Transmission HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 996 of 2189

l.

1.

2.

Remove the end cover {three 6 mm bolts, eleven 8

mm bolts).

Remove the manualvalve body lines A and B

3. Remove the snap ring securing the ring gear, then

remove the thrust shim and the ring gear'

4. Remove the snap ring securing the reverse brake

discs and plates, then remove the reverse brake end

plate. brake discs, brake plates, and disc spring'

5. Remove the carrier with the thrust washers and the

thrust needle bearing from the forward clutch

6. Remove the sun gear and the input shaft as a sub

assembly bY Pulling it

The sun gear is press fitted tightly into input shaft'

7. Remove the snap ring securing the forward clutch,

and remove the snap ring securing the forward clutch

end plate, then remove the forward clutch end plate'

8. Reinstall the carrier on the forward clutch, then

secure the carrier with the snap ring on the forward

clutch end Plate.

9. Remove the forward clutch and carrier assembly

together.

'10. lnstall the special tool to remove the snap ring

securing the reverse brake return spring retainer as

snown.

REVERSE BBAKESPRING COMPRESSOR07TAE - PaV0110

11. Compress the return springs. then remove the snap

ring

CAUTION: lf the spring retainer tab is on the

rsverse braks piston, tho spting letainer may be

damaged. Be surs the spring letainer tab is not on

the piston.

SPfiING FETAIiGRTAB

Remove the special tool, then remove the spring

retainer/return spring assembly.

Remove the sealing bolt securing the reverse brake

pressure insPection hole.

Apply air pressure to the inspection hole to remove

the reverse brake Piston

12.

13.

14.

16.'t7

SPBING REYAINER/RETURiI SPRIiIGASSEMALY

REVERSE BNAXEPISTON

o-RrllcsReplace.

FCVERSE BRAKEPRESSURE INS?ECTK)NHOtl

SEALINGWASHERReplace.

8 x 1.25 mm18 N.m 11.8 kgf.m, 13 lbf.ttl

Remove the snap ring retainer from the drive pulley

shaft.

Remove the manual valve body (five bolts)'

Remove the roller and push the control shaft assem-

bly toward the outside of the transmission housing,

then remove the intermediate housing (four bolts)'

SPECIAL TOOL

14-319

Page 1005 of 2189

Secondary Gear Shaft

25 x 35 mm Thrust Shim Selection

1. Measure the distance between the flywheel housing

surface and the ball bearing as shown, then note

the measurement (Measurement A).

FLYWHEELHOUSING

>dt?'

BALL BEARING

EALL FLYWHEELBEARING HOUSTNG

Install the secondary gear shatt in the transmission

housing.

Measure the distance between the transmission

housing surface and the thrust washer mounting

surface of the secondary gear shaft as shown, then

note the measurement (Measurement B).

O

Measuring Distance A

BALL

14-328

Calculate 25 x 35 mm thrust shim thickness bv fol-

lowing formula.

FORMULA;

25 x 35 mm Thrust Shim Thicknoss

= Measurement A - Measurement B + Flywheel

Housing Gasket Thickness: 0.5 mm {0.020 in}

Example:

Measurement A: 32.7 mm (1.287 in)

Moasurem.nt B: 30.! mm {1.185 in}

25 x 35 mm Thrust Shim Thickness

= 32.7 mm (1.287 in) - 30.1 mm (1.185 in)

+ 0.5 mm {0.020 in)

= 3.1 mm (0.122 inl

Select 25 x 35 mm Thrust Shim D.

Select the 25 x 35 mm thrust shim from the follow-

ing the table.

THRUST SHIM, 25 x 35 mm

No.Part NumberThickne3s

90551 - P4V - 0002.8 mm (0.110 in)

B90552-P4V-0002.9 mm (0.114 in)

c90553-P4V-0003.0 mm (0.118 in)

D90554-P4V-0003.1 mm (0.122 in)

E90555-P4V-0003.2 mm (0.126 in)

90556-P4V-0003.3 mm (0.130 in)

G90557-P4V-0003.4 mm (0.134 in)

H90558-P4V-0003.5 mm (0.138 in)

90559-P4V-0003.6 mm {0.142 in)

90560-P4V-0003.7 mm (0.146 in)

K90561 - P4V - 0003.8 mm (0.'150 in)

Page 1008 of 2189

l.

Oil Seal Removal

Remove the differential assembly.

Remove the oil seal from the transmission housing.

1.

2.

TRANSMISSONHOUSING

OIL SEALR€placa.

3. Remove the oil seal from the flywheel housing.

Oil Seal Installation/Side Clearance

1. lnstall a 2.50 mm (0.098 in) thick 80 mm wide set

ring in the transmission housing.

NOTE: Do not installthe oil seal yet.

TRANSMISSIONHOUStl{G

lnstall the differential assembly into the transmrs-

sion housing using the specialtool as shown

DIFFEREI{NALASSEMBLY(cont'd)

14-331

Page 1010 of 2189

Flywheel Housing

Input Shaft Oil Seal

l.

8. Install the oil seal in the transmission housing using

the sDecial tools as shown.

DRIVER07749 - 0010d)0

9.Install the oil seal in the flywheel housing using the

soecial tools as shown.

PILOT,26x30mmoTJAD - PH80200DRIVERATIACHMENT, 58 x 72 rnin

0?947 - d'40201

Replacement

1. Remove the input shaft oil seal from the flywheel

housing.

OIL SEAL

Instali the oil seal in the flywheel housing using the

soecialtools as shown.

FLYWHEEL

lmtalled depth:2.5- 3.5 mmro"nri':,ilii.rl

t@

14-333

Page 1011 of 2189

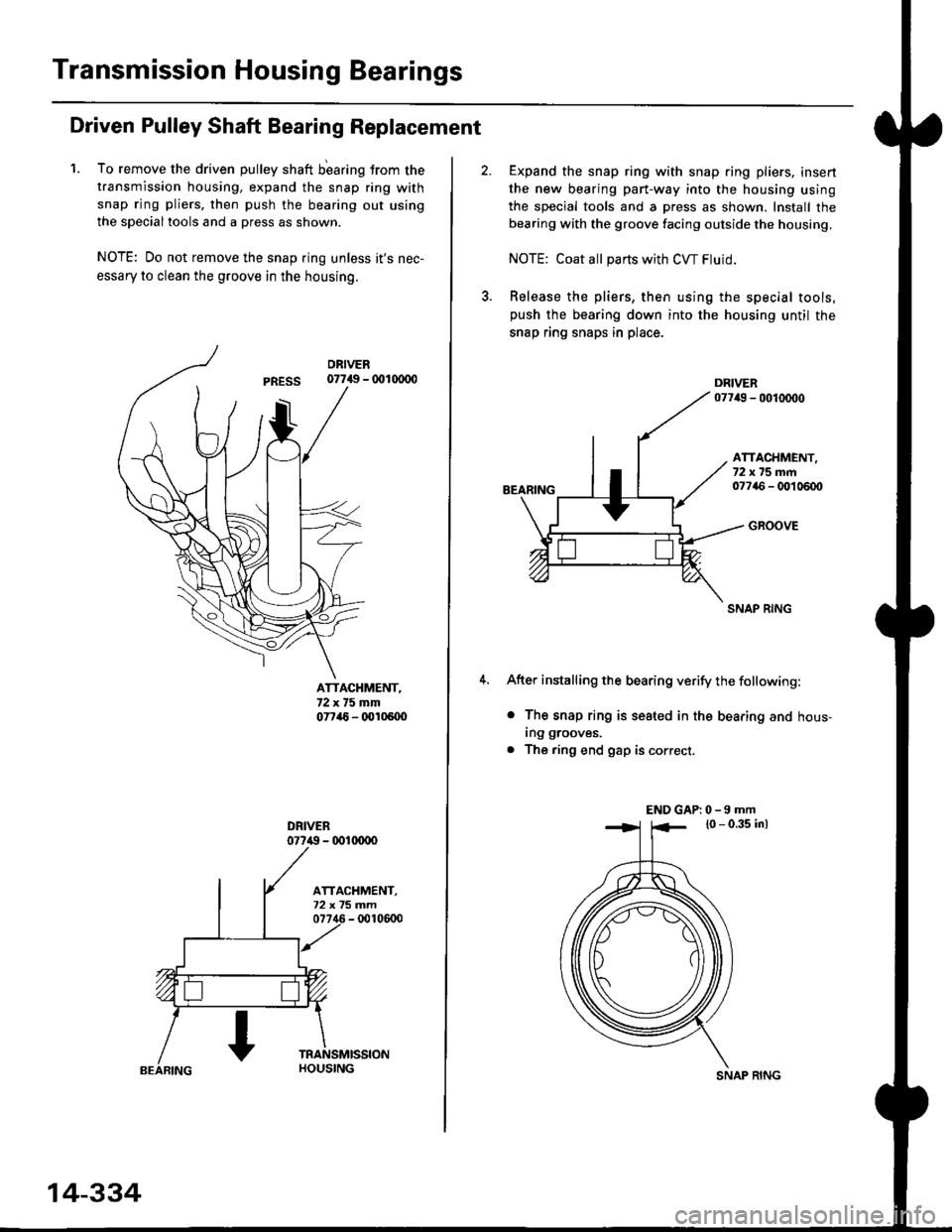

Transmission Housing Bearings

Driven Pulley Shaft Bearing Replacement

1. To remove the driven pulley shaft b'earing trom the

transmission housing, expand the snap ring with

snap ring pliers, then push the bearing out using

the specialtools and a press as shown.

NOTE: Do not remove the snap ring unless it's nec-

essary to clean the groove in the housing.

07749 - 001(xDo

ATTACHMENT,72x75mm07746 - (x'l05U)

077i() - 001(xrco

14-334

SNAP RING

Expand the snap ring with snap ring pliers, insert

the new bearing part-way into the housing using

the special tools and a press as shown. Install the

bearing with the groove facing outside the housing.

NOTE: Coat all pans with CW Fluid.

Release the pliers, then using the special tools,push the bearing down into the housing until the

snap ring snaps in place.

BEARING

ATTACHMENT,72x75mm07746 - OO1 0600

GROOVE

SNAP RING

After installing the bearing verify the following:

o The snap ring is seated in the bearing and hous-

ing grooves.

. The ring end gap is correct.

END GAP| 0 -9 mm

l0 - 0.35 inl

Page 1012 of 2189

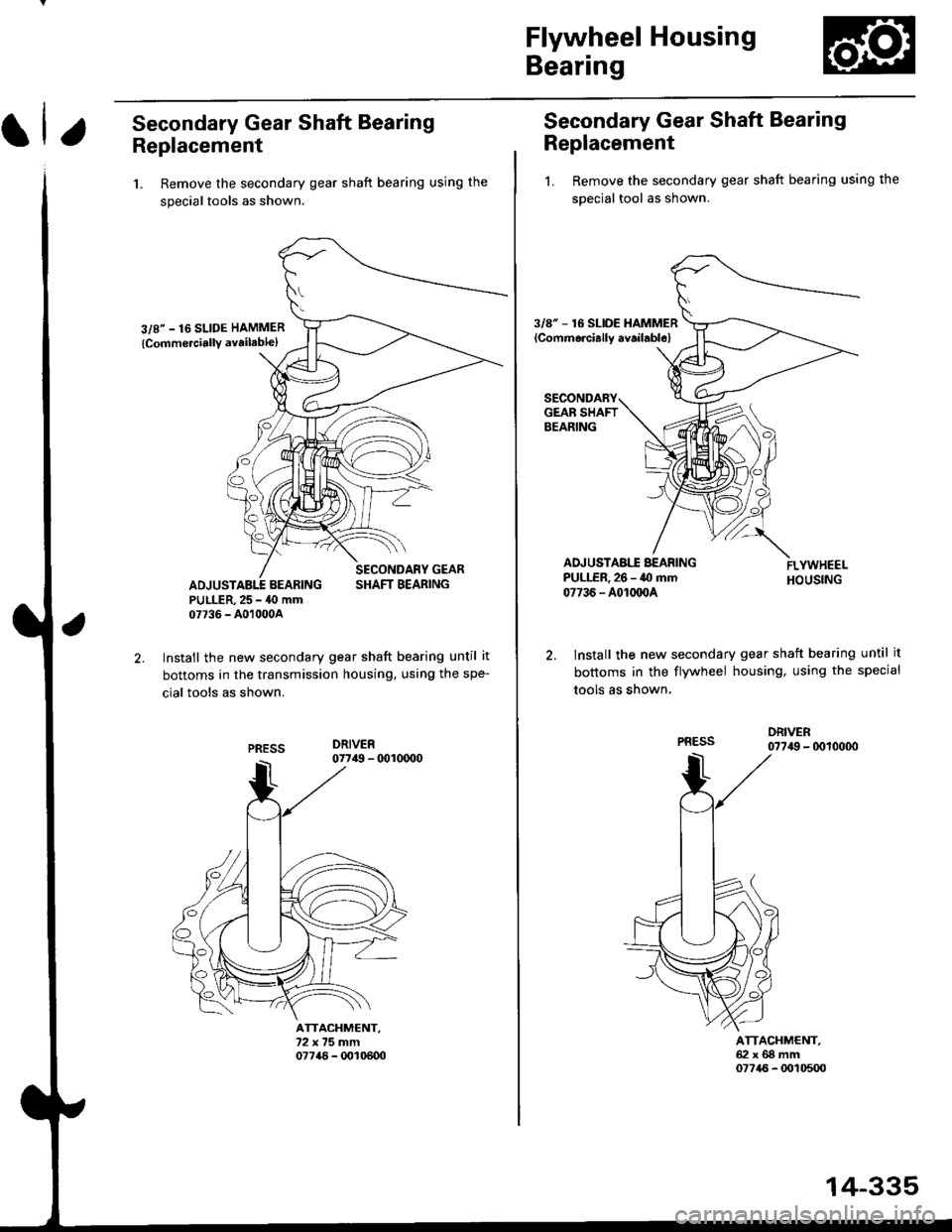

Flywheel Housing

Bearing

Secondary Gear Shaft Bearing

Replacement

1. Remove the secondary gear shaft bearing using the

special tools as shown.

3/8" - 16 SLIDE HAMMER

{Comm6rciallY availablel

SECONDARY GEAR

ADJUSTABI.T BEARING SHAFT BEARINGPULLER.25 - 40 mm07736 - A01000A

Install the new secondary gear shaft bearing until it

bottoms in the transmission housing. using the spe-

cial tools as shown.

Secondary Gear Shaft Bearing

Replacement

1. Remove the secondary gear shaft bearing using the

soecial tool as shown.

3/8" - 16 SLIDE HAMMER

lCommorcially aY.ilabl6l

2. lnstall the new secondary gear shaft bearing until it

bottoms in the flywheel housing, using the special

tools as shown.

DRIVER07749 - (x)10000

ATTACHMENT.62xGgmm07745 - 0010500

14-335

Page 1013 of 2189

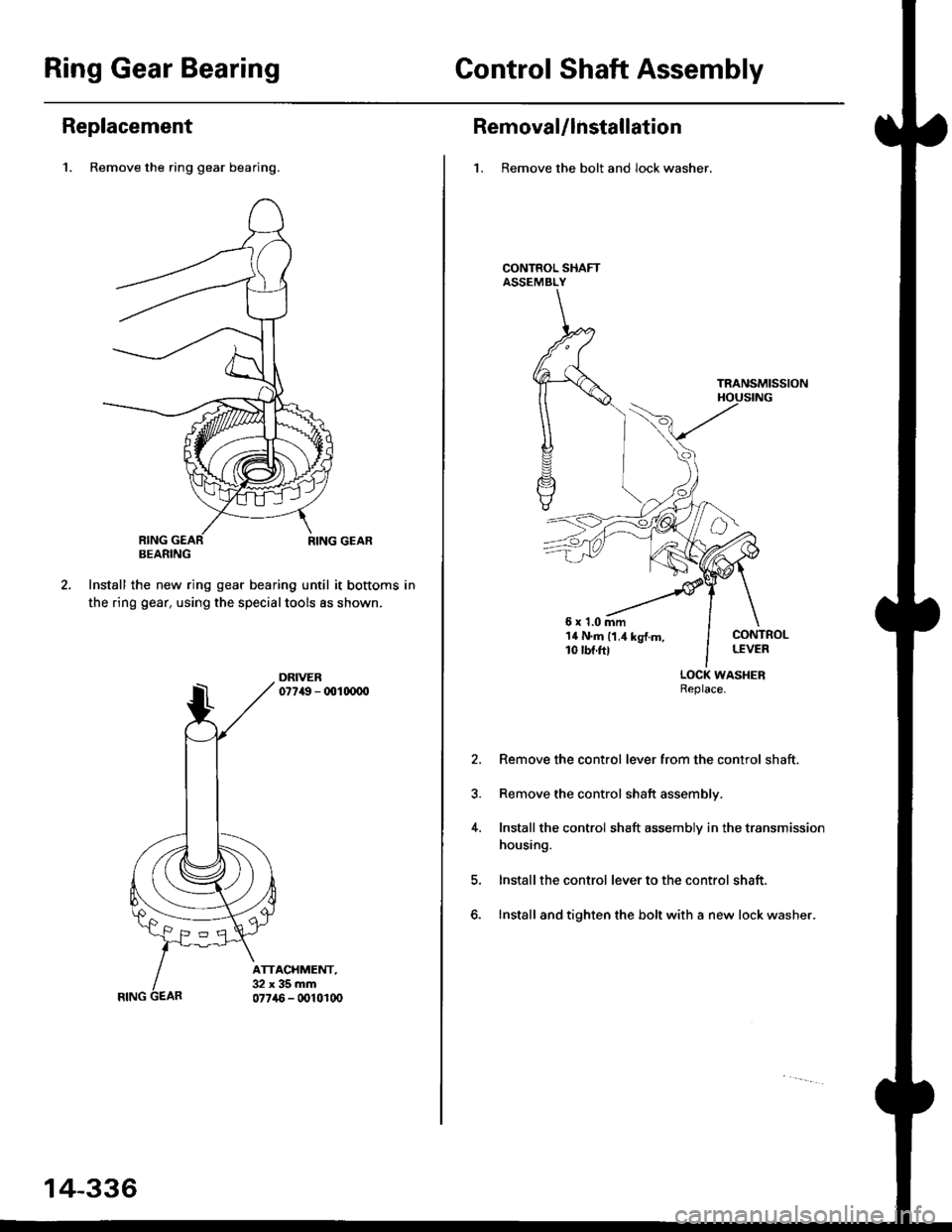

Ring Gear BearingControl Shaft Assembly

Replacement

1. Remove the ring gear bearing.

RING GEAR

Install the new ring gear bearing until it bottoms in

the ring gear. using the specialtools as shown,

DRIVER07?{9 - 001(xxxt

RING

14-336

RemovaUlnstallation

1. Remove the bolt and lock washer.

CONTROL SHAFTASSEMBLY

6r1.0mm14 N.ft 11.4 kg{.m,10 rbf.ftl

TRANSMISSION

CONTROLLEVER

LOCK WASHERReplace.

2. Remove the control lever from the control shaft.

3. Remove the control shaft assembly.

4. Install the control shaft assembly in the transmission

housing.

Install the control lever to the control shaft.

Install and tighten the bolt with a new lock washer.

Page 1014 of 2189

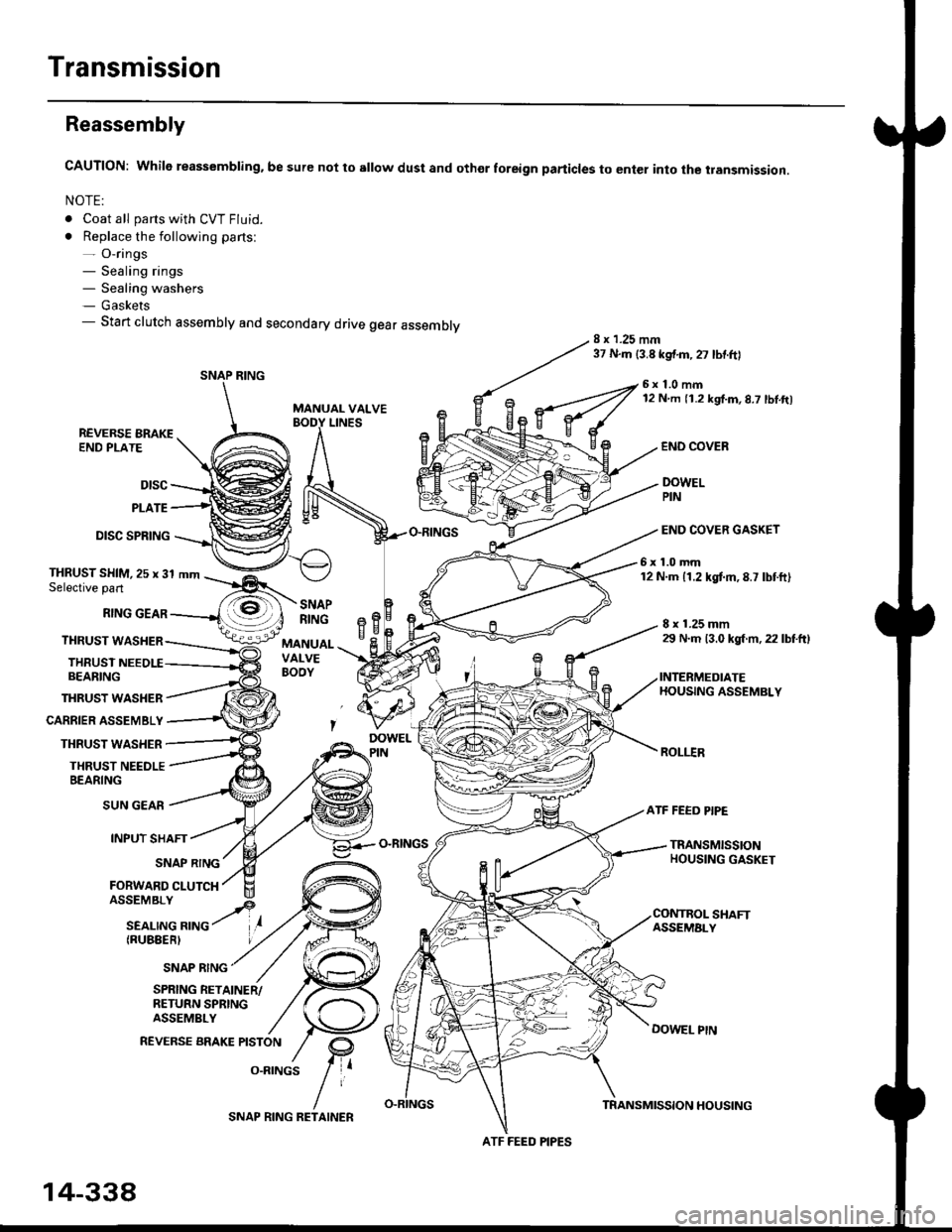

Transmission

Reassembly

CAUTION: While reassembling. be sure not to sllow dust and othor foreign particles to enter into the transmission.

NOTE:

. Coat all parts with CVT Fluid.

. Replace the following parts:- O-rings- Sealing rings- Sealing washers- Gaskets- Start clutch assembly and secondary drive gear assembly8 x 1.25 mm37 N.m {3.8 kgf.m,27 lbtftl

MANUAL VALVE

6x1.0mm12 N m 11.2 kgf.m,8.7 lbl.ft)

LINESREVERSE BRAKEEND PLATE

Dtsc

PLATE

DISC SPRING

THRUST WASHER

CARRIER ASSEMBLY

THRUST WASHER

THRUST NEEDLEBEARING

END COVEB

DOWELPIN

END COVER GASKET

6x1.0mm12 N.m 11.2 kgtm,8.7 lbtft)THRUST SHIM,25 x 31 mmSelective part

RING GEAR

THRUST WASHER

THRUSTBEARING

8 x 1.25 mm29 N.m 13.0 kgl m, 22 lbtftl

INTERMEDIATEHOUSING ASSEMBLY

ROLI.IR

SNAPRINGeBH^cMANUALVALVEBOOY

SUN GEAR

INPUT SHAFT

(RUBEERI

ATF FEED PIPE

O-RINGSTRANSMISSIONHOUSING GASKETSNAP RING

FORWARD CLUTCH

SNAP RING

SHAFTASSEMALY

DOWEL PtN

SPRING RETAINER/RETURN SPRINGASSEMBLY

REVERSE BRAKE PISTON

O.RINGS

SNAP RING

ATF FEED PIPES

14-338

SNAP RING RETAINERTRANSMISSION HOUSING

Page 1015 of 2189

1.

7.

lnstall the ATF feed pipe in the transmission hous-

ing, and install the three ATF feed pipes with new

O-rings in the transmission housing,

Install the two dowel pins and new transmission hous-

ing gasket on the transmission housing.

Push the control shaft assembly toward the outside

of the transmission housing, then install the inter-

mediate housing assembly (four bolts).

lnstall the manual valve body separator plate and

the two dowel pins on the intermediate housing,

then install the rnanual valve body with the detent

spring (five bolts).

Put the control shaft assembly back, then install the

roller in the intermediate housing.

lnstall the reverse brake piston in the intermediate

housing.

Install the spring retainer/return spring assembly on

the reverse brake Piston.

NOTE: Installthe return springs on the spring guides

of the reverse brake piston securely

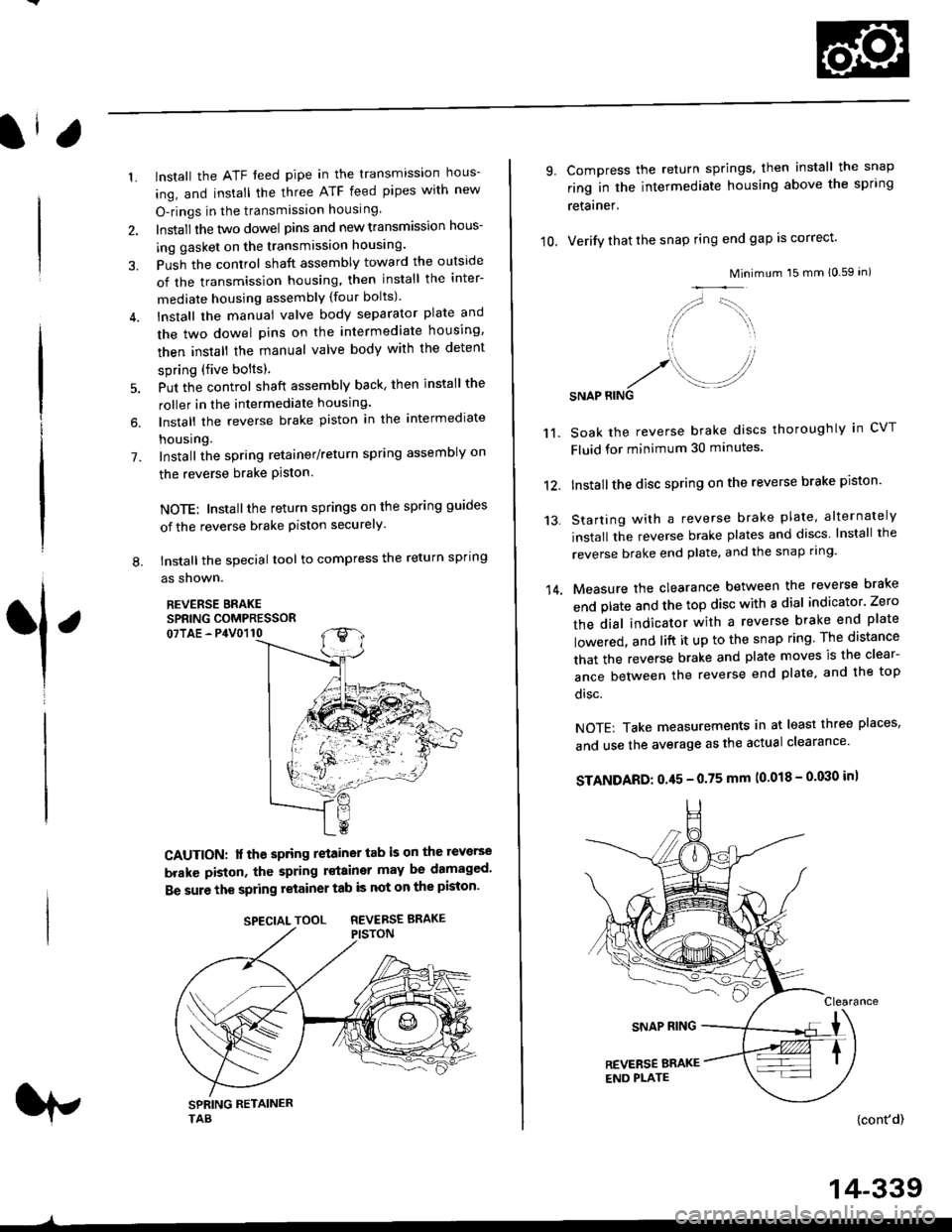

tnstall the special tool to compress the return spring

as shown.

REVERSE BRAKESPRING COMPRESSOR07TAE - P4V0110

6.

L

1

CAUTION: lf the spring retainer tab is on the reverse

brakc piston, the spring rstainer may be damaged'

Be sure the spring retainer tab is not on the piston'

rp

SPECIALTOOL REVERSEBRAKE

-^

14-339

10.

9.

14.

Compress the return springs, then install the snap

ring in the intermediate housing above the spring

retainer.

Verify that the snap ring end gap is correct'

Mini

/,,- '-t,,,,.

// \i/ ',r

'1 ,

.r' //'/. .-J?RINGSNAP

mum 15 mm 10.59 in)

Soak the reverse brake discs thoroughly in CVT

Fluid for minimum 30 minutes.

Installthe disc spring on the reverse brake piston'

Starting with a reverse brake plate, alternately

install the reverse brake plates and discs lnstall the

reverse brake end plate, and the snap ring'

Measure the clearance between the reverse brake

end plate and the top disc with a dial indicator' Zero

the dial indicator with a reverse brake end plate

lowered, and lift it up to the snap ring The distance

that the reverse brake and plate moves is the clear-

ance between the reverse end plate, and the top

disc.

NOTE: Take measurements in at least three places'

and use the average as the actual clearance'

STANDARD: 0.45 - 0.75 mm (0.018 - 0'030 in)

{cont'd)

11.

12.

13.

Page 1016 of 2189

Transmission

16.

Reassembly (cont'dl

21.

17.

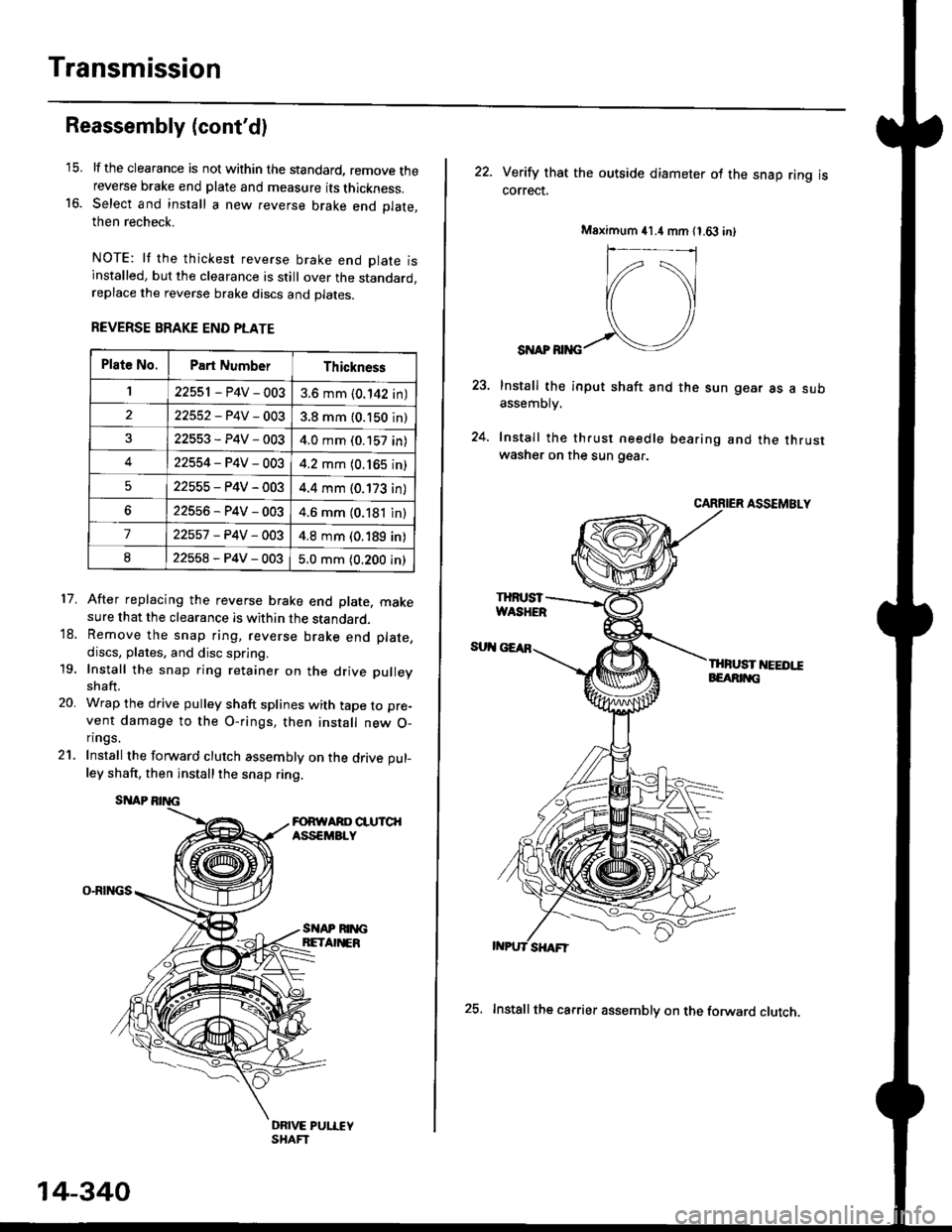

lf the clearance is not within the standard, remove thereverse brake end plate and measure its thickness.Select and install a new reverse brake end Dlate.then recheck.

NOTE: lf the thickest reverse brake end olate isinstalled, but the clearance is still over the standard,replace the reverse brake discs and plates.

REVERSE BRAKE END PLATE

After replacing the reverse brake end plate, makesure that the clearance is within the standard.Remove the snap ring, reverse brake end plate,

discs, plates. and disc spring.

Install the snap ring retainer on the drive pulley

shaft.

Wrap the drive pulley shaft splines with tape to pre-

vent damage to the O-rings, then install new O-n ngs.

Install the forward clutch assembly on the drive pul-

ley shaft, then installthe snap ring.

SITAP

O-RINGS

18.

19.

20.

SI{AP RIM;BETA EB

DRIVE PUI.IEYSHAFT

Plat6 No.Part NumberThickness

122551 - P4V - 0033.6 mm (0.142 in)

22552-P4V-0033.8 mm (0.150 in)

22553-P4V-0034.0 mm (0.157 in)

422554-P4V-0034.2 mm (0.165 in)

522555-P4V-0034.4 mm (0.173 in)

622556-P4V-0034.6 mm (0.181 in)

722557 -P4V -OO34.8 mm (0.189 in)

822558-P4V-0035.0 mm (0.200 in)

14-340

25. Installthe carrier assembly on the forward clutch.

22. Verity that the outside diameter ol the snap ring iscorrect.

SI{AP RIiIG

Install the input shaft and the sun gear as a subassemDry.

Install the th.ust needle bearing and the thrustwasher on the sun gear.

CARRIER ASSEMBLY

THFUST I'IEEDI!EEARIT{G

Msximum 41.4 mm 11.63 in)

IHruST