Transmission fluid HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 786 of 2189

Mai nshaft/Cou ntershaft

Linear Solenoid AssemblySpeed Sensors

Replacement

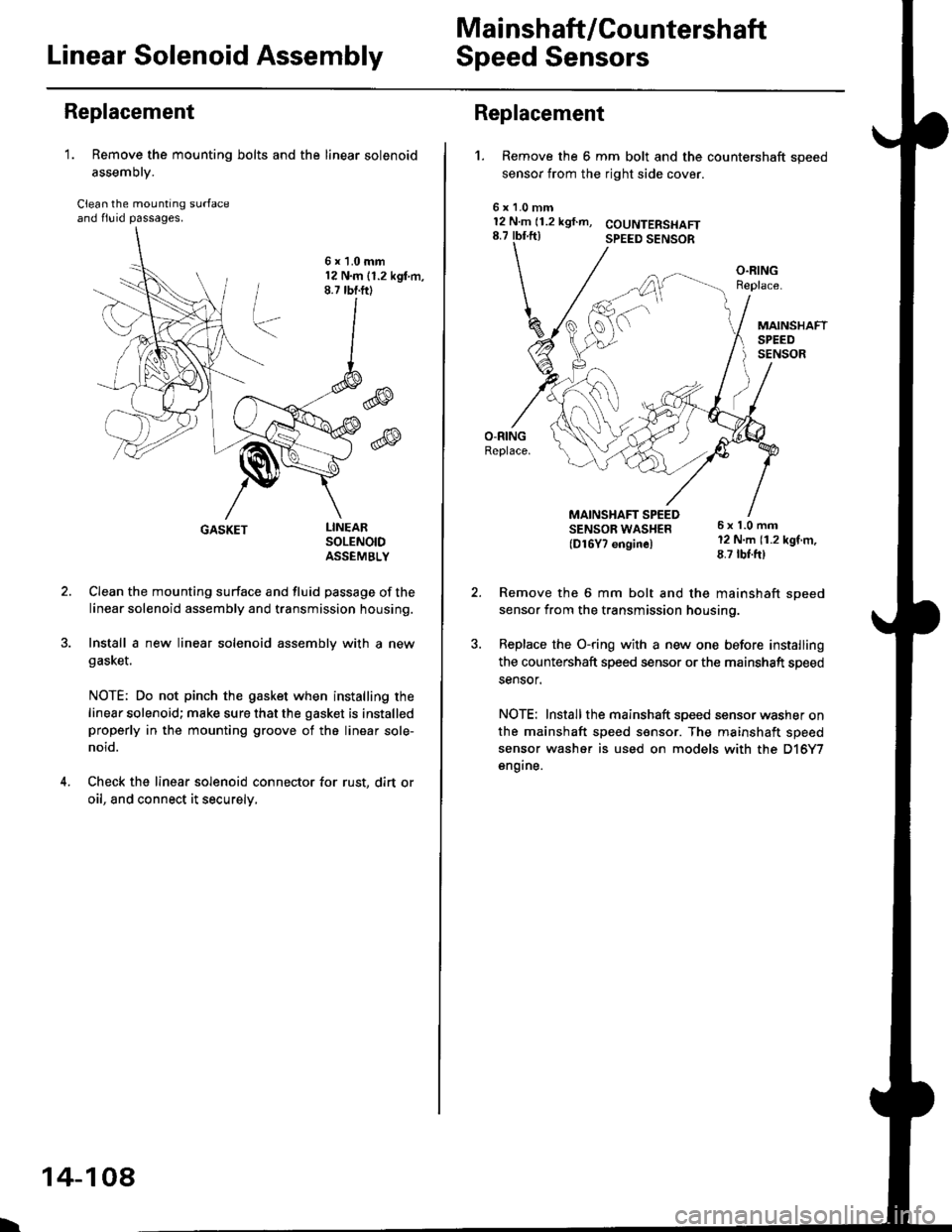

1. Remove the mounting bolts and the linear solenoid

assemory.

Clean the mounting surfaceand flu id passages.

6x1.0mm12 N.m 11.2 kgl m,8.7 tbf.ftl

@

@

GASKET

Clean the mounting surface and fluid passage of the

linear solenoid assembly and transmission housing.

Install a new linear solenoid assembly with a new

gasl(et.

NOTE; Do not pinch the gasket when installing the

linear solenoid; make sure that the gasket is installedproperly in the mounting groove of the linear sole-

noid.

Check the linear solenoid connector for rust, dirt or

oil, and connect it securely,

LINEARSOLENOIDASSEMELY

I

14-108

Replacement

't.

6x128.7

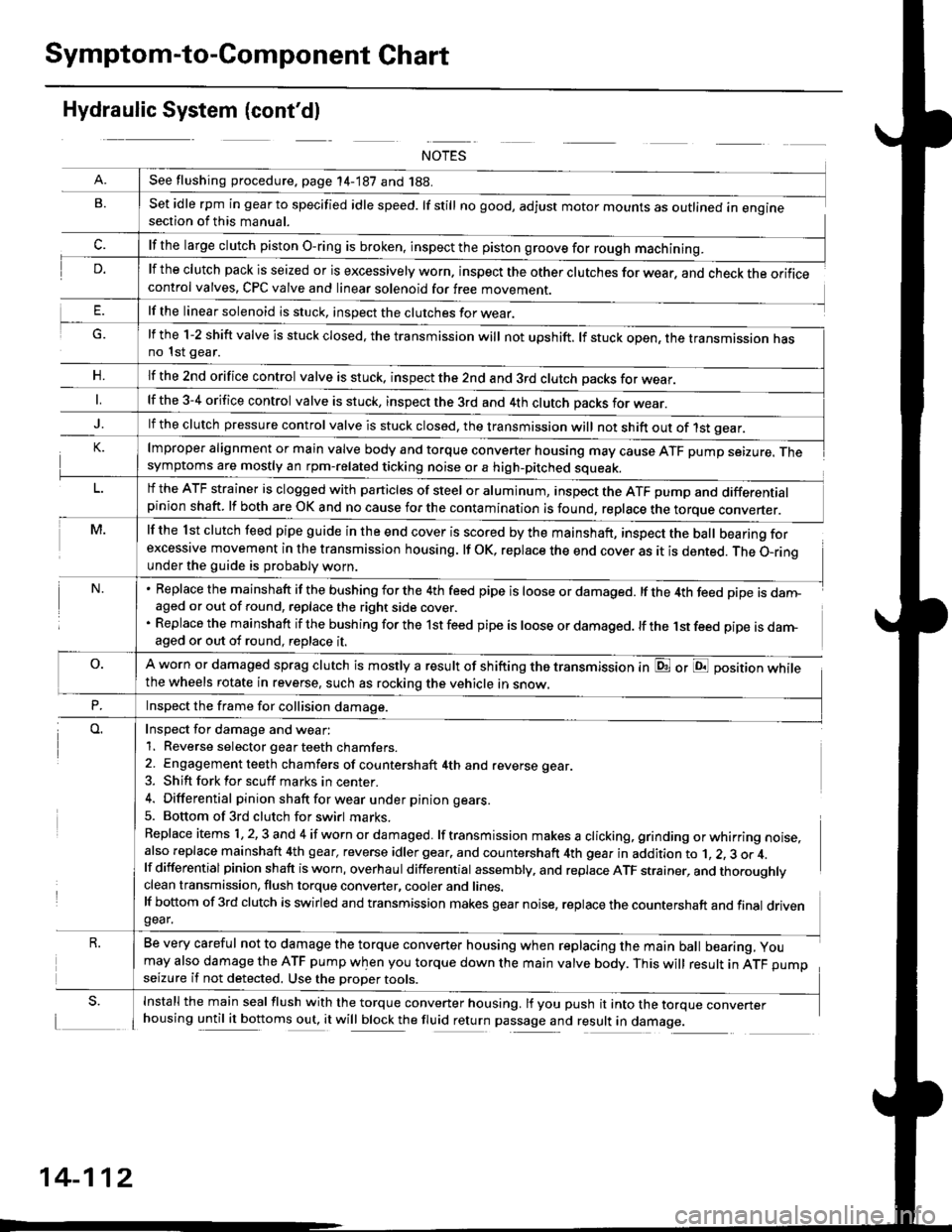

Remove the 6 mm bolt and the countershaft speed

sensor from the right side cover.

COUNTERSI{AFTSPEED SENSOR

O.RINGReplace.

MAINSHAFTSPEEDSENSOR

MAINSHAFT SPEEDSENSOB WAS}IER(D16Y7 enginel

6x1.0mm12 N.m (1.2 kgf m,8.7 tbf.ft)

1.0 mmN.m (1.2 kgf.m,rbf ft)

\\

/,

%/E:)

Remove the 6 mm bolt and the mainshaft sDeed

sensor from the transmission housino.

Replace the O-ring with a new one before installing

the countershaft speed sensor or th€ mainshaft speed

sensor.

NOTE: Installthe mainshaft speed sensor washer on

the mainshaft speed sensor. The mainshaft speed

sensor washer is used on models with the D'|6Y7

engine.

Page 790 of 2189

Symptom-to-Component Chart

Hydraulic System (cont'dl

G.

n,

set idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

lf the clutch pack is seized or is excessively worn. inspect the other clutches for wear, and check the orificecontrol valves, CPC valve and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lmproper alignment or main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

lf the l st clutch feed pipe guide in the end cover is scored by the mainshaft, inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged. lf the 4th feed pipe is danFaged or out of round, replace the right side cover.

Replace the mainshaft if the bushing for the 1st feed pipe is loose or damaged. lf the 1st feed pipe is darn-aged or out of round, replace it.

A worn or damaged sprag clutch is mostly a result of shifting the transmission inthe wheels rotate in reverse, such as rocking the vehicle in snow.

or E position while

Inspect for damage and wear:

1. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear u nder pin ion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1,2,3 and 4 if worn or damaged. lf transmission makes a clicking, grinding orwhirring noise,also replace mainshaft 4th gear, reverse idler gear. and countershaft 4th gear in addition to 1, 2, 3 or 4.lf differential pinion shaft is worn, overhaul differential assembly, and replace ATF strainer, and thoroughlyclean transmission, flush torque converter, cooler and lines.lf bottom of 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and final drivengear.

Be very careful not to damage the torque converter housing when replacing the main ball bearing, you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the oroper roors.

Install the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

See flushing procedure, page 14-187 and 188.

lf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

lf the l-2 shift valve is stuck closed, the transmission will not upshift. lf stuck open, the transmission hasno 1st gear.

lf the znd orifice control valve is stuck. inspect the 2nd and 3rd clutch oacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch oacks for wear.

lf the clutch pressure control valve is stuck closed, the transmission will not shift out of 1st gear.

lf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Inspect the frame for collision damage.

14-112

Page 794 of 2189

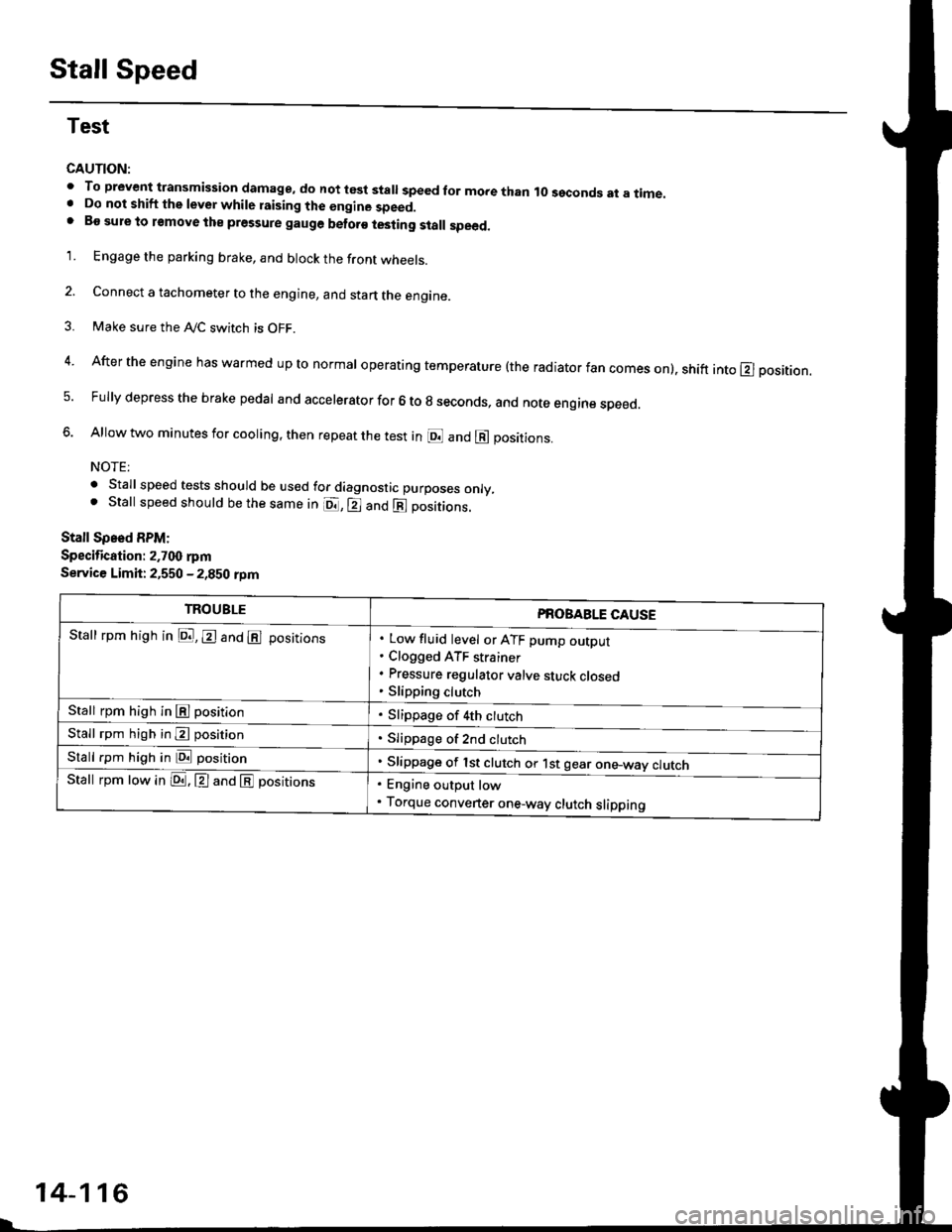

Stall Speed

Test

CAUTION:

. To prev€nt transmission damage, do not t6st stall speed for more than ro sgconds at a time.. Do not shift the levor while raising the engine speed.. Bo sule lo remove the pressure gauge betoro testing stall speed.

'1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the Ay'C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on). shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to g seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in @ and @ positions.

NOTE:

. Stall speed tests should be used for diagnostic purposes only,. Stall speed should be the same in o., E and E positions.

Stall Spsed RPM:

Specification: 2.700 rpm

Service Limit: 2,550 - 2,850 rDm

TROUBLEPROBABLE CAUSE

. Low fluid level or ATF pump outDur. Clogged ATF strainer. Pressure regulator valve sluck closeo. Slipping clutch

. Slippage of 4th ctutch

. Slippage of 2nd clutch

. Slippage of lst clut"tr or. t"t g""io*-*"y "lut"h

Stall rpm high in D., E and E positions

Stall rpm high in El position

Stall rpm high in E posirion

Stall rpm high in E position

Stall rpm low in LDa . El and E positrons. Engine output low. Torque converter one-way clutch slipping

14-116

Page 795 of 2189

Fluid Level

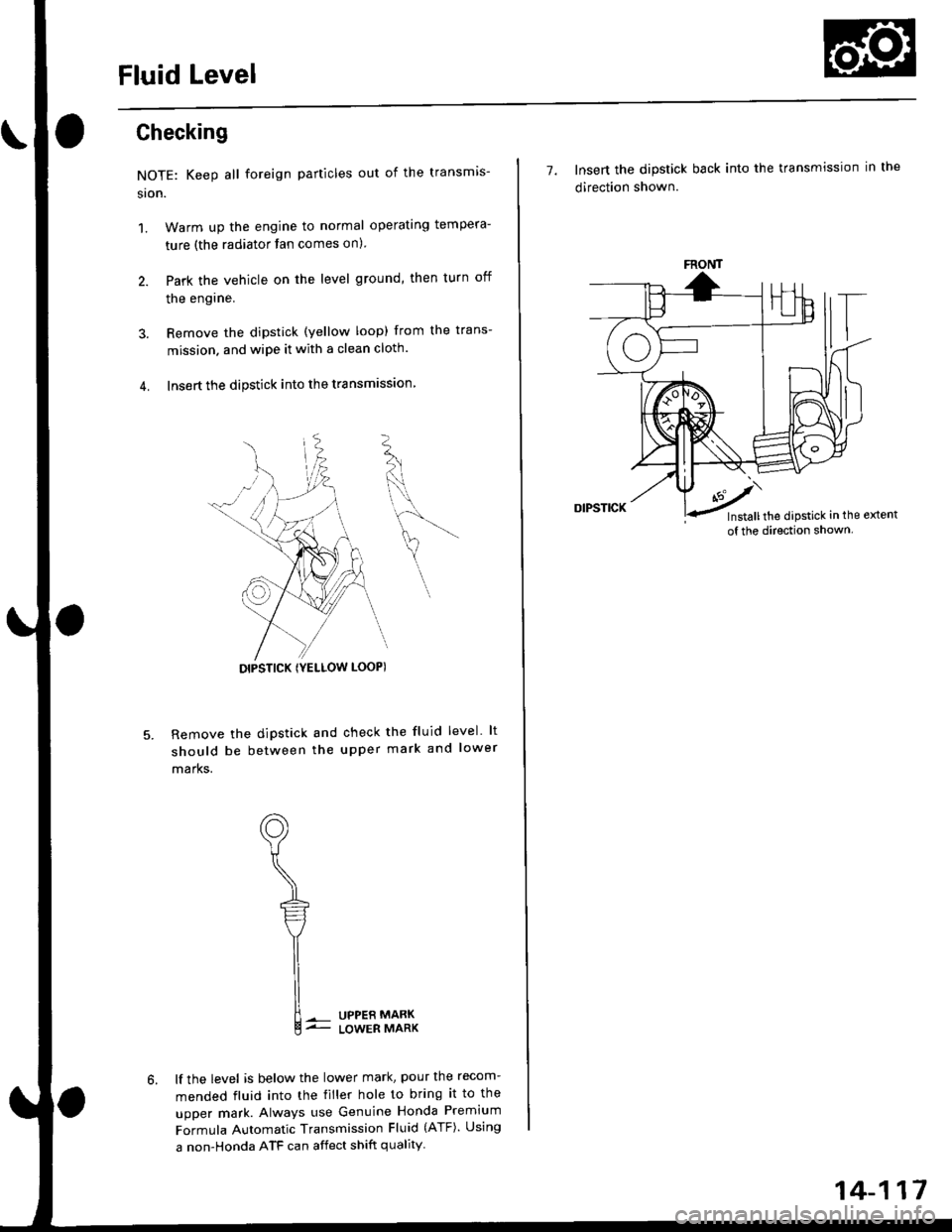

Ghecking

NOTE: Keep all foreign particles out of the transmis-

sron.

1.Warm up the engine to normal operating tempera-

ture (the radiator fan comes on)

Park the vehicle on the level ground, then turn off

the engrne.

Remove the dipstick (yellow loop) from the trans-

mission. and wipe it with a clean cloth.

Insert the dipstick into the transmrssron

Remove the dipstick and check the fluid level lt

should be between the upper mark and lower

marks.

UPPER MABKLOWER MARK

lf the level is below the lower mark, pour the recom-

mended fluid into the tiller hole to bring it to the

upper mark. Always use Genuine Honda Premium

Formula Automatic Transmission Fluid (ATF). Using

a non-Honda ATF can affect shift quality

K

L

DIPSTICK IYELLOW LOOPI

7. Insert the dipstick back into the transmission in the

direction shown.

FRONT

Installthe dipstick in the extent

of the direction shown.

14-117

Page 796 of 2189

Fluid Level

Changing

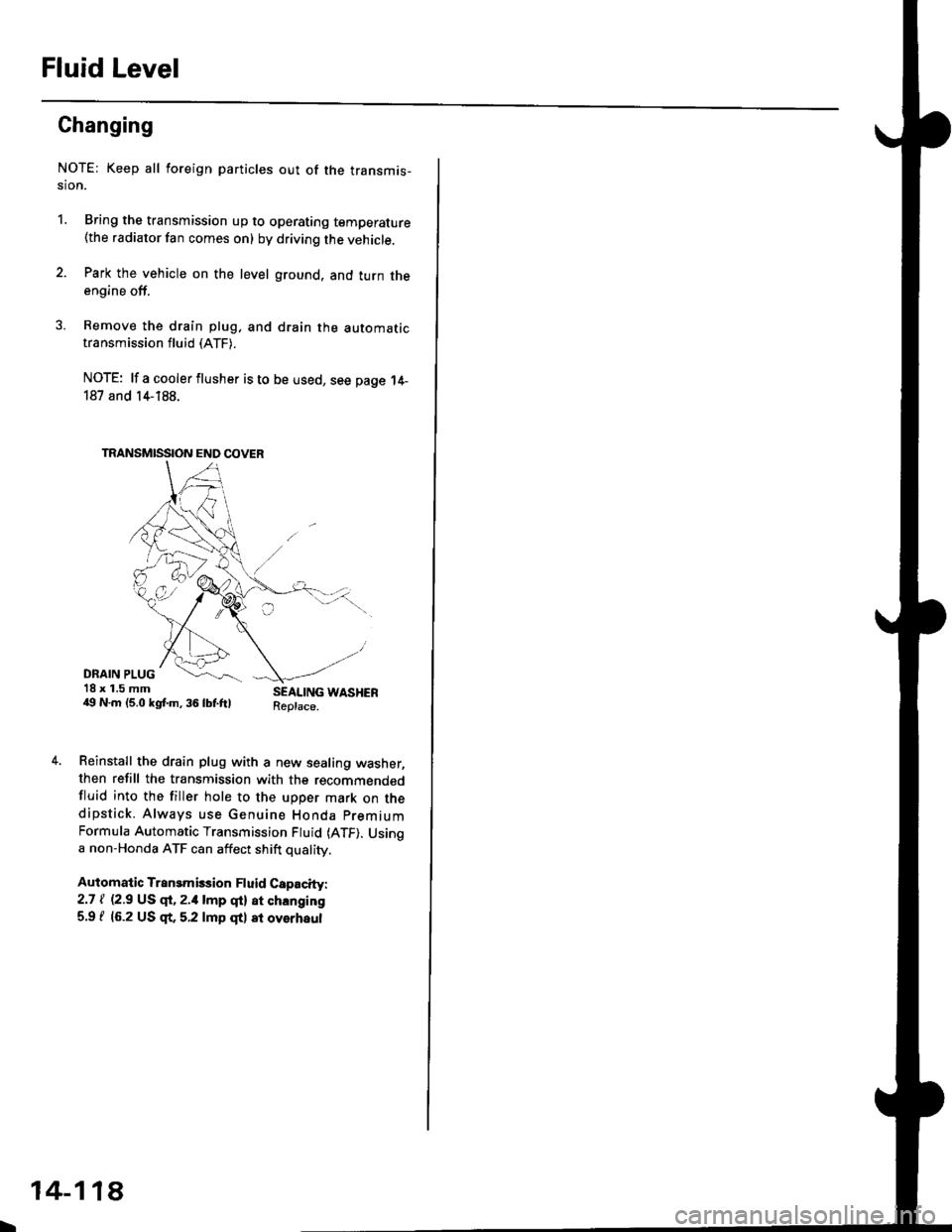

NOT€: Keep all foreign particles out of the transmis-sion.

'1.Bring the transmission up to operating temperature(the radiator fan comes on) by driving the vehicle.

Park the vehicle on the level ground, and turn theengine off.

Remove the drain plug. and drain the automatictransmission fluid (ATF).

NOTE: lf a cooler flusher is to be used, see page 14-187 and 14-188.

TRANSMISgION END OOVER

DNAIN PLUG18 x 1.5 mm49 N.m (5.0 kgtm, 36lbf.ftlSEALING WASHERReplace.

Reinstall the drain plug with a new sealing washer,then refill the transmission with the recommended

fluid into the filler hole to the upper mark on thedipstick. Always use Genuine Honda premium

Formula Automatic Transmission Fluid (ATF). Usinga non-Honda ATF can aftect shift quality.

Automatic Transmission Fluid Capacity:

2.7 | |'2.9 US ql,2.a lmp qtl at Ghlnging

5.9 f 16.2 US qt. 5.2 lmp qt) at overhaul

I

14-11A

Page 797 of 2189

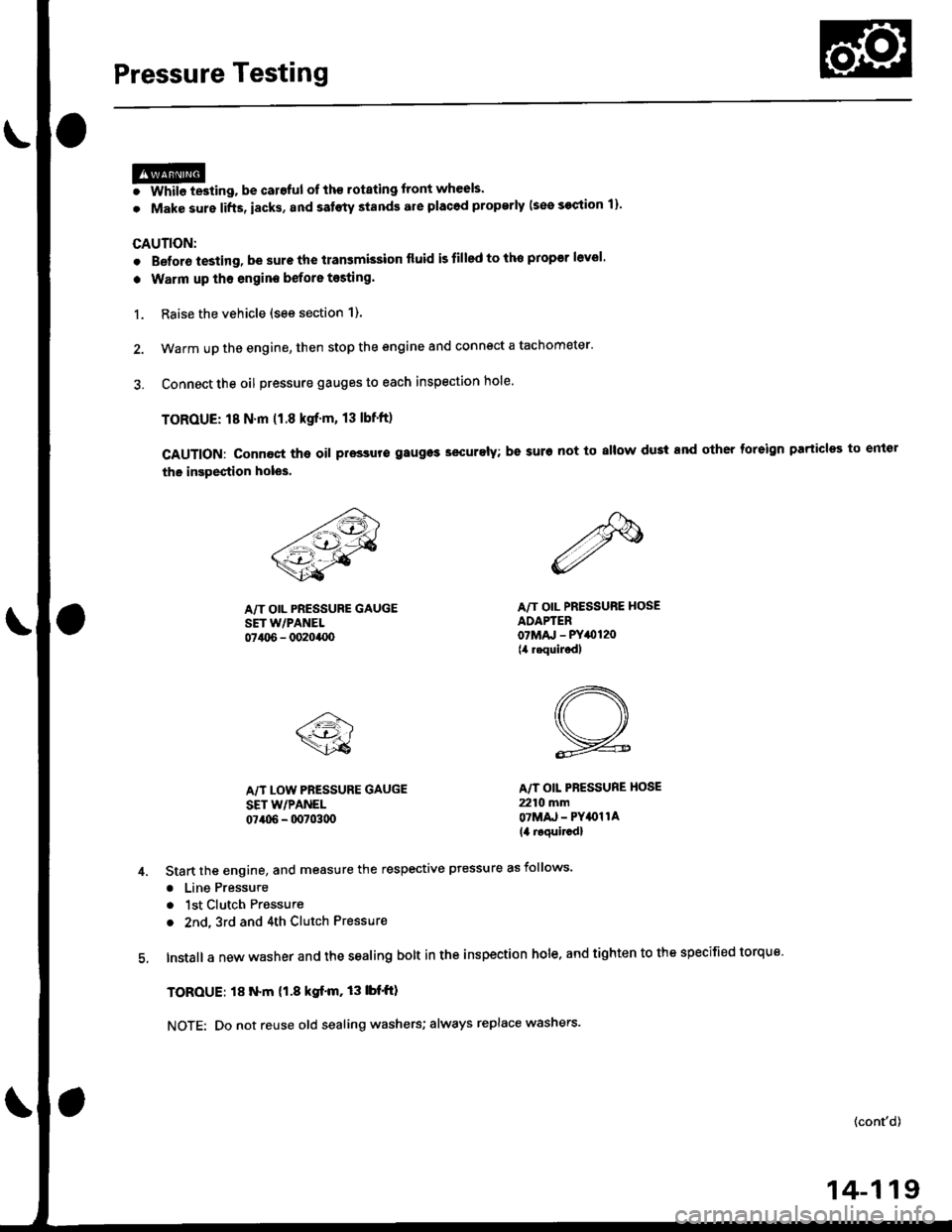

Pressure Testing

@I While testing, be caroful of th€ rotating front wheels.

. Make sure lifts, iacks, and satoty stands are placod properly (see section 1)'

CAUTION:

. Beforo iesting, be sure the transmission fluid is tilled to tho proper level'

. Warm up tho engine before testing'

1. Raise the vehicle (see section 1).

2. Warm up the engine, then stop the engine and connect a tachometer'

3. Connect the oil pressure gauges to each inspection hole.

TOROUE: 18 N.m (1.8 kgf'm, 13 lbnft)

cAUTloN: connact the oil pressuro gauges securely; be suro not to allow dust and other foreign Parlicles to entel

the inspestion holos'

A/T OIL PRESSURE GAUGESET w/PANEL07t06 - 0020400

A/T LOW PRESSURE GAUGE

SET WPANEL07406 - 0070300

A/T OIL PRESSURE HOSEADAPTER07Mru - PY0120(4 requiJedl

A/T OIL PBESSURE HOSE

2210 mmOTMAJ - PY4{)llA

14 roquircdl

Start the engine, and measure the respective ptessure as follows'

a Line Pressure

. 1st Clutch Pressure

. 2nd,3rd and 4th Clutch Pressure

Install a new washer and the sealing bolt in the inspection hole. and tighten to the specified torque'

TOROUE: l8 N.m (1.8 kgf'm,13lbf'ft)

NOTE: Do not reuse old sealing washers; always replace washers'

(cont'd)

14-119

Page 801 of 2189

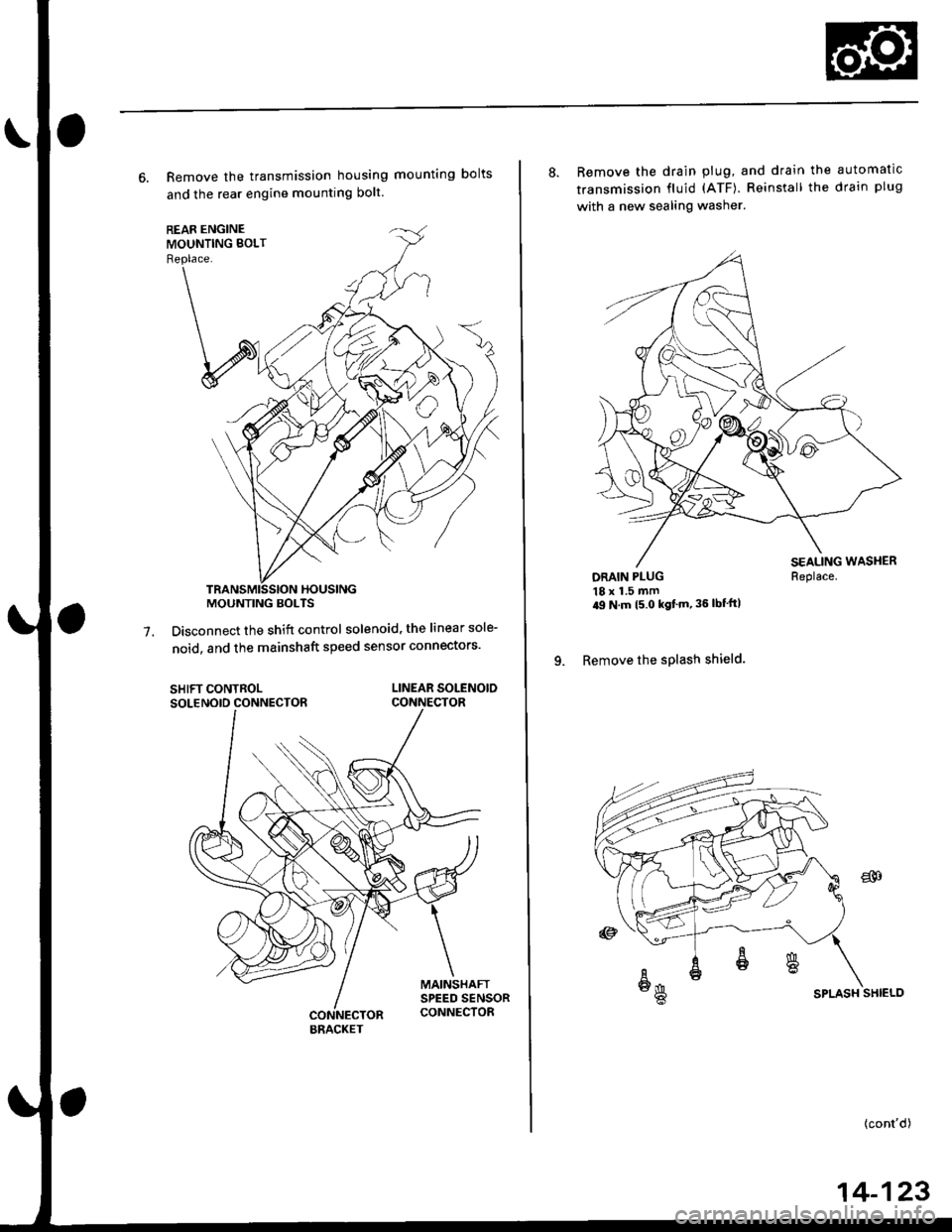

6. Remove the transmission housing mounting bolts

and the rear engine mounting bolt.

Disconnect the shift control solenoid, the linear sole-

noid, and the mainshaft speed sensor connectors'7.

SHIFT CONTROLSOLENOID CONNECTORLINEAR SOLENOIDCONNECTOR

MOUNTING BOLTS

BRACKET

8. Remove the drain plug, and drain the automatic

transmission fluid (ATF). Reinstall the drain plug

with a new sealing washer.

DRAIN PLUG18 x 1.5 mm'9 N m t5 o kgf'm' 36 lbf'ft|

9. Remove the splash shield.

Replace.

SPLASH SHIELD

{cont'd)

14-123

Page 864 of 2189

Transmission

Installation {cont'd)

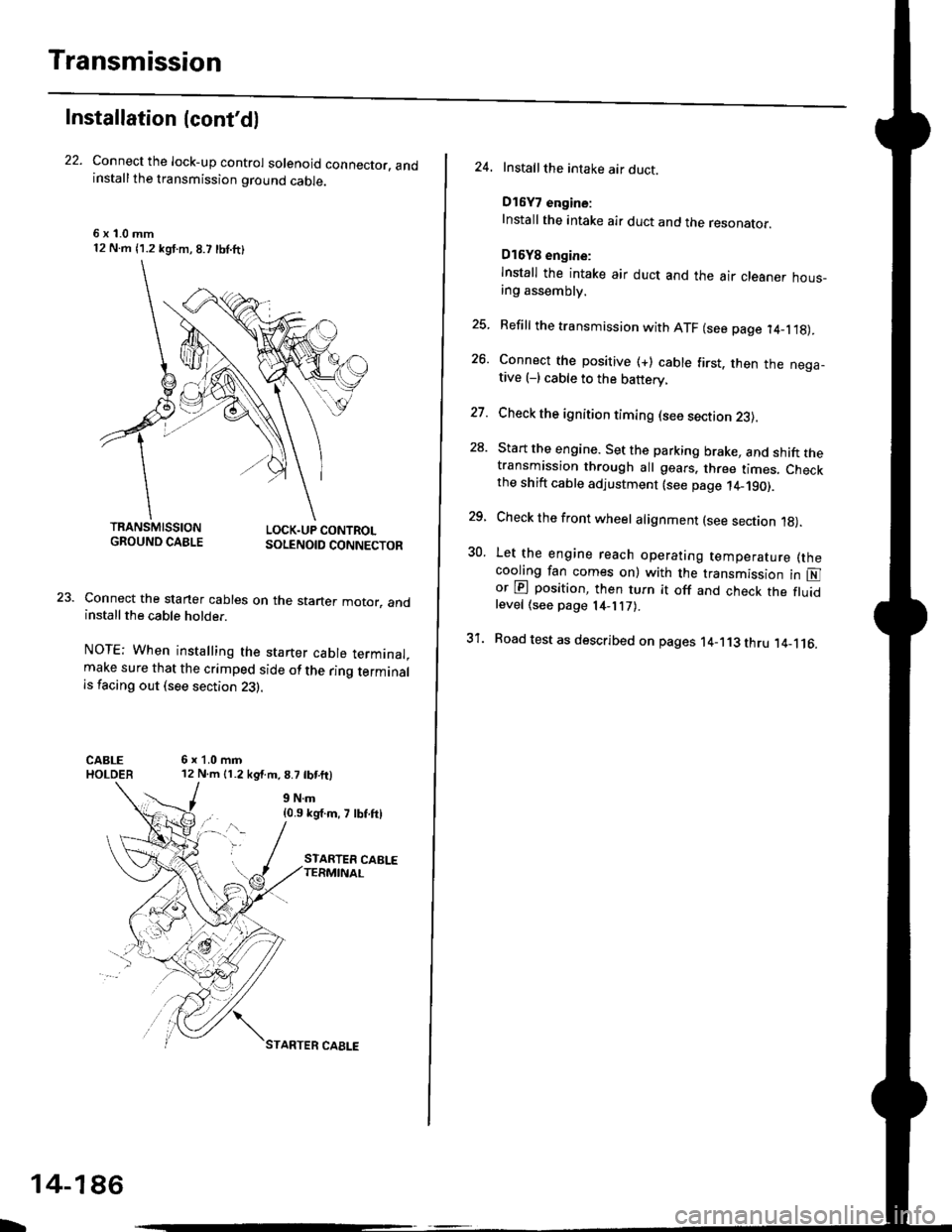

Connect the lock-up control solenoid connector. andinstall the transmission ground cable.

6 x '1.0 mm12 N.m {1.2 kgf.m, 8.7 lbl.ft}

LOCK.UP CONTROLSOLENOID CONNECTOR

Connect the staner cables on the staner motor. andinstall the cable holder.

NOTE; When installing the starter cable terminal.make sure that the crimped side of the ring terminalis facing out (see section 23).

6x1.0mm12 N.m 11.2 kg{.m.8.7 tbtftl

{0.9 kg'f.m, 7 lbf.ftl

TRANSMISSIONGROUND CABLE

b

14-186

STARTER CAELE

24. Installthe intake air duct.

D16Y7 engine:

Install the intake air duct and the resonaror.

D16Y8 engine:

lnstall the intake air duct and the air cleaner hous_ang assembly.

25. Refill the transmission with ATF (see page 14_1.18).

26. Connect the positive (+) cable first. then the nega-tive (-) cable to the battery.

27. Check the ignition timing (see section 23).

28. Start the engine. Set the parking brake, and shift thetransmission through all gears. three times. Checkthe shift cable adjustment (see page 14_190).

29, Check the front wheel alignment (see section 1g).

30. Let the engine reach operating temperature (thecooling fan comes on) with the transmission in Nor @ position, then turn it off and check the fluidlevel (see page 14- 7).

31. Road test as described on pages 14-113 thru ,14_116.

Page 865 of 2189

Cooler Flushing

!!!@ To prevent iniury to. face and eyas, always

-ea. safetv glasses ot a face shield when using the

transmission flusher.

NOTE: This procedure should be performed before rein-

stalling the transmission.

1. Check the tool and hoses for wear and cracks before

using. lf wear or cracks are found, replace the hoses

before using.

Using the measuring cup, fill the tank with 2'l ounces

(approximately 2/3 full) of biodegradable flushing

fluid (J35944 - 20). Do not substitute with any other

fluid. Follow the handling procedure on the fluid

contarner.

Secure the flusher filler cap, and pressurize the tank

with compressed air to between 550 - 829 kpa (5 6 -

8.45 kgflcm'�. 80 - 120Psi).

NOTE: The air line should be equipped with a water

trap to ensure a dry air system.

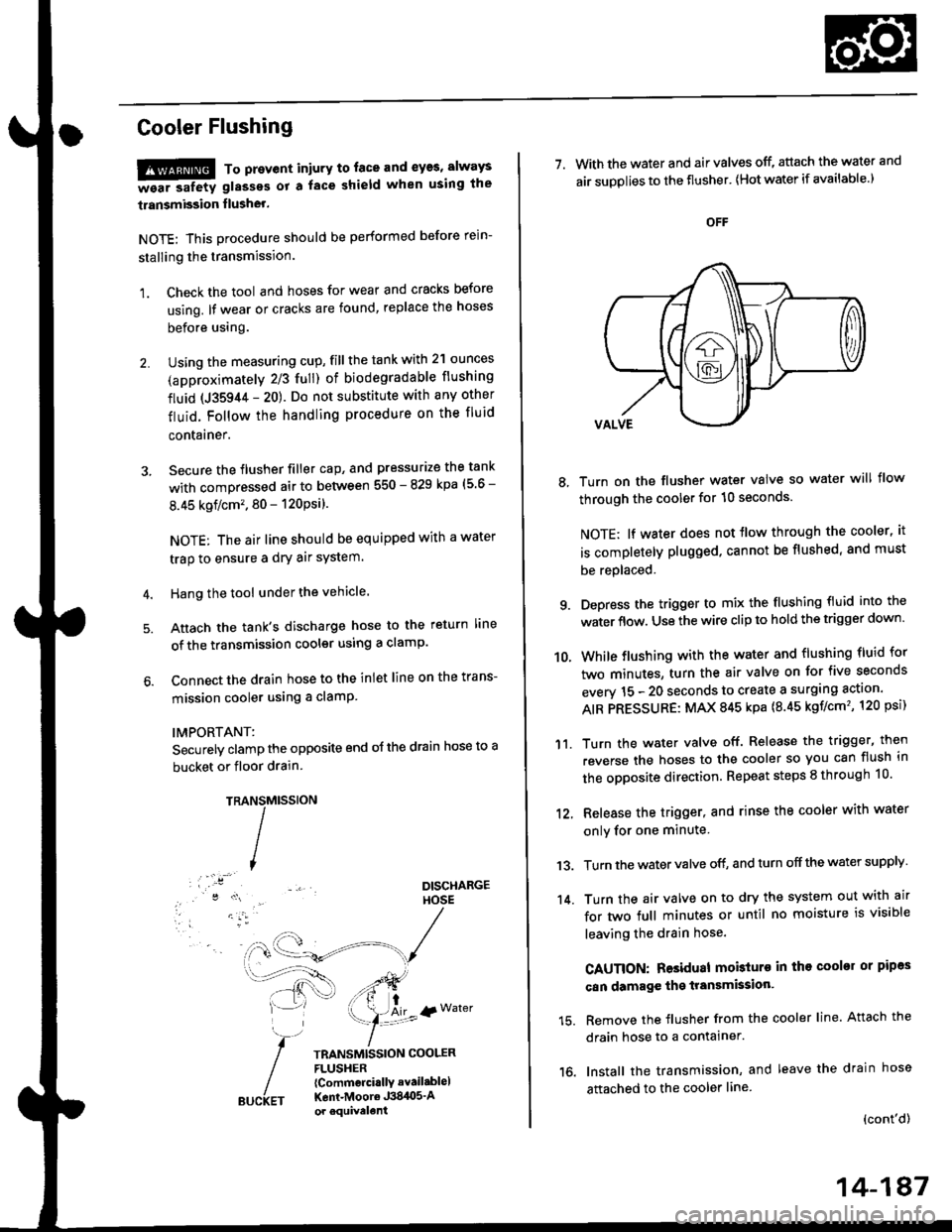

Hang the tool under the vehicle.

Attach the tank's discharge hose to the return line

of the transmission cooler using a clamp.

Connect the drain hose to the inlet line on the trans-

mission cooler using a clamP

IMPORTANT:

Securely clamp the opposite end oJ the drain hose to a

bucket or floor drain.

TRAMtssroN

TRANSMISSION COOLERFLUSHER{Commcrci.llY avail.blel

Kent-Moore J384O5'Aor equivelent

NS

I

{r Water

7. With the water and air valves off, attach the water and

air suDolies to the flusher' lHot water if available.)

8, Turn on the flusher water valve so water will flow

through the cooler for 10 seconds.

NOTE; lf water does not tlow through the cooler, it

is completely plugged. cannot be flushed, and must

be replaced.

9. Depress the trigger to mix the flushing fluid into the

water flow. Use the wire clip to hold the trigger down'

While flushing with the water and flushing fluid for

two minutes, turn the air valve on for five seconds

everv 15 - 20 seconds to create a surging action'

AIR PRESSURE: MAX 845 kpa {8.45 kgf/cm'�, 120 psi)

Turn the water valve off. Release the trigger, then

reverse the hoses to the cooler so you can flush in

the opposite direction. Repeat steps 8 through 10'

12, Release the trigger, and rinse the cooler with water

onlv for one minute

13. Turn the water valve off, and turn off the water supply

14. Turn the air valve on to dry the system out with air

for two full minutes or until no moisture is visible

leaving the drain hose.

CAUTION: Residual mobturo in tho cooler or pipas

can damage the transmksion'

15. Remove the flusher from the cooler line. Attach the

drain hose to a contalner.

16. Install the transmission, and leave the drain hose

attached to the cooler line

{cont'd)

10.

'11.

14-187

Page 866 of 2189

Transmission

17.

Cooler Flushing (cont'dl

Make sure the transmission is in the E position.

Fill the transmission with ATF, and run the enginefor 30 seconds or until approximately 0.95 f (1.0 USqt.,0.8 lmp qt.) is discharged.

Remove the drain hose, and reconnect the coolerreturn hose to the transmission (see page l4-192).

Refill the transmission with ATF to the oroDer level(see page 14-118).

18.

19.

b

14-18A

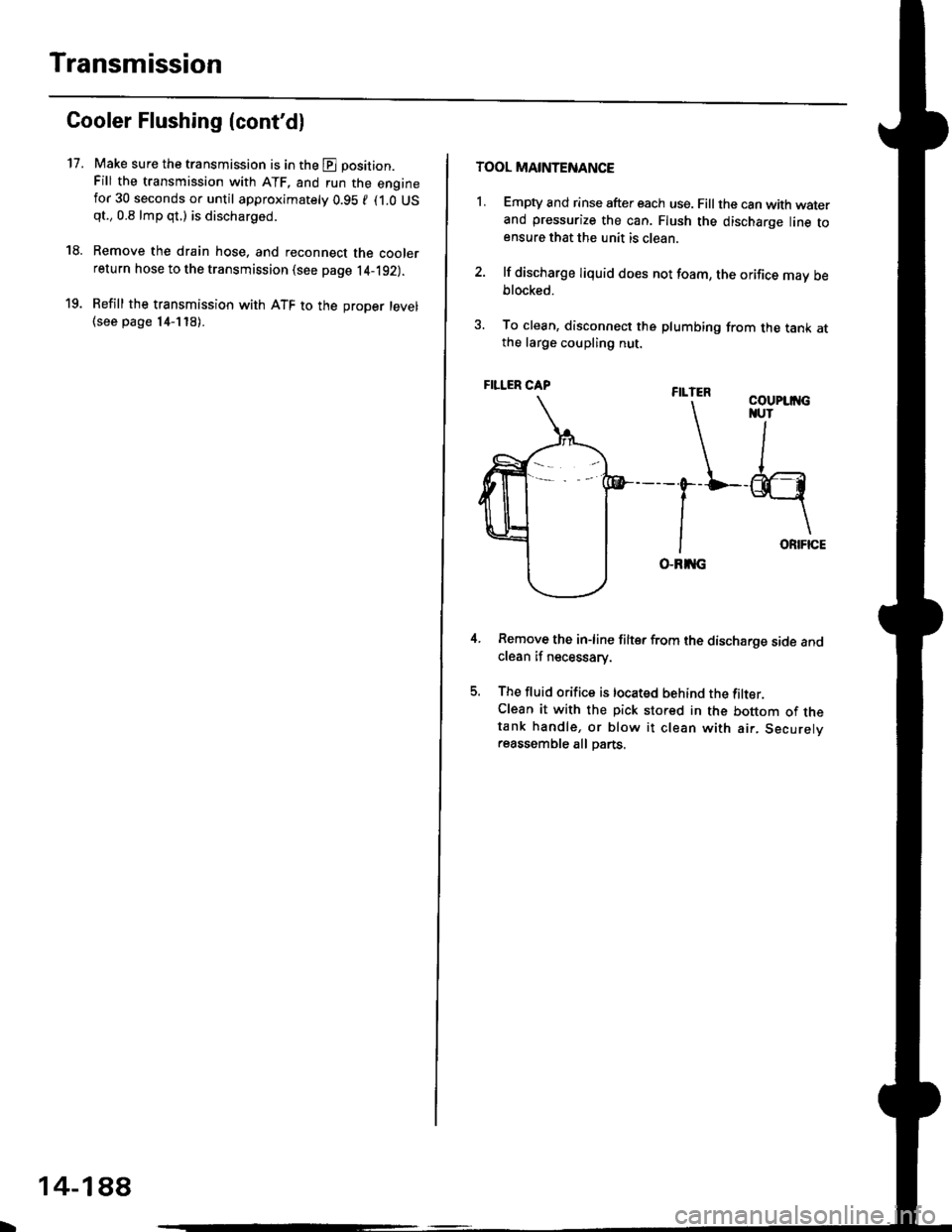

TOOL MAINTENANCE

1. Empty and rinse after each use. Fill the can with waterand pressurize the can. Flush the discharge line toensure that the unit is clean.

2. lf discharge liquid does not foam, the orifice may beblocked.

3. To clean, disconnect the plumbing from the tank atthe large coupling nut.

ORIFICE

GRT{G

Remove the in-line filter from the discharge side andclean if necessary.

The fluid orifice is tocated behind the filter.Clean it with the pick stored in the bottom of thetank handle, or blow it clean with air. Securelvreassemble all Darts.

FILLER CAP