HONDA CIVIC 1999 6.G Workshop Manual

Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1191 of 2189

t-

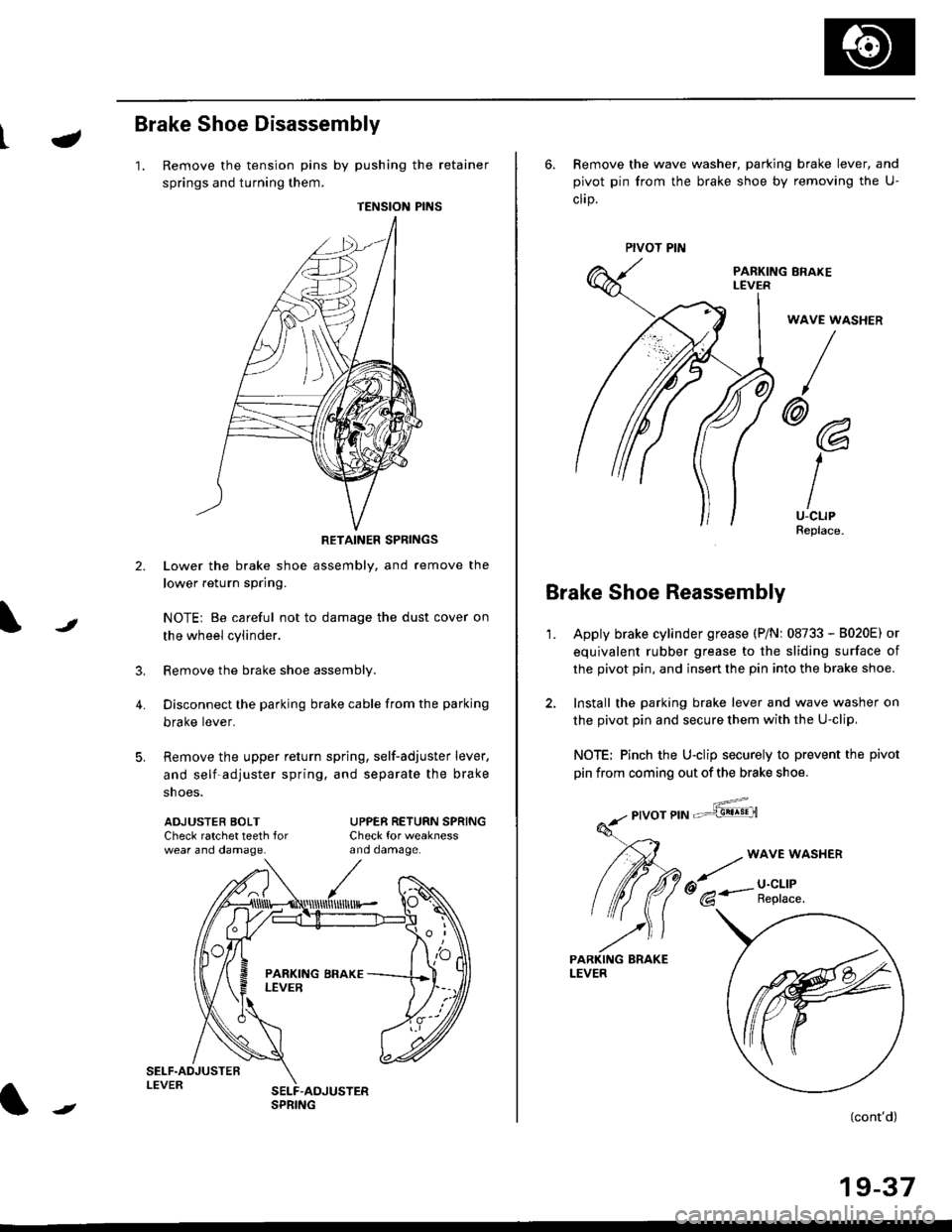

Brake Shoe Disassembly

1. Remove the tension pins by pushing the retainer

springs and turning them.

TENSION PINS

RETAINER SPRINGS

Lower the brake shoe assembly, and remove the

lower return spring.

NOTEi Be careful not to damage the dust cover on

the wheel cylinder.

Remove the brake shoe assembly.

Disconnect the parking brake cable from the parking

brake lever.

Remove the upper return spring, self-adjuster lever,

and self-adjuster spring, and separate the brake

snoe5.

t

3.

4.

ADJUSTEB BOLTCheck ratchet teeth forwear ano oamage.

UPPER RETURN SPRINGCheck for weaknessano oamage.

ll

,'/

N

r

//

t

6. Remove the wave washer, parking brake lever, and

pivot pin from the brake shoe by removing the U-

clrp.

PARKING ERAKEI-EVER

WAVE WASHER

/

@@

I

IU-CLIPReplace.

Brake Shoe Reassembly

1.Apply brake cylinder grease (P/Nr 08733 - B020E) or

equivalent rubber grease to the sliding surface of

the pivot pin, and insert the pin into the brake shoe.

Install the parking brake lever and wave washer on

the pivot pin and secure them with the U-clip,

NOTE: Pinch the U-clip securely to prevent the pivot

pin from coming out of the brake shoe.

,6;::"'

(cont'd)

19-37

LEVER

Page 1192 of 2189

Rear Drum Brake

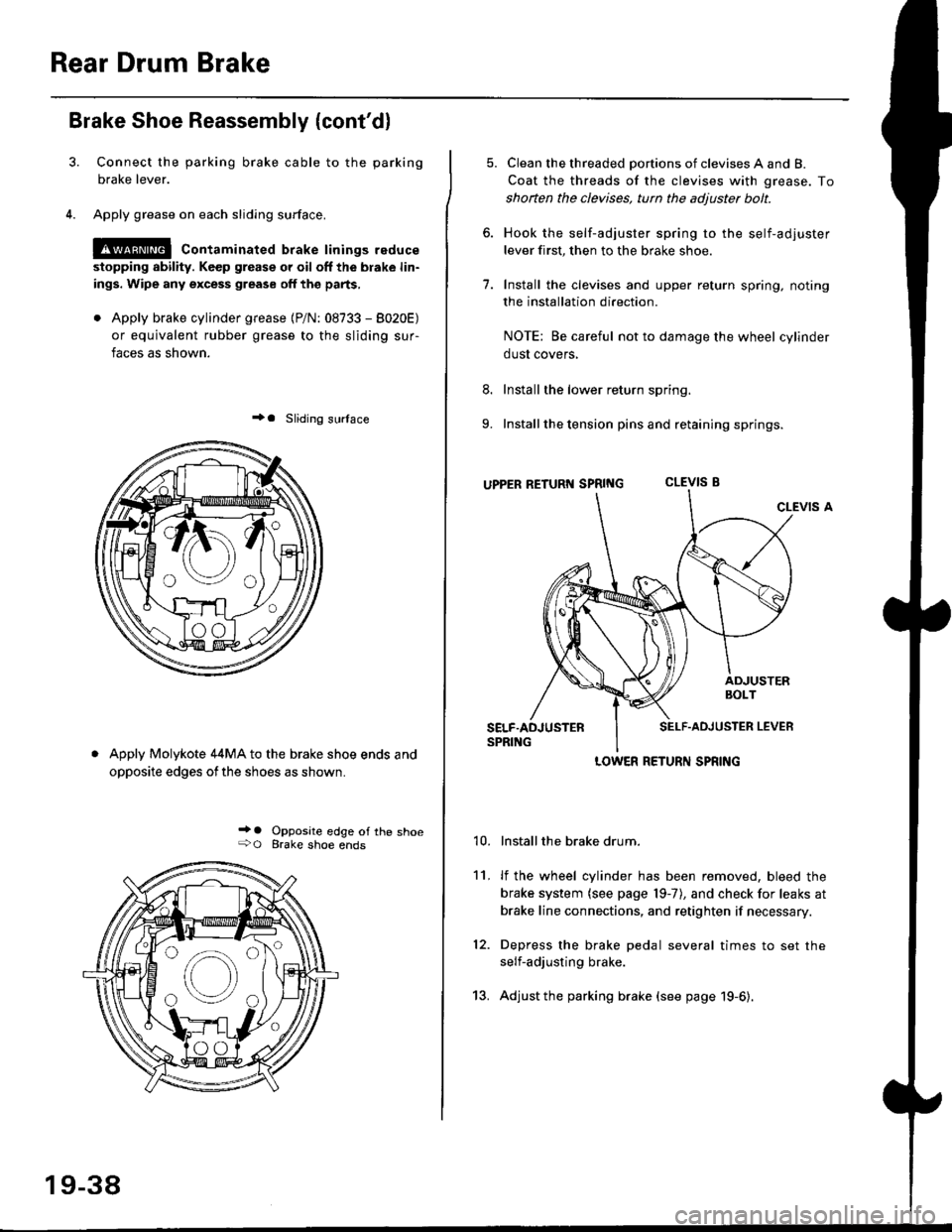

Brake Shoe Reassembly {cont'dl

Connect the parking brake cable to the parking

brake lever.

Apply grease on each sliding surface.

!@ contaminated brake linings reduce

stopping ability. Keep grease or oil off the blake lin-

ings. Wipe any excess grease off the parts,

. Apply brake cylinder grease {P/N: 08733 - 8020E)

or equivalent rubber grease to the sliding sur-

faces as shown.

+a Sliding surlace

Apply Molykote 44MA to the brake shoe ends and

opposite edges ofthe shoes as shown.

_' o Opposite edge of the shoe+O Brake shoe ends

19-38

13.

5. Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with grease. To

shoften the clevises, tun the adjuster bolt.

6. Hook the self-adjuster spring to the self-adjuster

lever first, then to the brake shoe

7. Install the clevises and upper return spring. noting

the installation direction.

NOTE: Be careful not to damage the wheel cylinder

dust covers,

8. Install the lower return spring.

9. Install the tension pins and retaining springs.

uppER RETURT{ SpRtNG CLEVIS B

CLEVIS A

Installthe brake drum.

lf the wheel cylinder has been removed, bleed the

brake system (see page 19-7), and check for leaks at

brake line connections, and retighten if necessary.

Depress the brake pedal several times to set the

self-adjusting brake.

Adjust the parking brake (see page 19-6).

't0.

11.

12.

LOWER RETURN SPRING

Page 1193 of 2189

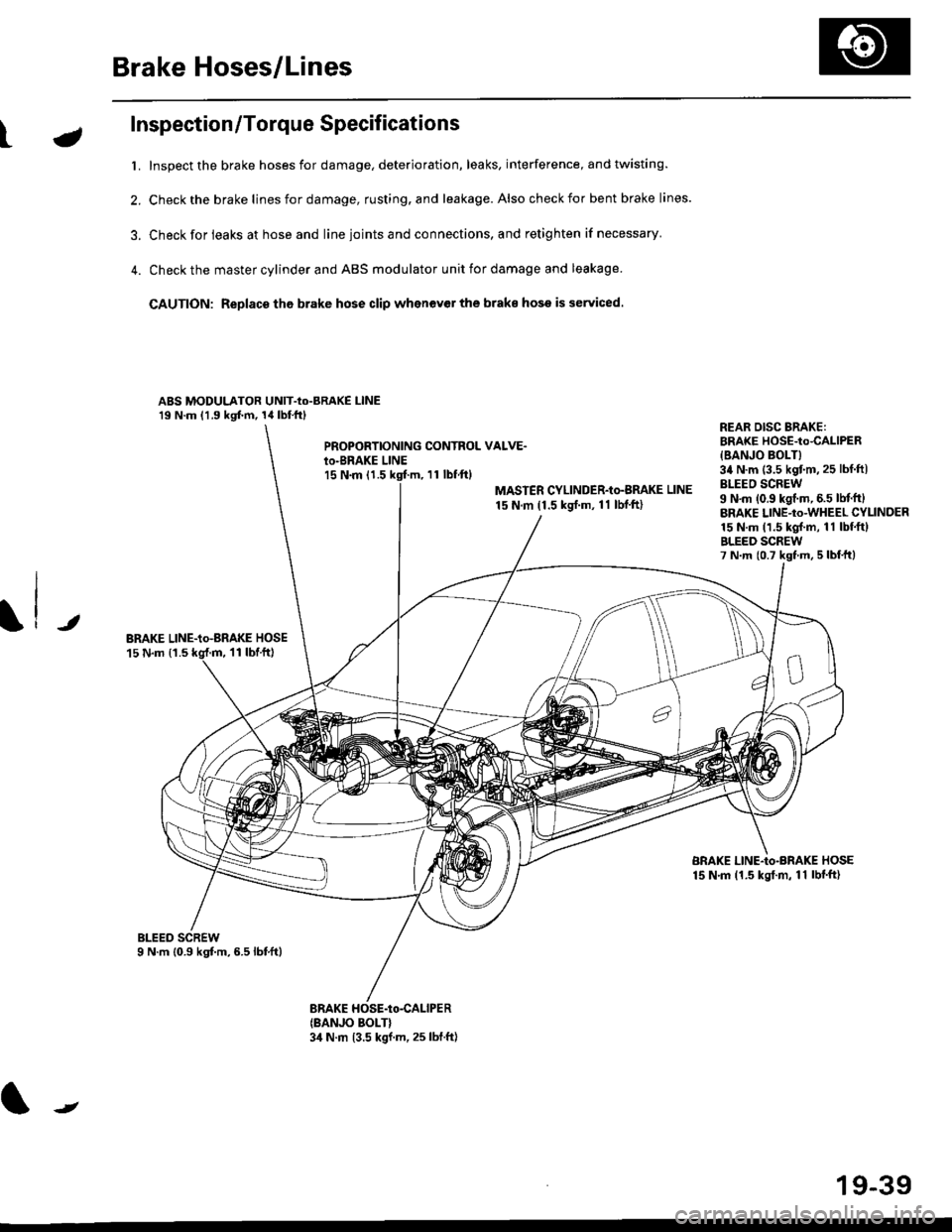

Brake Hoses/Lines

LJ

Inspection/Torque Specifications

t. Inspect the brake hoses for damage, deterioration, leaks, interference, and twisting.

2. Check the brake lines for damage, rusting. and leakage. Also check for bent brake lines.

3. Check for ieaks at hose and line ioints and connections, and retighten if necessary'

4. Check the master cylinder and ABS modulator unit for damage and leakage

CAUTION: Replace tho brake hose clip whenev€r the brake hose is serviced.

ABS MODULATOR UNIT-Io-BRAKE l-lNE19 N.m (1.9 kgf.m, 14lbl.ftl

PROPOBTIONING CONTROL VALVE.io-BRAKE LINEl5 N.m (1.511 tbf.ftl

MASTER CYLINDER-Io-BMKE LINE

15 N.m (1.5 ksrf.m, 11 lbf'ft)

REAR DISG BRAKE:BRAKE HOSE-to4ALlPER

{BANJO BOLT}34 N.m (3.5 kgtm,25 lbf ftlBLEEO SCREW9 N'm (0.9 kgf.m, 6.5 lM.ftlBRAKE LINE-to-WHEEL CYLINDER15 N.m (1.5 kgl.m, 11 lbf.ftlBLEED SCREW7 N.m {0.7 kst m, 5 lbf,ttl

JBRAKE LINE-io-aRAKE HOSE15 N.m {1.511 tbtft)

BRAKE LINE-Io-BRAKE HOSE15 N.m (1.5 kgt.m, 11 lbf'ft)

(BANJO BOLT}3,1 N.m 13.5 kgf.m, 25 lbf.ft)

J

19-39

Page 1194 of 2189

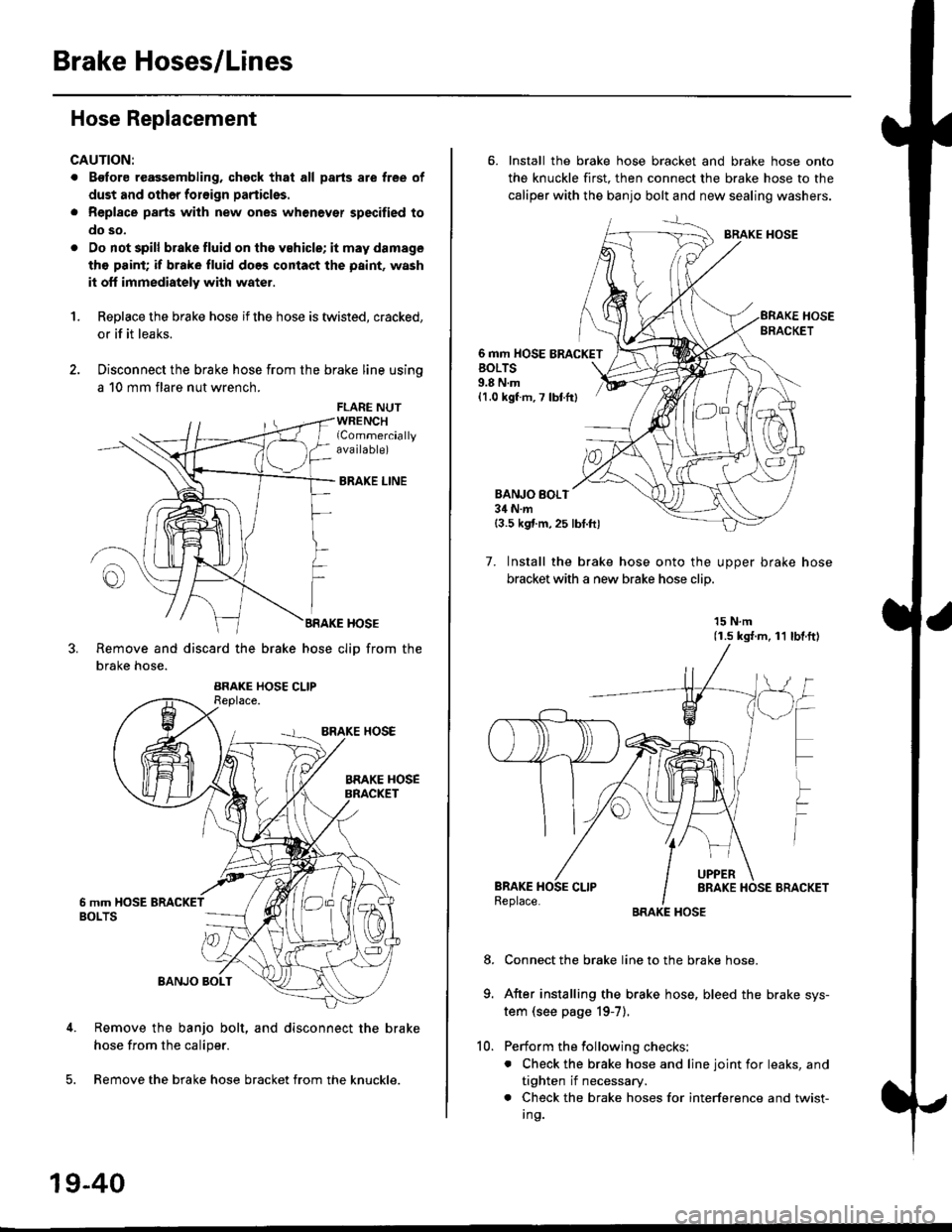

Brake Hoses/Lines

Hose Replacement

CAUTION:

. Bgfore reagsembling, chgck that all parts are free of

dust and othor foroign particles.

. Repl8ce parts with new ones whenever specified to

do so,

. Do not spill brake fluid on th6 vehicle; it may damage

tho paint; if brake fluid does contact the paint, wash

it off immediately with water.

1.Replace the brake hose if the hose is twisted, cracked,

or if it leaks.

Disconnect the brake hose from the brake line using

a 10 mm flare nut wrench.

FLARE NUTWRENCHlCommerciallyava ilable)

BRAKE LINE

BRAKE HOSE

Remove and discard the brake hose cliD from the

brake hose.

Remove the banjo bolt, and disconnect the brake

hose from the caliper.

Remove the brake hose bracket from the knuckle.

19-40

10.

6. Install the brake hose bracket and brake hose onto

the knuckle first. then connect the brake hose to the

caliper with the banjo bolt and new sealing washers.

BRAKE HOSE

6 mm HOSE BRACKETBOLTS9.8 N.m{1.0 kgf m, 7 lbtfr}

BANJO BOI.T34 N.m{3.5 kgf.m,25 lbt.ftl

7. Install the brake hose onto the uooer brake hose

bracket with a new brake hose clip

15 N.m(1.s ks{.m, 11 lbl.ftl

Connect the brake line to the brake hose.

After installing the brake hose, bleed the brake sys-

tem (see page 19-7).

Perform the following checks:

. Check the brake hose and line joint for leaks, and

tighten if necessary.

. Check the brake hoses for interference and twist-

I ng.

8.

Page 1195 of 2189

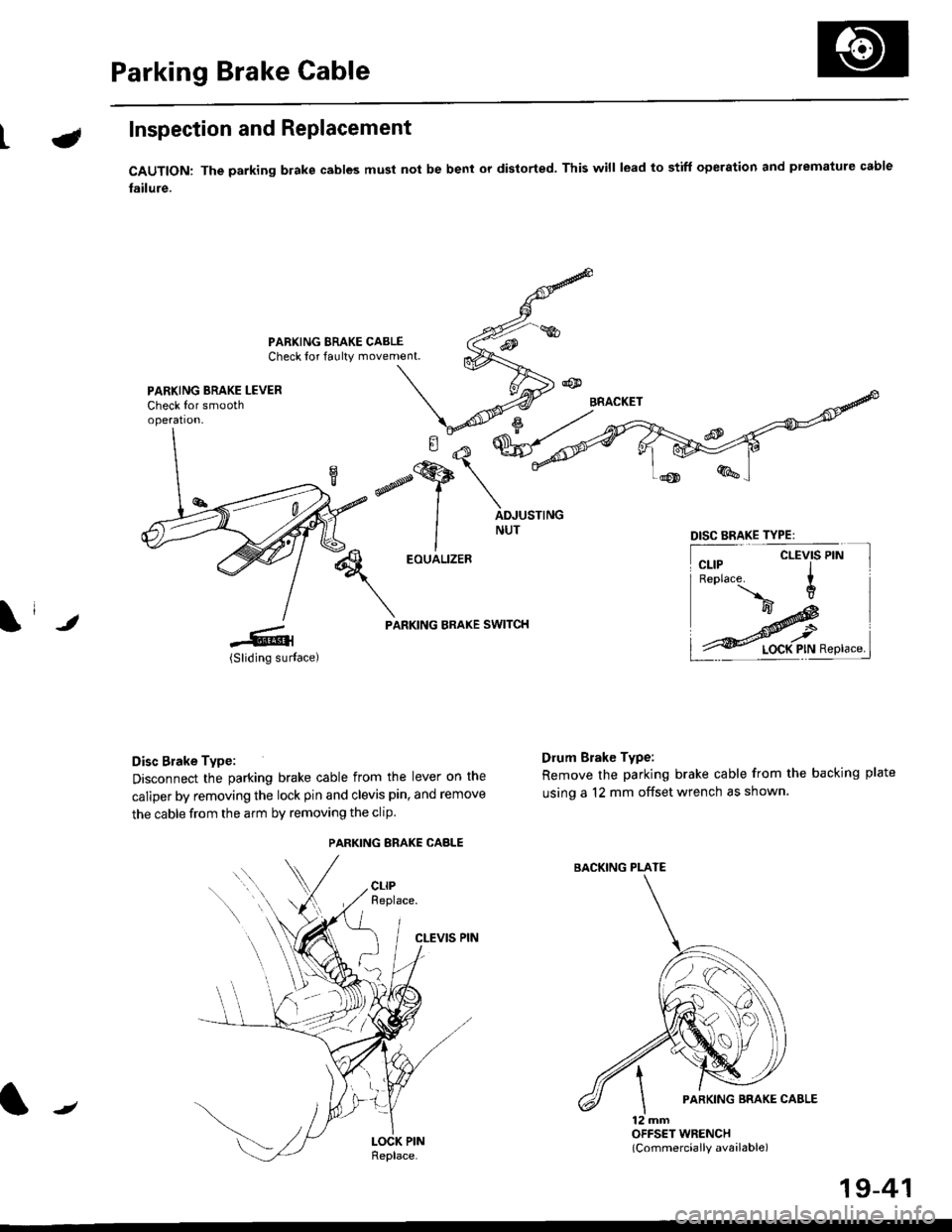

Parking Brake Cable

LInspection and Replacement

CAUTION: The parking blake cables must not be bent or distorted. This will lead to stiff operation and premature cable

failure.

PARKING BRAKE CABLECheck for faulty movement.

PARKING BRAKE LEVERCheck for smoothoperation.

\i ,

EOUALIZER

PARKING BRAKE SWITCH

Disc Brake Type:

Disconnect the parking brake cable from the lever on the

caliper by removing the lock pin and clevis pin, and remove

the cable from the arm by removing the clip

CLEVIS PIN

Drum Brake Type:

Remove the parking brake cable from the backing plate

using a 12 mm offset wrench as shown.

12 mmOFFSET WRENCH(Commercially available)

DISC BRAKE TYPE:

CLEVIS PIN

PARKING ERAKE CABLE

{tt

BACKING PLATE

/

19-41

Page 1196 of 2189

L-

t

Anti-lock Brake System (ABSI

Special Tools ............. 19-44

Component Locations ......................... 19-45

Anti-lock Brake System (ABS)

Features/Construction ..................., 19-46

Operation ............... 19-47

Circuit Diagram ......... 19-50

ABS Control Unit Terminal

Arrangement ......... 19-52

Troubleshooting Precautions ............. 19-54

Diagnostic Trouble Code (DTCI

Diagnostic Trouble Gode (DTCI

Indication ........... 19-56

DTC Erasure ........... 19-57

Symptom-to System Chart ............. 19-58

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-60

ABS Indicator Light Does Not

Go Off ............................................ 19-62

Wheel Sensor ........ 19-64

Solenoid ................. 19-60

ABS Pump Motor ............................. 19-68

Main Relay ............. 19-71

lgnition Voltage .... 19-73

Central Processing Unit {CPU} ........ 19-74

Modulator Unit

Removal/lnstallation ....................... 19-75

ABS Control Unit

Replacement ......... 19-76

Pulsers/Wheel Sensors

Inspection .............. 19-76

Wheel Sensor Replacement ............ 19-77

t/

Page 1197 of 2189

Special Tools

Ret. No. I Tool Number I Description I O,V I page Reference

(!) I 07PM- 0010100 I SCS Service Connector t I 19_s6

19-44

Page 1198 of 2189

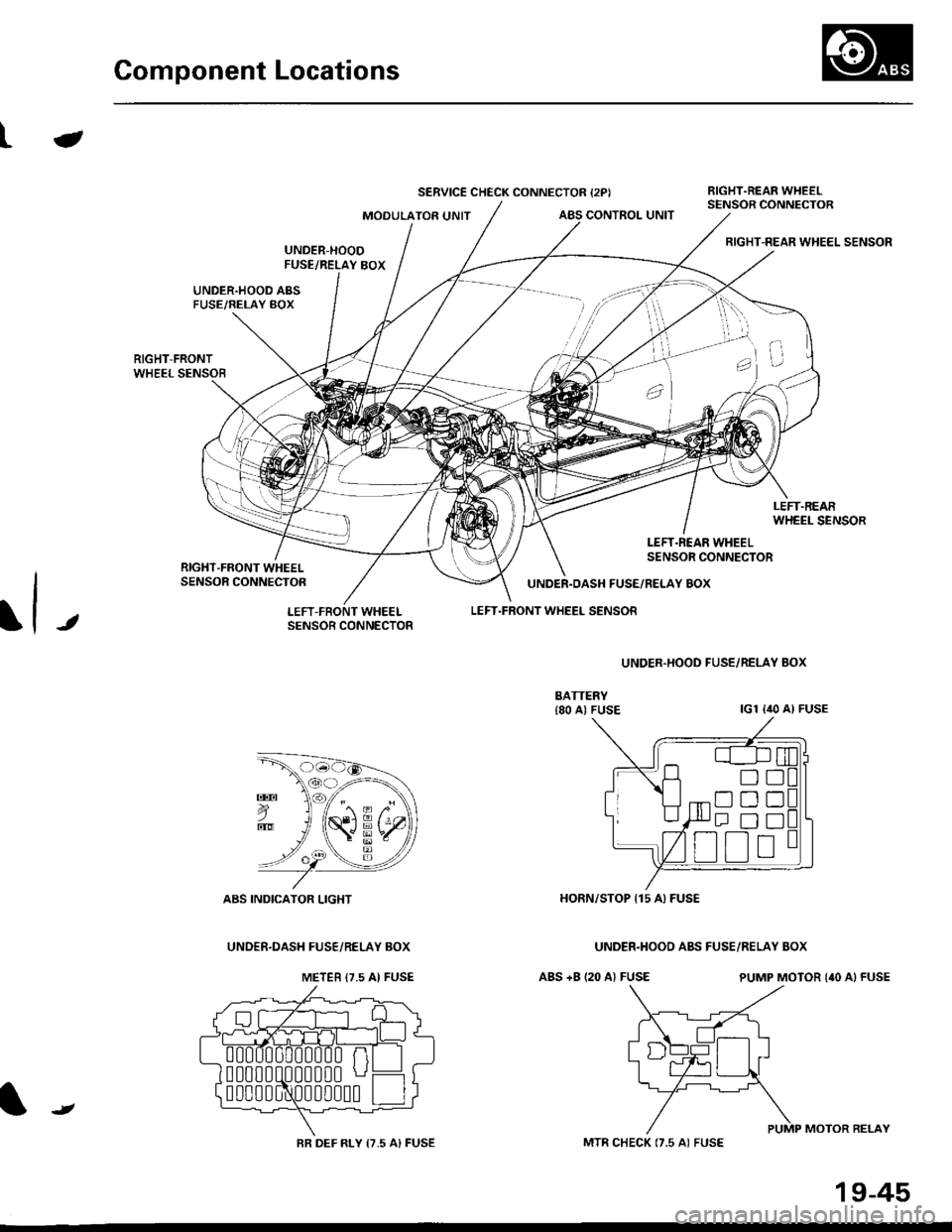

Component Locations

ta

SERVICE CHECK CONNECTOR {2PIBIGHT.REAR WHEELSENSOR CONNECTORMOOULATOR UNITABS CONTROL UNIT

RIGHT-REAR WHEEL SENSOR

LEFT.R€AR WHEELSENSOR CONNECTOR

J

UNDER.DASH FUSE/RELAY 8OX

LEFT.FRONT WHEEL SENSOR

ABS +B (20 A) FUSE

UNDER.HOOD FUSE/RELAY BOX

lcl lilo Al FUSE

ABS INDICATOR LIGHT

UNOEF.DASI{ FUSE/RELAY BOX

HORN/STOP I15 A) FUSE

UNDER.HOOO ABS FUSE/RELAY BOX

PUMP MOTOR {'O A} FUSE

PUMP MOTOR BELAY

E

o

METEB I7.5 AI FUSE

0

0

0

00000 n

00000 u

BR DEF RLY 17,5 A) FUSE

t

MTR CHECK (7.5 AI FUSE

19-45

Page 1199 of 2189

Anti-lock Brake System (ABSI

Featu res/Construction

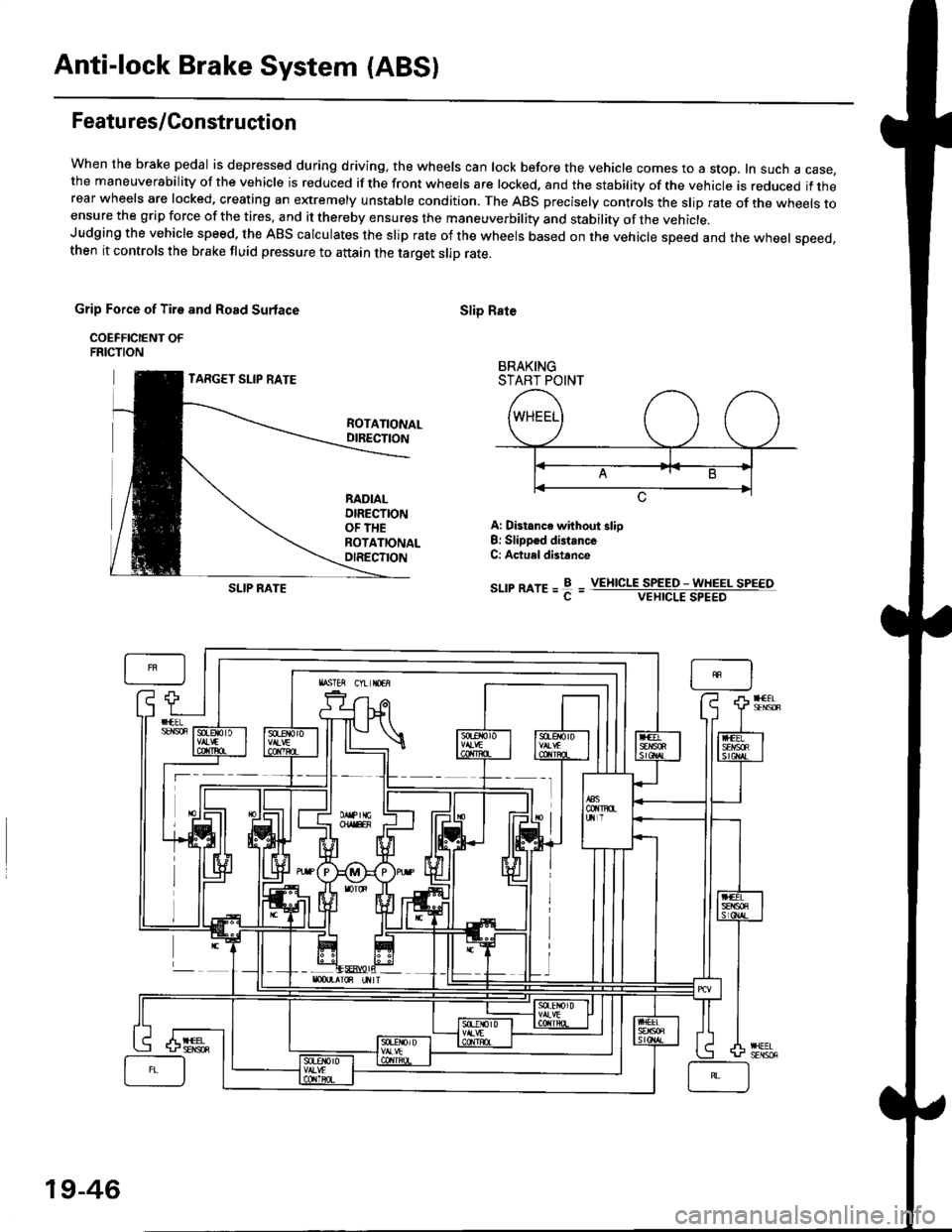

When the brake pedal is depressed during driving, the wheels can lock before the vehicle comes to a stop, In such a case,the maneuverability of the vehicle is reduced if the front wheels are locked, and the stability of the vehicle is reduced if therear wheels are locked, creating an extremely unstable condition. The ABS precisely controls the slip rate of the wheels toensure the grip force of the tires. and it thereby ensures the maneuverbility and stability of the vehicle.Judging the vehicle speed. the ABS calculates the slip rate of the wheels based on the vehicle speed and the wheel speed,then it controls the brake fluid pressure to attain the target slip rate.

Grip Force of Tire and Road Surlace

COEFFICIENT OFFRICTION

TARGET SLIP RATE

Slip Rate

BRAKINGSTART POINT

ROTATIONALDIRECTION

RADIALDIRECTIONOF THEROTATIONALOIRECTION

A: Distance without slio8: Slippsd distanceC: Actuel distance

sr-rrmre=f=SLIP RATEVEIIICLE SPEED - WHEEL SPEEOVEHICLE SPEED

19-46

Page 1200 of 2189

t-Operation

t

ABS Control Unit

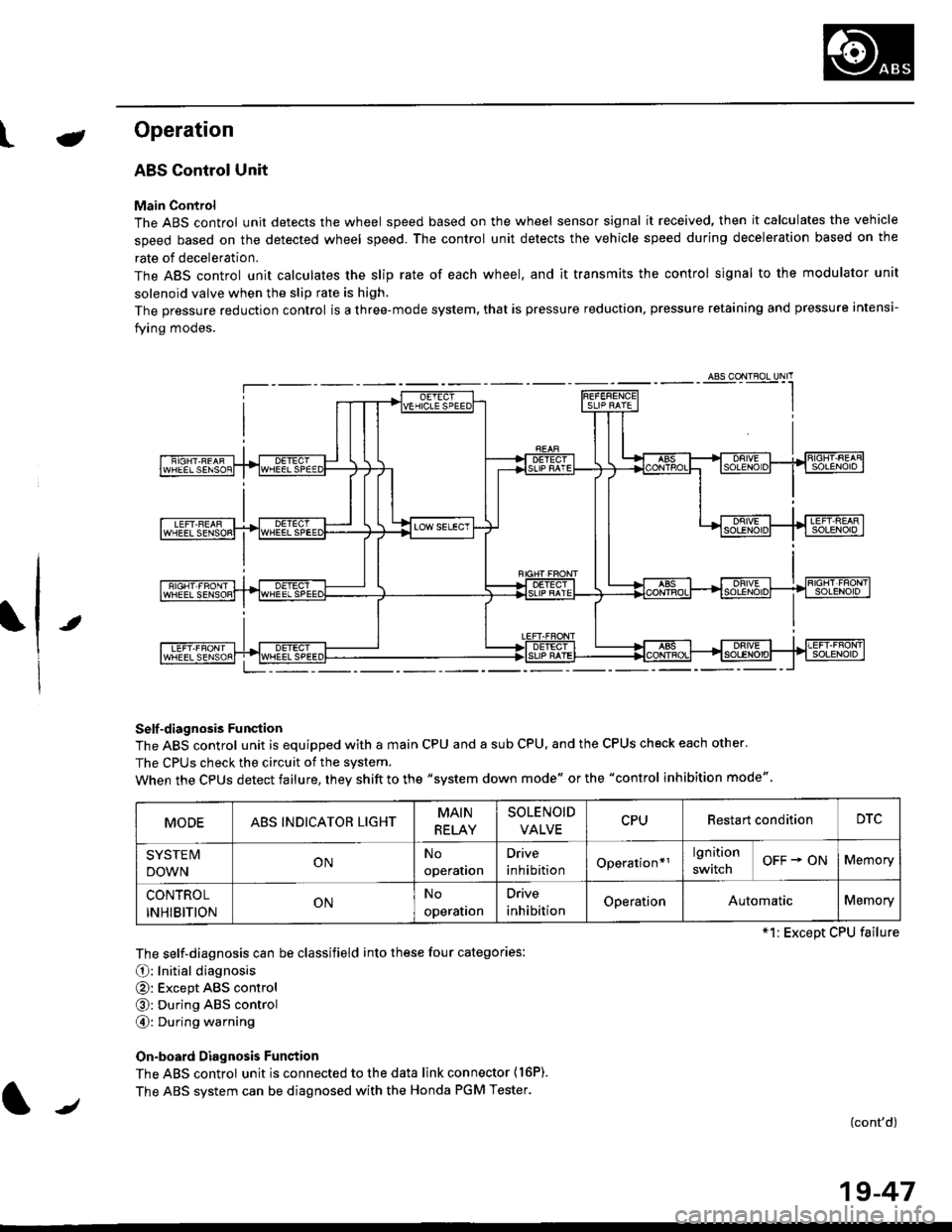

Main Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehicle

speed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on the

rate of deceleration.

The ABS control unit calculates the slip rate of each wheel. and it transmits the control signal to the modulator unit

solenoid valve when the slip rate is high.

The pressure reduction control is a three-mode system, that is pressure reduction, pressure retaining and pressure intensi-

fying modes.

Self -diagnosis Funqtion

The ABS control unit is equipped with a main CPU and a sub CPU, and the CPUS check each other'

The CPUs check the circuit of the svstem.

When the CPUS detect failure, they shift to the "system down mode" or the "control inhibition mode"

The self-diagnosis can be classifield into these four categories:

O: Initial diagnosis

@: Except ABS control

@: During ABS control

@: During warning

On-board Diagnosis Funstion

The ABS control unit is connected to the data link connector {16P).

The ABS system can be diagnosed with the Honda PGM Tester.

(cont'd)

MODEABS INDICATOR LIGHTMAIN

RELAY

SOLENOID

VALVECPURestart conditionDTC

SYSTE IV

DOWNONNo

operation

Drive

inhibitionOperation*rlgnition

switchOFF + ONMemory

CONTROL

INHIBITIONONNo

operalron

Drive

inhibitionOperationAutomaticMemory

*1: Except CPU failure

/

19-47