exhaust HONDA CIVIC 1999 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 168 of 2189

Valve Clearance

I

I

I

Adjustment {cont'd)

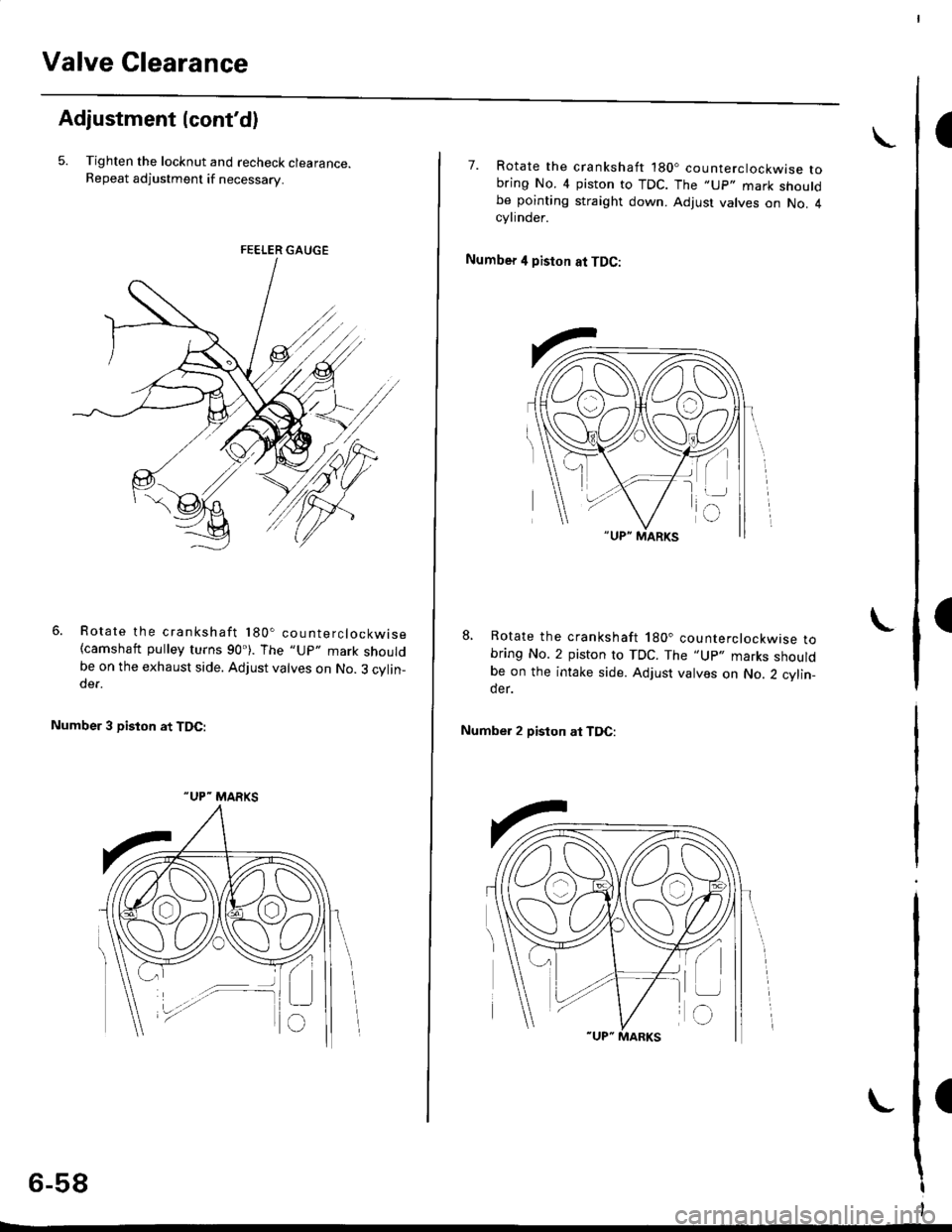

5. Tighten the locknut and recheck clearance.Repeat adjustment if necessary.

Rotate the crankshaft 180. counterclockwise(camshaft pulley turns 90'). The "Up" mark shouldbe on the exhaust side. Adjust valves on No. 3 cylin-der.

Number 3 piston at TDC:

FE€LER GAUGE

"UP- MARKS

6-58

7. Rotate the crankshaft '180. counterclockwise tobring No. 4 piston to TDC. The ,,Up,. mark shouldbe pointing straight down. Adjust valves on No. 4cylinder.

Number 4 piston at TDC:

8, Rotate the crankshaft 180. counterclockwise tobring No. 2 piston to TDC. The "Up., marks shouldbe on the intake side. Adjust valves on No. 2 cylin_der.

Number 2 piston at TDC:

L

Page 173 of 2189

7.

8.

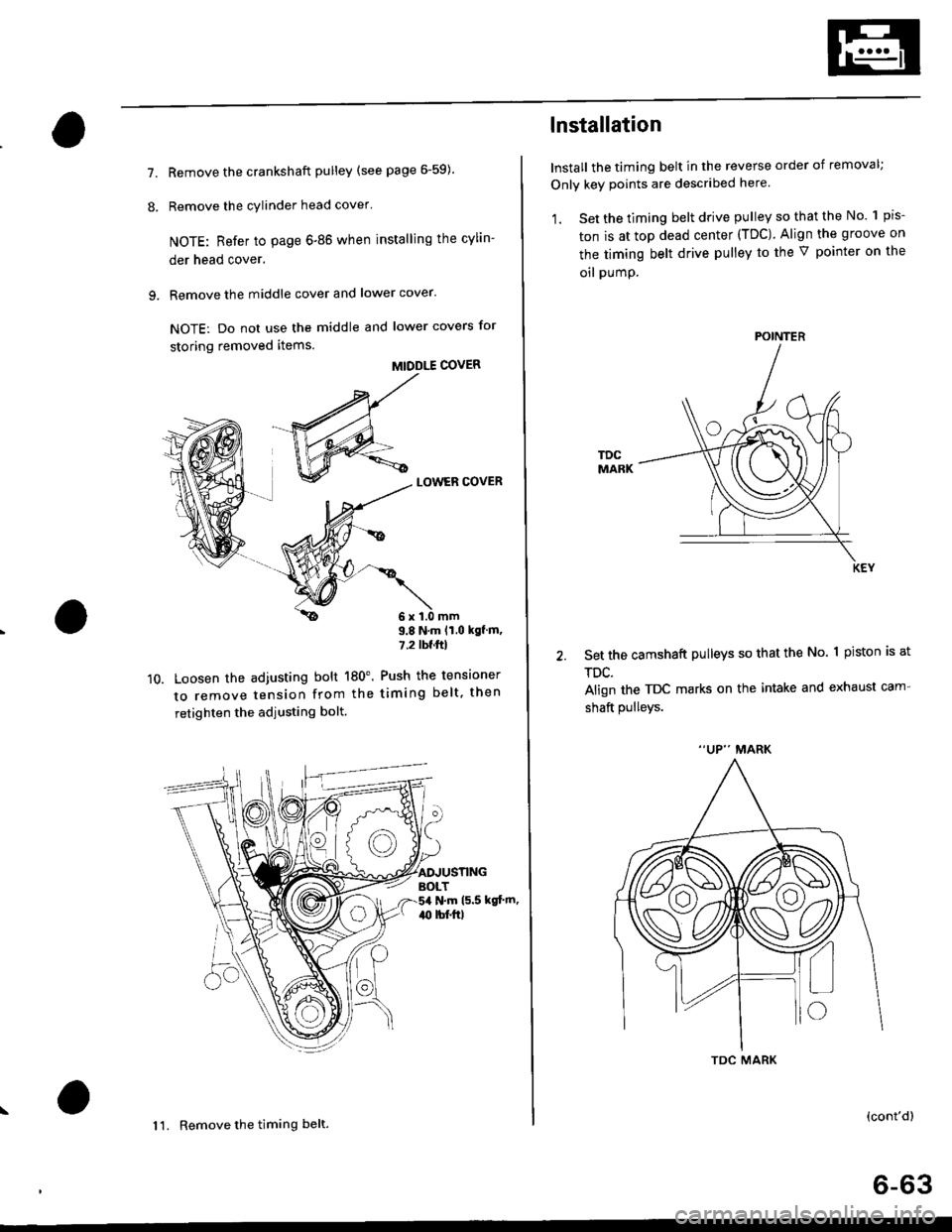

Remove the crankshaft pulley (see page 6-59).

Remove the cylinder head cover'

NOTE: Refer to page 6-86 when installing the cylin-

der head cover.

Remove the middle cover and lower cover.

NOTE: Do not use the middle and lower covers for

storing removed items.

MIDDLE COVER

LOWER COVER

9.

10.Loosen the adjusting bolt 180'.

to remove tension from the

retighten the adjusting bolt.

9.8 N.m lt.o kgf m,

7.2lw'ftl

Push the tensioner

timing belt, then

N.m (5.5 kgt'm,

1 1. Remove the timing belt.

TDC

lnstallation

Install the timing belt in the reverse order of removal;

Only key points are described here.

1. Set the timing belt drive pulley so that the No. 1 pis'

ton is at top dead center (TDC). Align the groove on

the timing belt drive pulley to the V pointer on the

oil pumP.

set the camshaft pulleys so that the No. 1 piston is at

TDC.

Align the TDC marks on the intake and exhaust cam-

shaft pulleys.

MARK

(cont'd)

6-63

POINTER

Page 174 of 2189

Timing Belt

lnstallation (cont'dl

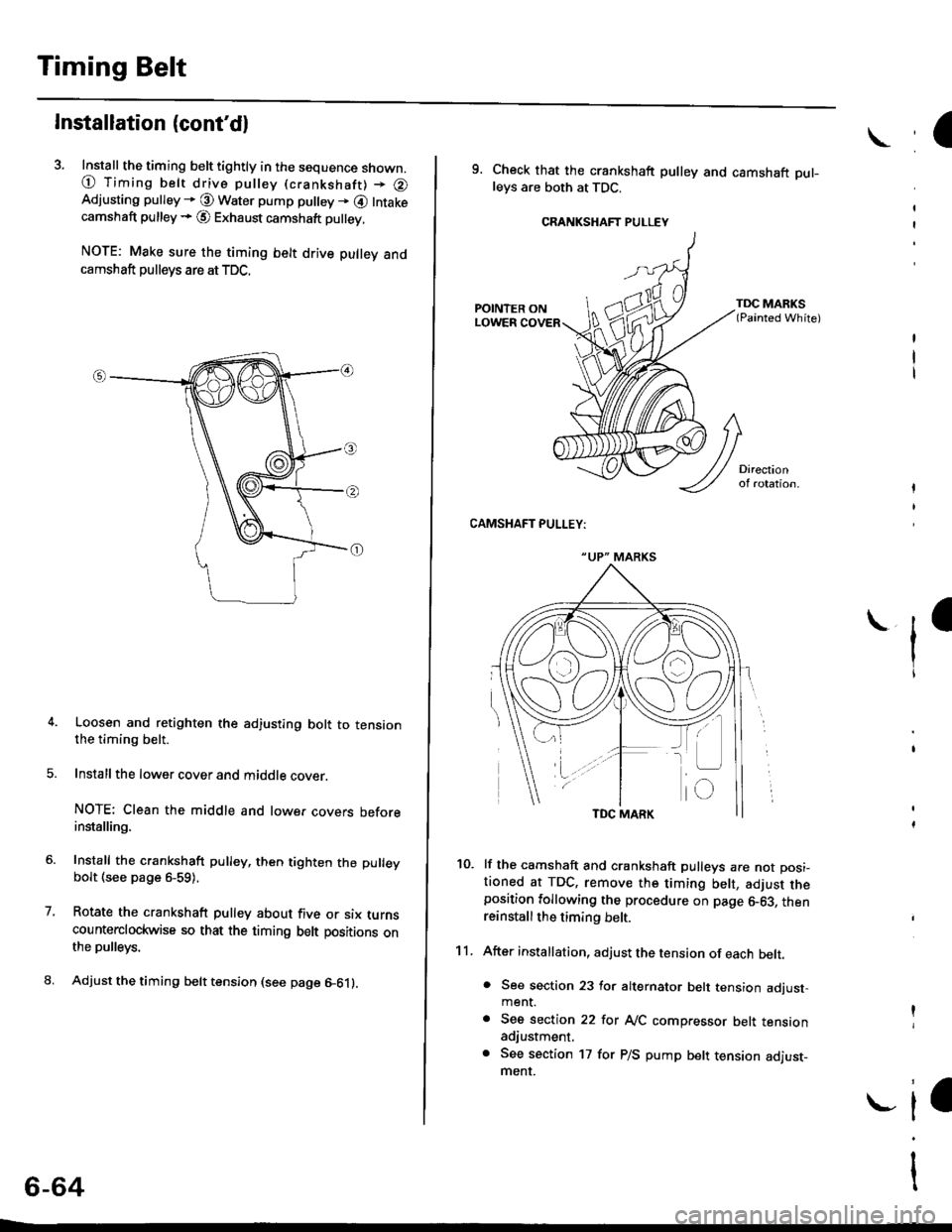

3. Install the timing belt tightly in the sequence shown.

@ Timing belt drive pulley (crankshaft) + @Adjusting pulley * @ Water pump pu ey + @ Intakecamshaft pulley + @ Exhaust camshaft pulley,

NOTE: Make sure the timing belt drive pulley andcamshaft pullevs are at TDC,

Loosen and retighten the adjusting bolt to tensionthe timing belt.

Install the lower cover and middle cover.

NOTE: Clean the middle and lower covers beforeinstalling.

Install the crankshaft pulley, then tighten the pulleybolt (see page 459).

Rotate the crankshaft pulley about five or six turnscounterclockwise so that the timing belt positions onthe pulleys.

Adjust the timing belt tension (see page A611.

7.

6-64

a

9. Check that the crankshaft pulley and camshaft pul-leys are both at TDC.

CRANKSHAFT PULLEY

CAMSHAFT PULLEY:

lf the camshaft and crankshaft pulleys are not posi-tioned at TDC, remove the timing belt, adjust theposition following the procedure on page &63, thenreinstall the timing belt.

After installation, adjust the tension of each belt.

. See section 23 for alternator belt tension adjust-ment.

. See section 22lor NC compressor belt tensionadiustment,

. See section 17 for P/S pump belt tension adjust-ment.

'l

10.

11.

I

"UP" MARKS

Page 175 of 2189

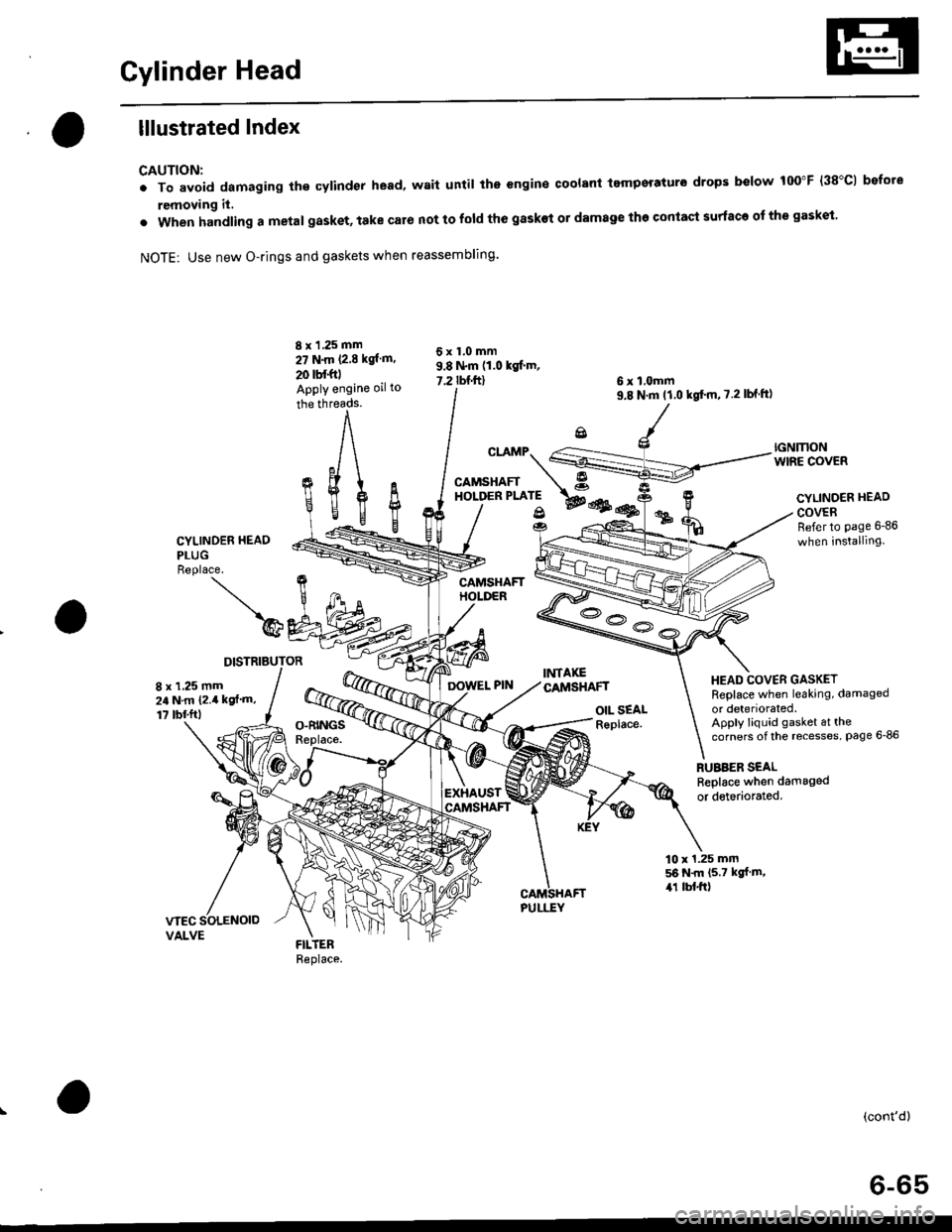

Cylinder Head

lllustrated Index

CAUTION:

. To avoid damaging the cylinder head, wait until the engine coolant tempsraturo drops below 100"F (38"C1 bofote

removing it,

. when handling a metal gasket, take caro not to fold the gaskot or damage the contact surface of the gasket.

NOTE: Use new O-rings and gaskets when reassembling.

CYLINDER HEAO

PLUGReplace.

)@

DISTRIBUTOR

8 x 1 ,25 mm

27 N.m P.E kgl m.

20 tbf.foApply engine oil to

the threads.

cr.rMp.S

CAMSHAFT A"o''*t*'; wes@

OIL SEALReplace.

6 x l,omm9.8 N'm tl.0 kgt'm,7.2lbf ft)

RUBBER SEALReplace when damaged

or detedorated.

6x1.0mm9.8 N.m (1.0 kgf'm,

7.2 rbnftl

fi%

IGNMONWIRE COVER

CYLINOER HEAD

COVERRefer to page 6-86

when installing

HEAD COVER GASKETReplace when leaking, damaged

or deteriorated.Apply liquid gasket at thecorners of the recesses, Page 6-86

8 x 1,25 mm24 N.m {2.4 kgf'm,

1? tbf.ftl

EXHAUST

10 x 1.25 mm56 N.m (5.7 kgf m,,r1 lbl.ft)

(cont'd)

6-65

Page 176 of 2189

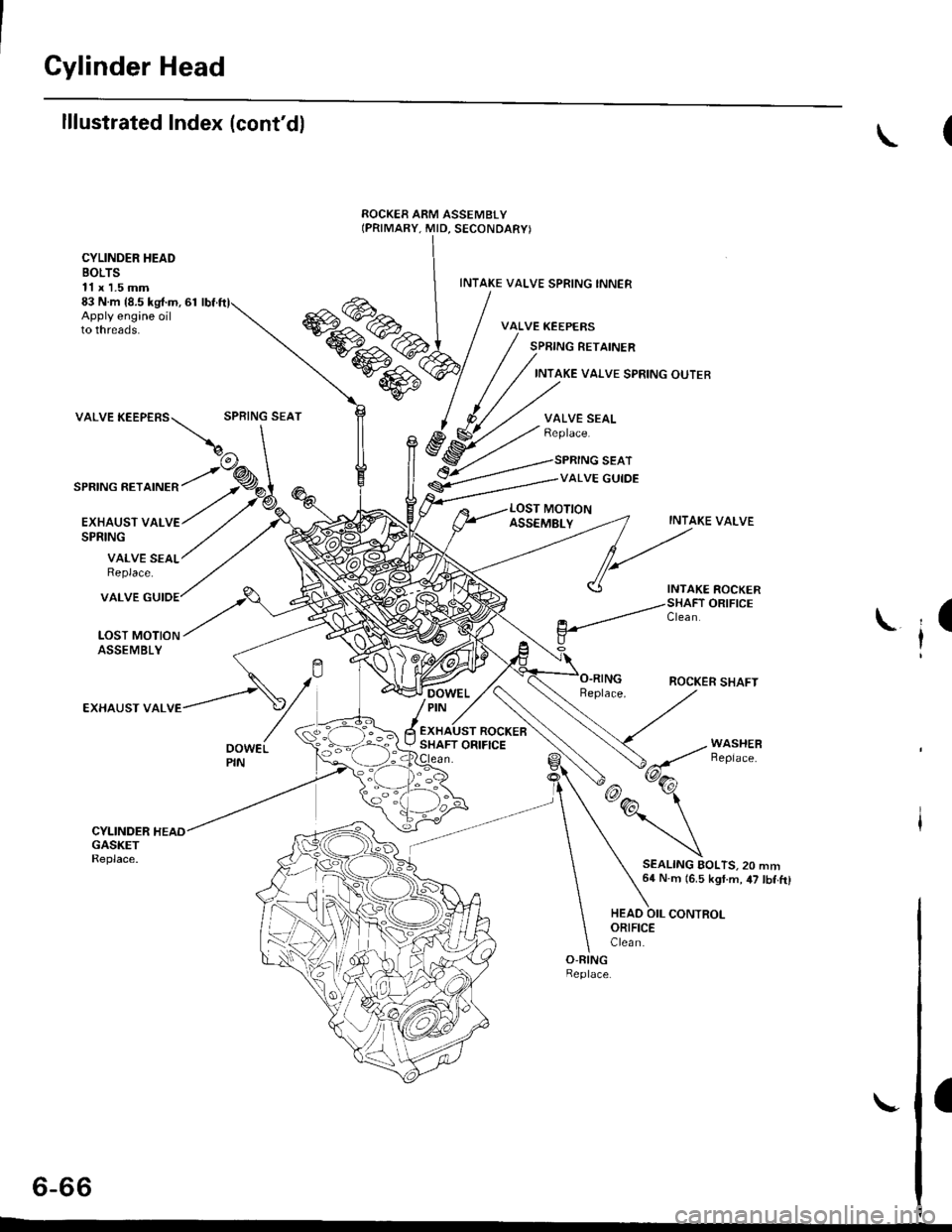

Cylinder Head

lllustrated Index (cont'dl

CYLINDER HEADBOLTS11 x 1.5 mm83 N.m {8.5 kg{.m, 61Apply engine oilto threads.

INTAKE VALVE SPRING INNER

VALVE KEEPERS

SPRING RETAINER

INTAKE VAI.VE SPRING OUTER

valvEKEEPEBS\:""j"*'

SPRING RETAINER

EXHAUST VALVESPRING

VALVE SEALReplace.

VALVE

LOST MOTIONASSEMBLY

EXHAUST VAL

VALVE SEALReplace.

SPRING SEAT

VALVE GUIDE

INTAKE VALVE

ROCKER SHAFT

SEALING AOLTS.20 mm64 N.m (6.5 kgt.m, 47 tbf.ft)

t

il

HEAO OIL CONTROLORIFICEClea n.

a

6-66

Page 180 of 2189

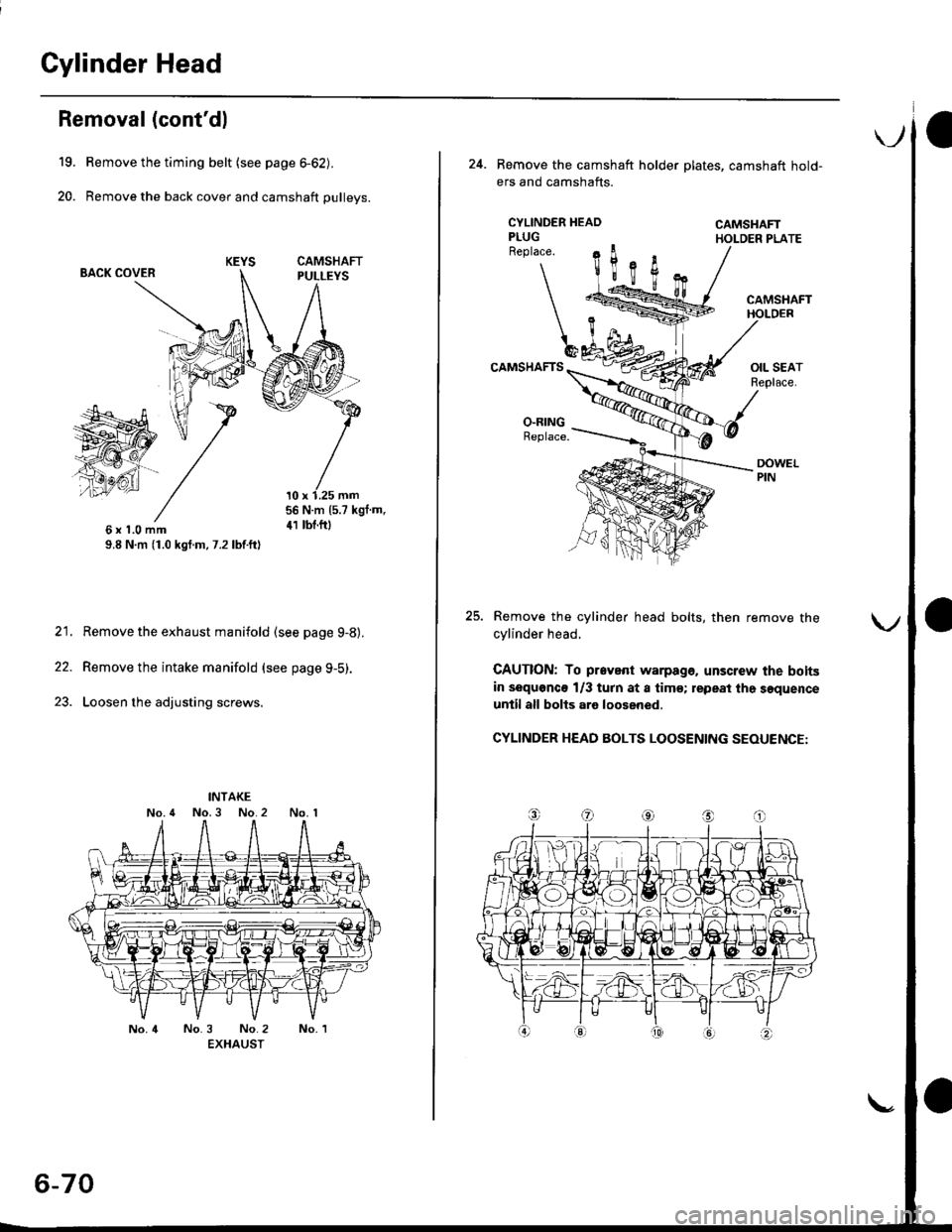

Cylinder Head

19.

20.

Removal (cont'dl

Remove the timing belt {see page 6-62).

Remove the back cover and camshaft pulleys.

BACK COVER

56 N.m (5.7 kgf m,

41 tbt.f06xl.0mm9.8 N,m (1.0 kgf.m, 7.2 lbf.ft)

21, Remove the exhaust manifold (see page 9-8).

22. Remove the intake manifold (see page g-5).

23. Loosen the adjusting screws.

INTAKE

No.4 No.3 No.2 No. 1

6-70

24. Remove the camshaft holder plates, camshaft hold-ers and camshafts.

CAMSHAFTHOLDER PLATE

Remove the cylinder head bolts, then remove the

cylinder head.

CAUTION: To prevsnt warpage. unscrew the bolts

in sequonc€ 1/3 turn at a tim€; lepeat lh6 sequence

until all bolts aro loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENCE:

CYLINDER HEADPLUGReplace. t

\1

\€\i

b4CAMSIIAFTS -

Page 181 of 2189

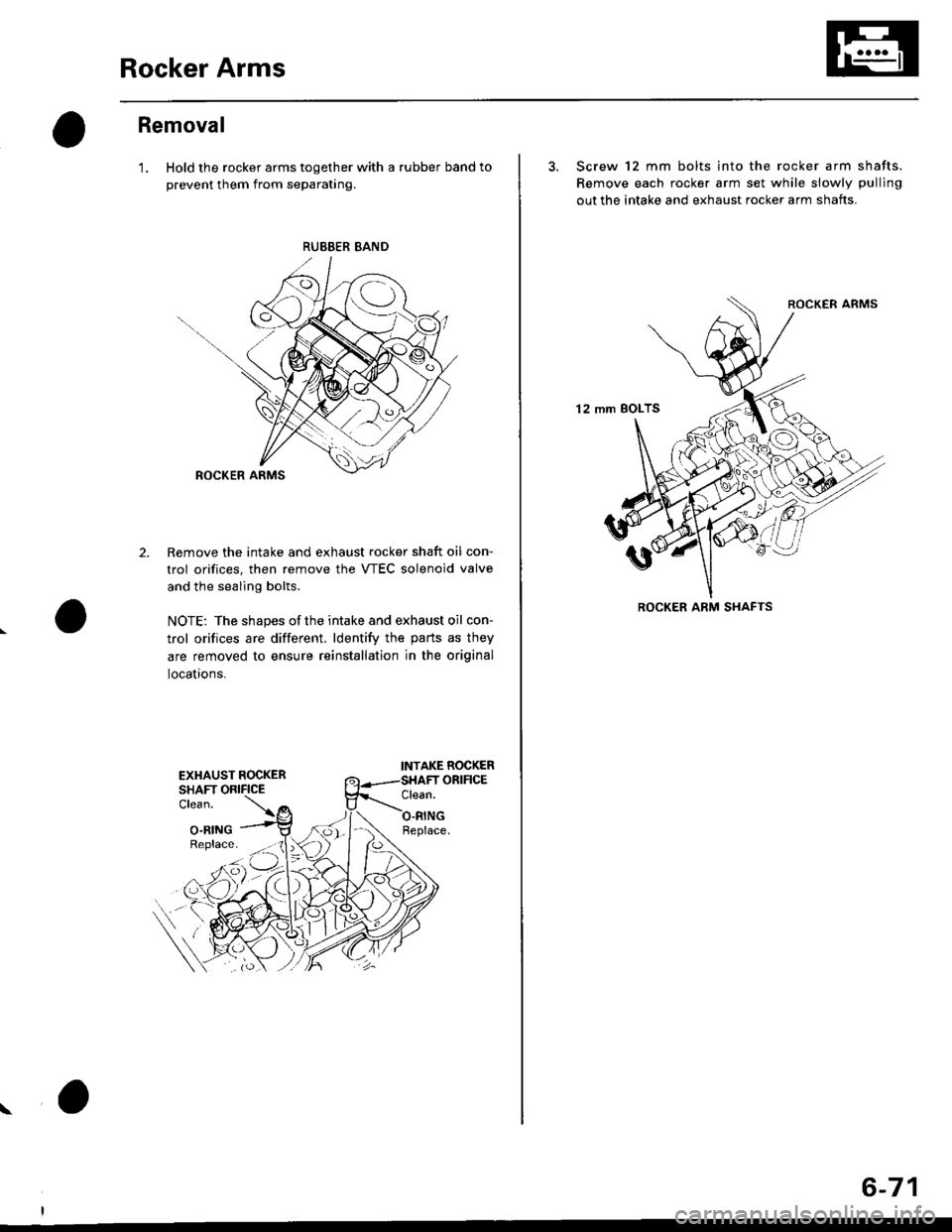

Rocker Arms

Removal

'1. Hold the rocker arms together with a rubber band to

prevent them from separating.

Remove the intake and exhaust rocker shaft oil con-

trol orifices, then remove the VTEC solenoid valve

and the sealing bolts.

NOTE: The shapes ofthe intake and exhaust oil con-

trol orifices are different, ldentify the parts as they

are removed to ensure reinstallation in the original

locauons.

2.

EXHAUST ROCKERSHAFT ORIFICE

INTAKE ROCKERORIFIGEClean.Clean.

O.RINGO.RINGReplace.

RUEBER BAND

Replace. _ (lX

-dJ'v-l-

6-71

3. Screw 12 mm bolts into the rocker arm shafts.

Remove each rocker arm set while slowly pulling

out the intake and exhaust rocker arm shafts.

12 mm BOLTS

ROCKER ARM SHAFTS

Page 184 of 2189

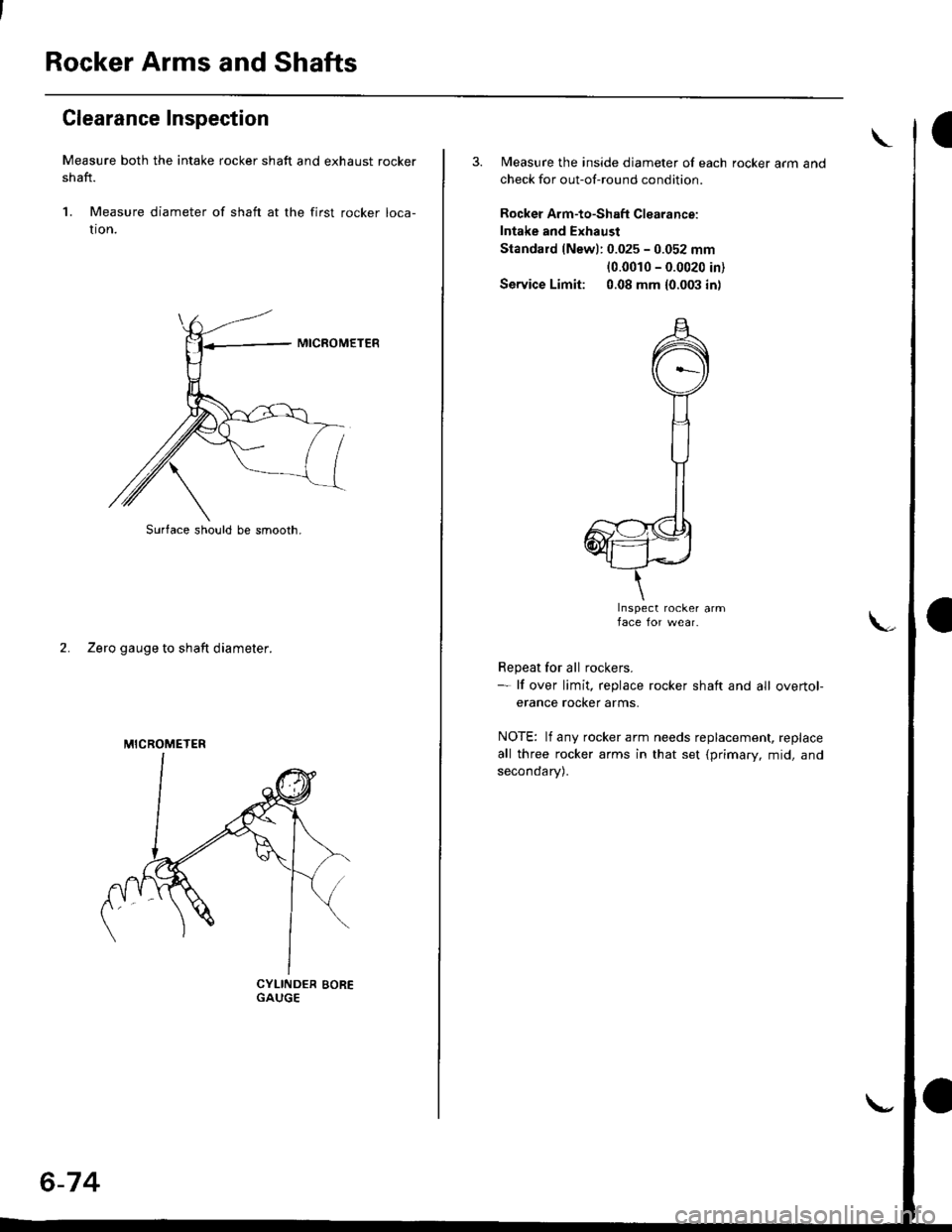

Rocker Arms and Shafts

Clearance Inspection

Measure both the intake rocker shaft and exhaust rocker

shaft.

1. Measure diameter of shaft at the first rocker loca-

tron.

2. Zero gauge to shaft diameter.

Surlace shor/ld be smooth.

MICROMETER

6-74

3. Measure the inside diameter of each rocker arm and

check for out-of-round condition

Rocker Arm-to-Shaft Clearance:

Intake and Exhaust

Standard {Newl: 0.025 - 0.052 mm

{0.0010 - 0.0020 in)

Service Limit: 0.08 mm {0.003 in)

Inspect rocker armface for wear.

Repeat for all rockers.- lf over limit, replace rocker shaft and all overtol-

erance rocker arms.

NOTE: lf any rocker arm needs replacement, replace

all three rocker arms in that set {primary, mid, and

seconoary).

Page 186 of 2189

Gamshafts

Inspection (cont'dl

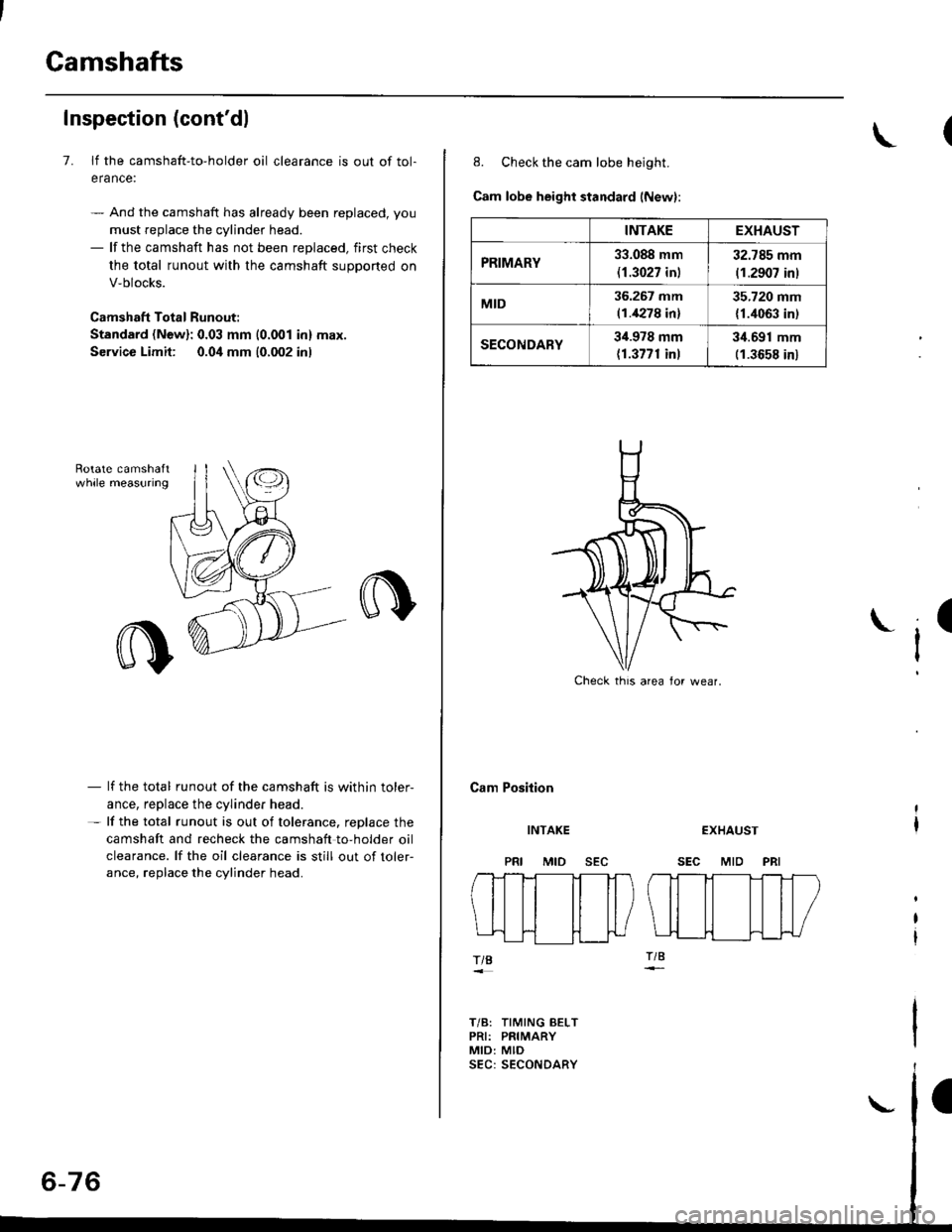

7. lf the camshaft-to-holder oil clearance is out of tol-

erance:

- And the camshaft has already been replaced, you

must replace the cylinder head.- lf the camshaft has not been replaced, first check

the total runout with the camshaft supported on

V-blocks.

Camshaft Total Runout:

Standard (New): 0.03 mm {0.001 in} max.

Service Limit: 0.04 mm (0.002 inl

- lf the total runout of the camshaft is within toler,

ance, replace the cylinder head.- lf the total runout is out of tolerance. replace the

camshaft and recheck the camshaft to,holder oil

clearance. lf the oil clearance is still out of toler-

ance, replace the cylinder head.

INTAKEEXHAUST

PRIMARY33.088 mm

{1.3027 in)

32.785 mm

(1.2907 inl

MID36.267 mm(1.4278 in)

35.720 mm

{1.4063 in)

SECONDARY34.978 mm(1.3771 inl

3i1.691 mm(1.3658 in)

8. Check the cam lobe height.

Cam lobe height standard (New):

Cam Position

I

INTAKE

MID

EXHAUST

SEC MID PRI

TIB

T/B: TIMING BELTPRI: PRIMARYMID: MID

Check thrs area lor wear.

Page 187 of 2189

Valves, Valve Springs and Valve Seals

Removal

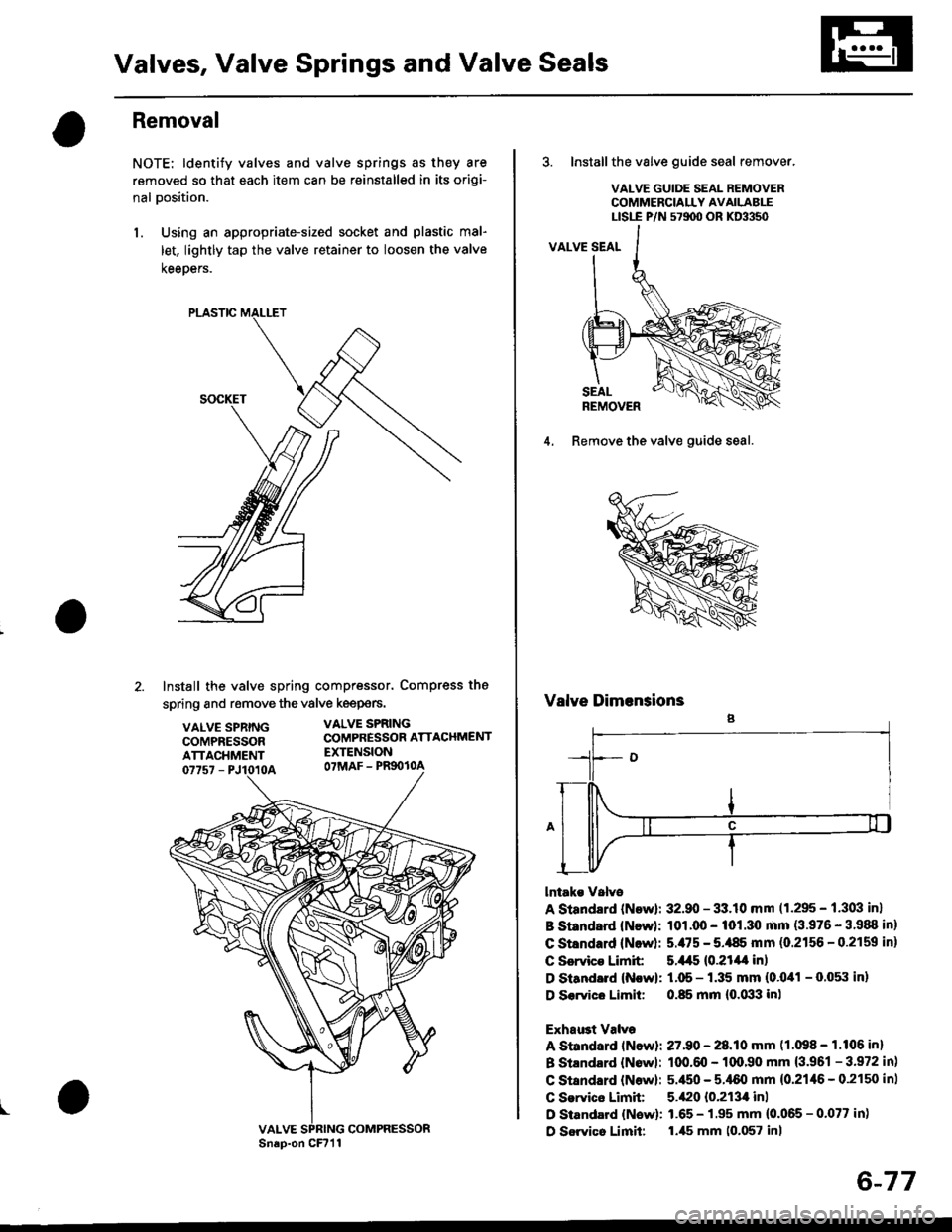

NOTE: ldentify valves and valve springs as they are

removed so that each item can be reinstalled in its origi-

nal Dosition.

l. Using an appropriate-sized socket and plastic mal-

let, lightly tap the valve retainer to loosen the valve

keeoers.

PLASTIC

Install the valve spring compressor. Compress the

spring and remove the vSlve keepers.

VALVE SPRINGCOMPRESSORATTACHMENT07757 - PJ1010A

VALVE SPRINGCOMPRESSOR ATTACHMENTEXTENSIONOTMAF - PRgOIOA

I

Sn.p-on CFr1lCOMPRESSOR

6-77

3. Installthe valve guide seal remover.

VALVE GUIDE SEAL REMOVERCOMMERCIALLY AVAILABLELtst-E P/N 571100 ()R KD3350

4. Remove the valve guide seal.

Valve Dimensions

lntake Valvo

A Standsrd {Newl; 32.90 - 33.10 mm (1.295 - 1.303 in}

B St ndard {New}: 101.00 - 101.30 mm (3.976 - 3'988 in}

C Stsndard (Nowl: 5./t5 - 5.,185 mm (0.2156 - 0.2159 in)

C Servico Limit 5.445 {0.21/l| in)

D Siandard (N!w): 1.05 - 1.35 mm (0.041 - O.05il inl

D S€.vice Limit: 0.85 mm {0.033 inl

Exhaust Valve

A Standard lNewli 27.90 - 28.10 mm (1.098 - 1.106 in)

B Stlndard {Nowl: 100.m - 1qr,90 mm {3.961 - 3.972 in)

C Stsndard {Now}: 5.450 - 5.,[60 mm {0.21,16 - 0.2150 in)

C Service Limit 5.420 10.213,0 inl

D Standard {New): 1.65 - 1.95 mm (0.065 - 0.077 in)

D Sorvico Limit: l.ils mm 10.057 inl