no. 25 HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1421 of 2189

Mode Control Motor

2.

Test

1.

4.

Disconnect the 7P connector from the mode control

motor.

Connect battery power to the No, 1 terminal, and

ground the No.7 terminal,

CAUTION: Never connecl the battery in iho oppo-

site direction.

Using a jumper wire, connect the No. 7 terminal

individually to the No. 2,3, 4,5 and 6 terminals in

that order. Each time the connection is made, the

mode control motor should run smoothly and stop.

NOTE: lf the mode control motor does not run when

jumping the first terminal, jump that terminal again

after jumping the other terminals. The mode control

motor is OK if it runs when jumping the first termi-

nal again.

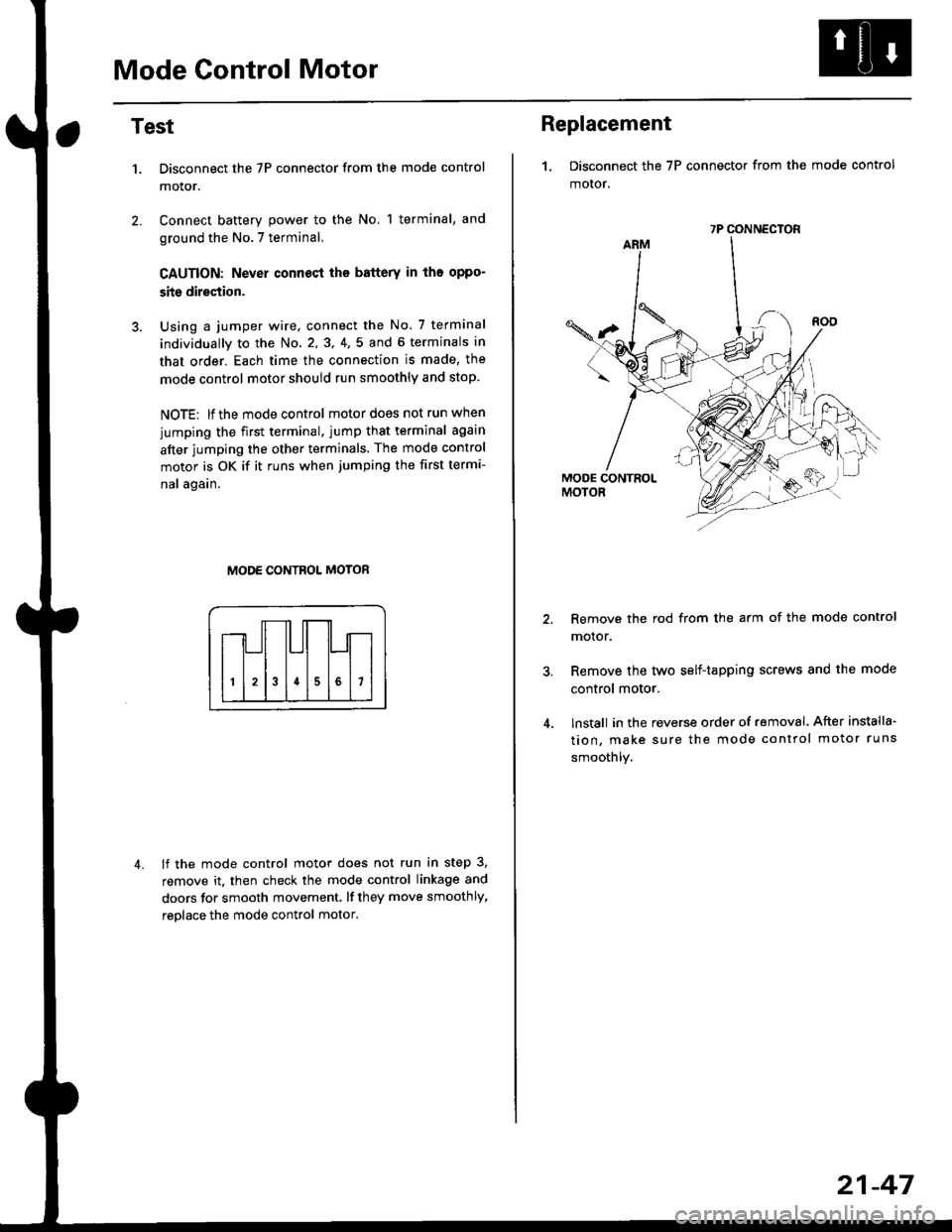

MODE CONTROL MOTOR

lf the mode control motor does not run in step 3,

remove it. then check the mode control linkage and

doors for smooth movement. lf they move smoothly,

reolace the mode control motor,

Replacement

1. Disconnect the 7P connector from the mode control

motor,

Remove the rod from the arm of the mode control

motor.

Remove the tyvo self-tapping screws and the mode

control motor.

lnstall in the reverse order of removal. After installa'

tion, make sure the mode control motor runs

smoothly.

7P CONNECTOR

21-47

Page 1422 of 2189

Recirculation Control Motor

Test

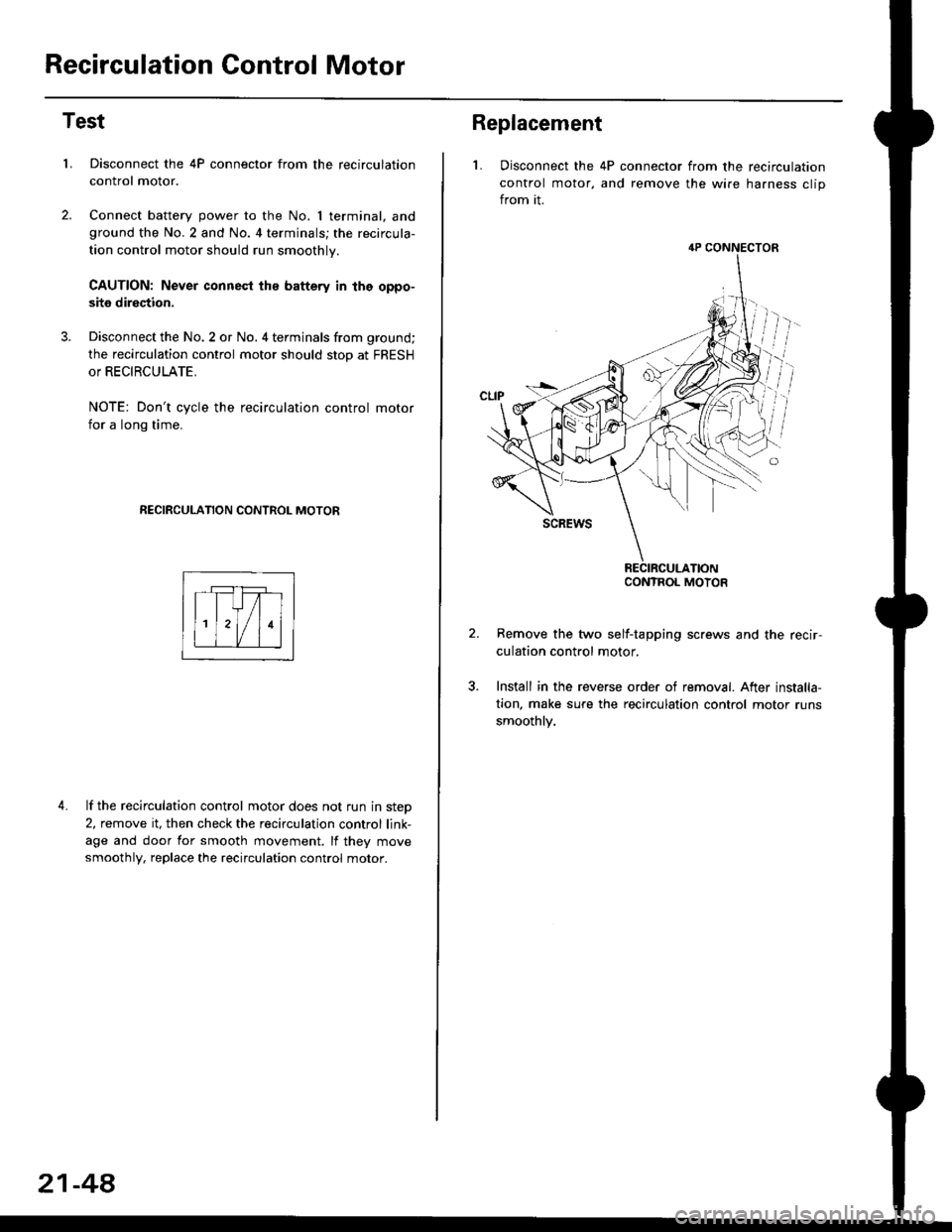

LDisconnect the 4P connector from the recirculation

control motor.

Connect battery power to the No. I terminal, andground the No.2 and No. 4 terminals; the recircula-

tion control motor should run smoothly.

CAUTION: Never connest ths battery in the oppo-

site direction.

Disconnect the No. 2 or No. 4 terminals from ground;

the recirculation control motor should stop at FRESH

or RECIRCULATE.

NOTE: Don't cycle the recirculation control motor

for a long time.

RECIRCULATION CONTROL MOTOR

4. lf the recirculation control motor does not run in step

2, remove it, then check the recirculation control link-

age and door for smooth movement. lf they move

smoothly, replace the recirculation control motor.

21-48

Replacement

L Disconnect the 4P connector from the recirculation

control motor, and remove the wire harness clip

from it.

Remove the two self-tapping screws and the recir-

culation control motor.

Install in the reverse order of removal. After installa,

tion, make sure the recirculation control motor runs

smoothly.

4P CONNECTOR

CONTROL MOTOR

Page 1423 of 2189

RelaysHeater Fan Switch

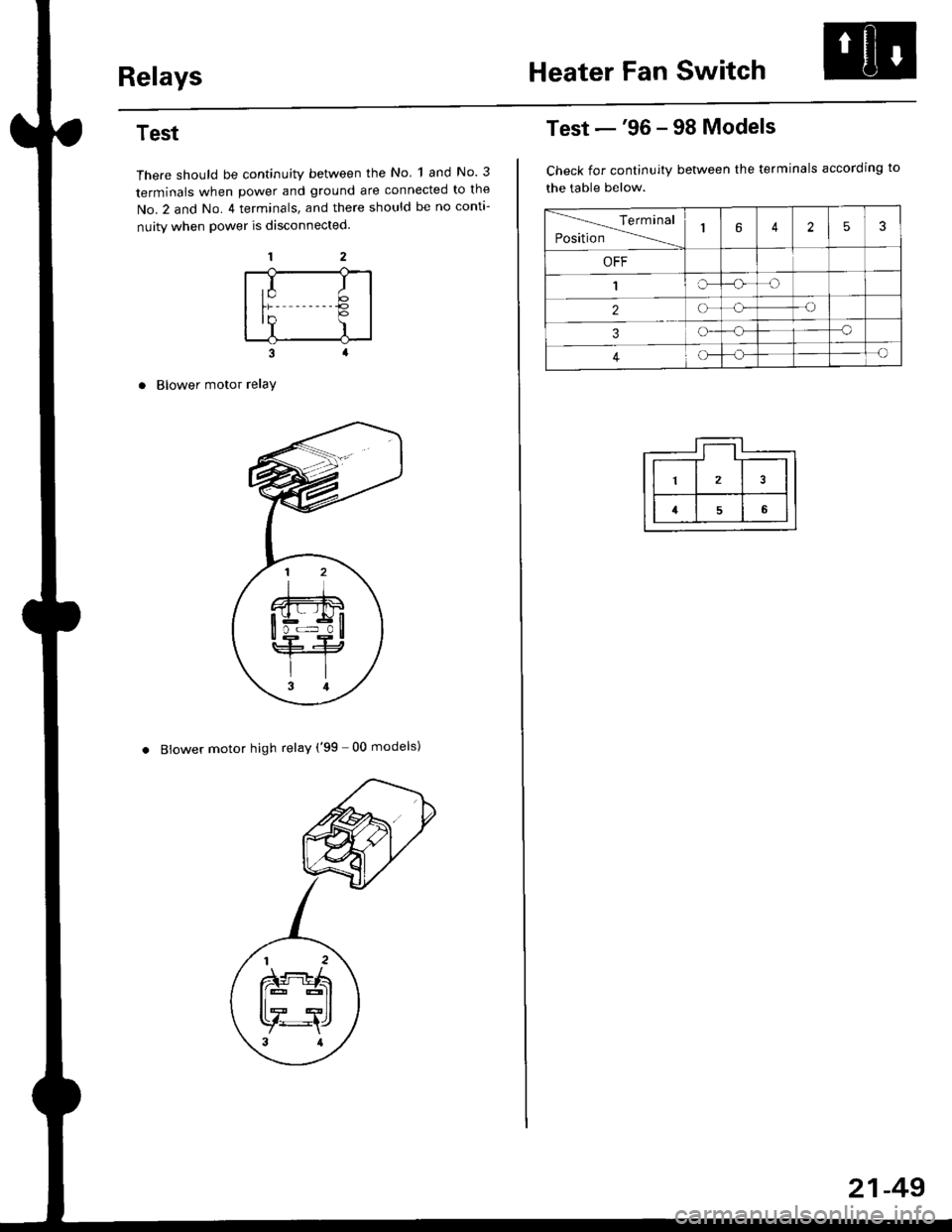

Test

There should be continuity between the No 1 and No. 3

terminals when power and ground are connected to the

No.2 and No. 4 terminals, and there should be no conta-

nuity when power is disconnected.

Blower motor relaY

. Blower motor high relay ('99 00 models)

,I It;€'Y )

Test -'96 - 98 Models

Check for continuity between the terminals according to

the table below.

lerminal

Position14253

OFF

1I�rJ

2o-o

3o-a

4c)-{

21-49

Page 1424 of 2189

Mode Control SwitchPower Transistor

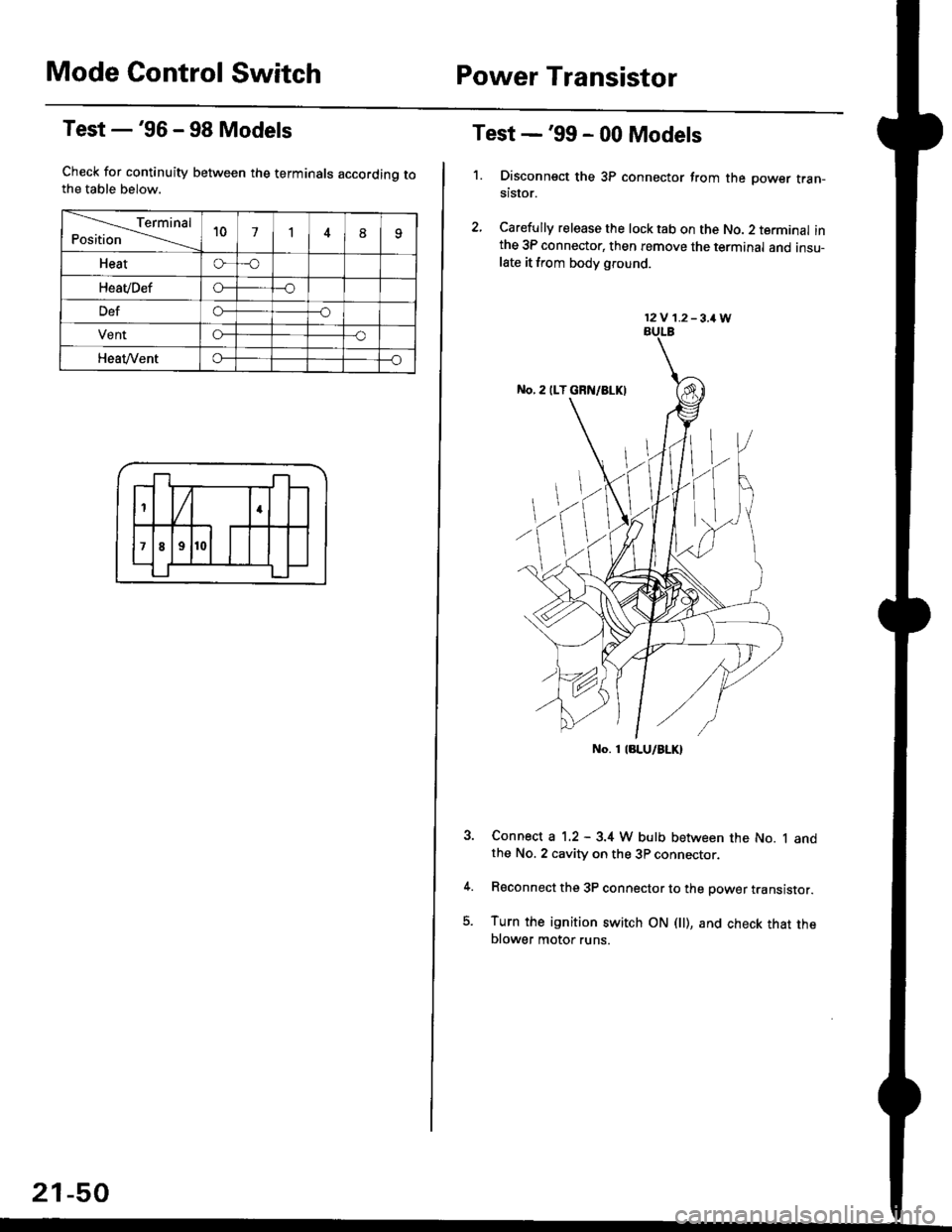

Test -'96 - 98 Models

Check for continuity between the terminals accordinq tothe table below.

Terminal

Position't071

Heato-o

HeaVDefo---o

Defo--o

VentG-o

HeaVVento--o

1

;l t

4

789

21-50

Test -'99 - 00 Models

1. Disconnsct the 3P connector from the oower tran-stsror.

2, Carefully release the lock tab on the No. 2 terminal inthe 3P connector, then remove the terminal and insu-late it from body glound.

Connect a 1.2 - 3.4 W bulb between the No. 1 andthe No. 2 cavity on the 3P connector.

Reconnect the 3P connector to the power translstor.

Turn the ignition switch ON fll), and check that theblower motor runs.

12V 1.2-3,1W

No. 1 laLU/aLK)

Page 1426 of 2189

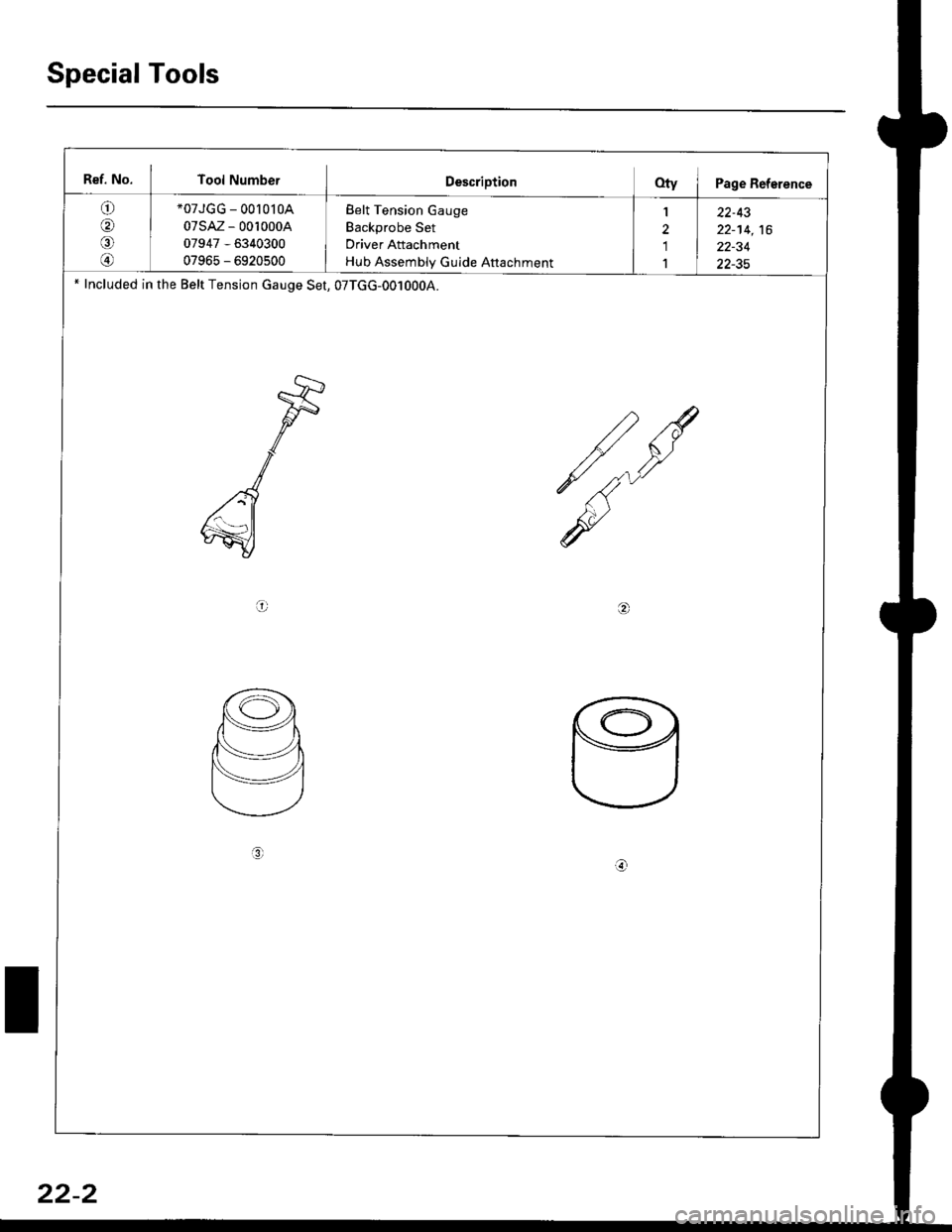

Special Tools

Bef. No. Tool NumberDescriptionQty I Page Reference

o

@

*07JGG - 00l0l0A

07sAz - 0010004

07947 - 6340300

07965 - 6920500

Belt Tension Gauge

Backprobe Set

Driver Attachment

Hub Assembly Gulde Attachment

1

'1

1

22-43

22-14,16

22-34

22-35' Included in the Belt Tension cauge Set, 07TGG-0010004.

a6r

L

3r

22-2

Page 1431 of 2189

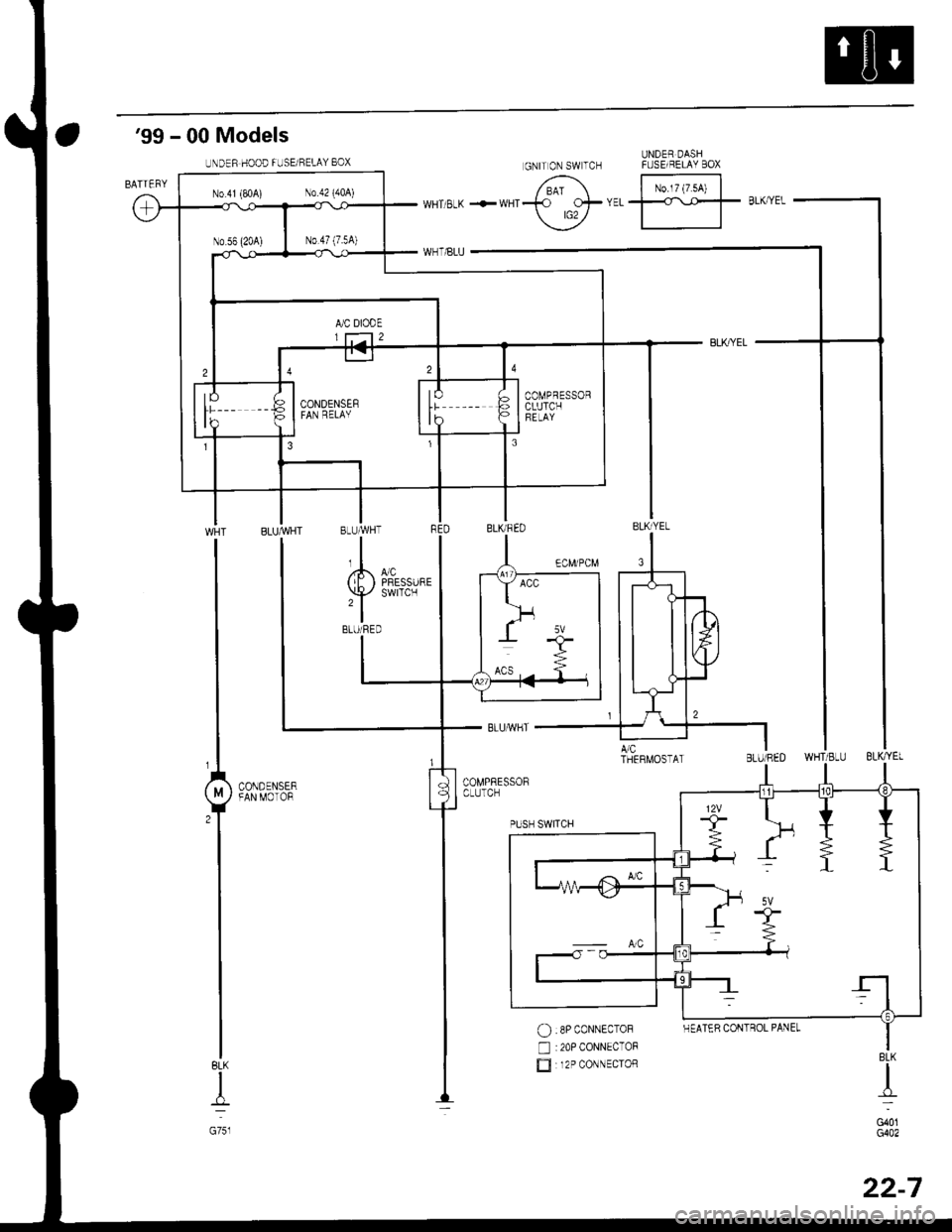

'99 - 00 Models

UNDER DASHFUSE/BELAY BOX

No.l7 (7.54)

BLK

I

G751

$*"

O :8P coNNEcToF

n :20P CONNECToF

E 12P coNNEcroRBLK

d-

G401G402

UNDER HOOD FUSE/RELAY 8OX

N0.41 (P,0A) N0.42 (404)

COMPRESSORCLUTCHFELAY

GNITON SWTCH

HEATER CONTROL PANEL

22-7

Page 1432 of 2189

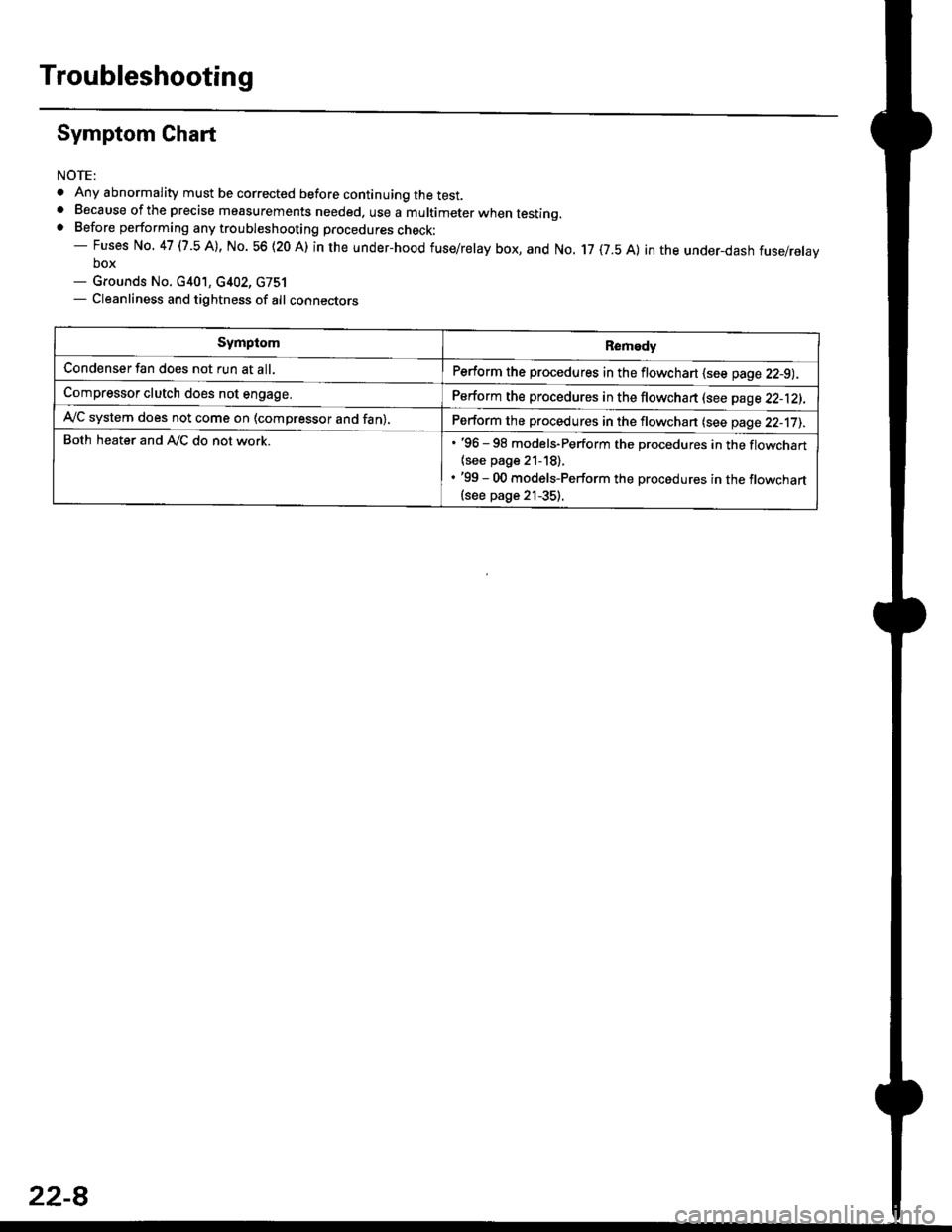

Troubleshooting

Symptom Chart

NOTE:

. Any abnormality must be corrected before continuing the test.. Because of the precise measurements needed. use a multimeter when testinq.. Before performing any troubleshooting procedures check:- Fuses No. 47 l7 -5 Al, No. 56 (20 A) in the under-hood fuse/relay box, and No. 17 (7.5 A) in the under_dash fuse/relavbox- Grounds No. c401, c402, G751- Cleanliness and tightness of alt connectors

SymptomRemedy

Condenser fan does not run at all.Perform the procedures in the flowchart {see page 22-9).

Compressor clutch does not engage.Perform the procedures in the flowchart lsee page 22-12).

Ay'C system does not come on (compressor and fan),Perform the procedures in the flowchan (see page 22-17).

Both heater and A,/C do not work.. '96 - 98 models-Perform the procedures in the flowchart

{see page 21-18).. '99 - 00 models-Perform the procedures in the flowchart(see page 21-35).

22-8

Page 1433 of 2189

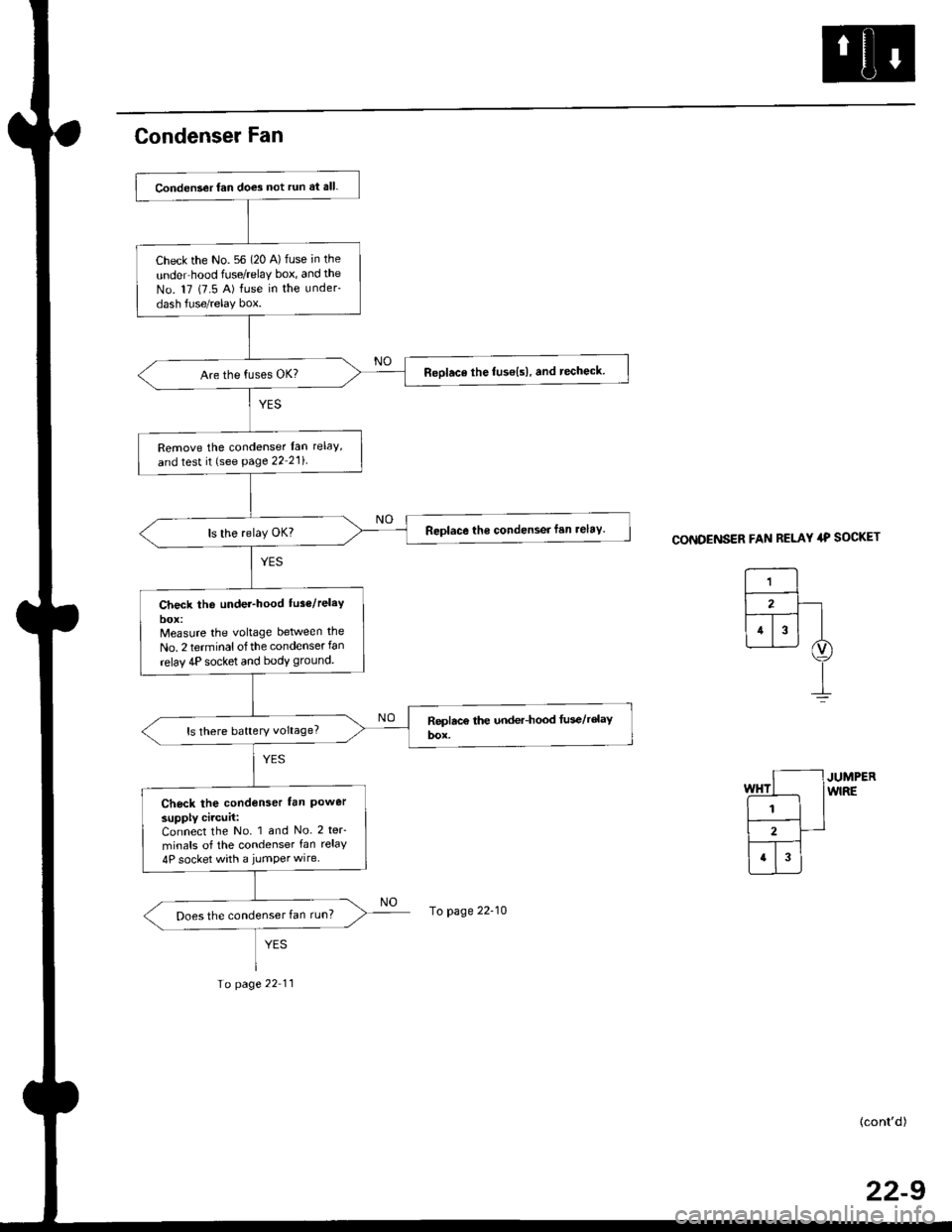

Condenser Fan

CONDENSER FAN RELAY 4P SOCKET

JUMPERwlRE

(cont'd)

22-9

Conden3er fan does not run at all.

Check the No. 56 (20 A) fuse in the

unde.hood frJse/relaY box, and the

No. 17 (7.5 A) fuse in the under-

dash fuse/relay box.

Reolace the fuse{s), and techeck

Remove the condenser lan rclaY'

and test it (see page 22 21i

Replace the condensei fan relav.

Check the under-hood tus6/relaY

Measure the vohage between the

No. 2 terminalofthe condenser fan

relav 4P socket and bodv ground.

ls there battery voltage?

Check the condenser lan Powersupply circuit:Connect the No. 1 and No. 2 teF

minals of the condenser fan relay

4P socket with a jumper wire

Does the condenser fan run?To page 22-10

Io page 22 11

Page 1434 of 2189

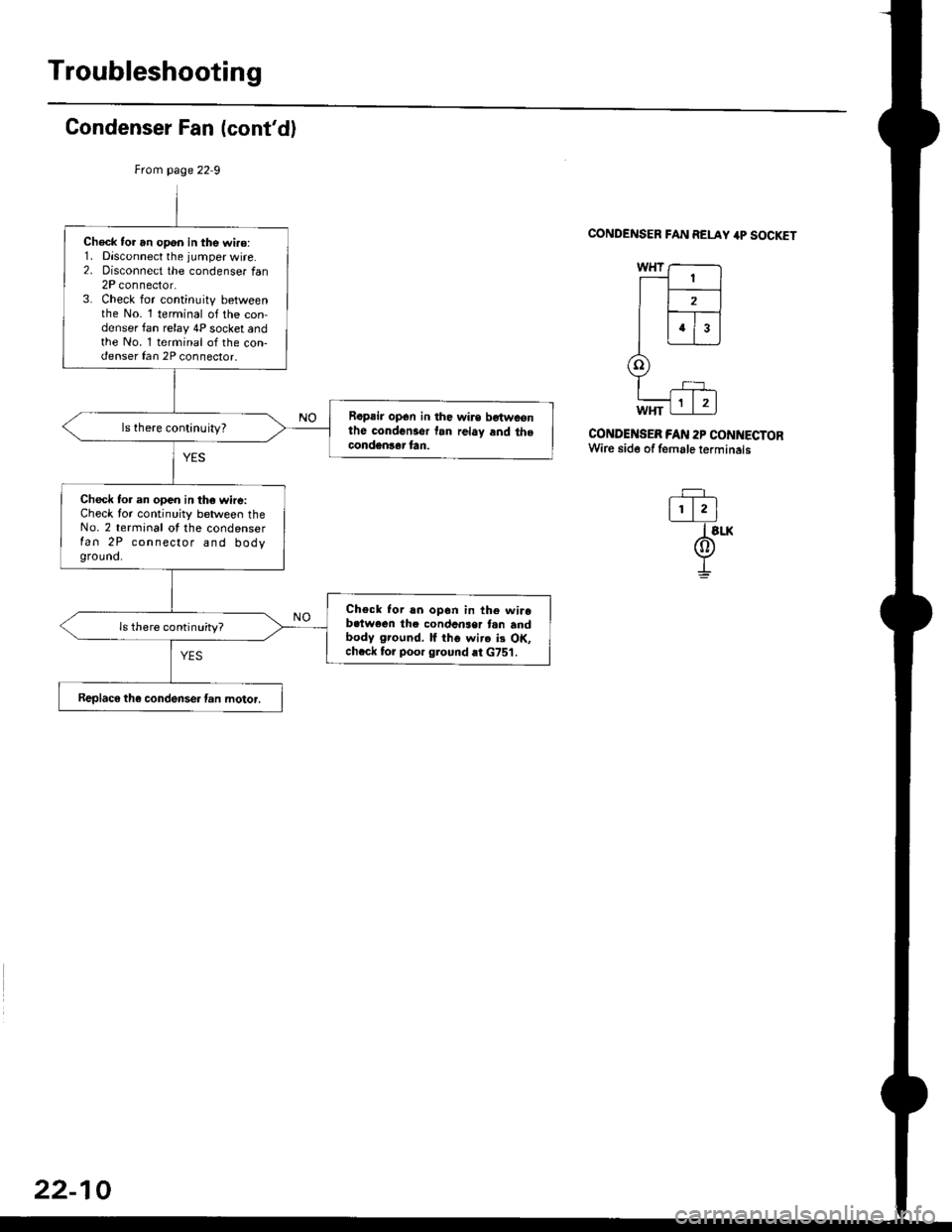

Troubleshooting

Condenser Fan (cont'd)

CONDENSER FAN RELAY 4P SOCKET

CONDENSEB FAN 2P CONNECTORWire side of female terminals

-=F_

l!.lI slx

@I

Check tor an opon in the wi.o:1. Disconnect the jumper wire.2. oisconnect the condenser tan2P connector.3. Check for continuity betweenthe No. 1 terminal of the con-denser fan relay 4P socket andthe No. 1 terminal of the con-denser fan 2P connector.

Rapair op6n in the wirs bgtwconthe condcnsor tan rclay and thecondgnlar fan.

ls there continuity?

Check to. en open in the wire:Check for continuity between theNo. 2 terminal ot the condenserfan 2P connector and bodyground.

Check Ior rn opon in th6 wirebctwoen the condcnser tan andbody ground, lf iho wirc ii OK,chcck for poor ground at G751.

ls there continuity?

Replaco the condense. fan motor.

22-10

Page 1435 of 2189

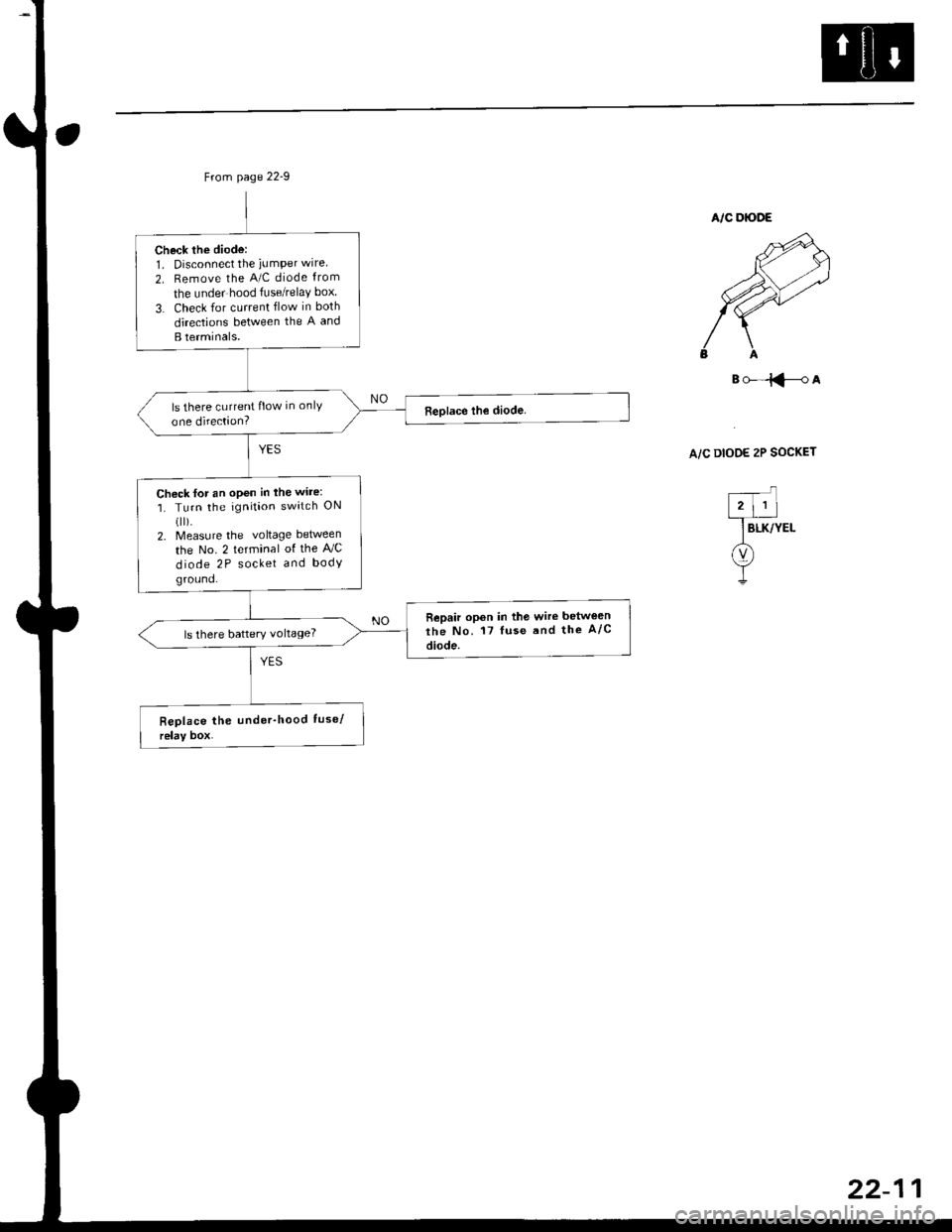

Check the diode:1. Disconnect the iumPer wire

2. Remove the A/C diode from

the under hood fuse/relaY box

3. Check for current flow in both

directions between the A and

B terminals.

ls there current flow in onlY

one direction?

Chock for an open in the wire:

1. Turn the ignition switch ON(ll).

2. Measure the voltage between

the No. 2 terminal of the AJC

diode 2P socket and body

ground.

Repair opon in the wire betwe€n

the No. 17 luse and the A/c

diode.ls there battery voltage?

B()-=iFA

A/C DIOOE 2P SOCKET