charging system HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1468 of 2189

Condenser

Replacement

1.Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271.

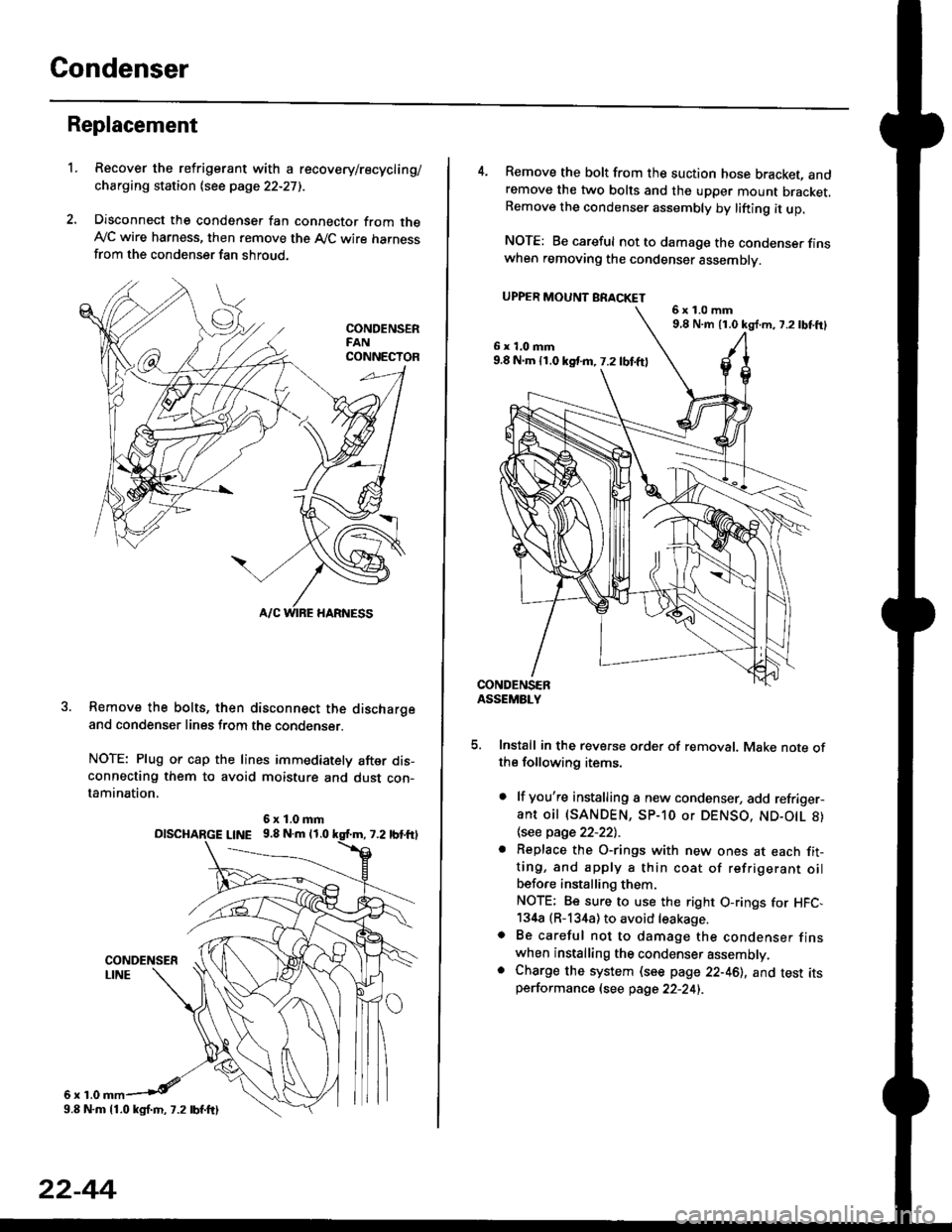

Disconnect the condenser fan connector from theAy'C wire harness, then remove the A,/C wire harnessfrom the condenser fan shroud.

Remove the bolts, then disconnect the dischargeand condenser lines from the condenser.

NOTE: Plug or cap the lines immediately after dis-connecting them to avoid moisture and dust con-tamination,

6r1.0

6x1.0mmolscHARGE L|NE 9.8 N.m 11.0

9.8 N.m 11.0 kgl.m, 7.2 lbf.ftl

22-44

4. Remove the bolt from the suction hose bracket, andremove the two bolts and the upper mount bracket.Remove the condenser assembly by lifting it up.

NOTE: Be careful not to damage the condenser finswhen removing the condenser assembly.

UPPER MOUNT BRACKET

5. Install in the reverse order of removal. Make note ofthe following items.

. lf you're installing a new condenser, add refriger-ant oil (SANDEN, SP-10 or DENSO, ND-O|L 8)

\see page 22-22l.-

. Replace the O-rings with new ones at each fit-ting, and apply a thin coat of refrigerant oilbefo.e installing them.

NOTE; Be sure to use the right O-rings for HFC,134a (R-134a) to avoid leakage.o Be careful not to damage the condenser finswhen installing the condenser assembly.. Charge the system (see page 22-46), and test itsperformance (see page 22-24i.

6x1.0mm9,8 N.m 11.0 kg{.m, 7.2lbtft}

6x1.0mm9.8 N.m 11.0 kst m, 7.2 lbf.ftl

Page 1469 of 2189

A/C System Service

Evacuation

Use only service equipment that is U L.-listed and is cer-

tified to meet the requirements oJ SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system'

CAUTION: Exposure to air conditioner reftig€lant and

lubricant vapor or misi can irrhaie eyes. noso and throat'

Avoid breathing the ail condhioner lefrigelant and lubri

cant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming servace.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comDressed air.

!!@@ some mixtures of air and R-13'[8 haYo boon

ffiiE-n to be "ombustible at elovatod pressurcs and can

result in fire or explosion causing iniury or propsrtY

damag€. Never uso complsssod air to pre3surs tost R-

1344 ssrvico equipment or vehicle air conditioner sy3-

tems,

Additional health and safety information may be obtained

from the refrigerant and lubricant manuJacturers'

When an A,/C System has been opened to the atmo-

sphere, such as during installation or repair, it must

be evacuated using a R-134a refrigerant recovery/

recycling/charging station. (lf the system has been

open for several days, the receiver/dryer should be

replaced, and the system should be evacuated for

several hours.)

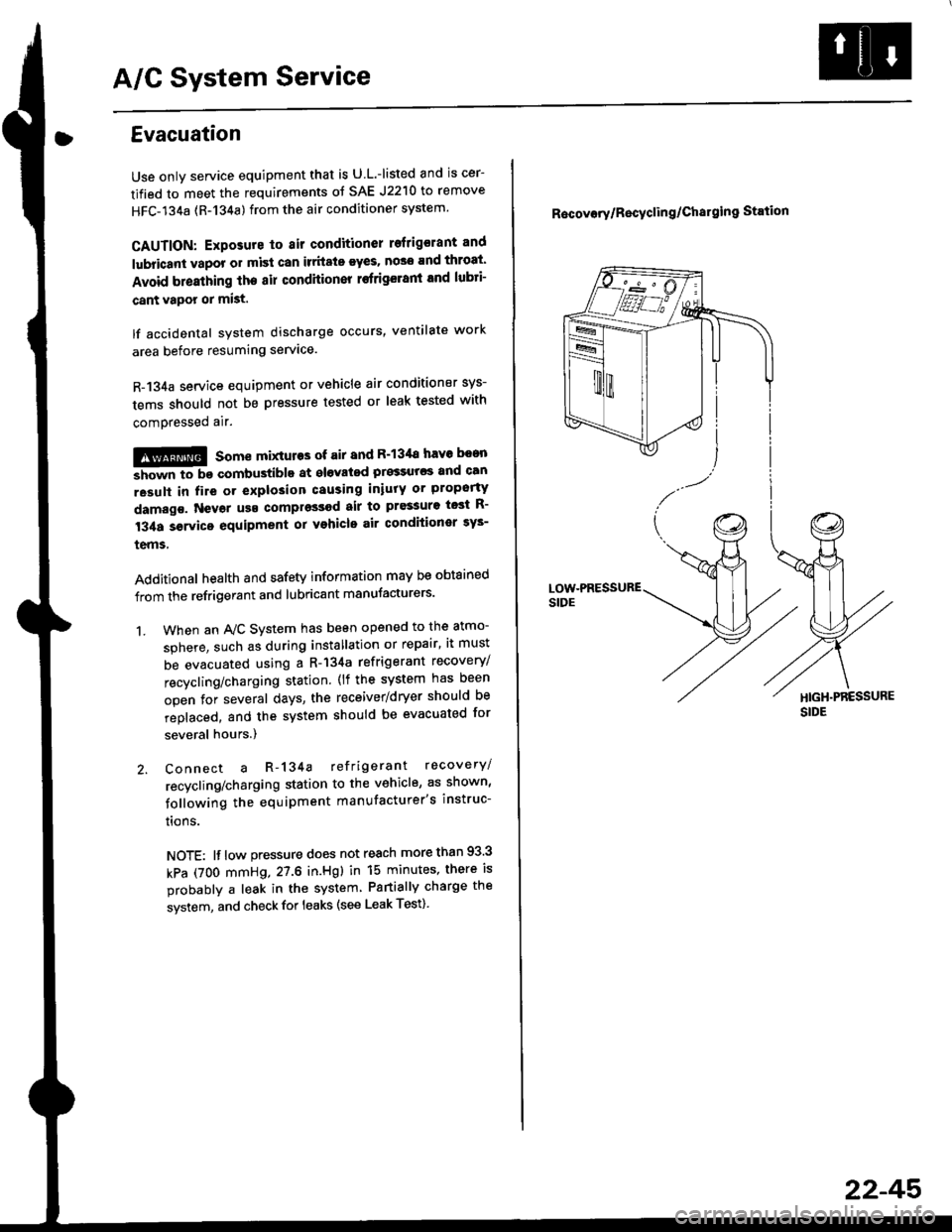

Connect a R-134a refrigerant recovery/

recycling/charging station to the vehicle, as shown'

following the equipment manufacturer's instruc-

trons.

NOTE: lf low pressure does not reach more than 93 3

kPa (7OO mmHg,27.6 in.Hgl in 15 minutes, there is

probably a leak in the system Partially charge the

system, and check for leaks (see Leak Test)

1.

R6covory/Recyclin g/Chal9ing Station

22-45'

Page 1470 of 2189

A/C System Service

Charging

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritale eyes, nose and

throat. Avoid breathing the air conditioner retrigerant

and lubricant vaoor or mist,

lf accidental system discharge occurs, ventilate workarea before resuming service, Additional health and

safety information may be obtained from the refrigerant

and lubricant manufacturers.

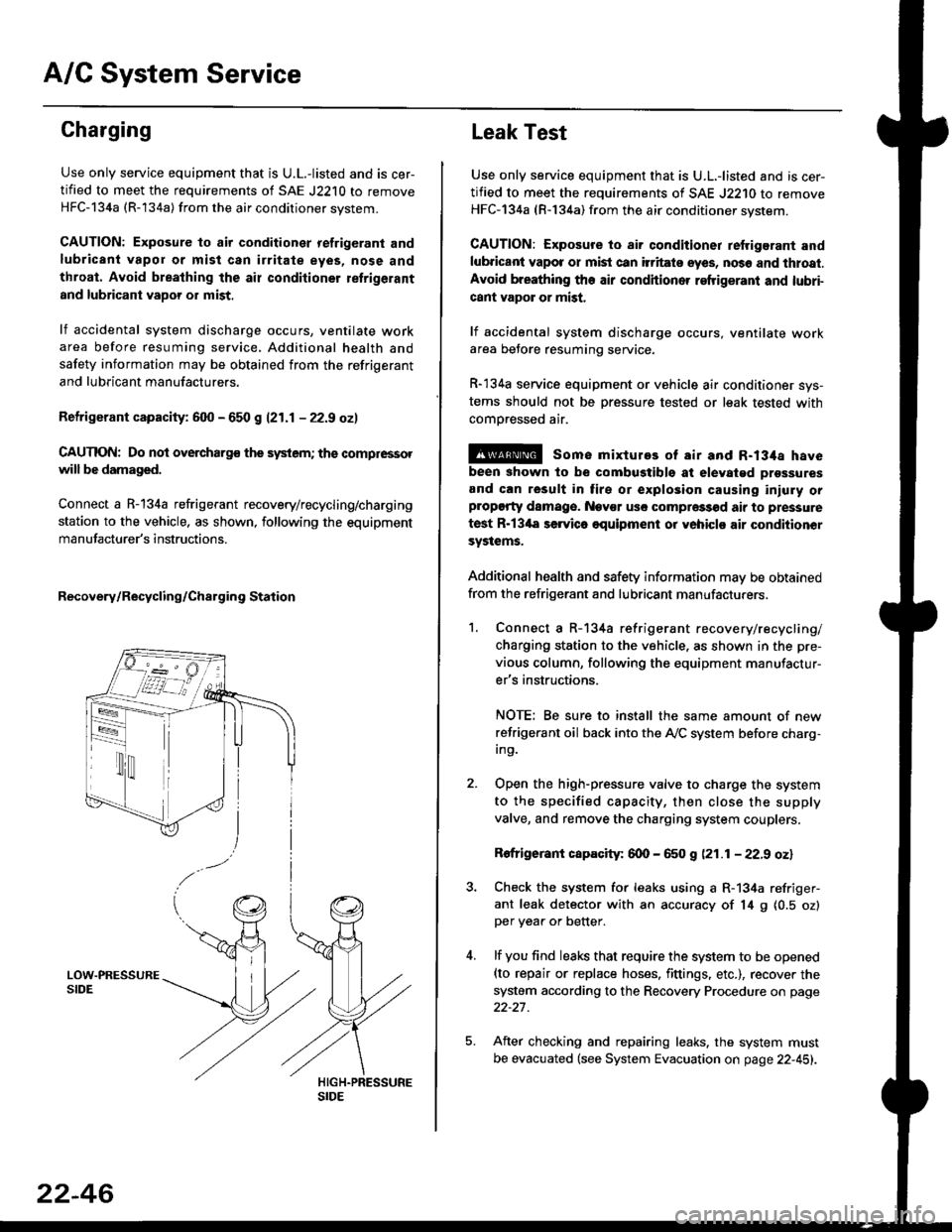

Refrigerant capacityt 600 - 650 g 121.1 - 22.9 ozl

CAUnON: Do not overcharg€ the system; the comprcssor

will be damaged.

Connect a R-134a refrigerant recovery/recycling/charging

station to the vehicle, as shown, following the equipment

manufacturer's instructions.

Recovery/Recycling/Charging Station

22-46

Leak Test

Use only service equipment that is U.L,-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure io air conditioner refrigerant and

lubricant vapot or mist can itritats eyes, no36 and thtoat.

Avoid breathing the air conditioner refrigeranl and lubri-

cant vapor or mist,

lf accidental system discharge occurs, ventilate workarea betore resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comoressed air.

@ some mixtures of air and R-134a have

been shown to be combugtibls at elevatgd prossures

and can result in tire or explosion causing iniuly orplopgrty damage. Nev€r usc compre33od air to pressure

test R-13'la servica oquipment or yohiclo air conditionor

systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown in the pre-

vious column, following the equipment manufactur-

er's instructions.

NOTE; Be sure to install the same amount of new

refrigerant oil back into the A,/C system before charg-In9.

Open the high-pressure valve to charge the system

to the specified capacity, then close the supply

valve, and remove the charging system couplers.

Rofrigerant capacity: 600 - 650 g (21.1 - 22.9 oz)

Check the system for leaks using a R-134a refriger-

ant leak detector with an accuracy of 14 9 10.5 ozlper yea. or better.

lf you find leaks that require the system to be opened(to repair or replace hoses. fittings. etc.), recover the

system according to the Recovery Procedure on page

22-27.

After checking and repairing leaks. the system must

be evacuated (see System Evacuation on page 22-451.

Page 1471 of 2189

l'f .

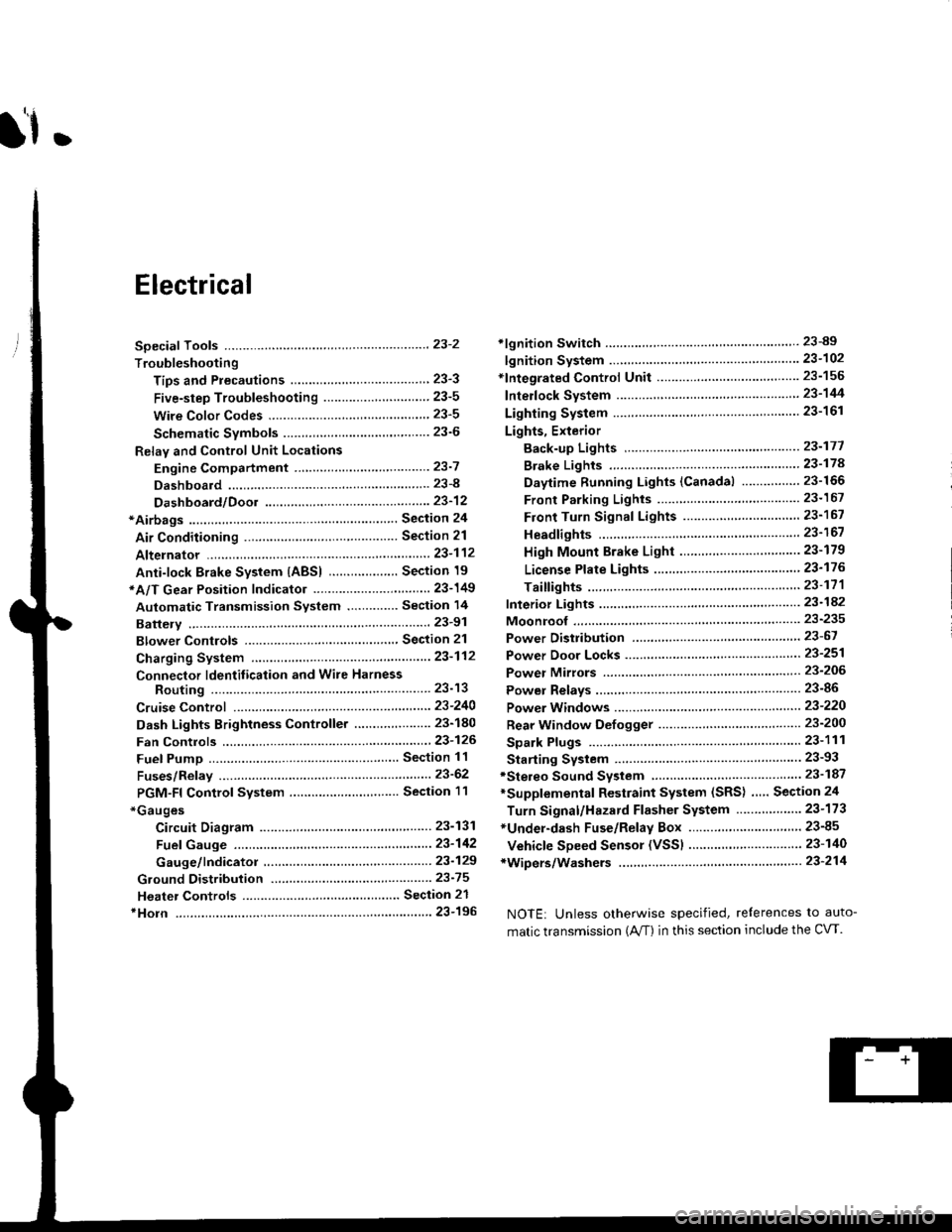

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1582 of 2189

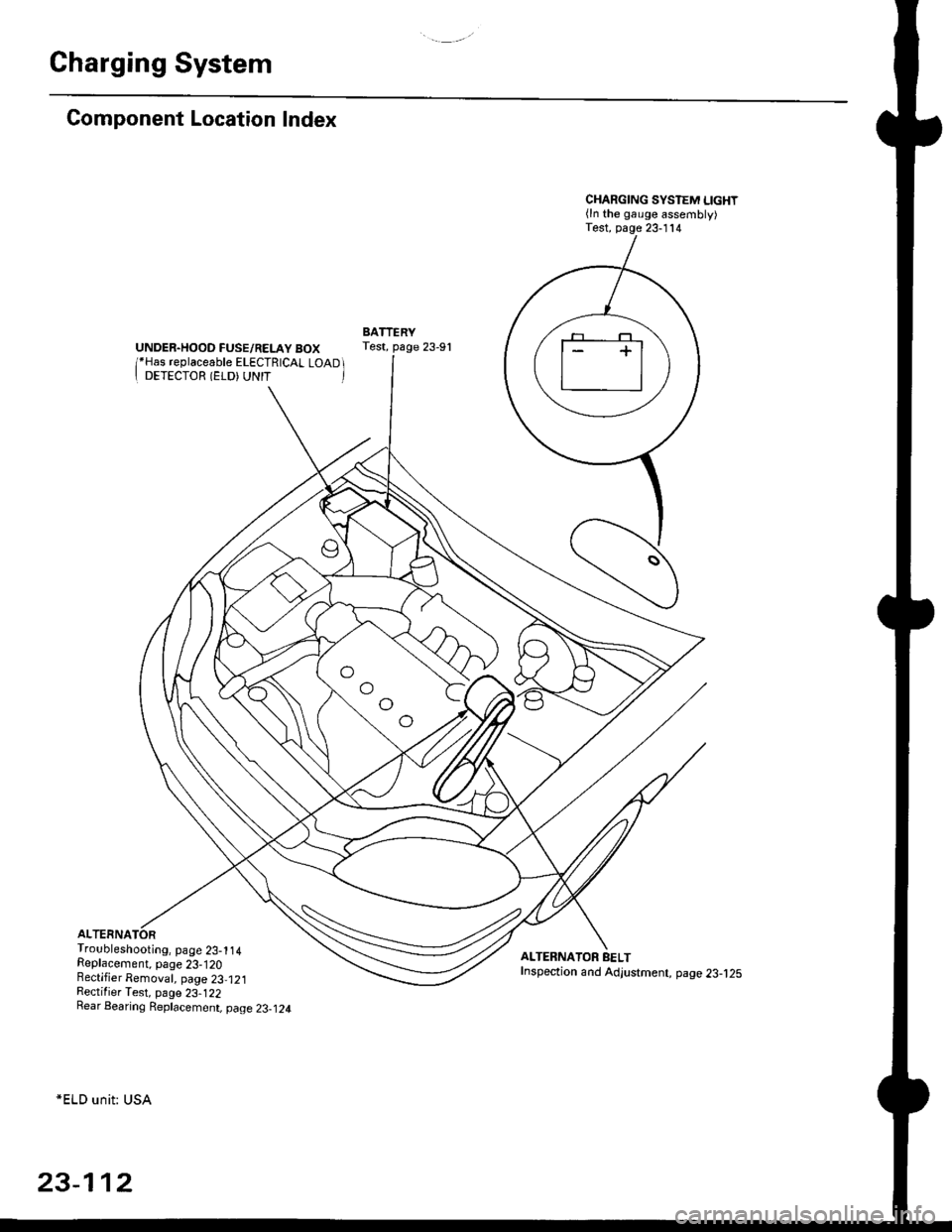

Charging System

Component Location Index

UNDER.HOOD FUSE/RELAY BOX/*Has replaceable ELECTRICAL LOAD II DETECTOR (ELD) UNIT '

Troubleshooting, page 23-1 14Replacement, page 23-120Bectifier Removal, page 23,121Rectifier Test, page 23-122Rear Bearing Replacement, page 23-j24

*ELD unit: USA

CHARGING SYSTEM LIGHT(ln the gauge assembly)Test, page 23- l14

BATTERYTest, page 23-91

ALTERNATOR BELTInspection and Adjustment, page 23-t25

[]

23-112

Page 1583 of 2189

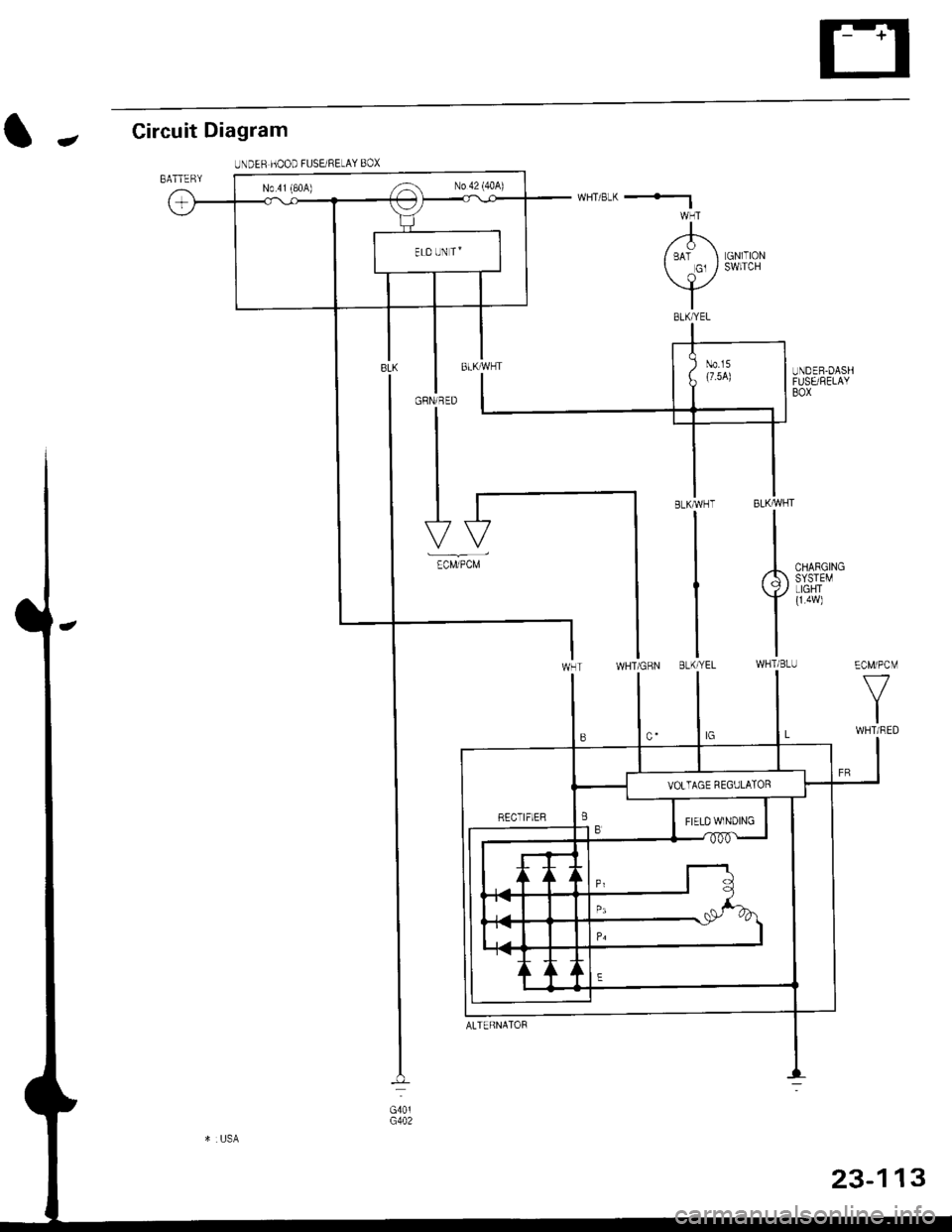

Circuit Diagram

IJNDER HOOD FUSEi RELAY BOX

-

BATTERY

LGNlTIONSWITCH

I

,'-F\I BAT I Gl /

\l_/

I

GRN/RED

I

N0.41 (80A) ,-a No 42 (40A)

ECM/PCM

f7

IWHT/RED

CHARGINGSYSTEMLIGHTI

TWHTi BLU

1323-1

ALTERNATOF

Page 1584 of 2189

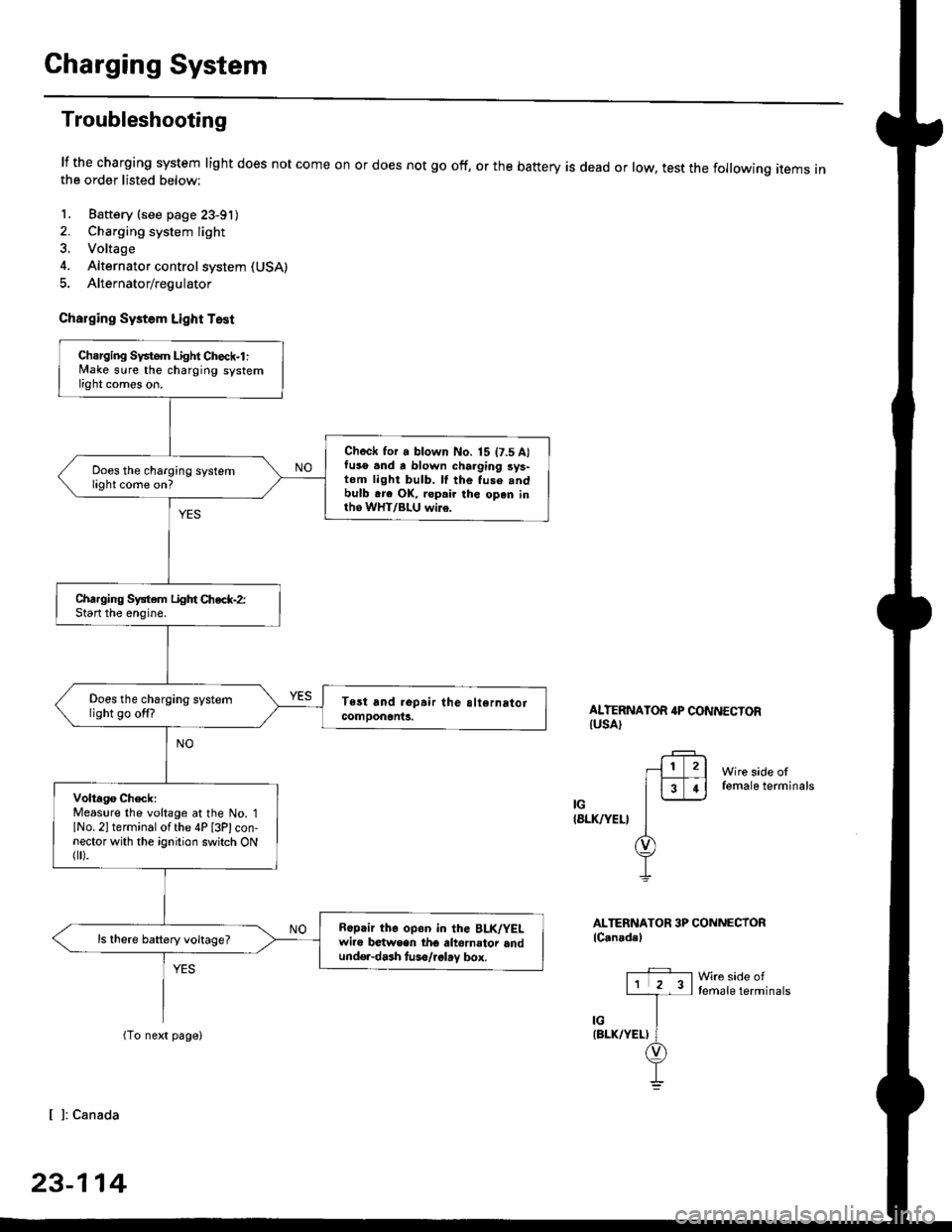

Charging System

Troubleshooting

lf the charging system light does not come onthe order listed below:

1. Baftery (see page 23-91)

2. Charging system light

3. Voltage

4. Alternator control system (USA)

5. Alternator/regulator

Charging Systom Light Test

or does not go off, or the battery is dead or low, test the following items in

ALTERNATOR 4P CONNECTORIUSA)

Wire side offemale terminals

IG(8LK/YEL}

ALTERNATOR 3P CONNECTORlC.nadal

Wre side oftemale terminals

[ ]: Canada

23-114

Charging Svstem Light Check-l :lvlake sure the charging systemlight comes on.

Check for a blown No. 15 t7.5 A)fuso .nd a blown charging sys-tom light bulb. ll the fuse .ndbulb .re OK, ropair the open inth6 WHT/BLU wi16.

Does the charging systemlight come on?

Charging System Light Chec*-2:Start the enoine.

Does the charging systemlight go off?

Volta96 ChecklMeaslre the voltage at the No. 1lNo. 2l terminal of the 4P [3Plcon-nector with the ignition switch ONflr).

R6p.ir the op6n in the BLK/YELwire b€twsen tho altornator andund€r-dash tuso/.glay box.

ls there battery voltage?

Page 1585 of 2189

-

Wire side offemale terminals

LtwHT/8LUl

ALTERNATOR 3P CONNECTOR

lCanada)

Wire side oftemale terminals

LIWHT/BLUI

L

{W}IT/BLU)

.+1lr l2l

l3T.l-l-

ir/

(WHT/BLUI

(cont'd)

23-115

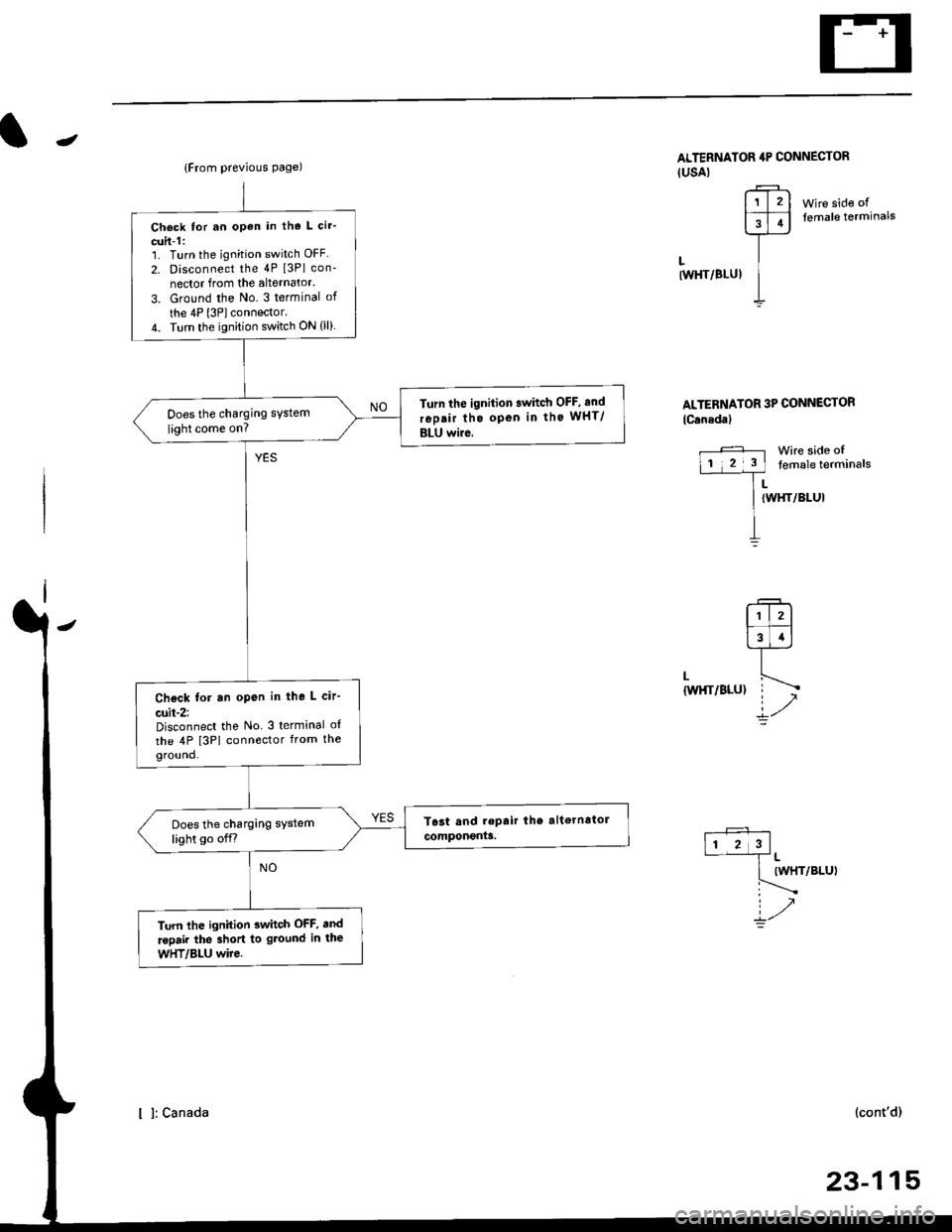

{From previous page)

Check tor an open in tho L cir'

cuit-1:1. Turn the ignition switch OFF

2. Disconnect the 4P [3Pl con-

nector from the alternator.

3. Ground the No. 3 terminal of

the 4P l3Plconnector.4. Turn the ignition switch ON (ll)

Turn the ignition swhch OFF, and

rep.ir tho open in tho wHT/

BLU wire.

Does the charging system

light come on?

Check for an open in the L cir-

cuit-2:Disconnect the No 3 terminal o{

the 4P [3PI connector from theground.

Does the charging system

light go off.r

Turn lhe ignition 3whch OFF, and

.epair the 3hort to gtound in the

wHT/Bl-U wire.

ALTERNATOR 4P CONNECTOR(USAI

r?-rl1l2l

FFI

]--

I

I l: canada

Page 1586 of 2189

Charging System

Troubleshooting (cont'd)

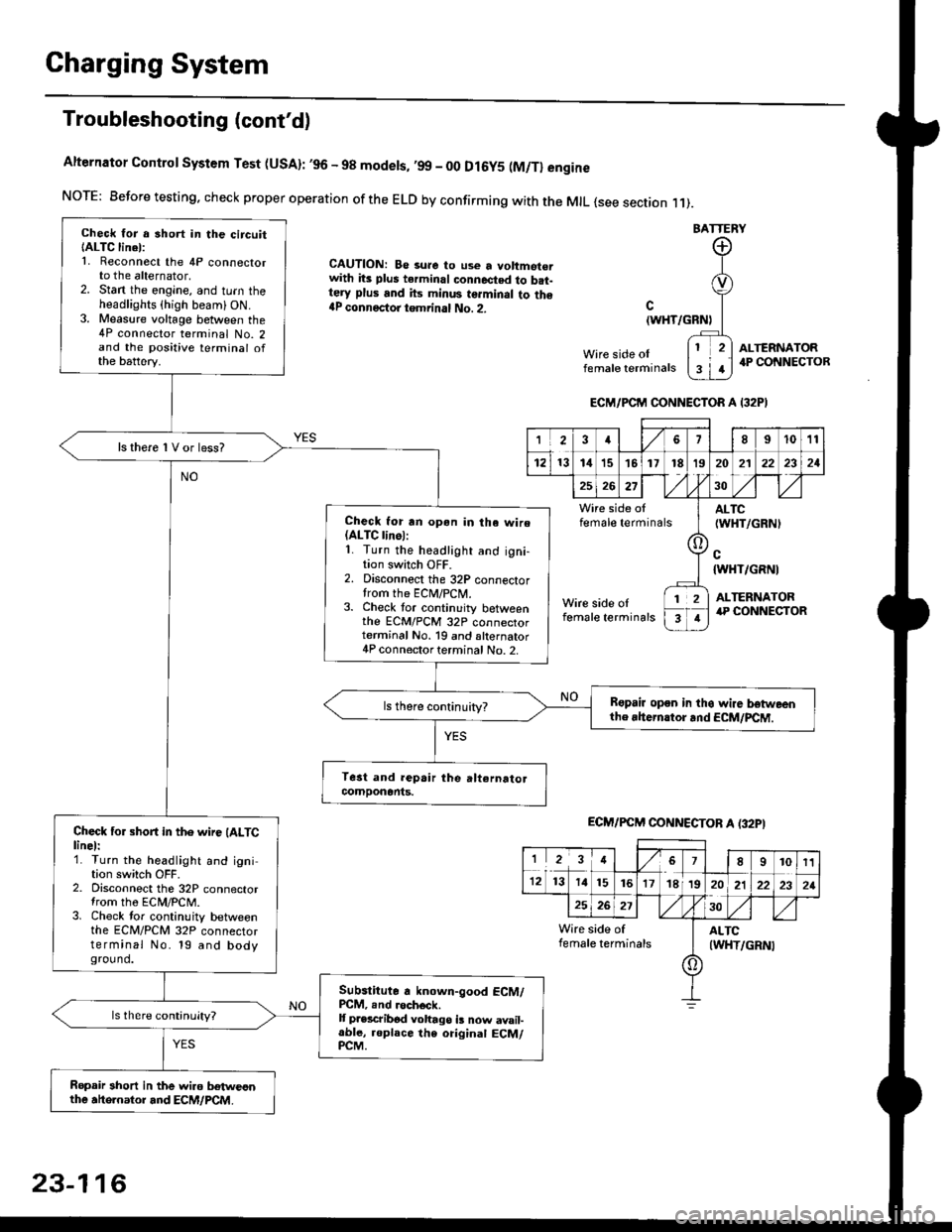

Alternator Control System Test (USA): ,96 - 98 modets, ,99 _ 00 Dl6y5 (M/Tl engine

NorE: Before testing. check proper operation of the ELD by confirming with the MrL {see section r 1).

BATTERY

CAUTION: Be 3ure to use a voltmot€.with its plus terminal connected to b.t-tery plus and its minus terminal to the{P connectoi tgmrinal No. 2.c

{WHT/GRNt

Wire side oIfemale terminals

ALTERNATOR.P CONNECTOB

Check for a 3hort in the circuitIALTC linel:1. Reconnect the 4P connectorto the alternator,2. Stan the engine, and turn theheadlights {high beam) ON.3. Measure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

ls there 1V or less?

Check for rn opon in tha wire(ALTC linol:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectortrom the ECM/PCN4.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and alternator4P connector terminal No. 2.

Bspair open in thg wire lrstweenthe rhern.tor .nd ECM/PCM.

Check for short in the wire (ALTClinel:1. Turn the headlight and ignition switch OFF.2. Disconnect the 32P connectortrom the ECM/PCM.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and bodyground.

Subslitute a known-good ECM/PCM, .nd .och6ck.It p.escribod vohago i! now avail-able, replace the original ECM/PCM.

Ropair 3hort in the wiro betweonthe ahe.nator and ECM/PCM.

ECM/PCM CONNECTOR A I32PI

'Ia18I1011

121314151718t9

7

202'l2221

262730

Wire side offemale terminalsALTC(WHT/GRNI

c{WHT/GRNI

ALTERNATORWire side oIfemale terminals

([l

T

12

1

ECM/PCM CONNECTOB A (32PI

I23478910t1

1213 14151617182021222321

262730

Wire side of I AITCfemate terminats

A

(WHT/GRN|

23-116

Page 1588 of 2189

Charging System

Troubleshooting (cont'd)

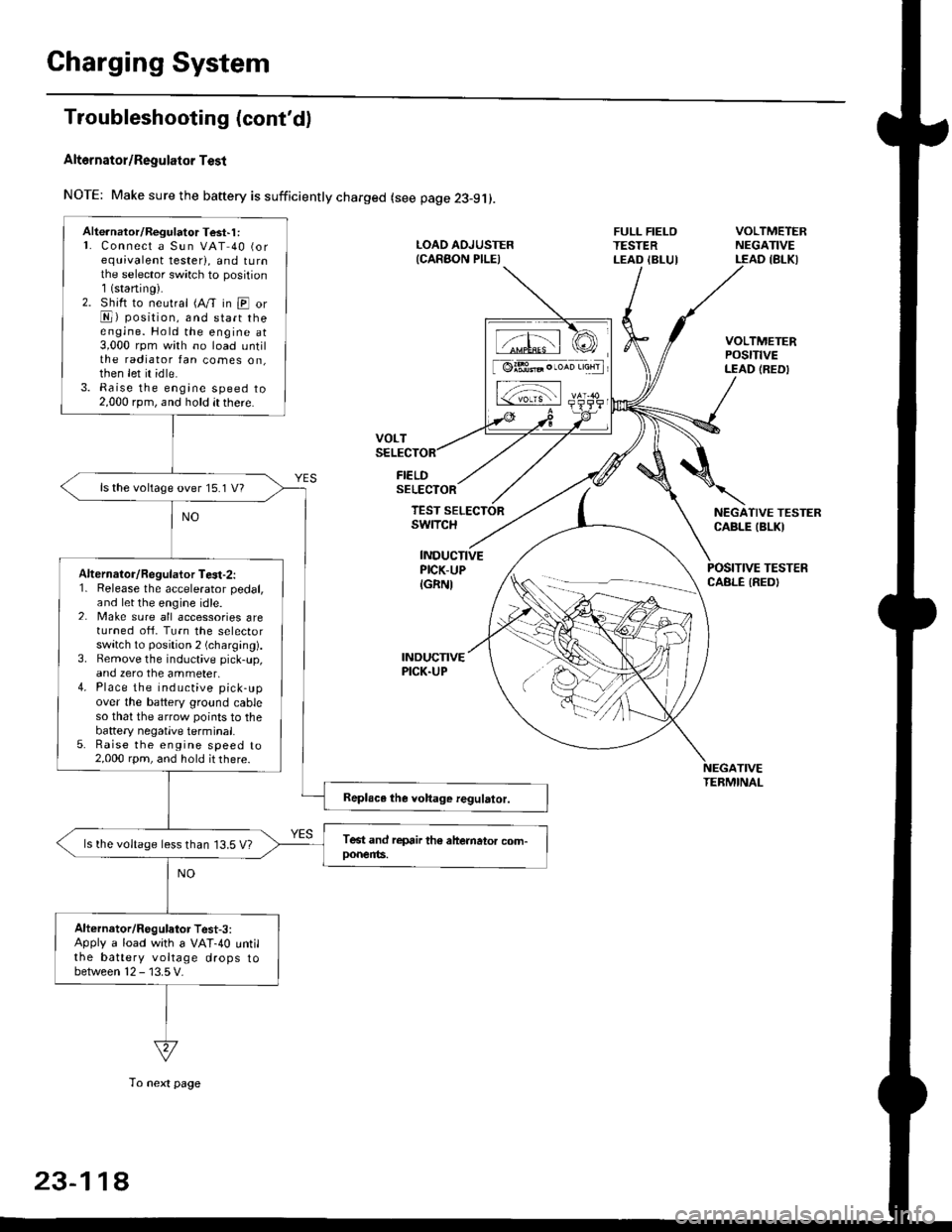

Alt6rnator/Regulator Test

NOTE: Make sure the baftery is sufficiently charged (see page 23-9j).

FIELDSELECTOR

LOAD AOJUSTER{CARAON PILEI

FULL FIELOTESTERLEAD IBLUI

VOLTMETERNEGATIVELEAD IBLKI

VOLTMETERPOStTtVELEAD (REDI

NEGATIVE TESTERCABLE IBLKI

POSITIVE TESTERCABLE IREDI

TEST SELECTORswrTcH

INDUCTIVEPICK-UP

IGRNI

INDUCNVEPICK.UP

TIVETEBMINAL

Alte.nator/Regulator Test'1 :L Connect a Sun VAT 40 (orequivalent tester), and tu rnthe selector sw;tch to position1(staning).2. Shift to neutral (A/T in E orE) position, and start theengine. Hold the engine at3,000 rpm with no load untilthe radiator fan comes on,then let it idle.3. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

Alternalor/Regulator Te3t-2:1. Release the accelerator pedal,and let the engine idle.2. Make sure all accessories areturned ofi. Turn the selectorswitch to position 2 (charging).3. Bemove the inductive pick-up,and zero the ammeter,4. Place the inductive pick-upover the battery ground cableso that the arrow points to thebattery negatlve terminal.5. Raise the engine speed to2,000 rpm, and hold it there.

ls the voltage less than 13.5 V?

Alternator/Regulator Test-3:Apply a load with a VAT-40 untilthe battery voltage drops tobetween 12 - 13.5 V.

tffil rCI

[ @lBt* . ,*n 'aHrl

L-;-;l rs-

23-11A

To next page