cover HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1636 of 2189

Lighting System

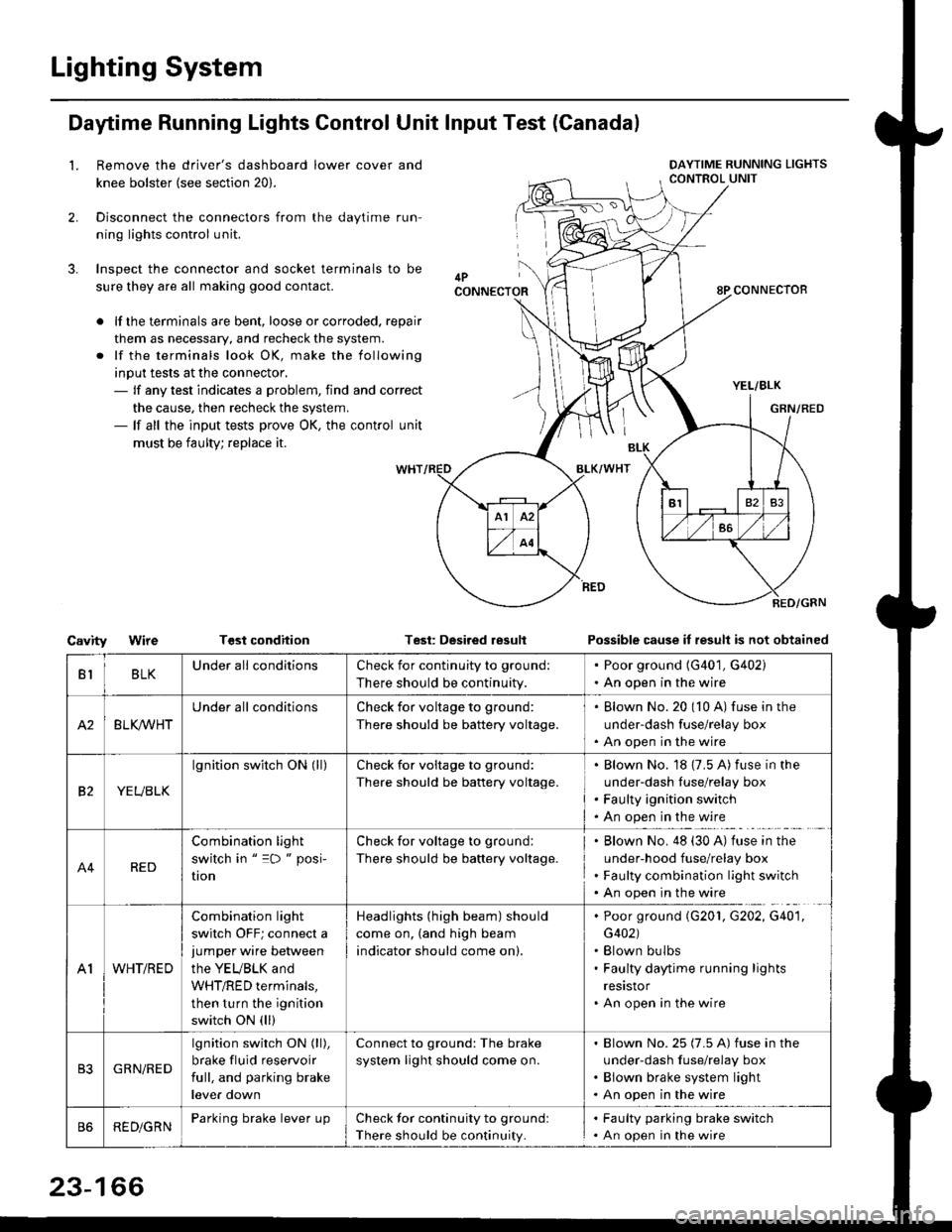

Daytime Running Lights Control Unit Input Test (Canadal

2.

3.

LRemove the driver's dashboard lower cover and

knee bolster (see section 20).

Disconnect the connectors from the daytime run-

ning lights control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

lf the terminals are bent, loose or corroded. repair

them as necessary, and recheck the system.

lf the terminals look OK, make the following

input tests at the connector,- lf any test indicates a problem, find and correct

the cause, then recheck the system.- lf all the input tests prove OK, the control unit

must be faulty; replace it.

CavityWireTGst conditionTest: Desired resultPossible cause it result is not obtained

BLKU nderall conditionsCheck for continuity to g.ound:

There should be continuity.

. Poor ground (G401, G402). An open in the wire

A2BLK /VHT

Underall conditionsCheck for voltage to ground:

There should be battery voltage.

Blown No.20 (10 A) fuse in the

under-dash fuse/relay box

An open in the wire

etYEUBLK

lgnition switch ON (ll)Check for voitage to ground:

There should be battery voltage.

Blown No. 18 {7.5 A) fuse in the

under-dash luse/relay box

Faulty ignition switch

An open in the wire

A4RED

Combination light

switch in " =D " posi-

UOn

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 (30 A) tuse in the

under-hood fuse/relay box

Faulty combination light switch

An open in the wire

A1WHT/RED

Combination light

switch OFF; connect ajumper wire between

the YEUBLK and

WHT/RED terminals,

then turn the ignition

switch ON (ll)

Headlights (high beam) should

come on, (and high beam

indicator should come on).

. Poor ground (G201, G202, G40'1,

G402). Blown bulbs. Faulty daytime running lights

resrstor. An open in the wire

GRN/RED

lgnition switch ON (ll),

brake fluid reservoir

full, and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No.25 (7.5 A) fuse in the

under-dash f use/relay box

Blown brake system light

An open in the wire

REDiGRNParking brake lever LrpCheck for continuity to groundl

There should be continuity.

. Faulty parking brake switch. An open in the wire

23-166

Page 1638 of 2189

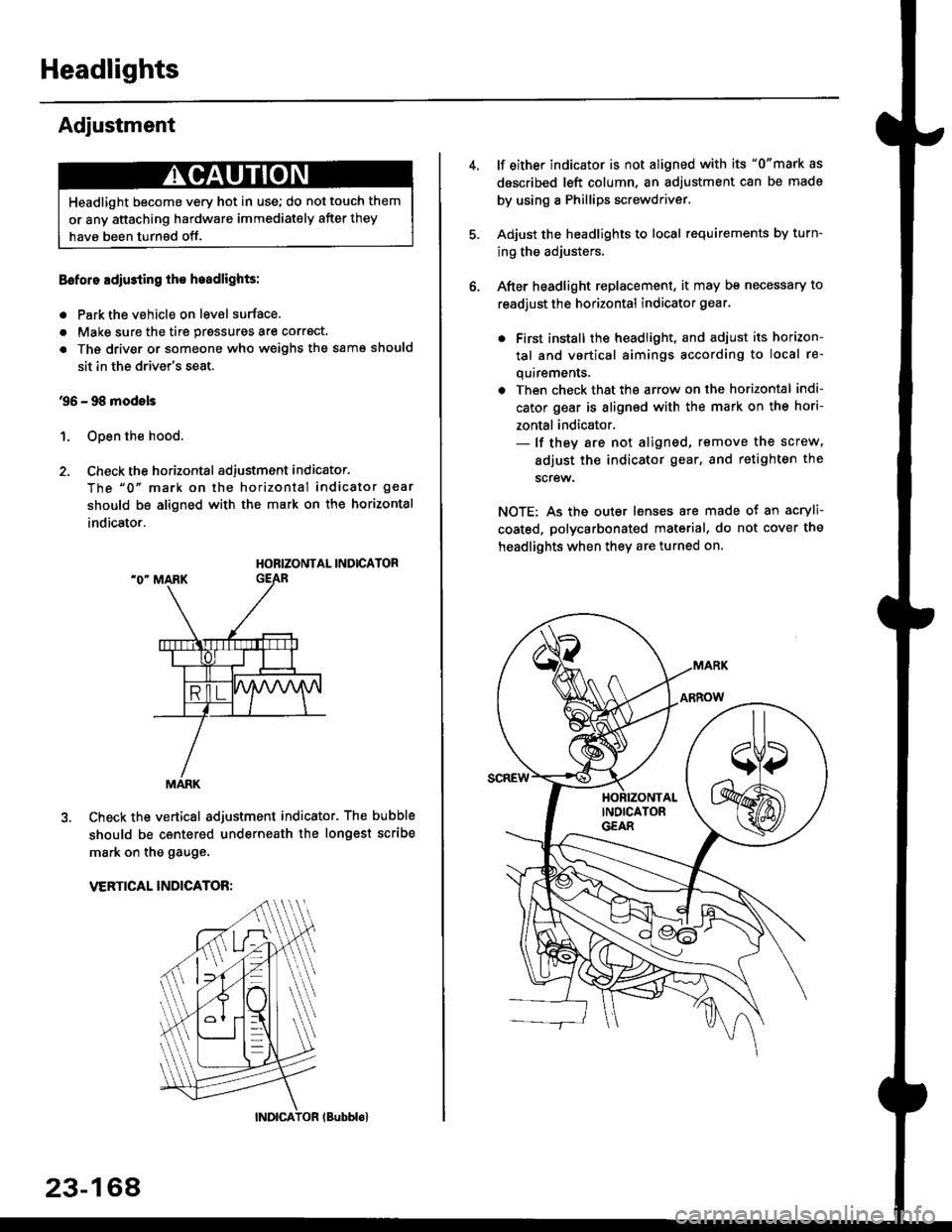

Headlights

Adjustment

Eoforo adiu3ting th€ h.adlights:

. Park the vehicle on level surface.

. Make sure the tire prgssures are correct.

a The driver or someone who weighs the same should

sit in the driver's seat.

96 - 98 modols

1. Open the hood.

2. Check the horizontal adjustment indicator.

The "0" mark on the horizontal indicator gear

should be aligned with the mark on the horizontal

indicator.

HORIZONTAL INDICATOR

Check the vertical adjustment indicator. The bubble

should be centered underneath the longest scribe

mark on the gauge.

VERTICAL INDICATOR:

Headlight become very hot in use; do not touch them

or any attaching hardware immediately after they

have been turnsd off.

MARK

23-164

(Bubblol

lf either indicator is not aligned with its "0"mark as

described left column, an adjustment can be made

by using a Phillips screwdriver.

Adjust the headlights to local requirements by turn-

ing the adjusters.

After headlight replacement, it may bs necessary to

readjust the horizontal indicator gear.

. First install the headlioht, and adjust its horizon-

tal and vertical aimings according to local re-

quirements.

. Then check that the arrow on the horizontal indi-

cator gear is aligned with the mark on the hori-

zontal indicator.- lf they are not aligned, remove the screw,

adiust the indicator gear, and retighten the

screw.

NOTE: As the outer lenses are made ot an acryli-

coated, polycarbonated material, do not cover the

headlights when they are turned on.

Page 1640 of 2189

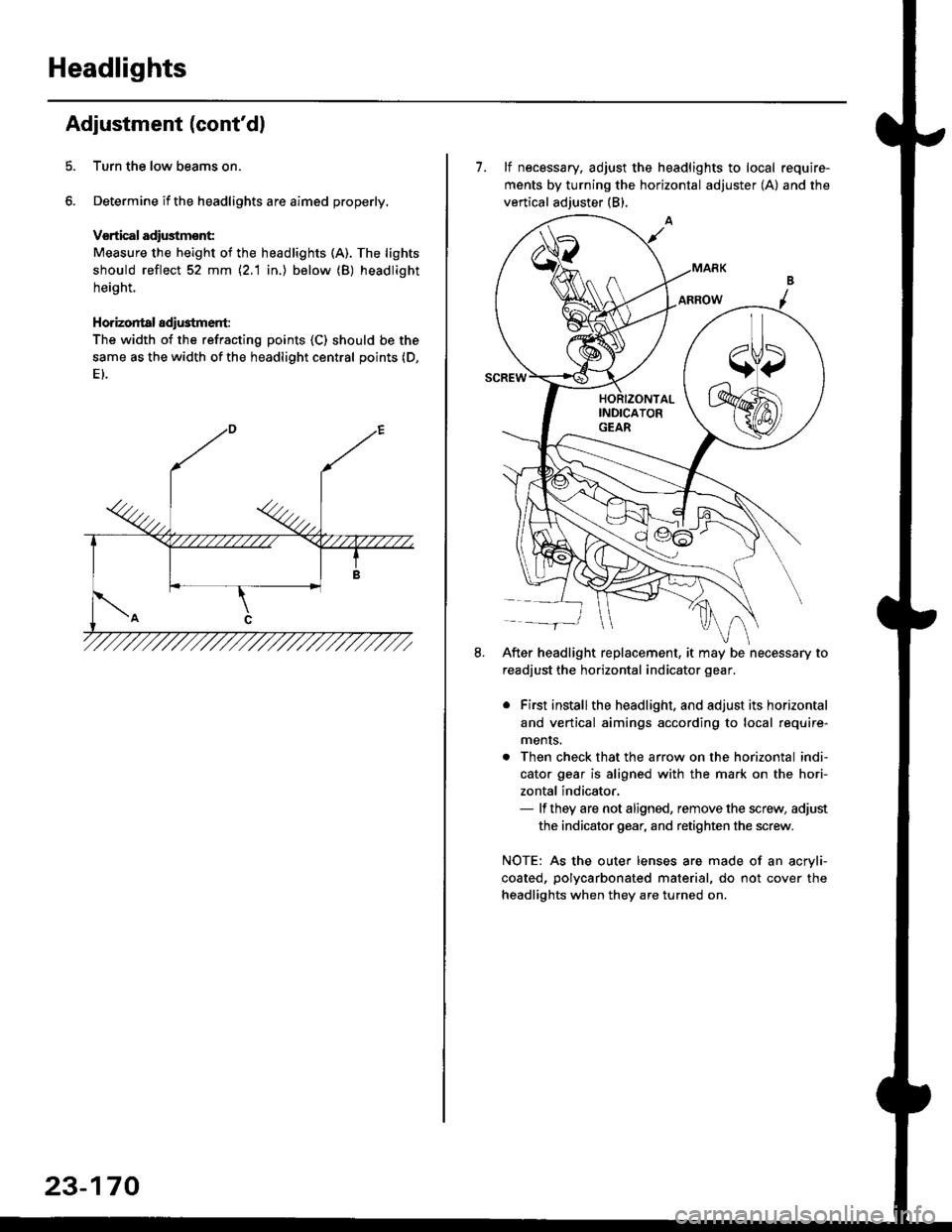

Headlights

Adjustment (cont'dl

Turn the low beams on.

Determine if the headlights are aimed properly.

Vsrtical adiustmsnt:

Measure the height of the headlights (A). The lights

should reflect 52 mm \2.1 in.) below (B) headlight

height.

Horizontal adi$tment:

The width of the refracting points (C) should be the

same as the width of the headlight central points (D,

23-170

7. lf necessary, adjust the headlights to local require-

ments by turning the horizontal adjuster (A) and the

vertical adjuster (B).

After headlight replacement, it may be necessary to

readjust the horizontal indicator gear.

. First installthe headlight, and adjust its horizontal

and vertical aimings according to local require-

ments.

. Then check that the arrow on the horizontal indi-

cator gear is aligned with the mark on the hori-

zontal indicator,- lf they are not aligned, remove the screw, adjust

the indicator gear, and retighten the screw.

NOTE: As the outer lenses are made of an acryli-

coated, polycarbonated material, do not cover the

headlights when they are turned on.

Page 1656 of 2189

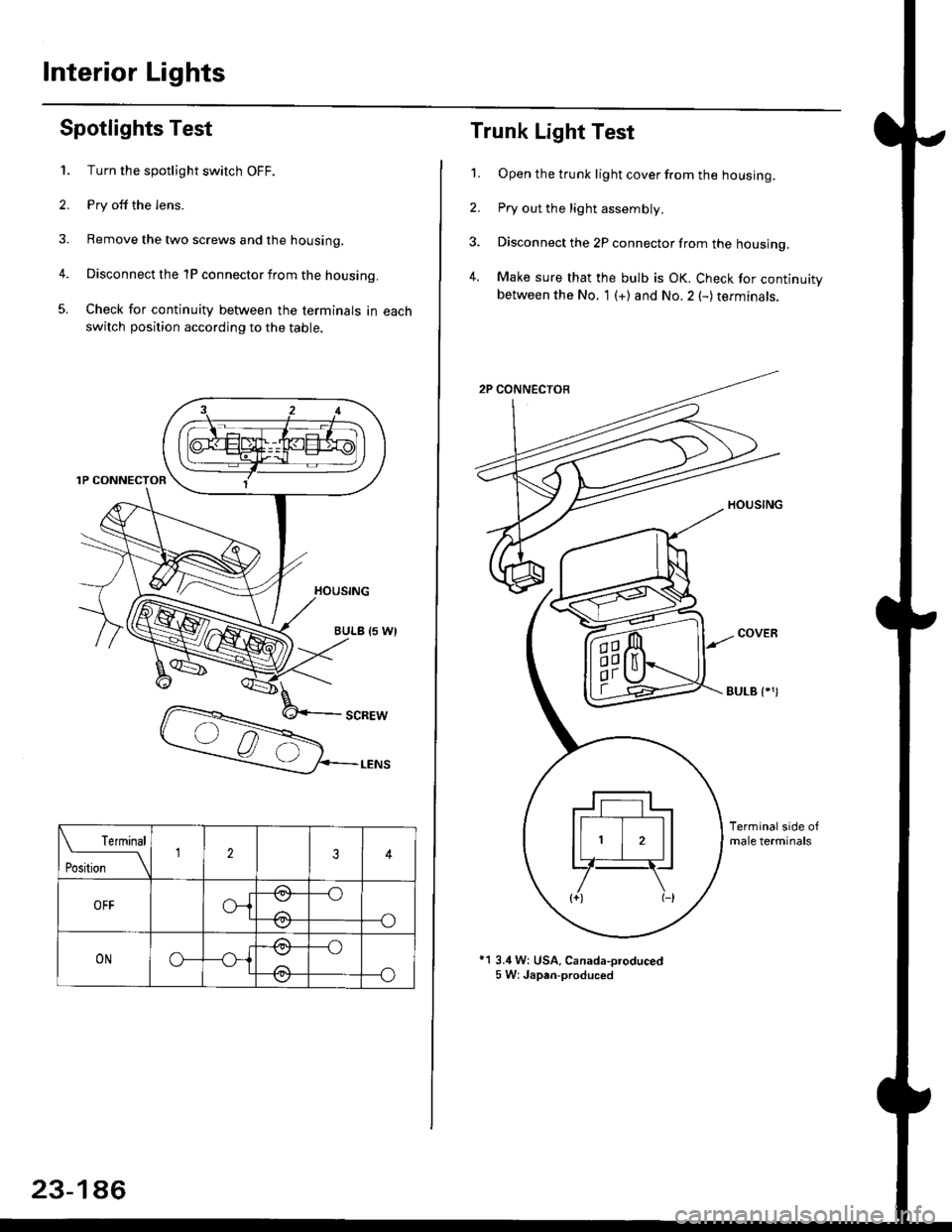

Interior Lights

Spotlights Test

1. Turn the spotlight switch OFF.

2. Pry off the lens.

3. Remove the two screws and the housing.

4. Disconnect the 1P connector from the housing.

5. Check for continuity between the terminals in each

switch position according to the table.

Terminal

t*'*-__\234

OFFo-{e,

//:\

--o

--o\:,/

ONo--*i@

/a\

-_o

--o\:.,/

23-186

Trunk Light Test

1. Open the trunk light cover from the housing.

2. Pry out the light assembly.

3. Disconnect the 2P connector from the housing,

4. Make sure that the bulb is OK. Check for continuitybetween the No. 1 (+) and No.2 (-) terminals.

EULB {.')

*1 3.4 W: USA, Canada-oroduced5 W: Japan-produced

Page 1661 of 2189

Removal

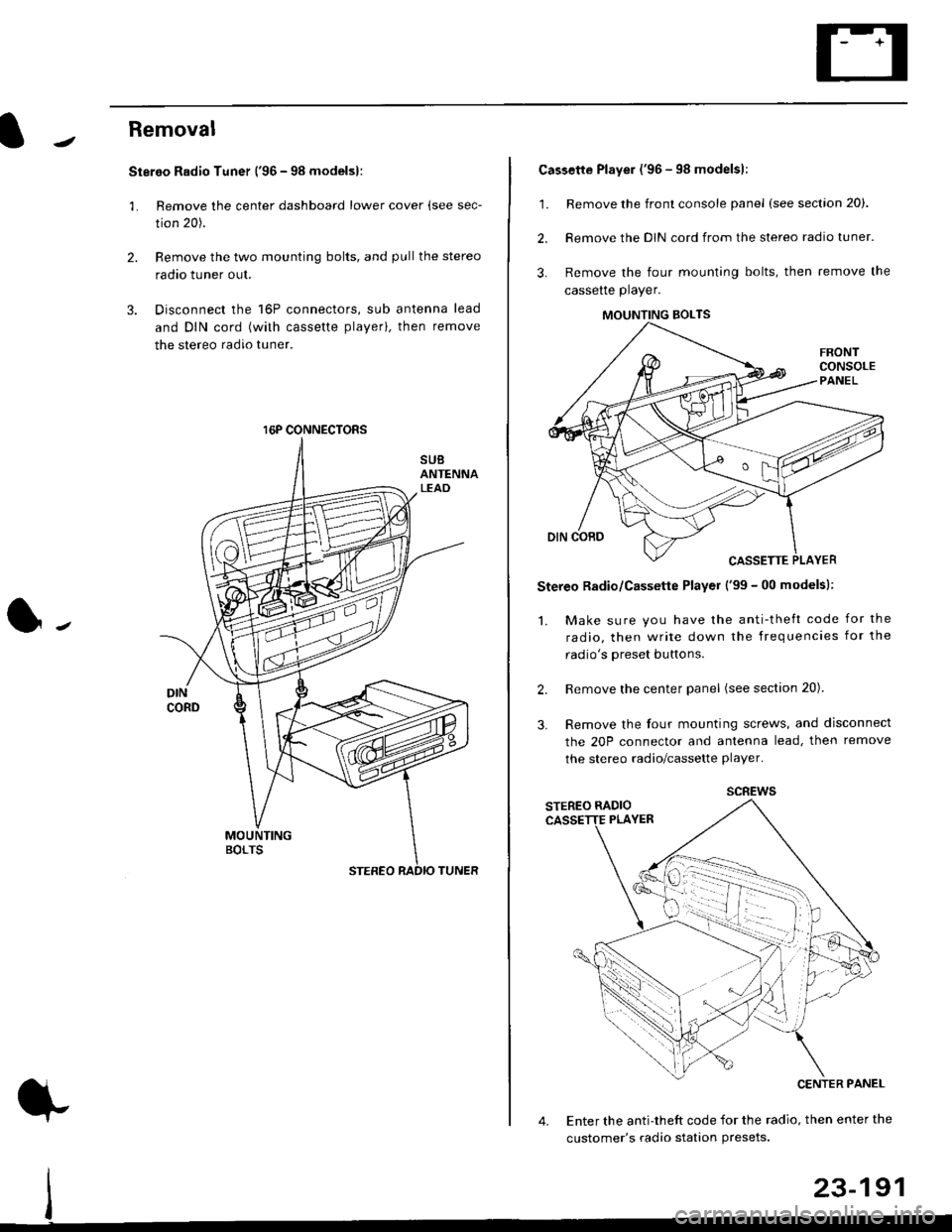

Stereo Radio Tuner ('96 - 98 modelsl:

3.

1.

2.

Remove the center dashboard lower cover (see sec-

tion 20).

Remove the two mounting bolts, and pullthe stereo

radao tuner out.

Disconnect the 16P connectors, sub antenna lead

and DIN cord (with cassette playerl, then remove

the stereo radio tuner.

16P CONNECTORS

1.

2.

Cassette Player ('96 - 98 modelsl:

Remove the front console panel (see section 20).

Remove the DIN cord from the stereo radio tuner.

Remove the four mounting bolts, then remove the

cassette player.

Stereo Radio/Cassette Player ('99 - 00 modelsl:

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's oreset buttons.

Remove the center panel (see section 20).

Remove the four mounting screws, and disconnect

the 20P connector and antenna lead, then remove

the stereo radio/cassette player.

2.

3.

MOUNTING BOLTS

scREws

Enter the anti-theft code for the radio, then enter the

customer's radio station Presets.

23-191

Page 1663 of 2189

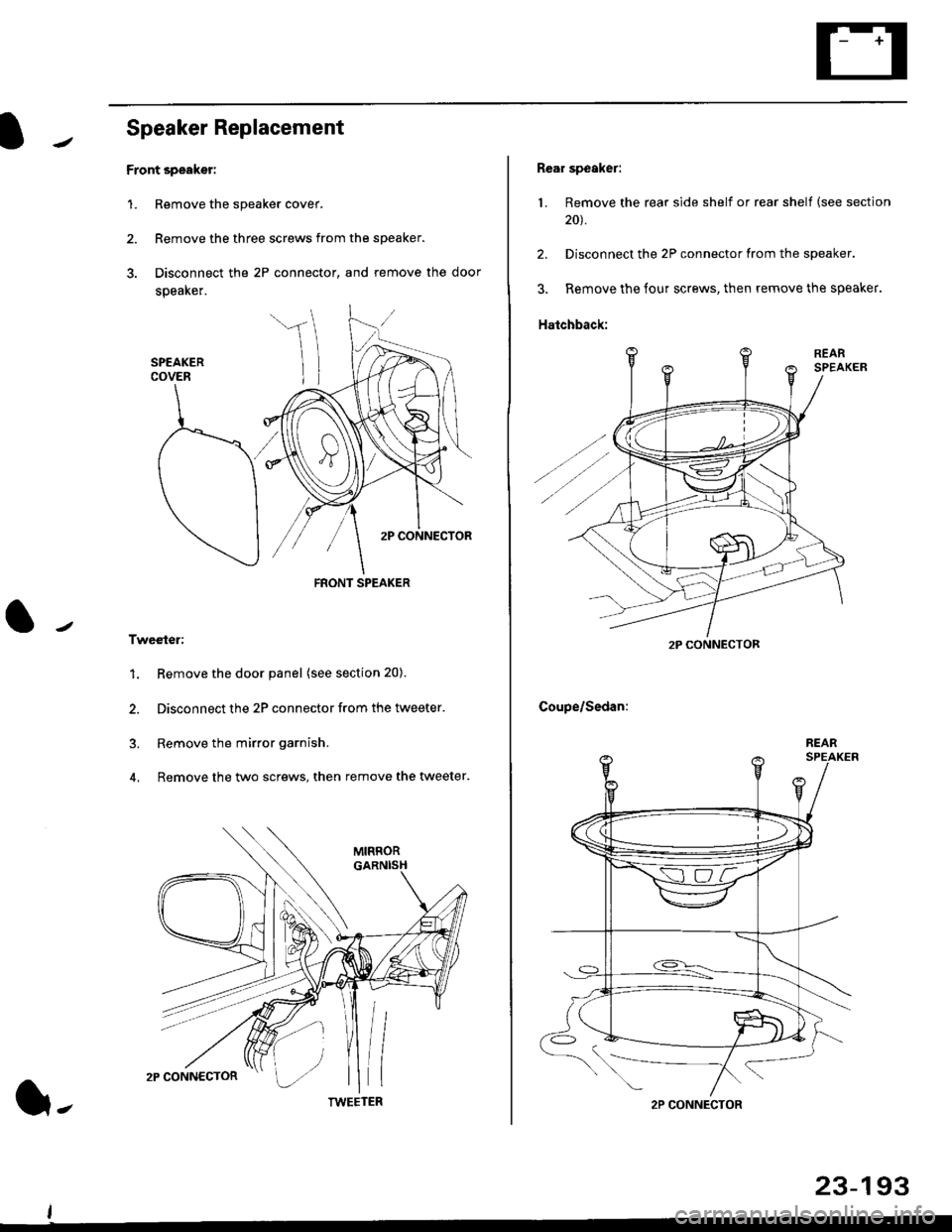

Speaker Replacement

Front speaker:

1. Remove the speaker cover.

2. Remove the three screws from the speaker.

3. Disconnect the 2P connector, and remove the door

speaker.

Tweeter:

1. Remove the door panel (see section 20).

2. Disconnect the 2P connector from the tweeter.

3. Remove the mirror garnish.

4, Remove the two screws, then remove the wveeter.

FRONT SPEAKER

TWEETER(}-

23-193

Rear speaker:

1. Remove the rear side shelf or rear shelf (see section

20t.

2. Disconnect the 2P connector from the speaker.

3. Remove the four screws, then remove the speaker.

Hatchback:

Coupe/Sedan:

2P CONNECTOF

2P CONNECTOR

REAR

Page 1669 of 2189

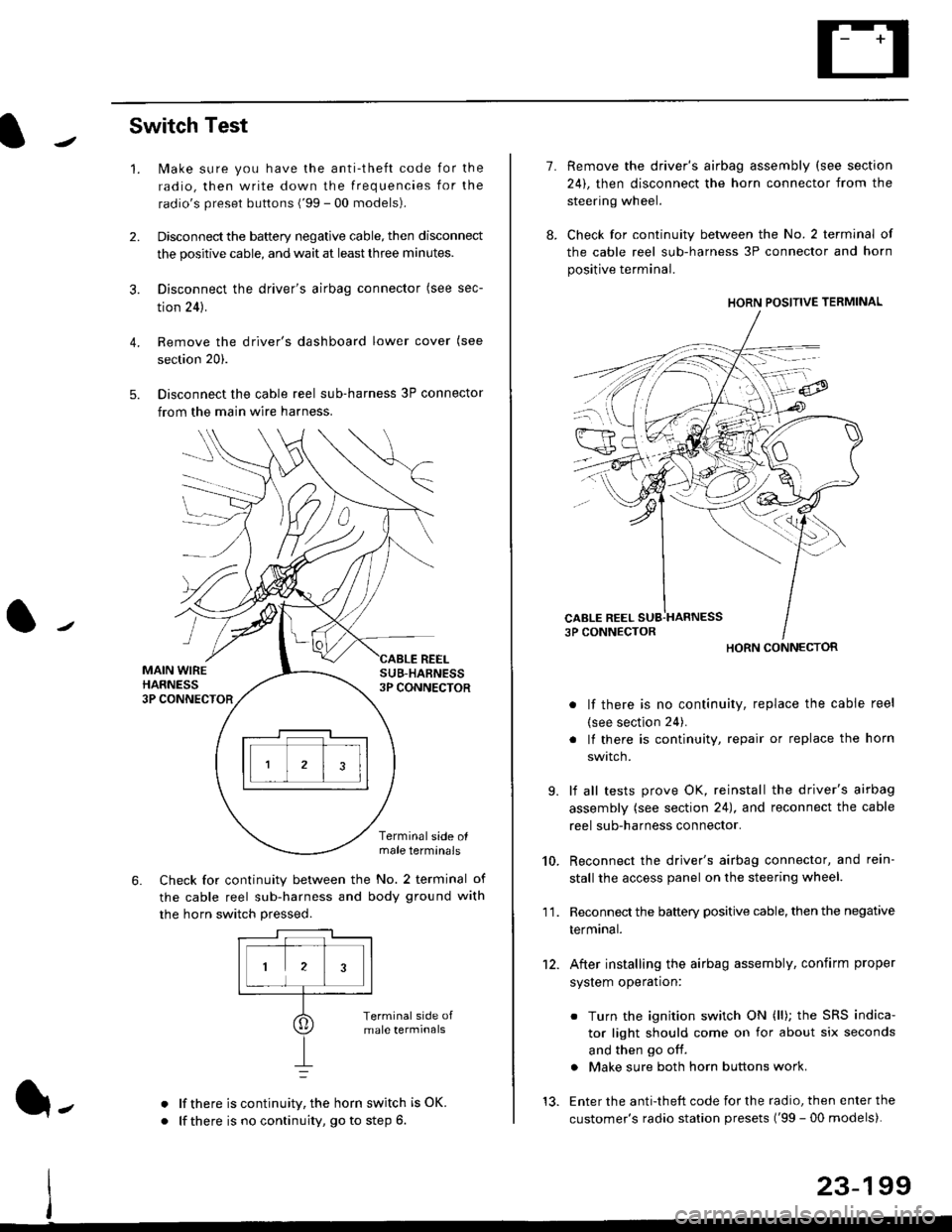

Switch Test

lMake sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable, then disconnect

the positive cable, and wait at least three minutes.

Disconnect the driver's airbag connector (see sec-

tion 24).

Remove the driver's dashboard lower cover (see

section 20).

Disconnect the cable reel sub-harness 3P connector

from the main wire harness.

2.

3.

4.

5.

1.

MAIN WIREHARNESS3P CONNECTOR

SUB-HABNESS3P CONNECTOR

REEL

6.

Terminalside olmale terminals

Check for continuity between the No. 2 terminal of

the cable reel sub-harness and body ground with

the horn switch pressed.

alf there is continuity, the horn switch is OK.

lf there is no continuity, go to step 6l-

-\

1.

8.

10.

'I 1.

9.

Remove the driver's airbag assembly (see section

24), then disconnect the horn connector from the

steering wheel.

Check for continuity between the No. 2 terminal of

the cable reel sub-harness 3P connector and horn

positive terminal.

lf there is no continuity, replace the cable reel

(see section 24).

lf there is continuity, repair or replace the horn

swtlcn,

lf all tests prove OK, reinstall the driver's airbag

assembly (see section 24), and reconnect the cable

reel sub-harness connector.

Reconnect the driver's airbag connector, and rein-

stall the access panel on the steering wheel.

Reconnect the battery positive cable, then the negative

termtnar.

After installing the airbag assembly, confirm proper

system operation:

12.

Turn the ignition switch ON (ll); the SRS indica-

tor light should come on for about six seconds

and then go off.

Make sure both horn buttons work.

13. Enter the anti-theft code for the radio, then enter the

customer's radio station presets ('99 - 00 models).

HORN CONNECTOR

23-199

Page 1679 of 2189

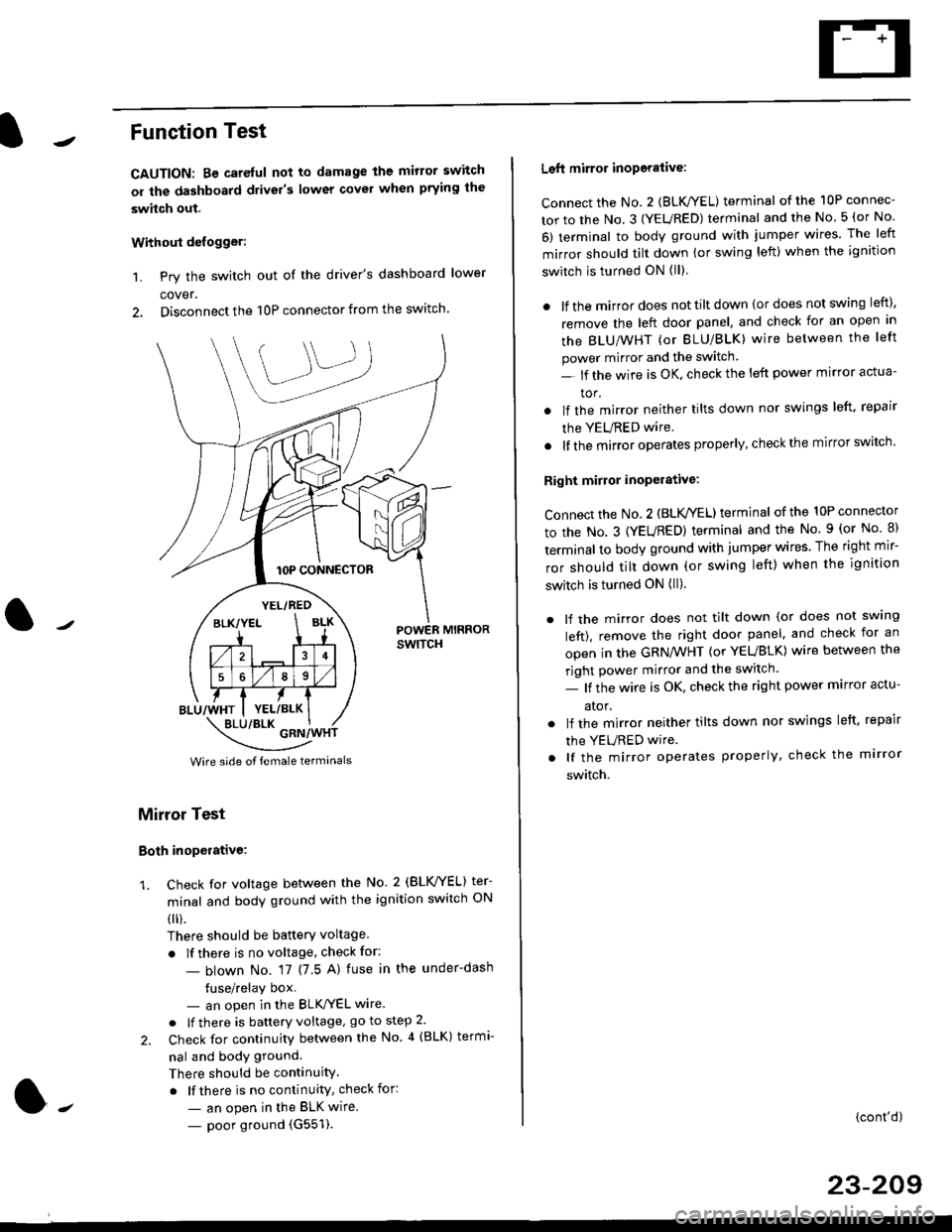

Function Test

CAUTION: Be careful not to damage the mirror switch

or the dashboard drivel's lower covel when prying the

swhch out.

Withoui defogger:

1. Pry the switch out of the driver's dashboard lower

cover.

2. Disconnect the 10P connector from the switch.

lOP CONNECTOR

BLU/WHT

YEL/RED

BLK/YELBLK

4

568

YEL/BLK

POWER MIRRORswtTcH

\:/"*jgil*-(

Wire side of female termanals

Mirror Test

Both inoperative:

1. check for voltage between the No. 2 (BLVYEL) ter

minal and body ground with the ignition switch ON

0 r).

There should be batterY voltage

. If there is no voltage, check for:

- blown No. 17 (7 5 A) fuse in the under-dash

tuse/relay box- an open in the BLK'/YEL wire.

o lf there is battery voltage, go to step 2.

2. Check for continuity between the No 4 (BLK) termi-

nal and body ground.

There should be continuity.

. lf there is no continuity, check for:

- an open in the BLK wire.

- poor ground (G551).

Left mirror inoporalive:

connect the No. 2 {BLK/YEL) terminal of the 10P connec-

tor to the No. 3 (YEURED) terminal and the No 5 (or No

6) terminal to body ground with jumper wires The left

mirror should tilt down (or swing left) when the ignition

switch is turned ON (ll)

. lf the mirror does not tilt down (or does not swing left),

remove the left door panel. and check for an open in

the BLU/WHT (or BLU/BLK) wire between the left

power mirror and the switch

- lf the wire is OK. check the left power mirror actua-

tor.

lf the mirror neither tilts down nor swings left. repair

the YEURED wire.

lf the mirror operates properly, check the mirror switch'

Right mirror inoperative:

Connect the No. 2 (BLK /EL) terminal of the 10P connector

to the No. 3 (YEURED) terminal and the No. 9 (or No 8)

terminal to body ground with jumper wires The right mir-

ror should tilt down (or swing left) when the ignition

switch is turned ON (ll).

. lf the mirror does not tilt down (or does not swlng

left), remove the right door panel. and check for an

open in the GRN/WHT (or YEUBLK) wire between the

right power mirror and the switch.

- lf the wire is OK, check the right power marror actu-

ator.

. lf the mirror neither tilts down nor swings left. repair

the YEURED wire

. lf the mirror operates properly, check the mirror

switch.

(cont'd)

23-209

Page 1680 of 2189

Power Mirrors

Funstion Test (cont'dl

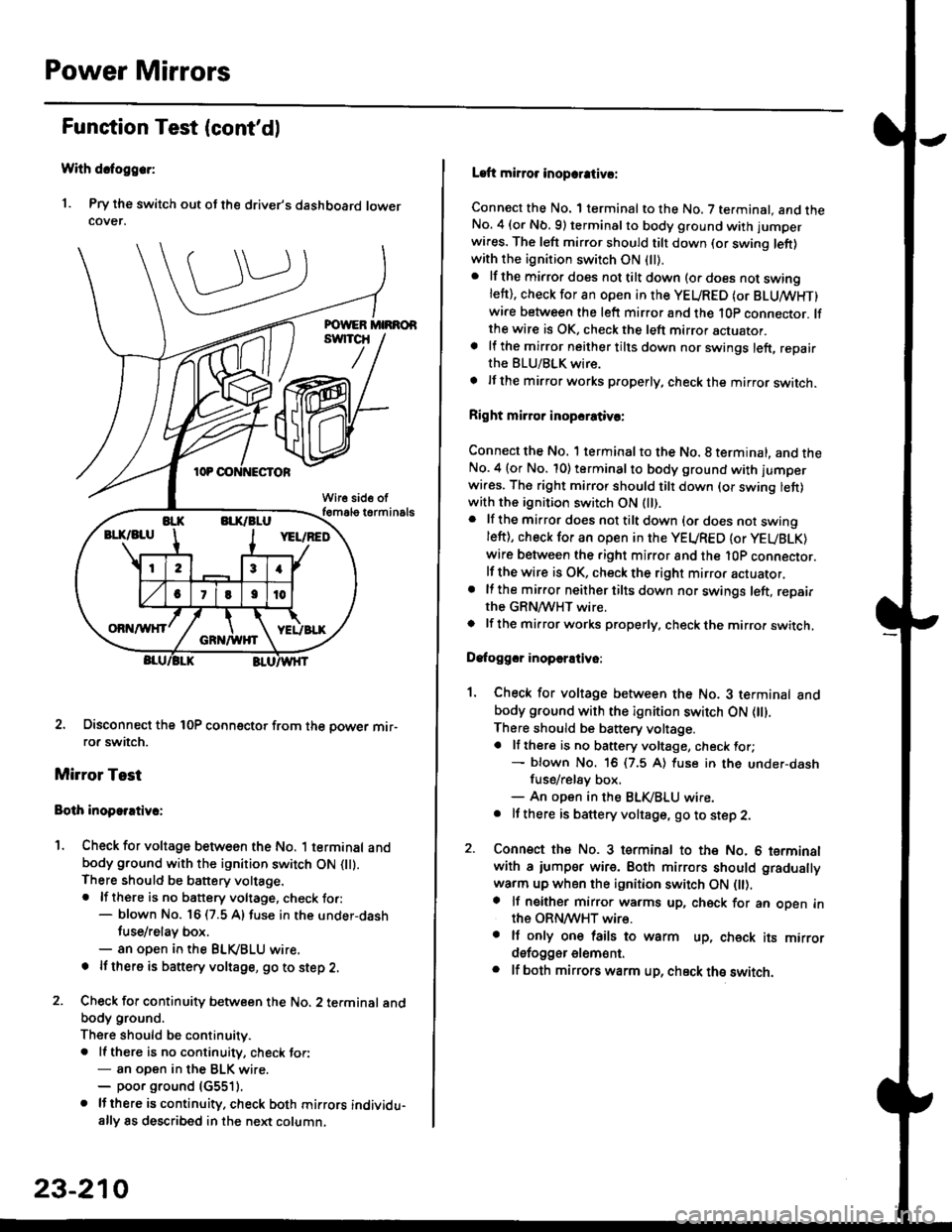

With dcfoggcr:

1. Pry the switch out ot the driver's dashboard lowercover.

2. Disconnect the 10P coonector from the oower mir-ror switch.

Mirror Test

Bolh inoparrtiv.:

1. Check for voltage between the No. 1 terminal andbody ground with the ignition switch ON flt).There should be battery voltage.. lf there is no battery voltage, check to.:- blown No. 16 (7.5 A) fuse in the under-dash

tuse/relay box.- an open in the BLVBLU wrre.

! lf thero is banery voltage, go to step 2.

2. Check for continuity b€tween the No. 2 terminal andbody ground.

There should be continuitv.. ll there is no continuity, check tor:- an open in the BLK wire.- poor ground (G5511.

. lJthere is continuity. check both mirrors individu-ally 8s described in the next column,

23-210

Laft mirror inopcrativ!:

Connect the No. 1 terminal to the No. 7 terminal. and theNo. 4 (or Nb.9) terminalto body ground with jumper

wires. The left mirror should tilt down (or swing left)with the ignition switch ON (ll).

. lf the mirror does not tilt down (o. does not swinglett), check for an open in the YEURED (or BLUMHT)wire between the left mirror and the 10p connector. lfthe wire is OK, check the left mirror actuator.a lf the mirror neither tilts down nor swings left, repairthe BLU/BLK wire.

t lf the mirror works properly, check the mirror switch.

Right mi.ror inopcrativc:

Connect the No. 1 terminal to the No. 8 terminal, and theNo.4 (or No. 10) terminalto body ground with l'umperwi.es. The right mirror should tilt down (or swing lett)with the ignition switch ON (ll).

. lf the mirror does not tilt down {or does not swingleft), check for an open in the YEURED {or YEUBLK)

wire between the right mirror and the l0P connector.lf the wire is OK, check the right mirror actuator,. lf the mirror neither tilts down nor swings left, repairthe GRN/WHT wire.o lf the mirror works properly. check the mirro. switch,

Dafoggcr inoperEtivo:

1. Check for voltage between the No. 3 terminal andbody ground with the ignition switch ON (||).

There should be battery voltage.a lf there is no battery voltage, check for;- blown No. 16 (7.5 A) luse in the under-dash

fuse/rel8y box,- An open in the BLK,iBLU wire.. It there is battery voltage, go to step 2.

2. Connsct the No. 3 tsrminal to the No. 6 terminalwith a iumpsr wire. Both mirrors should gradually

warm up when the ignition switch ON flt).a lf neither mirror warms up, check for an open inthe ORN/WHT wire.. It only on€ lails to warm up, check its mirrordsfogger elem6nt.. lf both mirrors warm up, check ths switch.

Page 1682 of 2189

Power Mirrors

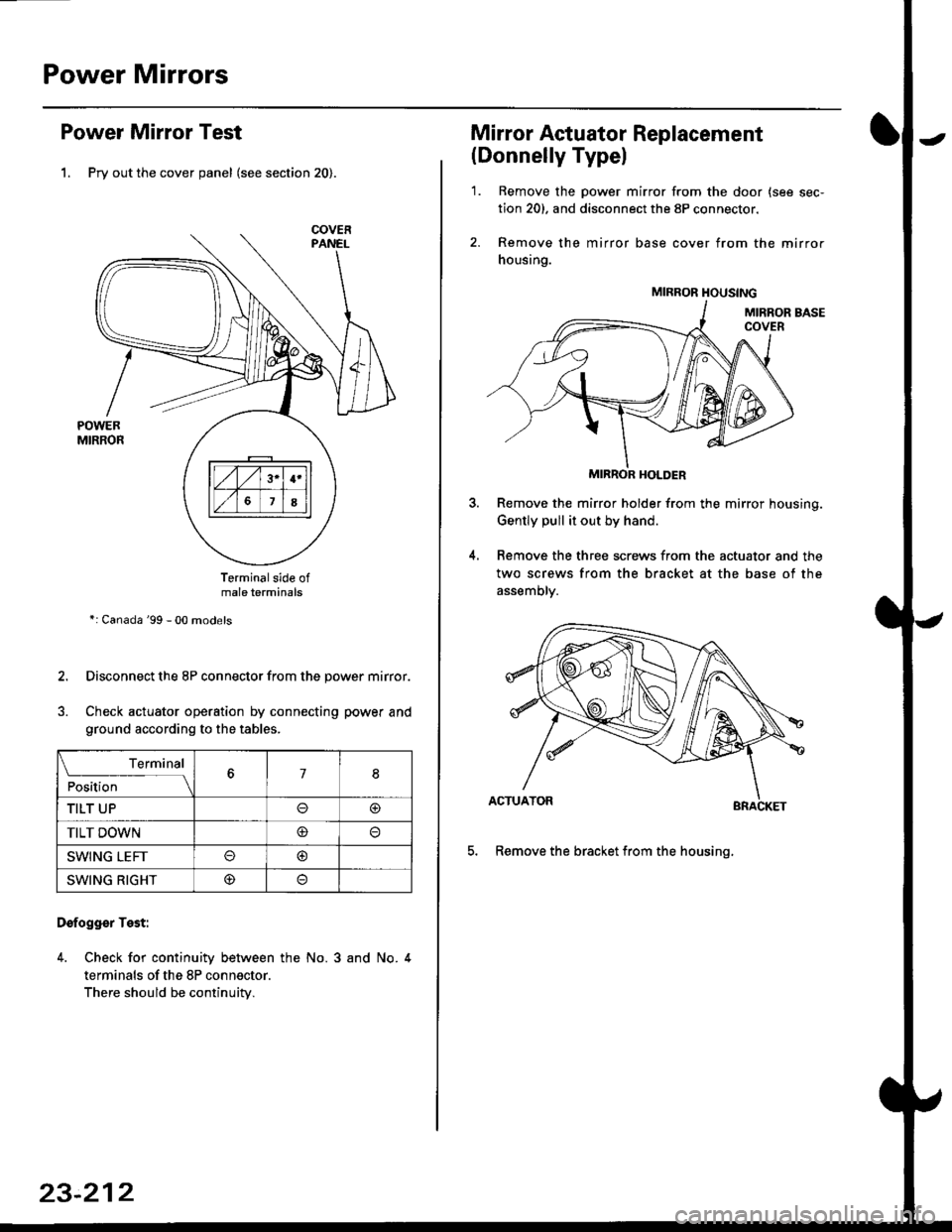

Power Mirror Test

1. Pry out the cover panel (see section 20).

Terminalside ofmale terminals

*: Canada '99 - 00 models

Disconnect the 8P connector from the power mirror.

Check actuator operation by connecting power and

ground according to the tables.

Dofogger Test:

4. Check for continuity between the No. 3 and No. 4

terminals of the 8P connector.

There should be continuity.

COVER

L___r"'ry1Position67I

TILT UPo@

TILT DOWN@

SWING LEFTo@

SWING RIGHT@

23-212

Mirror Actuator Replacement

(Donnelly Typel

'1. Remove the power mirror from the door {see sec-

tion 20). and disconnect the 8P connector.

2. Remove the mirror base cover from the mirror

housing.

MIRROR HOLDER

Remove the mirror holder from the mirror housing.

Gently pull it out by hand.

Remove the three screws from the actuator and the

two screws from the bracket at the base of the

assemory.

BRACKET

5. Remove the bracket from the housinq.

4.

MIRROR HOUSING