stop start HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 909 of 2189

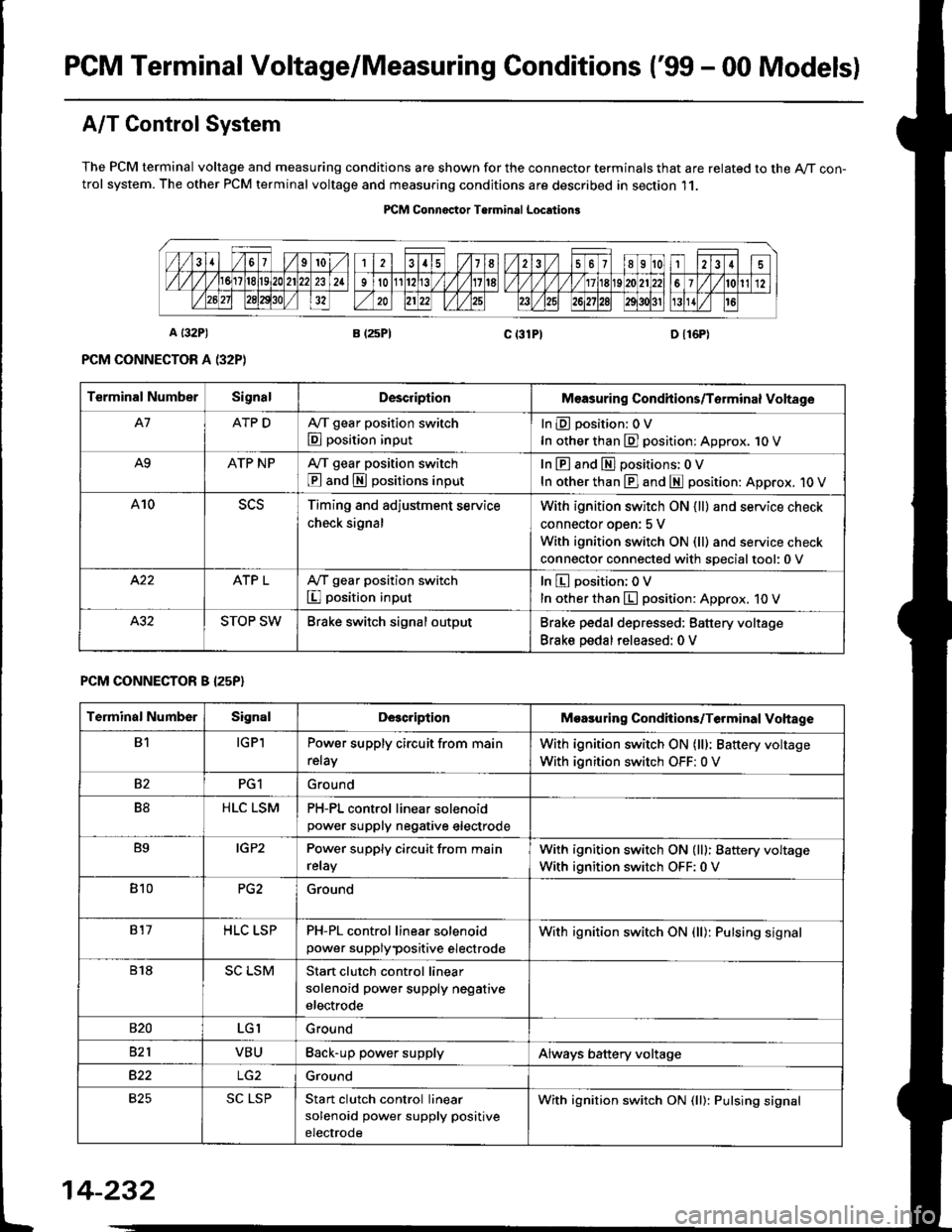

PGM Terminal Voltage/Measuring Conditions ('99 - 00 Modelsl

A/T Control System

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A/T con-trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

PICM Connoctor Terminrl Location3

Terminal NumberSignalDescriplionMeasuring Condhions/Torminal Voltage

A7ATP DA,/T gear position switch

E position input

InEposition:OV

In other than E] position: Approx. 1O V

A9ATP NPA/T gear position switch

@ and S positions input

In E and El positions: 0 V

In other than E] and E position: Approx. 1O V

A10Timing and adjustment service

check signal

With ignition switch ON {ll} and service check

connector oDen: 5 V

With ignition switch ON (ll) and service check

connector connected with soecialtool:0 v

ATP LA,/T gear position switch

I position input

In E position; OV

In other than E position: Approx. 10 V

STOP SWBrake switch signal outputBrake pedal depressed: Battery voltage

Brake pedal released: 0 V

PCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMoasuring Condhions/Terminal Vohage

B1IGPlPower supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF: 0 V

82PG1Ground

B8HLC LSMPH-PL control linear solenoidpower supply neqative electrode

B9IGP2Power supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF:0 V

810PG2Ground

817HLC LSPPH-PL control linear solenoid

power supplypositive electrode

With ignition switch ON {ll): Pulsing signal

818SC LSMStart clutch control linear

solenoid power supply negative

electrode

s20LGIGround

821VBUBack-up power supplyAlways battery voltage

B22Ground

825SC LSPStan clutch control linear

solenoid power supply positive

electrode

With ignition switch ON (ll): Pulsing signal

t

14-232

Page 971 of 2189

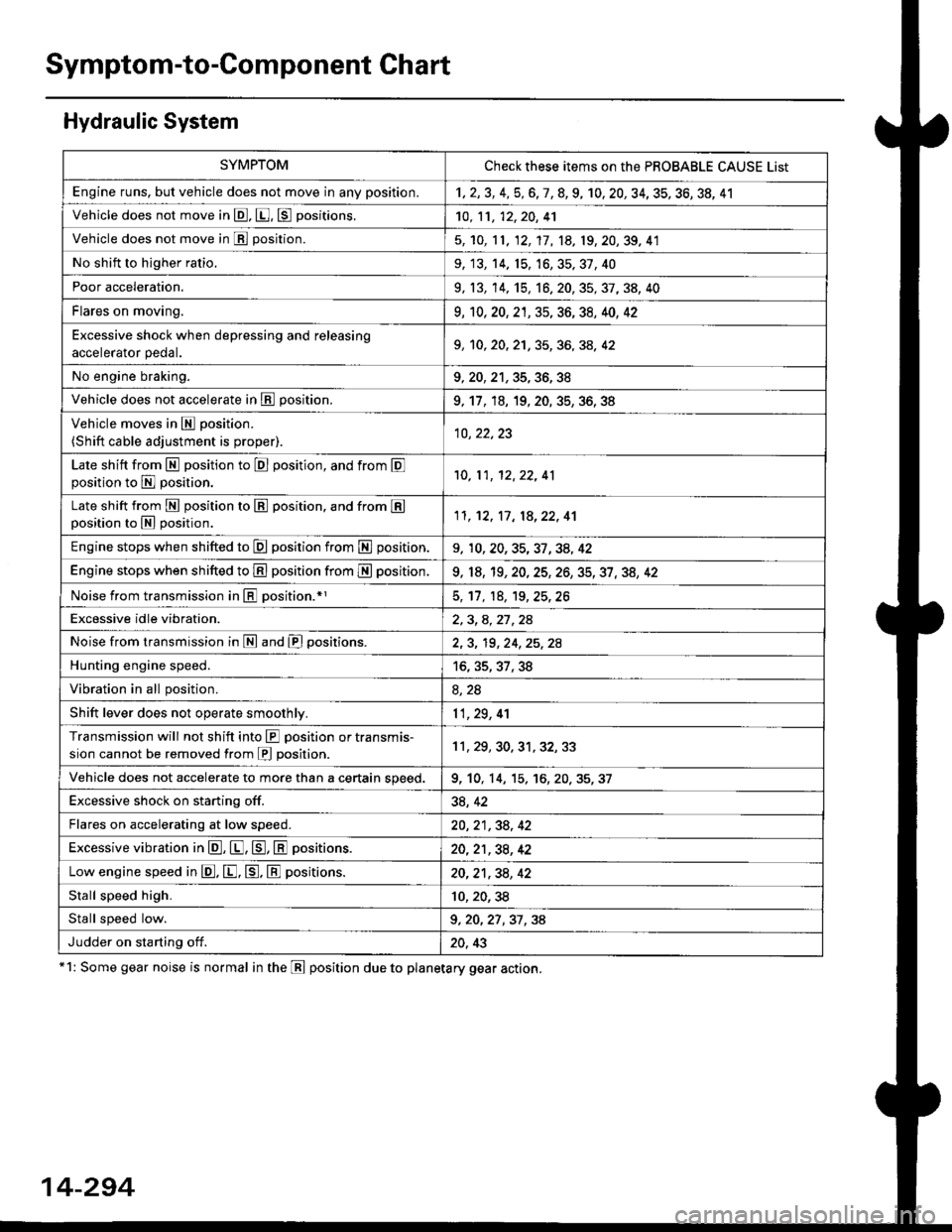

Symptom-to-Component Chart

Hydraulic System

*1: Some gear noise is normal in the Lll position due to planetary gear action.

14-294

SYMPTOMCheck these items on the PBOBABLE CAUSE List

Engine runs, but vehicle does not move in any position.'t,2,3,4,5,6,7,8,9, 10, 20, 34, 35, 36, 38, 41

Vehicle does not move in @, [. p positions.10,11, 12, 20, 41

Vehicle does not move in E position.5, 'to, 11, 12, 17, 1A, 19, 20,39, 41

No shift to higher ratio,9, 13, 14. 15, 16,35,37,40

Poor acceleration.9, 13,'�t4,'t5,16. 20, 35, 37, 38, 40

Flares on moving.9,'t0, 20, 2't, 35, 36, 38, 40, 42

Excessive shock when depressing and releasing.^^alA/.r^r ^A.1. I9, 10, 20, 2'1, 35, 36, 3A, 42

No engine braking.9,20,21,35,36,38

Vehicle does not accelerate in lll position.9, 17, 18, 19, 20. 35, 36, 38

Vehicle moves in E position.

(Shift cable adjustment is proper).10, 22,23

Late shift from N position to E position, and from Eposition to E position.'10,11, 12,22, 41

Late shift from E position to E position. and from Eposition to N position.1l,'t2, 17, 18,22, 41

Engine stops when shifted to E position from E position.9, 10,20,35,37,34, 42

Engine stops when shifted to E position from I position.9, 18, 19,20,25,26,35,37,38, 42

Noise from transmission in @ position.rl5, 17, 18, 't9,25,26

Excessive idle vibration.2,3,4,21,24

Noise from transmission in @ and @ positions.2,3, 19,24,25,2A

Hunting engine speed.16, 35, 37, 38

Vibration in all position.8, 2a

Shift lever does not operate smoothly.11,29, 4'l

Transmission will not shift into lll position or transmis-

sion cannot be removed from E position.11 , 29, 30, 31, 32,33

Vehicle does not accelerate to more than a certain speed.9, 10, 14, 15,'t6,20,35,37

Excessive shock on starting off.38, 42

Flares on accelerating at low speed.20, 21 ,38, 42

Excessive vibration in E, E, tr, E positions.20,21,38, 42

Low engine speed in E. E. tr. E positions.20,21,38,42

Stall speed high.10,20,38

Stall speed low.9, 20, 27 ,37 , 38

Judder on starting off.20, 43

Page 1088 of 2189

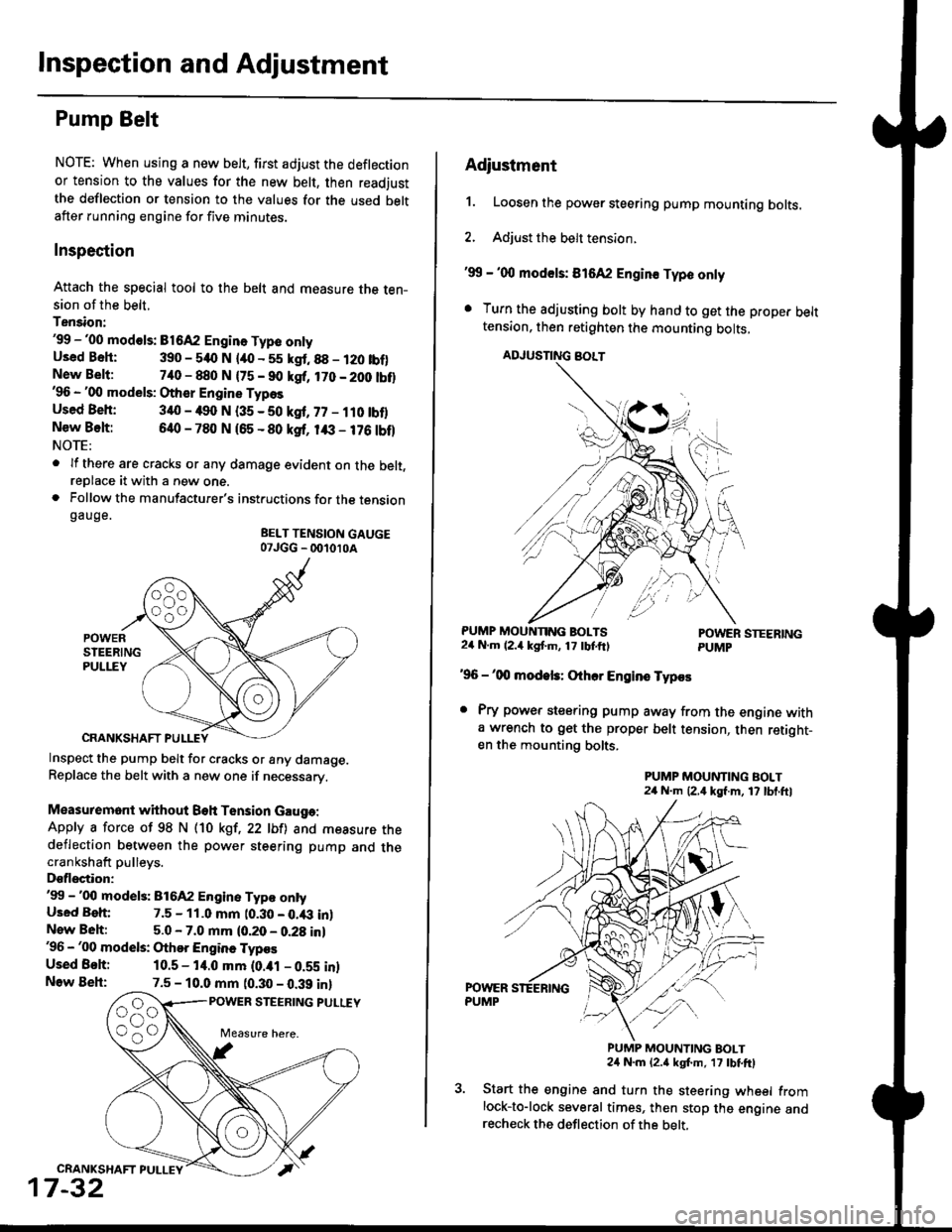

Inspection and Adjustment

Pump Belt

NOTE: When using a new belt, first adjust the deflection

or tension to the values for the new belt, then readjust

the deflection or tension to the values for the used beltafter running engine for five minutes.

Inspection

Attach the special tool to the belt and measure the ten-sion of the belt.

Tension:'99 -'00 mod€ls: B1642 Engin. Type onlyUsed Bsh: 390 - 540 N lao - 55 kgt.88 - 120 tbf)New Belt:740 - 880 N {75 - 90 kgf, 170 - 200 tbt}'96 - '00 models: Other Engine Types

Used Beh: 340 - 490 N (35 - 50 kgf, 77 - ilO tbflNew Belt:640 - 780 N 165 - 80 ksf, 1& - 176 tbf)NOTE:

. lf there are cracks or any damage evident on the belt,reDlace it with a new one.. Follow the manufacturer's instructions for the tensiongauge.

BELT TENSION GAUGE07JGG _ 001010A

Inspect the pump belt for cracks or any damage.Replace the belt with a new one if necessary.

Measuremont without Beh Tension Gauga:

Apply a force of 98 N (10 kgt,22 lbfl and measure thedeflection between the power steering pump and thecrankshaft pulleys.

Dsflectior:'99 -'00 model3: 816A2 Engine Typ€ ontyUsed Beh: 7.5 - 11.0 mm t0.30 - 0.43 inlNew Beh:5.0 - 7.0 mm (0.20 - 0.28 in)'96 - '00 models: Othor Engine Typos

Used Behi 10.5 - 14.0 mm (0.ial - 0.59 inlNow Beh:7.5 - 10.0 mm (0.30 - 0.39 inl

POWER STEERING PULUY

CRANKSHAFT PULLEY

17-32

Adiustment

1. Loosen the power steering pump mounting bolts.

2. Adjust the belt tension.

'99 - '00 mod€ls: 816A2 Engin€ Typo only

. Turn the adjusting bolt by hand to get the proper belttension, then retighten the mounting bolts,

ADJUSNNG BOLT

PUMP MOUNNNG BOLTS24 N.m (2.4 kgf'm, 17 tbtftlPOWER STEERINGPUMP

'96 -'00 modek: Othcr Engins Typos

. Pry power steering pump away from the engine witha wrench to get the proper belt tension, then retight-en the mounting bolts.

PUMP MOUNTING BOLT24 N.m (2,4 kgf.m, 17 lbl.ftl

PUMP MOUNTING BOLT24 N.m {2.a kgt m, 17 tbtftl

Start the engine and turn the steering wheel fromlock-to-lock several times, then stop the engine andrecheck the deflection of the belt,

Page 1089 of 2189

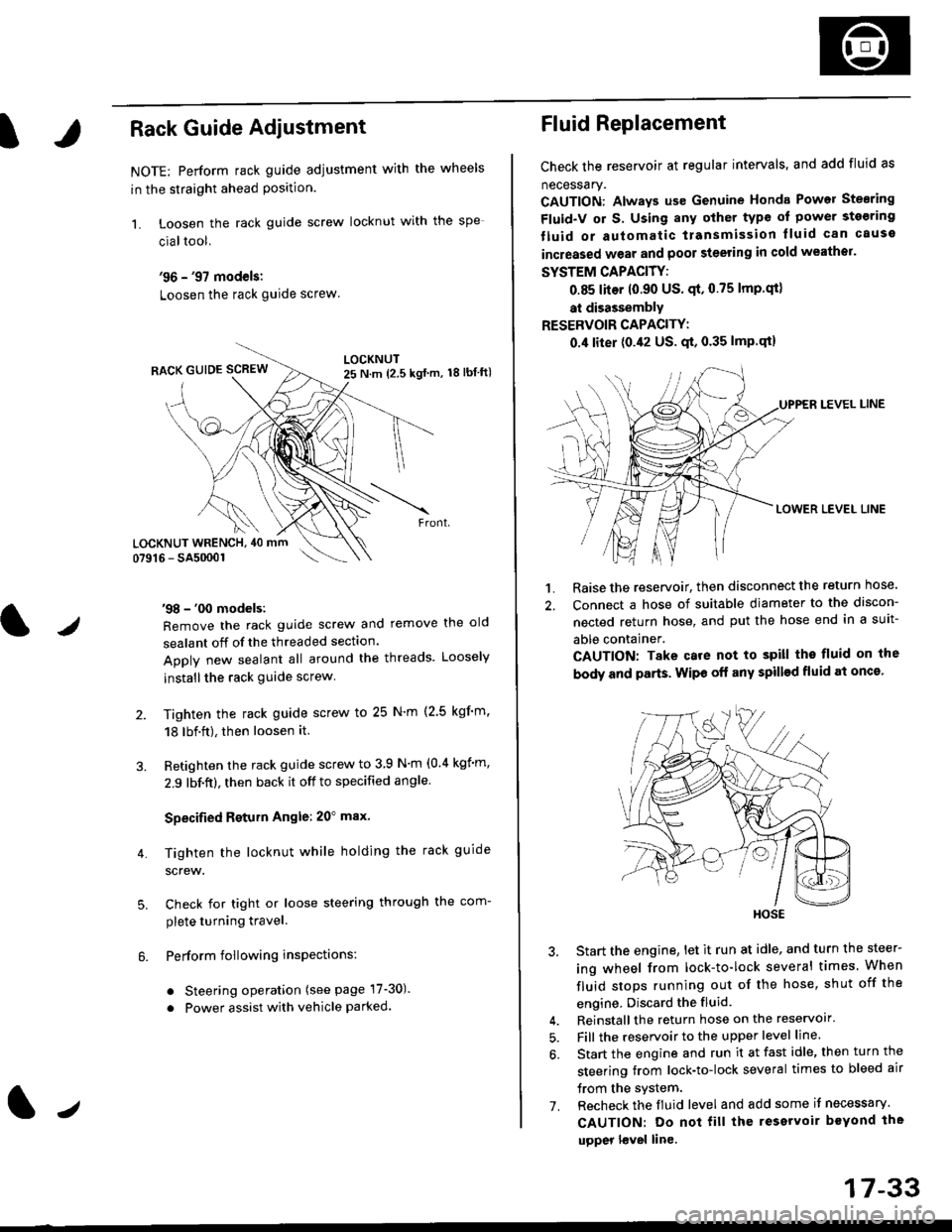

IRack Guide Adjustment

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead Position.

1. Loosen the rack guide screw locknut with the

cialtool.

'96 - '97 models:

Loosen the rack guide screw

'98 - '00 models:

Remove the rack guide screw and remove the old

sealant off of the threaded section.

Apply new sealant all around the threads. Loosely

installthe rack guide screw

Tighten the rack guide screw to 25 N'm (2.5 kgf'm.

18 lbf.ft), then loosen it.

Retighten the rack guide screw to 3 9 N'm (0.4 kgim,

2.9 lbf.ft), then back it off to specified angle.

Specified Return Angle: 20" max.

Tighten the locknut while holding the rack guide

screw.

Check for tight or loose steering through the com-

plete turning travel.

Perform following insPections:

. Steering operation (see page 17-30).

. Power assist with vehicle parked.

4.

LOCKNUT WRENCH, 40 mm

lr

17-33

Fluid Replacement

Check the reservoir at regular intervals, and add fluid as

necessary.

CAUTION: Always us€ Genuine Honda Power Stearing

Fluid-V or S. Using any other type of power sto€ring

tluid or automatic transmission lluid can cause

increased wear and poor steering in cold weathor.

SYSTEM CAPACITY:

0.85 liter 10.90 US' qt,0.75 lmp'qt)

at disassembly

RESERVOIR CAPACITY:

0.4 liter (0.42 US. qt, 0.35 lmP.qt)

LEVEL LINE

LOWER LEVEL LINE

1. Raise the reservoir, then disconnect the return nose.

2. Connect a hose of suitable diameter to the discon-

nected return hose, and put the hose end in a suit-

able container.

CAUTION: Take care not to spill tho fluid on the

body and parts. Wipe off any spill€d fluid at oncs'

3. Start the engine, let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times When

fluid stops running out of the hose, shut off the

engine, Discard the fluid.

4. Reinstall the return hose on the reservoir'

5. Fill the reservoir to the upper level line.

6. Start the engine and run it at fast idle, then turn the

steering trom lock-to-lock several times to bleed air

trom the system.

7. Recheck the fluid level and add some it necessary.

CAUTION: Do not fill the reservoir beYond the

upper l€vel line.

HOSE

Page 1177 of 2189

Brake Booster InsPection

FunctionalTest

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds lf

the pedal sinks' either the master cYlinder is

bypassing internally, or the brake system (master

cylinder. lines. modulator, proportioning control

valve, or caliPer) is ieaking.

2. Start the engine with the pedal depressed lf the

pedal sinks slightly, the vacuum booster is operating

normally. lf the pedal height does not vary, the

booster or check valve is faultY.

3. With the engine running. depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cvlinder is faulty. A slight change in

pedal height when the A'lC compressor cycles on

and off if normal. (The A/C compressor load

changes the vacuum available to the booster')

Leak Test

1. Depress the brake pedal with the engine running.

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises. the booster is

faulty.

2, With the engine stopped, depress the brake pedal

several times using normal pressure When the

Dedal is first depressed, it should be low On con-

secutive applications, the pedal height should grad-

uallv rise. lf the pedal position does not vary, checK

the booster check valve.

l./

19-23

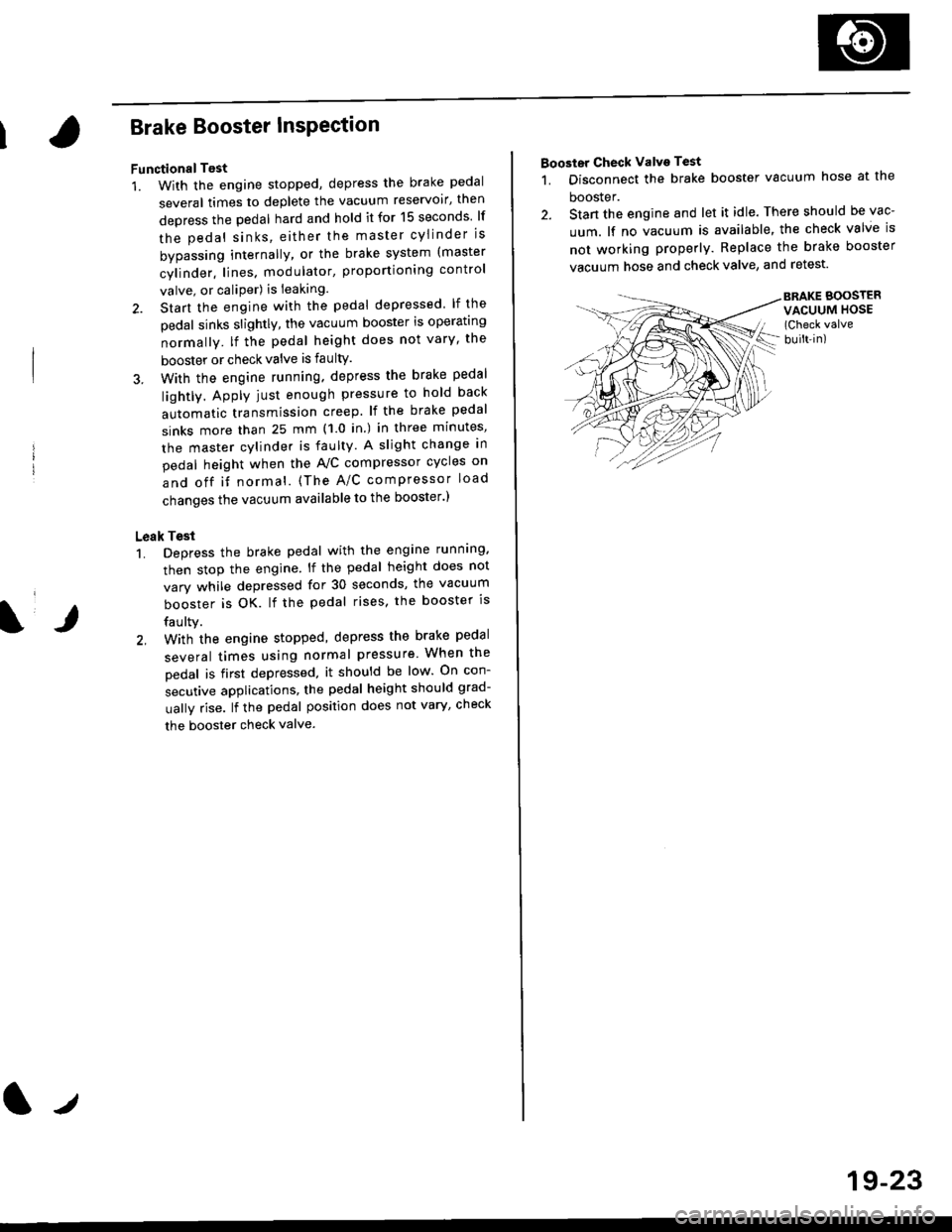

Booster Check Valve Test

1. Disconnect the brake booster vacuum hose at the

booster.

2. Stan the engine and let it idle. There should be vac-

uum. lf no vacuum is available, the check valve is

not working properly. Replace the brake booster

vacuum hose and check valve, and retest.

BRAKE BOOSTERVACUUM HOSE(Check valve

built-in)

Page 1199 of 2189

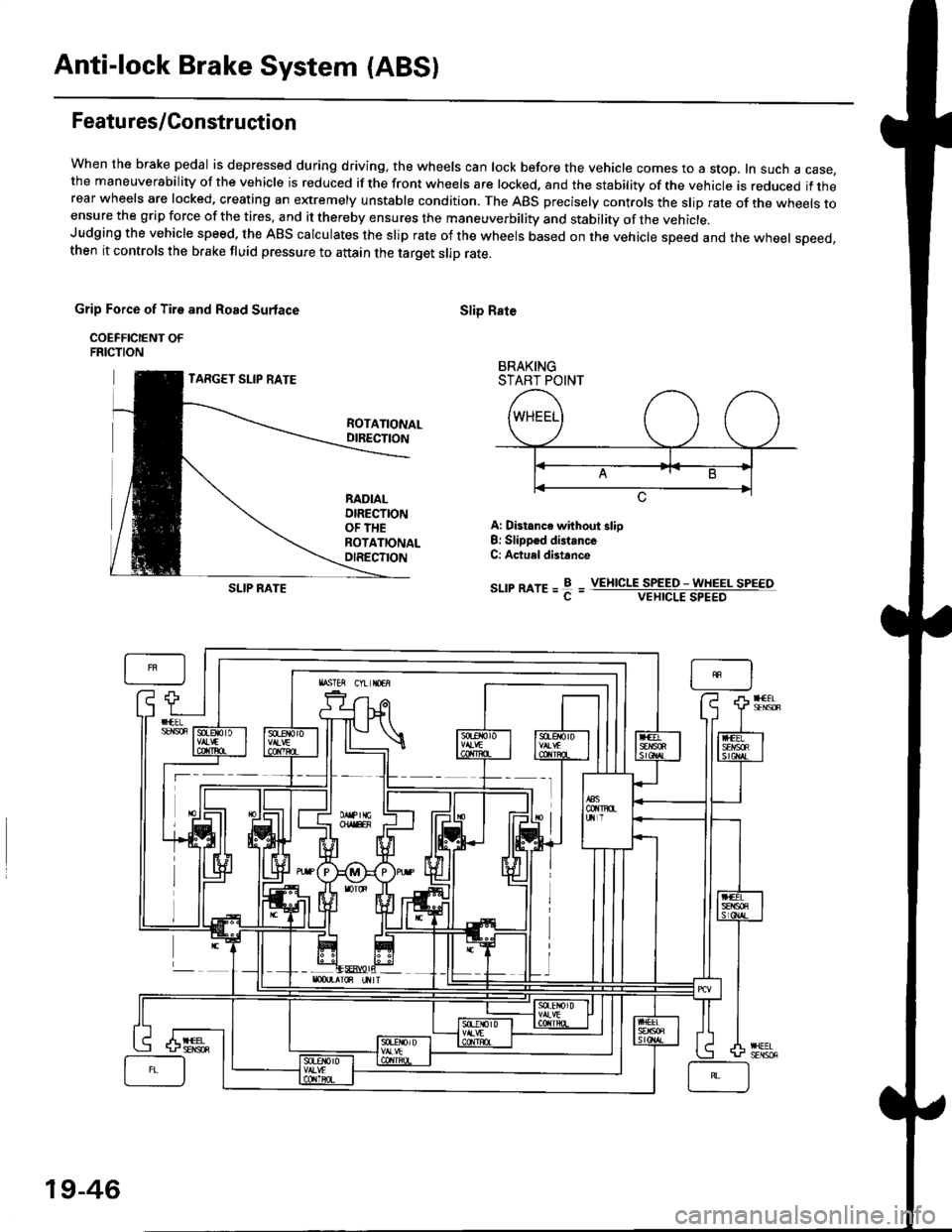

Anti-lock Brake System (ABSI

Featu res/Construction

When the brake pedal is depressed during driving, the wheels can lock before the vehicle comes to a stop, In such a case,the maneuverability of the vehicle is reduced if the front wheels are locked, and the stability of the vehicle is reduced if therear wheels are locked, creating an extremely unstable condition. The ABS precisely controls the slip rate of the wheels toensure the grip force of the tires. and it thereby ensures the maneuverbility and stability of the vehicle.Judging the vehicle speed. the ABS calculates the slip rate of the wheels based on the vehicle speed and the wheel speed,then it controls the brake fluid pressure to attain the target slip rate.

Grip Force of Tire and Road Surlace

COEFFICIENT OFFRICTION

TARGET SLIP RATE

Slip Rate

BRAKINGSTART POINT

ROTATIONALDIRECTION

RADIALDIRECTIONOF THEROTATIONALOIRECTION

A: Distance without slio8: Slippsd distanceC: Actuel distance

sr-rrmre=f=SLIP RATEVEIIICLE SPEED - WHEEL SPEEOVEHICLE SPEED

19-46

Page 1201 of 2189

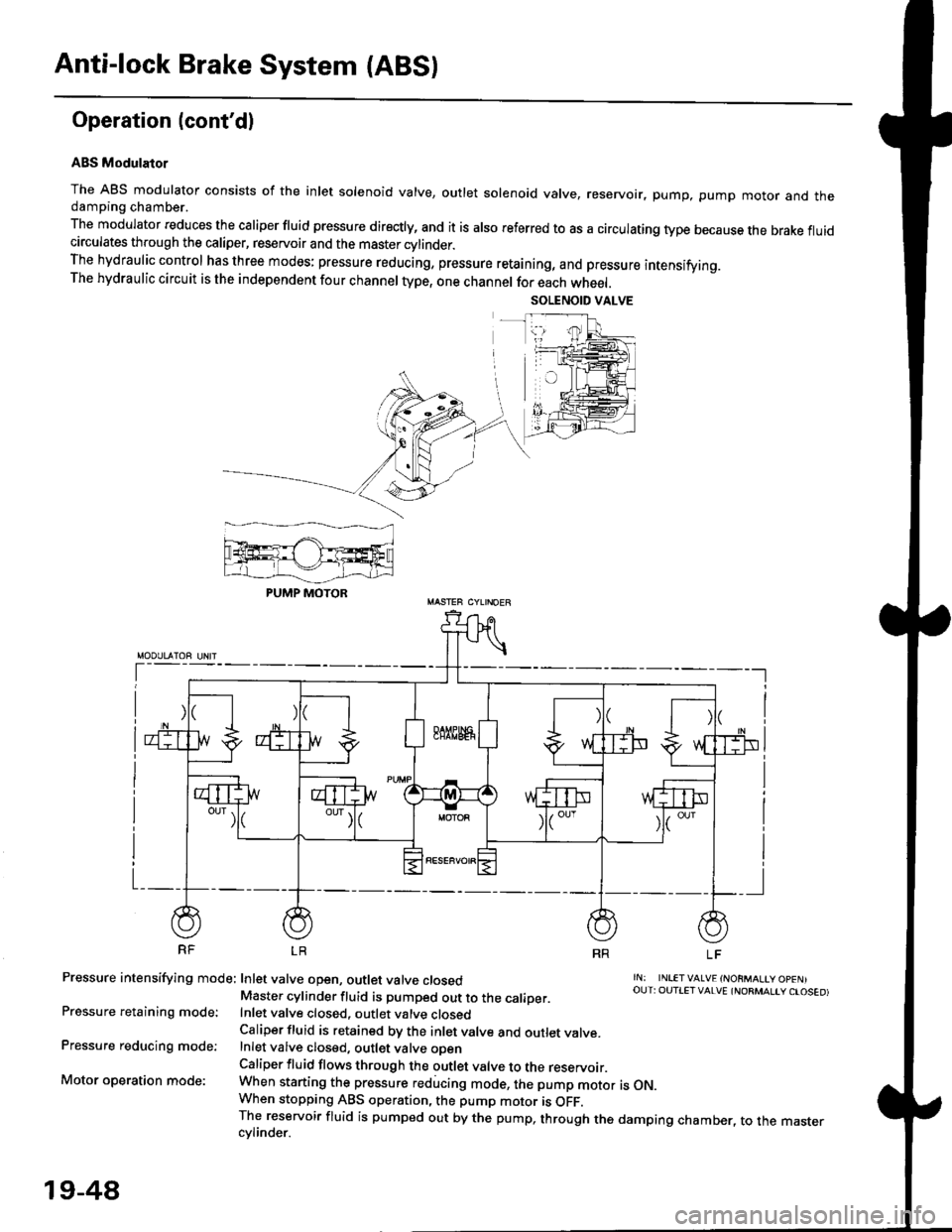

Anti-lock Brake System {ABS)

Operation (cont'dl

ABS Modulator

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and thedamping chamber.

The modulator reduces the caliper fluid pressure directly, and it is also referred to as a circulating type because the brake fluidcirculates through the caliper, reservoir and the master cylinder.The hydraulic control has three modes: pressure reducing, pressure retaining, and pressure intensifying.The hydraulic circuit is the independent four channel type, one channel for each wheel.

RF LR

Pressure intensifying mode: Inlet valve open, outlet valve closed

Pressure retaining mode:

Pressure reducing mode:

Motor operation mode:

rN: INLETVALVE {NORMALtY OpENIOUT: OUTIET VALVE {NORMALIY CTOSED)Master cylinder fluid is pumped out to the caliDer.Inlet valve closed, outlet valve closedCaliper fluid is retained by the inlet valve and outlet valve.Inlet valve closed, outlet valve oDenCaliper fluid flows through the outlet valve to the reservoir.When starting the pressure reducing mode, the pump motor is ON.When stopping ABS operation, the pump motor is OFF.The reservoir fluid is pumped out by the pump, through the damping chamber, to the mastercvlinder.

PUMP MOTOR

19-48

Page 1209 of 2189

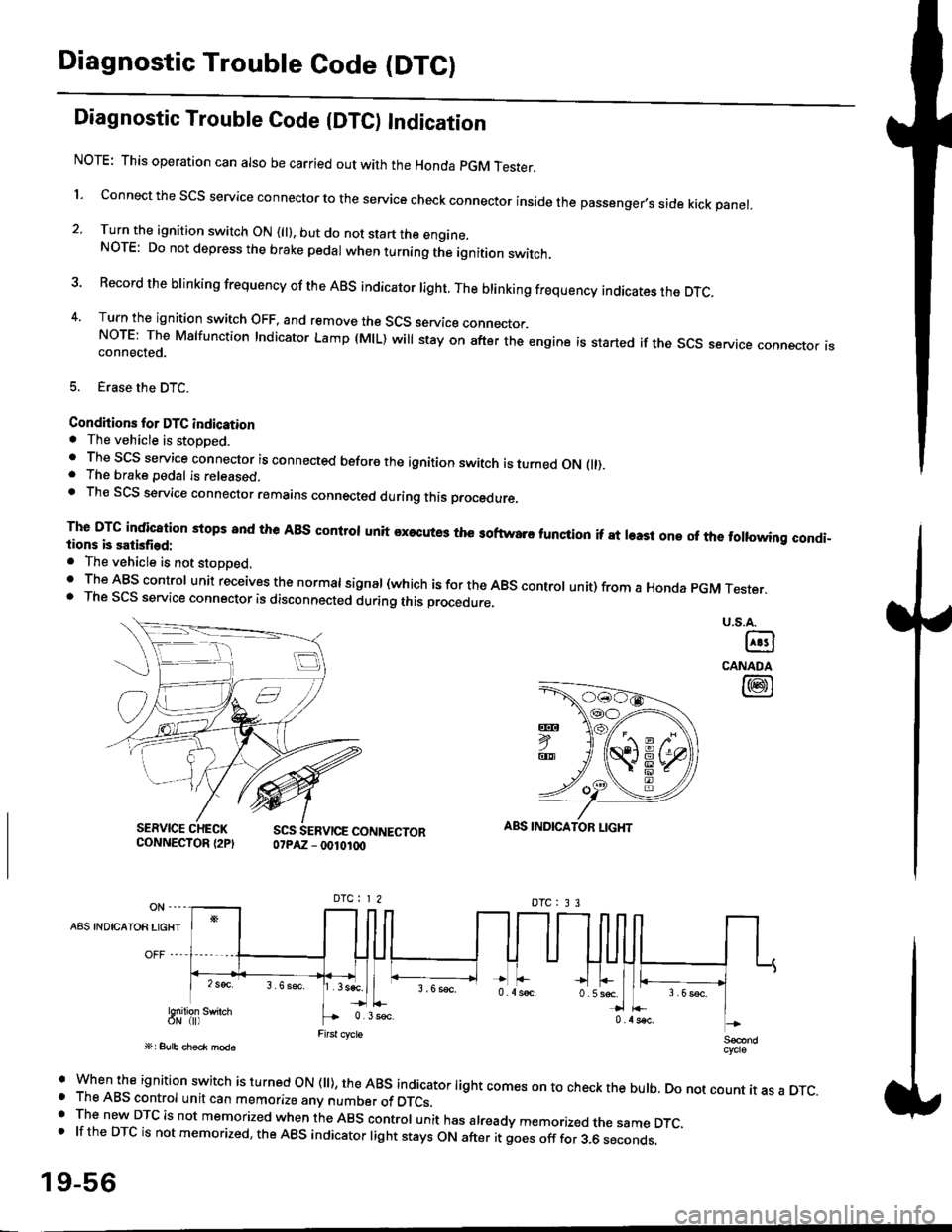

Diagnostic Trouble Code (DTCI

Diagnostic Trouble Code {DTC) Indication

NOTE: This operation can also be carried out with the Honda pGM Tesrer.

l connect the scs service connector to the service check connector inside the passenger,s side kick panel.

2. Turn the ignition switch ON (||). but do not start the engine.NOTE: Do not depress the brake pedal when turning the ignition switch.

3 Record the brinking frequency of the ABS indicator right. The brinking frequency indicates the DTc.

4, Turn the ignition switch OFF, and remove the SCS service connector.NorE: The Mslfunction Indicator Lamp (MlL) will stay on after the engine is started if the scs service connector isconnected.

5. Erase the DTC.

Condhions for DTC indication. The vehicle is stoDDed.. The SCS service connector is connected before the ignition switch is turned ON fll).. The brake pedal is released.. Th€ SCS service connector remains connected during this procedure

The DTG indication stops 8nd the ABs conltol unit executes the softwaro tunqtion if at least one of the following condi-tions b satisfied:

o The vehicle is not stoDoed.' The ABS control unit receives the normat signal (which is for the ABS controt unit) from a Honda pGM Tester.. The SCS service connector is disconnected during this procedu.e,

u.s.A.

@

CANADA

@

SERVICE CHECKCONNECTOR {2PISCS SERVICE CONNECTOR07PAZ - 0010100

ABS INDICATOR LIGHT

DTC : 3 3

A8S INDICAIOR LIGHT

Snilion swirch

' when the ignition switch is turned oN (ll), the ABs indicator light comes on to check the bulb. Do not count it as a DTc.o The ABS control unit can memorize any number of DTCs.. The new DTC is not memorized when the ABS control unit has already memorized the same DTC,.lftheDTCisnotmemorized,theABSindicatorlightstaysONafteritgoesofffor3.6seconds.

19-56

Page 1210 of 2189

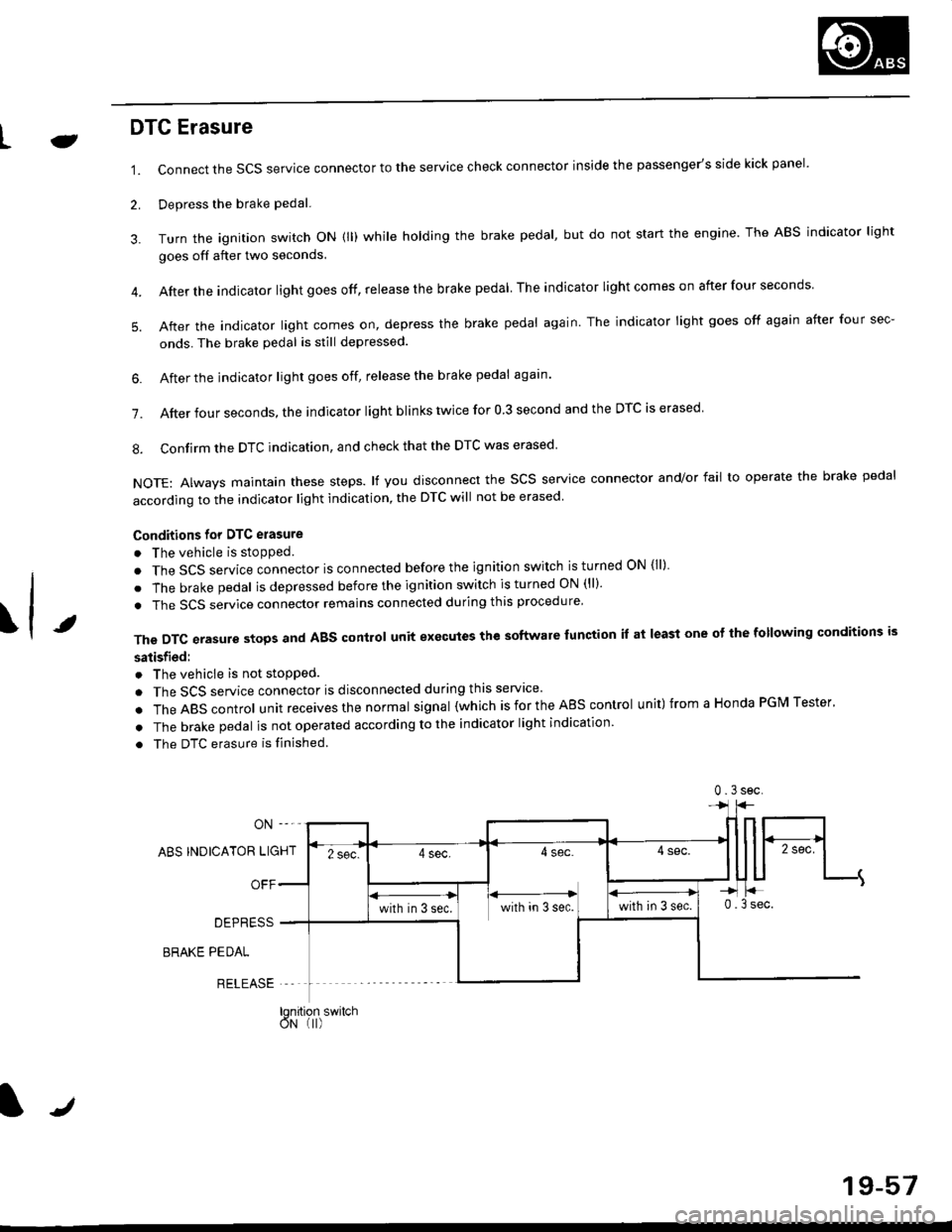

LJDTG Erasure

1.

2.

Connect the SCS service connector to the service check connector inside the passenger's side kick panel.

Depress the brake pedal.

Turn the ignition switch oN (ll) while holding the brake pedal, but do not start the engine. The ABS indicator light

goes off after two seconds.

After the indicator light goes off, release the brake pedal The indicator lightcomeson after four seconds

After the indicator light comes on, depress the brake pedal again. The indicator light goes off again after four sec-

onds. The brake pedal is still depressed.

4.

5.

\t

6. After the jndicator light goes off, release the brake pedal again'

7. After four seconds, the indicator light blinks twice for 0 3 second and the DTC is erased

8. Confirm the DTC indication, and check that the DTC was erased

NOTE: Always maintain these steps. lf you disconnect the scs service connector and/or fail to operate the brake pedal

according to the indicator light indication, the DTC will not be erased

Conditions for DTC erasure

o The vehicle is stopped.

. The SCS service connector is connected before the ignition switch is turned ON {ll)

. The brake pedal is depressed before the ignition switch is turned ON (ll)'

. The SCS service connector remains connected during this procedure

The DTC erasure stops and ABS control unit executes the software lunction it at least one ot the following conditions is

satisfied:

o The vehicle is not stopped.

. The SCS service connector is disconnected during this servace'

.TheABscontro|unitreceivesthenormaIsigna|(whichisfortheAEscontro|unit)fromaHondaPGMTester'

. The brake pedal is not operated according to the indicator light indication

. The DTC erasure is finished

ABS INDICATOR LIGHT

OFF

DEPRESS

BRAKE PEDAL

RELEASE

0.3sec

lqnition switchoN (I)

J

19-57

Page 1971 of 2189

How the Circuit Works

Seat Belt Warning

With the ignition switch in ON (ll) or START (lll),

battery voltage is applied to the seat belt reminder

light. When the seat belt is not buckled, the seat

belt reminder/key-on beeper circuit in the

integrated control unit senses ground through the

closed seat belt switch. The seat belt reminder light

comes on and stays on, and the beeper beeps for

6 seconds. The reminder light and beeper will stop

when the seat belt is buckled or the timer circuit

deactivates them.

lgnition Key Warning

Battery voltage is supplied at all times to the seat

belt reminder/key-on beeper circuit in the

integrated control unit. When you turn on the

ignition key switch the integrated control unit

senses ground. lf you open the driver's door, the

door switch closes, causing the beeper to sound

until the door is closed.

Refer to the Service Manual (Section 23, Electrical)

for specitic tests or troubleshootrng procedures.

73-1