vacuum line HONDA CIVIC 1999 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 526 of 2189

![HONDA CIVIC 1999 6.G User Guide \EGR VALVELIFT SENSOR#16 HOSE

I

(From page 11-256)

EGR VALVE LIFT SENSOR3P CONNECTOR lC14.l)

zF vcczI- . ] IYEL/BLU)ll 2l3l---l-r_ 7 |

v-,, ISG2IGRN/BLK) I ^ II{Vts

ECM CONNECTOR D {16P)

PUMP/GAUGE,0 HONDA CIVIC 1999 6.G User Guide \EGR VALVELIFT SENSOR#16 HOSE

I

(From page 11-256)

EGR VALVE LIFT SENSOR3P CONNECTOR lC14.l)

zF vcczI- . ] IYEL/BLU)ll 2l3l---l-r_ 7 |

v-,, ISG2IGRN/BLK) I ^ II{Vts

ECM CONNECTOR D {16P)

PUMP/GAUGE,0](/img/13/6068/w960_6068-525.png)

\EGR VALVELIFT SENSOR#16 HOSE

I

(From page 11-256)

EGR VALVE LIFT SENSOR3P CONNECTOR lC14.l)

zF vcczI- . ] IYEL/BLU)ll 2l3l---l-r_ 7 |

v-,, ISG2IGRN/BLK) I ^ II{Vts

ECM CONNECTOR D {16P)

PUMP/GAUGE,0 - 30 in.Hs4973X-041-XXXXX

sG2(GRN/BLKIvcc2IYEL/BLU}

Wire side ol temale terminals

PCM CONNECTORS C (31P}'

YES

Wire side of female terminals

1

(cont'd)

1-257

Check fo. a mallunction in theEGF valv€:1. ldove the vacuum pump/gauge

to the EGR valve.2. With the engine at idle, apply

26.7 kPa (200 mmHg,8.0 in.Hg)

ofvacuum to the EGR valve.

Does the engine stall or runrough and does the EGR valvehold vacuum?

Check for an open in the wire

IVCC2linel:1. Turn the ignition switch OFF.2. Disconnect the EGR valve liftsensor 3P connector.3. Turn the ignition switch ON (ll).

4. Measure voltage between theEGR valve lift sensor 3P con'

nector terminals No. 3 and

No.2.

ls lhere approx.5 V?

Check for an oDen in the wire

{VCC2 line}:Measure voltage between theECM/PCM connector terminalsD10 and Dl1 (C18 and C28)*.

Rep.ir open in the wire betweenrhe EGR valve snd ECM/PCM

{Dl0 {C28)*).lsthere approx.5 V?

Sub3titute t known-good ECM/PCM end recheck. lt 3ymptom/indication goos eway, replaceth6 original ECM/PCM.(To page 1l-258)*: '99 - 00 models

Page 528 of 2189

I

I

Wire side of lemale terminals

PCM CONNECTORS C (31P)*

ECM CONNECTOR O {I5PI

Wire side of temale terminals

t

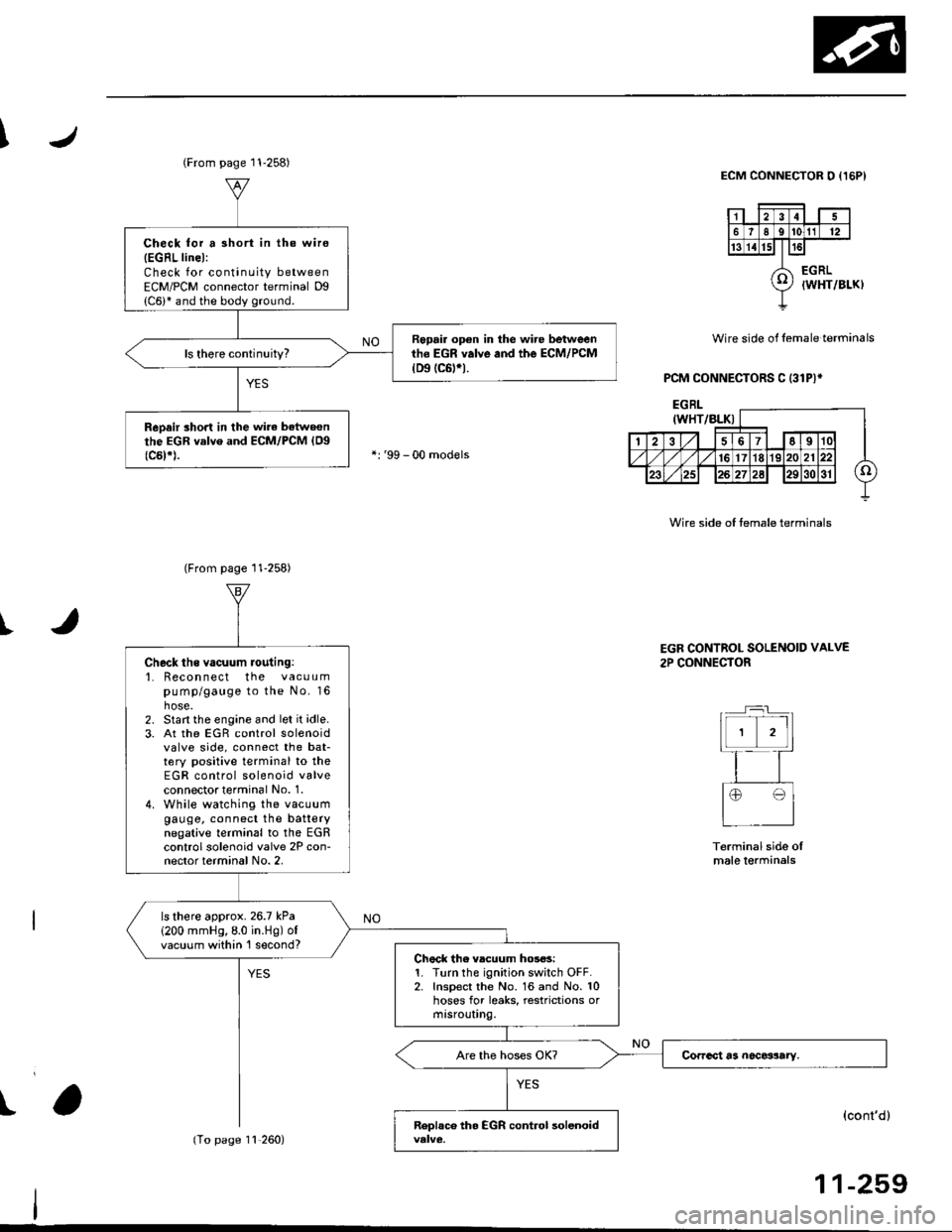

(From page 11-258)

Check for a 3hort in the wire

{EGRL linel:Check for continuity betweenECM/PCM connector terminal Dg

Repair op€n in the wire betweenth6 EGR valve and the ECM/PCM(D9 tc6trt.

ReDair short in the wirc batweonthe EGR valve and ECM/PCM {Og(c5t*).

(From page 11-258)

11,260)

Check ths vacuum routing:'1. Recon nect the vacuumpump/gauge to the No. 16hose.2. Start the engine and let it idle.3. At the EGR control solenoidvalve side, connect the bat-tery positive terminal to theEGR control solenoid valveconnectot terminal No. 1.4. While watching the vacuumgauge, connect the batterynegative terminal to the EGRcontrol solenoid valve 2P con-nector terminal No. 2,

ls there approx.26.7 kPa

1200 mmHg,8.0 in.Hg) ofvacuum within 'l second?Chock the vlcuum hos6s:1. Turn the ignition switch OFF.2. Inspect the No. 16 and No. 10hoses for leaks, restrictions ormtsrouUng.

EGR CONTROL SOLENOID VALVE

2P CONNECTOR

Terminal side oImale lerminals

(cont'd)

11-259

Page 540 of 2189

\J

\

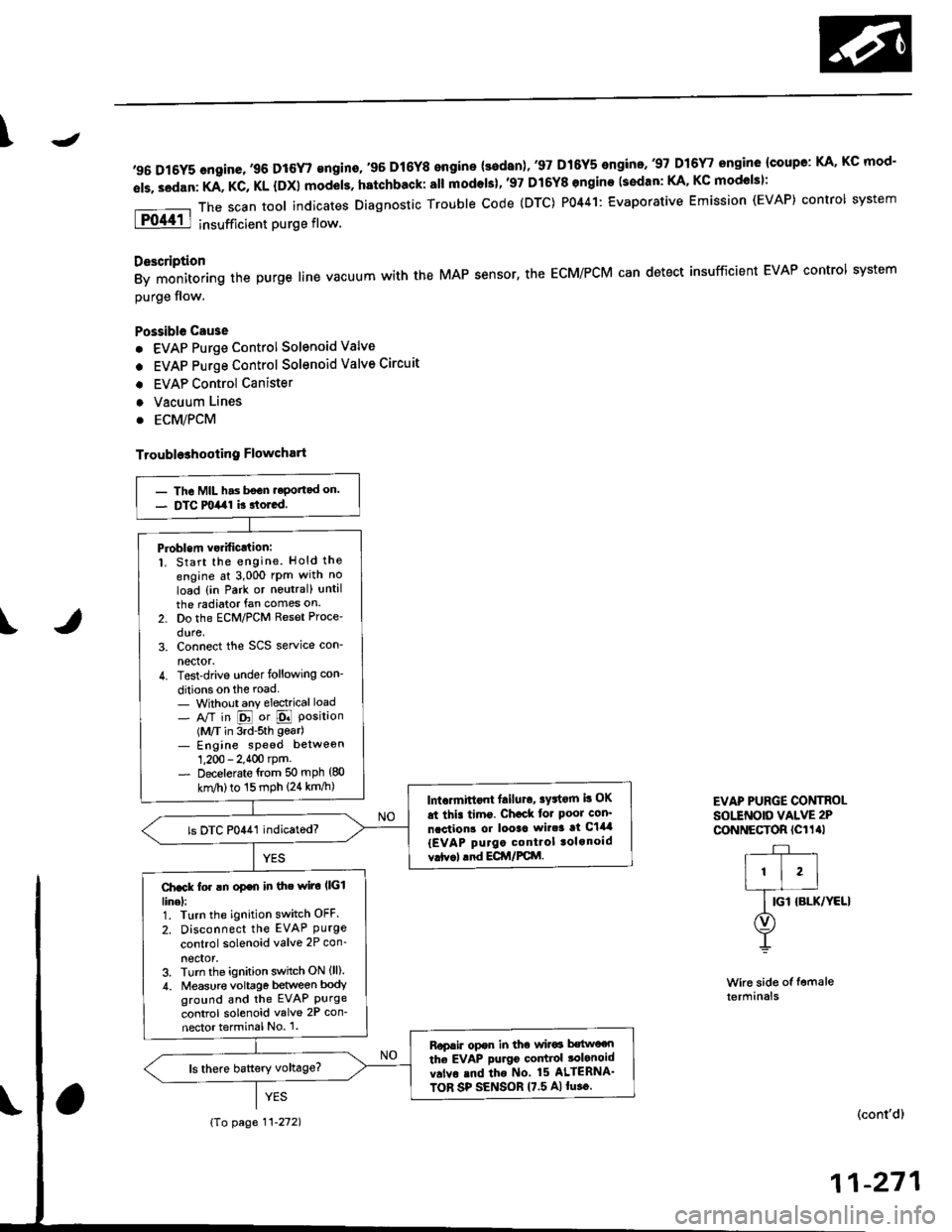

,96 D16Y5 engine,,96 D16r,gngino,,96 Dt6Y8 engine {3edan)' 37 D16Y5 engino..97 D16r, engine {coupe: KA, Kc mod-

els. sedan: KA, KC, KL {DX} models. hatchback: all modols}''97 Dl6Y8 ongine (s€dan: KA' KC mod€lsl:

The scan tool indicates Diagnostic Trouble code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the ECM/PCM can detect insufficient EVAP control system

purge flow.

Possible Cau3e

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. ECM/PCM

Troubl93hooting Flowchart

Wire side of femaleterminals

EVAP PURGE CONTROI-sottNotD vALvE 2P

CoNNECTOR (Cl1al

r-+-r

I'l'l

lG-ro.*l'rr"r

O)

Y

(cont'd)

11-271

- The MIL has bsGn.eportad on.- DTC milal k rtored.

Pioblem vsrificJtion:1. Start the engine. Hold the

engine at 3,000 rPm with no

load {in Park or noutral) until

the radiator fan comes on.

2. Do the ECM/PCM Reset Proce'

dure,3. Connect the SCS service con-

nector.4. Test-drive under following con-

ditions on the road- Without any electrical load- A/T in E or E Position(M/T in 3rd-sth gear)- Engine sPeed betweon

1,200 - 2.400 rpm.- Decelerate {rom 50 mph (80

knl/h)to 15 mph (24 km/h)lntormittont lailuro, sFtorn b OK

at thi. timo. Ch€ck tor Poor con'

ncction3 or looac wir.3 at C144

{EVAP purgo control tolonoid

vrtv.l .nd ECir/FCttl.

ls DTC P0441 indicatod?

Ch.ck fo. !n op€n in the wiro l|(illinel:1. Turn the ignition switch OFF.

2. Disconnect the EVAP Purgecontrol solenoid valve 2P con_

neclor,3. Turn the ignition switch ON (ll)

4. Measur€ voltage between bodyground and the EVAP Purgecontrol solenoid valve 2P con-

nector terminal No 1.

Rop.ir opor in tho wir6 b€two€n

the EVAP purgo codtiol tolonoid

v.lvo rnd tho No 15 ALIERNA'

TOR SP SENSOR 17.5 A)lu.o.

{To page 11-272)

Page 541 of 2189

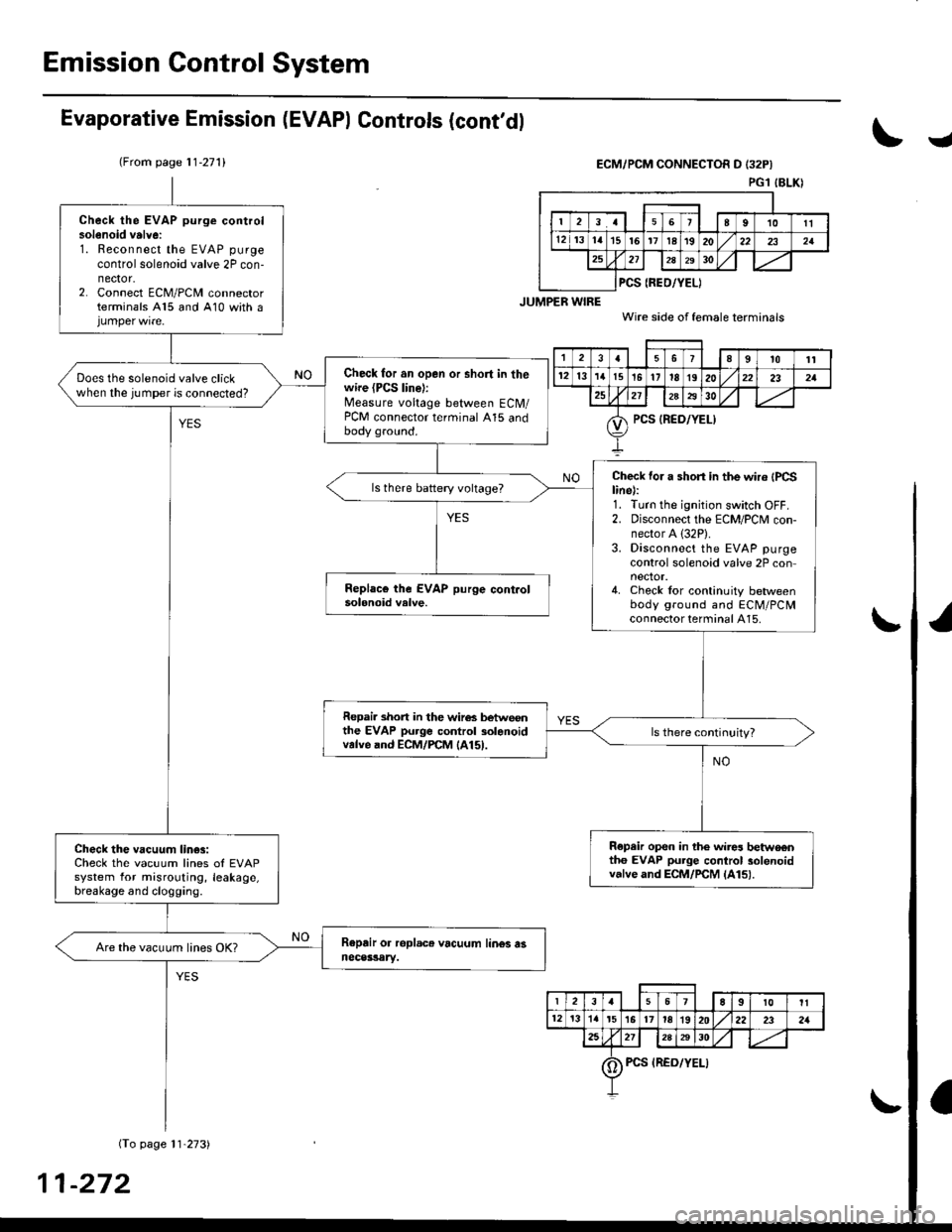

Emission Gontrol System

Evaporative Emission (EVAPI Controls (cont'dl

(From page 11-271)

I

ECM/PCM CONNECTOR D I32P}

PGl IBLKI

Check the EVAP purge controlsolenoid valvei1. Reconnect the EVAP purge

control solenoid valve 2P con-nector.2. Connect ECM/PCM connectorterminals A15 and 410 with a

Check for an open or short in thewire (PCS line):Measure voltage between ECM/PCM connector terminal A15 andbody gro!nd.

Does the solenoid valve clickwhen the jumper is connected?

Che'ck for a short in the wir6 {PCSline):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector A (32P).

3. Disconnect the EVAP purgecontrol solenoid valve 2P connector.4. Check lor continuity betweenbody ground and ECM/PCMconnector terminal A15.

Repai. short in the wir6s betwoonthe EVAP purge control solanoidvalve and ECM/rcM lA15l.

R€pair op€n in the wir$ betwo€ntho EVAP purge control solenoidvalve and ECM/rcM lA15l.

Check the vacuum lin€3:Check the vacuum lines ol EVAPsystem for misrouting, leakage,breakage and clogging.

Are the vacuum lines OK?

PCS {REO/YEL)

t389t0'tt

12l3'I'tt5t5'11IE1920232a

?5212A2930

PCS {RED/YEL)

23a67E9t0It

12t3'ta't5l617ta1920222321

2a2728A30

0) Pcs {REo/YELI

-272

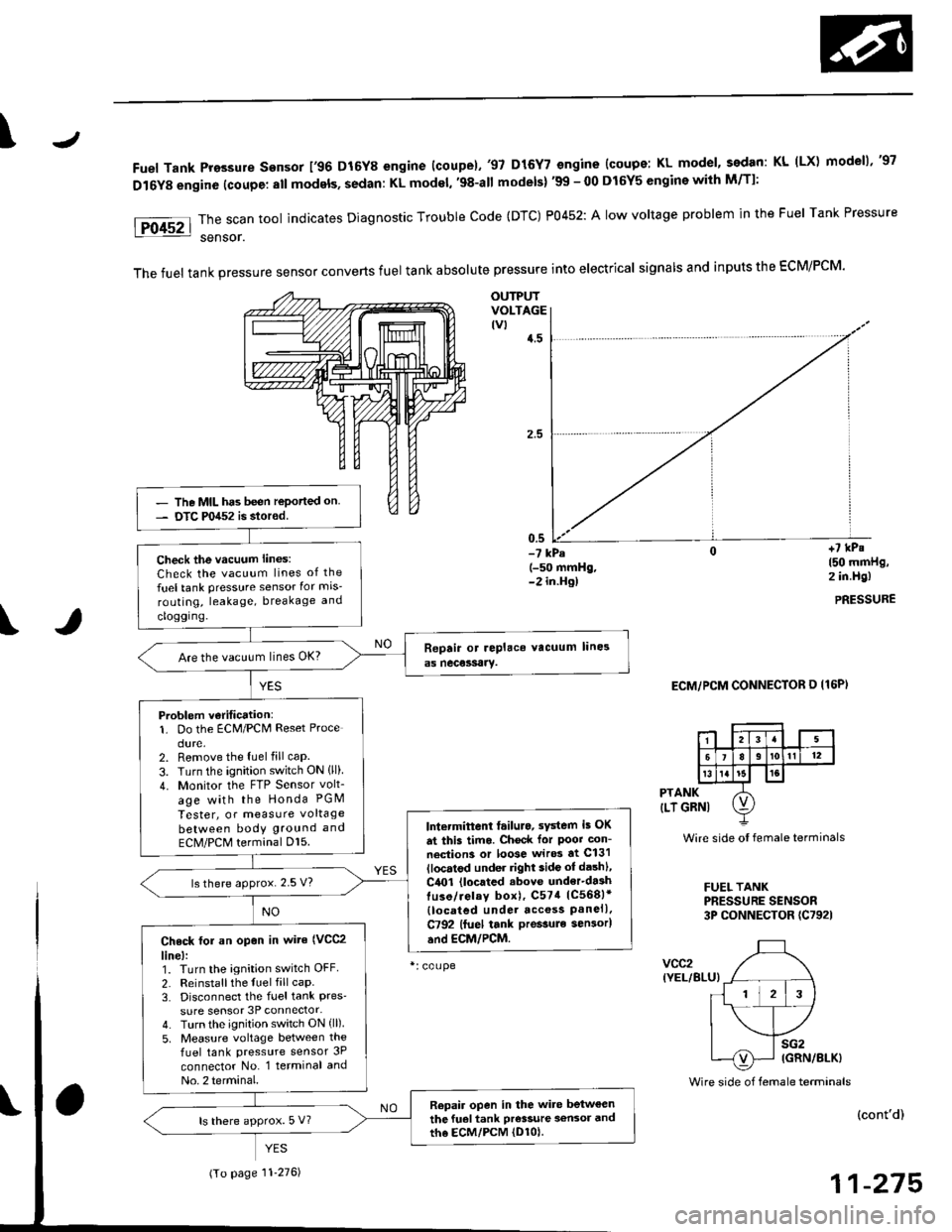

Page 544 of 2189

\J

Fuel Tank Pro3sure sensor 196 D16Y8 engine (coupe).'97 D15Y7 engine {coupe: KL model, sedan: KL (LX) modeu,'97

D16Y8 engine (coupe: all models, sedan: KL model, '98-all models) '99 - 00 D16Y5 engine with M/Tl:

\

PTANK

{LT GRNI

vcc2(YEL/BLU}

Wire side oI female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR (C7921

sG2IGRN/8LK)

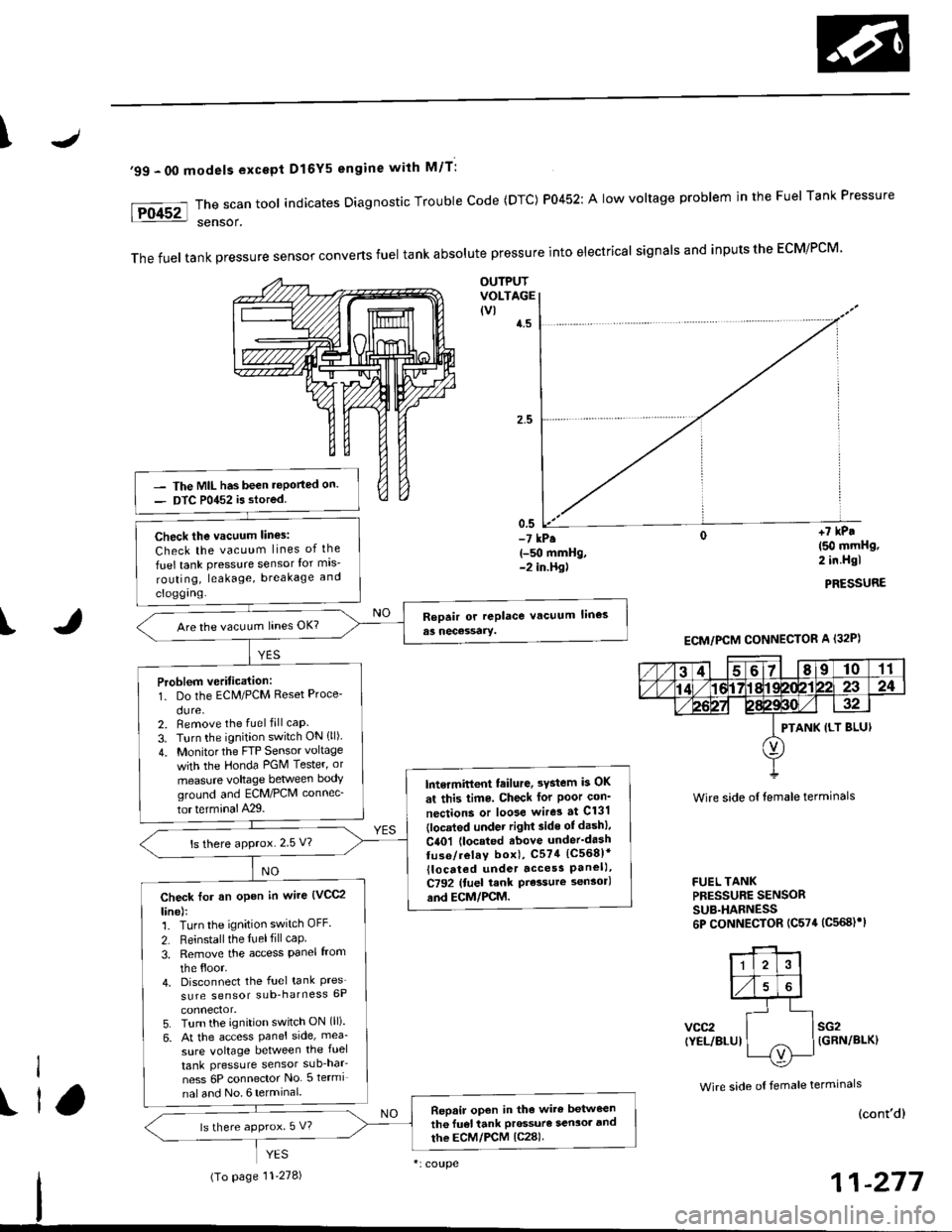

Foc2l::il":"toolindicatesDiagnosticTroublecode(DTc)P0452:A|owvo|tageprob|emintheFue|TankPressure

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the EcM/PCM.

OUTPUTVOLTAGEtvt4.5

-? kPa(-50 mmHg,-2 in.Hg)

ECM/PCM CONNECTOR O I16P)

Wire side of female terminals

+7 kPs150 mmHg,2 in.Hg)

PRESSURE

(cont'd)

11-275

- The MIL has been reported on- DTC P0452 is stored.

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum lines OK?

Problem v€ritication:1. Do the ECM/PCM Reset Proce

dure.2. Remove the luel fill caP.

3. Turn the ignition switch ON lll)4. Monitor the FTP Sensor volt_

age with the Honda PGM

Tester, or measure voltage

between bodY ground and

ECM/PCM terminal Dl5.lntermittent tailuro, sYstem i5 OK

dt this timo. Chock for Poot con-

neciion3 or loose wir* at C131

llocatod under right side ot dashl,

C4O1 (located .bove under'da3htuso/ielay box), C574 1C568)*

{located under acc€ss Panell.C792 lfuel tank pressule sen3or)

and EcM/PCM.

ls there approx. 2.5 V?

Check tol an op€n in wite (VCC2

line):1. Turn the ignition switch OFF

2. Reinstallthe fuel fill caP.3. Disconnect the fuel tank Pres'sure sensor 3P connector-4. Turn the ignition switch ON (ll)

5, Measure voltage between the

fuel tank pressure sensor 3P

connector No. l terminal and

No. 2 terminal.

Repair open in the wite betweenthe fuel tank Pr€s3ure a€n3or andth6 EcM/PcM (D1ol.ls there approx. 5 V?

(To page 11'276)

Page 546 of 2189

\

'99 - 00 models excepi Dl6Y5 engine with M/T:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensor.

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM

OUTPUTVOLTAGE(vlt.5

0.5-7 kP.(-g) mmHg,-2 in.Hgl

+7 kP.

150 mmHg,2 in.Hgl

PRESSURE

I

Wire side of lemale terminals

FUEL TANKPRESSURE SENSORSUB.HARNESS6P CONNECTOR (C574 (C568)rl

vcc2(YEL/BLUIsG2{GRN/BLK}

Wire side o{ temale terminals

The MIL has been .eported on.

DTC P0452 is stored

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor lor mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum hnes OK?

Problem veritication:1. Do the ECM/PCM Reset Proce-

du re,2. Bemove the fuel fill caP.

3. Turn the ignition switch ON {ll)

4. Monitorthe FTP Sensor voltage

with the Honda PGM Tester' or

measure voltage between body

groLrnd and ECM/PCM connec_

tor terminalA29.

lntermitlent tailure, 3Ystem b OK

at this time. Check for Poor con'

nections or loose wire3 at C131

{located under right side of dash},

C401 {located above under'dash

tuse/relay box), C574 (C568)*

llocdted under access Panel),C792 (tuel rank Prcssure sensorl

and ECM/PCM.

ls there approx.2 5 V?

Check for an open in wire {VCC2

line):1. Turn the ignition switch OFF.

2. Reinstall the ltrel fill caP

3, Remove the access Panel from

the floor.4. Disconnect the fuel tank Pres'sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll).

6. At the access Panel side, mea_

sure voltage between the fuel

tank Pressure sensor sub-nar-

ness 6P connector No 5termi

nal and No. 6 termlnal.

Repair open in tho wire between

th6 fu€l tank Prossuro sen3oa and

the ECM/PCM lc28).ls there approx 5 V?

ECM/PCM CONNECTOR A (32P)

PTANK {LT BLUI

I

ll

(To page '11-278)

(cont'd)

Page 548 of 2189

\

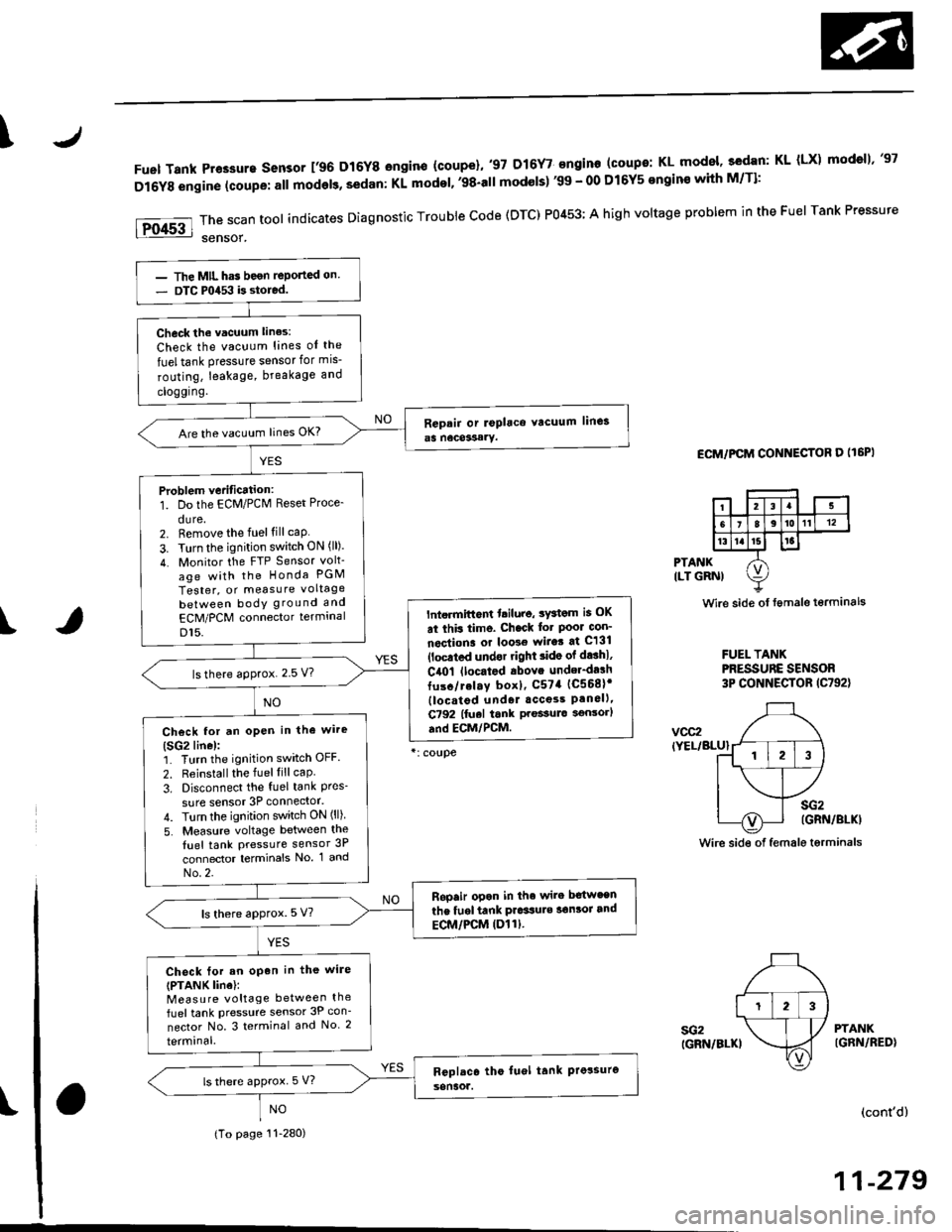

Fue| Tank Pr€ssure sensor 196 Dr6Y8 engine (coupe},,97 D16Y7 angino (coupo: KL mode|' 3edan: KL (Lxl modg||',97

Dl6Y8 engine (coupe: all modeb, sedan: Ki model.'98'all modols) 39 - 0O Dl6Y5 ongins with M/Tl:

rFoG'l::;Jl"too|indicatesDiagnosticTroub|ecode(oTc)P0453;Ahighvo|tageprob|emintheFue|TankPressure

ECM/PCM CONNECTOR D Il6PI

PTANKILT GRNI

\

Wire side of tgmale torminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR (C792)

vcc2(YEL/BLU}

sG2(GRN/BLKI

Wire sid€ of female terminals

I

sG2IGRN/BLKI

PTANKIGBN/RED}

(cont'd)

11-279

The MIL has beon reponed on

DTC P0453 b stored.

Check the vacuum lines:

Check the vacuum lines oI the

fueltank pressure sensor for mis-

routing, leakage, breakage and

clogging.

Are the vacuum lines OK?

Problem verification:1. Do the ECM/PCM Reset Proce-

dure.2. Femove the fuel fill cap

3. Turn the ignition switch oN (ll).

4. Monitor the FTP Sensor volt-

age with the Honda PGM

Tester, or measure voltage

between bodY ground and

ECM/PCM connector termrnal

D15.

lntormittont t iluro, 3Ystem is OK

at this time. Check lot Poor con_

noctiona or loo3e wirat at C131

{loc.ted undor right 3id6 of d8hl,

CaOl llocatod rbov. under-dalh

fus6/relay boxl, C574 (C568lr

llocatod und6l accoss Pan6ll,C792 lfuel tank Preasulo aonlorl

end ECM/PCM.

ls there approx. 2 5 V?

Check for an oPen in the wire(SG2line):1. Turn the ignition switch OFF.

2. Reinstall the fuellill cap

3. Disconnect the fuel tank Pres-sure sensor 3P connector.

4. Turn the ignition switch ON (ll)

5. Measure voltage between the

fuel tank Pressure sensor 3P

connector terminals No. 1 and

No.2.

Ropair opon in the wira b€tw€sn

the fuel tank prasure sonlor and

ECM/PCM (Dl1).ls there aPProx. 5 V?

Check for an open in the wire(PTANK line):Measure voltage between the

fueltank Pressure sensor 3P con-

nector No. 3 terminal and No. 2

termrnal,

ls there approx. 5 V?

*: coupe

{To page 11-280)

Page 550 of 2189

\

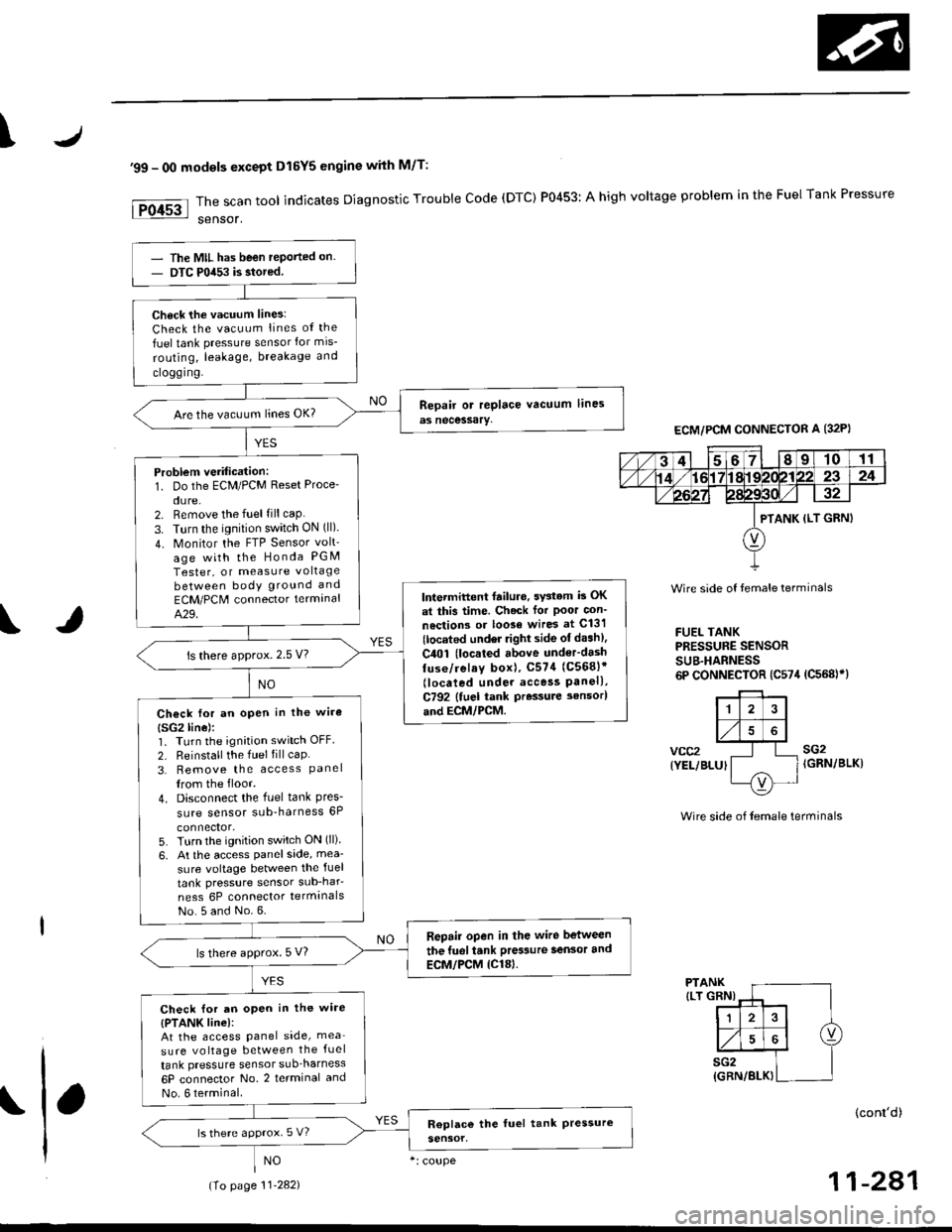

'99 - 0O modols except Dl5Y5 engine with M/T:

rFo45'::n":"tooIindicatesDiagnosticTroub|ecode(DTc)P0453:Ahighvo|tageprob|emintheFUelTankPressure

Wire side of temale terminals

FUEL TANKPRESSUNE SENSOR

SUB.HARNESS6P CONNECTOR {C574 (C568)}}

vcc2{YEL/BLUI

sG2IGRN/BLK)

Wire side of female terminals

PTANK{LT GRNI

(cont'd)

11-281

ECM/PCM CONNECTOR A {32P)

PTANK {LT GRN)

The MIL has been reported on.

DTC P0453 is stored.

Check the vacuum lines:

Check the vacuum lines ot the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

clogging.

Are the vacuum lines OK?

Problem verilication:1. Do the ECM/PCM Reset Proce-

du re,2. Remove the fuel fill caP

3. Turn the ignition switch ON (ll).

4. Monitor the FTP Sensor volt'

age with the Honda PGM

Tester, or measure voltage

between body ground and

ECM/PCM connector terminalA.29.

lntermittent failuro. svstem b OK

at this time. Check for Poor con_

noctions or loo3€ wire3 at C131

{located under tight side of dash),

C4Ol {located above underdash

fuse/relay boxl, C57{ (C5681'

llocaled unde. access Panell,C792 {fuel tank Pressure sensorl

aod ECM/PCM.

ls there approx.2.5 V?

Ch€ck for an open in the wira

{SG2line):1. Turn the ignition switch OFF.

2. Reinstall the fuel fill caP

3. Remove the access Panellrom the floor.

4. Disconnect the fuel tank Pres-sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll)

6, At the access Panelside, mea-

sure voltage between the fuel

tank pressure sensor sub_har-

ness 6P connector termlnals

No.5 and No.6.

Repair open in the wire between

the fueliank Pres3ure 3ensor and

ECM/PCM {Cl8).ls there approx.5 V?

Check lor an oPen in the wire

{PTANK linel:At the access Panel side, mea

sure voltage between the fuel

tank pressure sensor suo_harness

6P connector No. 2 terminal and

No. 6 terminal.

ls there approx. 5 V?

(To page 11.282)

Page 552 of 2189

\

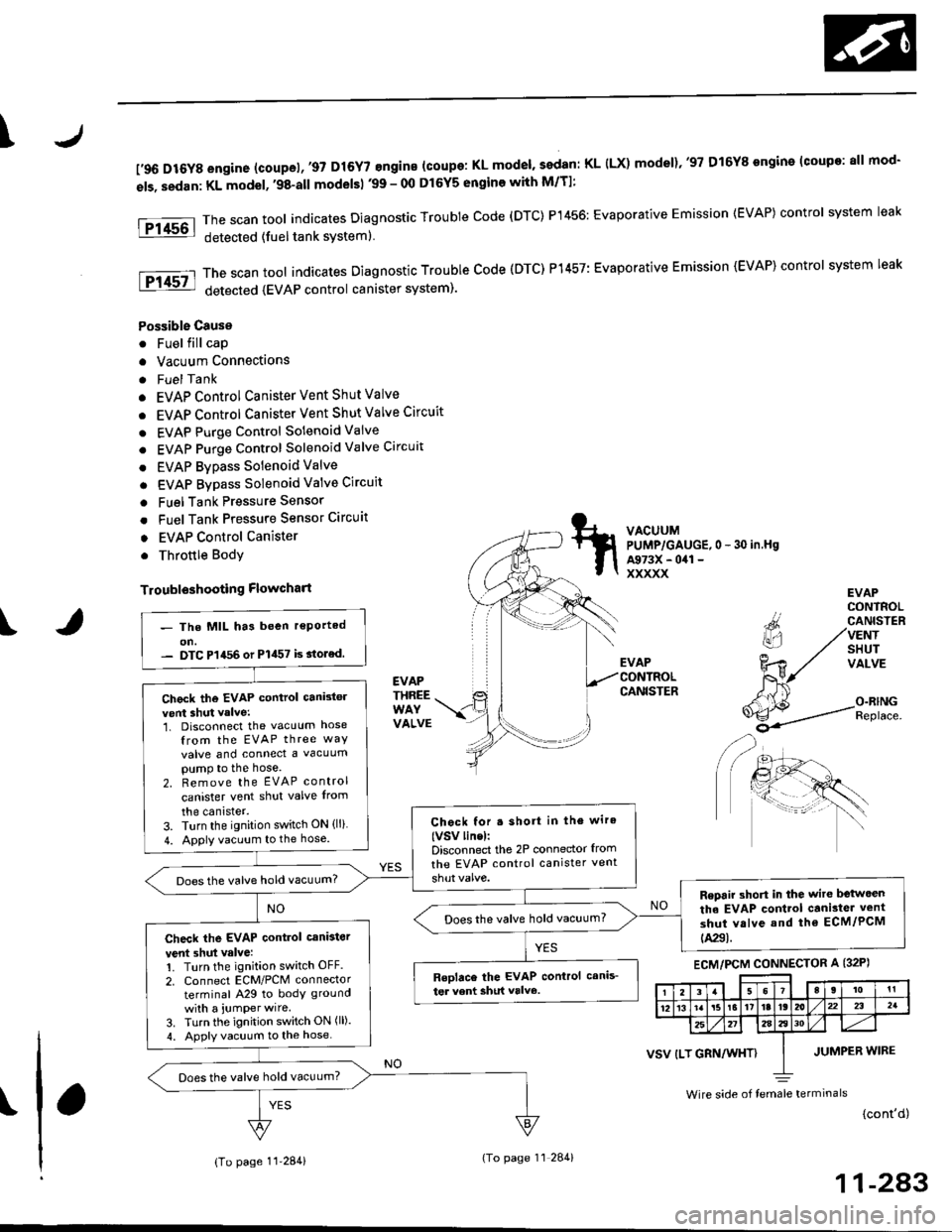

t,96 D16Y8 engine (coup6l,'9? Dl6Y7 engine (coupe: KL model, sedan: KL (LX) model)"g7 Dl6Y8 ongine (coupe: all mod-

els, sedan: KL model,'98-8ll modelsl 39 - 00 Dl5Y5 engine with M/Tl:

The scan tool indicates Diagnostic Trouble code (DTc) P1456: Evaporative Emission (EVAP) control system leak

detected (fuel tank sYsteml

The scan tool indicates Diagnostic Trouble Code (DTC) P1457: Evaporative Emission (EVAP) control system leak

detected (EVAP control canister system).

Fr4t6l

fF14s7

Possible Causs

. Fuel fill cap

. Vacuum Connections

. Fuel Tank

. EVAP Control Canister Vent Shut Valve

. EVAP Control Canister Vent Shut Valve Circuit

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Bypass Solenoid Valve

. EVAP Bypass Solenoid Valve Circuit

. Fuel Tank Pressure Sensor

. Fuel Tank Pressure Sensor Circuit

. EVAP Control Canister

. Throttle Body

Troublsshooting Flowchart

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X - 041 -

xxxxx

I

EVAPCONTROL

.4, cANrsrER

re ./ VALVE

{S----r*::n

\(cont'd)

- The MIL ha3 been rePofted

on.- DTC P1456 or P1457 is stored.

Check the EVAP control canbtol

vent shut valve:1. Disconnect the vacuum hose

Irom the EVAP three waY

valve and connect a vacuurnpump to the hose.

2. Remove the EVAP control

canister vent shut valve Irofi

the canrster.3. Turn the ignition switch ON (lli

4. Apply vacuum to the hose.

Chock for . shon in the wire(VSv linel:Disconnect the 2P connector {rom

the EVAP control canister vent

Does the valve hold vacuum?

Repair short in the wir€ betwcen

the EVAP control canister vent

shut v.lve and tho ECM/PCM

tA29|.

Does the valve hold vacuum?

Check the EVAP control canister

vent shui valve:1. Turn the ignition switch OFF.

2. Connect ECM/PCM connectorterminal A29 to body ground

with a iumPer wire.

3. Turn the ignition switch ON (ll).

4. Applyvacuum to the hose

Reohce the EVAP control canis-

ter vent shttt valve.

Does the valve hold vacuum?

ECM/PCM CONNECTOR A {32P)

37I9t01t't2t3t5t6ItItt9202a2a

25aA

ILT GRN/W{T) I JUMPER WIRE

Wire side of femll terminals

(To page 11-284i(To page 11 284)

11-283

Page 553 of 2189

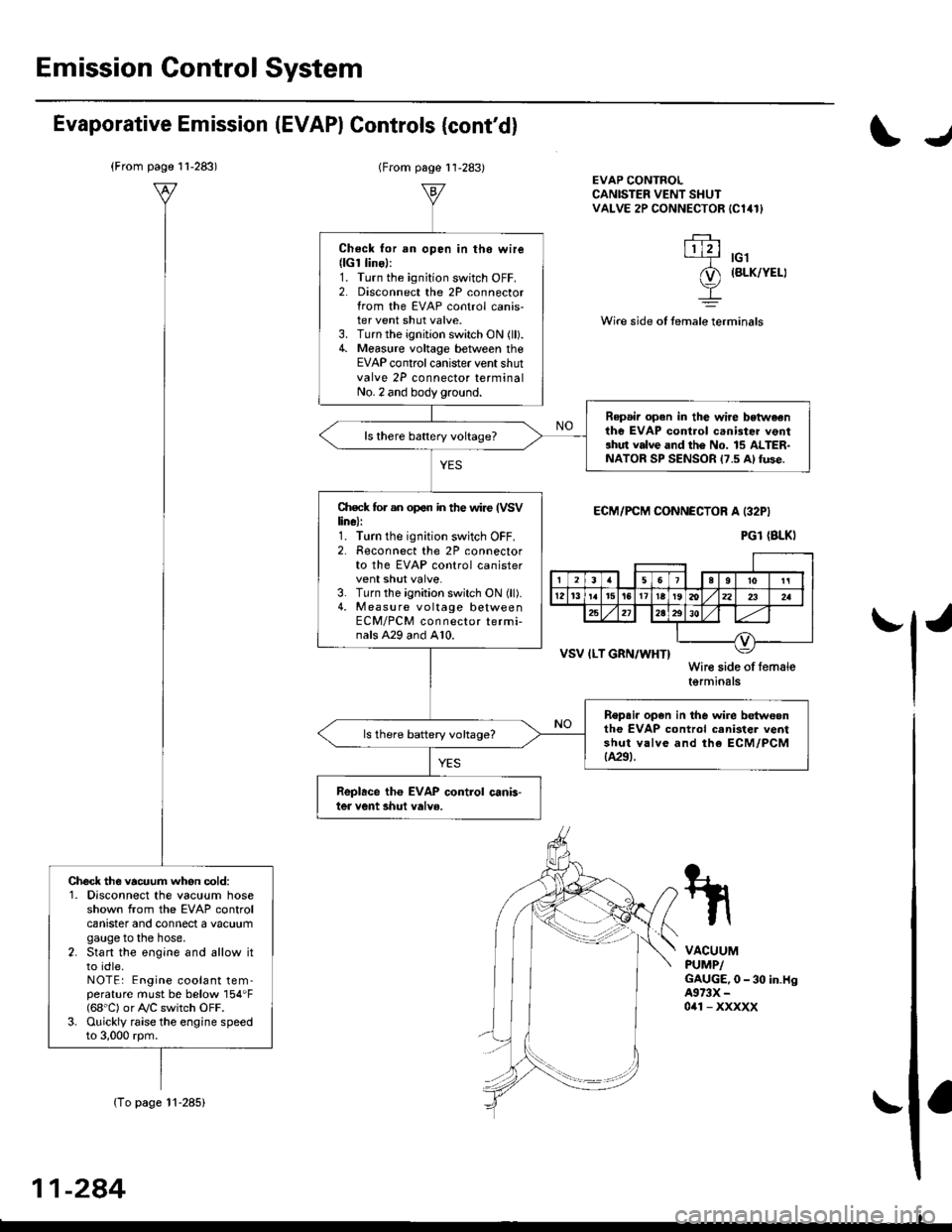

Emission Control System

Evaporative Emission (EVAPI Controls (cont'dl

1

EVAP CONTROLCANISTER VENT SHUTVALVE 2P CONNECTOR IC141}

lltrt+ rcl

o) (8LK/YErl

I

temale terminalsWire side ot

ECM/PCM CONNECTOR A (32PI

VSV ILT GRN/WHT}

'l'

Wiro side of lemaletgrminals

VACUUMPUMP/GAUGE,0 - 30 in.Hg4973X -

041 - XXXXX

(From page 1l-283)

{To page 1l-285}

Check the vacuum whon cold:1. Disconnect the vacuum hoseshown from the EVAP controlcanrster and connect a vacuumgauge to the hose,2. Start the engine and allow itto idle.NOTE: Engine coolant tem-perature must be below 154oF(68'C) or lVC switch OFF.3. Ouickly raise the engine speedto 3,000 rpm.

(From page l1-283)

Check for an open in tho wire(lGl line):1. Turn the ignition switch OFF.2. Disconnect the 2P connectorlrom the EVAP control canis-ter vent shut valve.3. Turn the ignition switch ON (ll).4. Measure voltage between theEVAP controlcanister vent shutvalve 2P connector terminalNo. 2 and body ground.

Repair open in the wire betwe€nthe EVAP control c.ni3tei ventshut valve and th6 No. 15 ALTER-NATOR SP SENSOR 17.5 Al fuse.

Cfisck tor an opon in the wire (VSVline):1. Turn the ignition switch OFF.2. Beconnect the 2P connectorto the EVAP control canistervent shut valve.3. Turn the ignition switch ON (ll).4. Measure voltage betweenECM/PCM connector termi-nals A29 and Al0.

Rep.ir open in the wire betwoonthe EVAP control canister ventshut valve and th€ ECM/PCMtA29t.

ls there battery voltage?

Replace th6 EVAP control canis-ter vent 3hut valve.

PGT (BLKI

:lI23l'ltl'l lelsl ro Ir I1213t6€lnltlr@/lzzl zs f il

25

11-284