TFO HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 443 of 2189

PGM-FI System

l-Fos3sl

tFos36l

tF1361 l

Fr362-1

tF13sil

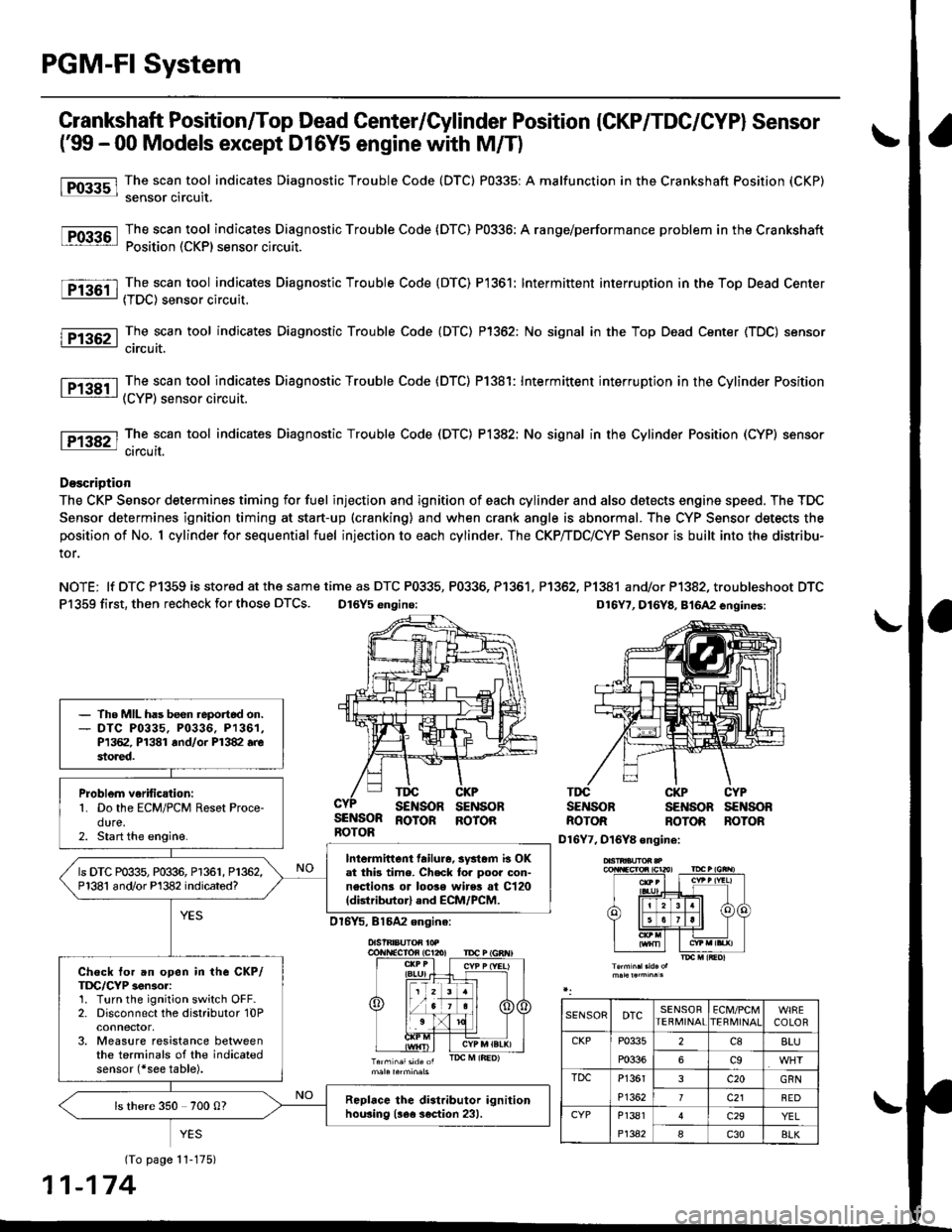

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

f99 - 00 Models except D16Y5 engine with M/T)

The scan tool indicates Diagnostic Trouble Code (DTC) P0335: A malfunction in the Crankshaft Position (CKP)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the Crankshaft

Position (CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1361: Intermittent interruption in the Top Dead Center

{TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1362: No signal in the Top Dead Center (TDC) sensor

circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position(CYP) sensor circuit.

lTiaSt The scan tool indicates Diagnostic Trouble Code (DTC) P1382; No signal in the Cylinder Position (CYP) sensor: circuil.

DoscriDtion

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDC

Sensor determines ignition timing at start-up (cranking) and when crank angle is abnormal. The CYP Sensor detects the

position of No. 1 cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-

tor.

NOTE; lf DTC P1359 is stored at the same time as DTC P0335, P0336, P1361. P1362, P1381 and/or P1382, troubleshoot DTC

P1359 first, then recheck for those DTCS. D16Y5 engino:

SENSORROTOR

TDGSENSORCKPSENSOBTDCSENSOBCKPSENSOBCYPs€NsonBOTORROTORBOTONROTOR ROTOR

D16Y7, D16Y8 ongine:

(To page 11-175)

1-174

- The MIL has been reportod on.- DTC P0335, P0336. P1361,P1362, P1381 rnd/or P1382.restored.

Problem verific{tion:1. Do the ECM/PCM Reset Proce-dure.2. Start the engine.

Intormittcnt failure, systom b OKat thb time. Check to. poor con-nections or loose wires at C120(dktributorl and ECM/PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or Pl382 indicated?

Check tor an open in the CKP/TDC/CYP 3enior:1. Turn the ignition switch OFF.2. Disconnect the distributor 10Pconnector,3. Measure resistance betweenthe terminals of the indicatedsensor (*see table).

Replrce the distributor ignitionhou3ing (!ee section 231.ls there 350 700 0?

SENSORDTCSENSORTEBMINAIECM/PCMTERI\,4INAICOLOR

CKPP0335

P0336

2c88LU

6c9

TDCP1361

P1362

3c20GRN

7c21BED

CYPP1381

P1342

c29YEL

Ic30BLK

Page 690 of 2189

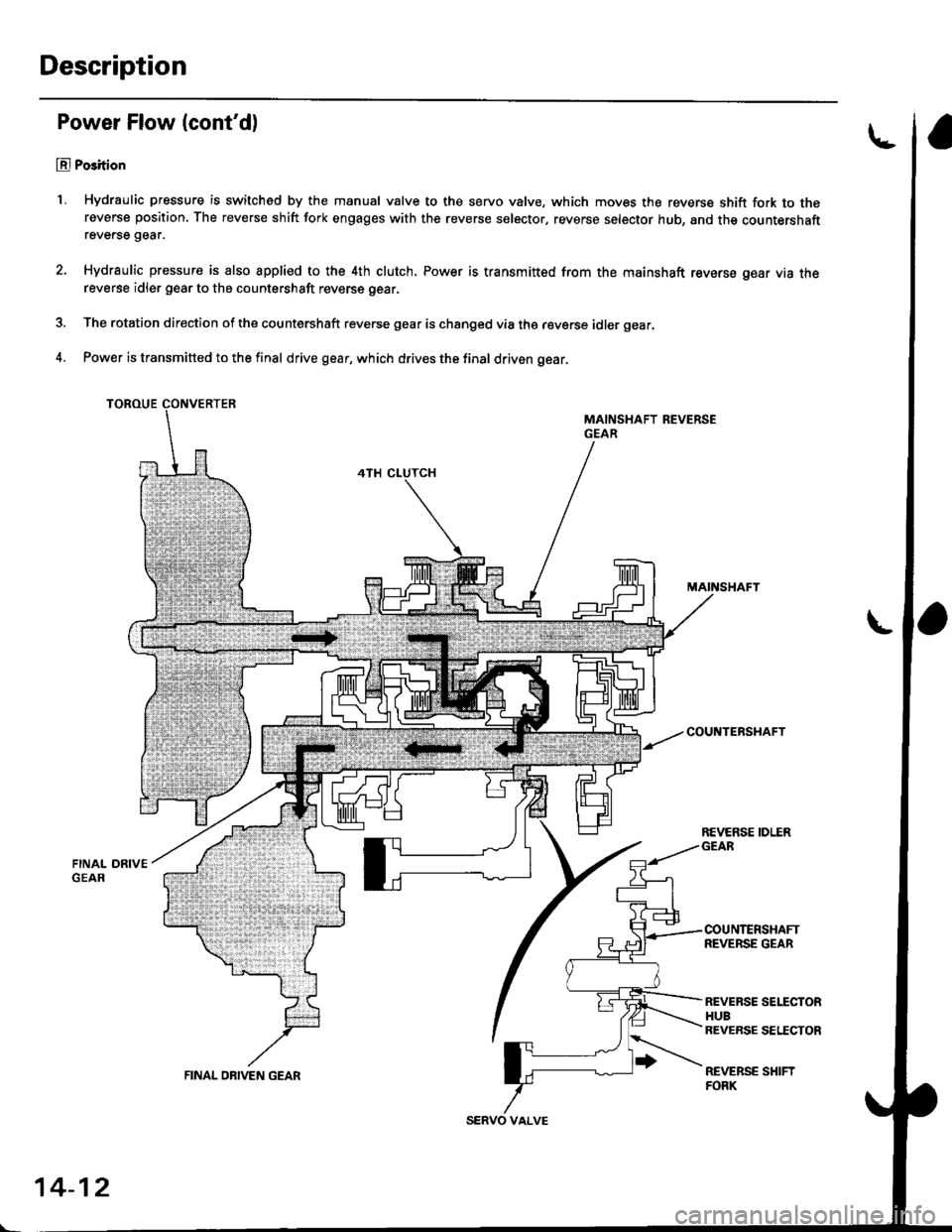

Description

Power Flow (cont'd)

El Po3ition

1, Hydraulic pressure is switched by the manual valve to the servo valve, which moves the reverse shift fork to thereverse position. The reverse shift fork engages with the reverse selector, reverse selector hub, and the countershaftreverse gear.

Hydraulic pressure is also applied to the 4th clutch. Power is transmitt€d from the mainshaft reverse gear via thereverse idler gear to the countershaft reverse gear.

The rotation direction of the countershaft reverse gear is changed via the reverse idler gear,

Power is transmitted to the final drive gear, which drives the final driven gear.

TOROUE

MAINSHAFT

COU TERSHAFT

REVERSE SELECTORHUBREVERSE SETICTOR

REVERSE SHIFTFORK

REVERSE IDLER

14-12

FINAL ON|VEN GEAR

Page 695 of 2189

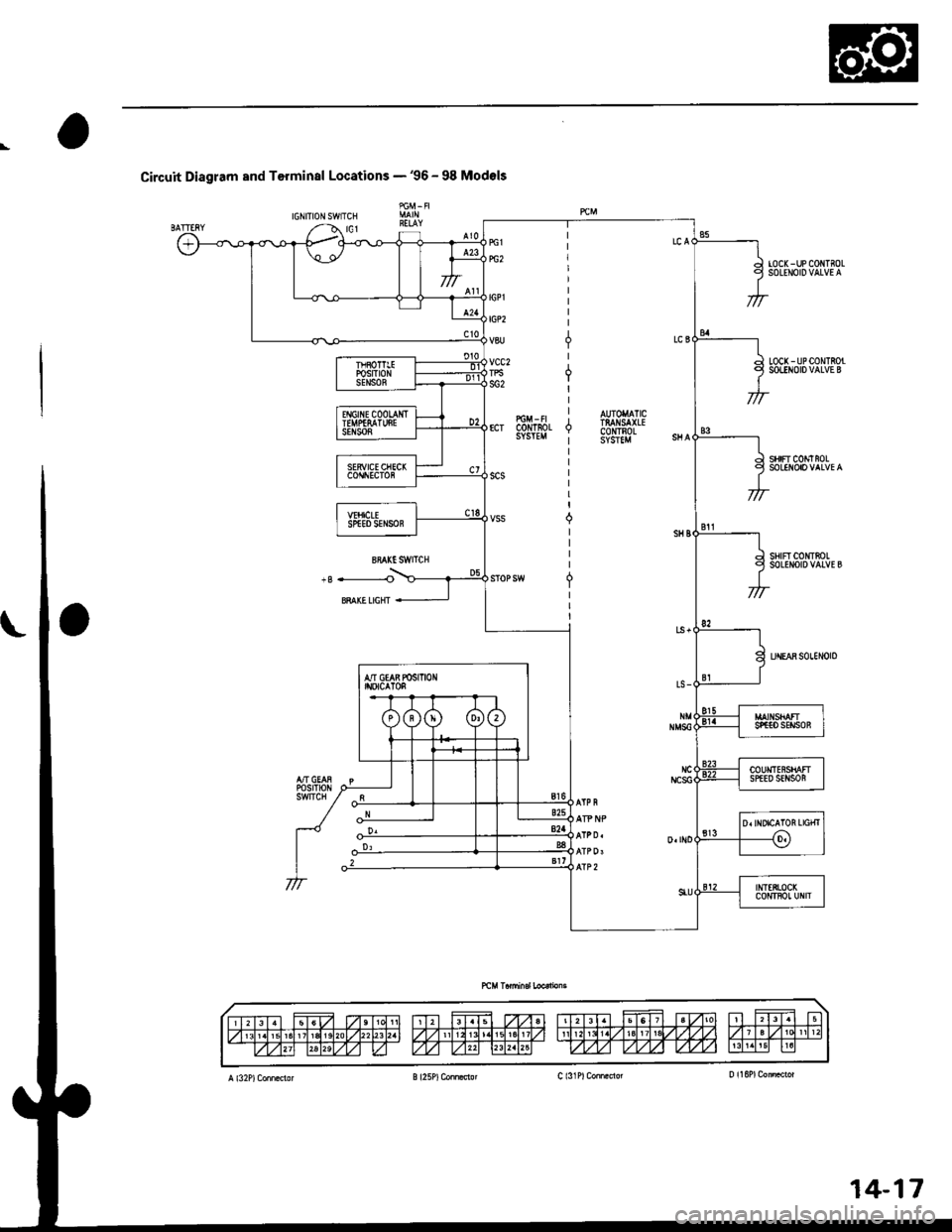

Circuit Diagram and Terminal Locations -'96 - 98 Modols

IGNITIONSWiTCHtc1

IOCI( - UP CONTBOLSOTENOID VALVE A

LOCK-UPCONTSOTsoLtNoto valvE I

SIIIFT CONTFOL

sHrFrc0mioLSOLENOIDVATVE B

UI{EAR SOLENOIO

IGPl

IGP2

vcc2TPSsG2

14-17

Page 696 of 2189

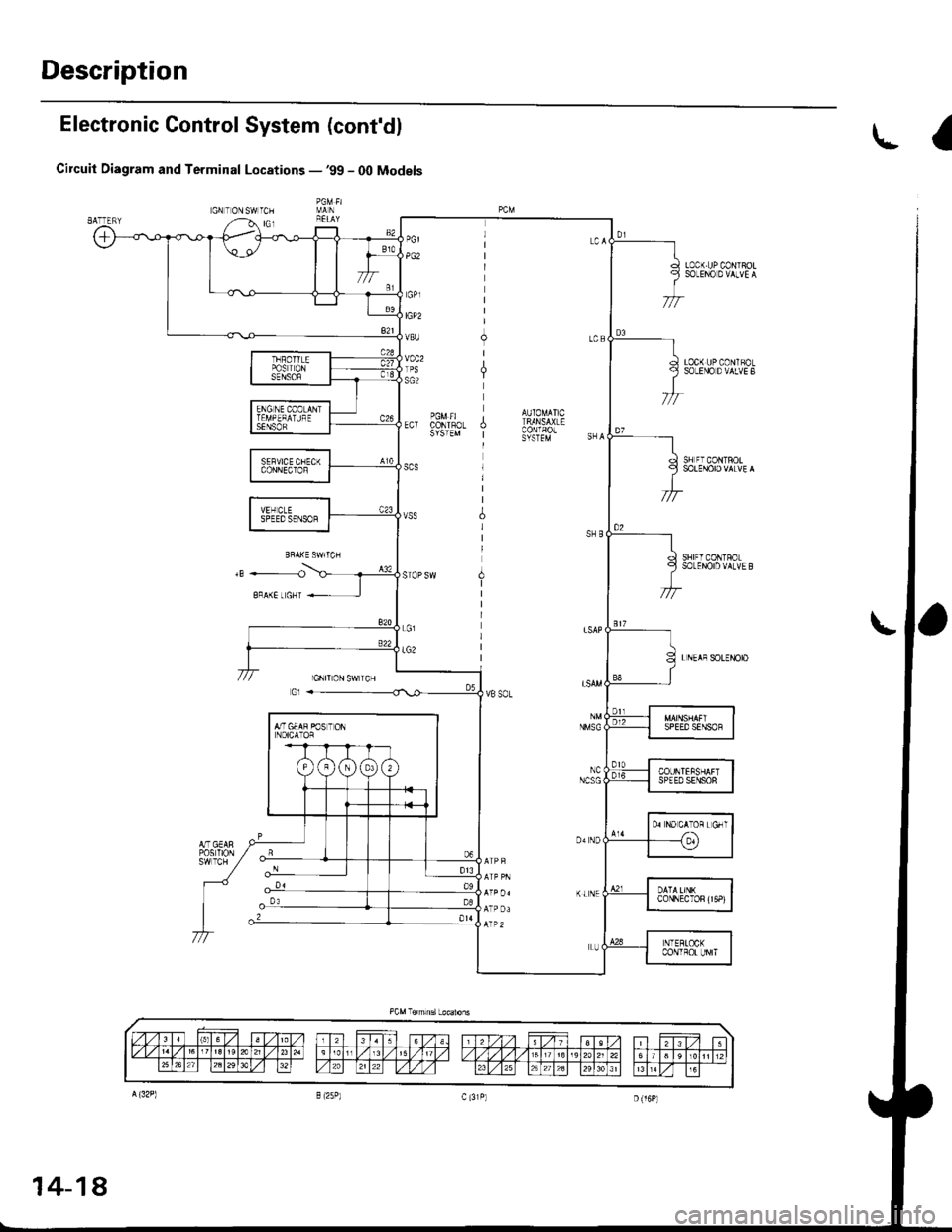

Description

Electronic Control System (cont'dl

Circuit Diagram and Terminal Locations -'99 - O0 Models

GNTONSWICH,,--b. rcj

LI

LOCK.UPCONIFOLSOLEI\Q D VALVE A

LOCK UP CON'IROLSOLENODVALVEB

SH FI CONTROL

SHIFTCONTFOLSOLENOIDVALVEE

L NEAF SOLEIOIO

PG2

IGP2

v3u

vcc2

sc2

6NII ON SWICH

14-18

Page 701 of 2189

\

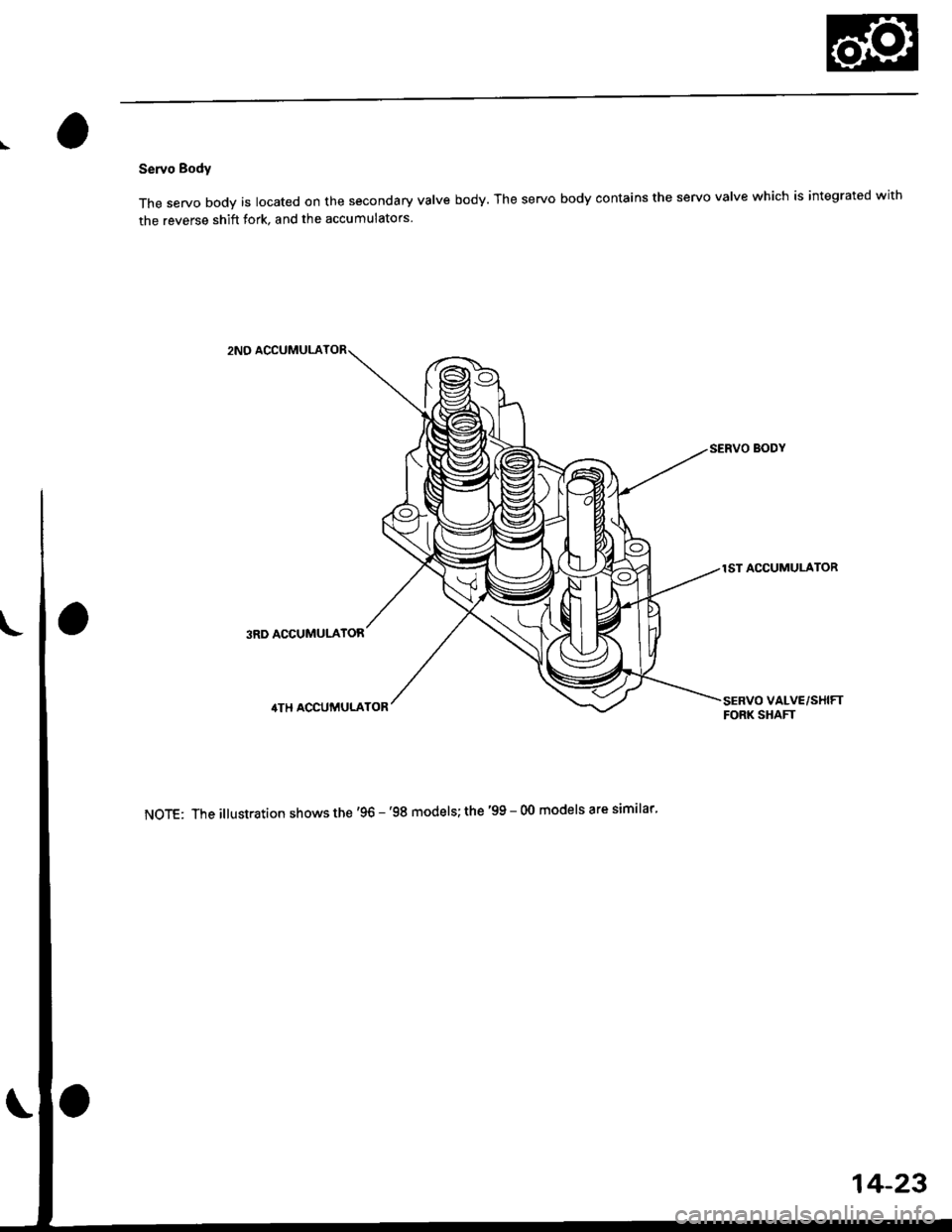

Servo Body

The servo body is located on the secondary valve body. The servo body contains the servo valve which is integrated with

the reverse shift fork, and the accumulators

2NO ACCUMULA

SERVO BODY

1ST ACCUMULATOR

3RD ACCUMULATOR

SERVO VALVE/SHIFTFORK SHAFT

NoTE: The illustration shows the'96 - '98 models; the '99 - 00 models are similar'

14-23

Page 722 of 2189

![HONDA CIVIC 1999 6.G User Guide PCM Gircuit Diagram (A/T Gontrol System:99 - 00 Models)

UNOEF DASIFL]SE/FELAY BOX

ta T06 T Dr.

INT€RLOCKCCNTFOLuN|l

ert*rll

I STARTEF

r-->lIl__ sL!

I

UISEF,DASHFISSIEL YmXr,Jo 25 (7 5A) GAUGE ISSEM HONDA CIVIC 1999 6.G User Guide PCM Gircuit Diagram (A/T Gontrol System:99 - 00 Models)

UNOEF DASIFL]SE/FELAY BOX

ta T06 T Dr.

INT€RLOCKCCNTFOLuN|l

ert*rll

I STARTEF

r-->lIl__ sL!

I

UISEF,DASHFISSIEL YmXr,Jo 25 (7 5A) GAUGE ISSEM](/img/13/6068/w960_6068-721.png)

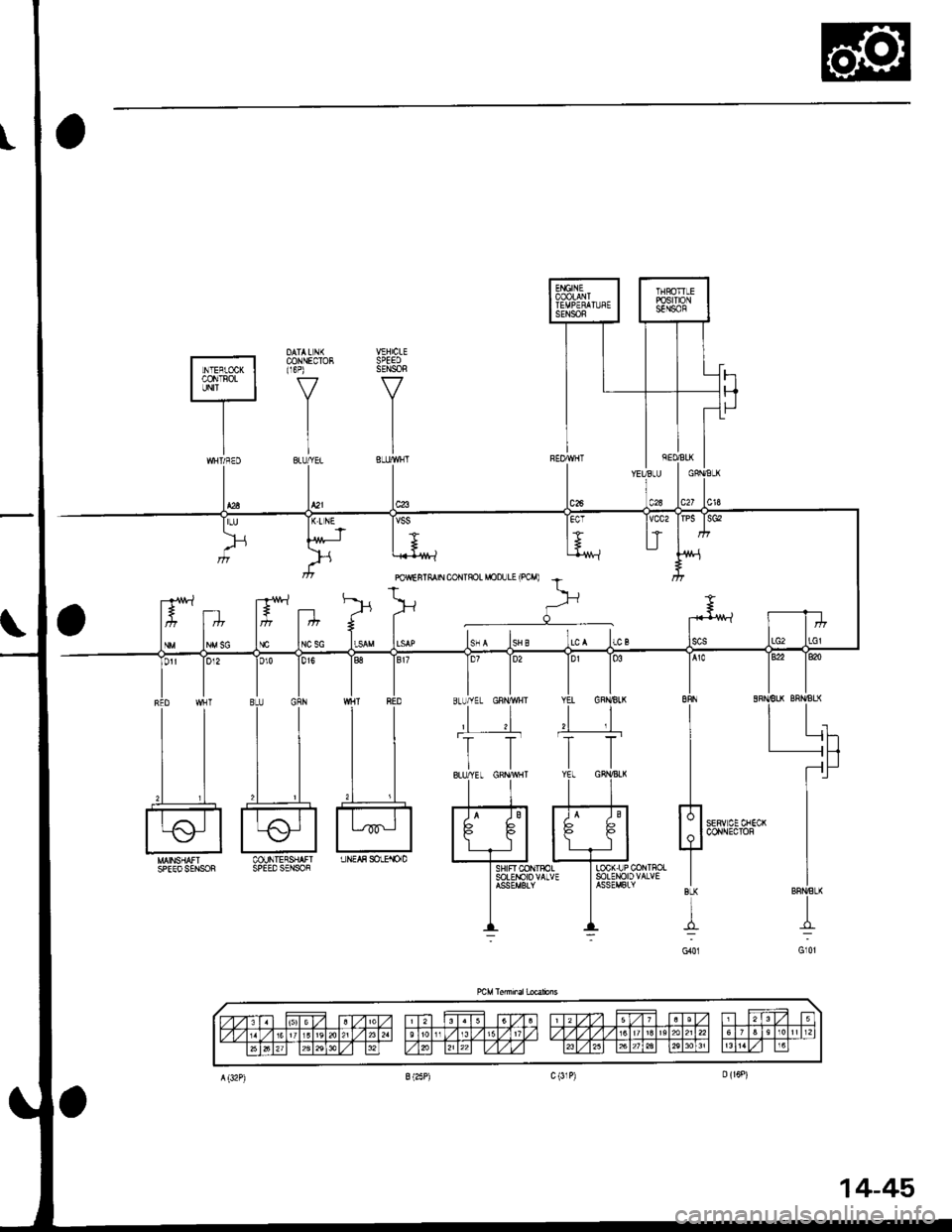

PCM Gircuit Diagram (A/T Gontrol System:'99 - 00 Models)

UNOEF DASIFL]SE/FELAY BOX

ta T06 T Dr.

INT€RLOCKCCNTFOLuN|l

ert*rll

I STARTEF

r-->lIl__ sL!

I

UISEF,DASHFISSIEL YmXr,Jo 25 (7 5A) GAUGE ISSEMBLY

Lr GRN -----l l"-- LTGRll

L eultru ----iF erk€Lu

14-44

Page 723 of 2189

SPEEOSENSOF

f7

III

I

CONNECTOF1r6P)

Y

II

I

ttt*'"

"*ttot **" 1*u)

,5-,

I

I

I

fl**',*"

IBLK

I

G401

ECI

SHIFI CONTFOLsolEt€to vALvEASSEMSLY

Page 1060 of 2189

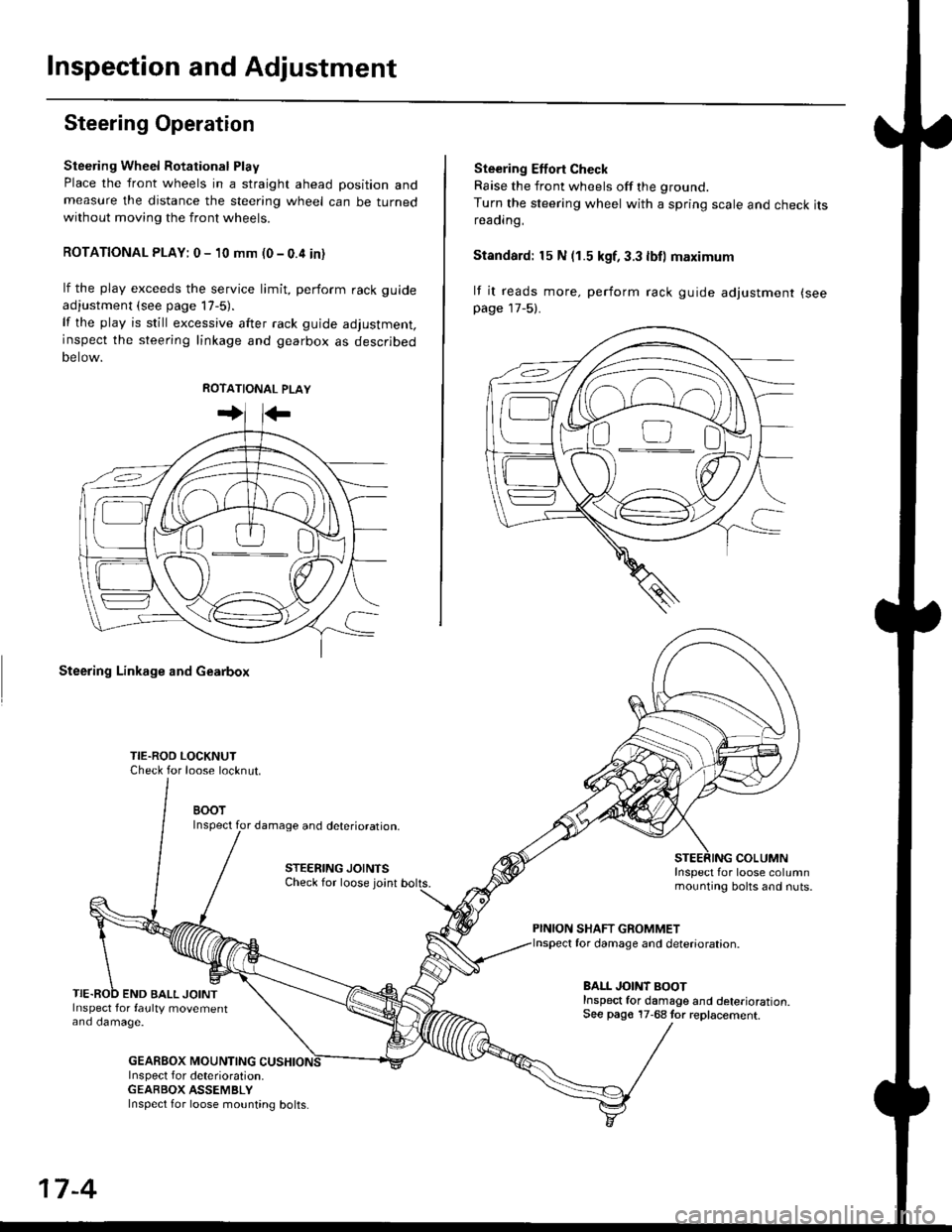

Inspection and Adjustment

Steering Operation

Steering Wheel Rotational Play

Place the front wheels in a straight ahead position andmeasure the distance the steering wheel can be turnedwithout moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.4 in)

lf the play exceeds the service limit, perform rack guide

adjustment (see page lT-5).

lf the play is still excessive after rack guide adjustment,inspect the steering linkage and gearbox as descrjbed

Detow.

Steering Linkage and Gearbox

TIE.ROO LOCKNUTCheck for loose locknut.

BOOTInspect for damage and deterioration.

STEERING JOINTSCheck for loose joint

END BALL JOINTInspect for faulty movementano oamage.

GEABBOX MOUNTINGInspect f or deterioration.GEABBOX ASSEMBLY

Ste€ring Effort Check

Raise the front wheels off the ground.

Turn the steering wheel with a spring scale and check itsreaorng,

Standard: 15 N (1.5 kgf, 3.3 lbll maximum

lf it reads more. perform rack guide adjustment (see

page 17-5).

COLUMNInspect for loose columnmounting bolts and nuts.

PINION SHAFT GROMMETfor damage and deterioration.

BALL JOINT BOOTInspect for damage and deterioration.See pago 17-68 tor replacement.

ao-\---------U

17-4

Inspect for loose mounting bolts.

Page 1087 of 2189

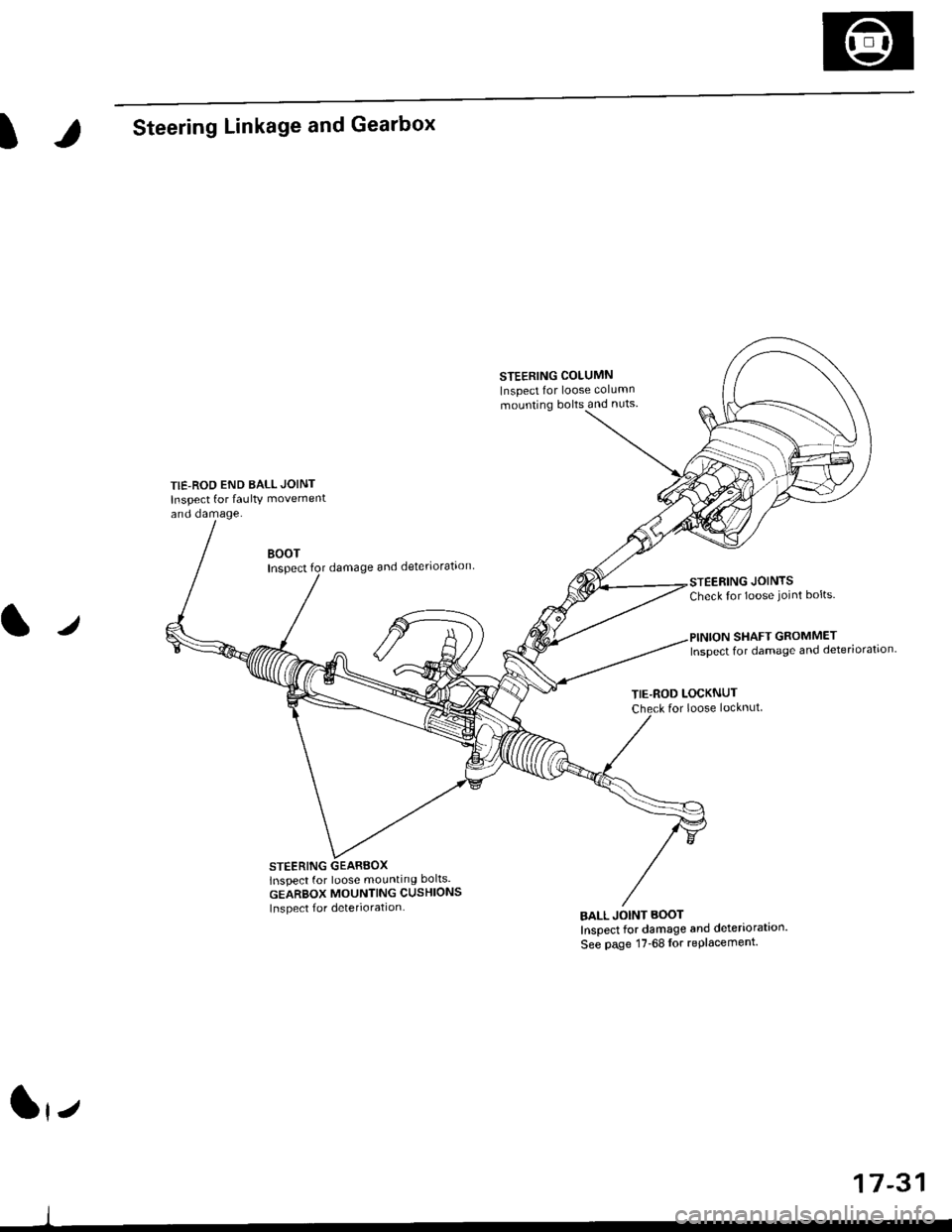

ISteering Linkage and Gearbox

TIE-ROD END BALL JOINT

Inspect for faulty movement

and damage.

STEERING COLUMN

Inspect for loose column

mounting bolts and nuts

BOOTInspectdamage and deteriorataon

STEERING GEARBOXlnspect for loose mounting bolts.

GEARBOX MOUNTING CUSHIONS

Inspect f or deterioration

STEERING JOINTSCheck for loose joint bolts.

l./

TIE-ROD LOCKNUTfor loose locknut

BALL JOINT BOOT

Inspect for damage and deteriorataon'

See page 17-68lor replacement.

SHAFT GROMMETInspect for damage and deteriorataon.

lrz

17-31

Page 1133 of 2189

I

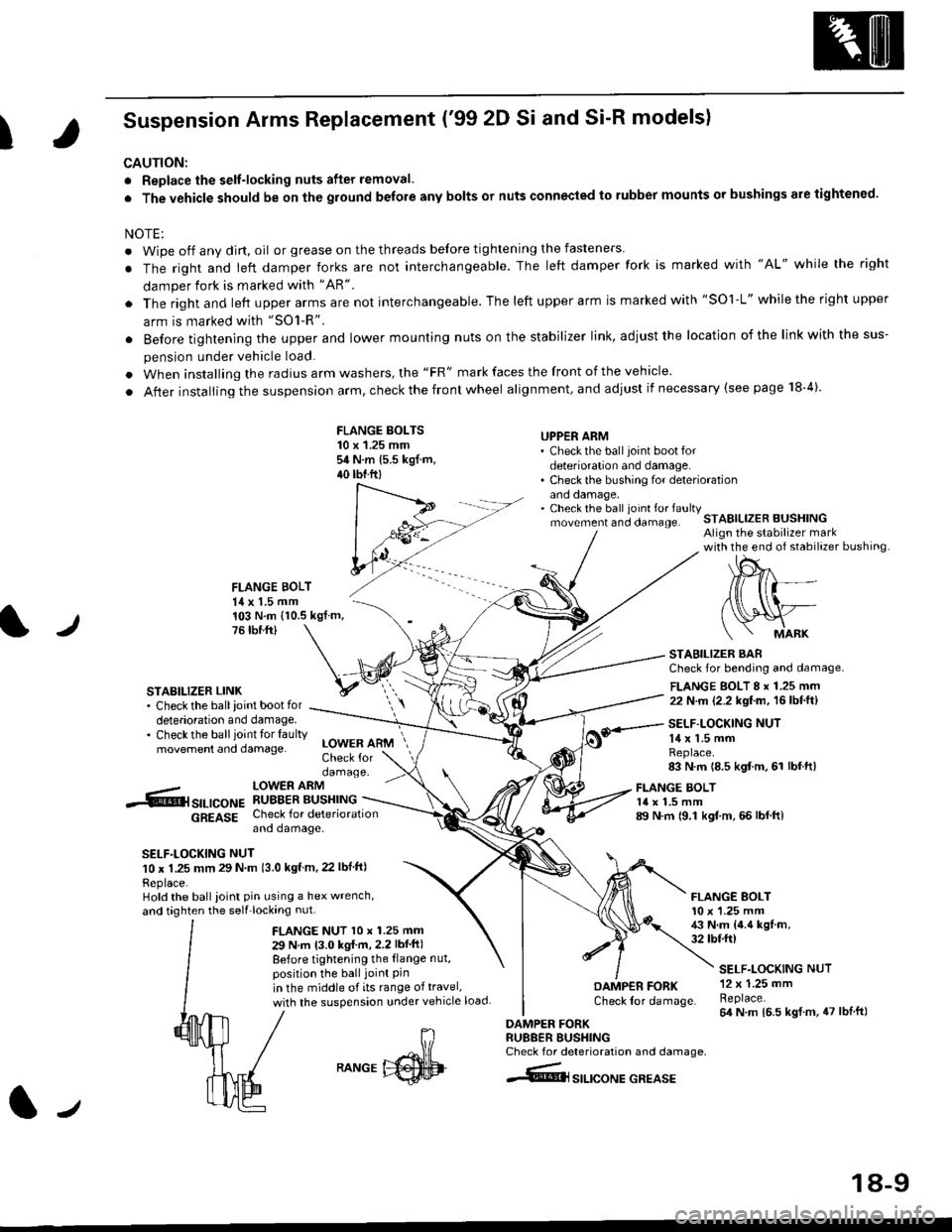

Suspension Arms Replacement ('99 2D Si and Si-R models)

CAUTION:

. Replace the selt-locking nuts after removal.

. The vehicle should be on the ground belore any bolts or nuts connected to rubber mounts or bushings are tightened.

NOTE:

. Wipe off any dirt, oil or grease on the threads before tightening the fasteners

. The right and ieft damper forks are not interchangeable. The left damper fork is marked with "AL" while the right

damper fork is marked with "AR"

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SOl-L" while the right upper

arm is marked with "SO1-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adiust the location of the link with the sus-

pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front of the vehicle.

. After installing the suspension arm, check the front wheel alignment, and adjust if necessary (see page 18-4).

FLANGE BOLTS10 x 1.25 mmsit N.m 15.5 kgf.m,40 tbtftl

UPPER ARM' Check the ball joint boot fordeterioration and damage.. Check the bushing for deteriorationano oamage,. Check the ball ioint fo. faultymovement and clamage.STABILIZER BUSHINGAlign the stabilizer markwith the end of stabilizer bushing

FLANGE BOLT14 x 1.5 mm

l./

103 N.m (10.5 kgf.m,76 tbr.ftl

STABILIZER LINK. Check the ballioint bootfordeterioration and damage.. Checkthe ballioint tor faultymovement and damage.

STABILIZER BARCheck for bending and damage.

FLANGE BOLT 8 x 1.25 mm22 N.m (2.2 kgf.m, 16lbf.ft)

SELF-LOCKING NUT14 x 1.5 mmReplace.83 N.m 18.5 kgf m, 61 lbf.ft)

-.6r srr-,co", hSHrtlrT.[*"u

6g619g Check for deteriorationano oamage.

SELF.LOCKING NUT10 x 1.25 mm 29 N m 13.0 kgf m, 22 lbf ftl

Replace.Hold the ball ioint pin using a hex wrench,

and taghten the self'locking nut.

LOWER ARMCheck fordamage.

FLANGE NUT l0 x 1.25 mm

29 N.m 13.0 kgI m,2.2 lbf ft)

Before tightening the {lange nut,position the ball joint Pinin the middle of its range of travel,

with the suspension under vehicle load

FLANGE BOLT14 x 1.5 mm89 N.m 19.1 kgf.m, 66 lbf.ft)

FLANGE BOLT10 x '1.25 mm43 N.m {4.4 kgf.m,32 tbtft)

DAMP€R FORKCheck lor damage.

DAMPER FORKRU88ER BUSHINGCheck for deterioration and damage.

4@lsrlrcoNE GREASE

SELF.LOCKING NUT12 x 1.25 mmReplace.64 N m 16.5 kgl.m, 47 lblft)

J

RANGE

18-9