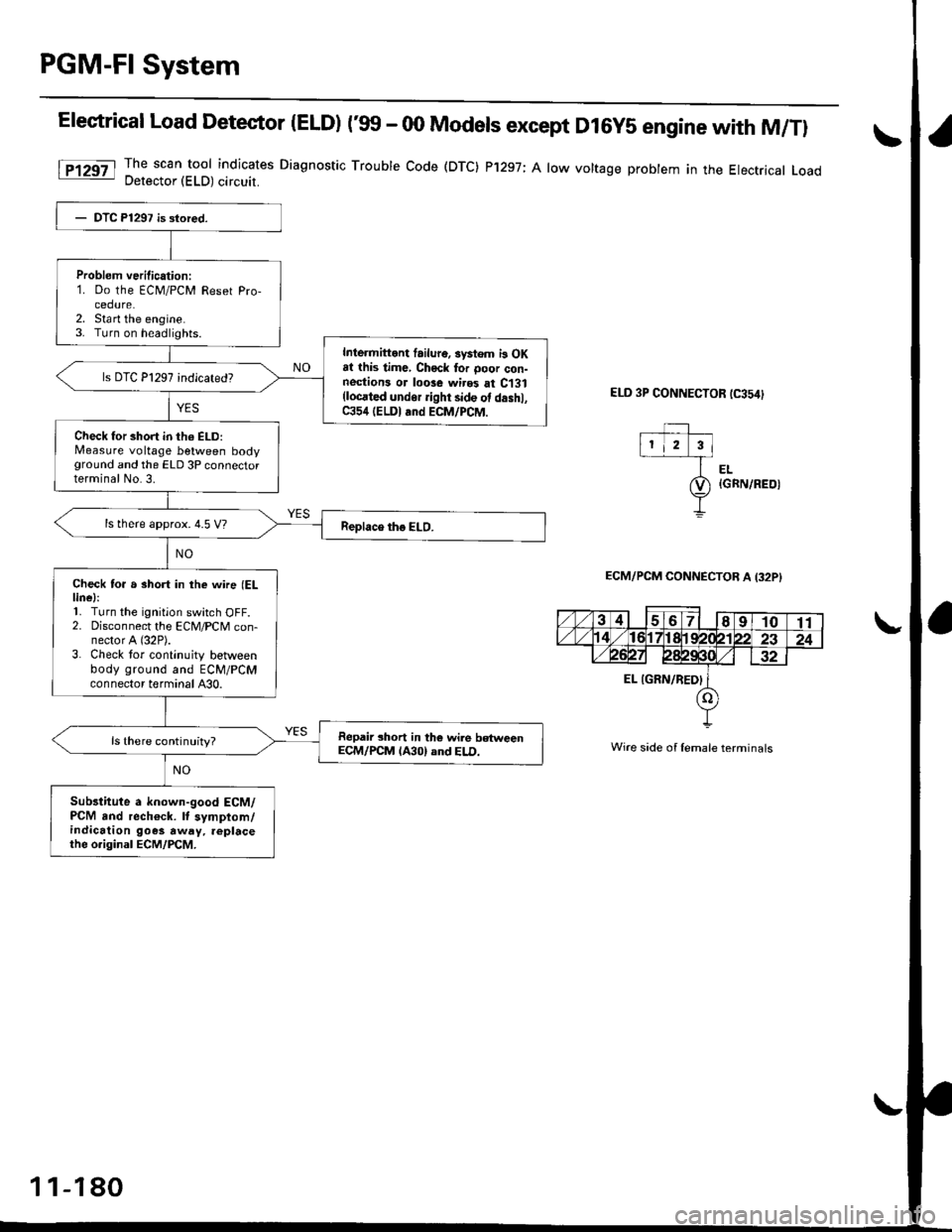

PGM-Fl System

Elestrical Load Detector |ELD) t'glf - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P'1297; A low voltage probtem in the Electrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR tC354)

EL{GRN/REOI

ECM/PCM CONNECTOB A I32PI

Wire side of lemale terminals

Problem verilication:1. Do the ECM/PCM Reset Pro-cedure.2. Sta rt the engine.3. Turn on headlights.

Inlermittont failur6. systom i3 OKat this time, Chock tor ooor con-nestions or loose wires at C131(locrted undor ight side ot d.shl,C354 (ELDI and ECM/PCM.

Check for short in th6 ELD:Measure voltage between bodyground and the ELD 3P connectorterminal No.3.

ls there approx. 4.5 V?

Check to. a short in the wne (ELlinel:'L Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector A (32P).

3. Check tor continuity betlveenbody ground and ECM/PCMconnector terminal A30.

Repair short in the wile betweenECM/PCM lA30) and ELD.ls there continuity?

Sub3titute a known-good ECM/PCM and rech€ck. It symptom/indication goes away. replacethe o.iginal ECM/PCM.

1 1-180

Page 450 of 2189

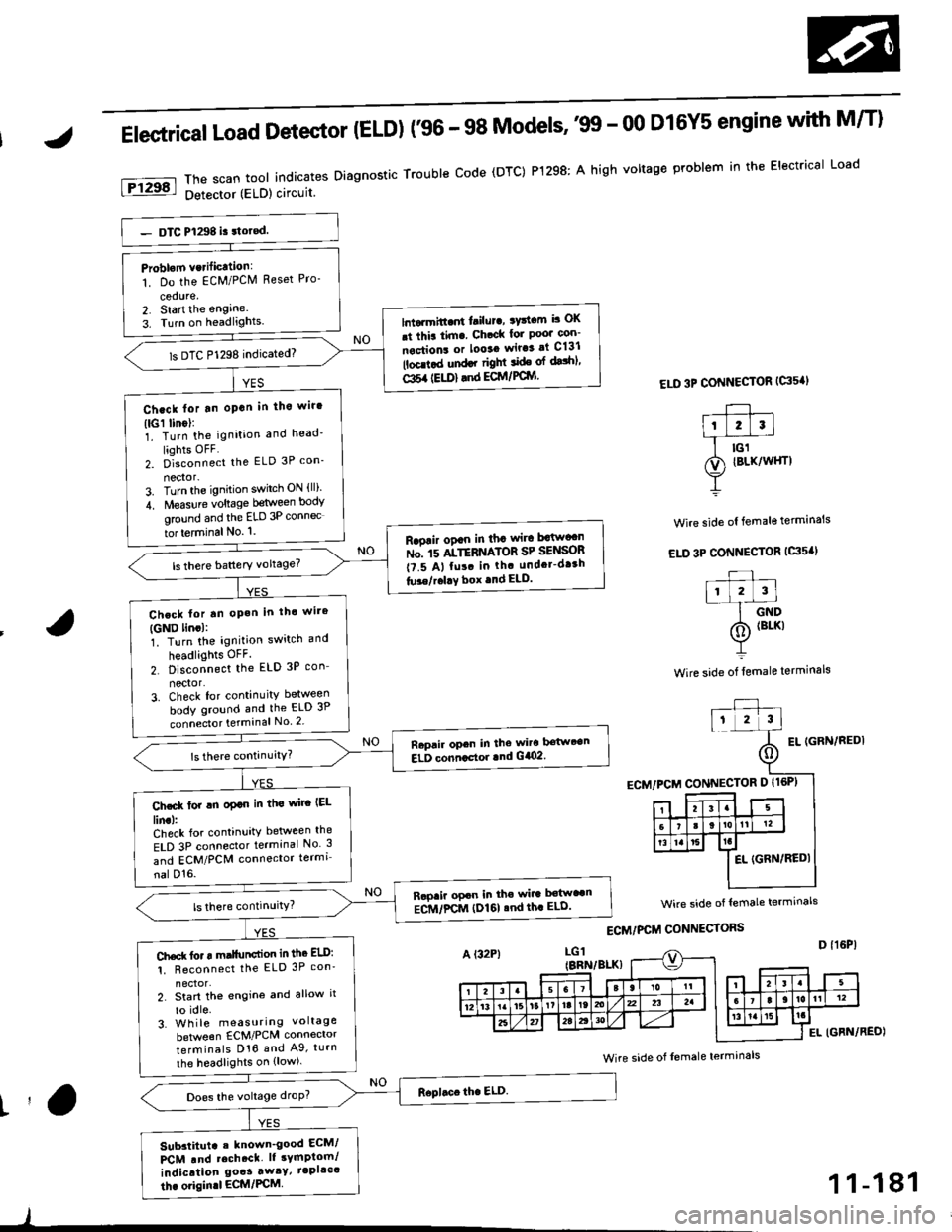

Elestrical Load Detector (ELD) f96 - 98 Models''99 - 00 D16Y5 engine with M/T)

ThescantoolindicatesDiagnosticTroubleCode(DTC)P1298:AhighvoltageproblemintheElectricalLoad

Detector (ELD) circuit

ELD 3P CONNECTOR {G's'I

Wire side ol female terminals

EL IGFN/REDI

Problom vcrificttion:

1. Do the EcM/PClVl Reset Pro-

cedure,2. Start the engine.

3. Turn on headlights.lntarmitt..rt l.ilur., ryttcm b OK

.t thia tim. Ch.ck lor Poo' con-

nections or looaa wir.3 at C131

lbcd.d und.r right ide ol dalhl'

Gl5a {EU)} .nd ECM/PCIYI

ls DTC P1298 indicated)

Ch.ck lor tn oPan in tho wir'

(lGl linol:1. Turn the ignition and head'

liohts OFF2. D]""onn""t the ELD 3P con_

nector-3. Turn the ignition switch ON {ll)'

4. Measure voltage between body

ground and the ELD 3P connec

tor terminal No. '1.

R.oair ogan in tha wira Mw"n

ru". rs ltTEnrlton SP SelSOn

t?.5 A, fu!. in th. undcr-dr3h

tu3e/r.l!Y box .nd ELD.

Chcck lor tn oP.h in thc wire

{GND lincl:1. Turn the ignition switch and

headlights OFF.

2. Disconnect the ELD 3P con_

nector'3. Check for continuity between

body ground and the ELD 3P

connecto. terminal No 2

Raprir opcn in the wira bstwt€n

ELD conncctor lnd G/O2.

Ch.ck lor !n oplo in tha wirc IEL

lin.l:Check for continuity between the

ELD 3P connector terminal No 3

and ECM/PCM connector termi

nal D'16.

Rapaii opcn in the wira b€tw"n

ECM/FCM (I)161 .nd th. ELD'

Ch.d( fo. r m.llunction in thc ELD:

1. Reconnect the ELD 3P con'

2. Start th€ engine and allow it

to idle.3. Wh ile measuring voltage

beNveen ECM/PCM connector

terminals D16 and A9, turn

the headlights on {low).

Does the voltage droP?

Sub3titut. . known_good ECM/

PCM .nd rcch.ct. lt sYmptom/

indication goas away/ iapllc'

thc origin.l ECM/PCM

wire side of lemale termrnals

Wire side of Iemale terminals

t'a

)

1 1-181

Page 451 of 2189

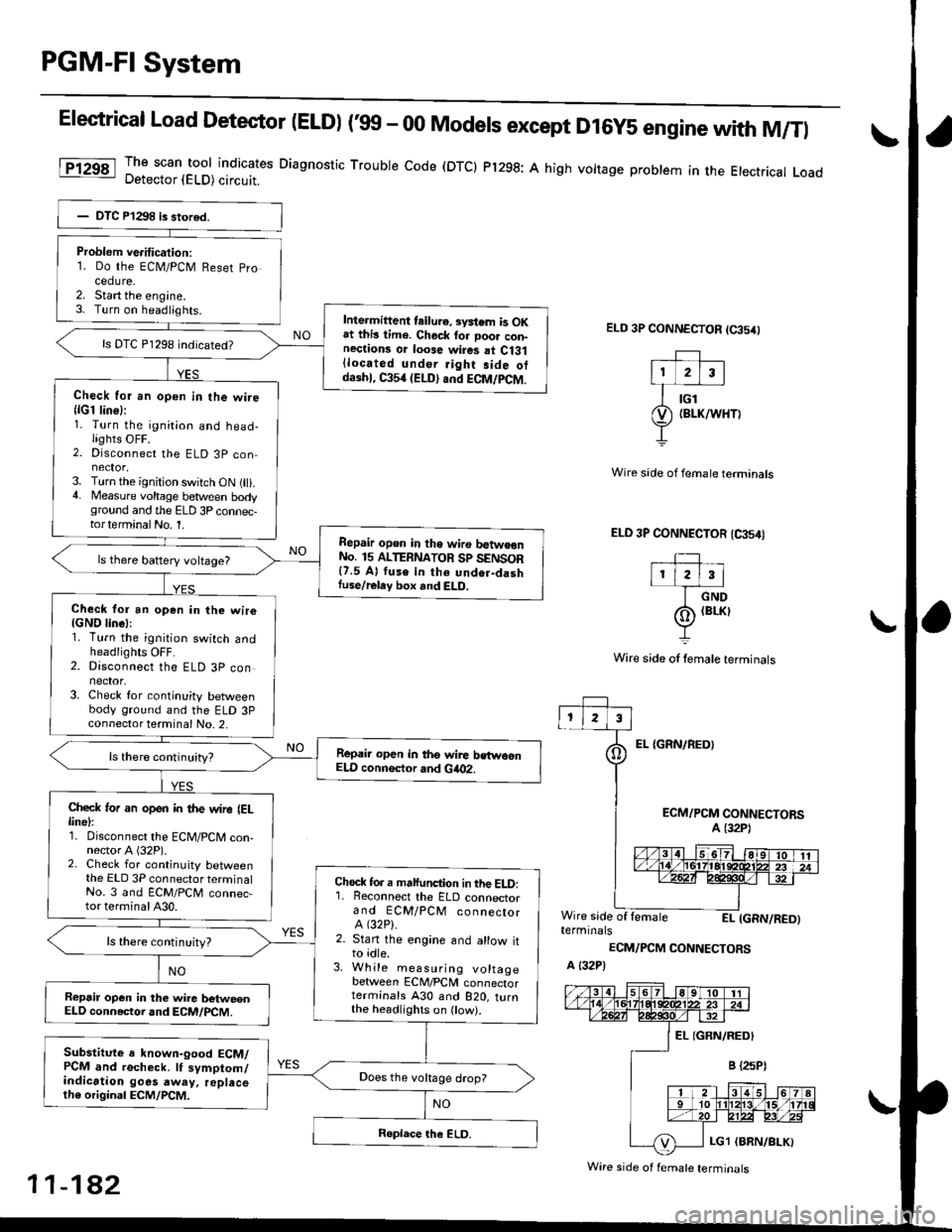

PGM-FI System

Elestrical Load Detector (ELDI ('99 - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble code (DTCI Pl298: A high vottage problem in the Etectrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR (65/0

EL {GRN/REOI

Wire side of fernale terminals

ELD 3P CONNECTOR (CA54I

TIr l2l3l

I crvo

(o) (BrKr

Y

Wire side of lemale terminals

ECM/PCM CONNECTORSA (32P1

Wire side of lemaleEI- IGRN/RED)terminals

ECM/PCM CONNECTORS

A {32P)

Problem ve.itication:1. Do the ECN4/PCM Reset pro

cedure.2. Start the engine.3- Turn on headiights.Inte.mittent teilu.e, svstem is OKat this lime. Chock for Door con-nections or loose wires at Ci31{located under Jight side otdaihl, C354 (ELD) and ECM/PCM.

ls DTC P1298 indicated?

Check for an open in the wire{lG1 line}:1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P con

3. Turn the ignition switch ON (ll).4. Measure voltage between bodyground and the ELD 3P connec-torterminalNo. 1.

Repair opon in tho wiro batwe€nNo. 15 ALTERNATOR Sp SENSOR{7.5 A} fuse in th6 undor-dashIuse/reley box and ELD.

ls there battery voltage?

Check for an open in the wiro{GND linel:1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P connector.3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2,

Repair open in the wire bstwoenELD connsctor and Gia02.

Check ,or an open in the wire IELlinel:1. Disconnect the ECM/PCM con-nector A (32P).2. Check for continuity betweenthe ELD 3P connector terminalNo. 3 and ECM/PCM connec-tor terminal A30.

Chock fo. a malfunction in the ELD:'1. Reconnect the ELD connectorand ECM/PCM connectorA (32P).

2. Stan the engine and allow itto idle.3. While measuring voltagebetween ECM/PCM connectorterminals A30 and B2O, turnthe headlighrs on ow).

ls there continuity?

Repsir op€n in the wire betweenELD connector and ECM/PCM.

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away. replacelh6 original ECM/PCM.

Does the vokage drop?

Wire side of f€male terminals

11-182

Page 452 of 2189

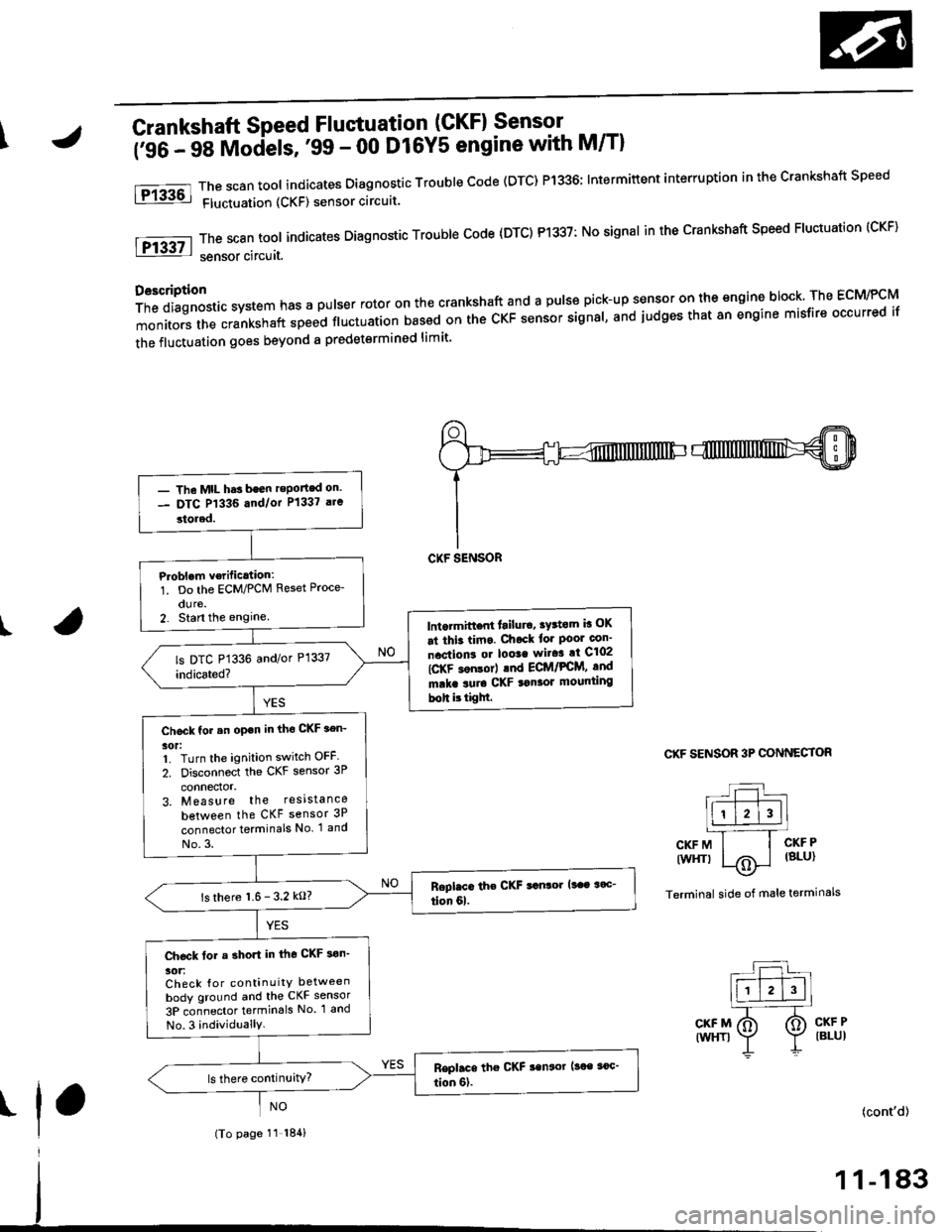

\Crankshaft Speed Fluctuation (GKFI Sensor .

firC- 48 Models, '99 - 00 D16Y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P1336; Intermiftent interruption in the Crankshaft Speed

Fluctuation (CKF) sensor circuit.

ThescantooIindicatesDiagnosticTroub|ecode{DTC)P1337:NosignaIinthecrankshaftspeedF|uctuation(cKF}

sensor circuit.

D6scription

Thediagnosticsystemhasapu|serrotoronthecrankshaftandapu|sepick-upsensorontheengineblock.TheEcM/PcM

monitors the crankshaft speed ftuctuation based on the cKF sensor signal, and judges that 8n engine misfire occurred if

the fluctuation goes beyond a predetermined limit'

I

fPrk6l

lFr3g7-l

CKF SENSOR 3P CONNECTOR

L:l.)l l.' -Ir-T--T---.]l1 l2l3llL-''---r

CKFM I I CKFP

twrfit 1,.^ | lsLul\.7

Terminal side of male terminals

CKF MIWHT}

CKF PIBLUI

I(cont'd)

- The MtL hds been reported on.- DTC P1336 and/or P1337 a.e

stored.

P.oblem v€rific.tion:1. Do the ECM/PCM Reset Proce-

dure.2. Stan the enginelntormittont lailur6, tY3tom b OK

at thit tima. Chock tor Poor con'

nactions or loota wito! at C102

IC-KF son$rl .nd ECt /PCM, and

mrka suro CKF tonaor mounting

boh ittigM.

Chock for .n open in tho CKF aen-

30t:1. Turn the ignition switch OFF

2. Disconnect the CKF sensor 3P

connector,3. Measure the resista nce

between the CKF sensor 3P

connector terminals No. 1 and

No.3.

ls there 1.6- 3.2 kO?

Ch€ck tor a short in the CKF son'

30tiCheck {or continuitY between

body ground and the CKF sensor

3P connector termin6ls No. 1 and

No.3 individuallY.

(To page 11 184)

1 1-183

Page 454 of 2189

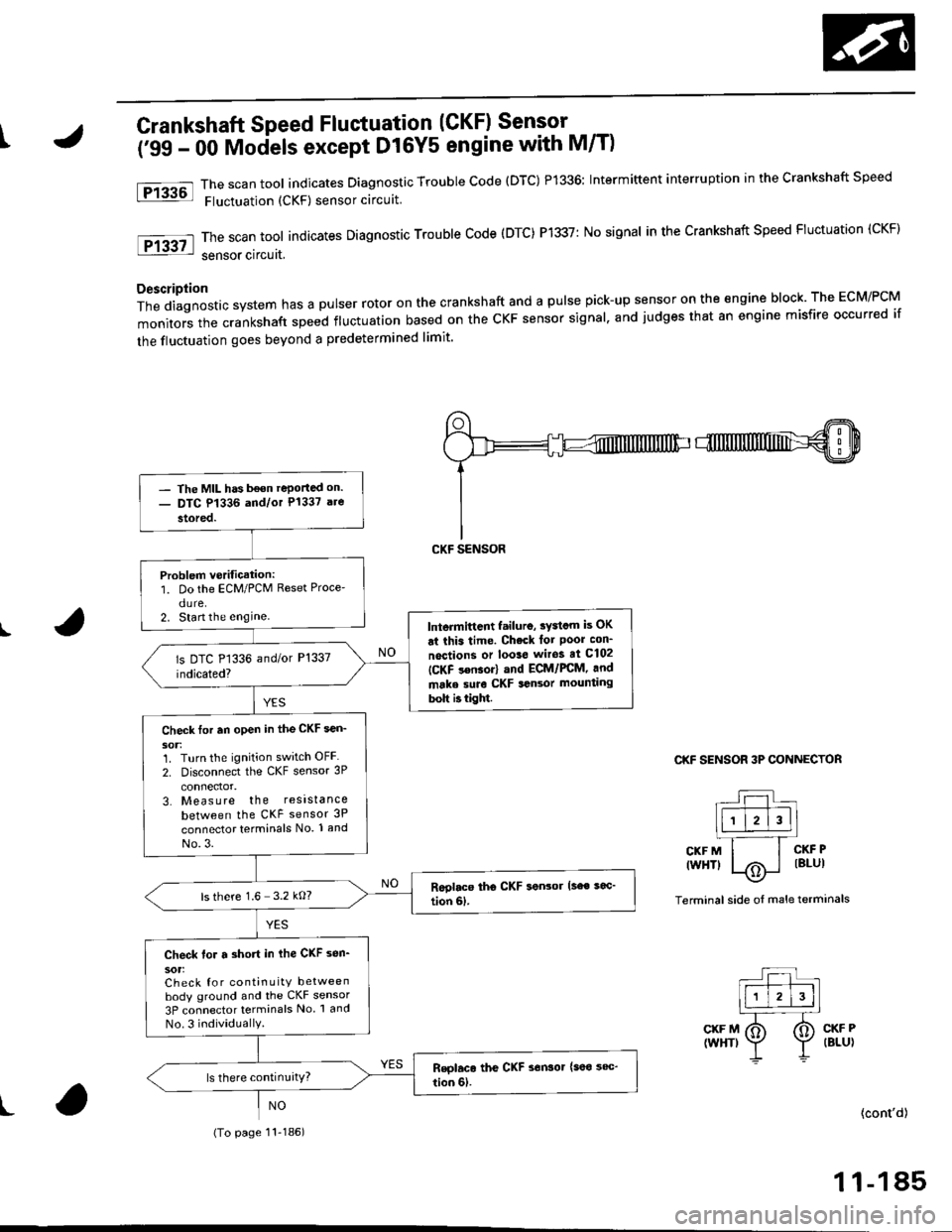

tCrankshaft Speed Fluctuation (CKF) Sensor -

('99 - 00 Mociels except D16Y5 engine with M/T)

The scan tool indicates Diagnostic Trouble code (DTC) P1336: Intermittent interruption in the crankshaft speed

Fluctuation (CKF) sensor circuit

The scan tool indicates Diagnostic Trouble Code (DTC) P1337: No signal in the Crankshaft Speed Fluctuation (CKF)

sensor circuat,

Description

Thediagnosticsystemhasapulserrotoronthecrankshaftandapu|sepick-upsensorontheengineb|ock.TheEcM/PcM

monitors the crankshaft speed fluctuation based on the cKF sensor signal. and judges that an engine misfire occurred if

the fluctuation goes beyond a predetermined limit'

I

Ftu6l

tF13g7l

CKF SENSOR 3P CONNECTOR

r--r t|-.r-r'--]llll l2l3ll.l---'.-T_

CKFM I I CKFP

twHTl |/Ai i lBlul--\9-

Terminal side oI male terminals

CKF M(WHT)CKF P(BLU)

t(cont'd)

1 1-185

- The MIL has b€on reportad on.- DTC P1336 and/or P1337 are

stored.

Problem verification:1. Do the ECM/PCM Reset Proce'

dure.2. Start the enginelntermittcnt failuro, sydcm is OK

ai this time. Check lot Poor con_

noctions or loo3e wiros at C102

ICKF s€nsor) and ECM/FCM, and

make suro CKF sansor mounting

bolt b tight.

Check tor an open in the CKF sen_

1. Turn the ignition switch OFF

2. Disconnect the CKF sensor 3P

3. Measure the resistance

between the CKF sensor 3P

connector terminals No. 1 and

No.3.

ls there 1.6 3.2 kO?

Check for a short in ihe CKF sen_

sot:Check for continuity betweenbody ground and the CKF sensor

3P connector terminals No 1 and

No.3 individuallY.

(To page 11-186)

Page 458 of 2189

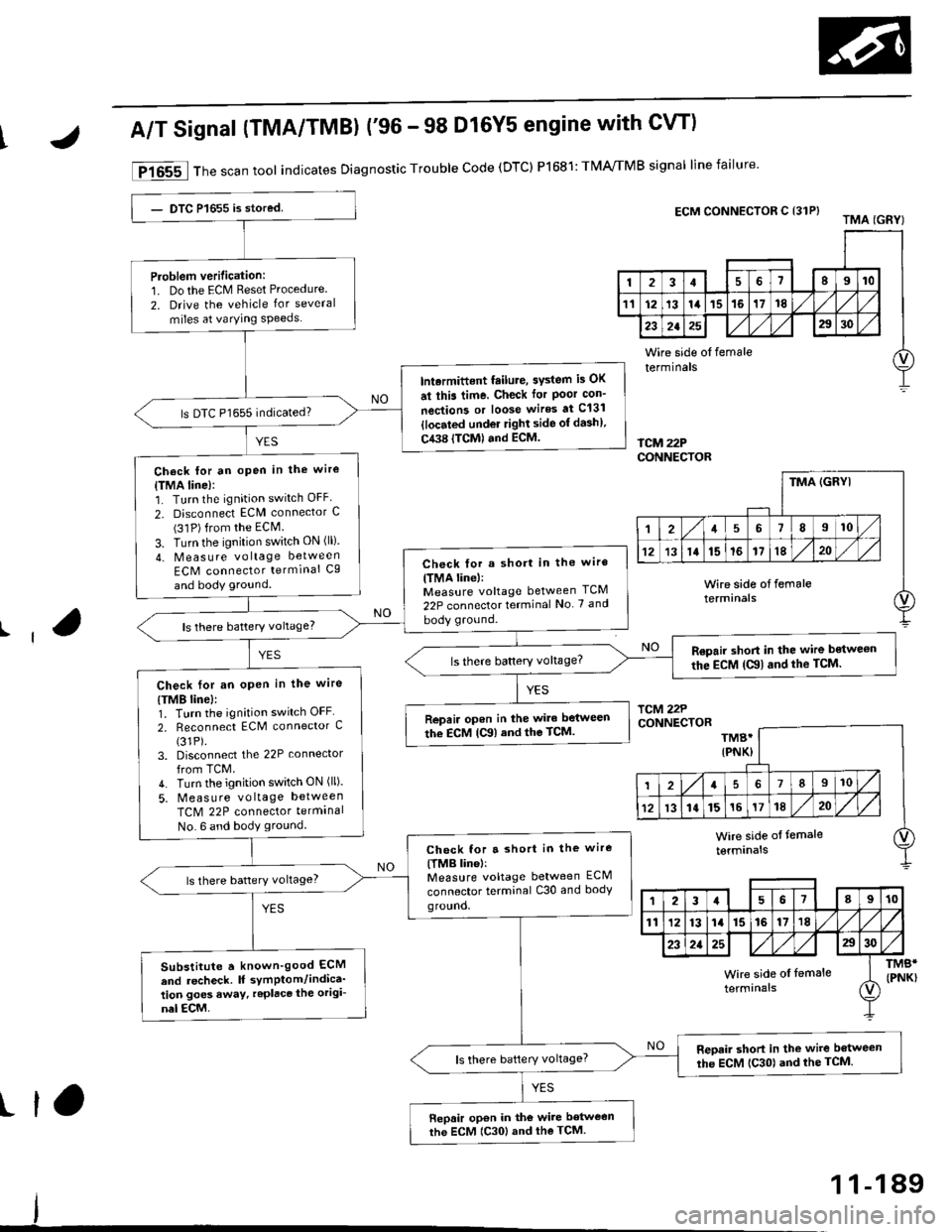

[F16551l Th" ""un toot indicates Diagnostic Trouble Code (DTC) P1681: TIVA,/TMB signal line failure

Problem verification:1. Do the ECM Reset Procedure.

2. Drive the vehicle Ior several

miles at varying speeds

lnt.rmittent failure, system is OK

at ihis time. Check tor Poor con-

nections or loos€ wires at C131

llocated under right side of dash),

C438 ITCM) and ECM.

ls DTC P1655 indicated?

Check lor an oPen in the wire(TMA line):1. Turn the ignition switch OFF

2. Disconnect ECM connector C(31P)from the ECM

3. Turn the ignition switch ON (ll).

4- Measure vo ltag e between

ECM connector terminal Cg

and body ground.

Check for a short in the wire

ITMA line,:Measure voltage between TCM

22P connector terminal No 7 and

body ground.ls there battery vohage?

Ropair shod in the wire bstwe€n

the EcM (C!l) and the TcM.ls there battery voltage?

Check for an open in the wire

{TMB line}:1. Turn the ignition switch OFF

2. Reconnect ECM connector c(31P).

3. Disconnect the 22P connector

from TCM.4. Turn the ignition switch ON (ll).

5. Measure vo ltage between

TCM 22P connector termlnal

No. 6 and body ground.

Repair open in the wire between

th€ EcM {Ca) and the TcM.

Check for a 3ho.t in the wire

{TMB lin6,:Measure voltage between ECM

connector terminal C30 and bodyground,

ls there battery voltage?

Substitute a known'good ECM

and recheck. It symPtom/indica'tion goes away, teplace the origi-

nal ECM.

Reoair short in the wile b6tween

the ECM {C30} and the TCM.ls there baftery voltage?

f,epair open in the wire between

the EcM (C30) and the TcM.

IJA/T Signal (TMA/TMBI ('96 - 98 Dl6Y5 engine with GW)

ECM CONNECTOR C 131P}TMA IGRYI

fcu22PCONNECTOR

ll

TMB*{PNK}

231678910

1t'12131415161718

232a252930

Wire side oI temale

terminals

tl,

1 1-189

Page 463 of 2189

ldle Control System

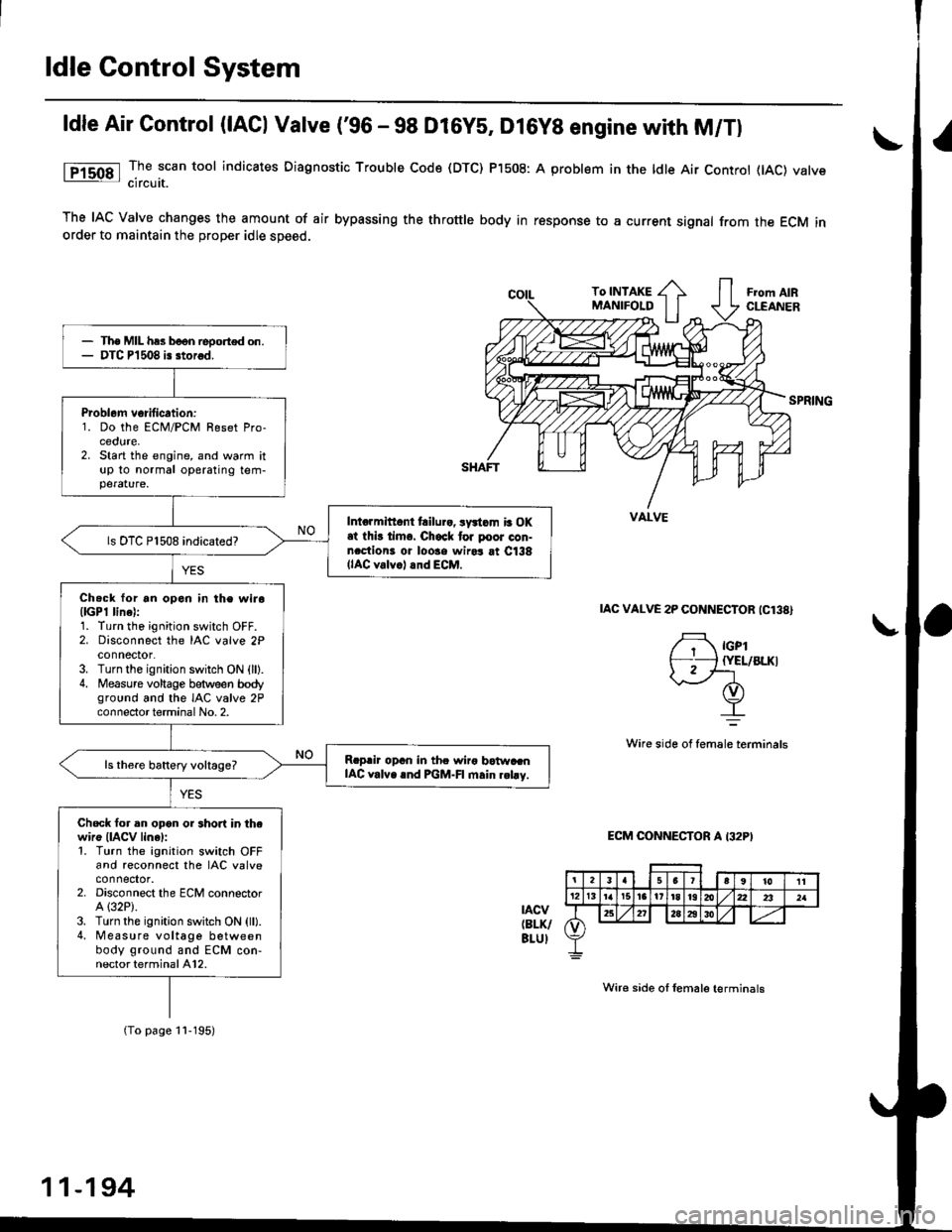

ldle Air Control (lACl Vatve ('96 - 98 Dl6ys, Dl6yB engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt flAC) varvecircuit.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM inorder to maintain the proper idle speed.

IAC VALVE 2P CONNECTOR ICl3A)

,flrcerh-:J iYEL/BLKI

!.__-,/ -lt(v)

-T-=

Wire side of female terminals

tAcv(BLK/

ELUI

ECM CONNECTOR A I32PI

Wire side oI lemal€ terminals

VALVE

6a10ll12t3r5t6l7t8t920232a

t*25&a2A3o

The MIL hss b€on repo.ted on.DTC P'l508 i. itorod.

Problem vorification:1. Do the ECM/PCM Reset Pro-cedure,Start the engine, and warm ituP to normal operating tem-perature.

Intormittont t!llur., sy.tcm b OKat thb tim6. Chsck fol poor con-ncctionr or loo3e wirot at C138(lAC valv.l.nd ECM.

ls DTC P1508 indicated?

Check for an opcn in the wiro(lGPl line):1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON (ll).

4. Measure vohage between bodyground and the IAC valve 2Pconnectorterminal No. 2.

R.prir opan in the wiro botwa.nIAC valv..nd PGM-FI main r.l.y.

Chock for an opon or sho in thewire (IACV linal:1. Turn the ignition switch OFFand reconnect the IAC valveconnector.2. Disconnect the ECM connectorA (32P).

3. Turn the ignit;on switch ON (ll).4. Measure voltage betweenbody ground and ECM con-nector terminal A12.

(To page 1l-195)

11-194

Page 465 of 2189

![HONDA CIVIC 1999 6.G Workshop Manual ldle Gontrol System

ldle Air Control (lAG) Valve (99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt HONDA CIVIC 1999 6.G Workshop Manual ldle Gontrol System

ldle Air Control (lAG) Valve (99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt](/img/13/6068/w960_6068-464.png)

ldle Gontrol System

ldle Air Control (lAG) Valve ('99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt AC) vatve- CtrCUtt.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM inorder to maintain the proper idle speed.

IAC VALVE 2P CONNECTOR IC138'

la rcprI - {YEL/8LKI 2t--d,

Y-=

Wire side ot female terminals

Wire side of lemale terminals

VALVE

The MIL has boon r€oorted on.DTC P1508 is srored.

Probl6m verification:1. Do the ECM/PCM Reset Pro-cedure.2. Start the engine, and warm itup to normal operating lem-perature.

Intermittent tailure, system is OKat this timg. Check to. poor con-noctions or loose wires at C138{lAC valvel and ECM.

ls DTC P1508 indicated?

Ch6ck for an open in the wir€{lGPl lino}:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the IAC valve 2Pconneclor termina I No.2,

Repair opon in the wire bgtwoenIAC valve and PGM-Fl main relay.

Check tof an open or short in thewire {IACV line}l1. Turn the ignition switch OFFand reconnect the IAC valve

2. Disconnect the ECM connectorB {25P).3. Turn the ignition switch ON (ll).

4. Measure voltage betweenbody ground and ECM conn€ctor terminal 823.

(To page 11-197)

1 1-1 96