hoist HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 803 of 2189

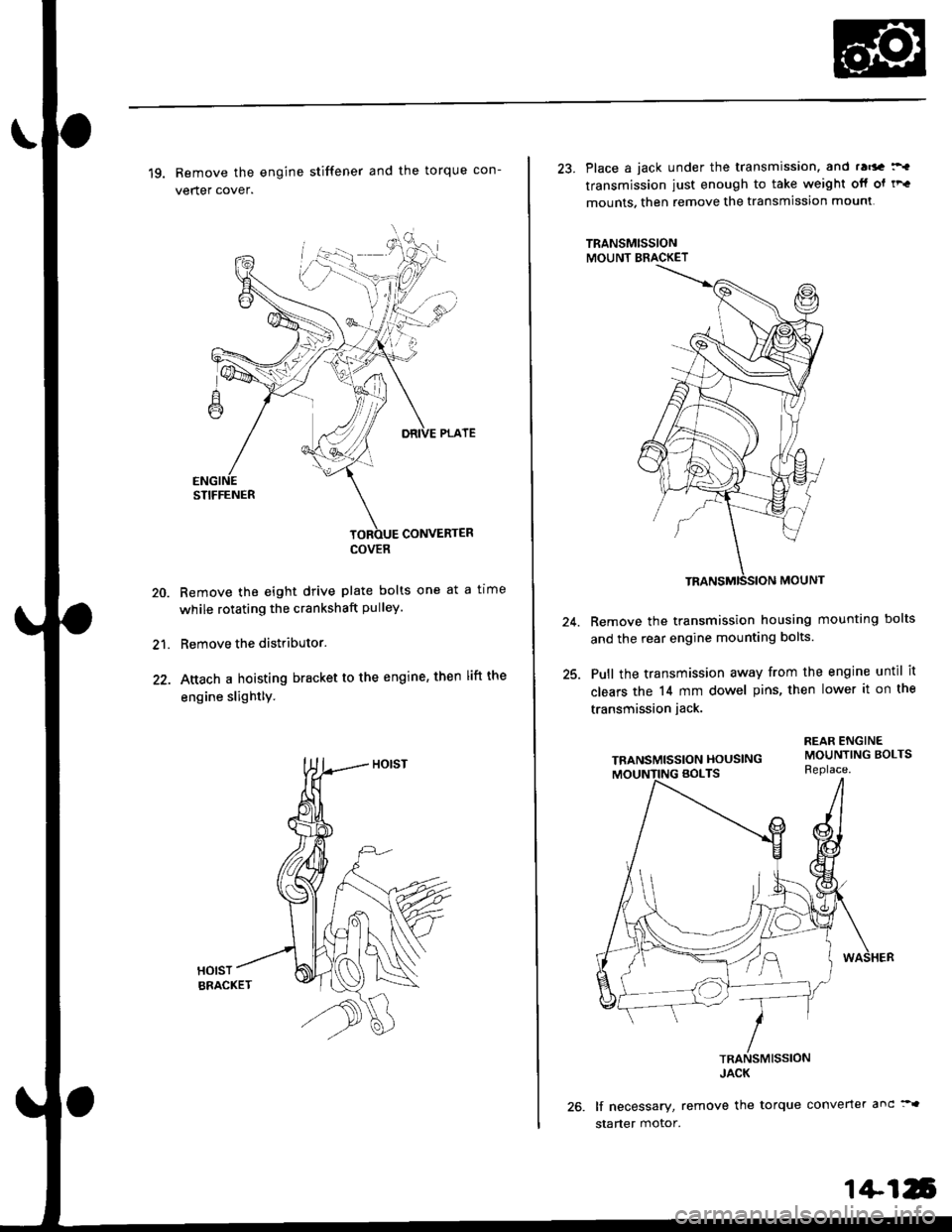

19. Remove the engine stiffener and the torque con-

verter cover.

Remove the eight drive plate bolts one at a tlme

while rotating the crankshaft pulley.

Remove the distributor.

Attach a hoisting bracket to the engine, then lift the

engine slightly.

HOISTBRACKET

20.

21.

COVER

23. Place a jack under the transmission. and ra6a :'.

transmission iust enough to take weight otf ol tF.

mounts. then remove the transmission mounl

TRANSMISSIONMOUNT BRACKET

Remove the transmission housing mounting bolts

and the rear engine mounting bolts.

Pull the transmission away from the engine until it

clears the 14 mm dowel pins, then lower it on the

transmission jack.

TRANSMISSION HOUSING

lf necessary, remove the torque converter anc:"

starter motor.

24.

25.

1+16

Page 984 of 2189

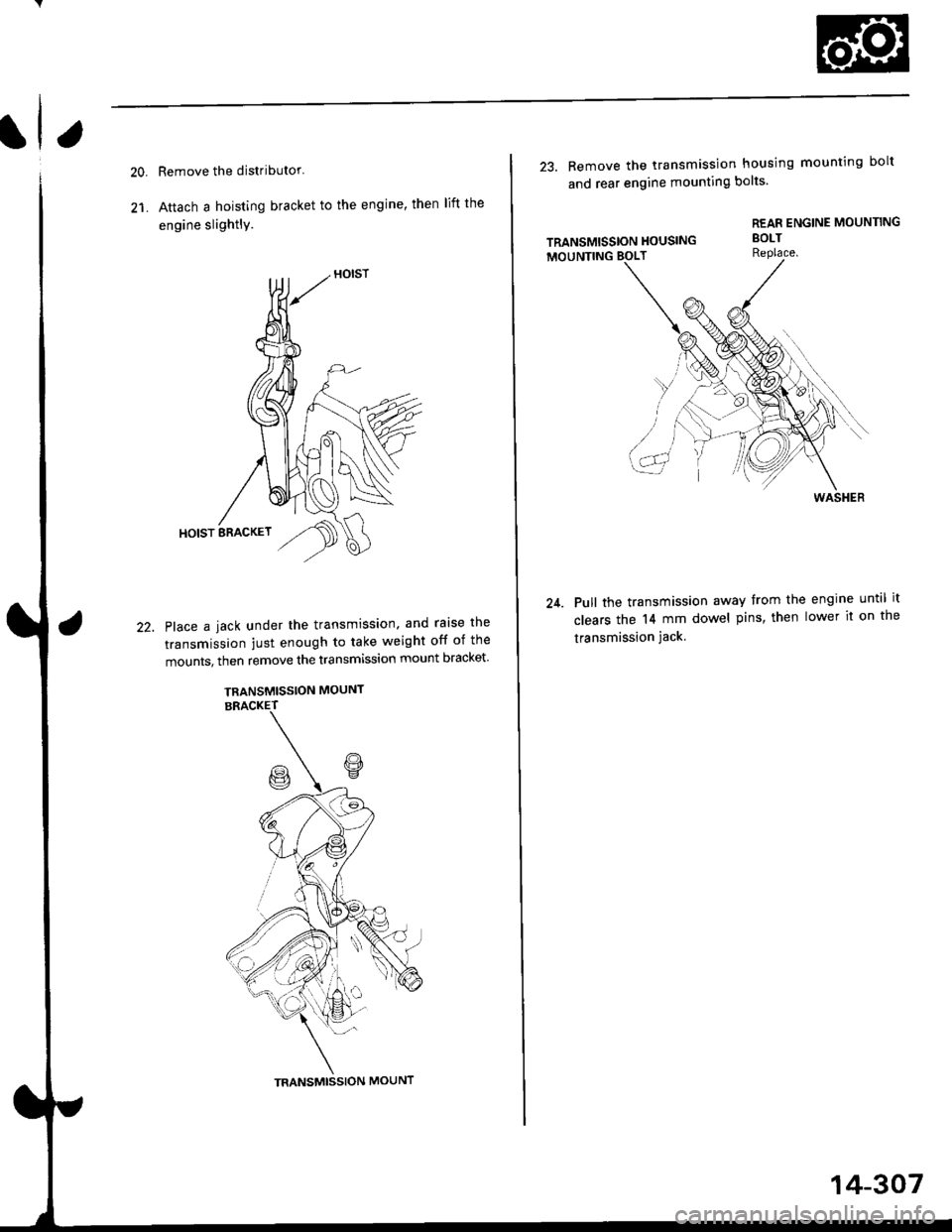

Remove the distributor'

Atach a hoisting bracket to the engine, then lift the

engine slightly.

Place a iack under the transmission. and raise the

transmission just enough to take weight off of the

mounts, then remove the transmission mount bracket

TRANSMISSION MOUNT

22.

TRANSMISSION MOUNT

14-307

23. Remove the transmission housing mounting bolt

and rear engine mounting bolts

REAR ENGINE MOUNTING

TRANSMISSION HOUSING

MOUNTING BOLT

Pull the transmission away from the engine until it

clears the l4 mm dowel pins, then lower it on the

transmission jack

WASI{ER

Page 1025 of 2189

l.

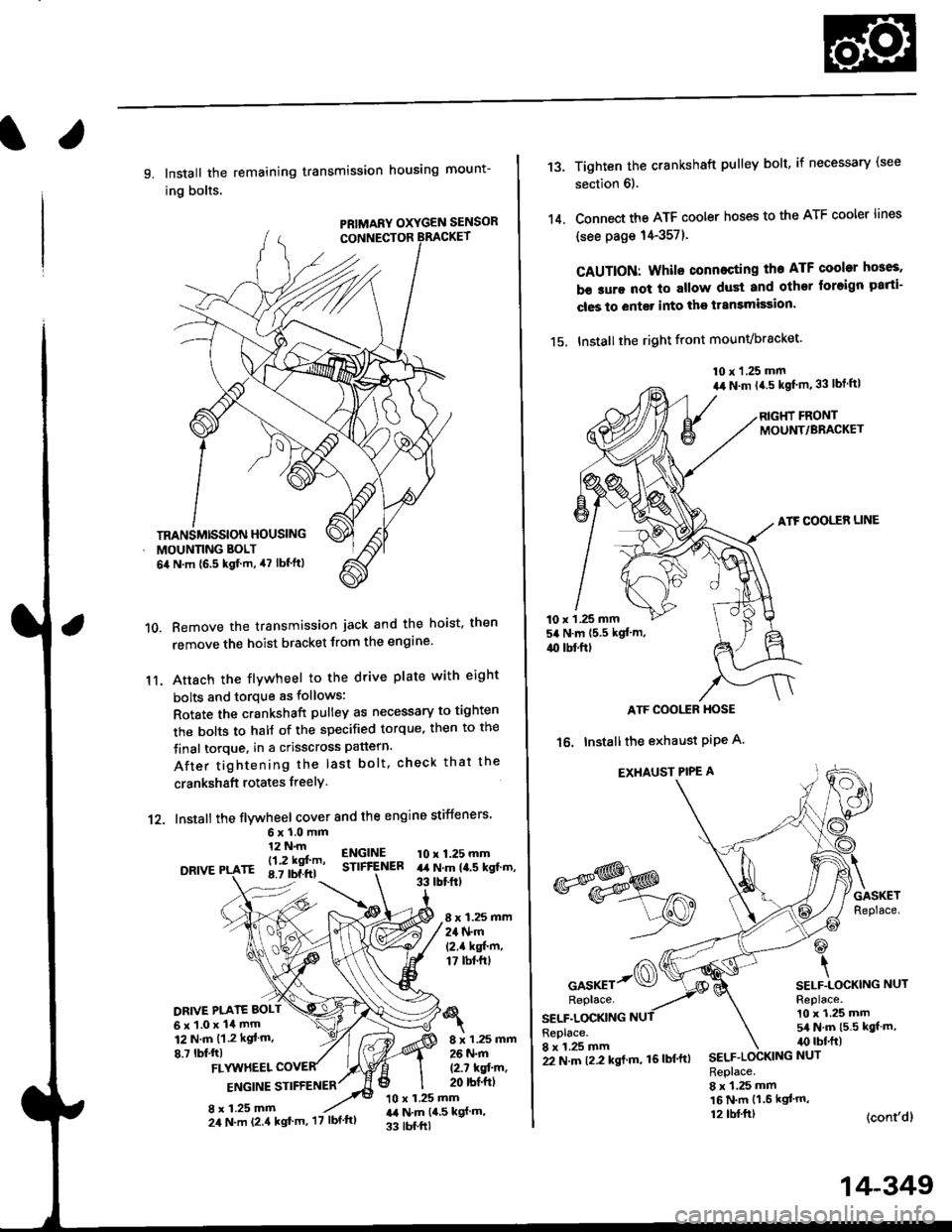

9. Install the remaining transmission housing mount-

ing bolts.

PRIMARY OXYGEN SENSOR

Remove the transmission jack and the hoist. then

remove the hoist bracket from the engine'

Attach the flvwheel to the drive plate with eight

bolts and torque as follows:

Rotate the crankshaft pulley as necessary to tighten

rhe bolts to half of the specified torque, then to the

final torque, in a crisscross pattern.

After tightening the last bolt. check that the

crankshaft rotates freelY.

10.

11.

12. Install the flywheel cover and the engine stiffeners

DRIVE

6xl.0mm12 N.m

- l12 kgf'm'rE 8.7 tbf.ftl

ENGINESTIFfENEB10 x 1.25 mmart N.m la.s kgt.m,33 tbtftt

8 x 1.25 mm24 N.m(2.1 kgf'm,17 tbt.ftt

DRIVE PI.ATE BOLT

6x1.0x14mm12 N.m {1.2 kgt m.

8.7 lbf,ftl8 x 1.25 mm26 N.m

12.7 kqfin,20 rbt'ftlFLYUTHEEL

ENGINE STIFFENER

8 x 1.25 mm10 x 1.25 mmr,a N.m {4,5 kgf m,

33 tbf.ftl

TRANSMISSION HOUSING

MOUNNNG BOLT

6il N.m {6.5 kgf.m, 47 lbf'ftl

24 N.m (2.4 kgt'm, '17 lbf'ftl

22 N.m t2.2 kgl m, 16lbf'ftl

14-349

13.

14.

Tighten the crankshaft pulley bolt, if necessary (see

section 6).

Connect the ATF cooler hoses to the ATF cooler lines

(see page 14-357).

CAUTION: Whilo connecting the ATF cooltr hGes,

b€ sure not lo allow dust and other loreign parti-

cles to entg. into the transmission.

15. Installthe right front mounvbracket'

10 x 1.25 mm

a,r N.m {4.5 kgf'm,33 lbt ftl

RIGHT FRONTMOUNT/BRACKET

ATF COOLER LINE

10 x 1 .25 mm54 N.m {5.5 kgt'm,

4{) tbl.ftt

ATF COOI,TR HOSE

16. Installthe exhaust PiPe A.

EXHAUST PIPE A

GASKETReplace.

@

\SELF.LOCKING NUTReplace.10 x 1.25 mm5/a N.m {5.5 kgt m,irc lbf.ft)

(cont'dl

*s$o

oor*rr-@Replace.

SELF.LOCKINGReplace.8 x 1.25 mmSELF.LOCKING NUT

Replace.8 x 1.25 mm16 N.m {1.6 kgl'm,12 tbl.ftt

Page 1145 of 2189

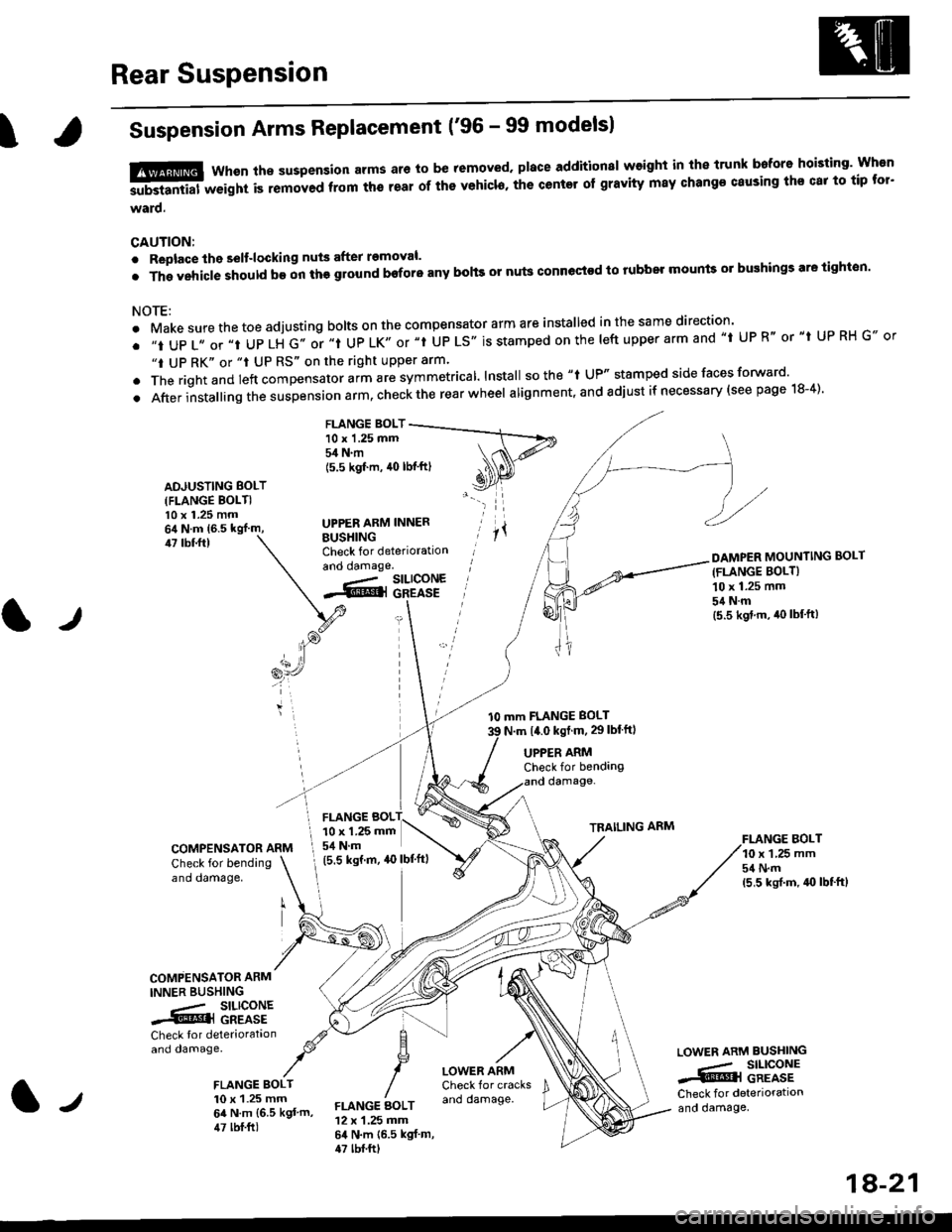

Rear Suspension

ISuspension Arms Replacement ('96 - 99 modelsl

tffi Whsn ths suspension arms ar6 to be removed. place additionsl weight in the trunk bafore hoisting' Wh€n

-substantial weight is removed ftom th6 teal of ths vehicl6, the center of gravity may change causing ths cat to tip tor'

ward.

CAUTION:

. Replace the selt-locking nuts after removal.

.Thgvehic|eshouldb€onthggroundboforeanybohsornutsconnectodtorubbelmountso]bughingsaretighton.

NOTE:

. Make sure the toe adjusting bolts on the compensator arm are installed in the same direction'

. ,,t UP 1,, or ,,t UP LH G,. or ,.t UP LK,, or "t UP LS'. is stamped on the |eft upper arm and ,,t UP R" or "t UP RH G., or

"t UP RK" or "t UP RS" on the right upper arm'

. The rightand left "ornp"n""to, uitt rre symmetrical lnstall sothe "t UP" stamped side faces forward'

.Afterinsta||ingthesuspens|onarm,checktherearwhee|alignment,andadjustifnecessary(seepagelS-4).

FLANGE BOLT10 x 1.25 mm54 N.m

ADJUSTING BOLT(FLANGE BOLTI10 x 1.25 mm

BUSHINGCheck for deteriorationand oamage.

(5.5 kgf'm, 40 lbf'ftl

UPPER ARM INNER

47 tbf.ftl

tJ

l0 mm FLANGE BOLT

N.m t4.0 kst m, 29lblftl

DAMPER MOUNTING BOLT(FLANGE BOLT}

10 x 1.25 mm

54Nm(5.5 kgd.m, iro lbf'ft)

FI.ANGE BOLT10 x 1,25 mm54 N.m(5,5 ksrf.m, 4{} lbf'ft}

UPPER ARMCheck for bendangdamage-

TRAILING ARM

COMPENSATOR ARM

Check for bendingano oamage,

COMPENSATOR ARM

INNER BUSHING

.- SILICONE.@] GREASE

Check tor deteriorataonand damage.

FLANGE BOLT10 x 1.25 mm64 N.m {6.5 kgt'm,47 lbf.ft)

LOWER ARMCheck for cracksano damage.

LOWEN ARM BUSHING

.,- SILICONE..i@l GREASECheck for deteriorationand oamage,FLANGE AOLT12 x 1.25 mm64 N.m {6.5 kgf m,47 tbf.ftt

FLANGE BOL10 x 1.25 mm

I 54 N.m

(5.5 ksrm, ao lbf'ftl

1A-21