Tire HONDA CIVIC 1999 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1267 of 2189

tlnstallation

'1.

3.

Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surface around the entire rear window opening

flange.

NOTE:

. Do not scrape down to the painted surface ol the

body; damaged paint will interfere with proper

bonding.

a Remove the rubber dams, spacers and fasteners

from the hatch.

. Mask off surrounding surfaces before applying

primer.

Clean the hatch bonding surface with a sponge

dampened in alcohol.

NOTE: After cleaning, keep oil, grease or water

from getting on the surface.

lf the old rear window is to be reinstalled, use a

putty knife to scrape off all traces of old adhesive,

then clean the rear window surface with alcohol

where new adhesive is to be applied.

NOTE; Make sure the bonding surface is kept free of

water, oil and grease.

CAUTION: Avoid setting the rear window on its

edges; the molding can be permanently deformed.

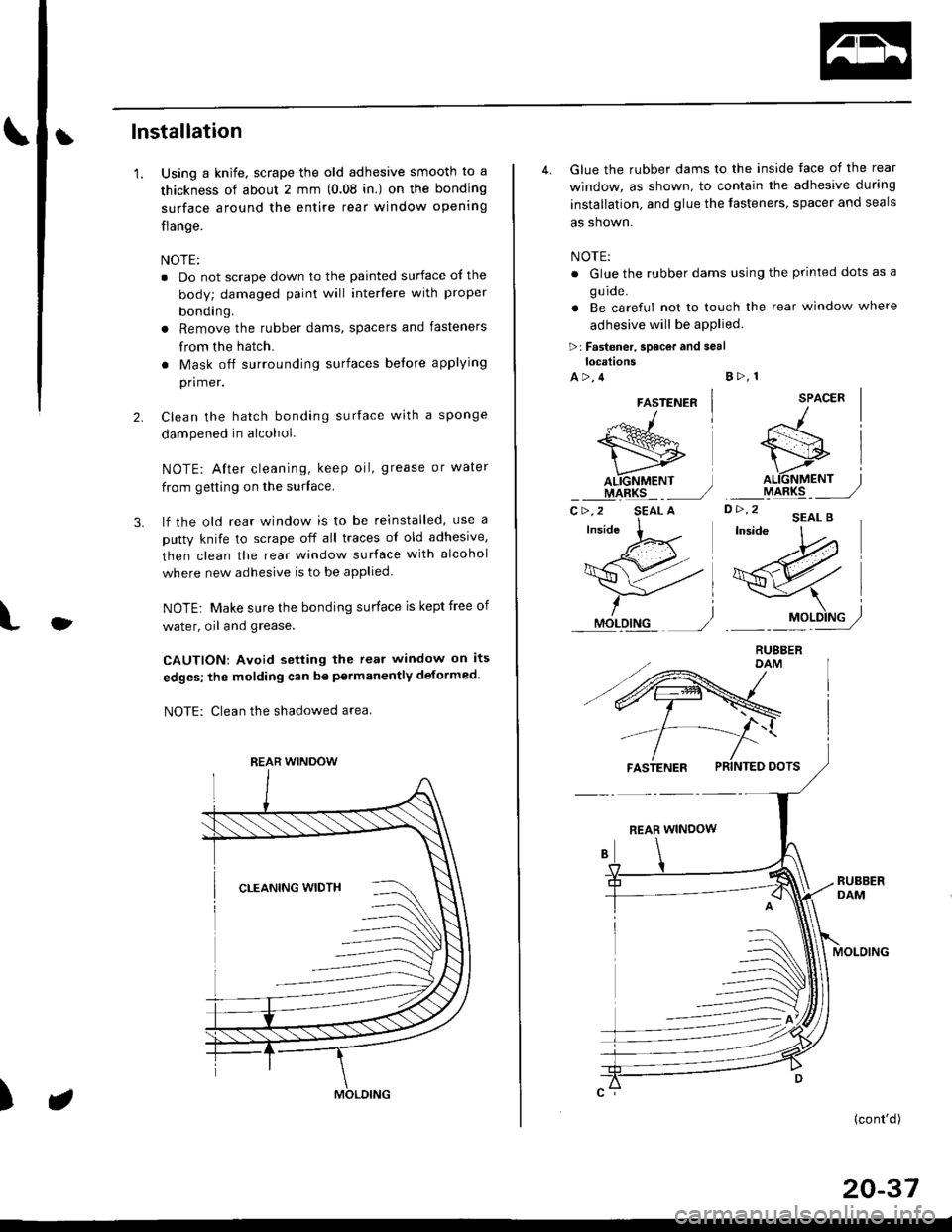

NOTE: Clean the shadowed area

2.

O

)

REAR WINDOW

4. Glue the rubber dams to the inside face of the rear

window, as shown, to contain the adhesive during

installation, and glue the fasteners, spacer and seals

as shown.

NOTE:

. Glue the rubber dams using the printed dots as a

g u ide.

. Be careful not to touch the rear window where

adhesive will be aPPlied

>r Fastener, spacor and seallocations

A>,4B>, 1

SPACER

D> '2 'EAL B'W

/l

si

o.\6fif,", j

ryt48rq _ _ ,,/

-\l

19Pry/

FASTENER PRINTED DOTS

REAR WINDOW

MOLOING

(cont'd)

20-37

FASTENER

"-*^1

wAL.IGNMENT ]IIARKS _ _,/C>,2 SEAL A

Page 1270 of 2189

Rear WindowOuarter Glass

Installation {cont'd)

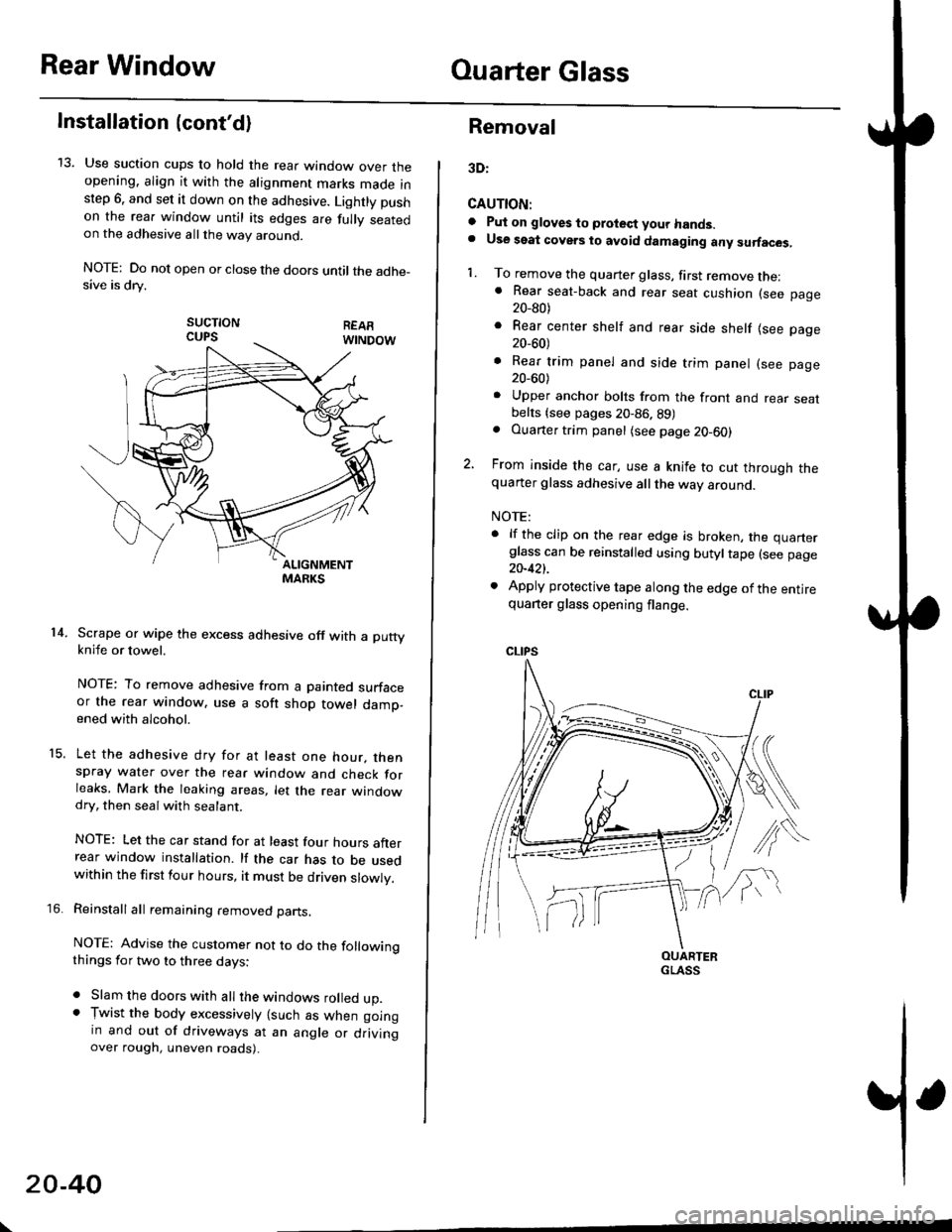

13. Use suction cups to hold the rear window over theopening. align it with the alignment marks made inslep 6. and set it down on the adhesive. Lightly pushon the rea. window until its edges are fully seatedon the adhesive allthe way around.

NOTE: Do not open or close the doors until the adhe_sive is drv.

sucTtoNCUPS

Scrape or wipe the excess adhesive off with a puttyknife or towel.

NOTE: To remove adhesive from a painted surfaceor the rear window. use a soft shop towel damp-ened with alcohol.

Let the adhesive dry for at least one hour. thenspray water over the rear window and check forleaks, Mark the leaking areas, let the rear windowdry, then seal with sealant.

NOTE: Let the car stand for at least four hours afterrear window installation. lf the car has to be usedwithin the first four hours, it must be driven slowly.

Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the followingthings for two to three days:

. Slam the doors with all the windows rolled up.. Tr,vist the body excessively lsuch as when goingin and out of driveways at an angle or drivingover rough, uneven roads).

14.

15.

\

20-40

Removal

3D:

CAUTION:

a Pul on gloves to protect your hands.. Use seat covers to avoid damaging any surfaces,

1. To remove the quarter glass, first remove the:. Rear seat-back and rear seat cushion (see page20_80)

. Rear center shelf and rear side shelf lsee page20_60)

. Rear trim panel and side trim panel (see page20_60)

. Upper anchor bolts from the front and rear seatbelts {see pages 20-86. 89). Ouarter trim panel (see page20-60)

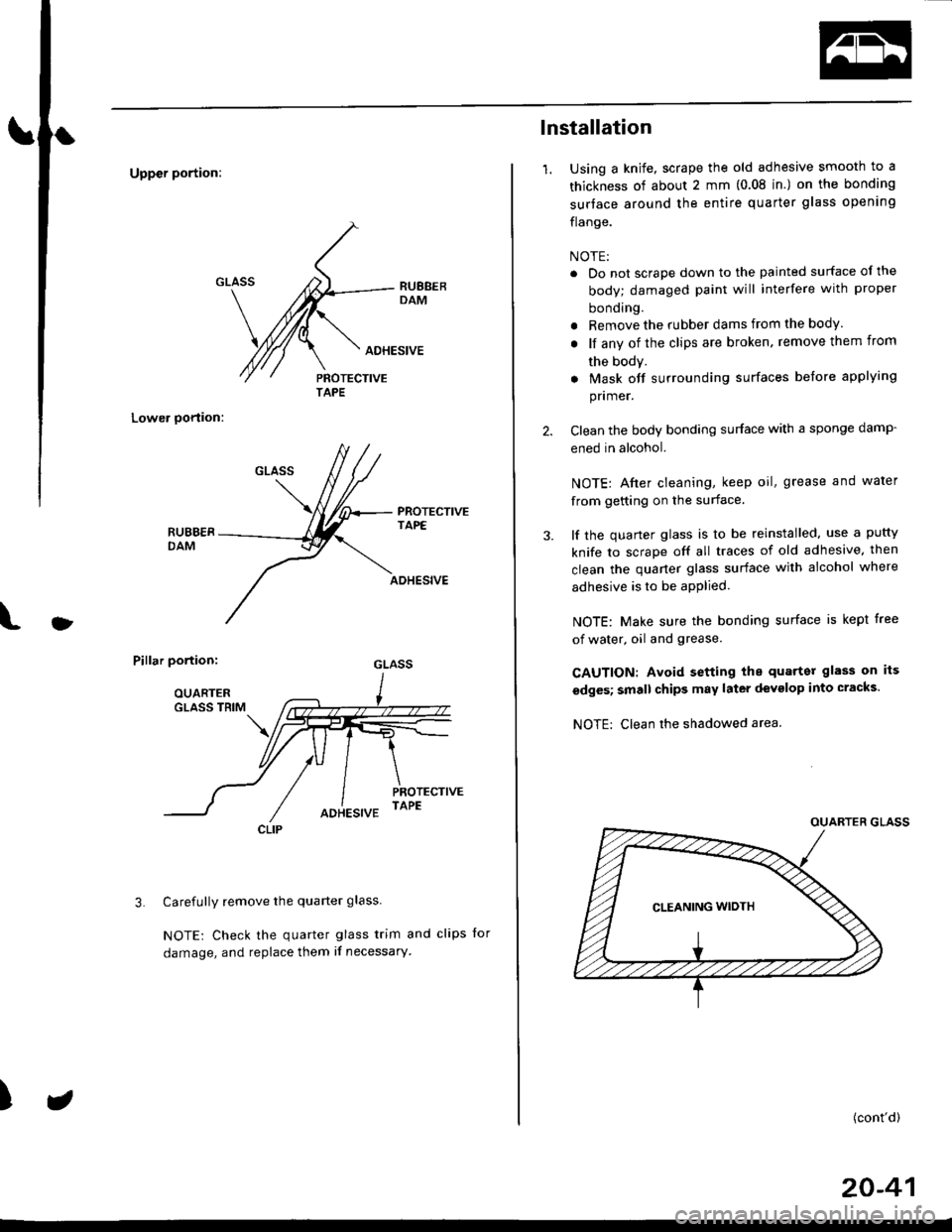

2, From inside the car, use a knife to cut through thequarter glass adhesive all the way around.

NOTE:

. lf the clip on the rear edge is broken, the quarterglass can be reinstalled using butyltape (see page20-421.

. Apply protective tape along the edge of the entirequarter glass opening flange.

OUARTERGLASS

Page 1271 of 2189

Uppcr portion:

Lower oortion:

PROTECTIVETAPE

l

ADHESIVE

Pillar portion:

Carefully remove the quarter glass

NOTE: Check the quarter glass trim and clips for

damage, and replace them if necessary'

3.

)

AOHESIVE

TAPE

CLIP

lnstallation

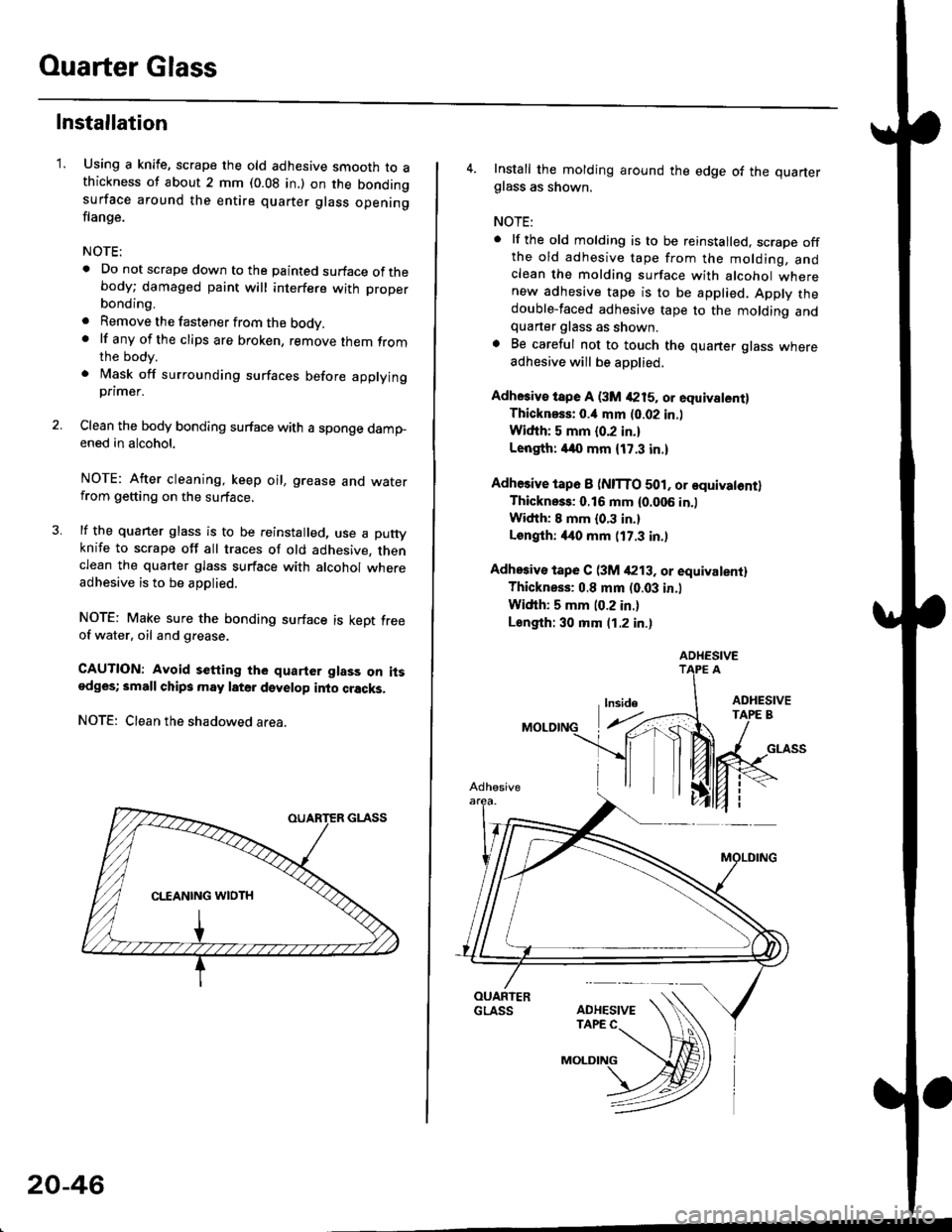

1.Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surtace around the entire quarter glass opening

flange.

NOTE:

. Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding.

r Remove the rubber dams from the body.

. lf any of the clips are broken, remove them from

the body.

. Mask off surrounding surfaces before applying

pnmer.

Clean the body bonding surface with a sponge damp-

ened in alcohol.

NOTE: Afier cleaning, keep oil, grease and water

from getting on the surface.

lf the quarter glass is to be reinstalled, use a putty

knife to scrape off all traces of old adhesive. then

clean the quaner glass surface with alcohol where

adhesive is to be apPlied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting the quarter glass on its

edges; small chips may later devglop into cracks.

NOTE: Clean rhe shadowed area.

(cont'd)

20-41

Page 1275 of 2189

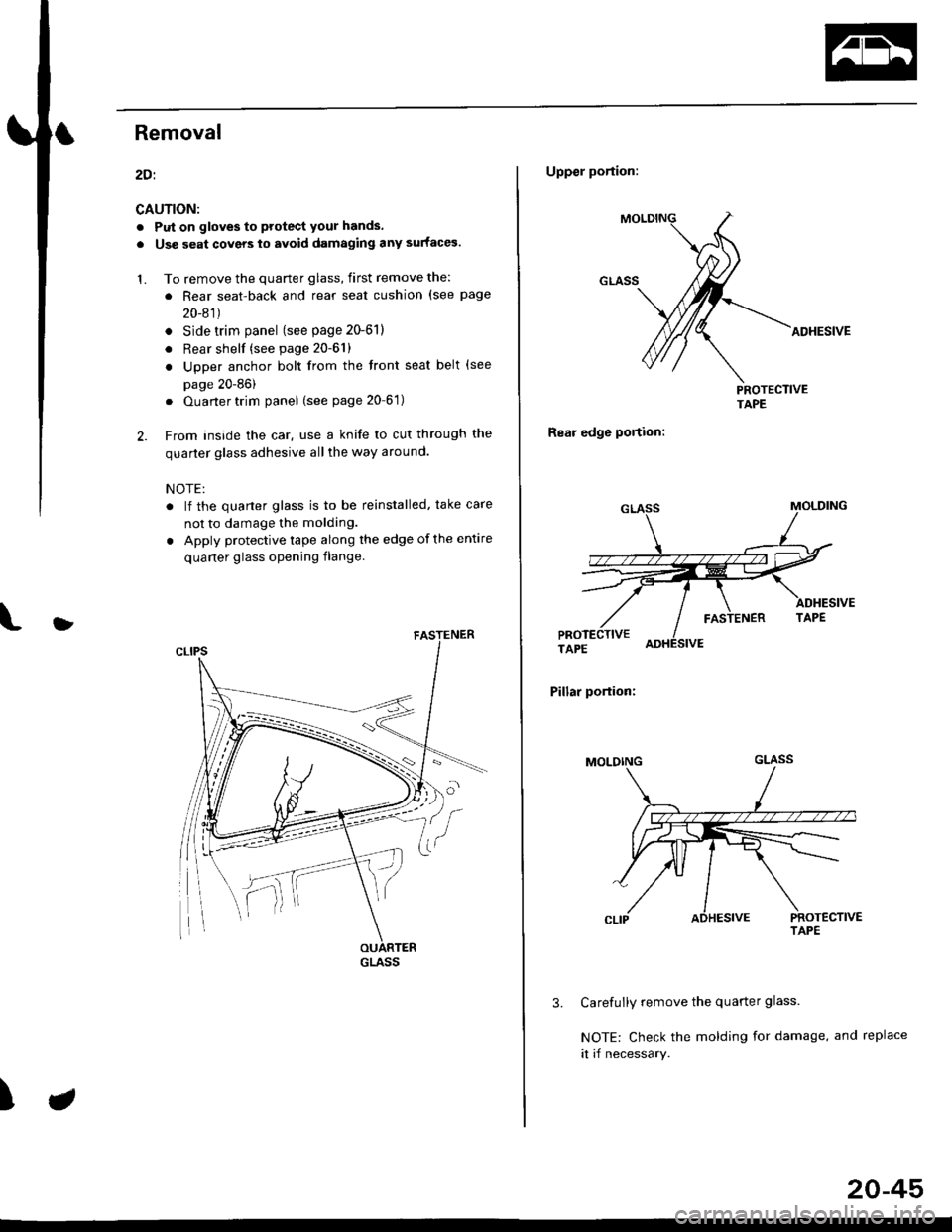

Removal

2Oi

CAUTION:

. Put on gloves to protect your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the quarter glass, first remove the:

. Rear seat-back and rear seat cushion (see page

20_81)

o Slde trim panel (see page 20-611

. Rear shelf (see page 20-61)

o Upper anchor bolt from the front seat belt (see

page 20-86)

. Ouarter trim panel (see page 20-6'l)

2. From inside the car. use a knife to cut through the

quarter glass adhesive allthe way around.

NOTE:

. lf the quarter glass is to be reinstalled, take care

not to damage the molding.

. Apply protective tape along the edge ofthe entire

quaner glass oPening flange

D

I

GLASS

Upper portion:

ADHESIVE

PROTECTIVETAPE

Rear edge portion:

Pillar portion:

Carefully remove the quarter glass.

NOTE: Check the molding for damage, and replace

it if necessary.

3.

TAPE

20-45

Page 1276 of 2189

Ouarter Glass

1.

Installation

Using a knife, scrape the old adhesive smooth to athickness of about 2 mm (0.08 in.) on the bondingsurface around the entire quarter glass openingflange.

NOTE:

. Do not scrape down to the painted surface of thebody; damaged paint will interfere with proper

a

a

bonding.

Remove the fastener from the body.lf any of the clips are broken, remove lhem fromthe body.

Mask off surrounding surfaces before applyingpnmer.

Clean the body bonding surface with a sponge dampened in alcohol.

NOTE: After cleaning, keep oil, grease and waterfrom getting on the surface.

lf the quarter glass is to be reinstalled, use a puttyknife to scrape off all traces of old adhesive. thenclean the quarter glass surface with alcohol whereadhesive is to be applied.

NOTE: Make sure the bonding surface is kept freeof water. oil and grease.

CAUTION: Avoid setting the quarter glass on itsodges; small chips may later develop into cracks,

NOTE: Clean the shadowed area.

20-46

4. Install the molding around the edge of the quarterglass as shown.

NOTE:

. lf the old molding is to be reinstalled, scrape offthe old adhesive tape from the molding, andclean the molding surface with alcohol wherenew adhesive tape is to be applied. Apply thedouble-faced adhesive tape to the molding andquarter glass as shown.. Be careful not to touch the quarter glass whereadhesive will be aoDlied.

Adhesiv€ tspe A (3M 4215, or equivalent)Thicknsss: o.il mm (0.02 in.l

Widih: 5 mm {0.2 in.}

Length: /140 mm {17.3 in.)

Adhesive tap6 I (NITTO 501, or equivatontlThickness: 0.16 mm {0.006 in.)

Width: I mm {0.3 in.}

Longlh: 4it0 mm (17.3 in.)

Adhosiv€ tape C (3M /P13. or equivalentl

Thickness: 0.8 mm (0.03 in.l

Width: 5 mm (0.2 in.)

Length: 30 mm (1.2 in.)

ADHESIVE

Page 1338 of 2189

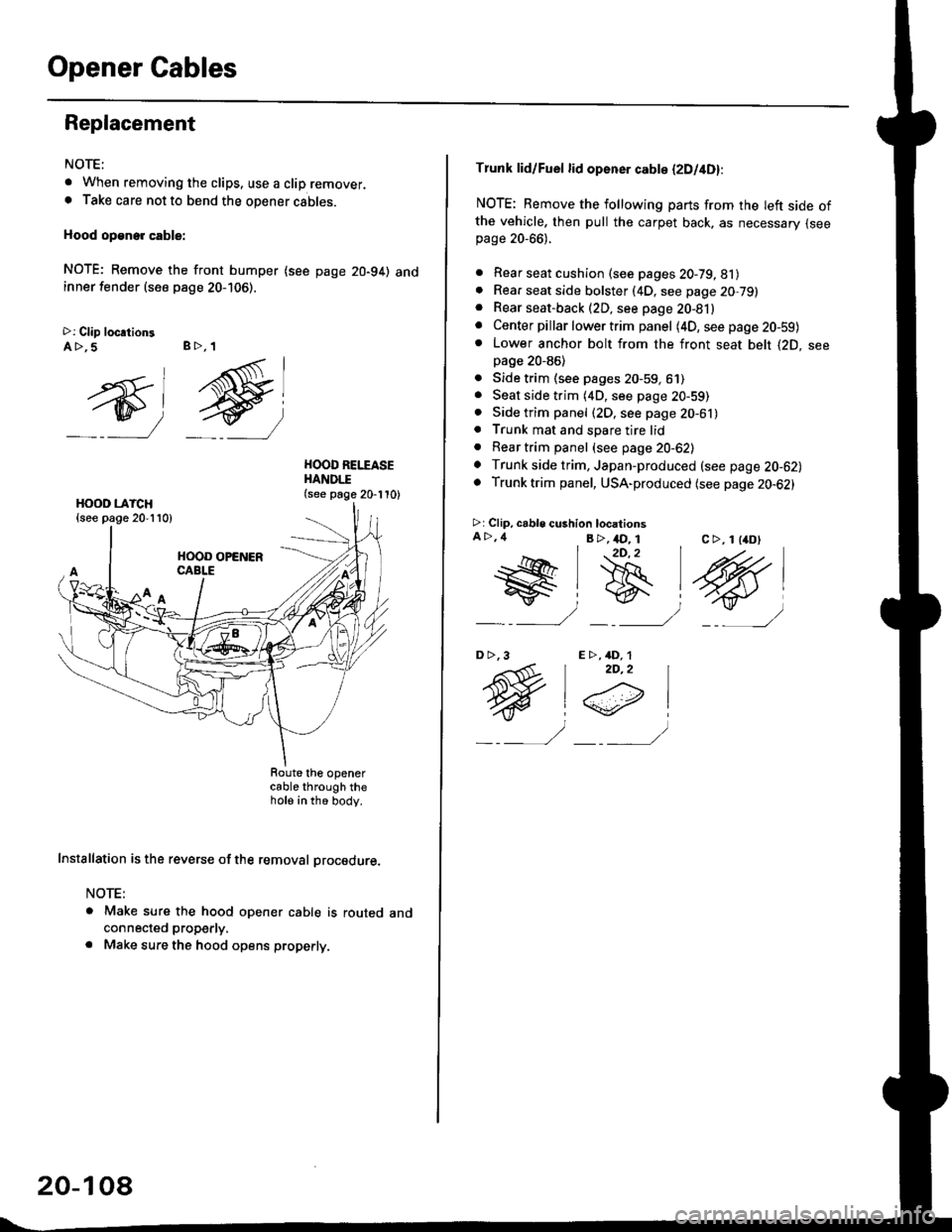

Opener Cables

Replacement

NOTE:

t When removing the clips. use a clip remover.. Take care not to bend the opener cables.

Hood op€ne. cable:

NOTE; Remove the front bumper (see page 20-94) andinner fender (see page 20-106).

>: Clip loc.tionsA >,5 B>, 1

ry)

g

HOOD REI.TASEHANDI.I(see page 20-110)

cable through thehote in th6 body.

Installation is the reverse of the removal procedure.

NOTE:

a Make sure the hood opener cable is routed andconnected properly.

. Make sure the hood opens properly.

20-10a

Tlunk lid/Fuel lid opener cabte (2Dl4D):

NOTE: Remove the following parts from rhe Ieft side ofthe vehicle, then pull the carpet back, as necessary {seepage 20-66).

. Rear seat cushion (see pages 20-79, 81). Rear seat side bolster (4D, see page 20,79). Rear seat-back (2D, see page 20-81). Center pillar lower trim panel (4D, seepage20-59)o Lower anchor bolt from the front seat belt {2D. seepage 20-86)

. Side trim (see pages 20-59, 61). Seat side trim (4D, see page 20-59). Side trim panel (2D, see page 20-61). Trunk mat and spare tire lid. Reartrim panel (see page 20-62). Trunk side trim, Japan-produced (see page 20-62). Trunk trim panel, USA-produced (see page 20-62)

>r Clip, cable cushion locationsA >,4 B >,4D_ 1c >, 1 l4D)2D,2

t@#lB

_ : _/ _-___)

E >,4D, 12D,2

@i

_ _,, -/

D>,3

Page 1340 of 2189

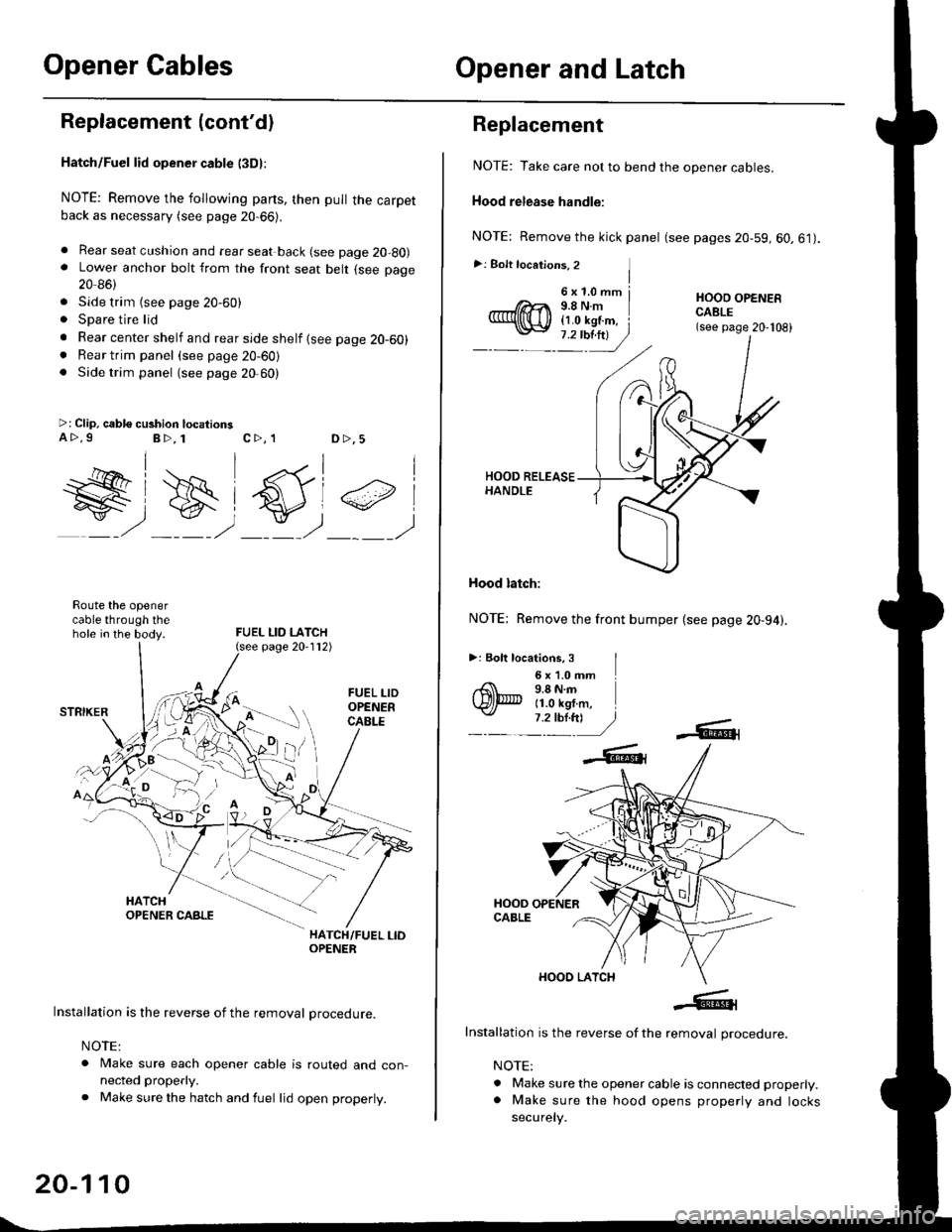

Opener CablesOpener and Latch

Replacement (cont'dl

Hatch/Fuel lid opener cable l3Dl:

NOTE: Remove the following parts, then pull the carpetback as necessary (see page 20-66).

. Rear seat cushion and rear seat back (see page 20-80). Lower anchor bolt from the front seat belt (see page

20 86)

. Side trim {see page 20-60). Spare tire lid

. Rear center shelf and rear side shelf {see page 20-60). Rear trim panel (see page 20-60). Side trim panel (see page 20,60)

>: Clip, cable cushion locationsa>.9B>, 1c>, 1D >,5

W#)

FUEL LID LATCH

#,

Route the openercable through thehole in the body.

HATCH/FUEL LIOOPENER

Installation is the reverse of the removal procedure.

NOTE:

. Make sure each opener cable is routed and con-nected properly.

. Make sure the hatch and fuel lid open properly.

page 20-112)

20-110

6x1.0mm j9.8Nm{1.0 kgf.m, i

Replacement

NOTE: Take care not to bend the opener cables.

Hood release handle:

NOTE: Remove the kick panel (see pages 20-59, 60.61).

>: Bolt locations, 2 ]I

HOOO OPENERCABLE(see page 20-108)

Hood latch:

NOTE: Remove the front bumper (see page 20-94).

>: Eolt locations, 3 I6 x '1.0 mm9.8 N.m11.0 kgf.m,

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the opener cable is connected properly.. Make sure the hood opens properly and locks

securely.

Page 1346 of 2189

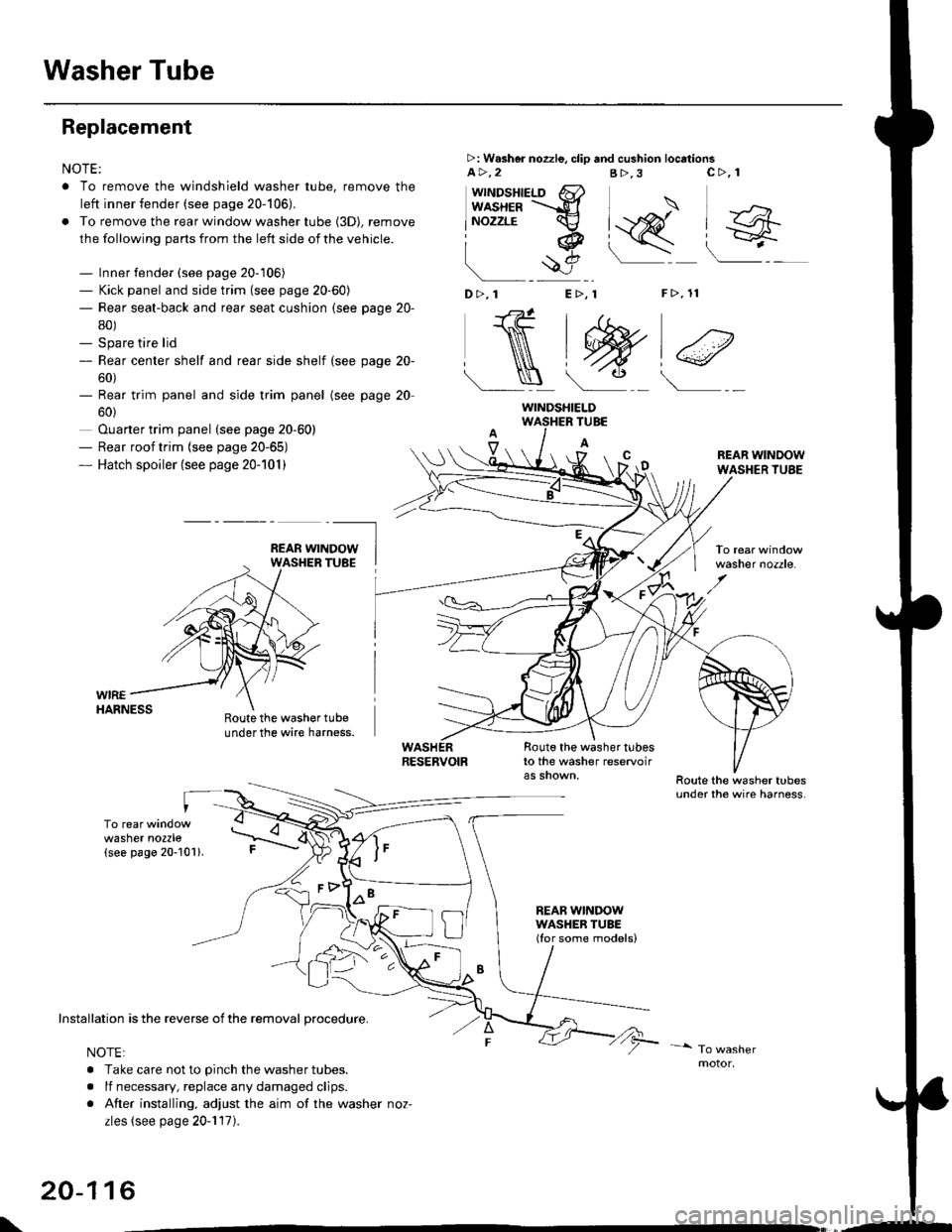

Washer Tube

Replacement

NOTE:

. To remove the windshield washer tube, remove the

left inner fender (see page 20-106),

. To remove the rear window washer tube {3D), remove

the following parts from the left side of the vehicle.

- Inner fender (see page 20-106)- Kick panel and side trim (see page 20-60)- Rear seat-back and rear seat cushion (see page 20-

80)- Spare tire lid- Rear center shelf and rear side shelf (see page 20-

60)- Rear trim panel and side trim panel

60)

Ouarter trim panel (see page 20-60)- Rear roof trim {see page 20-65)- Hatch spoiler (see page 20-101)

(see page 20

WIREHARNESS

>: W.sher nozzle, clip and cushion locationsa>,2B>,3

"J>)

[q@"

F>, 11

c>, 1

wttrtosnteLo 6}usxea =-d

lNozzrE cv

iq

!$e

D>,1 E>, 1

NtW)€

Roote the washer tubeunder the wire harness.

TUBE

A

Route the washer tubesto the washer reservoir

REAB WINDOWWASHER TUBE(Ior some models)

REAR WINDOWWASHER TUBE

washer nozzle.

washer nozzle(see page 20-101).

oo\

Installation is the reverse of the removal procedure.

NOTE:

. Take care not to pinch the washer tubes.

. lf necessary, replace any damaged clips.

. After installing, adjust the aim of the washer noz-

zles (see page 20-117).

20-116

WINDSHIELD

\,--

Page 1359 of 2189

Washer Tube

Replacement (cont'dl

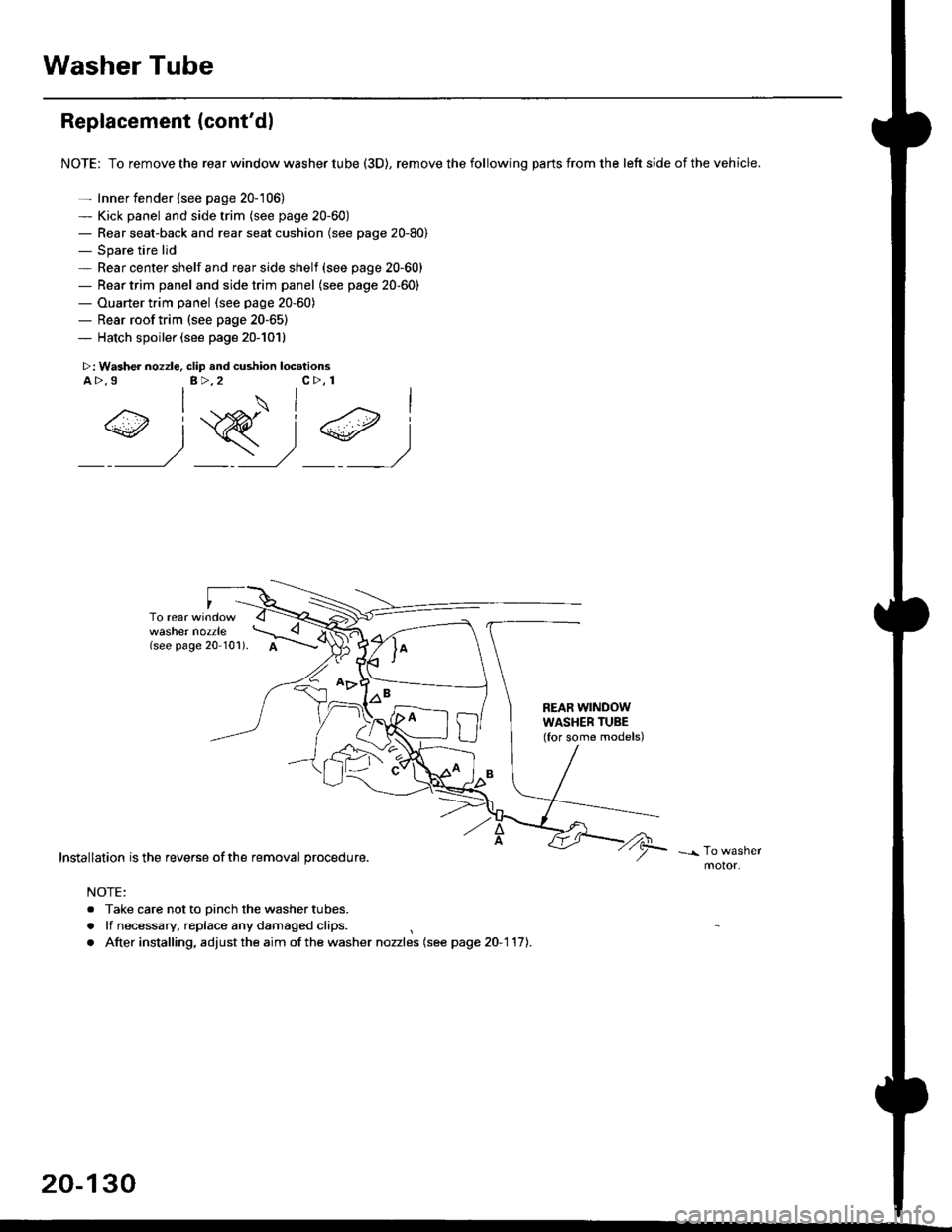

NOTE: To remove the rear window washer tube (3D), remove the following parts from the left side of the vehicle.

- Inner fender (see page 20-'106)- Kick panel and side trim (see page 20-60)- Rear seat-back and rear seat cushion (see page 20-80)- Spare tire lid- Rear center shelf and rear side shelf (see page 20-60)- Rear trim panel and side trim panel (see page 20-60)- Ouarter trim panel (see page 20-60)- Rear roof trim (see page 20-65)- Hatch spoiler (see page 20-1011

>: Washer nozzle, clip and cushion locationsA >.9 B>,2 C>, 1

I sl -..._, 1

aj\

(see page 20 101).

REAR WINDOWWASHER TUBE(for some models)

Installation is the reverse ofthe removal procedure.

NOTE:

. Take care not to pinch the washer tubes.

. lf necessary, replace any damaged clips.

. After installing, adjustthe aim ofthe washer nozzles (see page2O-1111.

motor.

20-130

Page 1446 of 2189

A/C Service Tips and Precautions

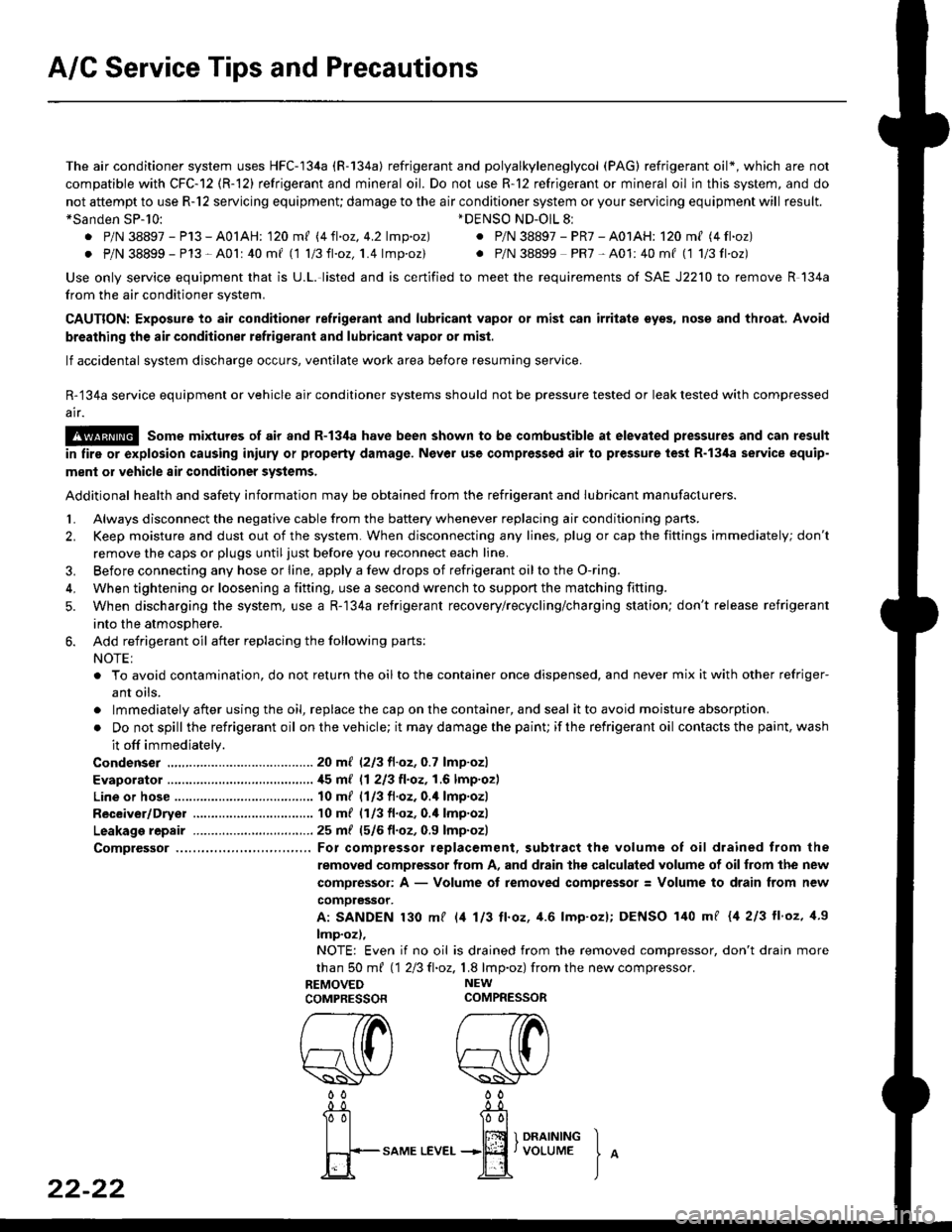

The air conditioner system uses HFC-134a (R-134a) refrigerant and polyalkyleneglycol (PAG) refrigerant oil*, which are not

compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not use R-12 refrigerant or mineral oil in this system, and do

not attempt to use R-12 servicing equipmenU damage to the air conditioner system or your servicing equipment will result.*Sanden SP-10:

. P/N 38897 - P13 - A0lAH: 120 ml 14ll.oz, 4.2lmp.oz)

. P/N 38899 - P13 - A0l | 40 mf 11 1/3ll.oz,1.4 lmp'oz)

Use only service equipment that is U.L. listed and is certified to meet the requirements of SAE J2210 to remove R 134a

from the air conditioner system.

CAUTION: Exposure to air conditioner ref;ige;ant and lubricant vapol or mist can irritate syes, nose and throat, Avoid

breathing the air conditioner refrigerant and lubricant vapor or misl.

lf accidental system discharge occurs, ventilate work area before resuming service.

R-'134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressed

ai.

!@@ some mixtures of air and R-t3ila have been shown to be combustible at elevated pressures and can result

in tire or explosion causing iniury or property damage. Never use compressed air lo pressure tesl R-134a service equip-

ment or vehicle 8ir conditioner systoms.

Additional health and safety information may be obtained from the refrigerant and Iubricant manufacturers.

L Always disconnect the negative cable from the battery whenever replacing air conditioning pans.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line, apply a few drops of refrigerant oilto the O-ring.

4, When tightening o. loosening a fitting, use a second wrench to support the matching fitting.

5. When discharging the system, use a R-134a refrigerant recovery/recycling/charging station; don't release refrigerant

into the atmosphere,

6. Add refrigerant oil after replacing the following parts:

NOTE:

. To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriger-

ant oils.

. lmmediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

. Do not spill the refrigerant oil on the vehicle; it may damage the paint; if the refrigerant oil contacts the paint, wash

it off immediately.

Condenser .......2o ml (2/3 fl.oz, 0.7 lmp.ozl

Evaporator .,.,.,. i[5 m{ 11 213 tl.oz,1,6lmp.ozl

Line or hose ..... 10 mf (1/3 fl.oz, 0.4 lmp.ozl

Receiver/Dryer 10 m{ (1/3 fl.oz,0.'l lmp.ozl

Leakage repair 25 m{ (5/6 fl.oz, 0.9 lmp.ozl

Comptessor ... For compressor replacement. subtract the volume of oil drained trom the

removed compressor from A, and drain the calculated volume of oilfrom the new

compressor: A - Volume of removed compressor: Volume to drain from new

comoressor.

A: SANDEN 130 mf l/t 113 ll.oz, 4.6 lmp'ozl; DENSO 140 mf {4 213 ll'oz, 1.9

lmp.oz),

NOTE: Even if no oil is drained from the removed compressor, don't drain more

than S0 m{ 112Ell.oz,1.8 lmp.oz) fromthe new compressor.

REMOVED NEW

COMPRESSORCOMPRESSOR

*DENSO ND-OlL 8l

. P/N 38897 - PR7 - A01AH: 120 ml (4 fl.oz)

. P/N 38899 PR7-A01:40mf (1 1/3fl'oz)

rereW W0000

22-22

-0_!- -0_a

Tol l00l

| | lffi 1 onrrrutrc I

fi+-sAME

LEvEr...+jEf,voLUME

J

^