TMA HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 368 of 2189

,'o

L

*:The E indicator light and the Maltunction Indicator Lamp (MlL) may come on simultaneously.*1: D16Y5 engine (CVT)"5: '96 D16Y5 engine, D16Y7 engine, D16Y8 engine (sedan).'97 D16Y5 engine, Dl6Y7 engine (coupe: KA, KC models, sedan: KA.

KC, KL (DX) models, hatchback: all models), D16Yg engjne (sedan: KA, KC models)*6: '96 D16Y8 engine (coupe),'97 Dl6Y7 engine (coupe: KL model, sedan: KL (LX) model),'97 D'16Y8 engine (coupe: all models,

sedan: KL model),'98-all models,'99-all models,'00-all models*12: Except A,,/T (D16Y7, D16Y8 enginei*13: A"/T (D16Y7, D16Y8 engine)!l*14:'97 model*16:'98 model" 17: '99 - 00 models

(cont'd)

1 1-99

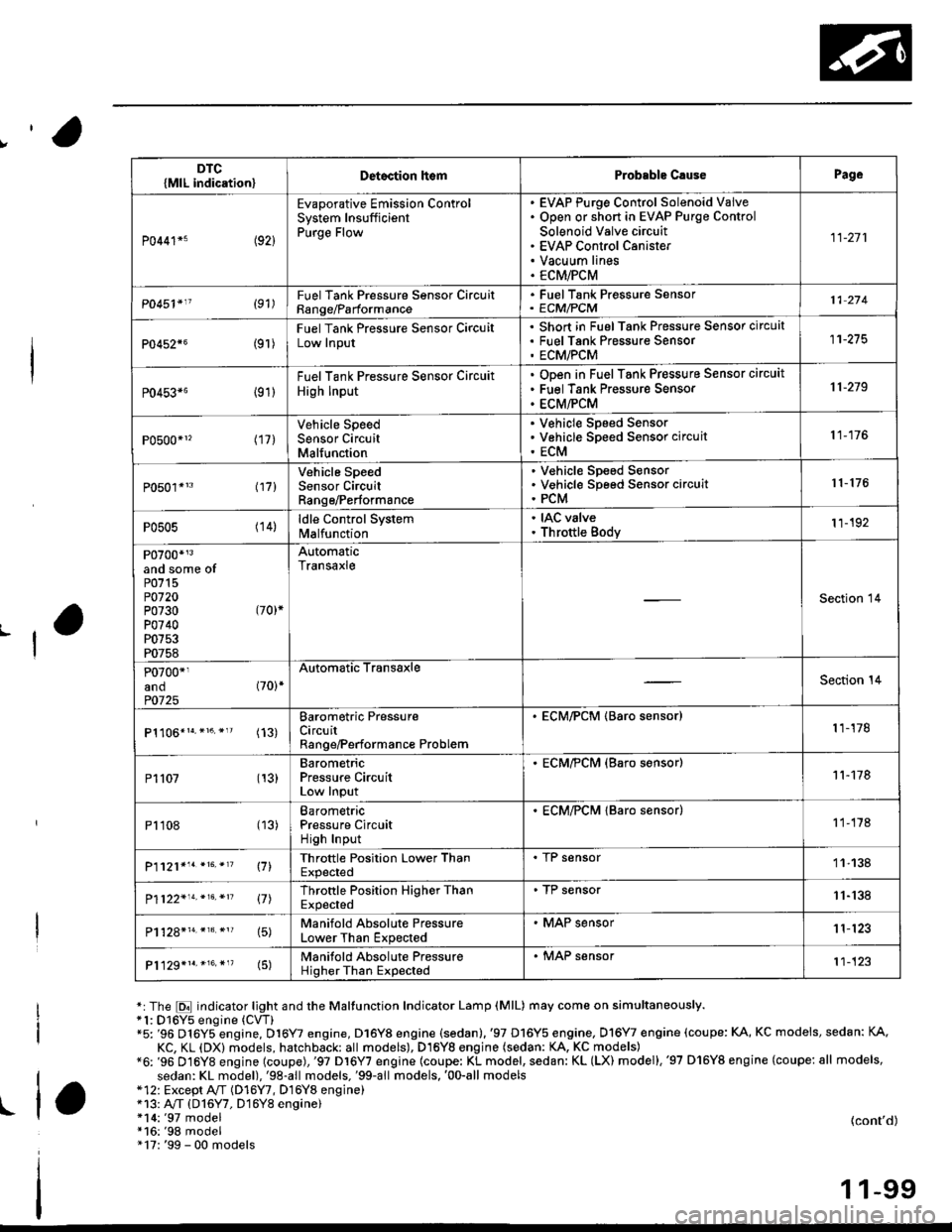

DTC{MlL indication}Detoction lt€mProbable C.usePage

P0441*5 (92)

Evaporative Emission ControlSystem InsufficientPurge Flow

EVAP Purge Control Solenoid VaiveOpen or short in EVAP Purge Control

Solenoid Valve circuitEVAP Control CanisterVacuum linesECM/PCM

11-271

P0451'11 (91)FuelTank Pressure Sonsor CircuitRange/Parformance

. FuelTank Pressure Sensor' ECM/PCM11 274

P0452{6(9r )

Fuel Tank Pressure Sensor CircuitLow Input

Short in FuelTank Pressure Sensor circuatFuel Tank Pres$ure SensorECM/PCM

11-275

P0453*6 {91)

Fuel Tank Pressure Sensor Circuit

High Input

ODen in Fuel Tank Pressure Sensor circuit

Fuel Tank Pressure Sensor

ECM/PCM

11-219

P0500*1, (17)Vehicle SpeedSensor CircuitMalfunction

V€hicle Speed SensorVehicle Speed Sensor circuit

ECM

11-176

P0501*'3 l17l

Vehicle SpeedSensor CircuitRange/Performance

V€hicle Sp€ed SensorVehicle Speed Sensor circuitPCM

r 1- 176

P0505 (14)ldle Control Systemlvl a lfu n ctio n

. IAC valve. Throttle Body11-192

P0700*r3and some ofP0715P0720P0730 (70)*

P0740P0753P0758

AutomaticTransaxle

Section 14

P0700*1and (70)*

P0725

Automatic TransaxleSection 14

(13)Barometric PressureCircuitRange/Performance Problem

. ECM/PCM (Baro sensor)1 1-178

P1107 (13)BarometricPressure CircuitLow Input

. ECM/?CM (Baro s€nsor)11-178

P1108 (13)BarometricPressure CircuitHigh Input

. ECM/PCM lBaro sensor)1 1-178

P1121*'. *16. *'? \71Throttle Position Lower ThanExpected

. I r sensor11-138

P1122'14.*16.*n 17lThrottle Position Higher ThanExpected

. TP sensor11-'138

15)Manifold Absolute PressureLower Than Expected

. MAP sensor1 1'123

P1129*1r.*16.*"(5)Manifold Absolute PressureHigher Than Expected

. MAP sensor't1-123

Page 369 of 2189

Troubleshooting

Diagnostic Trouble Code (DTGI Chart (cont'dl

*7: D16YS engine (M/T)*8: D16Y5, D'16Y8 engine*9: USA model*14r'97 model*15r '96 model

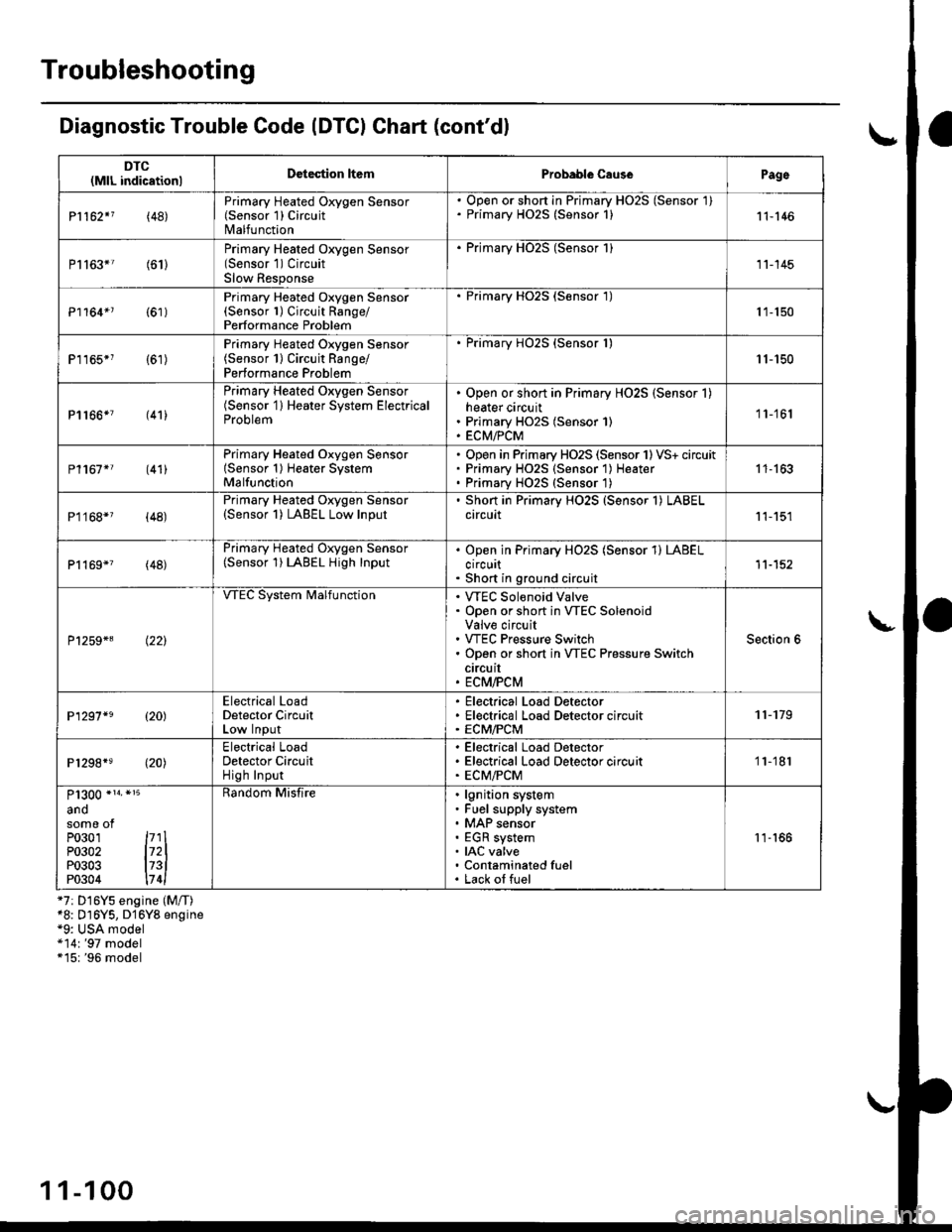

DTC(MlL indicationlDetection lt6mProbablc CausePage

P1162+1 (48)Primary Heated Oxygen Sensor(Sensor 1) CircuitMalfunction

Open or short in Primarv HO2S (Sensor 1Primary H02S (Sensor 1)1 1- 146

P]163' (61)Primary Heated Oxygen Sensor(Sensor '1) CircuitSlow Response

. Primary HO2S (Sensor 1)

11-145

Pl164*r (61)Primary Heated Oxygen Sensor(Sensor l) Cjrcuit Range/Performance Problem

. Primary HO2S (Sensor 1)

1 1- 150

P1165*? (61)Primary Heated Oxygen Sensor(Sensor 1) Circuit Range/Performance Problem

. Primary HO2S (Sensor 1)

11-150

P1166' (41i

Primary Heated Oxygen Sensor(Sensor '1) Heater System ElectricalProblem

Open or short in Primary HO2S (Sensor 1)heater circuitPrimary HO2S (Sensor 1)ECM/PCM

1 1-'161

P1167*' (41)Primary Heated Oxygen SensorlSensor 1) Heater SystemMalfunction

Open in Primary HO2S (Sensor 1) VS+ circuitPrimary HO2S (Sensor 1) HeaterPrimarv HO2S {Sensor 1)1 1- 163

P1168*' (48)Primary Heated Oxygen Sensor(Sensor 1) LABEL Low Input

. Short in Primary HO2S (Sensor 1) LABELcircuit11-151

Pl169*? (48)

Primary Heated Oxygen Sensor(Sensor 1)IABEL High Input. Open in Primary HO2S (Sensor 1)IABELcircuit. Short in ground circuit11.152

P1259*3(221

WEC System MalfunctionWEC Solenoid ValveOpen or short in WEC SolenoidValve circu itVTEC Pressure SwitchOpen or short in VTEC Pressure SwitchcircuitECM,FCM

Section 6

P1297*s (20)Electrical LoadDetector CircuitLow Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM11-179

Pr298+' l20l

Electrical LoadDetector CircuitHigh Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM1 1-181

anosome ofP0301P0302P0303P0304

l71ll72ll73ll7 4l

Bandom Misfirelgnition systemFuel supply systemMAP sensorEGR systemIAC valveContaminated fuelLack ol fuel

11-166

1 1-100

Page 371 of 2189

Troubleshooting

Diagnostic Trouble Code (DTCI Ghart (cont'd)

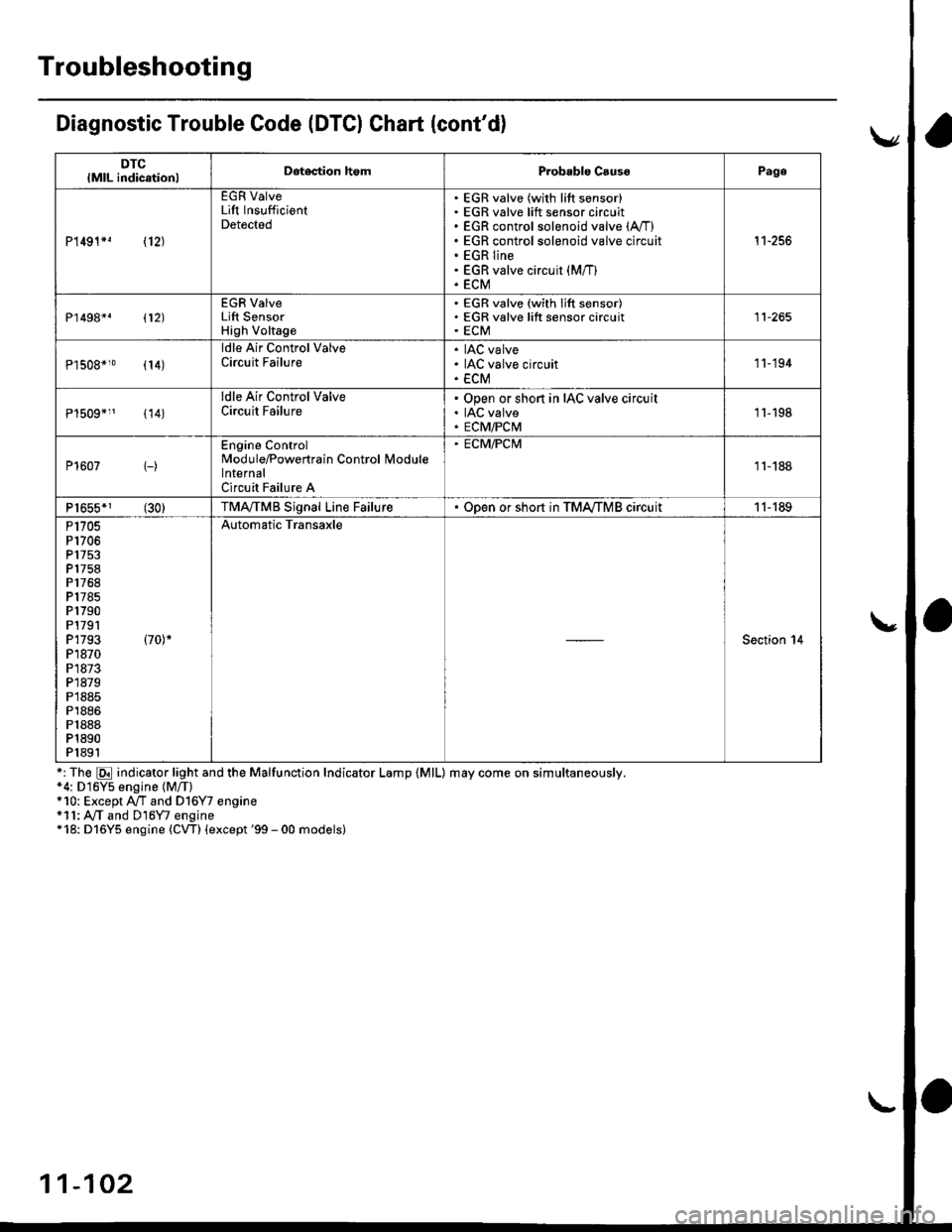

DTClMlL indicationlDetegtion homProbablo CsussPage

P1491*! \12J

EGR ValveLift InsufficientDetected

EGR valve (with lift sensor)EGR valve lift sensor circuitEGR control solenoid valve (A,/I)

EGR control solenoid valve circuitEGR lineEGR valve circuit (M/T)

ECM

't1-256

P1498*. 112)

EGR ValveLift SensorHigh Voltage

EGR valve (with lift sensor)EGR valve lift sensor circuitECM11-265

Pl508*10 (14)

ldle Air Control ValveCircuit FailureIAC valveIAC valve circuitECM

'11-194

{14)

ldle Air Control ValveCircuit FailureOpen or short in IAC valve circuitIAC valveECM/PCM1l-198

P1607 1-)

Engine ControlModule/Powertrain Control lvlodulelnternalCircuit Failure A

. ECM/PCM

11-188

P1655*1 (30)TMA,/TMB Signal Line FailureODen or sho.t in TMA,/TMB circuit11-189

P1705P1706P 1753P1758P1768P1785P1790P1791P1793 (70)*

P1870P1873P1879P1885P1886P1888P1890P1891

Automatic Transaxle

Section 14

*: The E indicator light and the Malfunction Indicator Lamp {MlL) may come on simultaneously.*4: D16Y5 engine (M/T)+10: Except A/T and Dl6Y7 engine*11: A,/T and D16Y7 engine*18: D16Y5 engine (CW) (except '99 - 00 models)

11-102

Page 410 of 2189

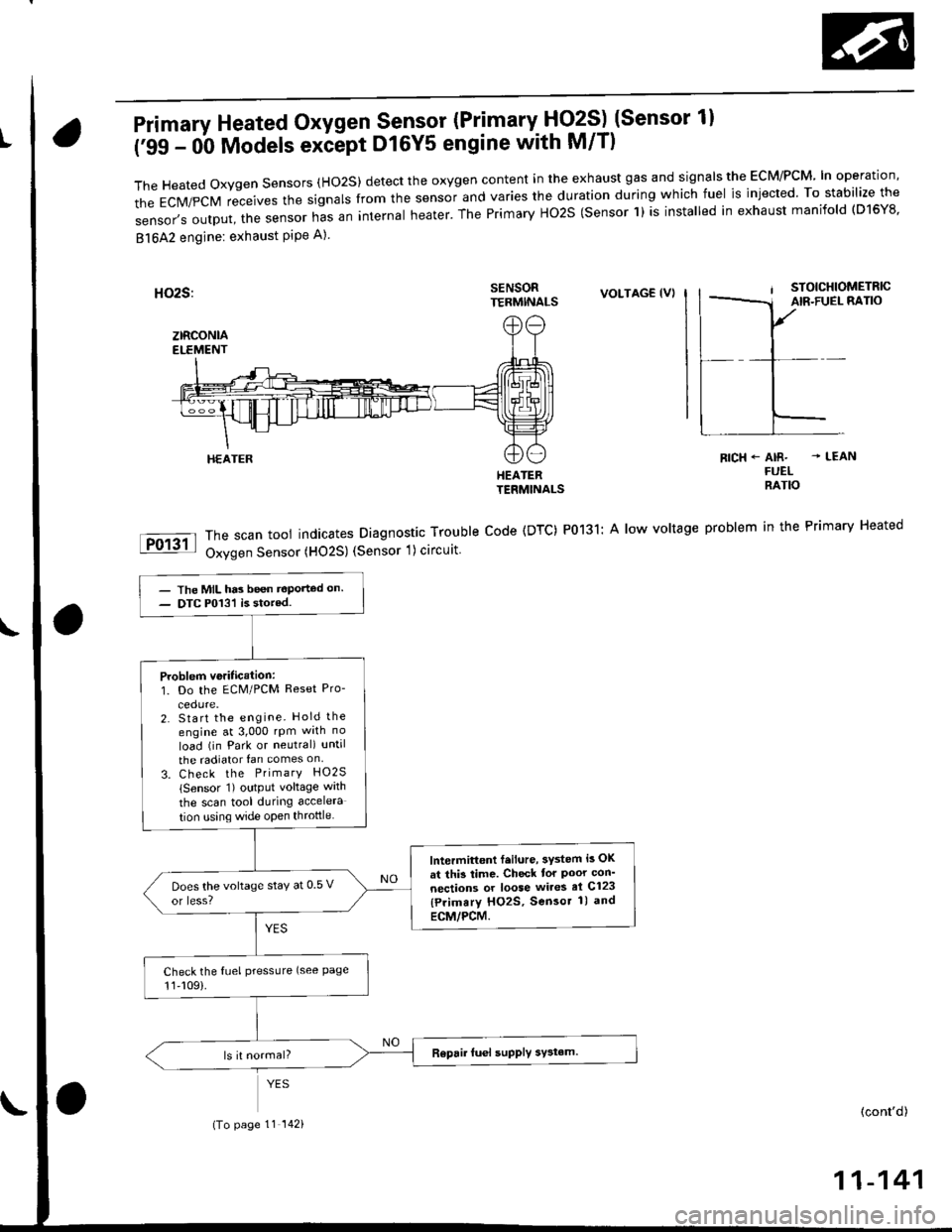

Primary Heated Oxygen Sensor (Primary- Fjq?S) (Sensor 1l

('99 - 0b Models exiept D16Y5 engine with M/T)

TheHeatedoxygensensors(Ho2S)detecttheoxygencontentintheexhaustgasandsigna|stheEcM/PcM'|noperation,

the EcM/pcM receives the signars from the sensor and varies the duration during which fuel is injected. To stabilize the

sensor,soutput,thesensornasaninternaIheater.ThePrimaryHo2S(sensorl)isinsta|ledinexhaustmanifo|d(D16Y8.

81642 engine: exhaust PiPe A)

SENSORTERMINALSVOLTAG€ (VI

HEATERTERMINALS

The scan tool indicates Diagnostic Trouble Code (DTC) P0131: A low voltage

Oxygen Sensor (HO2S) (Sensor 1) circuit

RICH+ AIR- - LEANFUELRATIO

problem in the Primary Heated

HEATER

- The MIL has been t€Ported on.- DTC P013'l is stored.

Problem veritication:1. Do the ECM/PCM Reset Pro-

2. Start the engine. Hold the

engine at 3,000 rpm wrth no

load (in Park or neutral) until

the radiator fan comes on

3. Check the PrimarY HO2S

lSensor 1) output voltage wath

the scan tool during accelera

tion using wide open throttle

lntermittont f.ilure, 3ystem i3 OK

at thi3 time. Check tor Poor con'

nections or loose wires el C123

{Primary HO2S, Sensor 1) and

ECM/PCM.

Does the voltage stay at 0 5 v

or less?

Check the fuel pressLlre (see Page11,109).

(To page 11 142)(cont'd)

11-141

Page 421 of 2189

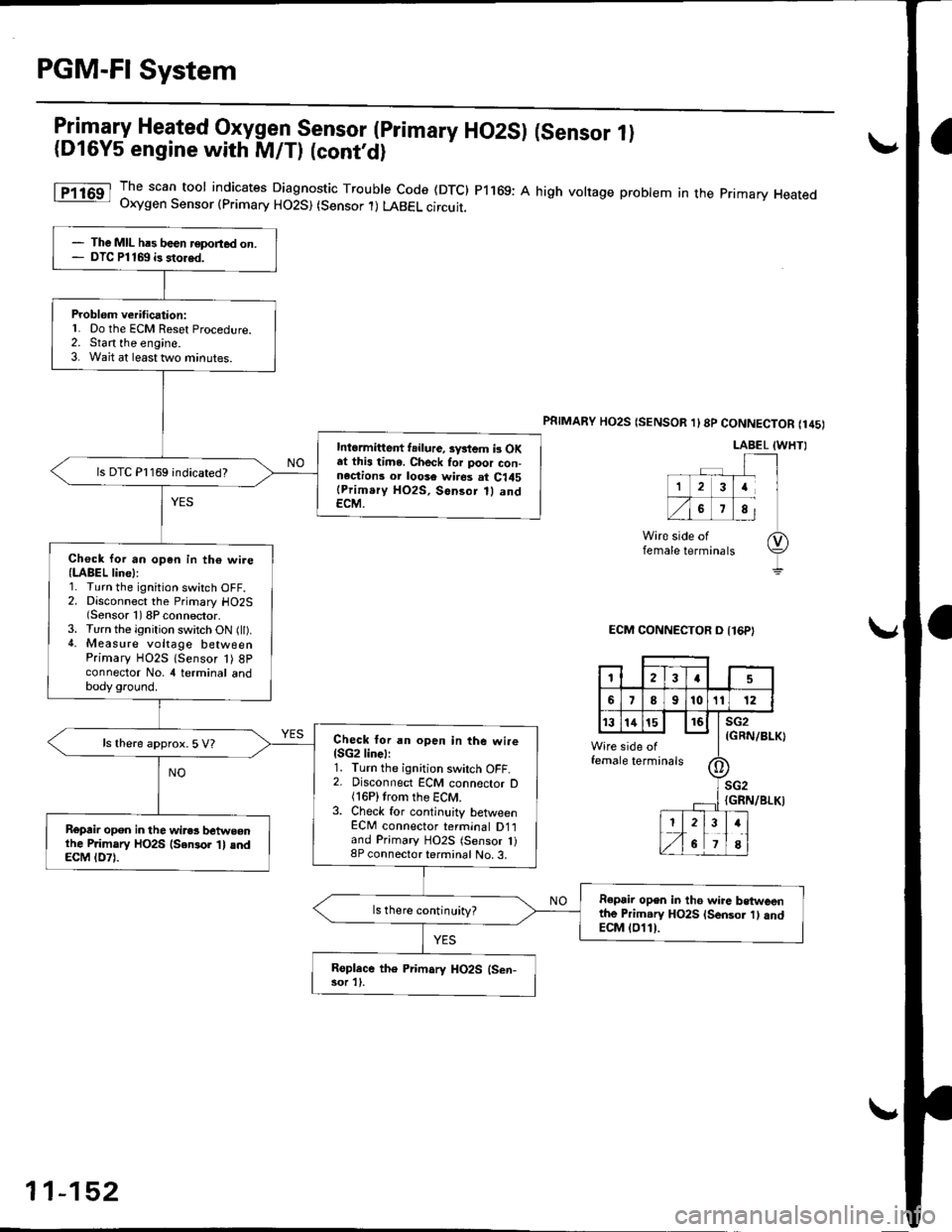

PGM-FI System

IiT-"-w Heated 9{ygglSensor (primary HO2SI (Sensor 1)(Dl6Y5 engine with M/Tl lconr'd)

1T1163 Ih" scan tool indicates Diagnostic Trouble code (DTc) P1169: A high volrage probtem in the pnmary Heated- Uxygen Sensor {primary HO2S) (Sensor .l) LABEL circuit.

PSTMARY HO2S (SENSOR 1l8p CONNECTOR (145)

LABEL IWHTI

ECM CONNECTOR O {16P}

(GRN/BLK)

female

IGRN/BLKI

- The MIL hrs been reported on.- DTC Pl169 i3 stored.

Problem verification:L Do the ECM Reset Procedure.2. Start the engine.3. Wait at least two minutes.

Intormittent f.ilure, sv*em b OKat this time. Check for poor con-n.ctions or loose wires at C145(Prim.ry HO2S, Sensor 1l andECM.

ls DTC P1169 indicated?

Ch€ck Ior an op6n in th€ wire(LABEL line):1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) 8P connector.3. Turn the ignition switch ON (ll).4. Measure voltage betweenPrimary HO2S lsensor 1) 8Pconnector No, 4 terminal andbody ground.

Check lor an open in the wire{SG2linel:1. Turn the ignition swilch OFF.2. Disconnect ECM connector D(16P)trom the ECM.3. Check for continuity betlveenECM connector terminal D1land Primary HO2S (Sensor 1)8P connector terminal No. 3.

ls there approx. 5 V?

Ropair opon in the wires betweonlhe P.imary HO2S {Sensor 't} andECM tD7l.

R€pair open in th6 wire betweenthe Primary HO2S lsensor 1) andECM (011).

ls there continuity?

Roplace the Primary HO2S (Sen-sor 1).

123a5

689101t12

t3141516sG2

side ofe terminalstll

II-- rl

;G2

I2

6

34

8

11-152

Page 458 of 2189

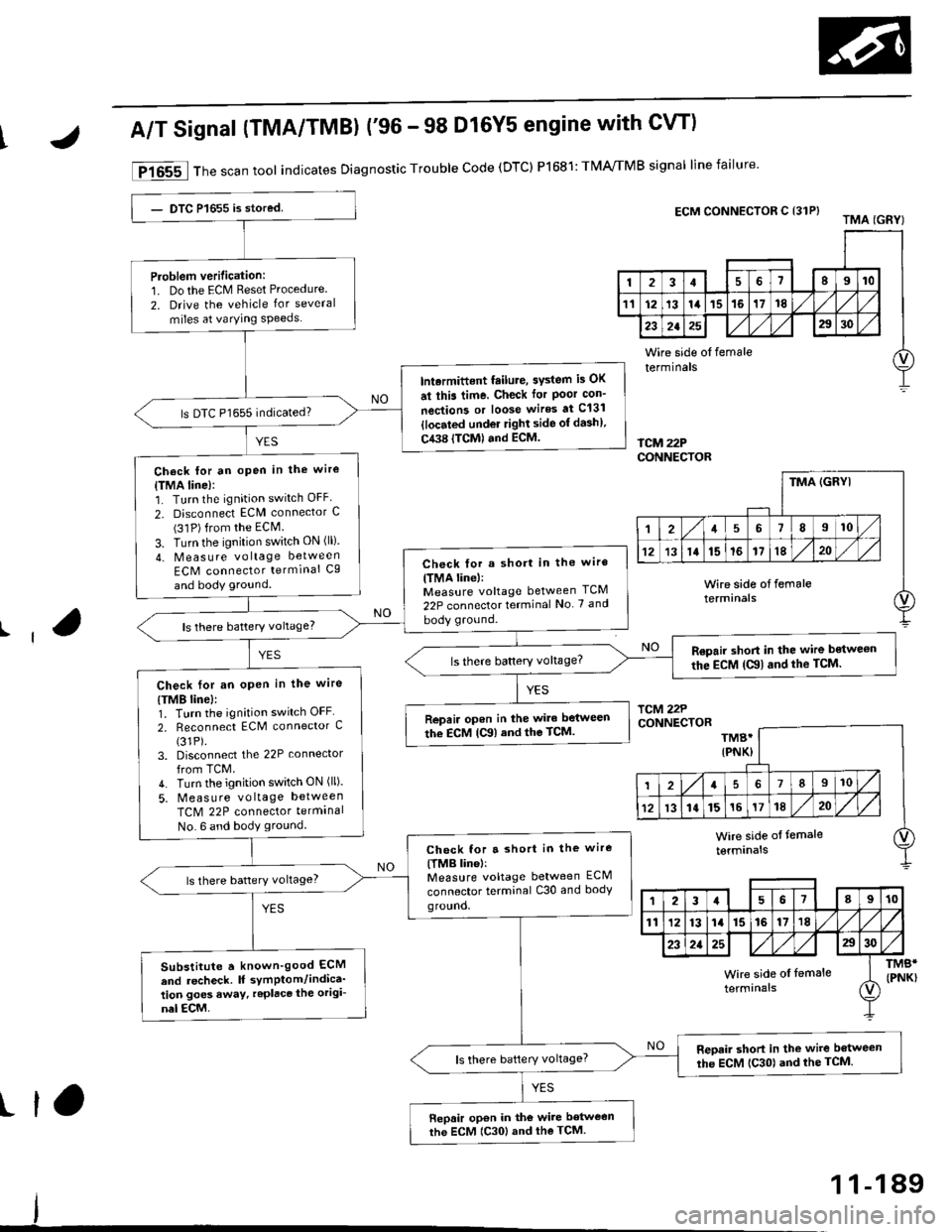

[F16551l Th" ""un toot indicates Diagnostic Trouble Code (DTC) P1681: TIVA,/TMB signal line failure

Problem verification:1. Do the ECM Reset Procedure.

2. Drive the vehicle Ior several

miles at varying speeds

lnt.rmittent failure, system is OK

at ihis time. Check tor Poor con-

nections or loos€ wires at C131

llocated under right side of dash),

C438 ITCM) and ECM.

ls DTC P1655 indicated?

Check lor an oPen in the wire(TMA line):1. Turn the ignition switch OFF

2. Disconnect ECM connector C(31P)from the ECM

3. Turn the ignition switch ON (ll).

4- Measure vo ltag e between

ECM connector terminal Cg

and body ground.

Check for a short in the wire

ITMA line,:Measure voltage between TCM

22P connector terminal No 7 and

body ground.ls there battery vohage?

Ropair shod in the wire bstwe€n

the EcM (C!l) and the TcM.ls there battery voltage?

Check for an open in the wire

{TMB line}:1. Turn the ignition switch OFF

2. Reconnect ECM connector c(31P).

3. Disconnect the 22P connector

from TCM.4. Turn the ignition switch ON (ll).

5. Measure vo ltage between

TCM 22P connector termlnal

No. 6 and body ground.

Repair open in the wire between

th€ EcM {Ca) and the TcM.

Check for a 3ho.t in the wire

{TMB lin6,:Measure voltage between ECM

connector terminal C30 and bodyground,

ls there battery voltage?

Substitute a known'good ECM

and recheck. It symPtom/indica'tion goes away, teplace the origi-

nal ECM.

Reoair short in the wile b6tween

the ECM {C30} and the TCM.ls there baftery voltage?

f,epair open in the wire between

the EcM (C30) and the TcM.

IJA/T Signal (TMA/TMBI ('96 - 98 Dl6Y5 engine with GW)

ECM CONNECTOR C 131P}TMA IGRYI

fcu22PCONNECTOR

ll

TMB*{PNK}

231678910

1t'12131415161718

232a252930

Wire side oI temale

terminals

tl,

1 1-189

Page 679 of 2189

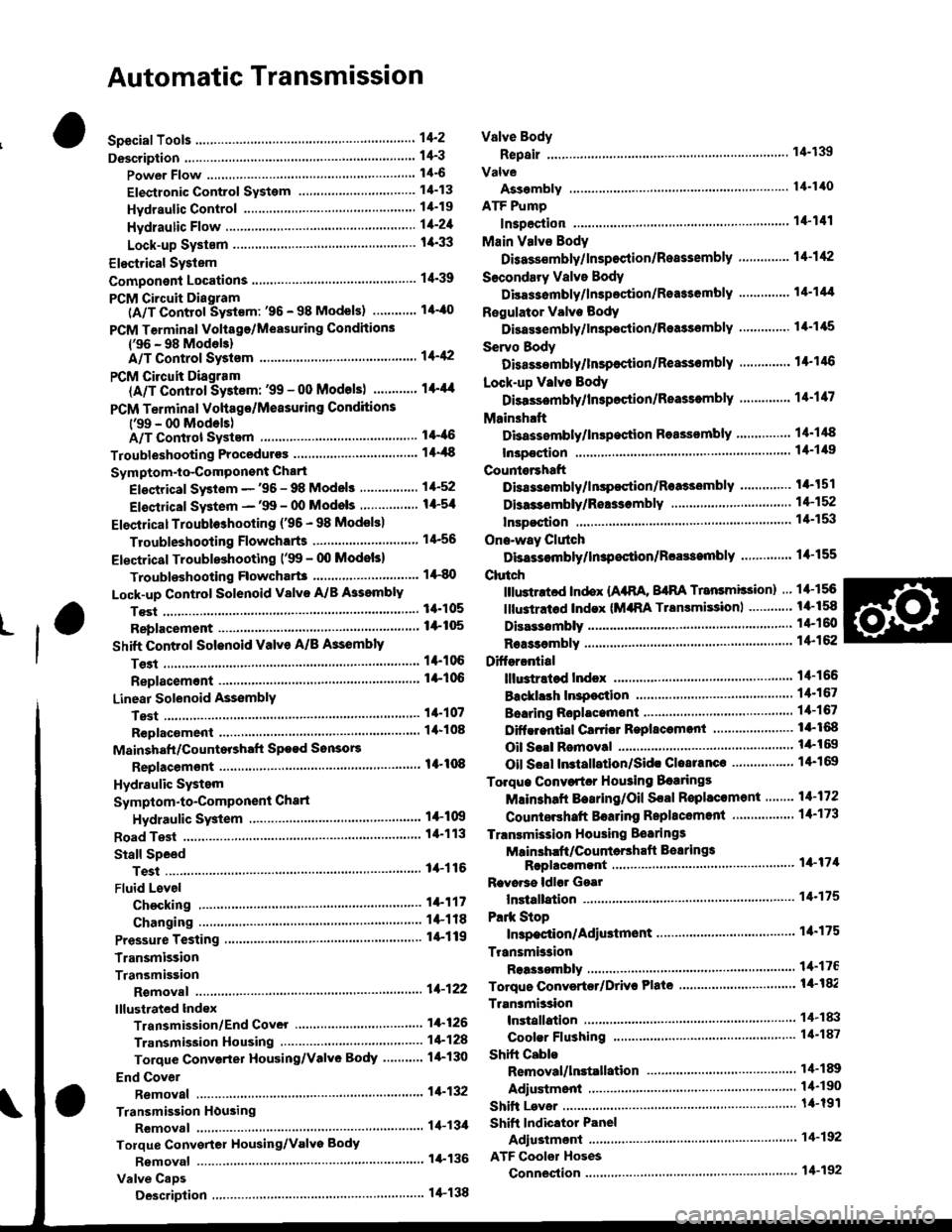

Automatic Transmission

Special Tools ......... .....'."".'-.-.' 14'2

Description .,....................-...... 14-3

power Flow ......,................. 14"6

Elestronic Control System .... . ................'..'.'.. 14-13

Hvdraulic Control .....'......" 1'l-19

Hydraulic F|ow...... .'.'.".'....11-21

Lock-up System '............ ... t/t'33

Electrical System

Component Locations....,.............'......'.............'.,. 14'39

PCM Circuit Diagram

lA/T Control Syst€m: '96 - 98 Models) .........'.. 1/t-40

PCM Tarminal Volt8ge/Measuring Condhions

{'96 - 98 ModeblA/T Control System ............

PCM Circuit Disgram(A/T Conlrol System: '99 - 00 Modsls) '..........' 14-44

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)A/T Control System ...

Troubleshooting Proceduros ....

Symptom-to-ComPonent Chari

Efectricaf SFiem - '96 - 98 Models '..-.-..."'.'..11-52

Eloqtrical System -'99 - 00 Modols ... .........". 1+54

EleclricatTroubl$hooting ('96 - 98 Models)

Valve Body

Repair .................... ........'.... 14-139

Valve

Assembly

ATF Pump

1,1-1i10

Inspection ...........'.......... 14-141

Main Valvs Body

Disass€mbf y/lnspoction/R.sssembly .'.'.'.'.. -. -. 1 1-1 12

Secondsry Valve BodY

Disa$embfy/lnspoction/Rsassembly ......'.'.'.'. 11-111

Regulator Valve Body

Disa$embly/lnspoction/Rea3sembly ..........'... 14-1{5

Servo Body

Disassombly/lnsp€ction/Reassembly .".'........ 14-146

Lock-up Valv6 Body

Dis$s.mbf y/ln3poction/Rea$embly .'.. -. -..'.'.' 1 1-1 17

Mainsh!ft

Dkassembly/lnep€ction Reassembly ..'...'........ 14'148

Inspoction .............'..........'. l it-149

Countsrshaft

Disa$embly/lnspeqtion/Rea3sembly .......'...'.. 1a-l51

Dba$ombly/Re$s.mblY11-152

til-46

I rl-48

Troubleshooting Flowcharts

Electrical Troubleshooting ('9!t - 00 Models)

Troublsshooting Flowchart3

Lock-up Control Solenoid vslvo A/B AssemblY

RePlacoment

Shift Cont.ol Solenoid Valve A/B A3sembly

Inspestion

Ona-way Clutch

Disassembh/lrupoction/Rca$embly .. "'........ l4-155

Clutch

lllustlttcd Ind.x {A48A, B4RA Transmlssion) ..' 14-156

tustr.tod Index (MrnA Transmi$ionl ............ til-158

...................... 14-153

L

14-56

1+81'

14-105

1+105

Replacoment ......

Mainshaft/Countorshaft Spo€d Sonsors

Replacemsnt ......'."'........... lit'108

Hydraulic System

Symptom-to-Componeni Chart

Hydraulic Sydemr+109

t4-113

1+116

11-117

Rea$emblY

14-106 Difforrr ial

llhdraied Index........ t4-156

B.ckhrh ln3poction. 14-167

Boaring Roplacemont..-..........11-167

..... 14-108 Diftrrsniial Carrior Repl8cemeni .'.-.............'...' lil-168

Oil Sall Romovalt4-t 59

Oil Soal ln3tallstion/Sidc Clearance'......'.....'... 1'l'169

Torqua Convertcr Housing Boarings

Mlin3haft Besring/Oil Scal Roplac.ment ."..'.. lil-172

Counio6hatt Betring R.plscem.nt ..'...... ....... 14-173

Test.....,......14-106

14-107

14-160

11-162

11-171

11-175

Replacement

Test .....,.,..........

Road Te3t

Linear Solenoid AsssmblY

Stall Speed

lllustrated Indax

Transmission/End Cover'. ....

Transmission Hou3ing,.............'.'......'....""..-.-.. 11-128

Torque Conve.ter Housing/Valvo Body ........... 14-130

End Cover

14-itB Park Stop

1+119 In3pection/Adiustmsnt...'......'.'............'...."""'14-175

Transmbgion

Reassombly

11-122 Torquo Convertet/Drivr Plsie ............'.'............'.. . l4-182

Transmission

11.726 Inrtallation

Tranlmission Housing Boarings

Msinsh.ft /CounteEhaft Bearings

B!pltcomgnt

Rcvo.3s ldlor Gear

lnrtallation

Cooler Flushing ..

Shift Cabls

Test

Fluid Level

Checkin9 .........."..'.'.....

Changing

Pressure Testing

Transmission

Transmission

Rgmoval ..

lil-176

.'..........'.'.'..... 1'l-183

.... lil-187

11-132Adiustmont

RemovaUlnttallation1,1-190

lit-191Transmisgion Housing

Removal ... '.'...... ......'..... 14-l3il

Tolque Convgrter Housing/valvs Body

Rsmoval .........,...... ............. 14-136

Valve CaDs

Description .......'................. t 4'138

Shift lndicator Panel

Adiu3tmant ..'.................. 14-192

ATF Coolor Hoses

Connection ..,............,.,....... l'l-192

Shift Lever .,........

Page 680 of 2189

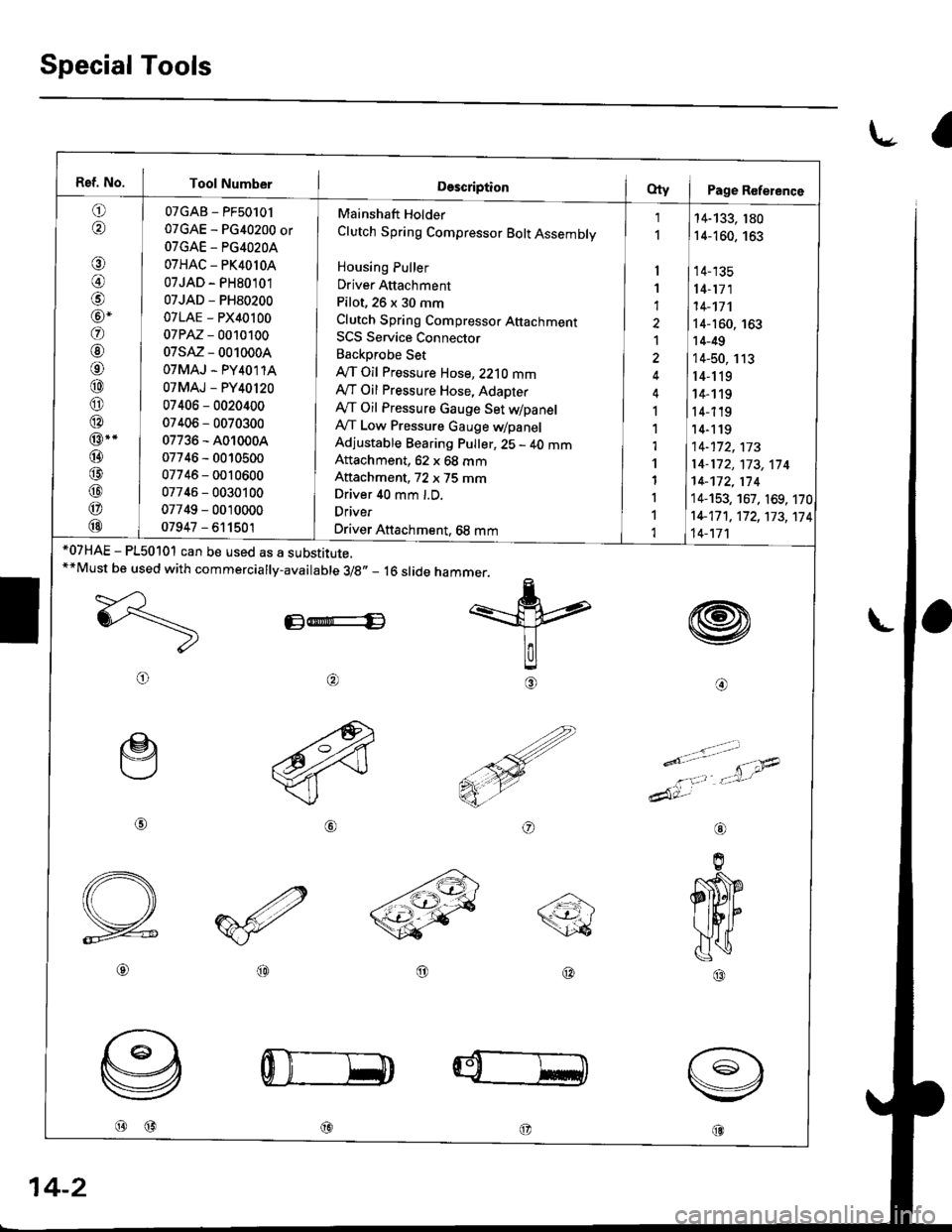

Special Tools

l.- a

Ref. No. Tool Number

o,6'\

€)

@)

@-

@

@

o

@

@

@

@..

@

@

@

@

@

07GAB - PF50101

07GAE - PG40200 or

OTGAE - PG4O2OA

07HAC - PK4010A

07JAD - PH80101

07JAD - PH80200

07LAE - PX40100

07PM - 0010100

07sM - 0010004

OTMAJ - PY4O1 1A

07MAJ - PY40120

07406 - 0020400

07406 - 0070300

07736 - A010004

07746 - 0010500

07746 - 0010600

07746 - 0030100

07749 - 0010000

07947 - 611501

Mainshaft Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Driver Attachment

Pilot, 26 x 30 mm

Clutch Spring Compresso. Attachmenr

SCS Service Connector

Backprobe Set

IVT Oil Pressure Hose, 2210 mmAy'T Oil Pressure Hose, Adapter

Ay'T Oil Pressure Gauge Set dpanelA,/T Low Pressure Gauge WpanelAdjustable Bearing Pulter, 25 - 40 mmAftachment, 62 x 68 mm

Aftachment, 72 x 75 mmDriver 40 mm l.D.

Driver

Driver Attachment, 68 mm

I

1

1

1

I

1,l

'l

1

I

1

1

14-133, 180

14-160, 163

14-135

14-171

14-'�t7'l

14-160, 163

14-49

14-50, 113

r4-119

14- 1 19

14-119'14-1 19

14-172,173

14-172,'t73,114

14-172,174

14-153, 167. 169, 170

1+17 1 , 17 2, 173, 17

14-'t7'l

4

w

@o

*07HAE - P150101 can be used as a substitute.**Must be used with commercially-available 3/8,, _ 16 slide

E-E

@

@@

hammer.

=k

lalg

€)

ry

o

e

@

o

----a\\<-t-'- /\26

@@

@@@

aL

14-2

Page 797 of 2189

Pressure Testing

@I While testing, be caroful of th€ rotating front wheels.

. Make sure lifts, iacks, and satoty stands are placod properly (see section 1)'

CAUTION:

. Beforo iesting, be sure the transmission fluid is tilled to tho proper level'

. Warm up tho engine before testing'

1. Raise the vehicle (see section 1).

2. Warm up the engine, then stop the engine and connect a tachometer'

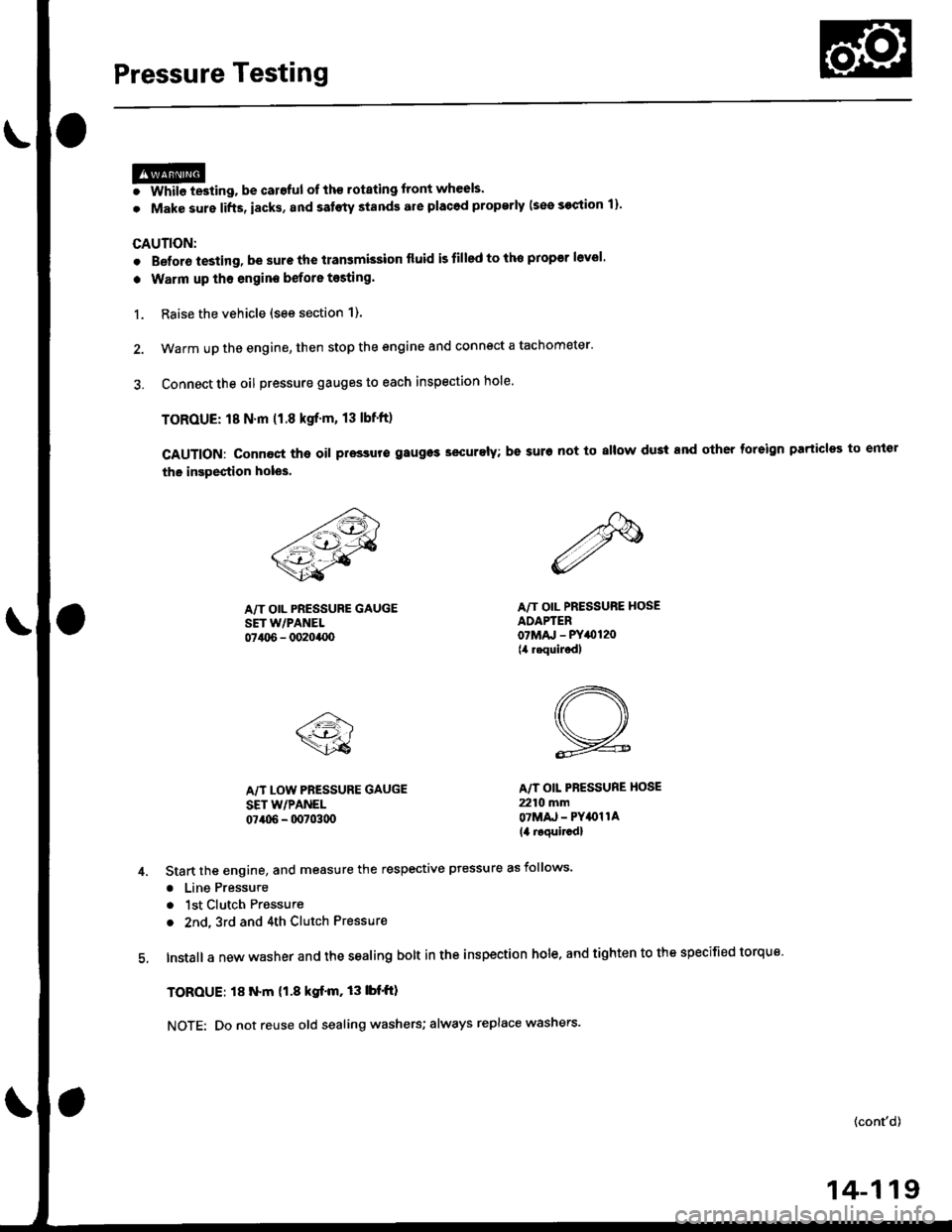

3. Connect the oil pressure gauges to each inspection hole.

TOROUE: 18 N.m (1.8 kgf'm, 13 lbnft)

cAUTloN: connact the oil pressuro gauges securely; be suro not to allow dust and other foreign Parlicles to entel

the inspestion holos'

A/T OIL PRESSURE GAUGESET w/PANEL07t06 - 0020400

A/T LOW PRESSURE GAUGE

SET WPANEL07406 - 0070300

A/T OIL PRESSURE HOSEADAPTER07Mru - PY0120(4 requiJedl

A/T OIL PBESSURE HOSE

2210 mmOTMAJ - PY4{)llA

14 roquircdl

Start the engine, and measure the respective ptessure as follows'

a Line Pressure

. 1st Clutch Pressure

. 2nd,3rd and 4th Clutch Pressure

Install a new washer and the sealing bolt in the inspection hole. and tighten to the specified torque'

TOROUE: l8 N.m (1.8 kgf'm,13lbf'ft)

NOTE: Do not reuse old sealing washers; always replace washers'

(cont'd)

14-119

Page 906 of 2189

TCM CONNECTOR B (22P}

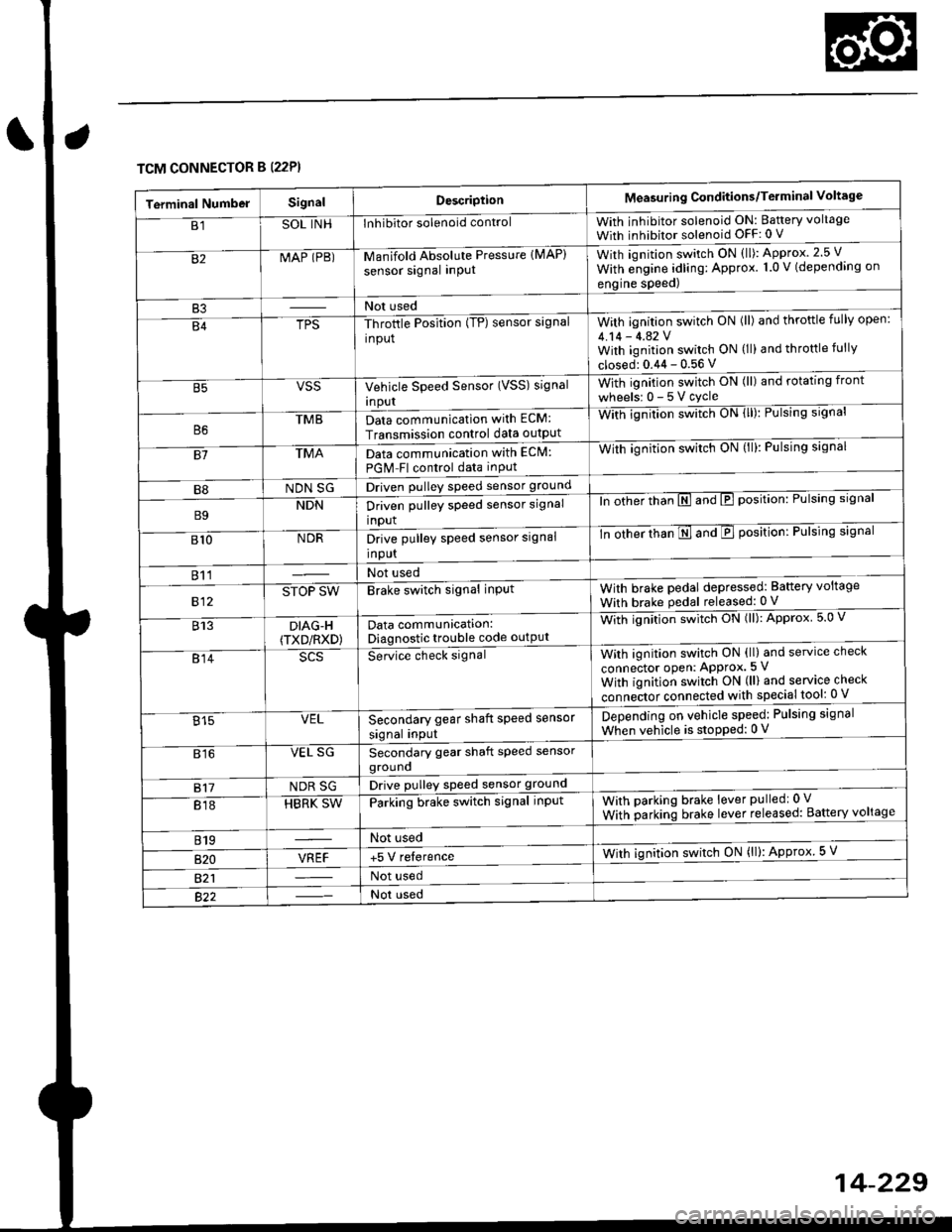

Terminal NumbelSignalDescriptionMeasuring Conditions/Terminal Voltage

B1SOL INHInhibitor solenoid controlWith inhibitor solenoid ON: Baftery voltage

With inhibitor solenoid OFF: 0 V

82MAP (PB)-M an if old Absol r-rte Pressure IMAP)

sensor signal inPUtWith iqnition switch ON (ll): Approx.2.5 V

With e;gine adling: Approx. 1.0 V (depending on

engine speed)

B3Not used

B4TPS-Throttle Position (TP) sensor signal

input

With ignition switch ON (ll) and throftle fully open:

4.14 - 4.42 VWith ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

VSSVehicle Speed Sensor (VSS) signal

Inpur

With ignition switch ON (ll) and rotating front

wheelsr 0-5Vcycle

TMBData communication with ECM:

Transmission control data outpUt

With ignilion swltch UN lll): rulslng slgnar

81TMAData communication with EClvl:

PGM Fl control data inPut

With ignition swltch uN {ll,: l-ulslng slgnal

B8NDN SGDriven pulley speed sensor ground

B9NDNDriven pulley speed sensor signal

input

ln other thTnE and E position: Pulsing signal

810NDRDrive pulley speed sensor signal

Input

-tn ottrer ttran E ana E position: Pulsing signal

811Not used

812STOP SWBrake switch signal inPutWith brake pedal depressed: Battery voltage

With brake pedal released: 0 V

813DIAG-H(TXD/RXD)Data communication:Diagnostic trouble code outPut

Wittr ignitio.r s*itct' ON (ll): Approx 5.0 V

814Se-ice ctrect signatWith ignition switch ON (ll) and service check

connector oPen: APProx.5 V

With iqnition switch ON (ll) and service check

"onn"itot. connect"d with special tool: 0 V

Secondary gear shaft speed sensor

signal input

Depending on vehicle speed: Pulsing signal

When vehicle is stoPped: 0 V815VEL

816VEL SGSecondary gear shaft speed sensorgrouno

817NDR SGDrive pulley speed sensor ground

818HBRK SWParking brake switch signal inPutWith parking brake lever pulledr 0 V

With parking brake lever released: Battery voltage

819Not used

B�20VREF+5 V relerenceWith ignition switch ON (ll): Approx 5 V

821Not used

Not used