Seat HONDA CIVIC 1999 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1037 of 2189

Driveshafts

Removal (cont'd)

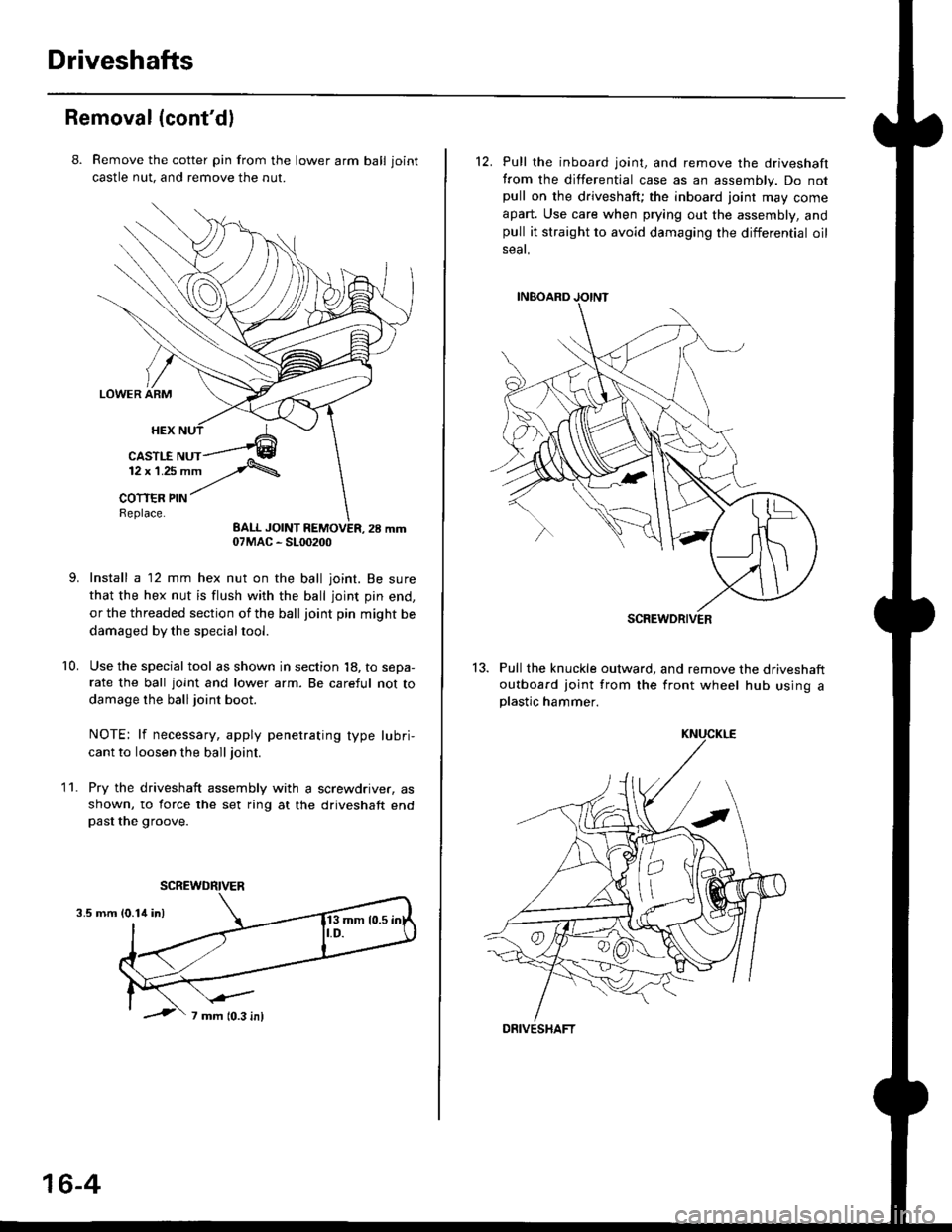

8. Remove the cotter pin from the lawer arm ball joint

castle nut. and remove the nut.

Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end,

or the threaded section of the ball joint pin might be

damaged by the special tool.

Use the special tool as shown in section 18, to sepa-

rate the ball joint and lower arm. Be careful not to

damage the ball joint boot.

NOTE: lf necessary, apply penetrating type lubri,

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft endpast the groove.

10.

11.

3.5 mm

07MAC - SL00200

SCREWDRIVER

16-4

12. Pull the inboard joint, and remove the driveshaft

from the differential case as an assembly. Do notpull on the driveshaft; the inboard joint may come

apart. Use care when prying out the assembly, andpull it straight to avoid damaging the differential oil

seat.

13. Pull the knuckle outward, and remove the driveshaft

outboard joint from the front wheel hub using aplastic hammer.

SCREWDRIVER

DRIVESHAFT

Page 1044 of 2189

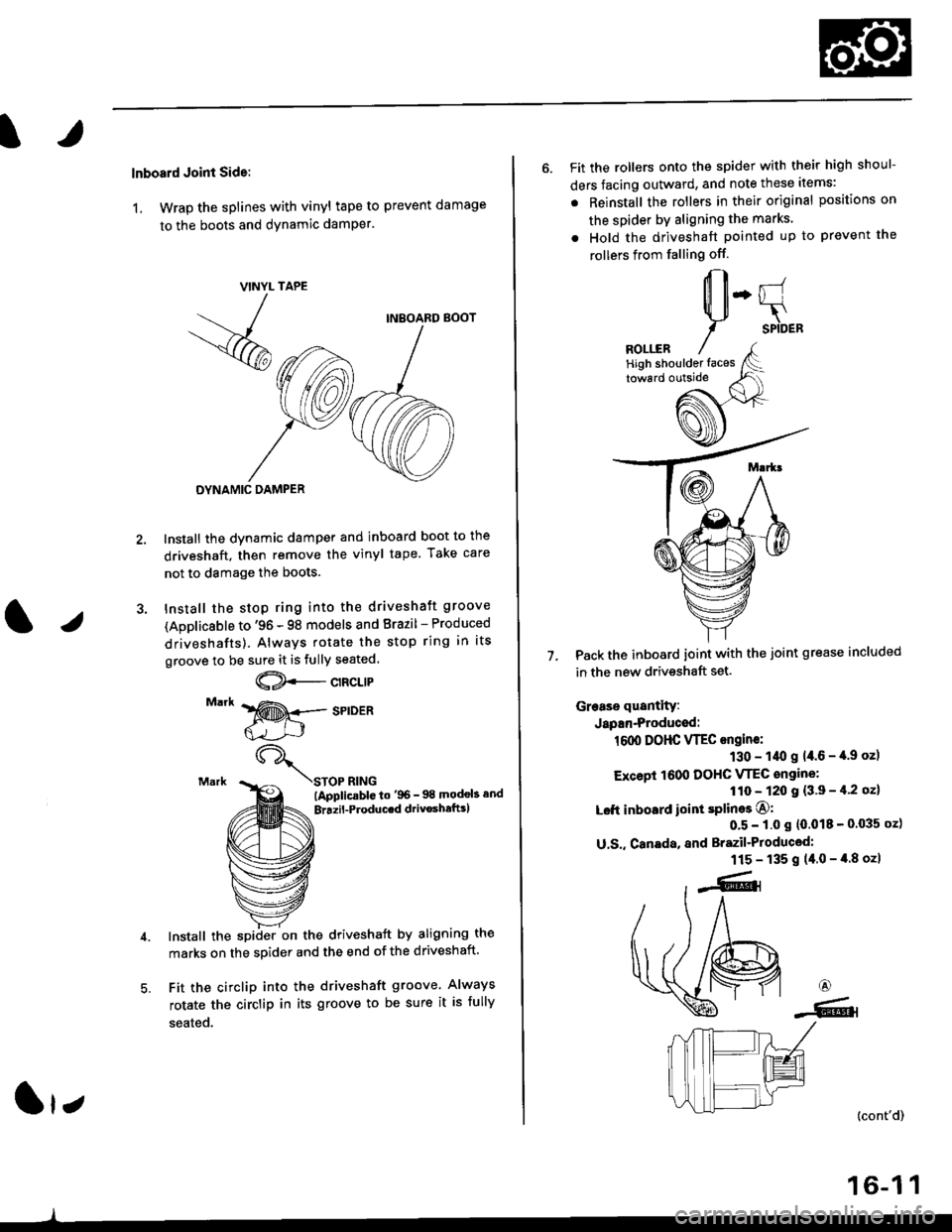

lnboard Joint Side:

1, Wrap the splines with vinyl tape to prevent damage

to the boots and dynamic damPer.

TAPE

INBOARD BOOT

DYNAMIC DAMPER

Install the dynamic damper and inboard boot to the

driveshaft, then remove the vinyl tape. Take care

not to damage the boots.

Install the stop ring into the driveshaft groove

(Applicsble to '96 - 98 models and Brazil - Produced

driveshafts). Always rotate the stop ring in its

groove to be sure it is fully seated.

@--c't"t't

STOP RING(ApplicablG to'96- 98 modob and

Brrzil-Producrd drivoshaftrl

Install the spiiler on the driveshaft by aligning the

marks on the sDider and the end of the driveshaft.

Fit the circlip into the driveshaft groove. Always

rotate the circlip in its groove to be sure it is fully

seated.

VINYL

- -

/

-<@

lr;

6. Fit the rollers onto the spider with their high shoul-

ders facing outward, and note these items:

. Reinstall the rollers in their original positions on

the spider by aligning the marks

. Hold the driveshaft pointed up to prevent the

rollers from falling off.

Pack the inboard joint with the joint grease included

in the new driveshaft set.

Grease quantity:

Japan-Produced:

1600 DOHC VTEC ongine:

130 - 1/t0 g 14.6 - '[.9 oz)

Except 1600 DOHC VTEC angine:

110 - 120 I {3'9 - il'2 oz}

Left inboard ioint splines O:

0'5 - 1.0 s (0.018 - 0'035 oz)

U.S,, Canada, and Brazil'Produced:

115 - 135 g (40-4.8ozl

7.

6

-6.l

(cont'd)

16-1 1

High shoulder faces

Page 1045 of 2189

Driveshafts

Reassembly (cont'dl

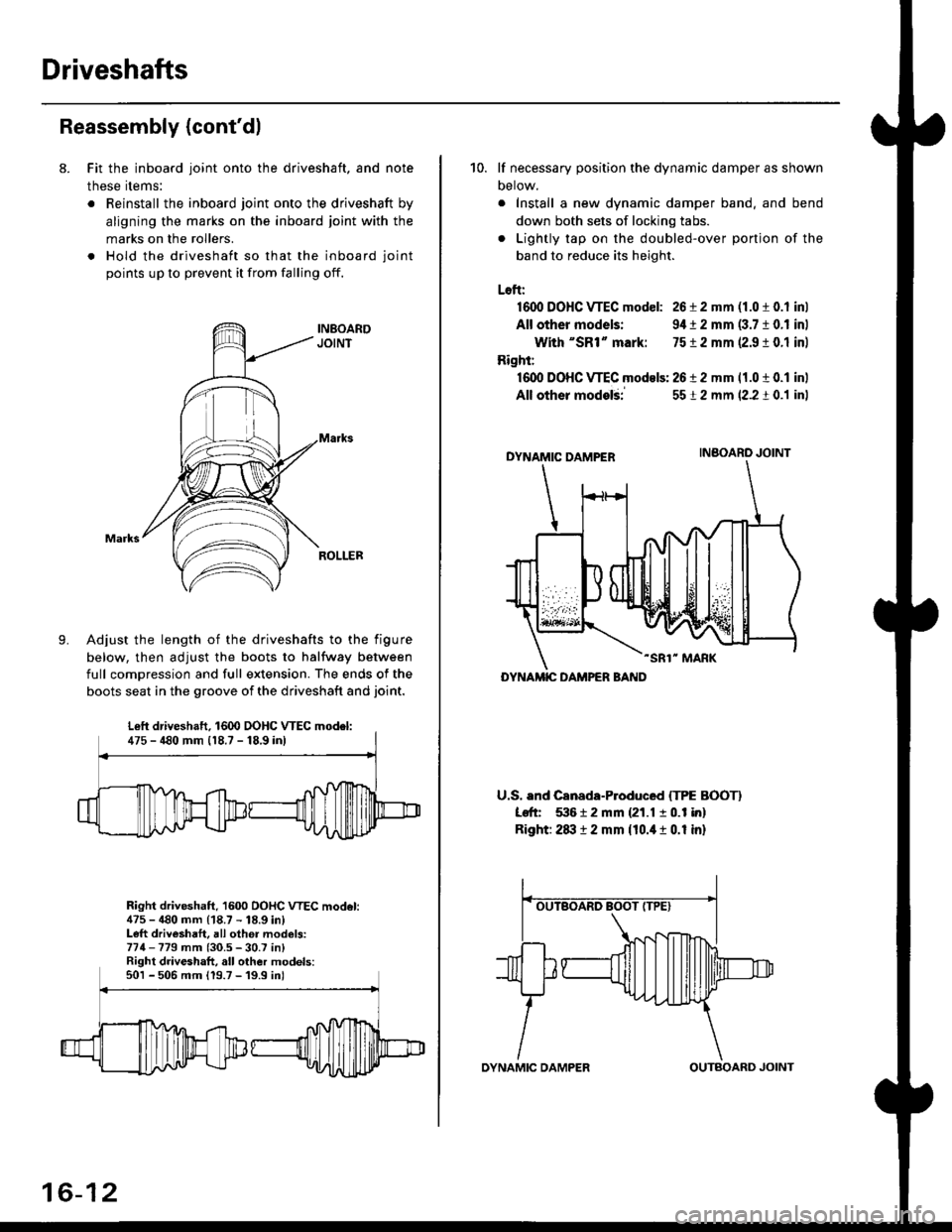

8. Fit the inboard joint onto the driveshaft, and note

these items:

. Reinstall the inboard joint onto the driveshaft by

aligning the marks on the inboard joint with the

marks on the rollers.

. Hold the driveshaft so that the inboard joint

points up to prevent it from falling off.

Adjust the length of the driveshafts to the figure

below, then adjust the boots to halfway between

full comDression and full extension. The ends of the

boots seat in the groove of the driveshaft and joint.

Right driveshaft, 1600 OOHC VTEC model:475 - 480 mm (18.7 - 18.9 in)Left driveshaft, all othei models:774-779 mm (30.5 - 30.7 in)Right driveshaft, all other models:501 - 506 mm 119.7 -'19.9 inl

Left driveshaft. 1600 DOHC WEC model:475 - 480 mm 118.7 - 18,9 inl

16-12

OYNAMIC DAMPEROUTBOARD JOINT

10. lf necessary position the dynamic damper as shown

Detow.

. Install a new dynamic damper band. and bend

down both sets of locking tabs.

. Lightly tap on the doubled-over ponjon of the

band to reduce its height.

Loft:

1600 DOHC VTEC model: 26 i 2 mm (1.0 t 0.1 inl

All other models: 9,1t 2 mm (3.7 10.1 inl

With "SR1" mark: 7512 mm 12.9 ! 0.1 inl

Right:

16dl DOHC VTEC models: 2612 mm 11.0 t 0.1 inl

All other modelii

DYNAMIC DAMPER

-SR1" MARK

U.S. and Canada-Produced ITPE BOOTI

Left 53612 mm {21.1 10.1 in}

Right: 2txt 12 mm {10.it 1 0.1 in}

5512 mm (2.2 t 0.1 inl

INBOARO JOINT

DYNAMIC DAMPER BAND

Page 1048 of 2189

J)

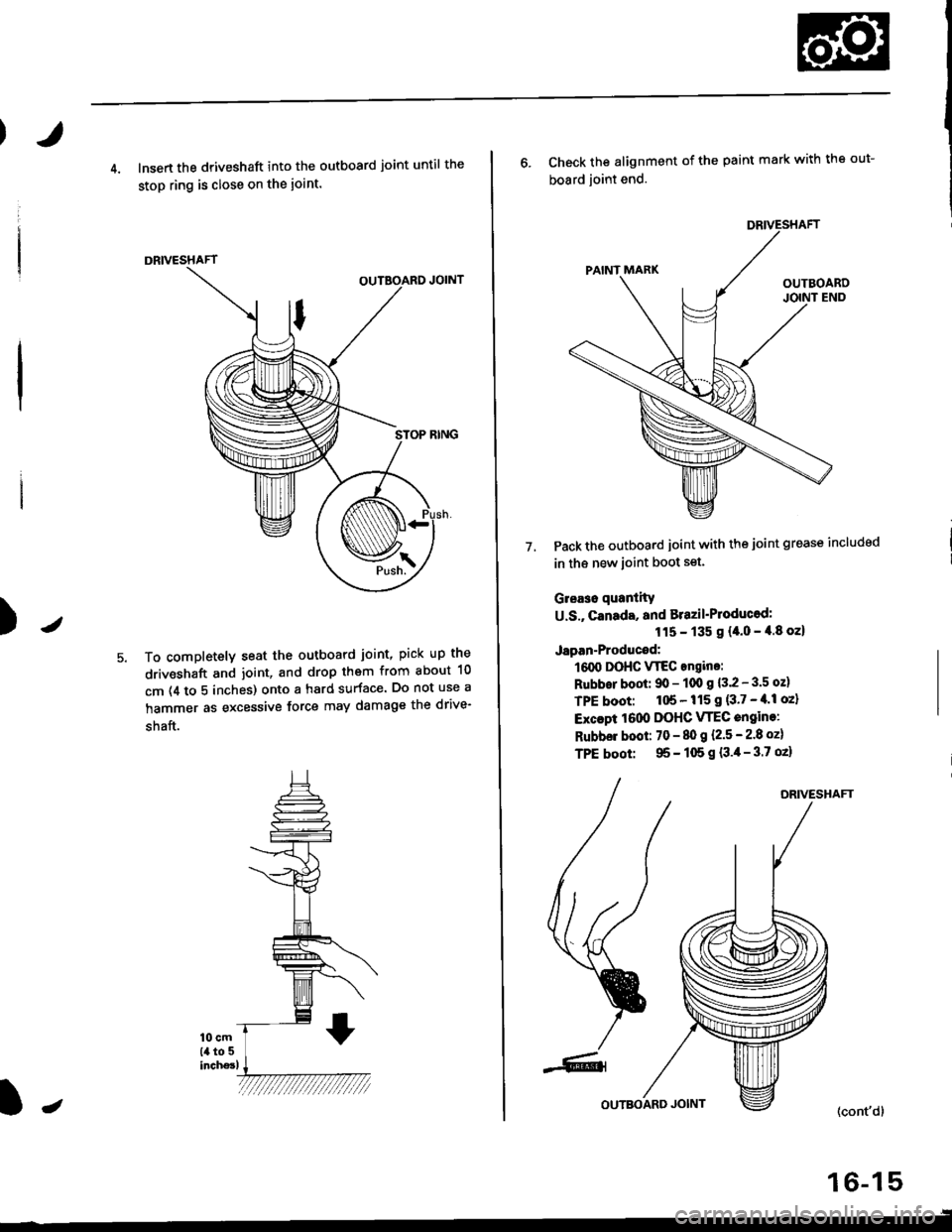

4. lnsert the driveshaft into the outboard joint until the

stop ring is close on the ioint.

DRIVESHAFT

To completely seat the outboard joint, pick up the

driveshaft and joint, and drop them from about 10

cm (4 to 5 inches) onto a hard surface. Do not use a

hammer as excessive force may damage the drive-

shaft.

16-15

J

6. Check the alignment of the paint mark with the out-

board joint end.

Pack the outboard joint with the joint grease includsd

in th€ new ioint boot set.

Gleaso quanlity

U.S., canada, and Brazil'Ploducod:

115 - 135 g {4.0 - 4.8 oz}

Japan-Producod:

161X, DOHC VTEC angino:

Rubbor boot: 90 - 100 g 13.2 - 3.5 oz)

TPE boot: 1tl6 - 115 I {3'7 - tl'l oz}

Excapt 1000 DOHC VTEC engine:

Rubbel boot: 70 - 80 g l.2.5 - 2.8 ozl

TPE boot: 95 - 105 g {3.4- 3.7 oz}

7.

DRIVESHAFT

(cont'd)

Page 1052 of 2189

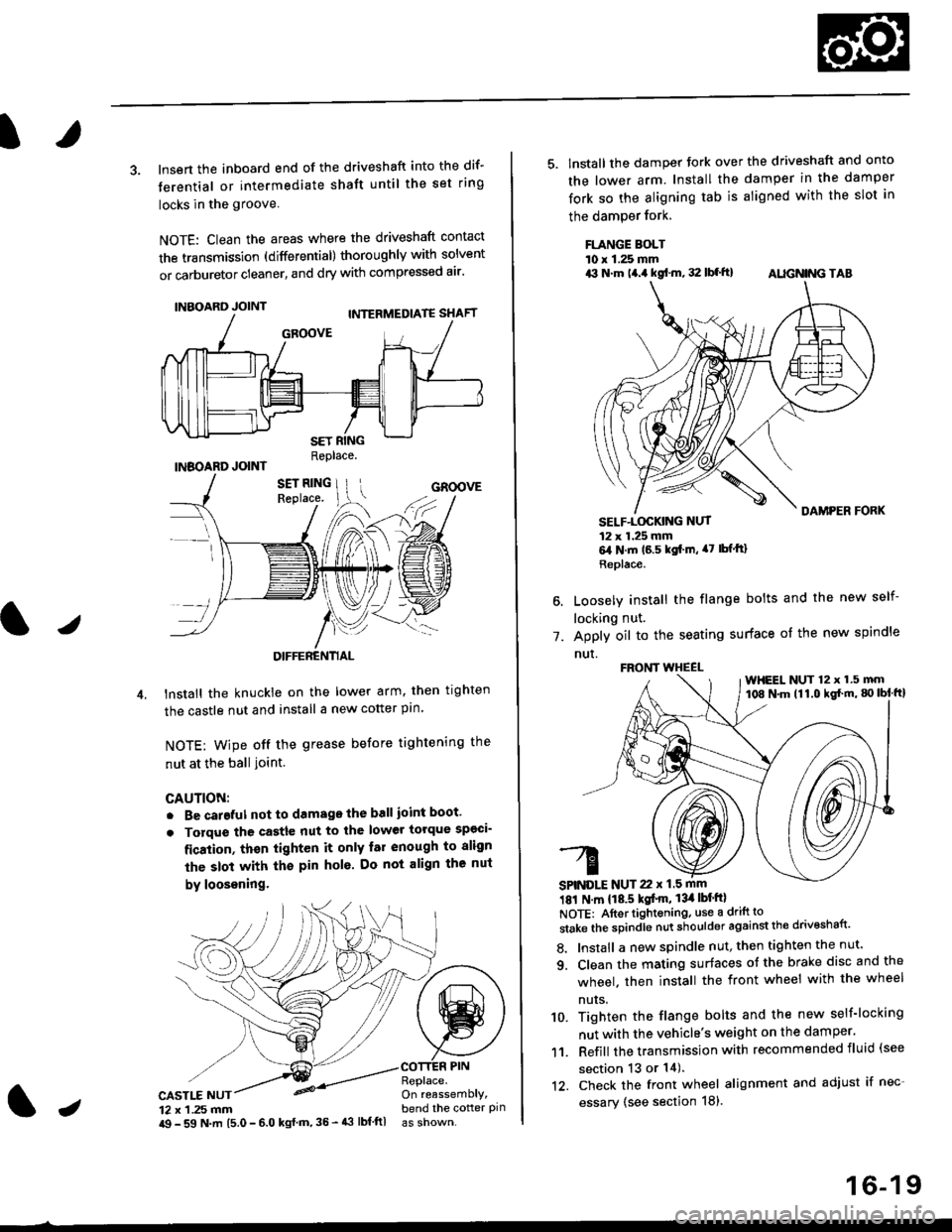

3. lnsert the inboard end of the driveshaft into the dif-

terential or intermediate shaft until the set ring

locks in the groove

NOTE: Clean the areas where the driveshaft contact

the transmission (differential) thoroughly with solvent

or carburetor cleaner, and dry with compressed air'

INBOARD JOINT

INBOARD JOINTReplace.

GROOVE

an

DIFFERENTIAL

lnstall the knuckie on the lower arm. then trghten

the castle nut and install a new cotter pin

NOTE: wipe off the grease before tightening the

nut at the ball ioint.

CAUTION:

. Be careful not to damago the ball ioint boot'

. Torque the castle nut to the lower torque sp€ci-

fication, thsn tighten it only far enough to align

the slot with th€ pin hol6. Do not align the nut

by loosening.

CASTLE NUT12 x 1 .25 mm

COTTER PINReplace.On reassemblY,bend the cotter pinJi$ - 59 N.m 15.0 - 6.0 kgl m,35 - 43 lbf ftl

16-19

5. lnstall the damper tork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damPer fork.

FLANGE BOLTl0 r 1.25 mmrit N.m t4.a kgf.m, 32 lbf.ft) AIIGN|NG TAB

1.

SELF-LOGKING NUT12 x 1.25 mm6,1N.m 16.5 kgi.m, a7 lbfftl

Replace.

Loosely install the flange bolts and the new self-

locking nut.

Apply oil to the seating surface of the new spindle

nut.

181 N m 118.5 kgt'm, 13il lbt'ftl

NOTE: Aftortightening, use a drift to

stake the spindle nut shoulder against the drivoshaft'

8. Install a new spindle nut, then tighten the nut'

9. Clean the mating surfaces ot the brake disc and the

wheel. then install the front wheel with the wheel

nuts.

10. Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

11. Refill the transmission with recommended fluid (see

section 13 or 14).'t2. Check the front wheel alignment and adjust if nec-

essary (see section 18),

FRONT WHEEL

SPINDLE NUT 22 x 1.5 mm

WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgl'm, g) lbl ftl

Page 1054 of 2189

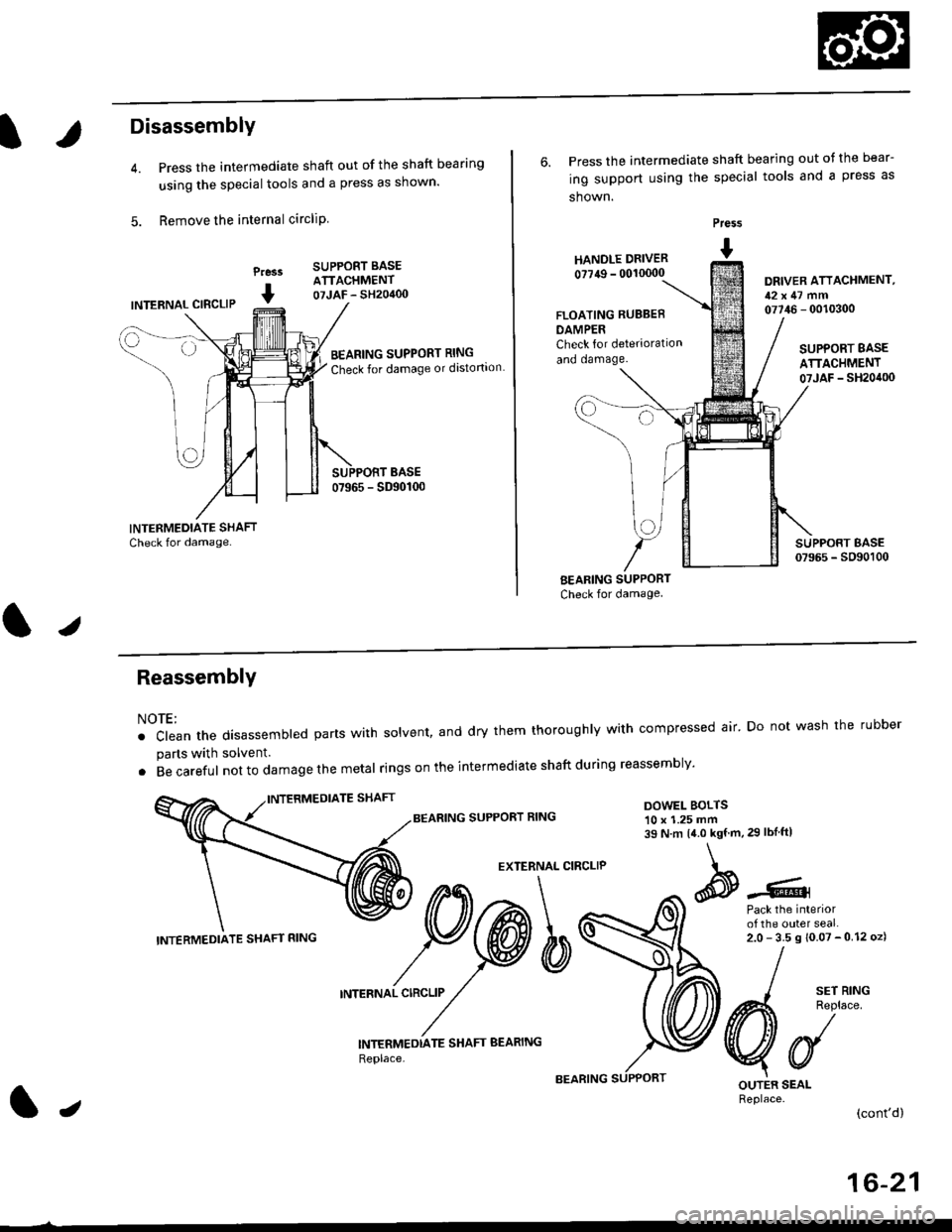

Disassembly

Press the intermediate shaft out of the shaft bearing

using the special tools and a press as shown.

Remove the internal circliP

Press

I

SUPPORT BASEATTACHMENT07JAF - SH20400INTERNAL CIBCLIP

BEARING SUPPORT RING

Check for damage or distortion

6. Press the intermediate shaft bearing out ot the bear-

ing support using the special tools and a press as

shown.

HANOLE DRIVER

0?749 - 00'�10000

Press

I

DRIVER ATTACHMENT,12x47 mm07746 - 0010300FLOATING RUBBEB

DAMPERCheck for deterioration

and oamage.SUPPORT BASE

ATTACHMENT07JAF _ SH20it00

BEARING SUPPORT

Check for damage

I sErR'NG

A4 Reolace

VUOUTER SEALReplace.(cont'd)

ReassemblY

NOTE:

. clean the disassembted parts with solvent, and dry them thoroughly with compressed air' Do not wash the rubber

parts with solvent.

. Becareful not to da mage the metal ringson the intermediate shaftduring reassembly'

BEARING SUPPORT RINGDOWEL BOLTS10 x 1.25 mm39 N.m 14.0 kgf.m,29 lbIftl

EXTERNAL CIRCLIP

Pack the interiorof the outer seal.2.0-35s10.07-012oz)

INTERNAL CIRCLIP

INTERMEDTATE SHAFT BEARING

Replace,

INTERMEDIATE SHAFT RING

lJ

16-21

Page 1055 of 2189

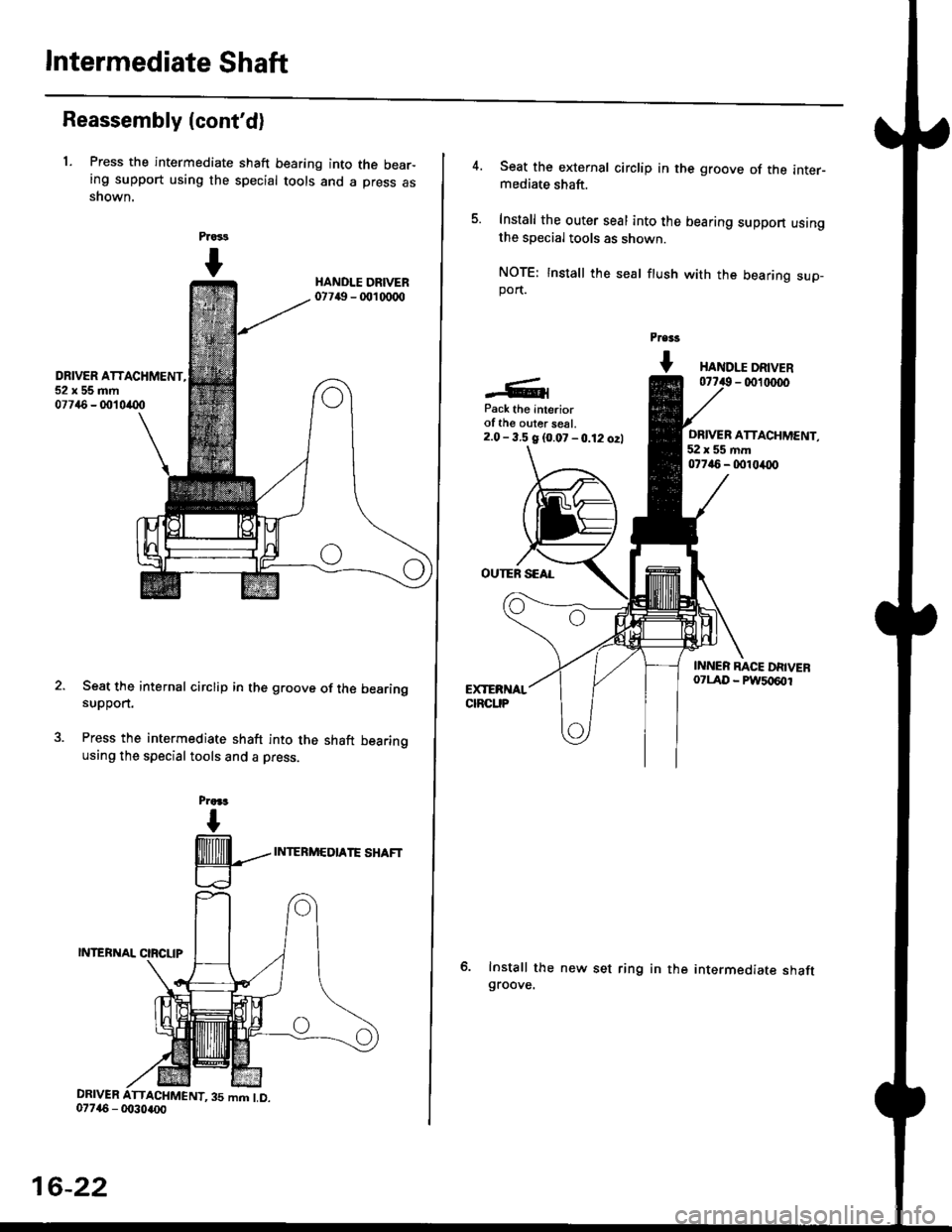

lntermediate Shaft

Reassembly (cont'd)

1. Press the intermediate shaft bearing into the bear-ing support using the special tools and a press asshown.

Prass

I

DRIVER ATTACHMENT,52x55mm07746 - 001 0(X)

Seat the internal circlip in the groove of the bearingsuppon.

Press the intermediate shaft into the shaft bearingusing the special tools and a press.

Praa.r

I

@---

LJ

INTERMEDIATE SHAFT

DRIVER ATTACHMENT,35 mm LD.

16-22

Seat the external circlip in the groove of the inter-mediate shaft.

Install the outer seal into the bearing support usingthe special tools as shown.

NOTE: Install the seal ftush with the bearing sup-port.

Pre$

t HANDr.r DRTVER- 0011r(x)0

Pack the Interiorof the ouler seal.2.0- 3.5 g {0.07 -0.12 ozl

OUTEN SEAL

Install the new set ringgroove.

ORIVER ATTACHMENT,52x55mm077i16 - 0010/O0

in the intermediate shaft

Page 1061 of 2189

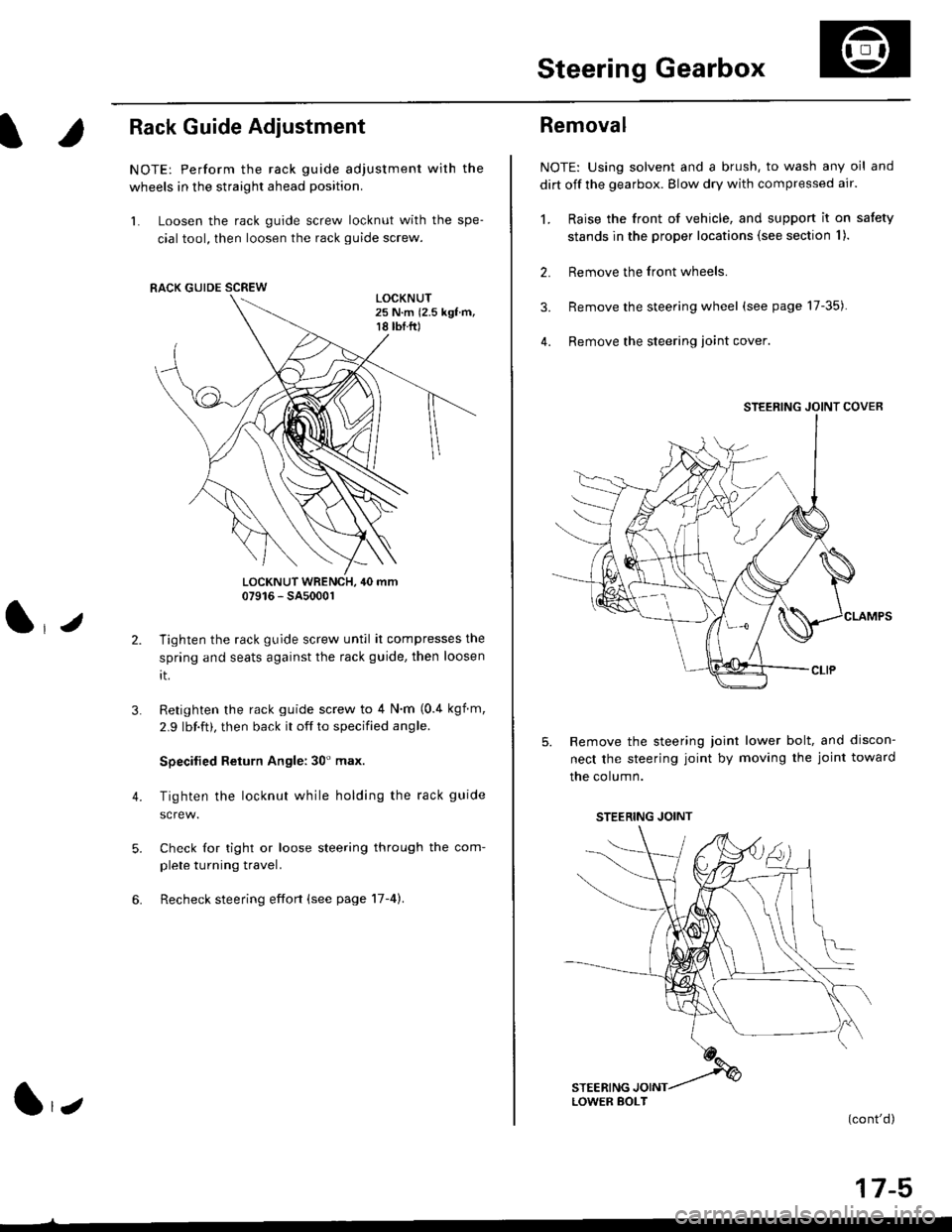

Steering Gearbox

l.r

Rack Guide Adjustment

NOTE: Perform the rack guide adjustment with the

wheels in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cial tool, then loosen the rack guide screw.

LOCKNUT WRENCH, 40 mm07916 - SA5000r

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

rt.

Retighten the rack guide screw to 4 N'm (0.4 kgf m,

2.9 lbf.ft), then back it off to specified angle.

Specilied Return Angle: 30' max.

Tighten the locknut while holding the rack guide

Check for tight or loose steering through the com-

plete turning travel.

Recheck steering effort (see page 17-4).

4.

RACK GUIDE SCREW

l,z

Removal

NOTE: Using solvent and a brush, to wash any oil and

dirt off the gearbox. Blow dry with compressed air.

1. Raise the front of vehicle, and support it on satety

stands in the proper locations (see section I ).

2. Remove the front wheels.

3. Remove the steering wheel (see page 17-35).

4. Remove the steering loint cover

Remove the steering joint lower bolt, and discon-

nect the steering joint by moving the joint toward

the column.

(cont'd)

17-5

STEERING JOINT COVER

LOWER BOLT

STEERING JOINT

Page 1066 of 2189

Steering Gearbox

Reassembly (cont'dl

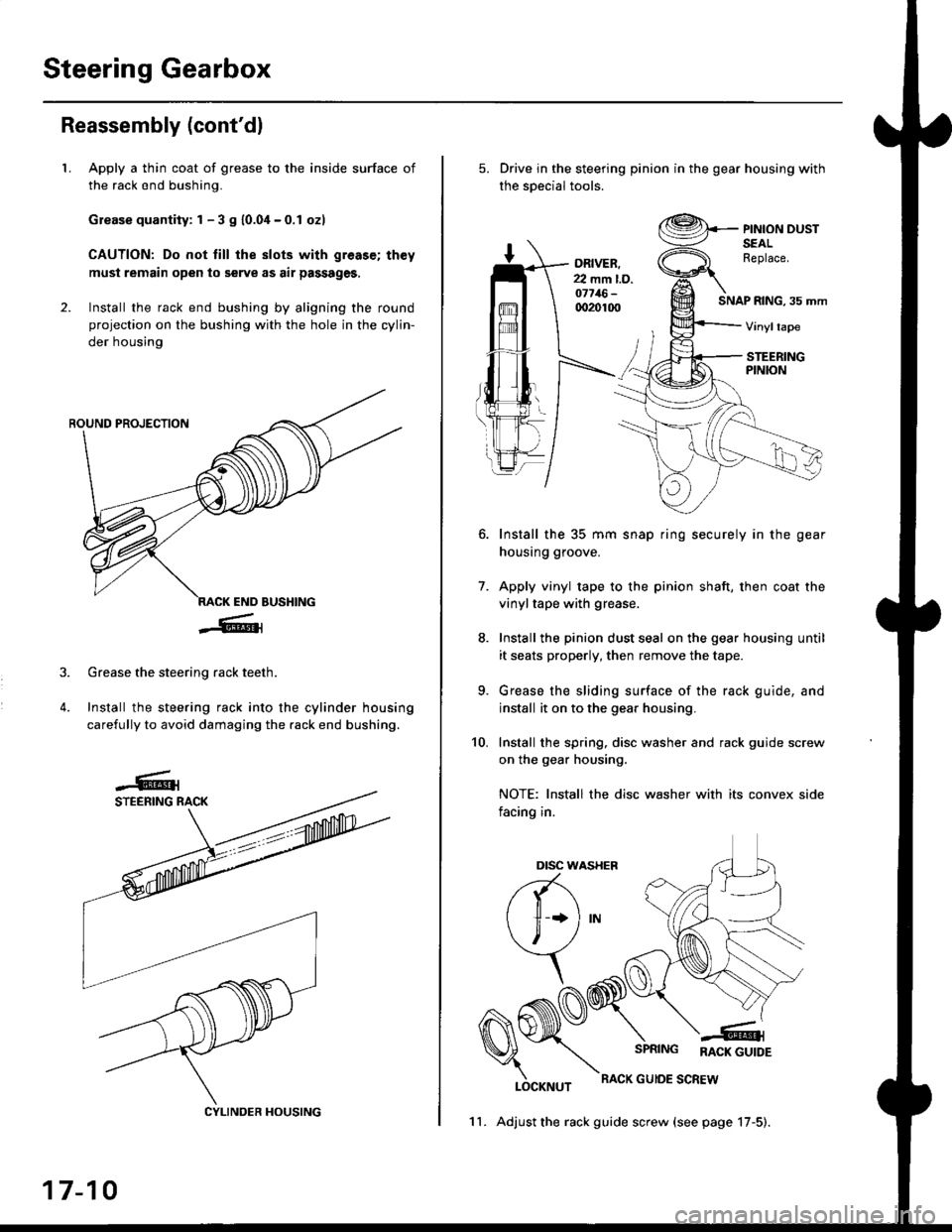

LApply a thin coat of grease to the inside surface of

the rack end bushing.

Grease quantity: 1 - 3 S 10.04-0.1 ozl

CAUTION: Do not till the slots with greas€; th€y

must remain open to serve as air passages,

Install the rack end bushing by aligning the round

projection on the bushing with the hole in the cylin-

der housing

4.

Grease the steering rack teeth.

Install the steering rack into the cylinder housing

carefully to avoid damaging the rack end bushing.

CYLINDER HOUSING

17-10

11. Adjust the rack guide screw (see page 17-5).

Drive in the steering pinion in the gear housing with

the soecial tools.

ORIVER.22 mm l.D.o7716-qr20100SNAP RING, 35 mm

PINION DUSTSEALReplace.

Vinyltape

STEERINGPINION

7.

Install the 35 mm snap ring securely in the gear

housing groove.

Apply vinyl tape to the pinion shaft, then coat the

vinyltape with grease.

Install the pinion dust seal on the gear housing until

it seats properly, then remove the tape.

Grease the sliding surface of the rack guide, and

install it on to the gear housing.

Install the spring, disc washer and rack guide screw

on the gear housing.

NOTE: Install the disc washer with its convex side

facing in.

LOCKNUT

SPRING RACK GUTDE

RACK GUIOE SCREW

10.

Dtsc w,

a(-\

l1 *l

\, ,/

\

Page 1093 of 2189

Steering Column

I

Removal/lnstallation

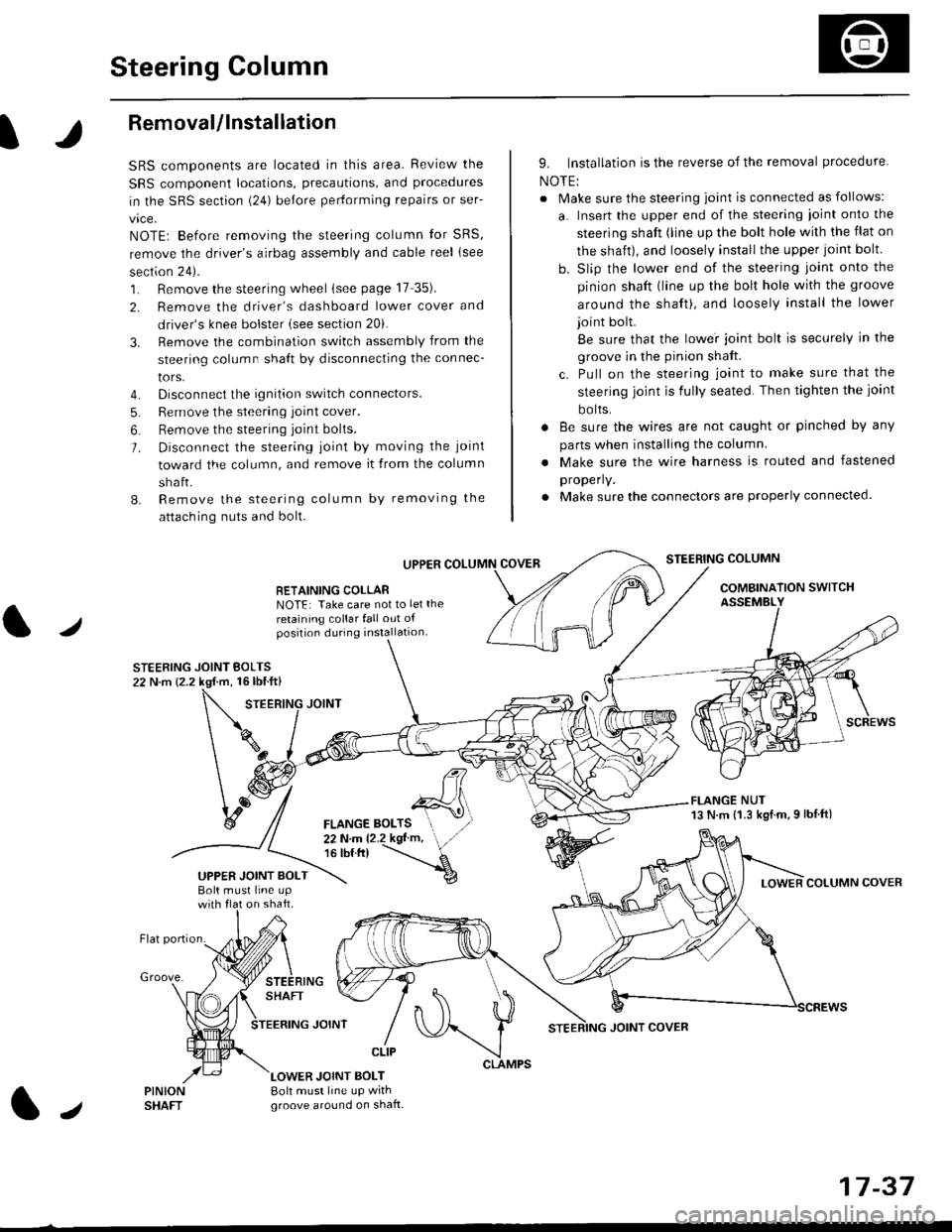

SRS components are located in this area. Review the

SRS component locations, precautions, and proceclures

in the SRS sectron (24) before pertorming repairs or ser-

vice.

NOTE: Before removing the steering column for SRS,

remove the driver's airbag assembly and cable reel lsee

section 24).

1. Remove the steering wheel (see page 17 35).

2. Remove the driver's dashboard lower cover and

driver's knee bolster (see section 20).

3. Remove the combination switch assembly from the

steering column sha{t by disconnecting the connec-

tors.

4. Disconnect the ignition switch connectors.

5. Remove the steering joint cover.

6. Bemove the steering joint bolls.

7. Disconnect the steering ioint by moving the joint

toward the column, and remove it from the column

shaft.

8. Remove the steering column by removing the

attaching nuts and bolt.

UPPER

RETAINING COLLABNOTE: Take care not to let the

retaining collar fall out ofposition during installation.

STEERING JOINT BOLTS22 N.m {2.2 kgf.m, 16lbtft}

9. Installation is the reverse of the removal procedure

NOTE:

. Make sure the steering joint is connected as follows:

a. Insert the upper end of the steering ioint onto the

steering shaft (line up the bolt hole with the flat on

the shait), and loosely install the upper joint bolt.

b. Slip the lower end of the steering joint onto the

pinion shaft (line up the bolt hole with the groove

around the shaft), and loosely install the lower

joint bolt.

Be sure that the lowei joint bolt is securely in the

groove in the pinion shaft.

c. Pull on the steering joint to make sure that the

steering joint js fully seated. Then tighten the ioint

bolts.

. 8e sure the wires are not caught or pinched by any

parts when installing the column

. Make sure the wire harness is routed and fastened

properly.

. Make sure the connectors are properly connected.

STEERING COLUMN

COMBINATION SWITCHASSEMBLY

FLANGE NUT13 N.m {1.3 kgl.m.9 lbf ft)

COLUMN COVER

FLANGE BOLTS22Nm12.2kgl'm,16 tbt.tr)

UPPER JOINT BOLTBolt musl line upon shaft.

Groove.

LOWER JOINT BOLT8oh must line up wrthgroove around on shaft.

CLIP

J

JOINT COVER

17-37