Synchro ring HONDA CIVIC 1999 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 651 of 2189

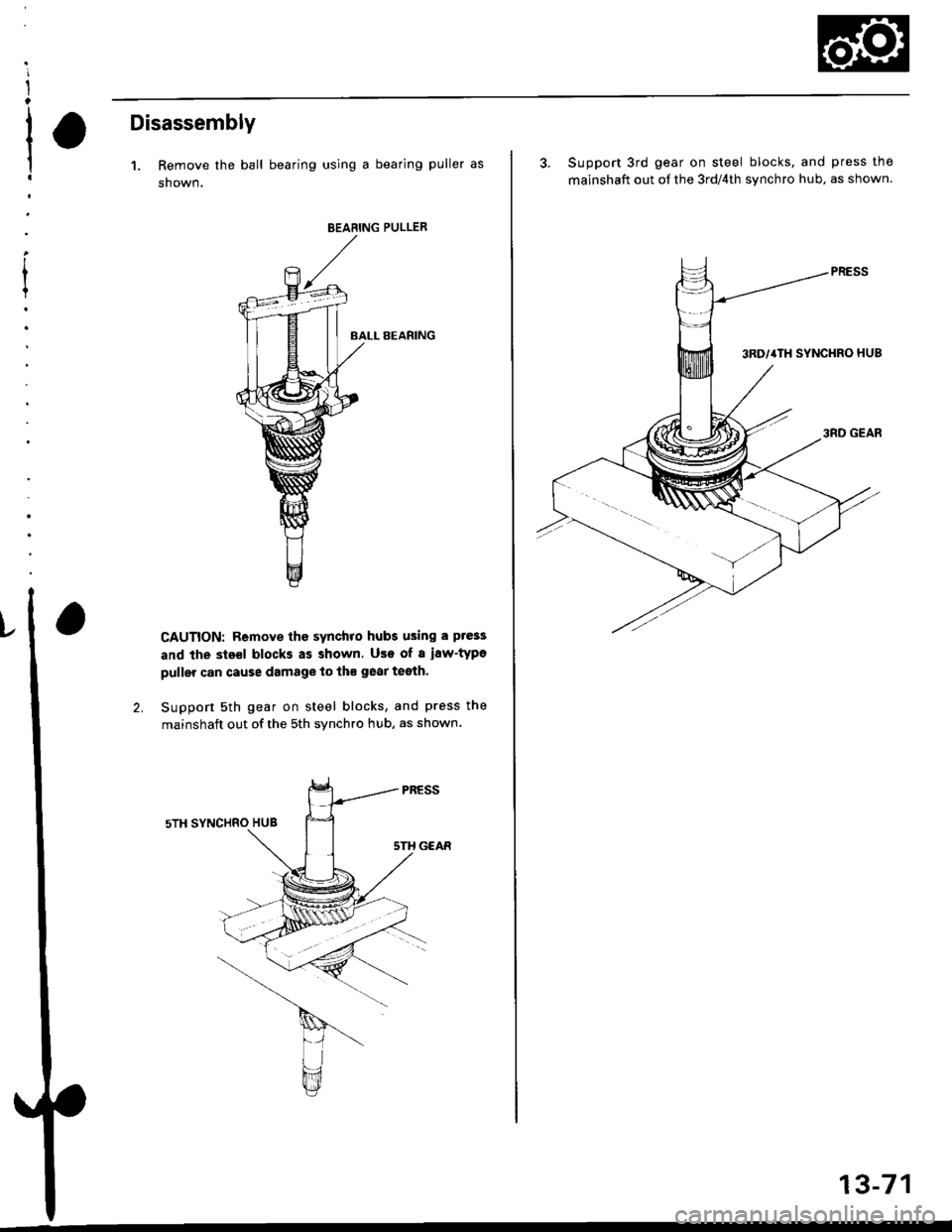

Disassembly

1. Remove the ball bearing using a bearing puller as

shown.

BEABING PULLER

BALL BEARING

CAUTION: Remove the synchro hubs using a ptess

and the sts€l blocks as shown. Use of a i8w'type

puller can cause damage to th€ gear teeth.

Support sth gear on steel blocks, and press the

mainshaft out of the sth synchro hub, as shown.

3. Support 3rd gear on steel blocks, and press the

mainshaft out of the 3rd/4th svnchro hub, as shown.

13-71

Page 653 of 2189

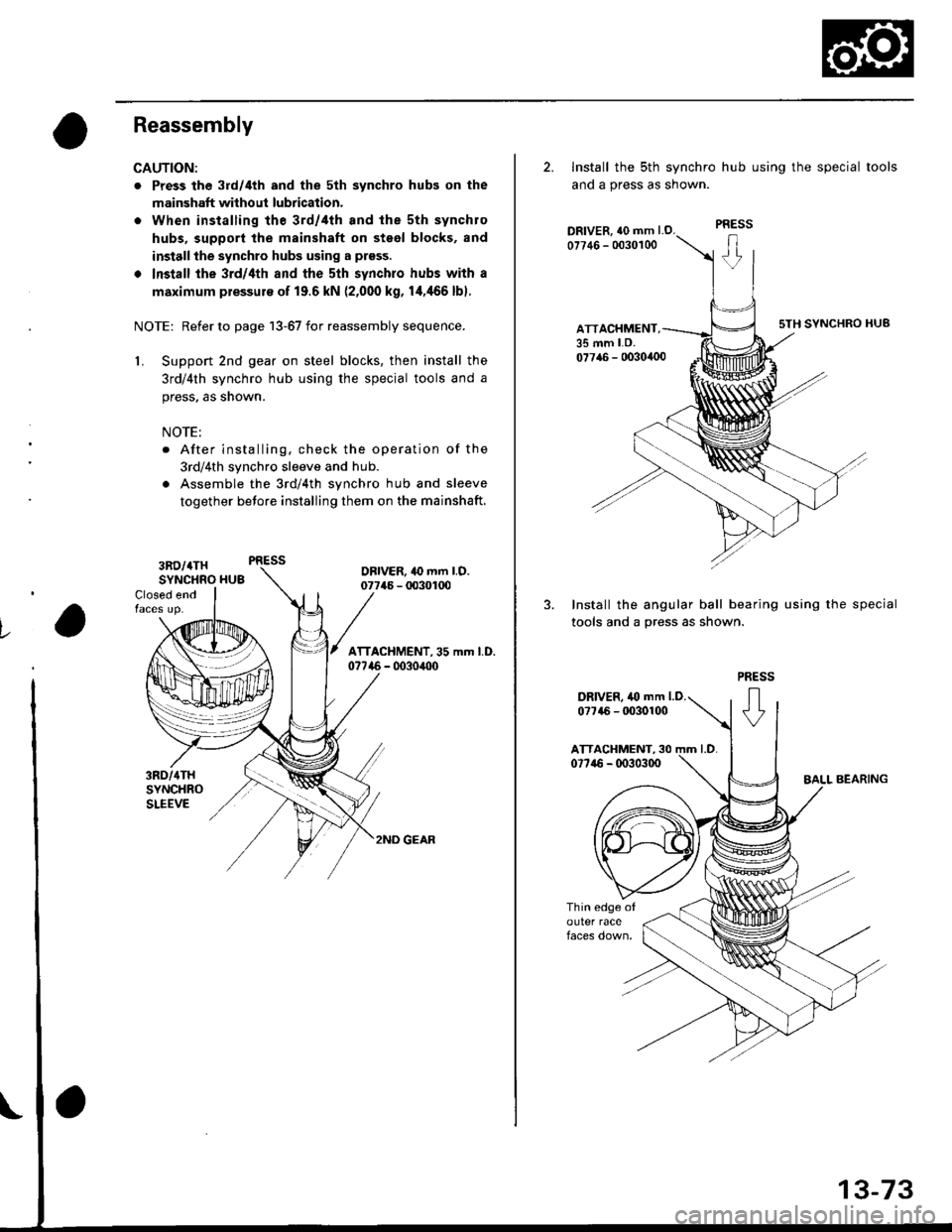

Reassembly

CAUTION:

. Press the 3rd/4th and the 5th synchro hubs on the

mainshaft without lubrication.

o When installing the 3rd/,lth and the sth synchro

hubs, support the mainshaft on steel blocks, and

installthe synchro hubs using a prsss.

. Install the 3rd/4th and the sth synchro hubs with a

maximum plessur€ of 19.6 kN (2,000 kg, 14,466 lbl.

NOTE: Refer to page 13-67 for reassembly sequence.

1, Support 2nd gear on steel blocks, then install the

3rd/4th synchro hub using the special tools and a

press, as snown.

NOTE:

. After installing. check the operation of the

3rd/4th synchro sleeve and hub.

. Assemble the 3rd/4th synchro hub and sleeve

together betore installing them on the mainshaft.

Closed end

3RD/4THSYNCHRO HU3DBIVER, 10 mm l.O.07746 - 00301U)

/ lrrlcHlileNr. ss .- t.o.07746 - 0030,100

l.

3RD/{THSYNCHROSLEEVE

2ND GEAR

2. Install the sth synchro hub using the special tools

and a press as snown.

DRIVER, {0 mm l.O.07746 - 0030100

ATTACHMENT,35 mm LD.

sTH SYNCHRO HUB

07716 - 0030,100

3. Install the angular ball bearing using the special

tools and a press as shown.

PRESS

+

DRIVER, 40 mm LD.0?7a6 - It030100

Page 654 of 2189

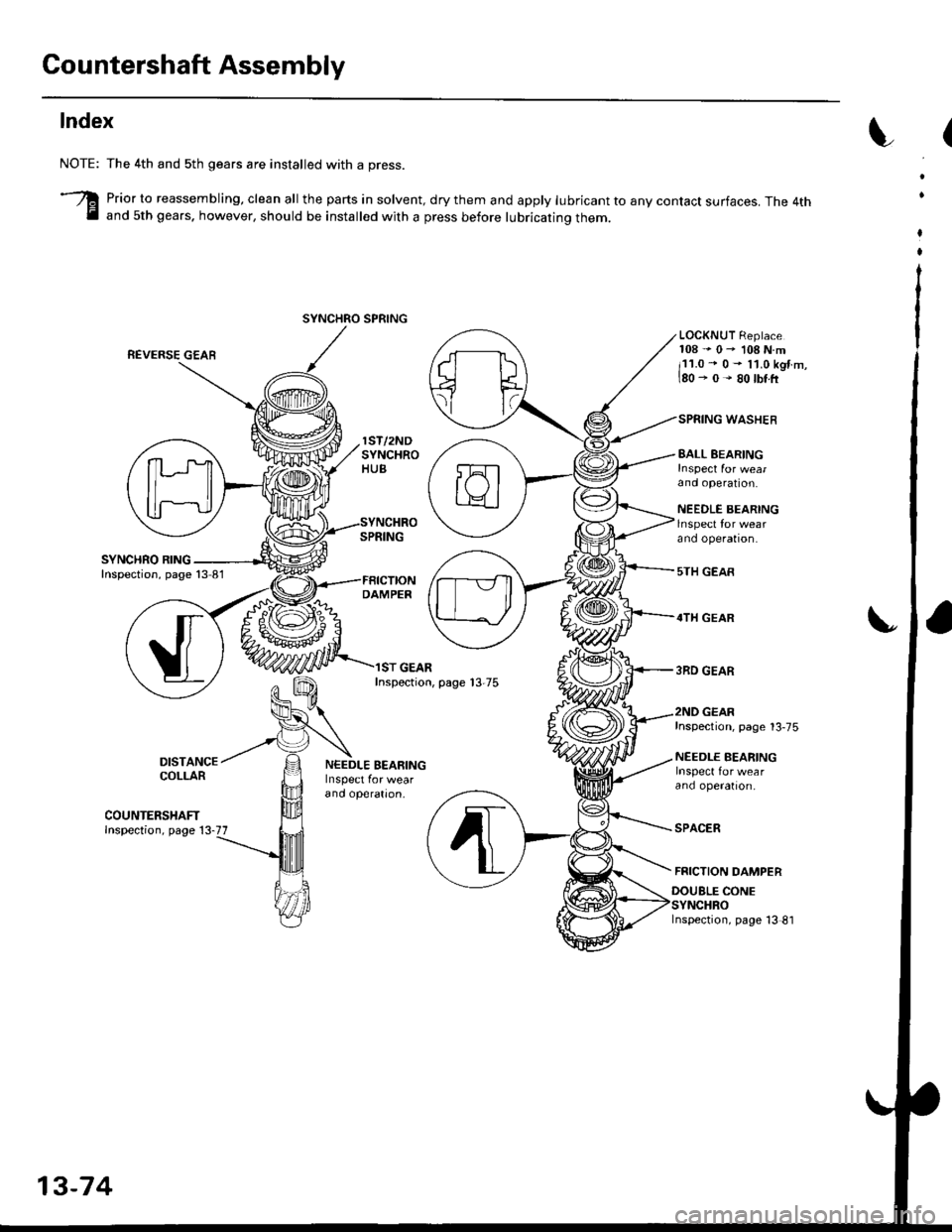

Gountershaft Assembly

Index

DAMPER

ST GEARInspection, page 13-75

EALL EEARING

and operation.

NEEDLE BEARINGlnspect for wearano operaton.

5TH GEAR

4TH GEAR

3RD GEAR

NOTE:

3

The 4th and sth gears are installed with a press.

Prior to reassembling, clean all the parts in solvent, dry them and apply lubricant to any contact surfaces. The 4thand 5th gears. however, should be installed with a press before lubricating them.

REVERSE GEAR

LOCKNUT Replace108"0-108N.m

i11.0 - 0- l1.0kgtm,180-0-80lbttr

WASHER

DISTANCECOLLAR

COUNTERSHAFTInspection, page 13-77

NEEDLE BEARING

and operatron,

Inspection, page 13-75

NEEDLE BEARING

ano operatron,

SPACER

FRICTION DAMPER

DOUBLE CONE

Inspection, page 13 81

SYNCHRO SPRING

13-74

Page 658 of 2189

Gountershaft Assembly

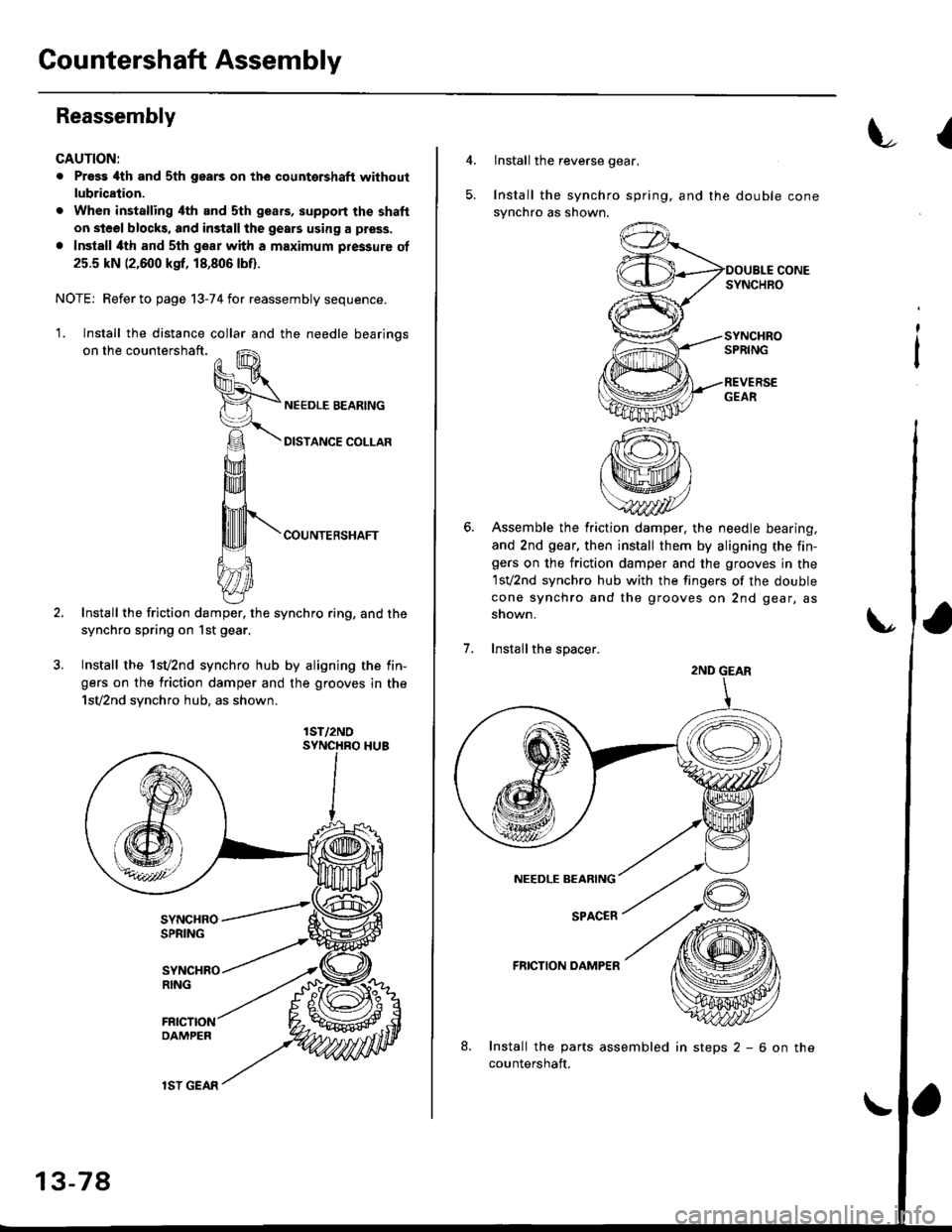

Reassembly

CAUTION:

. Pross 4th and sth gears on the countershaft without

lubrication.

. When installing ilth and sth geafs, support the shaft

on steel blocks, and install the gears using a press.

. Install ilth and sth gear with a maximum pressure of

25.5 kN (2,600 ksf, 18,806lbf).

NOTE; Refer to page 13-74 for reassembly sequence.

'1. Install the distance collar and the needle bearinos

on the countershaft.

COUNTERSHAFT

Install the friction damper, the synchro ring, and the

synchro spring on 1st gear.

Install the 1sv2nd synchro hub by aligning the fin-

gers on the friction damper and the grooves in the

1sv2nd synchro hub, as shown.

lST/2NO

13-78

lSI GEAR

insteps2-6onthe

{

4.lnstall the reverse gear.

Install the synchro spring. and the double cone

synchro as shown.

Assemble the friction damper, the needle bearing,

and 2nd gear, then install them by aligning the fin-gers on the friction damper and the grooves in the

1sv2nd synchro hub with the fingers of the double

cone synchro and the grooves on 2nd gear, as

snown.

Installthe spacer.

FRICTION DAMPER

Install the parts assembled

countershaft.

;

2ND GEAR

Page 660 of 2189

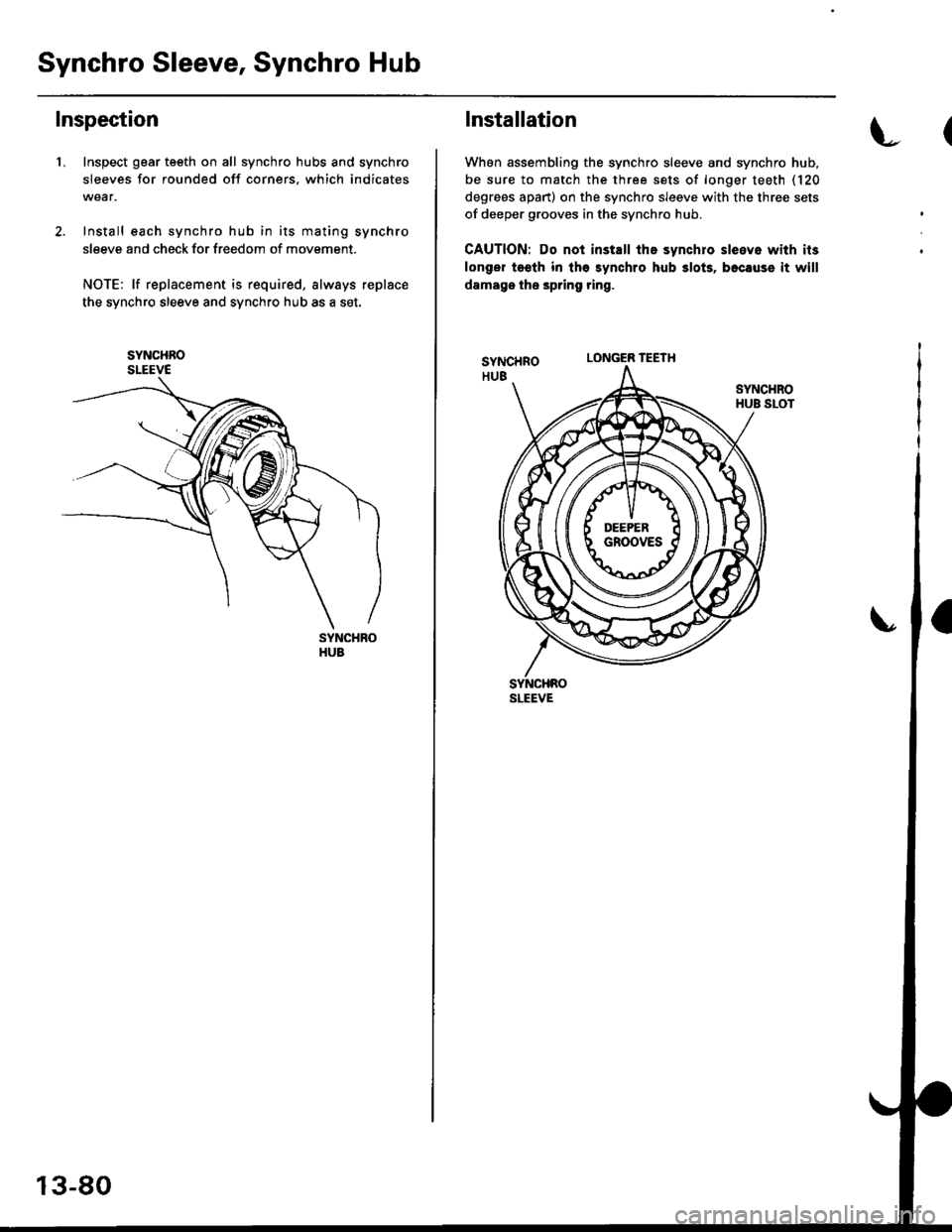

Synchro Sleeve, Synchro Hub

Inspection

1,Inspect gear teeth on all synchro hubs and synchro

sleeves for rounded off corners. which indicates

Install each synchro hub in its mating synchro

sleeve and check for freedom of movement.

NOTE: lf replacement is required, always replace

the synchro sleeve and synchro hub as a set.

Installation

When assembling the synchro sleeve and synchro hub,

be sure to match the three sets of longer teeth (120

degrees apart) on the synchro sleeve with the three sets

of deeper grooves in the synchro hub.

CAUTION: Do noi install tho synchro sleeve with its

longer toeth in the synchro hub slots, because it will

damage the spring ring.

SYNCItROSLEEVCLONGER TEETH

13-80

Page 661 of 2189

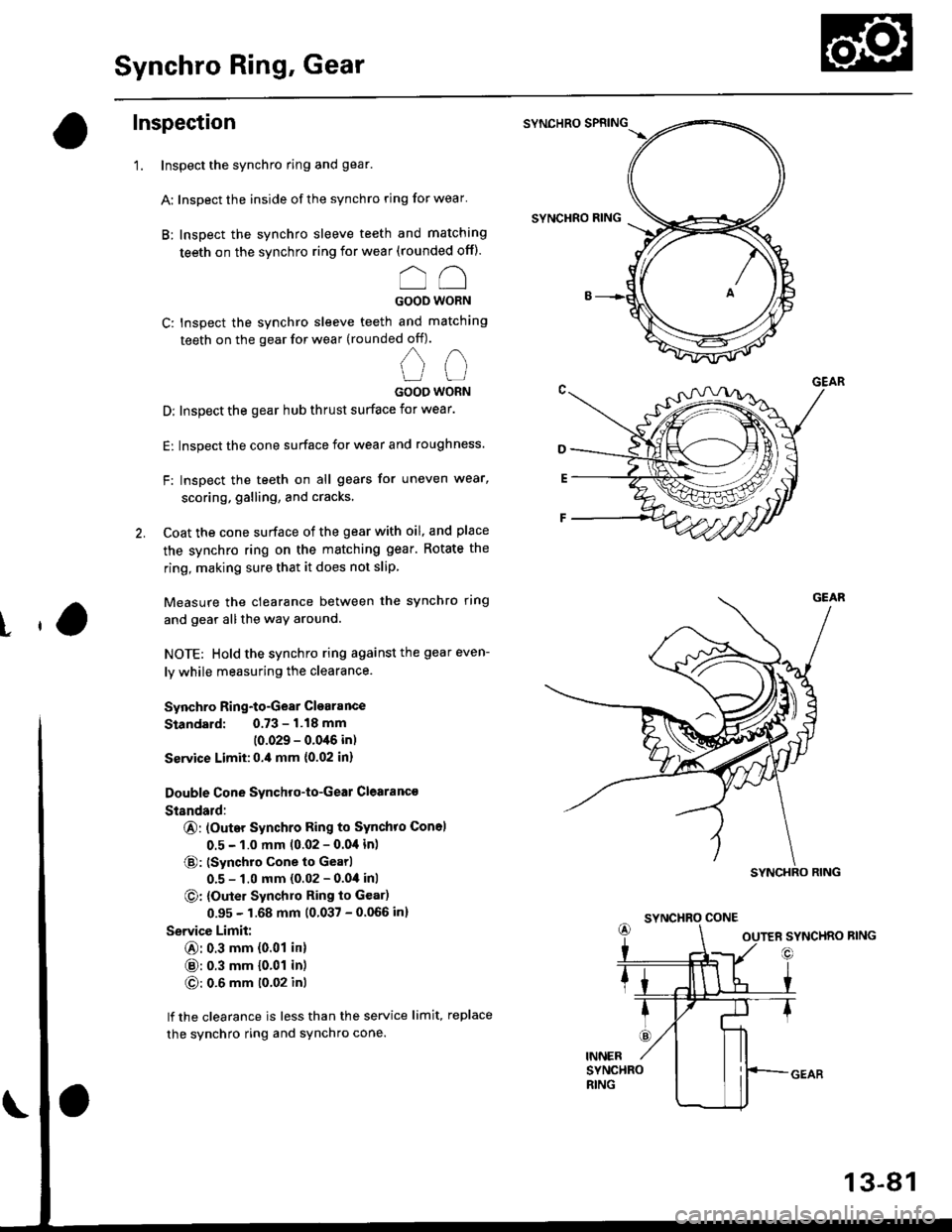

Synchro Ring, Gear

Inspection

'1. Inspect the synchro ring and gear.

A: Inspect the inside of the synchro ring for wear'

B: Inspect the synchro sleeve teeth and matching

teeth on the synchro ring for wear (rounded off).

oo

GOOD WORN

C: Inspect the synchro sleeve teeth and matching

teeth on the gear for wear (rounded off).

nn

UUGOOO WORN

D: Inspect the gear hub thrust surface for wear.

E: Inspect the cone surface for wear and roughness.

F: Inspect the teeth on all gears for uneven wear,

scoring, galling, and cracks'

2. Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear. Rotate the

ring, making sure that it does not slip

Measure the clearance between the synchro ring

and gear allthe way around.

NOTE: Hold the synchro ring against the gear even-

ly while measuring the clearance.

Synchro Ring-to-Gear Clearance

Standard: 0.73 - 1.18 mm

(0.029 - 0.0'16 in)

Ssrvice Limit:0.,0 mm {0.02 in}

Double Cone Synchro-to-Geal Clearanc€

Standald:

@: (Outer Synchro Ring to Synchro Con6l

0.5 - 1.0 mm 10.02 - 0.04 in)

@: (Synchro cone to Gearl

0.5 - 1.0 mm (0.02 - 0.04 inl

O: {Outer Synchlo Ring to Gear)

0.95 - 1.68 mm (0.037 - 0.066 in)

Service Limit:

@: 0.3 mm {0.01 in}

@: 0.3 mm {0.01 in)

O: 0.6 mm t0'02 inl

lf the clearance is less than the service limit, replace

the synchro ring and sYnchro cone.

SYNCHRO SPRING

SYNCHRO RING

t

SYNCHRO CONE

13-81

Page 668 of 2189

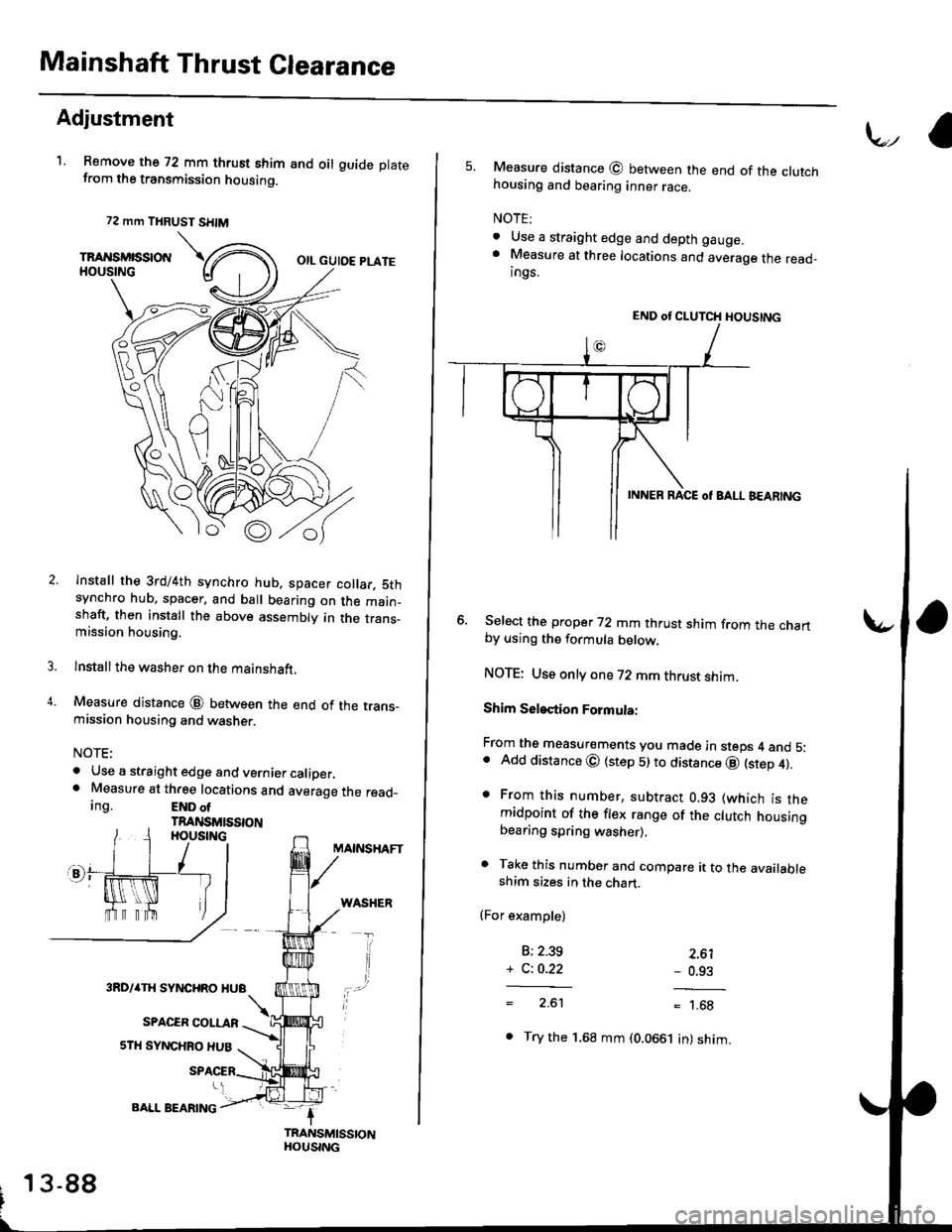

Mainshaft Thrust Clearance

Adjustment

1. Remove the 72 mm thrust shim and oil guide platefrom the transmission housing.

4.

TFANSMISSIONHOUSING

72 mm THRUST SH|M

TRAt{SMtSStONHOUSINGOIL GUIOE PLATE

lnstall the 3rd/4th synchro hub. spacer collar,5thsynchro hub. spacer, and ball bearing on the main_shaft, then install the above assembly in the trans_mission housing.

lnstall the washe[ on the mainshaft,

Measure distance @ between the end of the trans-mission housing and washer.

NOTE;

. Use a straight edge and vernier caliper.. Measure at three locations and average the read_ing.ENO otlnA sMtsstoNHOUSINGMAINSHAFT

3RD/irTH SYNCHRO HUB

SPACCR COLLAR

5TH SYNCHRO HUB

o

B

13-88

AALL BEARING

V.

5. Measure distance @ between the end of the clutchhousing and bearing inner race.

NOTE;

. Use a straight edge and depth gauge.. Measure at three locations and average the read-ings.

Select the prcpet 72 mm thrust shim from the chartby using the formula below.

NOTE: Us€ only one 72 mm thrust sntm.

Shim Selection Formula:

From the measurements you made in steps 4 and 5:. Add distance O lstep 5) to distance @ (step 4).

. From this number, subtract 0.93 (which is themidpoint of the flex range of the clutch housingbearing spring washer).

. Take this number and compare it to the availableshim sizes in the chart.

{For example)

B;2.39

+ C: 0.22- 0.93

2.61 = 1.68

Try the 1.68 mm (0.0661 in) shim.

INNER RACE ot EALL BEARING