Alternator HONDA CIVIC 1999 6.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1590 of 2189

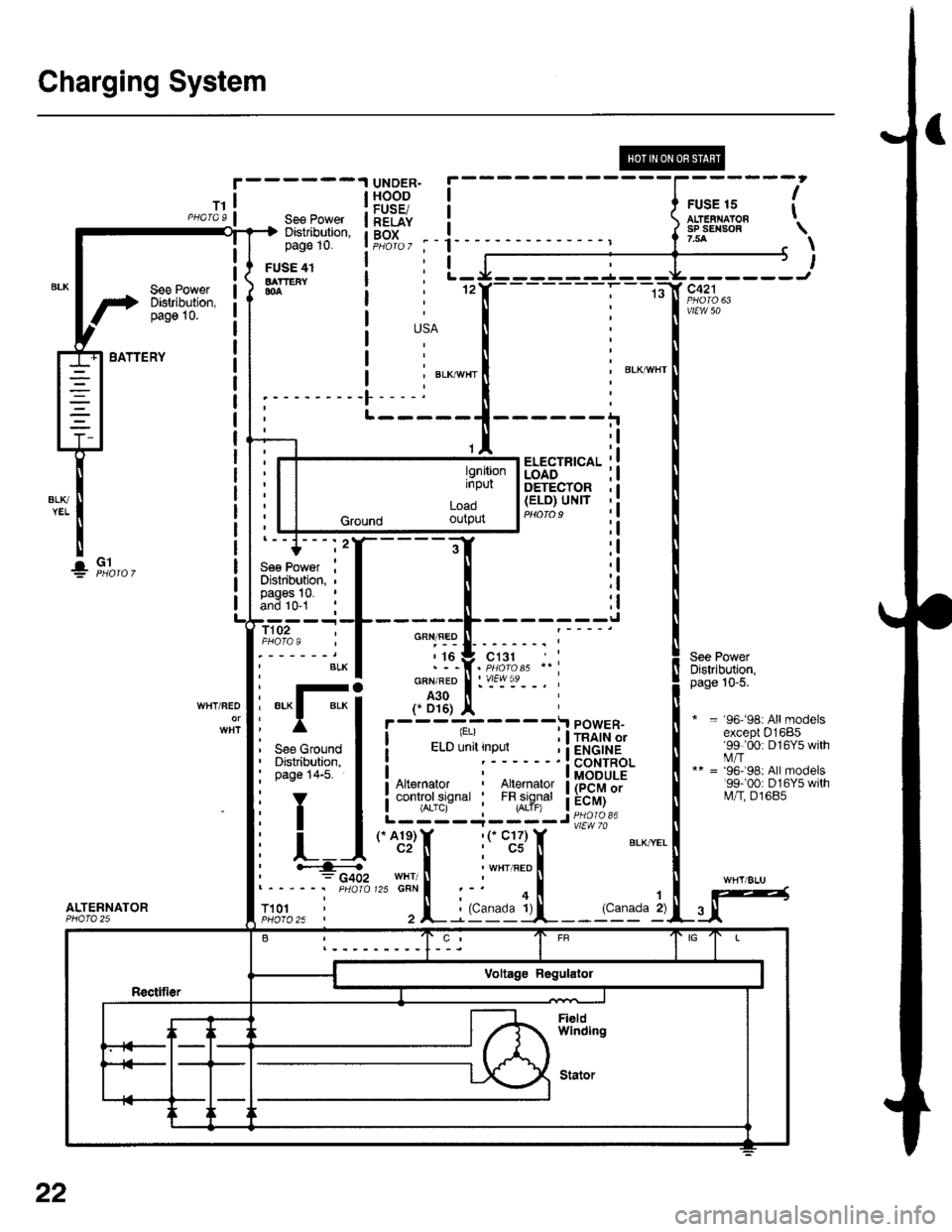

Charging System

Alternator Replacement

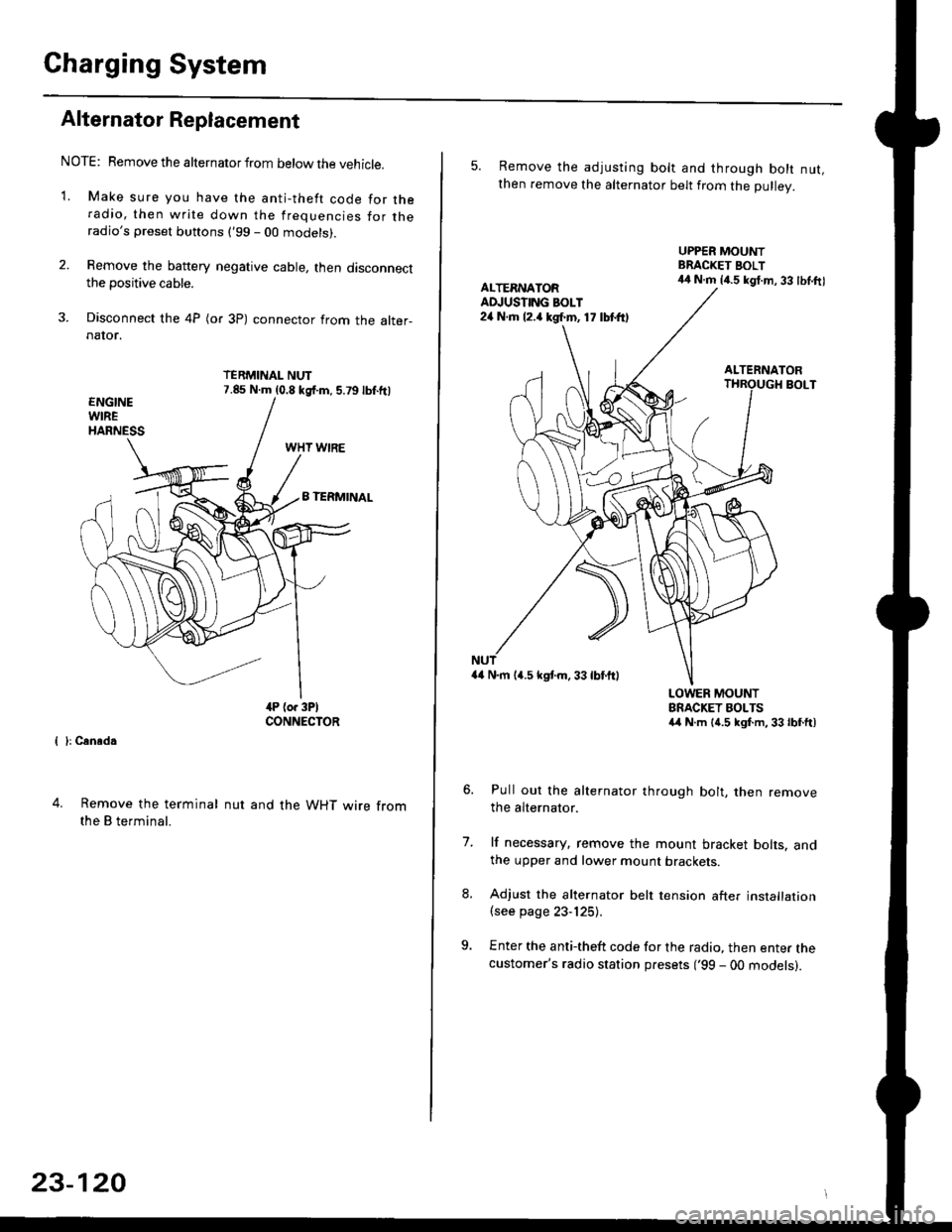

NOTE: Remove the alternator from below the vehicle.

'1. Make sure you have the anti-theft code for theradio, then write down the frequencies for theradio's preset buttons ('99 - 00 models).

2. Remove the battery negative cable, then disconnectthe positive cable.

3. Disconnect the 4P (or 3P) connector from the alter-naIor.

TERMINAL NUT7.85 N.m (0.8 kgf.m, 5.79lbf.ftl

{ }: Cansd.

4. Remove the terminal

the B terminal.

nut and the WHT wire from

23-120

5. Remove the adjusting bolt and through bolt nut,then remove the alternator belt from the Dullev.

UPPER MOUNTBRACKET BOLT44 N.m 14.5 kgt.m, 33 lbl.ftlALTERNATORAD.'USTING BOLT24 N.rh l2.a kgf.m, 17 lbtft)

ALTERNATORBOLT

a4 N.m 14.5 kstm.33lbf'ftl

LOWER MOUNTBRACKET BOLTSa4 N.m l{.5 kgf.m,33lbfft)

Pull out the alternator through bolt, then removethe alternator.

lf necessary, remove the mount bracket bolts. andthe upper and lower mount brackets

Adjust the alternator belt tension after installation(see page 23-125).

Enter the anti-theft code for the radio, then enter thecustomer's radio station presets ('99 - 00 models).

7.

Page 1592 of 2189

Charging System

Rectifier Removal (cont'd)

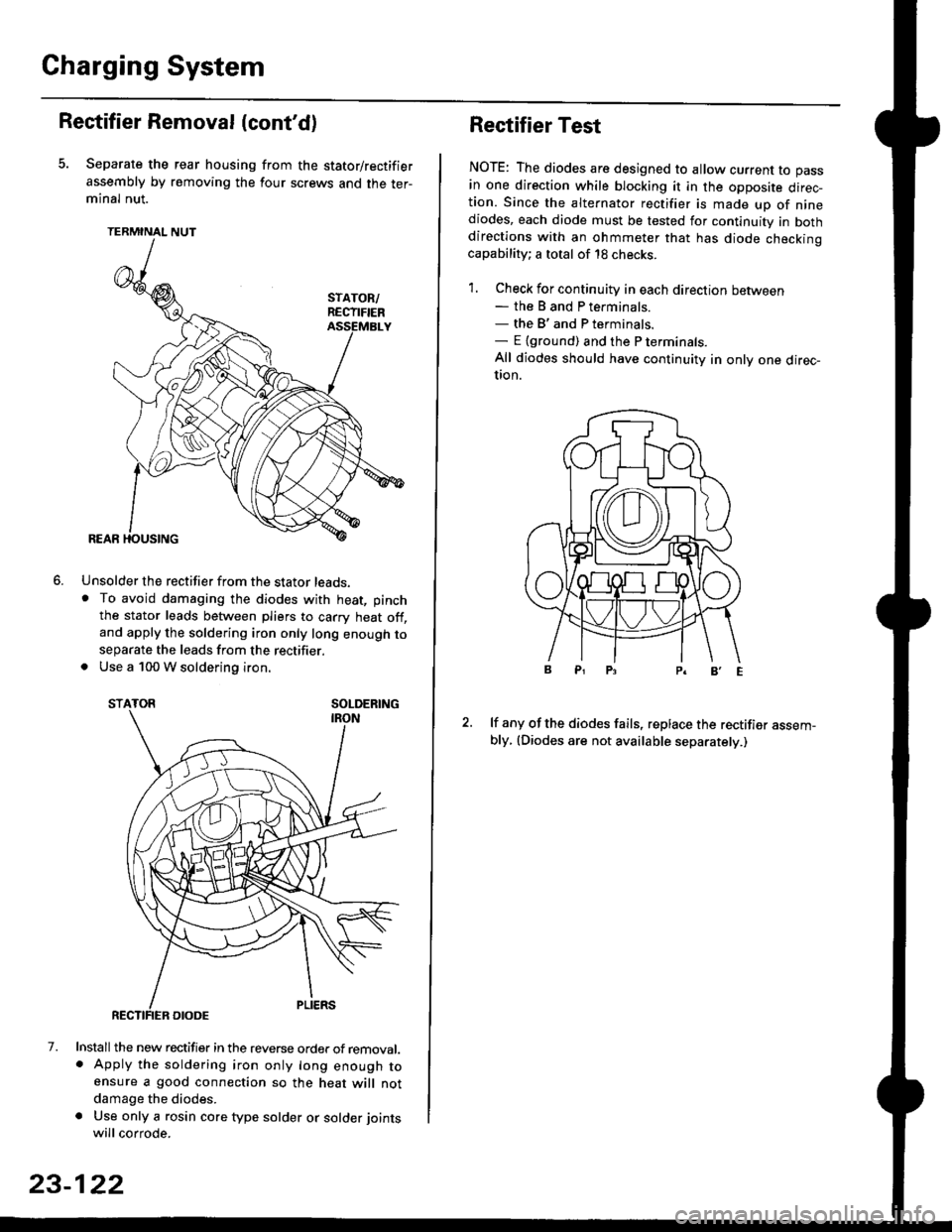

Separate the rear housing from the stator/rectifier

assembly by removing the four screws and the ter-minal nut.

TERMINAL NUT

Unsolder the rectifier from the stator leads,. To avoid damaging the diodes with heat, pinch

the stator leads between pliers to carry heat off,and apply the soldering iron only long enough toseparate the leads from the rectifier.. Use a 100 W soldering iron.

STATOR SOLDERING

7. Install the new rectifier in the reverse order of removal.. Apply the soldering iron only long enough toensure a good connection so the heat will notdamage the diodes.

a Use only a rosin core type solder or solder joints

will corrode.

6.

SOLDERING

23-122

Rectifier Test

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc-tion. Since the alternator rectifier is made up of ninediodes, each diode must be tested for continuity in bothdirections with an ohmmeter that has diode checkinocapability; a total of 18 checks.

1. Check for continuity in each direction between- the B and P terminals.- the B'and P terminals.- E {ground) and the P terminals.

All diodes should have continuity in only one direc-UOn.

lf any of the diodes fails, replace the rectifier assem-bly, (Diodes are not available separately.)

Page 1593 of 2189

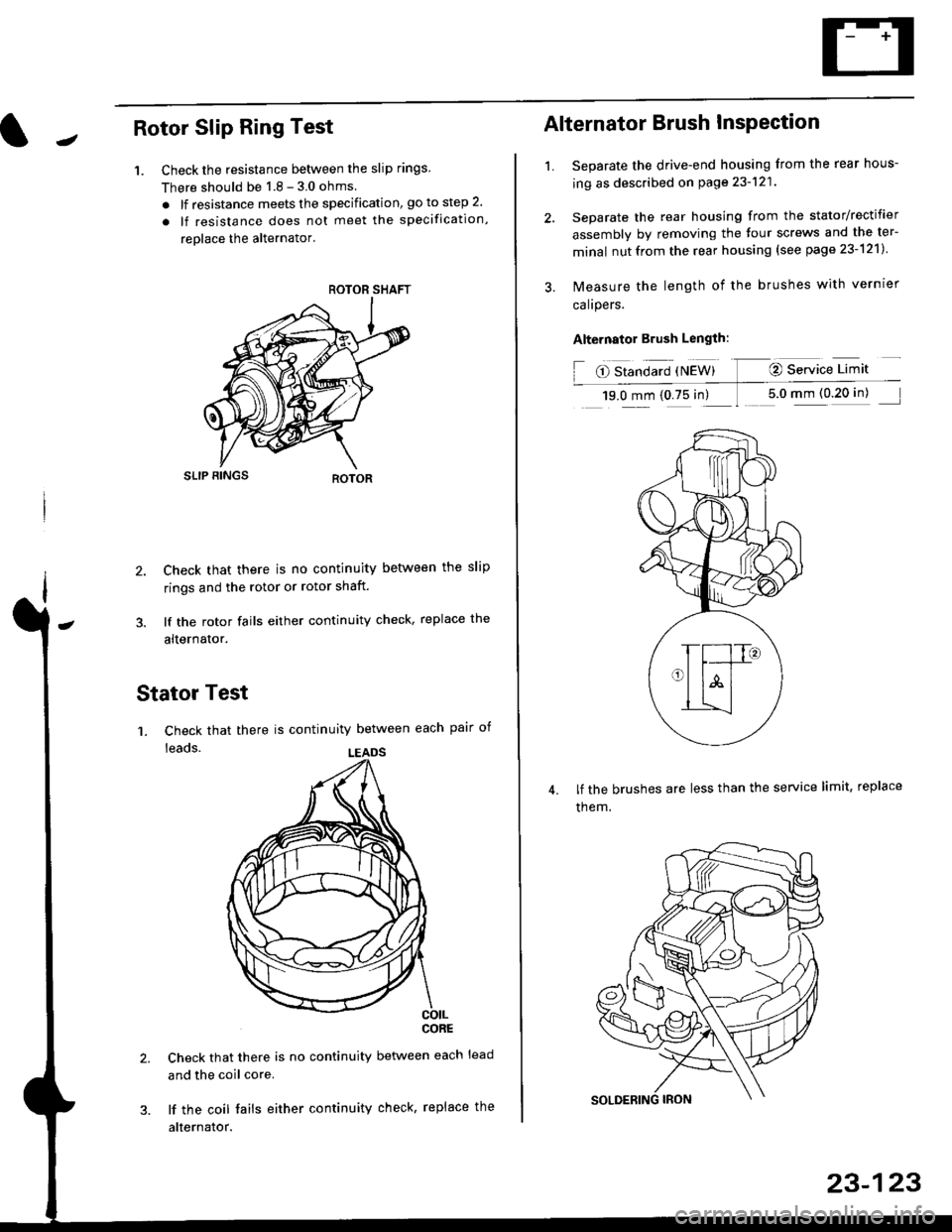

JRotor Slip Ring Test

1. Check the resistance betlveen the slip rings

There should be 1 8 - 3 0 ohms

. lf resistance meets the specification, go to step 2.

. lf resistance does not meet the specification,

reolace the alternator'

SLIP BINGS

2. Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

3. lf the rotor fails either continuity check, replace the

alternator.

Stator Test

'1. Check that there is continuity between each pair of

leads.

CORE

Check that there is no continuity between each lead

and the coil core.

lf the coil fails either continuity check, replace the

alternator.

ROTOR SHAFT

LEADS

1.

Alternator Brush InsPection

Separate the drive-end housing from the rear hous-

ing as described on page 23-121

Separate the rear housing from the stator/rectifier

assembly by removing the four screws and the ter-

minal nutfrom the rear housing {see page 23-121}

lvleasure the length of the brushes with vernrer

calrpers.

Alternator Brush Length:

O Standard {NEW} @ Service Limit

19.0 mm (0.75 in) 1 5.0 mm (0 20 in)

lf the brushes are less than the service limit, replace

them.

23-123

Page 1594 of 2189

Gharging System

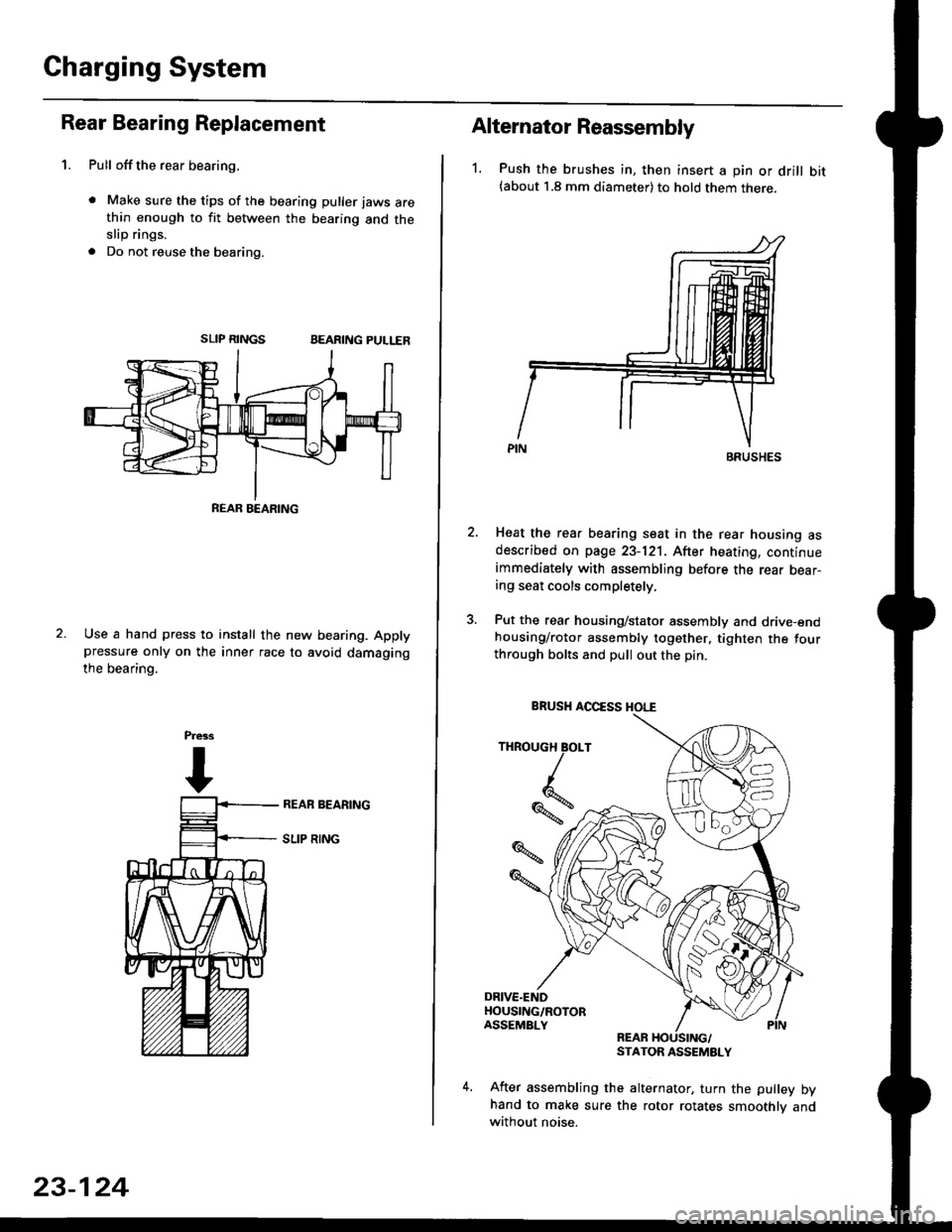

Rear Bearing Replacement

1. Pull offthe rear bearing,

. Make sure the tips of the bearing puller jaws arethin enough to fit between the bearing and theslip rings.

. Do not reuse the bearing.

SLIP RINGSBEARING PULLER

Use a hand press to install the new bearing. Applypressure only on the inner race to avoid damaging

the bearino.

REAB BEARING

23-124

Alternator Reassembly

1. Push the brushes in, then insert a pin or drill bit(about 1.8 mm diameter) to hold them there.

Heat the rear bearing seat in the rear housing asdescribed on page 23-121. After heating, continueimmediately with assembling before the rear bear-ing seat cools completely,

Put the rear housing/stator assembly and drive-endhousing/rotor assembly together. tighten the fourthrough bolts and pull out the pin.

REARSTATOR ASSEMBLY

After assembling the alternator, turn the pulley byhand to make sure the rotor rotates smoothlv andwithout noise.

BRUSHES

THROUGH BOLT

Iq

%*z

BRUSH AOCESS HOI."E

Page 1595 of 2189

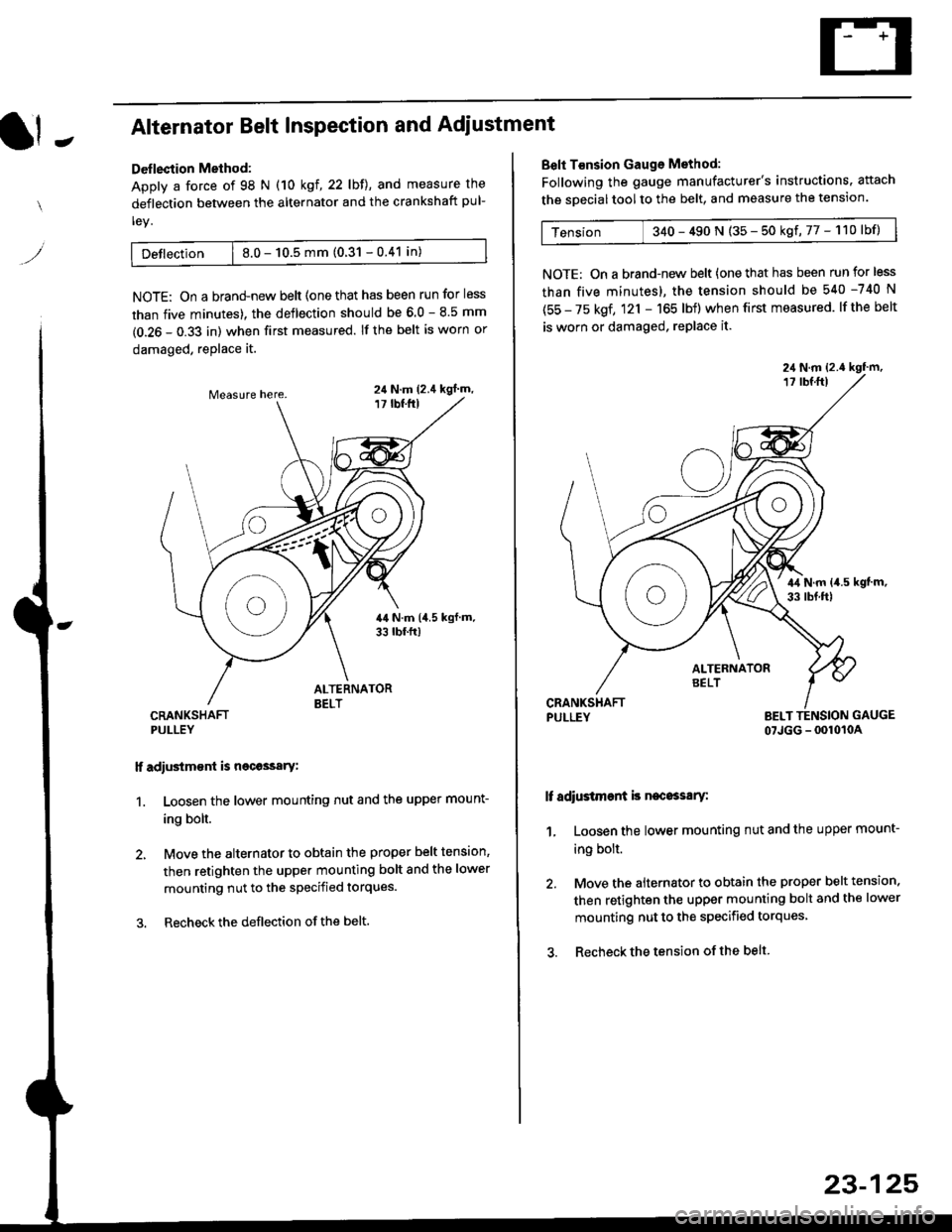

It -Alternator Belt Inspection and Adiustment

Deflection Method:

Apply a force of 98 N (10 kgl,22lbll, and measure the

deflection between the alternator and the crankshaft pul-

ley.

Detlection | 8.0 - 10.5 mm (0.31 - 0.41 in)

NOTE: On a brand-new belt {one that has been run for less

than five minutes). the deflection should be 6.0 - 8.5 mm

(0.26 - 0.33 in) when first measured. If the belt is worn or

damaged, replace it.

CRANKSHAFTPULLEY

lf adiustm€nt is necossary:

1. Loosen the lower mounting nut and the upper mount-

ing bolt.

2, Move the alternator to obtain the proper belt tension,

then retighten the upper mounting bolt and the lower

mounting nut to the specified torques.

3. Recheckthe deflection ofthe belt.

24 N.m (2.4 kgl m,

Belt T€nsion Gauge Method:

Following the gauge manufacturer's instructions. attach

the soecial tool to the belt, and measure the tension.

Tension 340 - 490 N (35 - 50 kgf,77 - 110lbf)

NOTE: On a brand-new belt {one that has been run for less

than five minutes), the tension should be 540 -740 N

(55 - 75 kgf, 121 - 165 lbf) when first measured. lf the belt

is worn or damaged, replace it.

PULLEY BELT TENSION GAUGE

07JGG - 0010104

It adiustment is necossary:

1, Loosen the lower mounting nut and the upper mount-

ing bolt.

2. Move the alternator to obtain the proper belt tension.

then retighten the upper mounting bolt and the lower

mounting nut to the specified torques

3. Recheck the tension of the belt

23-125

Page 1601 of 2189

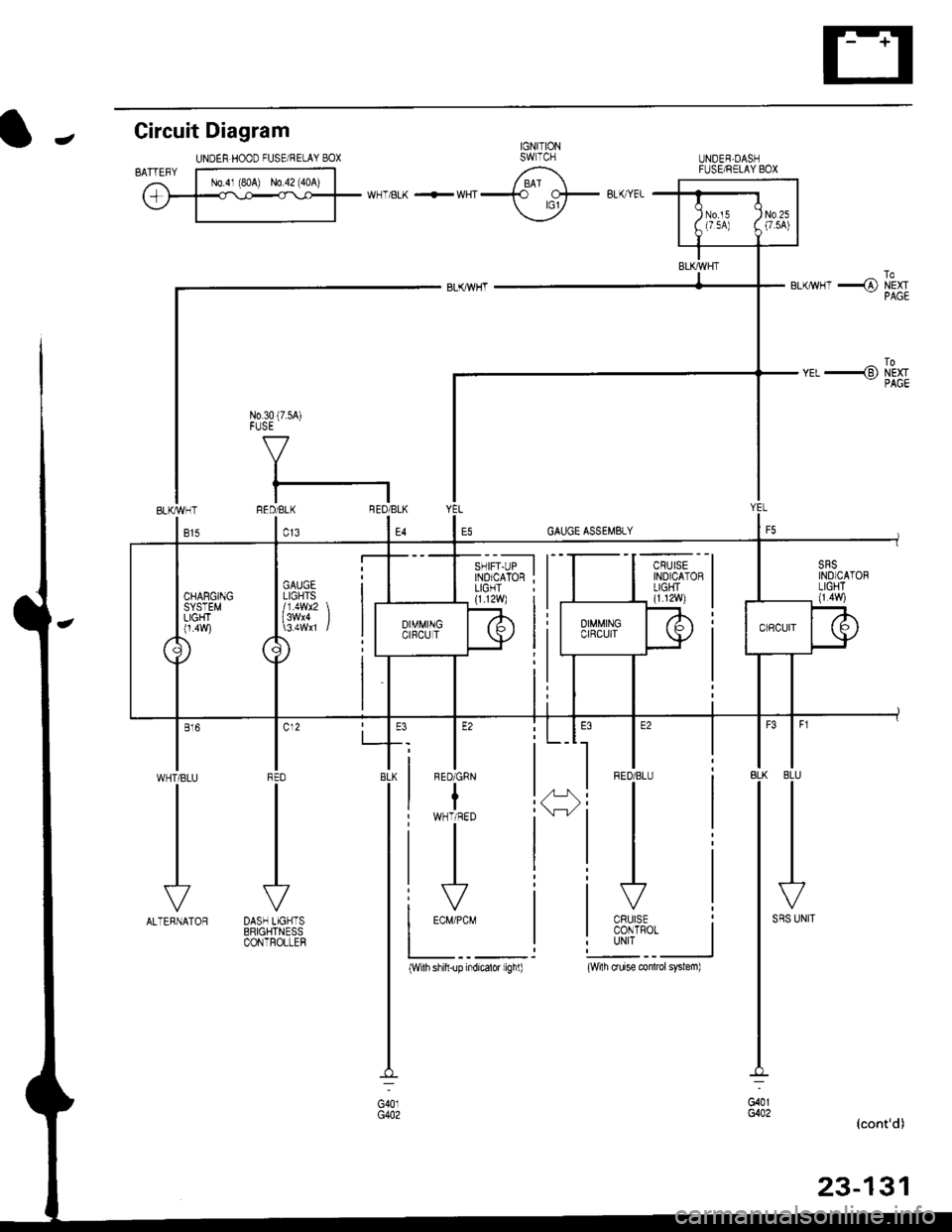

IJNOER,DASHFUSE/RELAY BOX

GAUGELIGHTS

l3wx4 l

CHARGINGSYSTEMLIGHT0.4w)

Gircuit Diagram

UNDEN HOOD FUSE/RELAY BOXIJ

N0.30 (7.54)FUSE

f7

I

tlRED/BLK BEO/BLK

l"l"8LK BLU

IJ

l'"^*

I

t-

G401G402

__l

tE2

IFED/BLU

CRUISECONTROTUNIT

fl ,,1:

tH

I c12

IFFD

VDASH LIGHTSBRIGHTNESSCONTROLLEF

l"'WHT/BLU

vALTERNATOR

(With shifi-up indicatd lighl)(wi1h cruise conlrcl system)

Page 1829 of 2189

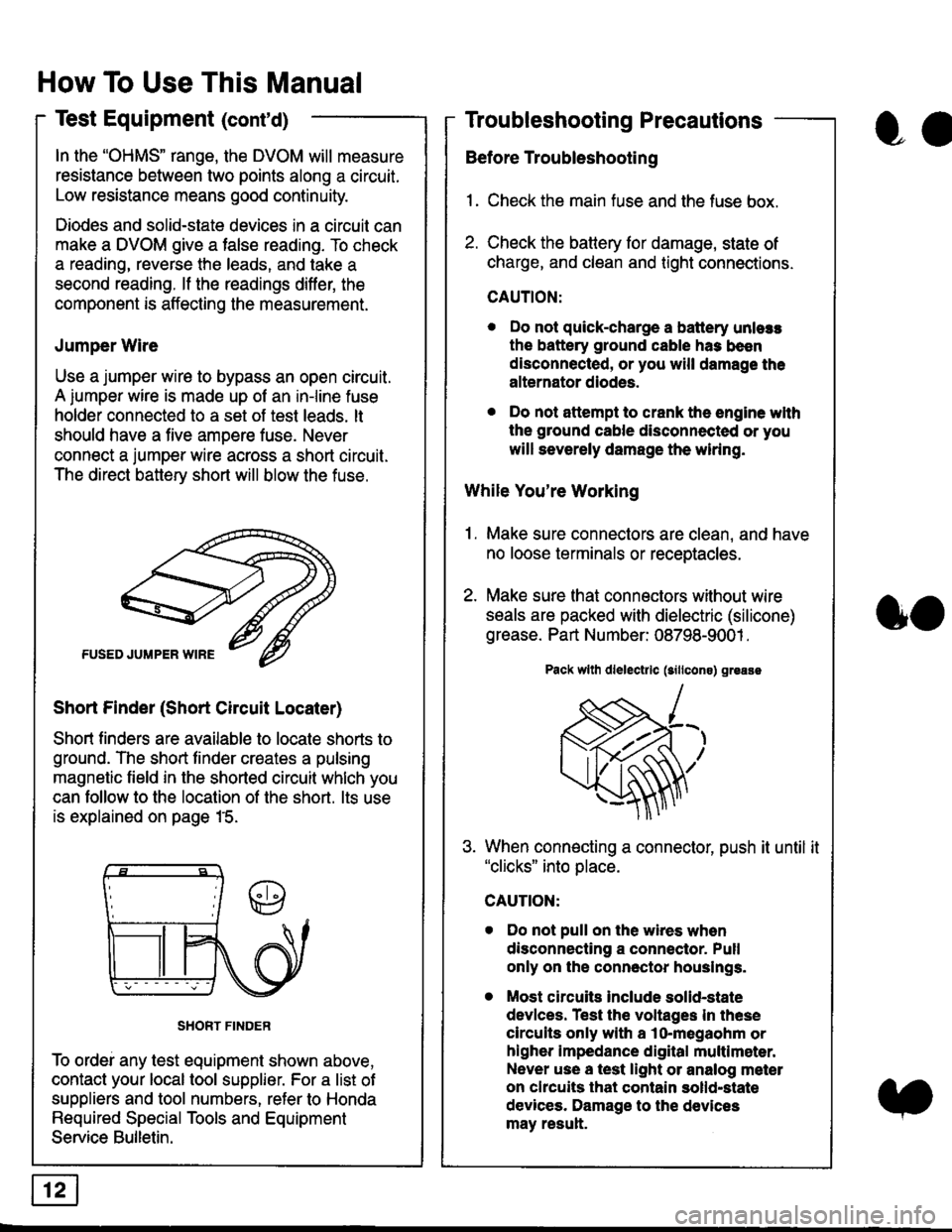

In the "OHMS" range, the DVOM will measure

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting lhe measurement.

Jumper Wire

Use a jumper wire to bypass an open circuit.

A iumper wire is made up ot an in-line fuse

holder connected to a set of test leads. lt

should have a five amoere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Short finders are available to locale shorts to

ground. The short tinder creates a pulsing

magnetic field in the shorted circuit whlch you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To ordei any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Honda

Required Special Tools and Equipment

Service Bulletin.

How To Use This Manual

Test Equipment (cont'd)

oa

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage, state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unlers

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine wlth

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receptacles.

2. Make sure lhat connectors without wire

seals are packed with dielectric (silicone)

grease. Part Number: 08798-9001 .

Pack wllh dlelectrlc (sillcons) greass

When connecting a connector, push it until it"clicks" into place.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector houslngs.

Most circuits Include solid-state

devlces. Test the voltages In these

circuits only with a lo-megaohm or

higher impedance digital multlm6ter.

Never use a test light or analog meter

on chcuits that contain solld-state

devices. Damage to the devices

may result.

oo

Page 1835 of 2189

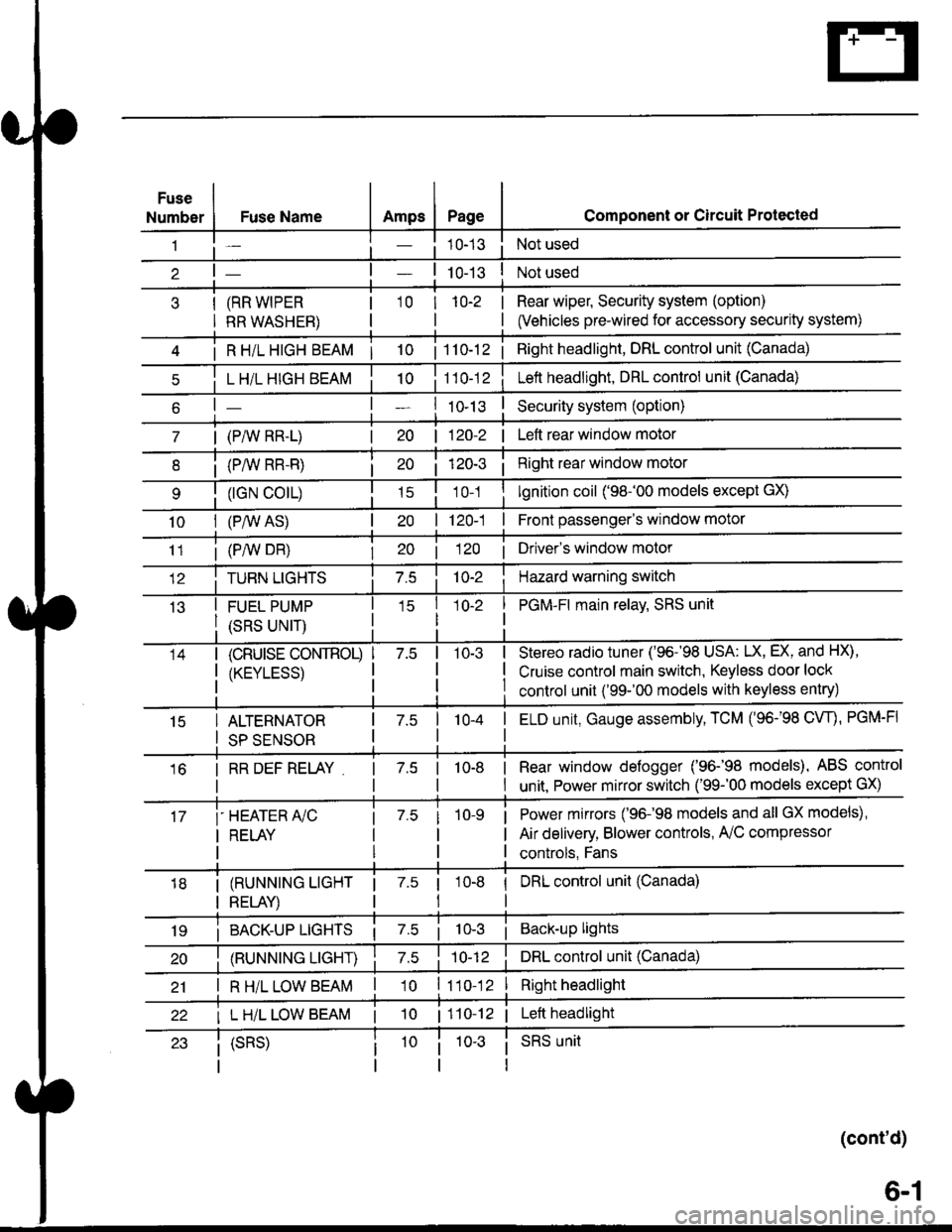

Fuse

NumberAmpsPageFuse Name

(RR WIPER

RR WASHER)

i R HiL HIGH BEAM | 10

L H/L HIGH BEAM

| (PAIV RR-L)

i (P/vv RR-R)

(rGN CO|L)

10I (P,^/V AS)

Component or Circuit Protected

Not used

Not used

Rear wiper, Security system (option)

(Vehicles pre-wired for accessory security system)

'10r 1n-2

I

| 1 10-12i Right headlight, DRL control unit (Canada)

Lett headlight, DRL control unit (Canada)

I ro-rsSecurity system (option)

| 120-2 | Left rear window motor

Right rear window motor

lgnition coil ('98-'00 models except GX)

| 120-1 | Front passenger's window motor

i (PiW DH)| 20 1 12O I Driver's window motor

TURN LIGHTSHazard warning switch

FUEL PUMP

(SRS UNIT)

PGM-FI main relav, SRS unit

(cRUrsE CoNTROL)

/KtrVt trSS\

Stereo radio tuner ('96-'98 USA: LX, EX, and HX),

Cruise control main switch, Keyless door lock

control unit ('99-'00 models with keyless entry)

15ALTERNATOR

SP SENSOR

l-a10-4I ELD unit, Gauge assembly, TCM (96-'98 CW, PGM-FI

16I RR DEF RELAY7.510-8I Rear window defogger ('96-'98 models), ABS control

I unit. Power mirror switch ('99-'00 models except GX)

i-HEATER r/C

I RELAY

Power mirrors ('96-98 models and all GX models),

Air delivery, Blower controls, AilC compressor

controls, Fans

I (RUNNING LIGHT

I RELAY)

1 7.5 1

tl

I DRL control unit (Canada)

i BACK-UP LTGHTSi Back-up lights

(RUNNING LIGHT)DRL control unit (Canada)

I R H/L LOW BEAM'10 l11o-12Right headlight

I L H/L LOW BEAM | 101110-12 | Left headlight

(cont'd)

(SRS)SRS unit

6-1

Page 1878 of 2189

Charging System

See PowerDistribution,pag6 10.

UNDER-HOODFUSE/RELAYBOX

FUSE 15ALT€IIIAIONsP SEII|SOF7.5A

I

t

USA

' BLKAVHTBLKI"VI/HT

-)l,------J

vtEw 50

See PowerDistribution,page 10-5.

* = 96-98rAllmodelsexcept 01685'99 '00: D16Y5 withi.4/T** = '96'�98: All models'99r00: D16Y5 witht\4/T, D1685

BATTERY

ALTERNATOR

See PowerDiskibution,page 10.

FUSE 41BATTEFY804

T101

L-----

ELECTFICALLOADDETECTOR(ELO) UNIT

'l

;l

:l

:l;l

:l

tl,l

:l

:l

G1!

- -I POWER-I -. ^ "'.1 , I rnlrn or

(.A1e)Y '('� C17)c2[ : cs

i ELD unit input i ietCrHe! ' ! coNrRoLI I MODULEI Art€rnator : lllerlato.r I (PCM or

i controrsrsnar i t",fl?il"' a:"^y]L- ----,1- - - - J Pq_oro 3'

*. B,'"',1; :.i

i:1E15_'_

_. i

GFN/FED

r i6

GFN/RED

A30

f D16)WHT/REO*Fi

See Ground IDistribution, Ipage 14-5. I

YT

L]

' ""- PHA|O

,.^;?f, :('c;3)T BLXYEL

I i 'r", ".o II'HT/ ll ' U,zscnrl :-' oi .l

, L : (c'r9ill-_- 'c11" 2)u

l9nitionrnput

LOaO

Ground ourpur

22

Page 2143 of 2189

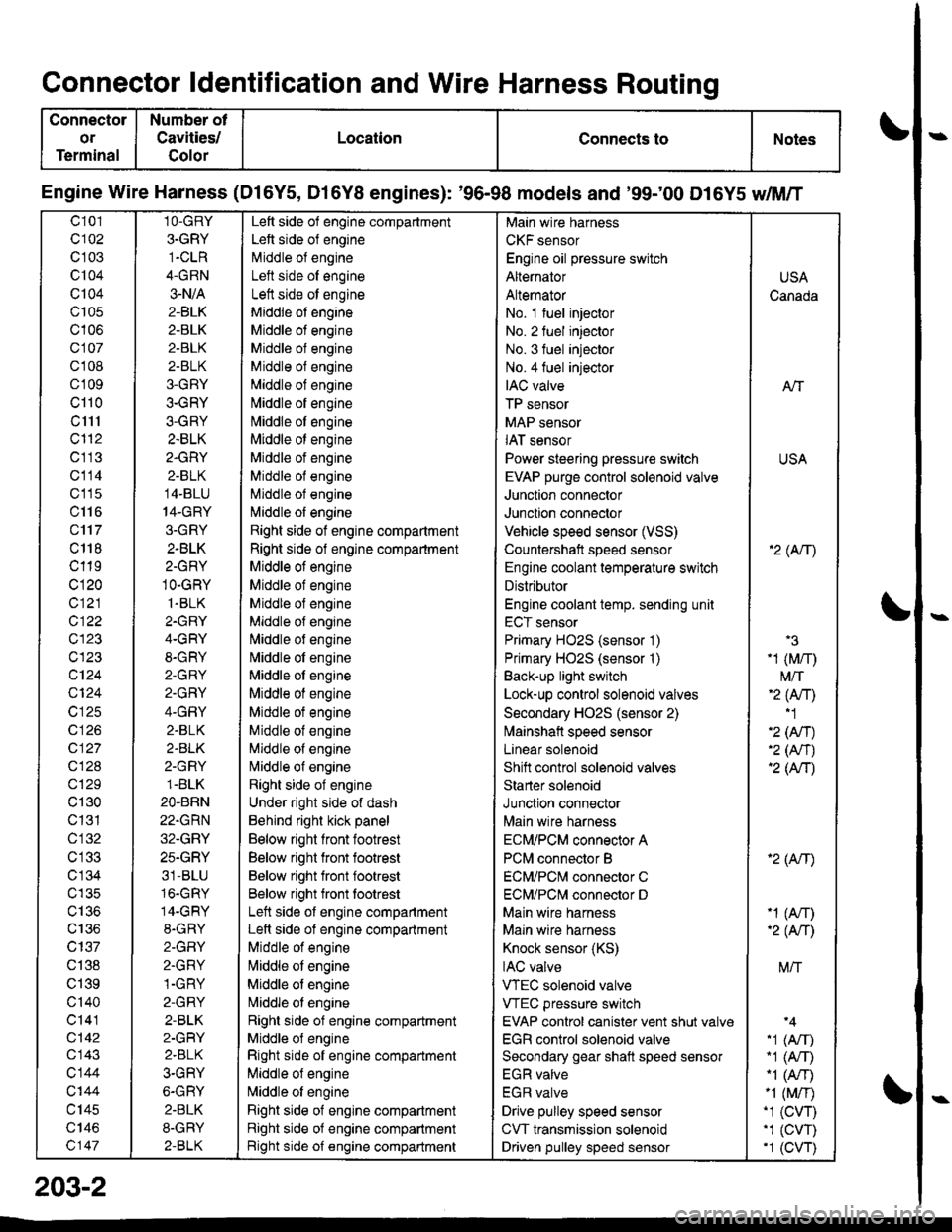

Connector ldentification and Wire Harness Routing

Connector

or

Terminal

Number ot

Cavities/

Golor

LocationConnects toNotes

Engine Wire Harness (Dl6Y5, D16Y8 engines): '96-98 models and '99;00 D16Y5 dM/T

c101

c102

c 103

c104

Q104

c105

c106

c107

cl 08

cl09

cl10

c1l1

cl'12

c113

c114

c'115

c116

c'117

c 118

c119

c120

c121

c122

c123

c123

c124

Q124

c125

c 126

c127

c128

c129

c130

c131

cl32

c 134

c135

c136

c137

c138

c139

c'140

c141

c142

c143

c144

c'|44

c145

c146

c147

1O-GRY

3.GRY

1-CLR

4-GRN

3-N/A

2-BLK

2-BLK

2-BLK

2-BLK

3-GRY

3-GRY

3-GRY

2.BLK

2.GRY

2-BLK

14-BLU

14-GRY

3.GRY

2-BLK

2-GRY

1O-GRY

1.BLK

2.GRY

4-GRY

8-GRY

2-GRY

2.GRY

4-GRY

2.BLK

2.BLK

2-GRY

1.BLK

2O.BRN

22.GRN

32.GRY

25.GRY

31-BLU

16.GRY

14-GRY

8.GRY

2-GFIY

2.GRY

1-GRY

2-GRY

2-BLK

2-GRY

2.BLK

3-GRY

6-GRY

2.BLK

8-GRY

2-BLK

Left side of engine compartment

Left side of engine

Middle of engineI att .i.la ^f an^i^6

Left side ot engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

[,liddle of engine

Middle ot engine

Middle ot engine

Middle of engine

Middle of engine

Middle of engine

l\,liddle of engine

Right side of engine compartment

Right side of engine compartment

Middle ot engine

Middle of engine

Middle of engine

Middle of engine

l\,liddle of engine

Nliddle of engine

Middle ot engine

Middle of engine

Middle ot engine

Middle of engine

Middle of engine

Nliddle of engine

Right side of engine

Under right side of dash

Behind right kick panel

Below right front footrest

Below right front footrest

Below right front footrest

Below right front tootrest

Left side ot engine compartment

Left side of engine compartment

Middle of engine

liliddle ot engine

Middle of engine

Nriddle ol engine

Right side of engine compartment

Middle ol engine

Right side of engine compartment

Middle of engine

N,liddle of engine

Right side of engine compartment

Right side of engine compartment

Bight side of engine compartment

Main wire harness

CKF sensor

Engine oil pressure switch

Alternator

Alternator

No. 1 fuel injector

No. 2 fuel injector

No. 3 fuel injector

No.4 fuel injector

IAC valve

TP sensor

MAP sensor

IAT sensor

Power steering pressure switch

EVAP purge control sol€noid valve

Junction connector

Junction connector

Vehicle speed sensor (VSS)

Countershatt speed sensor

Engine coolant temperature switch

Distributor

Engine coolant temp. sending unit

ECT sensor

Primary HO2S (sensor '1)

Primary HO2S (sensor '1)

Back-up light switch

Lock-up control solenoid valves

Secondary HO2S (sensor 2)

lvlainshafl speed sensor

Lanear solenoid

Shift control solenoid valves

Starter solenoid

Junction connector

Main wire harness

ECM/PCM connector A

PCM connector B

ECM/PCNI connector C

ECM/PCl\,,| connector D

Main wire harness

Maln wire harness

Knock sensor (KS)

IAC valve

VTEC solenoid valve

VTEC pressure switch

EVAP control canister vent shut valv€

EGR control solenoid valve

Secondary gear shatt speed sensor

EGR valve

EGR valve

Drive pulley speed sensor

CVT transmission solenoid

Driven pulley speed sensor

USA

Canada

AlT

USA

'2( tr\

'3

-1 (M/r)

t\4/T'2 (Anl'1

'2 (An)'2 (Nr)'2 (AtT)

'2 (Atr)

-1 (An)-2( fi|

M/T

.1 (Arr).1 (A,T)"1 (A/r)-1 (M/r).1 (CVT),1 (cw)'1 (CVT)

203-2