ac system HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1565 of 2189

-Starter Test

NOTE; The air temoerature must be between 59 and

100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described,

Alternate Procedurg:

. Use the following equipment:- Ammeter, 0 - 400 A

- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

- Tachometer, 0 - 1,200 rpm

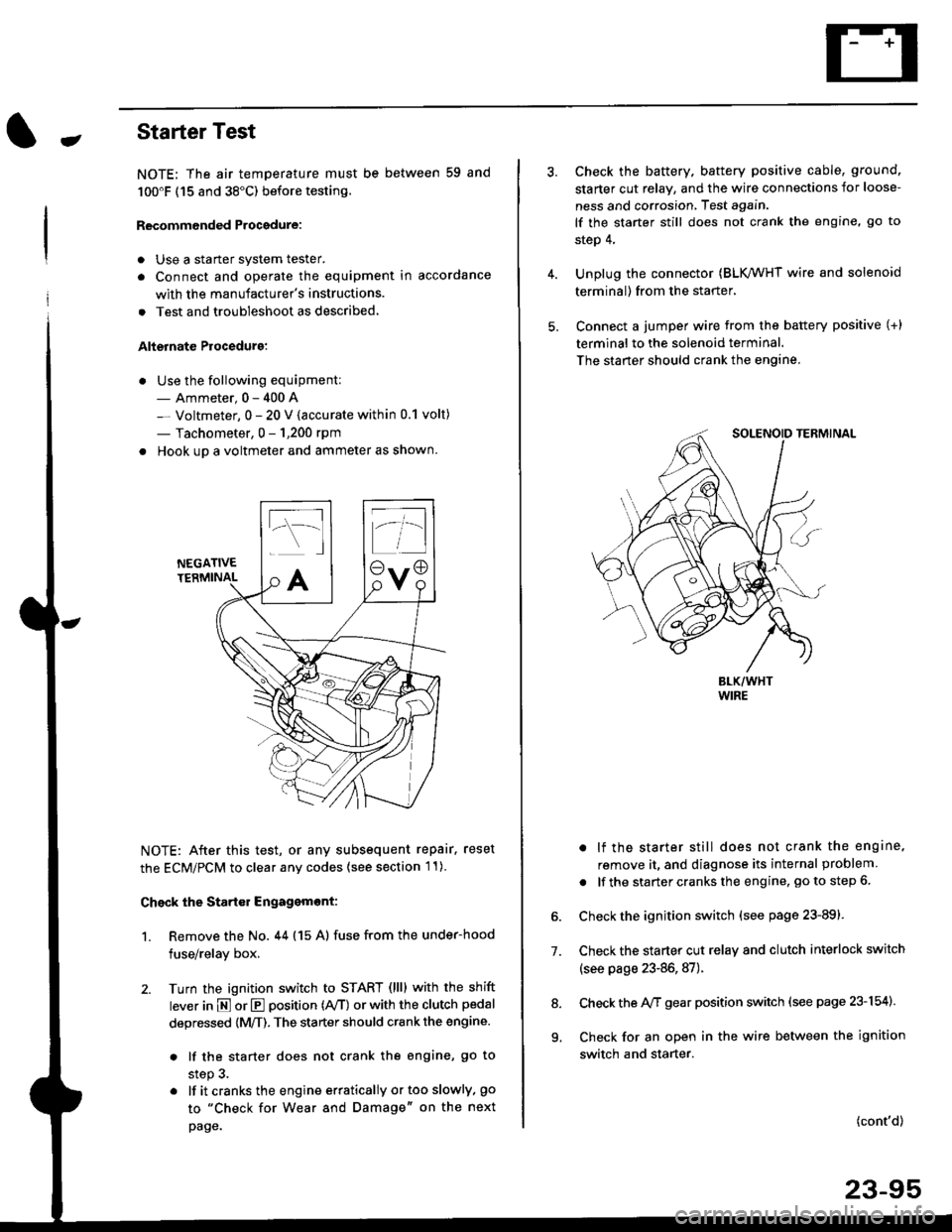

. Hook up a voltmeter and ammeter as shown.

NEGATIVETERMINAL

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section l1)

Check the Start€r Engagemont:

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

2. Turn the ignition switch to START (llll with the shift

lever in E or E position (rVT) or with the clutch pedal

depressed {M/T). The starter should crank the engine.

. lf the starter does not crank the engine, go to

step 3.

. lf itcranksthe engineerraticallyortooslowly, go

to "Check for Wear and Damage" on the next

page.

Check the battery. battery positive cable, ground,

starter cut relay, and the wire connections for loose-

ness and corrosion, Test again.

lf the starter still does not crank the engine, go to

step 4,

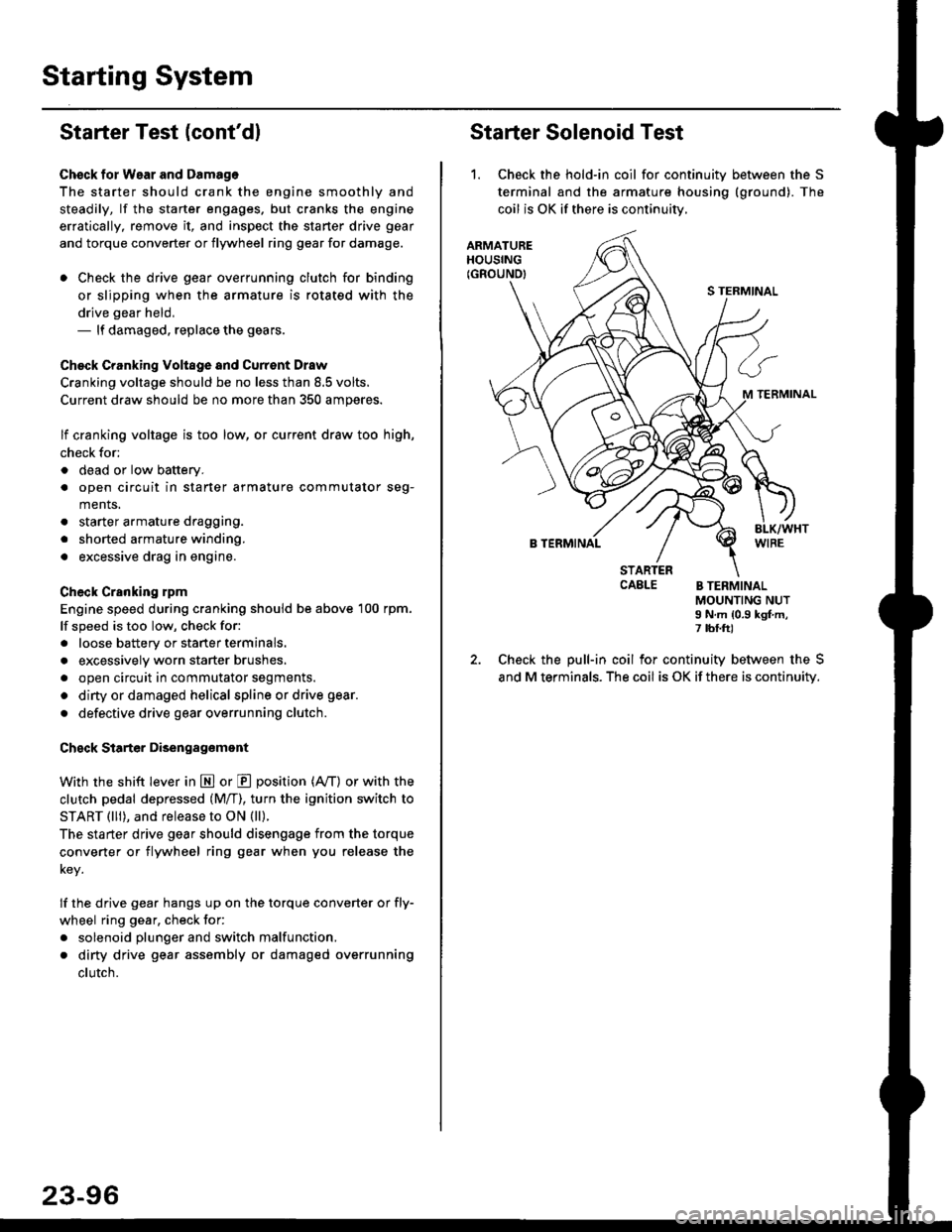

Unplug the connector (BLK,/WHT wire and solenoid

terminal) from the starter,

Connect a jumper wire from the battery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem

. lf the startercranksthe engine, goto step 6.

Check the ignition switch (see page 23-891.

Check the starter cut relay and clutch interlock switch

(see page 23-86,87).

Check the A/f gear position switch (see page 23-154).

Check for an open in the wire between the ignition

switch and starter.

7.

(cont'd)

23-95

9.

Page 1566 of 2189

Starting System

Starter Test lcont'dl

Ch€ck tor Wear and Damage

The starter should crank the engine smoothly and

steadily, lf the starter engages. but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter or flywheel ring gear for damage.

. Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the

drive gear held,- lf damaged. replace the gears.

Check Cranking Voltsge and Curr€nt Draw

Cranking voltage should be no less than 8.5 volts.

Current draw should be no more than 350 amperes.

lf cranking voltage is too low, or current draw too high,

check for;

. dead or low batterv.

. open circuit in starter armature commutator seg-

ments,

. starter armature dragging.

. shorted armature winding.

o excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm,

lf speed is too low, check for:

. loose battery or stanerterminals.

. excessively worn starter brushes,

. open circuit in commutator segments.

o dirty or damaged helical spline or drive gear.

. defective drive gear overrunning clutch.

Check Siarter Disengag€ment

With the shift lever in El or @ position (A/T) or with the

clutch pedal depressed (M/T), turn the ignition switch to

START (lll), and release to ON (ll).

The starter drive gear should disengage from the torque

converter or flywheel ring gear when you release the

Key.

lf the drive gear hangs up on the torque converter or fly-

wheel ring gear, check for:

. solenoid plunger and switch malfunction,

. dirty drive gear assembly or damaged overrunning

clutch.

Starter Solenoid Test

1. Check the hold-in coil for continuitv between the S

terminal and the armature housing (ground). The

coil is OK if there is continuitv,

ARMATUREHOUSING(GROUND)

S TERMINAL

M TERMINAL

B TERMINAL

STARTERCAELE B TERMINALMOUNTING NUTI N.m {0.9 kgf.m,7 tbf.ft)

Check the pull-in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

Page 1568 of 2189

Starting System

Armature Inspection and Test (cont'dl

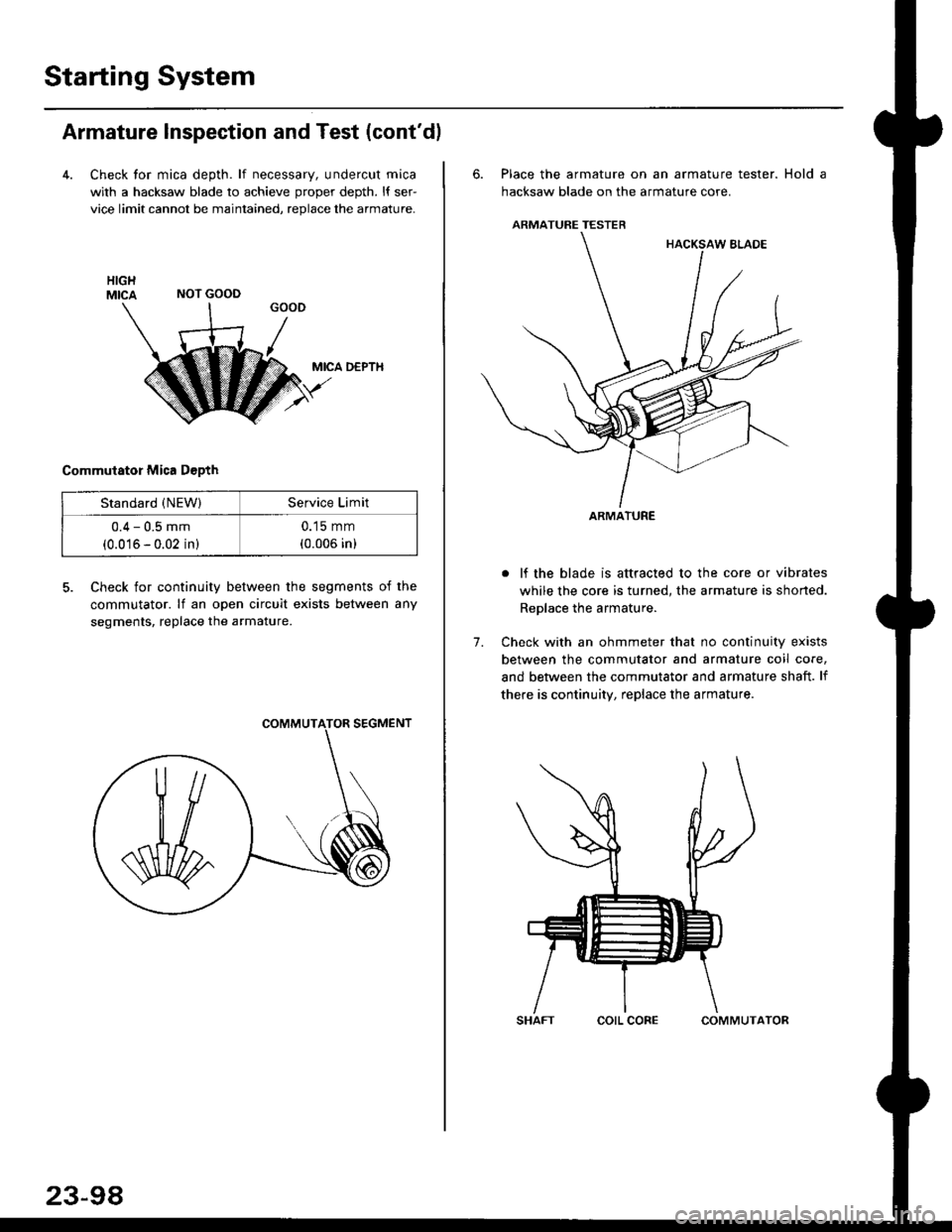

4. Check tor mica depth. lf necessary, undercut mica

with a hacksaw blade to achieve proper depth. l{ ser-

vice limit cannot be maintained, replace the armature.

MICA D€PTH

Commutator Mica D€pth

5. Check for continuity between the segments of the

commutator. lf an open circuit exists between any

segments, replace the armature.

NOT GOOD

Standard (NEW)Service Limit

0.4 - 0.5 mm

(0.016 - 0.02 in)

0.15 mm

(0.006 in)

23-98

corL coFECOMMUTATOR

6. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

ARMATURE TESTER

. lf the blade is attracted to the core or vibrates

while the core is turned, the armature is shorted.

Replace the armature.

7. Check with an ohmmeter that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. lf

there is continuity, replace the armature.

ARMATURE

Page 1570 of 2189

Starting System

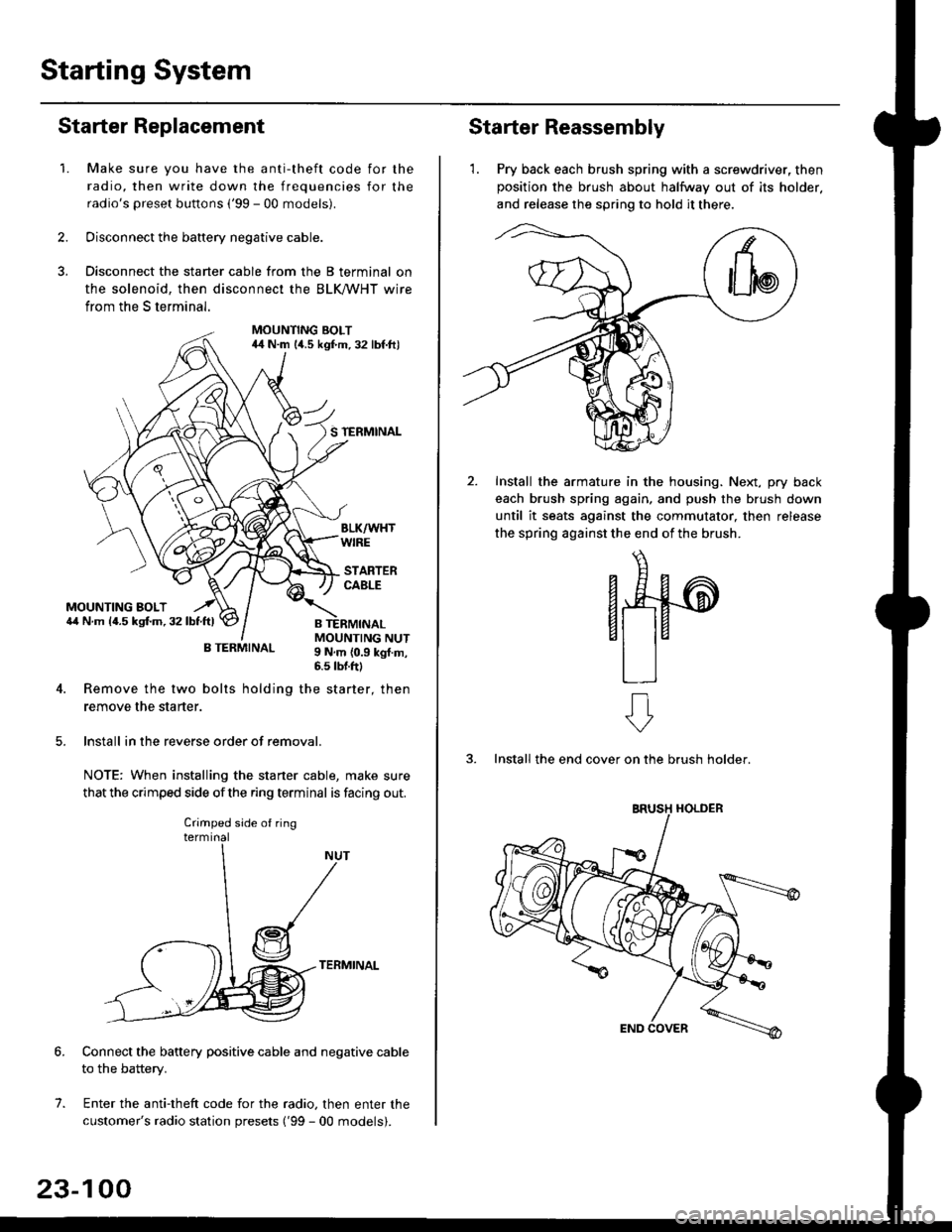

Starter Replacement

1.Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable.

Disconnect the starter cable from the B terminal on

the solenoid, then disconnect the BLK trHT wire

from the S terminal.

MOUNTING BOLT44 N.m l/t.s kgf.m. 32 lbf.ft)

S TERMINAL

MOUNTING BOLT6,1 N.m {4.5 kstm.32lbtftl

MOUNTING NUT9 N,m {0.9 kgl.m,6.s lbtftl

B TERMINAL

4. Remove the two bolts holding the starter, then

remove the starter.

lnstall in the reverse order of removal.

NOTE: When installing the staner cable, make sure

that the crimped side ofthe ring terminal is facing out.

TERMINAL

Connect the battery positive cable and negative cable

to the battery.

Enter the anti-theft code for the radio, then enter the

customer's radio station presets ('99 - 00 models).

7.

Crimped side of ring

23-100

Starter Reassembly

'1. Pry back each brush spring with a screwdriver, then

position the brush about halfway out of its holder.

and release the spring to hold it there.

Install the armature in the housing. Next, pry back

each brush spring again, and push the brush down

until it seats against the commutator, then release

the spring against the end of the brush.

aw

3. Install the end cover on the brush holder.

ERUSH HOLDER

Page 1572 of 2189

lgnition System

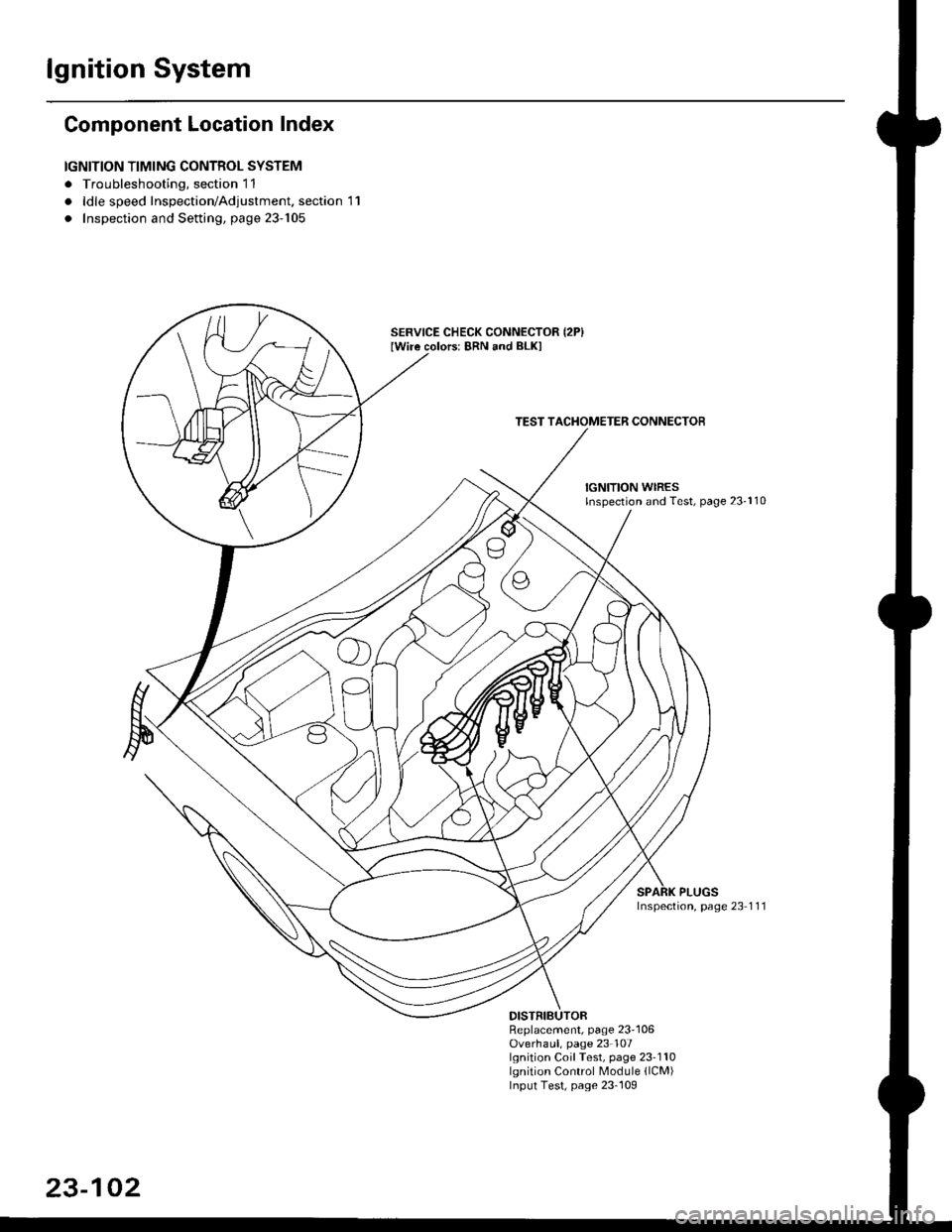

Component Location Index

IGNITION TIMING CONTROL SYSTEM

. Troubleshooting, section 11

. ldle speed Inspection/Adjustment. section 11

. Inspection and Setting, page 23-105

SERVICE CHECK CONNECTOR {2P}Iwiie colors: 8RN and BLKI

TEST TACI{OMETER CONNECTOB

IGNITION WIRESlnspection and Test, page 23-110

PLUGSInspection, page 23 1 11

Replacement, page 23'106Overhaul, page 23-107lgnition Coil Test, page 23'110lgnition Control Module llCM)Input Test, page 23-109

23-102

Page 1573 of 2189

lgnition System

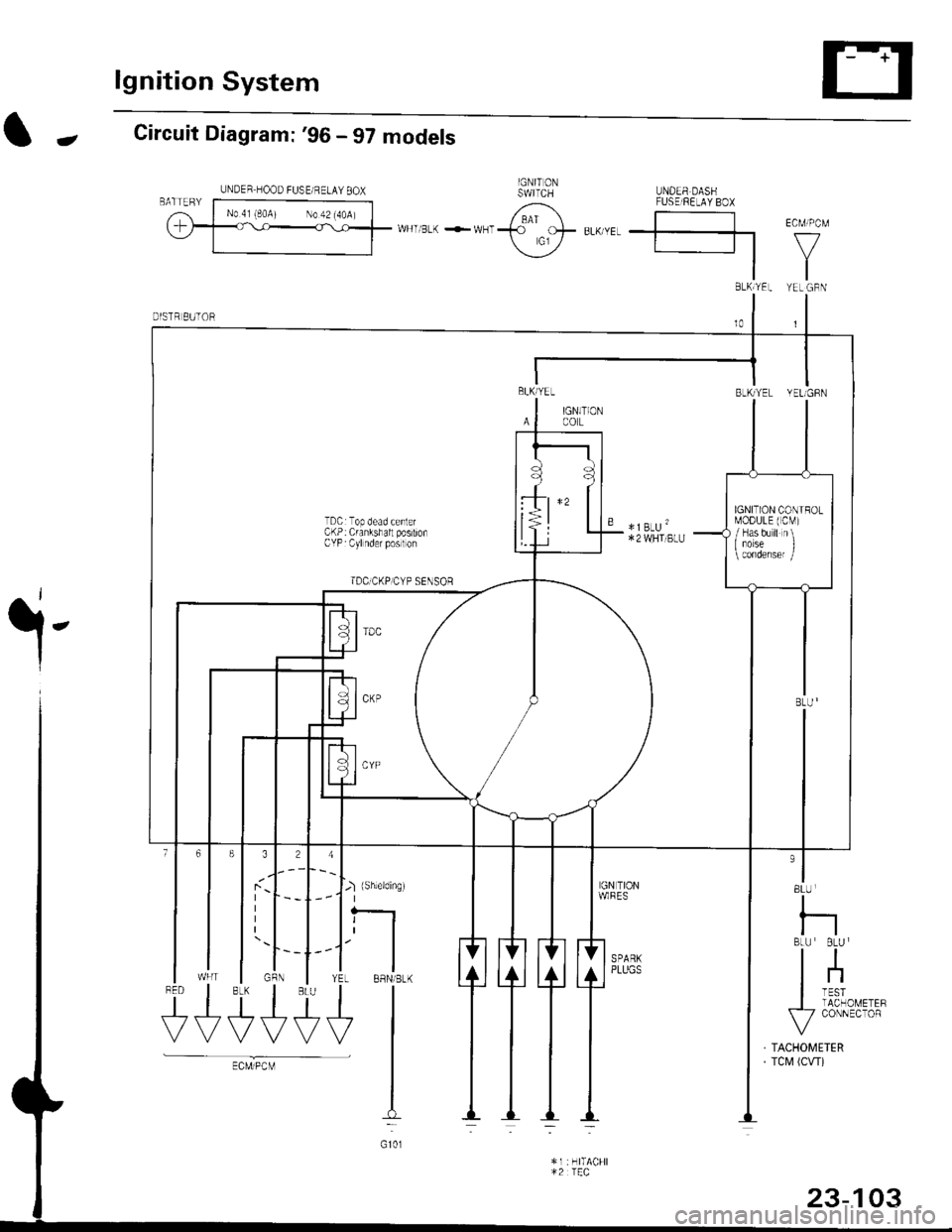

-Circuit Diagram: '96 - 97 models

.i-

8LU

I

nBLU BLU I

tl

lnI TESTI TACHOMETEF\-7 CONNECTOR

TACHOMETERTCM (CW)

J-) {sh,eldinsr't I

tfYEL BBN/BLK

+l

I:

G101

$t+++

UNDER HOOD FUSE/ RELAY 8OX

BLh TEL YEL GBN

BLKlYEL

IAl

BLK/YEL YELIGFN

IGN]TIONCOL

TDCrTop dead cenlerCKP: Crankshall postionCYP Cylnder poslon

TDC]CKP]CYP SENSoR

" *]BLU'*2 WHI BLU

IGNITION CONIROLMODULE (CM)

/ Has b'r ll n\I iorse I

rUSE FE-AV BO}

*u r-. .-*---{<9ot # u,,."r. | |

\j/ El v

tl

23-103

Page 1574 of 2189

![HONDA CIVIC 1999 6.G Workshop Manual lgnition System

Circuit Diagram :98-00 models

UNDER HOOD FUSUFELAY BOXxE;;;;-;;;;l /; l-*;- Ecw.cM

ffiwFnBLK<-wHr\9-

Y

tlBTKTYEL YEUGRN

IGN]TIONswtTcHUNDER,DASHFUSE/BELAY BOX

YEt

J

BLK

J

FED

+

*1 HONDA CIVIC 1999 6.G Workshop Manual lgnition System

Circuit Diagram :98-00 models

UNDER HOOD FUSUFELAY BOXxE;;;;-;;;;l /; l-*;- Ecw.cM

ffiwFnBLK<-wHr\9-

Y

tlBTKTYEL YEUGRN

IGN]TIONswtTcHUNDER,DASHFUSE/BELAY BOX

YEt

J

BLK

J

FED

+

*1](/img/13/6068/w960_6068-1573.png)

lgnition System

Circuit Diagram :'98-00 models

UNDER HOOD FUSUFELAY BOX'x'E;;;;-;;;;l /; l-*;- Ecw.cM

ffiwFnBLK<-wHr\9-

Y

tlBTKTYEL YEUGRN

IGN]TIONswtTcHUNDER,DASHFUSE/BELAY BOX

YEt

J

BLK

J

FED

+

*1 :H TACHI*2 :TEC

9 *IBLU'

23-104

Page 1576 of 2189

lgnition System

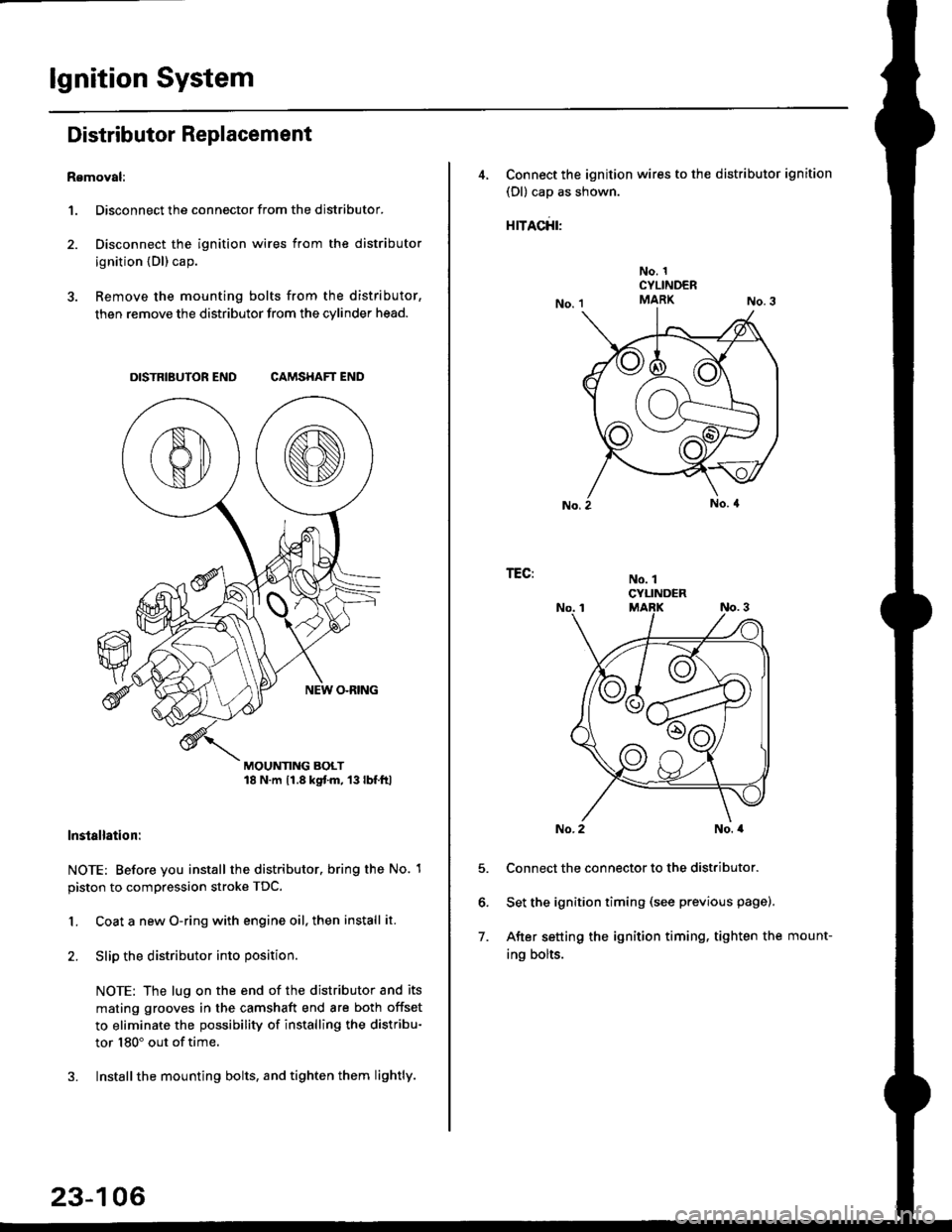

Distributor Replacement

Removal:

1. Disconnect the connector from the distributor.

2. Disconnect the ignition wires from the distributor

ignition {Dl) cap.

3. Remove the mounting bolts from the distributor,

then remove the distributor from the cylinder head.

DISTRIBUTOR END CAMSHAFT END

MOUNTING BOLT18 N.m 11.8 kgtm, 13lbf.ltl

lnstallation:

NOTE: Before you install the distributor. bring the No. 1

piston to compression stroke TDC.

1. Coat a new O-ring with engine oil, then install it.

2. Slip the distributor into position

NOTE: The lug on the end of the distributor and its

mating grooves in the camshaft end are both offset

to eliminate the possibility of installing the distribu-

tor 180" out of time.

3. Installthe mounting bolts, and tighten them lightly.

23-106

4, Connect the ignition wires to the distributor ignition

(Dl) cap as shown.

rracfit'

No. 1CYLINDERMARK

No. 1CYLINDER

TEG:

5.

6.

7.

No. 2No. a

Connect the connector to the distributor.

Set the ignition timing (see previous page).

After setting the ignition timing, tighten the mount-

ing bolts.

Page 1578 of 2189

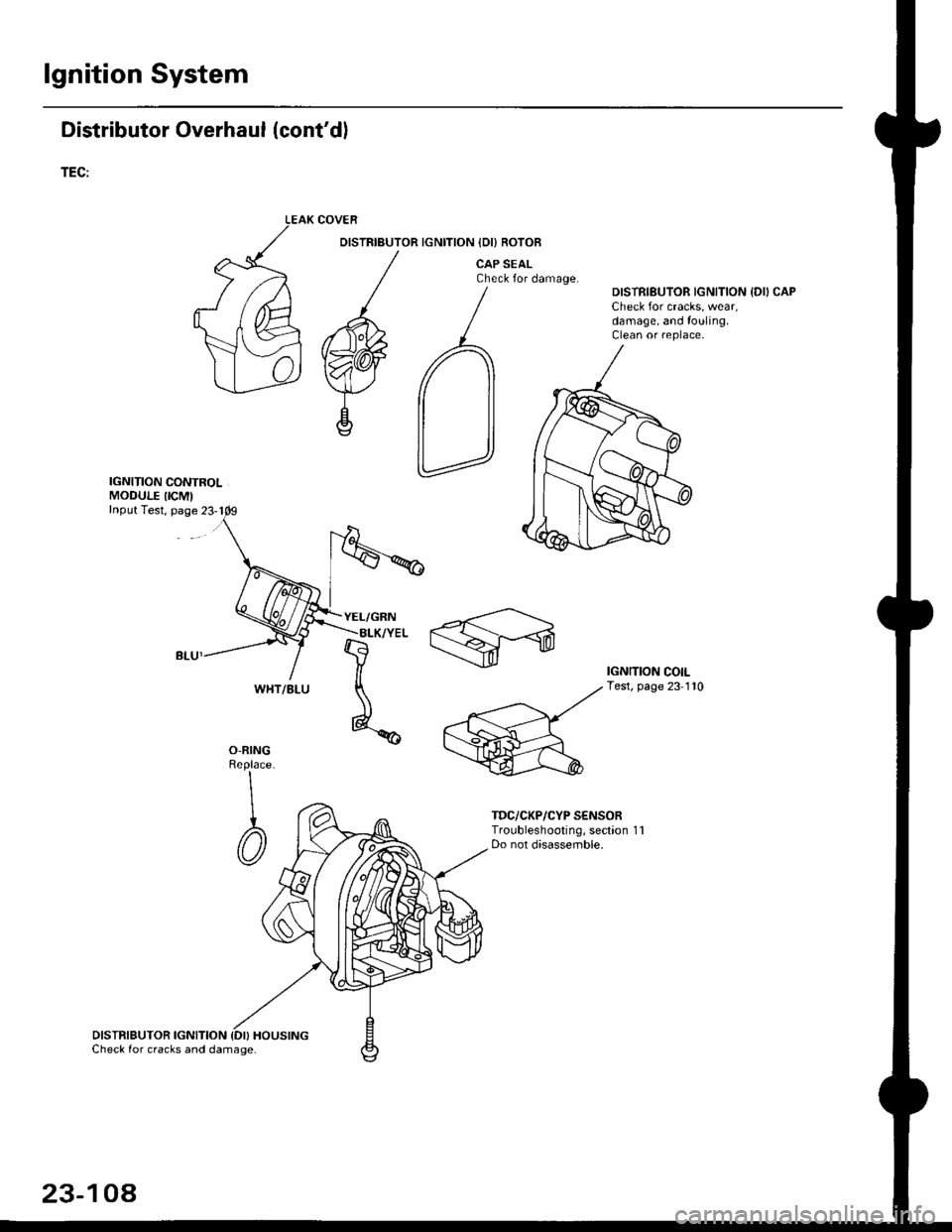

lgnition System

Distributor Overhaul (cont'dl

TEC:

IGNITION CONTROLMODULE IICM'Input Test, page 23-1

DISTRIBUTOR IGNITION {DI} HOUSINGCheck for cracks and damage.

COVER

DISTRIBUTOR IGNITION IDI) ROTOB

CAP SEALCheck for damage.DISTRIBUTOR IGNITION {DII CAPCheck for cracks, wear,damage, and fouling.Clean or replace,

IGNITION COILTest, page 23-110

O-RINGReplace

\

I

@

TDC/CKP/CYP S€NSORTroubleshooting, section 1 1Do not disassemble.

WHT/BLU

23-104

Page 1579 of 2189

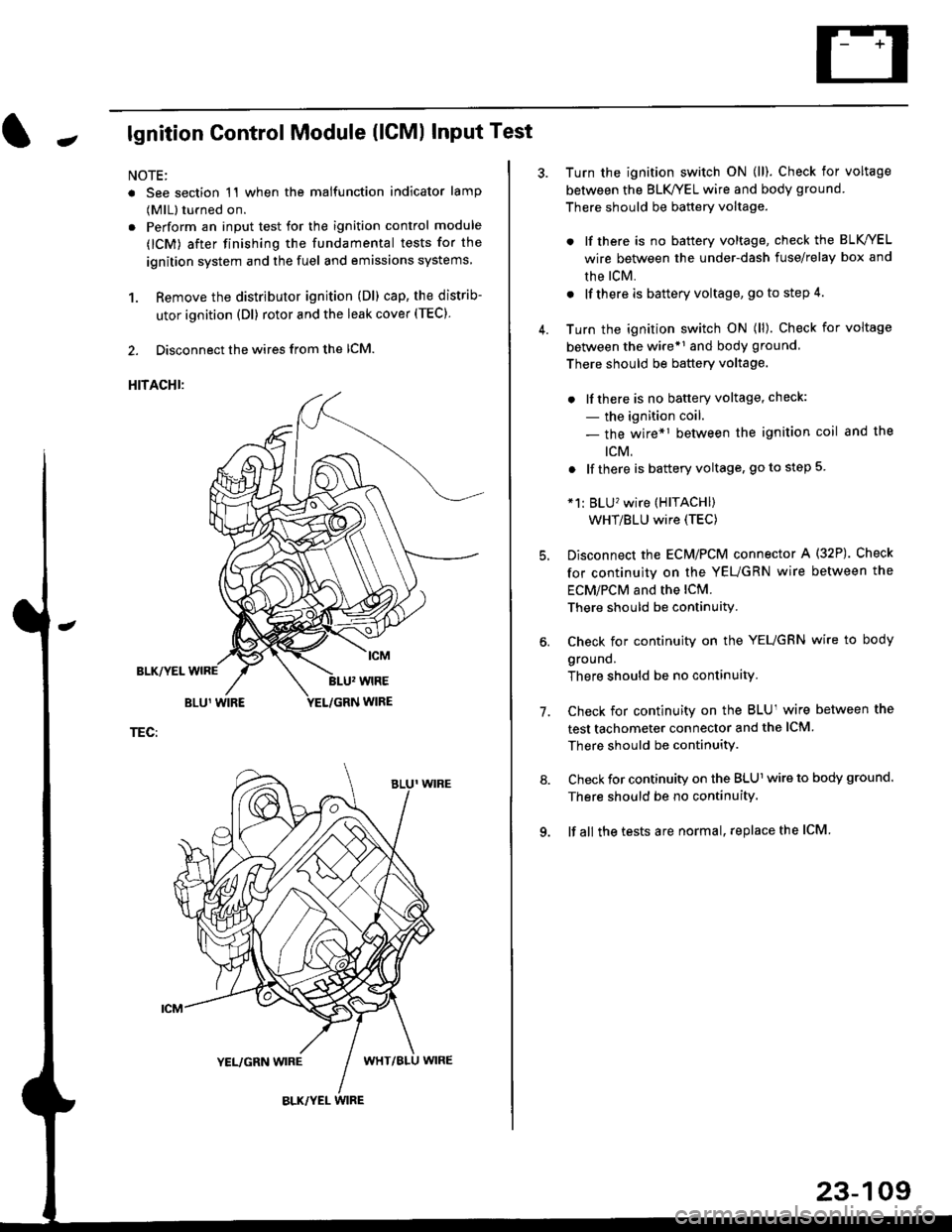

Jlgnition Control Module (lCMl Input Test

NOTE:

. See section 1'l when the malfunction indicator lamp

(MlL) turned on.

. Perform an input test for the ignition control module

(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems

1. Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor and the leak cover (TEC).

2. Disconnect the wires from the lCM.

HITACHI:

BLK/YEL

TEC:

Turn the ignition switch ON (ll). Check for voltage

between the BLK/YEL wire and body ground.

There should be battery voltage.

. lf there is no battery voltage, check the BLK/YEL

wire between the under-dash fuse/relay box and

rhe lcM.

. lf there is battery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the wire*r and body ground

There should be battery voltage.

. lfthere is no battery voltage, check:

- the ignition coil.

- the wire*1 between the ignition coil and the

tcM.

. lf there is battery voltage, go to step 5

*1: BLU'�wire (HITACHI)

WHT/BLU wire (TEC)

Disconnect the EcM/PCM connector A (32P). Check

for continuity on the YEUGRN wire between the

ECM/PCM and the lCM.

There should be continuity.

Check for continuity on the YEUGRN wire to body

ground.

There should be no continuity.

Check for continuity on the BLUl wire between the

test tachometer connector and the ICM

There should be continuitY.

Check for continuity on the BLUl wire to body ground.

There should be no continuity.

lf all the tests are normal, replace the ICM

7.

23-109