Bearing HONDA CIVIC 1999 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 621 of 2189

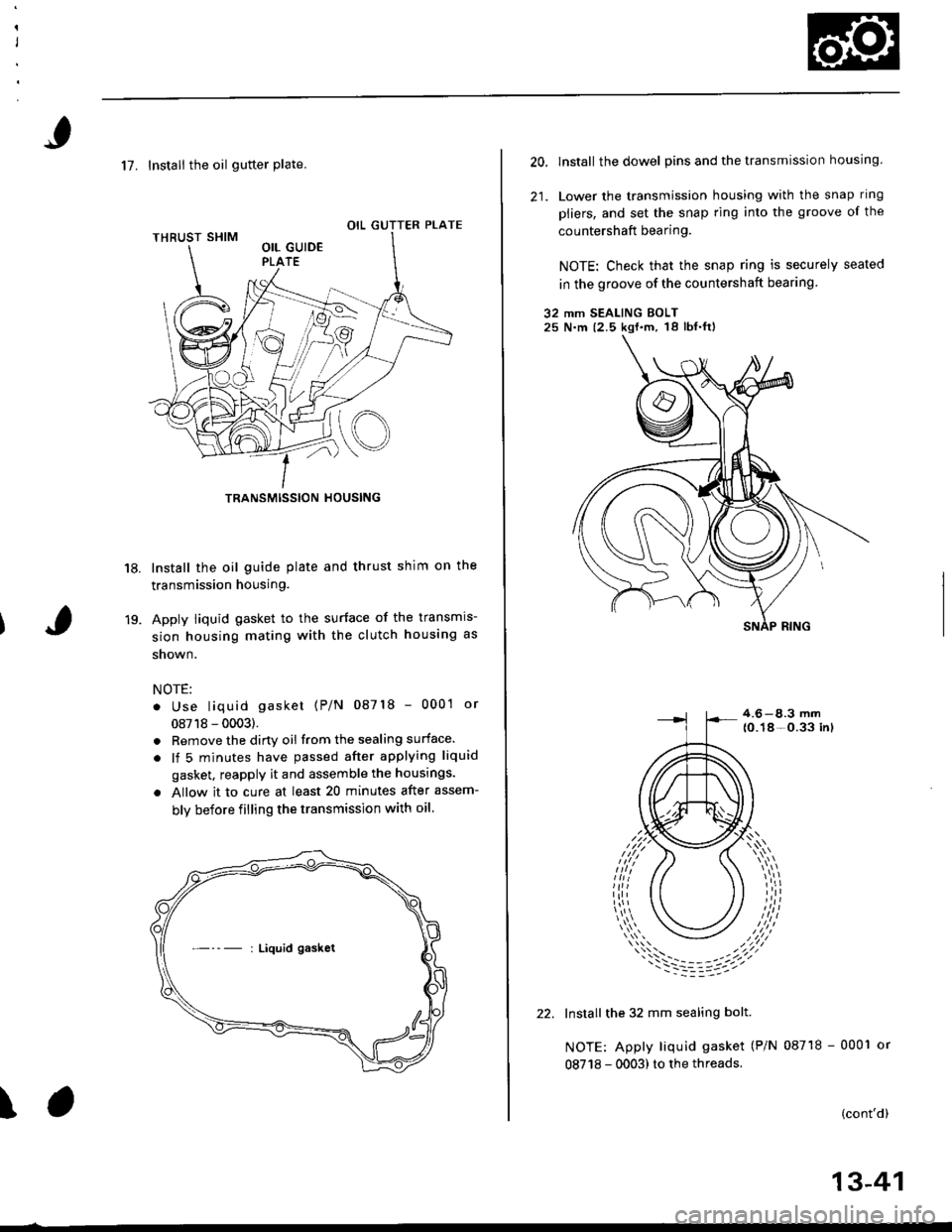

17. Instali the oil gutter Plate.

Install the oil guide plate and thrust shim on the

transmission housing.

Apply Iiquid gasket to the surface of the transmis-

sion housing mating with the clutch housing as

shown.

NOTE:

. Use liquid gasket {P/N 08718 - 0001 or

08718 - 0003).

. Remove the dirty oil fromthesealing surface.

. lf 5 minutes have passed after applying liquid

gasket, reapply it and assemble the housings.

. Allow it to cure at least 20 minutes after assem-

bly before filling the transmission with oil.

18.

19.

\

OIL GUTTER PTATE

TRANSMISSION HOUSING

Liquid gasket

20.lnstall the dowel pins and the transmission housing.

Lower the transmission housing with the snap ring

pliers, and set the snap ring into the groove of the

countershaft bearing.

NOTE: Check that the snap ring is securely seated

in the groove of the countershaft bearing

32 mm SEALING EOLT25 N.m (2.5 kgf.m, 18lbf.ftl

4.6 -8.3 mm10.14-0.33 inl

Install the 32 mm sealing bolt.

NOTE: Apply liquid gasket (P/N 08718 - 0001

08718 - 0003) to the threads.

(cont'd)

22.

13-41

Page 625 of 2189

S4C Model ('99 - 00 2-door Si, SiR)

Manual Transmission

Special Tools ............' 13-46

Maintenance

Transmission Oi1 ...................'.......... 13-47

Back-up Light Switch

Repfacement ...""" 13'47

Transmission Assembly

Removal ......'.......... 13-/tB

lnstallation ............. 13-52

lllustrated lndex ................................... 13-54

Transmission Housing

Removal ................. 13-55

Beverse Shift Holder, Reverse ldler Gear

Clearance lnspection ...................".. 13-57

Removal ................. 13-58

Change Holder Assembly

Clearance lnspection .................".... 13-59

Removal ....,,........... 13-61

Disassembly/Reassembly ............... 1 3-62

Mainshaft, Countershaft, Shift Fork

Removal ................. 13-63

Shift Rod

Removal .........."'.... 13-64

Shift Fork Assembly

lndex ................ ...... 13-65

Clearance lnspection .............'......... 13'66

Mainshaft Assembly

lndex ............"" ...... 13-67

Clearance lnspection ....................... 13-68

Disassembly .......... 13-71

fnspection '."'.......', 13'72

Reassembly .......'... 13-73

Countershaft Assembly

fndex ................ "....13-71

Glearance Inspection'......'...........'... 1 3'75

Disassembly .......... 13-76

fnspection .'............13'77

Reassembly "......... 13'78

Synchro Sleeve, Synchro Hub

Inspection .............. 13'8C

Installation ............. 13-80

Synchro Ring, Gear

Inspection .'............ 13-81

Differential

lndex ................ ...... 13-82

Backlash Inspection ..."..........."'...... 1 3-82

Final Driven Gear Replacement ...... 13-83

Bearing Replacement ....."'.......""'.. 13-83

Thrust Shim Adiustment ......""'..... 13-84

Clutch Housing Bearing

Replacement ..'...... 13-86

Mainshaft Thrust Glearance

Adiustment '.........'. 13-88

Transmission

Reassembly ."'....... 13-91

Oil Seals

Replacement ..'...... 13-96

Gearshift Mechanism

Overhaul ................ 13-97

\

Page 626 of 2189

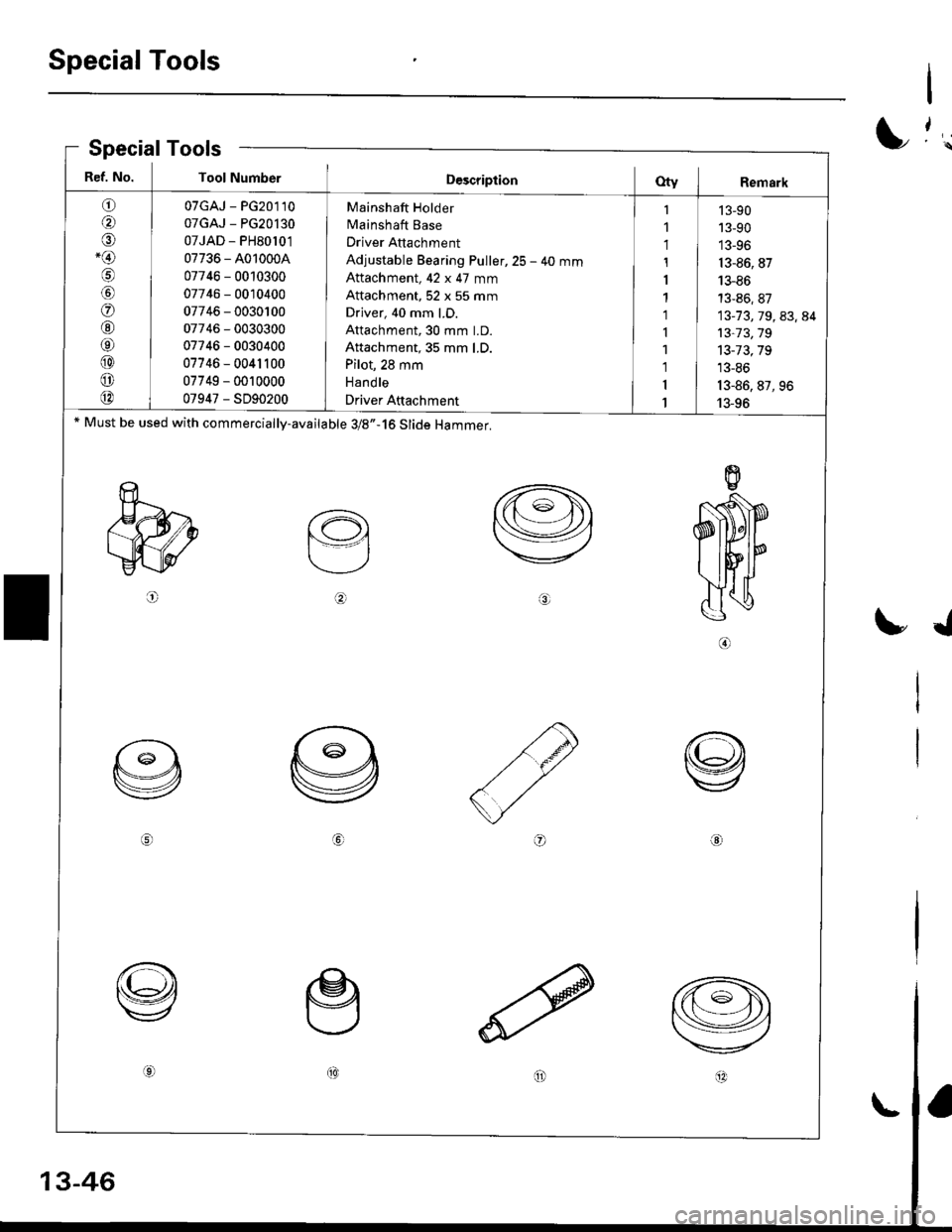

Special Tools

SpecialTools

I

I

I

./

Ref. No. Tool NumberD€scriptionOty I Remark

o

@

o-@

@

o

@

@

@

o

@

07GAJ - PG20110

07GAJ - PG20l30

07JAD - PH80l0'1

07736 - A010004

07746 - 0010300

07746 - 0010400

07746 - 0030100

07746 - 0030300

07746 - 0030400

07746 - 0041100

07749 - 0010000

07947 - SD90200

Mainshaft Holder

Mainshaft Base

Driver Attachment

Adjustable Bearing Puller,25 - 40 mm

Attachment, 42 x 47 mm

Attachment, 52 x 55 mm

Driver, 40 mm LD.

Attachment, 30 mm LD.

Attachment, 35 mm LD.

Pilot, 28 mm

Hand le

Driver Attachment

I

1

1

1

I

1'l

I

1

1

1'I

13-90

13-90

13-96

13-86, 87

13-86

13-86, 87

13-73,79,83,84

13-73,19

13-73,79

13-86

13-86,87,96

13-96* Must be used with commercially-available 3/8,,-16 Slide Hammer.

o

aol@(t4^

Page 632 of 2189

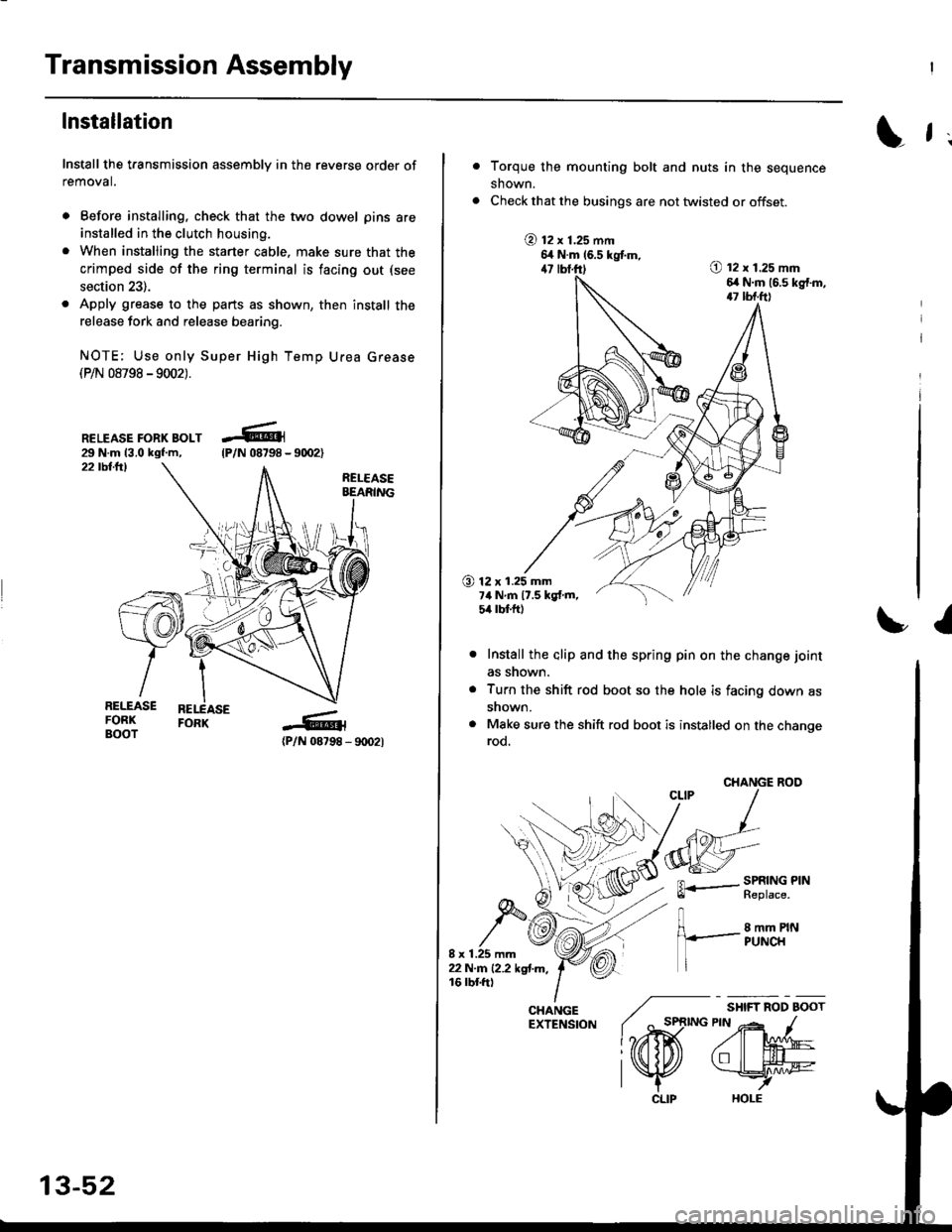

Transmission Assembly

lnstallation

Install the transmission assembly in the reverse order of

removal.

. Before installing, check that the two dowel pins are

installed in the clutch housing.

. When installing the starter cable. make sure that the

crimped side of the ring terminal is facing out (see

section 23).

. Apply grease to the parts as shown, then install the

release fork and release bearing.

NOTE; Use only Super High Temp Urea Grease(P/N 08798 -9002).

RELEASE FORK BOLT29 N.m 13.0 kgf.m,22 tbllrl

(P/N 08798 - 9rD2l

-R1

tP/N 08798 -

13-52

CLIP

L f ;

Torque the mounting bolt and nuts in the sequence

shown.

Check that the busings are not twisted or offset.

@ t2 x 1.25 mm6,t N.m 16.5 kgtm,47 lbf.ft)O t2 x 1.25 mm6,r N.m (6.s kg{.m,17 tbf.ft)

O 12 x 1.25 mm7ilNm17.5kgf.m,5it lbt ft)

I

Install the alip and the spring pin on the change joint

as snown.

Turn the shift rod boot so the hole is facing down as

snown.

Make sure the shift rod boot is installed on the changerod.

CHANGE ROO

FL.- SPRING PINll heptace,

8 mm PINPUNCH

/ "*,*

lo,iD(

CHANGE ./EXTENSfoN ( ^ st

l?rffi

l\K

Page 634 of 2189

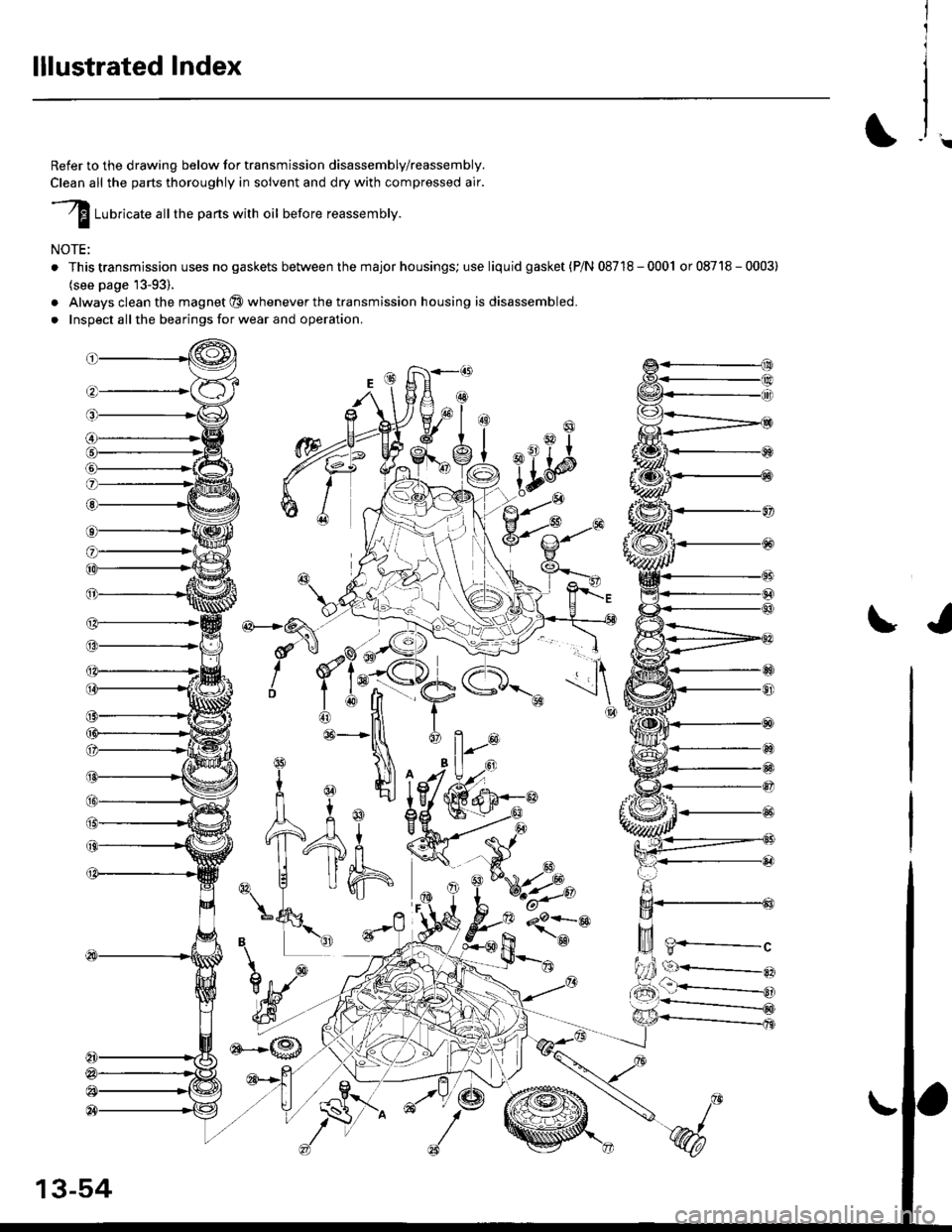

lllustrated Index

t

Refer to the drawing below for transmission disassembly/reassembly.

Clean all the parts thoroughly in solvent and dry with compressed air.

I Luoricate att the pans with oil before reassembly.

NOTE:

. This transmission uses no gaskets between the majorhousings; use liquid gasket (P/N 08718-0001 or08718-0003)

(see page '13-93).

. Always clean the magnet @ whenever the transmission housing is disassembled.

. Inspect all the bearings for wear and operation.

?-c

\I

ir 6d

a h Plt tia.fl

) K1T\A

l,l 1r

@rt? u

L6q

i"\^Br 'u

t@)

E,M A

#&f

o-*ffiX,

@

I

R

h"ii

'F@

,

€D

13-54

Page 635 of 2189

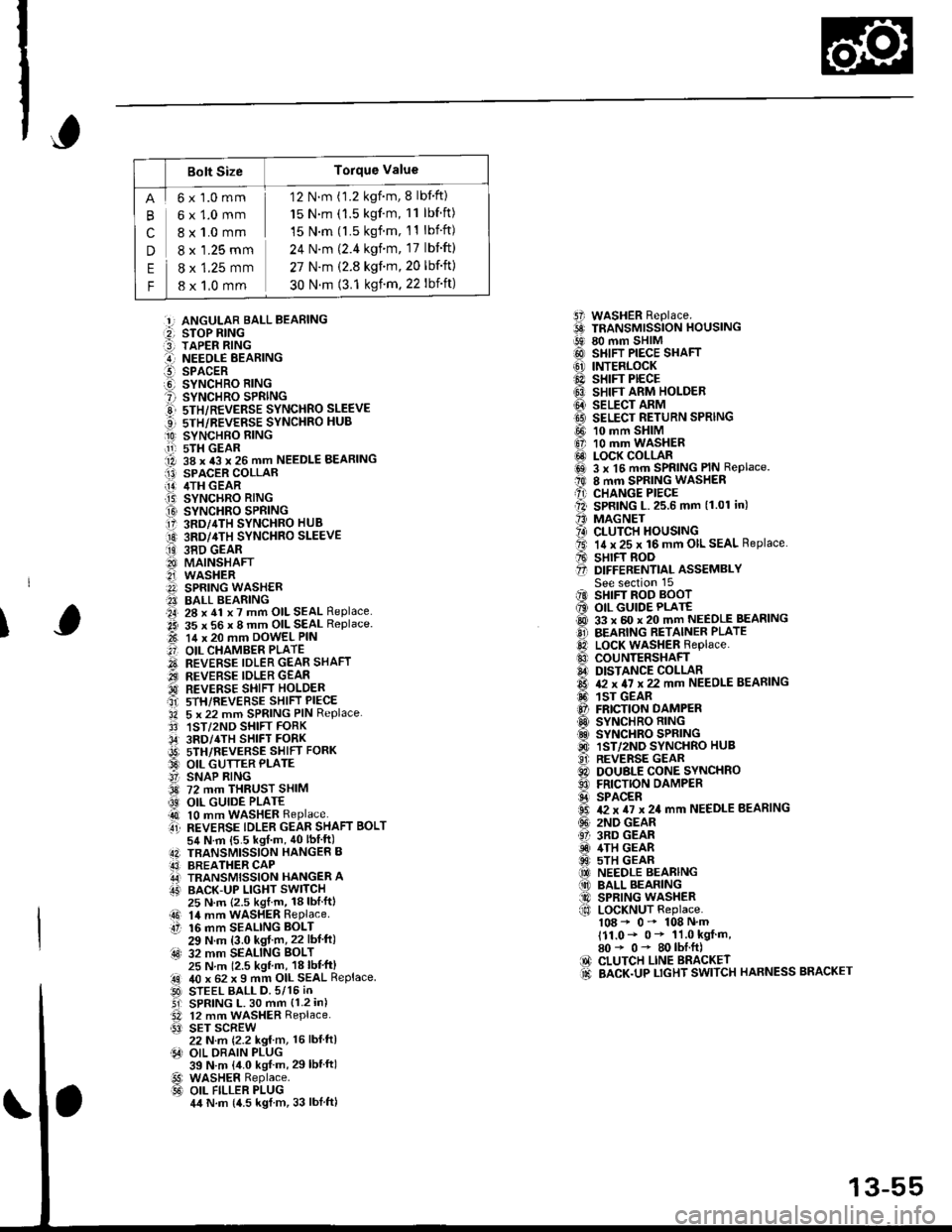

Bolt SizeTorque Value

cn

E

F

6x1.0mm

6x1.0mm

8 x 1.0 mm

8 x '1.25 mm

8 x 1.25 mm

8 x 1,0 mm

12 N.m (1.2 kgnm, 8 lbf'ft)

15 N.m (1.5 kgf'm, 11 lbf ft)

15 N.m (l.5 kgf.m, 11 lbift)

24 N'm (2.4 kgim, 17 lbift)

27 N.m (2.8 kgf.m,20 lbf'ft)

30 N.m (3.1 ksf m. 22 lbift)

5i WASHER Replace.6 TRANSMrssioN HouslNG!9 80 mm SHIM@ SHIFT PIECE SHAFT(6' INTERLOCK@ sHrFr PECE6} SHIFT ARM HOLDER@ seucr nnrvtI9 SELECT RETURN SPRING

@ 10 mm SHIM6, 10 mm WASHER@ LOCK COLLARi6sl 3 x l5 mm SPRING PIN Replace.t0 8 mm SPRING WASHERA) CHANGE PIECEll SPRING L.25.6 mm (1.01 in)'' MAGNET?4) CLUTCH HOUSINGta. 14 x 25 x 16 mm OIL SEAL Replace.A sHrFT BooO D|FFERENT|aL ASSEMBLYSee section 15iIO SHIFT ROD BOOT6 OIL GUIDE PLATE@ 33 x 60 x 20 mm NEEDLE BEASINGO BEARING RETAINER PLATElD LocK WASHER Replace..0 couNTERSHAFIA DISTANCE COLLAR6 & x 4I x 22 mm NEEDLE BEARING6. 1sr GEAR@ FRICTION DAMPERO SYNCHRO RING.d SYNCHRO SPRING@ 1ST/2ND SYNCHRO HUB..9i. REVERSE GEARC) DOUBLE CONE SYNCHROO FRICTION DAMPERS SPACER6 T2 x TI x 24 mm NEEDLE BEARING(!' 2ND GEAR61 3RD GEARiD 4TH GEAR@ 5TH GEAR(O NEEDLE BEARING(10 BALL BEARING@ SPRING WASHERf,o LoCKNUT Replace.108 - 0- 108 N'm111.0- 0* 11.0 kgf m,80* 0- 80lbI.ft)IO CLUTCH LINE BRACKET.d BACK.UP LTGHT SWITCH HARNESS BRACKET

:!, ANGULAR BALL BEABING:2, STOP RING:3] TAPER RING..-I NEEOLE BEARINGl!-- SPACERO SYNCHRO RING? SYNCHRO SPRINGE 5TH/REVERSE SYNCHRO SLEEVE...] sTH/REVERSE SYNCHRO HUB

O SYNCHBO EING.11-r sTH GEAR1A 38 x 43 x 26 mm NEEDLE BEARINGI13) SPACER COLLAR[!] /ITH GEAR.T5) SYNCHRO RING

O SYNCHRO SPRING17 3RD/4TH SYNCHRO HUB

O 3RD/4TH sYNcHRo SLEEVE

ii9 38D GEAR8I MAINSHAFT2i WASHERA SPRING WASH€R?I BALL BEARING.a4, 28 x 41 x 7 mm OIL SEAL Replace..2i 35 x 56 x 8 mm OIL SEAL Replace.t-t 14 x 20 mm DowEL PIN

.'] OIL CHAMBER PLATE

O REVERSE IDLER GEAR SHAFT.iI.., REVERSE IDLER GEAR'd REVERSE SHIFI HOLDERait srH/REVERSE sHIFT PIECE'34 5 x 22 mm SPRING PIN Replace.3' 1ST/2ND SHIFT FORK,34' 3RD/4TH SHIFT FORKi9t) srH/nevense sstrr ronx33 OIL GUTTER PLATE!' SNAP RING3d 72 mm THRUST SHIM

@ OIL GUIDE PLATE4t 10 mm WASHER Replaceti REVERSE TDLER GEAR SHAFT BoLT54 N.m {5.5 kgf m, 40lbIft)4N TBANSMISSION HANGER B43] BREATHER CAPA,J TRANSMISSION HANGER AIT' BACK-UP LIGHT SWITCH

I

25 N.m {2.5 kgl.m, 18lblftl14 mm WASHER RePlaceaO 14 mmtt 16 mm16 mm SEALING BOLT29 N.m (3.0 kgf m,22 lbf ft):4s) 32 mm SEALING BoLT25 N m 12.5 kgl m, 18 lbl'ft)40 x 62 x I mm OIL SEAL ReplaceSTEEL BALL D.5/15 iNSPRING L. 30 mm {1.2 in)12 mm WASHER Replace.SET SCREW22 N.m {2.2 kg{ m, 16 lbl ftlOIL DRAIN PLUG39 N.m {4.0 kgf m, 29lbtftlWASHER Replace.OIL FILLER PLUG4,t N.m {4.5 kgl m, 33 lblftl

.!rl00

@l

13-55

Page 647 of 2189

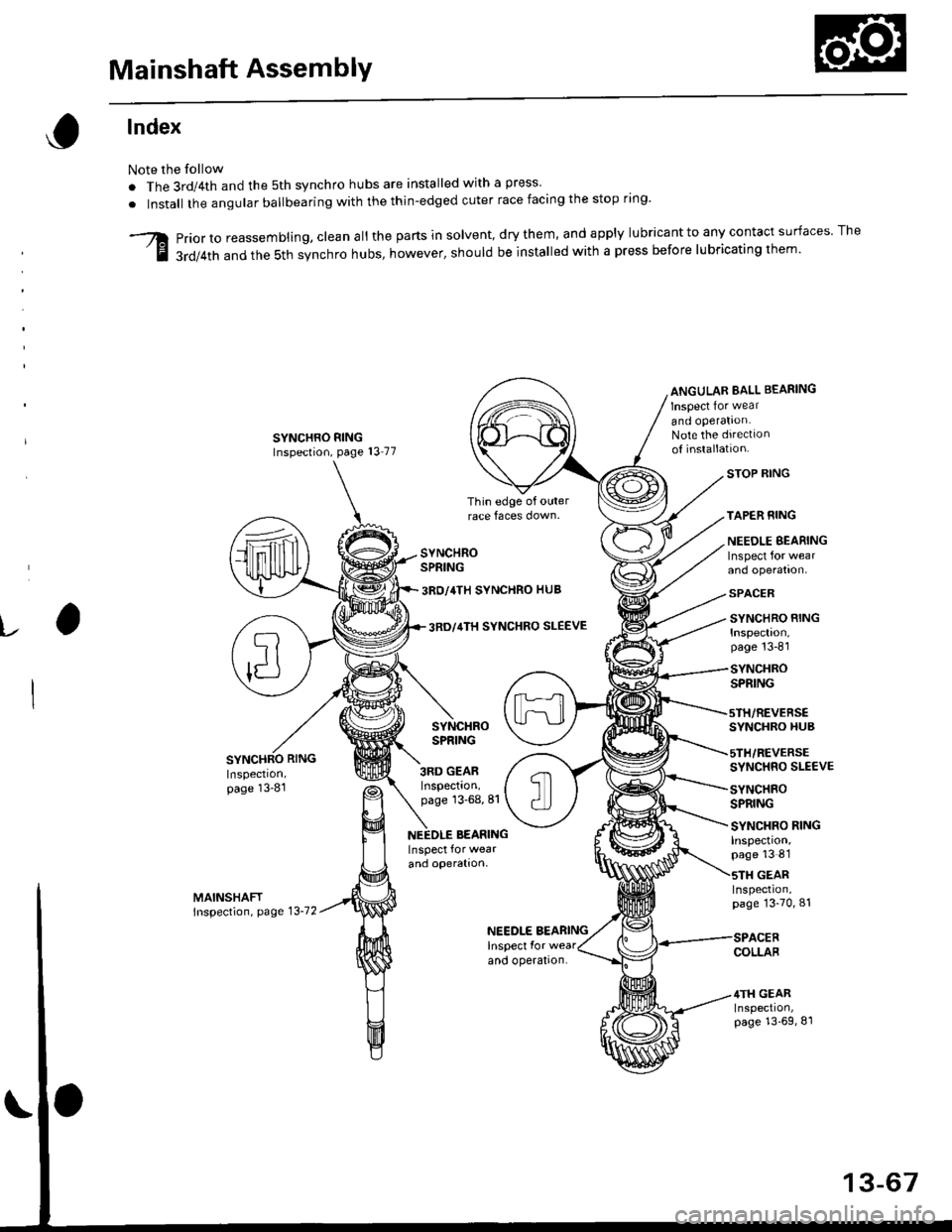

Mainshaft AssemblY

lndex

Note the follow

. The 3rd/4th and the 5th synchro hubs are installed with a press

. Install the angular ballbearing with the thin-edged cuter race facing the stop rrng'

Priorto reassembling. clean all the parts in solvent,drythem, and apply lu brica nt to any contact su rfaces The

3rd/4th and the sth synchro hubs, however, should be installed with a press before lubricating them'

ANGULAR BALL BEARING

Inspect lor wear

and operation.Note the drrectlonoI installatton.

v

SYNCHROSPRING

3RO/4TH SYNCHRO HUB

3RD GEARInspection,page 13-68,81

3RO/4TH SYNCHRO SLEEVE

SYNCHROSPRING

STOP RING

TAPER RING

NEEOLE EEARINGInspect for wearand operation.

SPACER

SYNCHRO RINGInspection.page 13-81

SYNCHROSPRING

SYNCHRO HUB

5TH/REVERSESYNCHRO SLE€VE

SYNCHEOSPRING

Inspection,page 13-81

NEEDLE BEARING

and operation.

SYNCHRO RINGInspection,page 13 8'1

GEARInspeclron,page 13-70,81

NEEDLE BEARINGInspect Ior wear

and operation.COLLAB

4TH GEARInspection,page 13'69,81

13-67

Page 651 of 2189

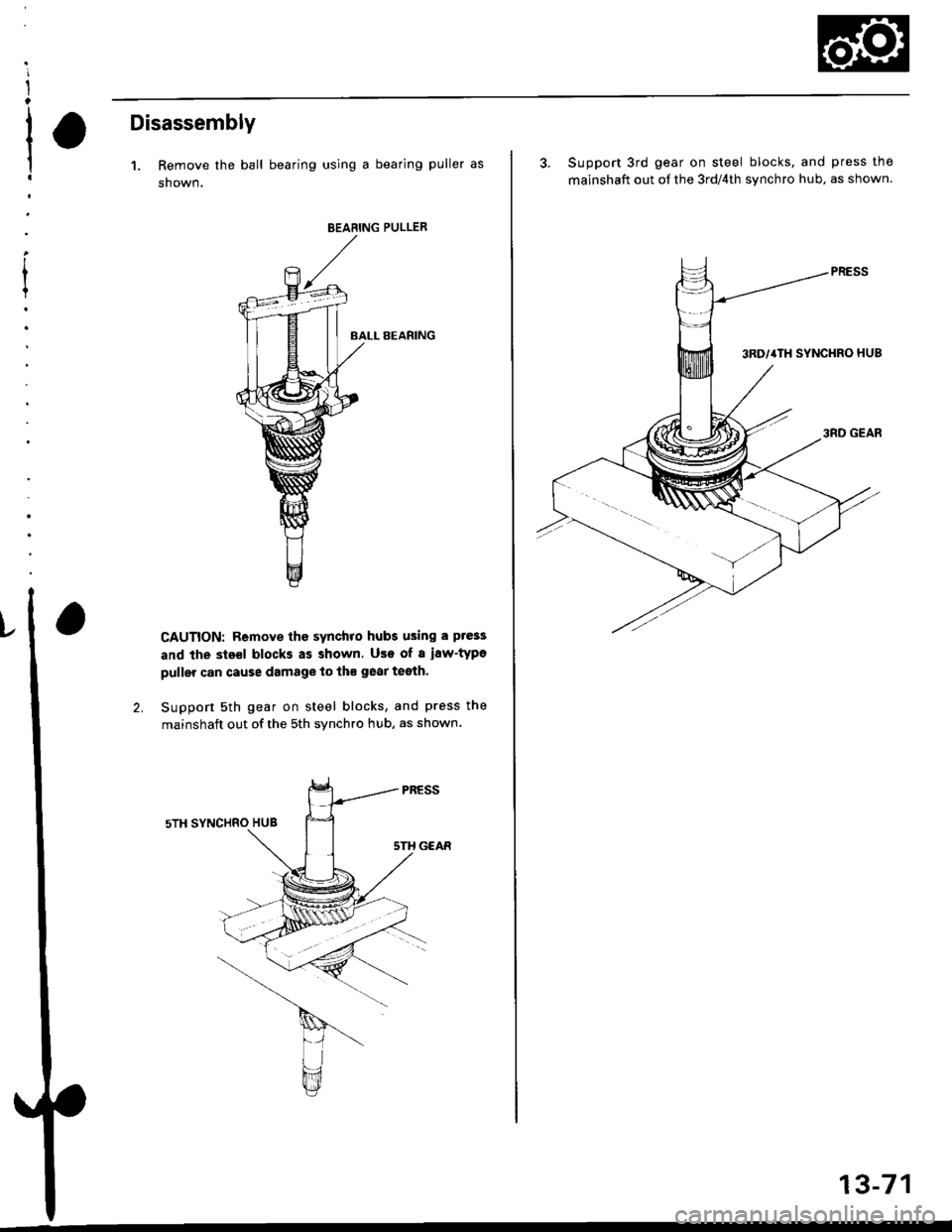

Disassembly

1. Remove the ball bearing using a bearing puller as

shown.

BEABING PULLER

BALL BEARING

CAUTION: Remove the synchro hubs using a ptess

and the sts€l blocks as shown. Use of a i8w'type

puller can cause damage to th€ gear teeth.

Support sth gear on steel blocks, and press the

mainshaft out of the sth synchro hub, as shown.

3. Support 3rd gear on steel blocks, and press the

mainshaft out of the 3rd/4th svnchro hub, as shown.

13-71

Page 652 of 2189

Mainshaft Assembly

Inspection

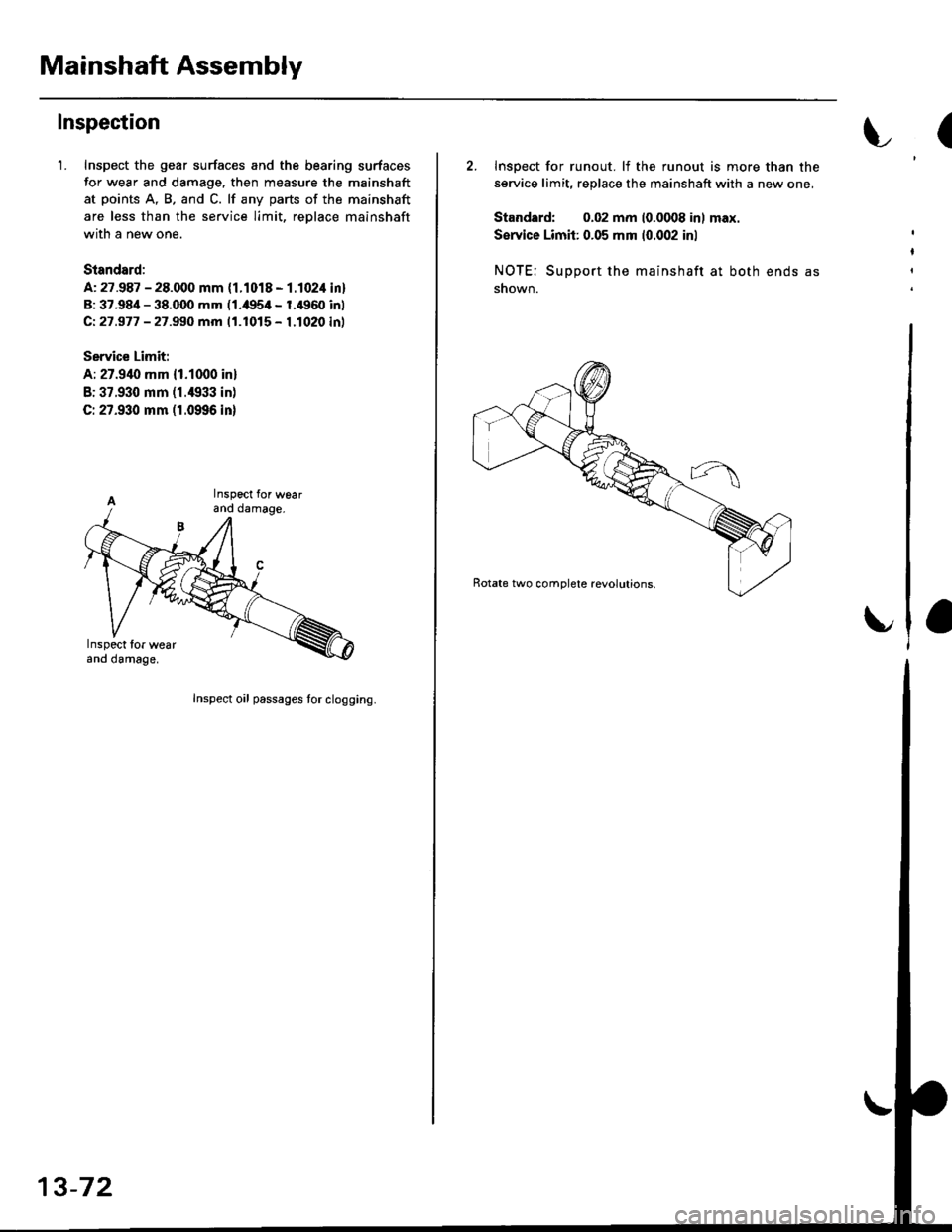

1. Inspect the gear surfaces and the bearing surfaces

for wear and damage. then measure the mainshaft

at points A, B, and C. lf any parts of the mainshaft

are less than the service limit, reDlace mainshaft

with a new one.

Standard:

A: 27.987 - 28.000 mm {1.1018 - 1.1024 in}

B: 37.98i1 - 38.fi)0 mm (1.,|!t5,0 - 1.4960 inl

Ci27.977 - 27.990 mm 11.1015 - 1.1020 inl

Service Limit:

A; 27.940 mm {1.1000 in}

B: 37.930 mm (1./{133 in)

C:27.930 mm (1.0996 inl

(

2. Inspect for runout. lf the runout is more than the

service limit, replace the mainshaft with a new one,

Standard: 0.02 mm 10.0008 inl max.

Ssrvice Limit: 0.05 mm 10.002 inl

NOTE: Suooort the mainshaft at both ends as

shown.

t

Inspect for wearano oamage.

Inspect oil passages tor clogging.

13-72

Page 653 of 2189

Reassembly

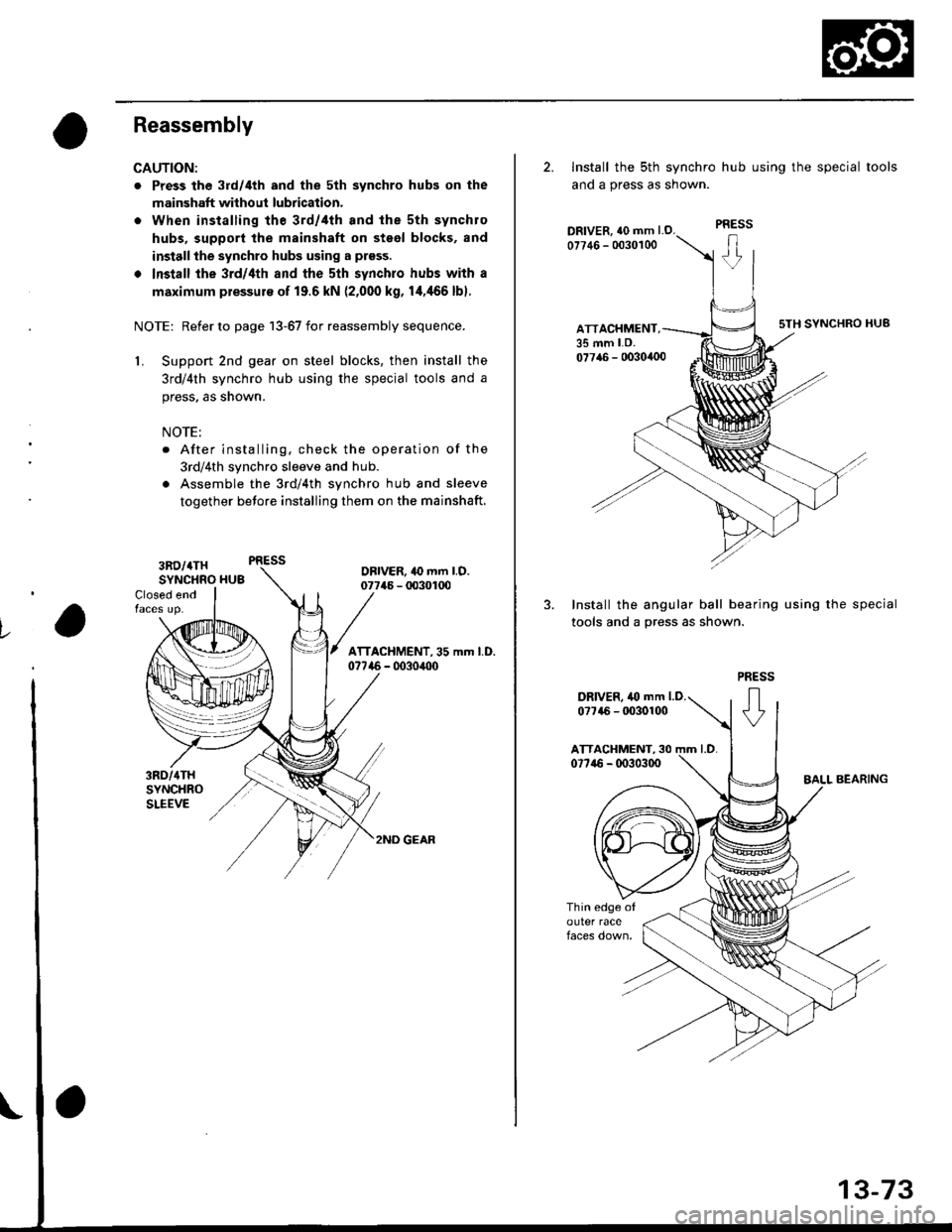

CAUTION:

. Press the 3rd/4th and the 5th synchro hubs on the

mainshaft without lubrication.

o When installing the 3rd/,lth and the sth synchro

hubs, support the mainshaft on steel blocks, and

installthe synchro hubs using a prsss.

. Install the 3rd/4th and the sth synchro hubs with a

maximum plessur€ of 19.6 kN (2,000 kg, 14,466 lbl.

NOTE: Refer to page 13-67 for reassembly sequence.

1, Support 2nd gear on steel blocks, then install the

3rd/4th synchro hub using the special tools and a

press, as snown.

NOTE:

. After installing. check the operation of the

3rd/4th synchro sleeve and hub.

. Assemble the 3rd/4th synchro hub and sleeve

together betore installing them on the mainshaft.

Closed end

3RD/4THSYNCHRO HU3DBIVER, 10 mm l.O.07746 - 00301U)

/ lrrlcHlileNr. ss .- t.o.07746 - 0030,100

l.

3RD/{THSYNCHROSLEEVE

2ND GEAR

2. Install the sth synchro hub using the special tools

and a press as snown.

DRIVER, {0 mm l.O.07746 - 0030100

ATTACHMENT,35 mm LD.

sTH SYNCHRO HUB

07716 - 0030,100

3. Install the angular ball bearing using the special

tools and a press as shown.

PRESS

+

DRIVER, 40 mm LD.0?7a6 - It030100