compressor HONDA CIVIC 1999 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 1447 of 2189

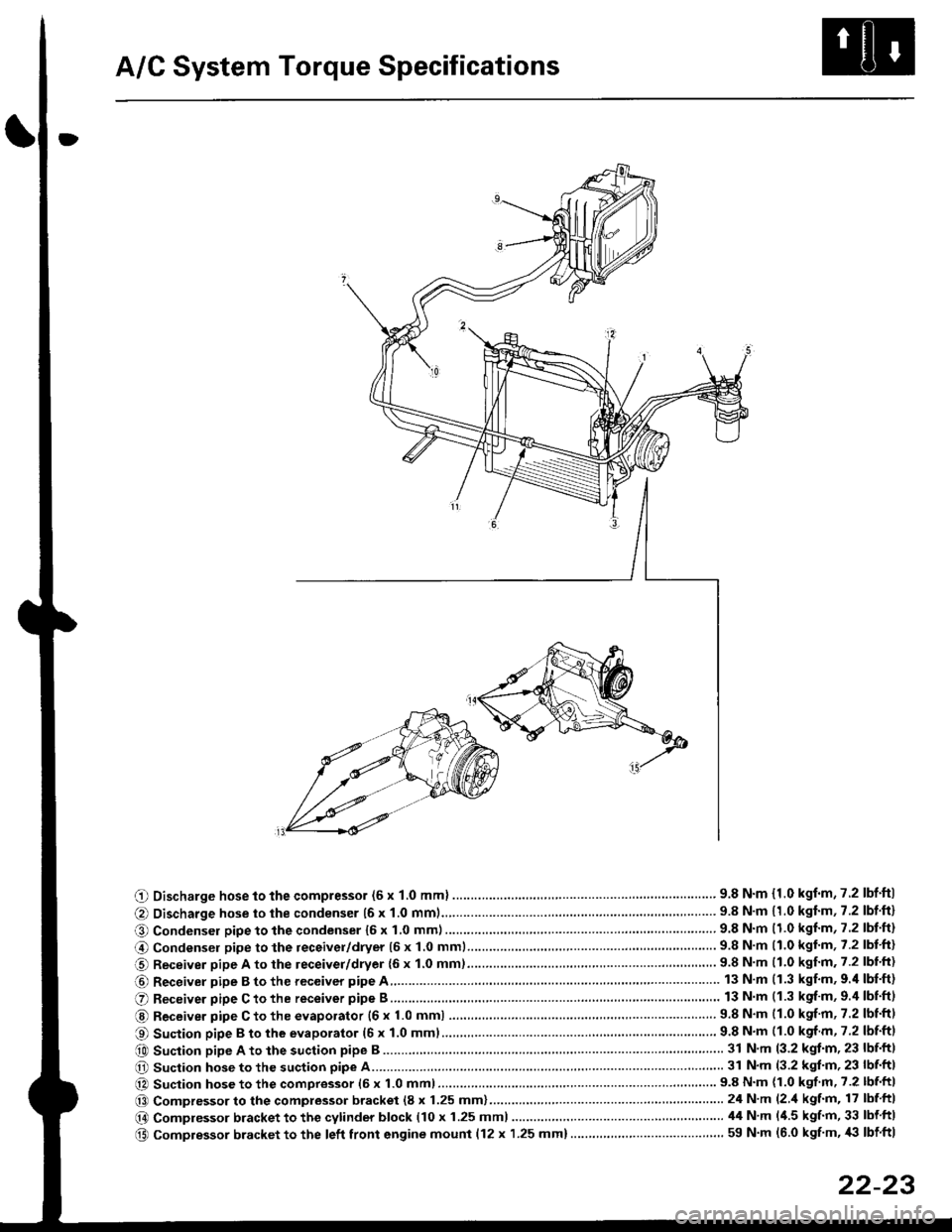

A/C System Torque Specifications

O Discharge hose to the compressor (6 x 1.0 mml ............... .. .... ...............' 9.8 N'm {1.0 kgf'm,7.2 lbf'ftl

@ Discharge hose to the condenser {6 x 1.0 mm1................... '... ...... . ......... 9.8 N'm 11.0 kgf'm, 7.2 lbf'ft}

O Condenser pipe to the condenser 16 x 1,0 mm)...............'. . . . ...........'..... 9.8 N'm (1.0 kgl'm, 7.2 lbt'ft)

@ Condensel pipe to the receivel/dryer (5 x 1.0 mml......... ..... . ... . '.......... 9.8 N'm (1.0 kgl'm, 7.2 lbt'ft)

O Receiver pipe A to the leceiver/dryer {6 x 1.0 mm)......... ... .......... .. . . .... 9.8 N'm 11.0 kgf'm. 7.2 lbl'ft)

@ Receiver pipe B to the receiver pipe A 13 N m (1.3 kgf'm, 9.'l lbf'ft)

O Receiver pipe C to the receiver pipe B 13 N m (1.3 kgf'm, 9.4 lbnftl

@ Receiver pipe C to the evaporator {6 x 1.0 mm) ....... 9.8 N'm (1.0 kgf'm, 7.2 lbtftl

O Suction pipe B to the evaporator (6 x 1.0 mml................ . .........'......'....... 9.8 N'm (1.0 kgf m, 7.2 lbf'ftl

e0 Suction pipe A to the suction pipe B ...'. . ...... . ... ...... 31 N'm (3.2 kgt'm, 23 lbf'ftl

O Suction hose to the suction pipe A... ............ . . '......... 31 N'm (3.2 kgl'm, 23 lbf'ft|

@ Suction hose to the compressor (6 x 1.0 mm)................... .. . ... .. ............ 9.8 N'm (1.0 kgf'm' 7.2 lbf'ft|

@@ Compressor to the compressor bracket (8 x 1.25 mm)... ..-........'.'......-.......24 N'm (2 'l kgf'm, 17 lbf ftl

@ Compressor bracket to the cytinder block (10 x 1.25 mml 44 N'm l'1.5 kgf'm, 33 lbf ftl

@ Compressor bracket to the left front engine mounl {12 x 1.25 mm}..... . . . . .. ................. ... ... 59 N'm (6.0 kgf'm, '|i} lbf ftl

22-23

Page 1450 of 2189

A/C System Service

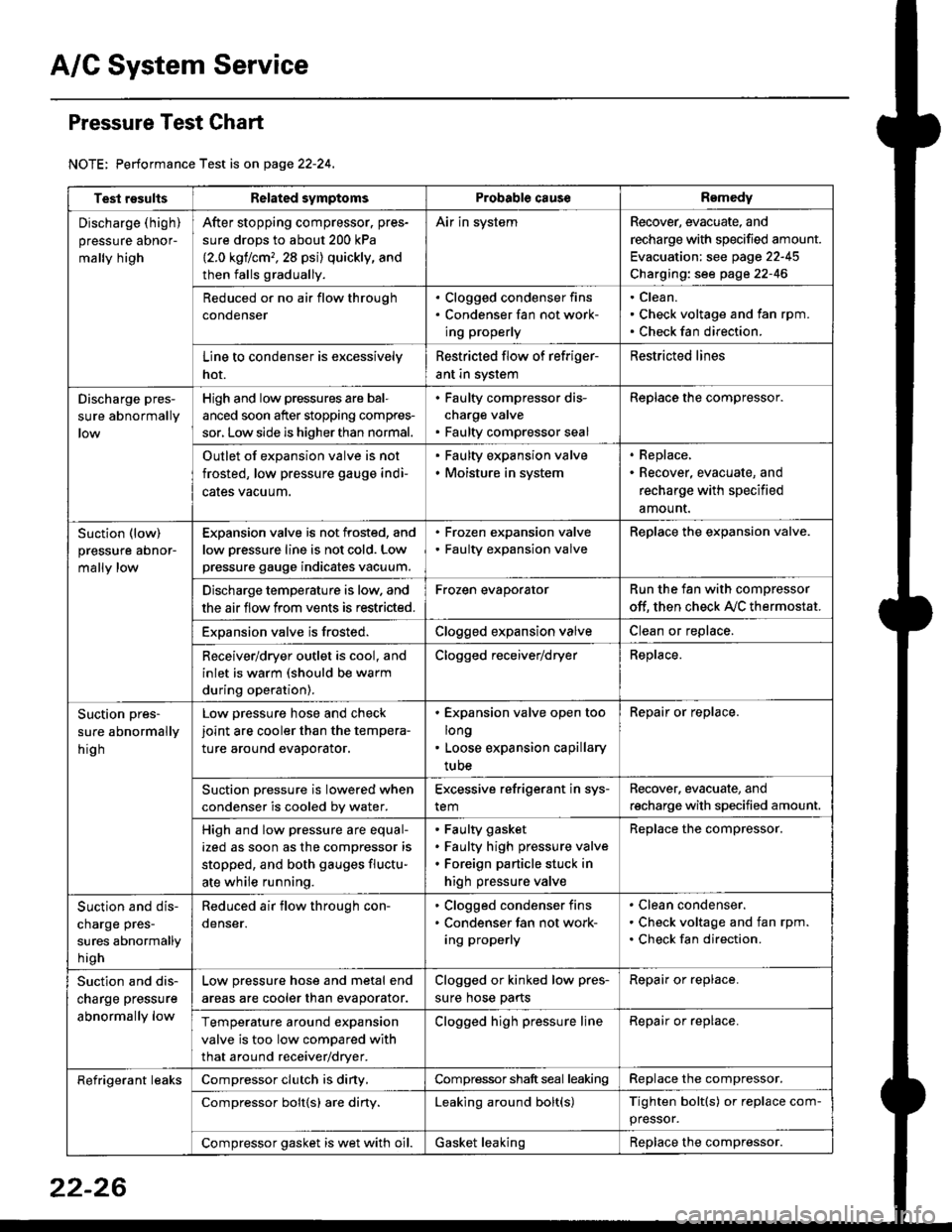

Pressure Test Chart

NOTE: Performance Test is on page 22-24,

Test resultsRelated symptomsProbabl€ causeRemedy

Discharge (high)

pressure aDnor-

mally high

After stopping compressor. pres-

sure drops to about 200 kPa

{2.0 kgflcm,,28 psi) quickly, and

then falls gradually.

Air in systemRecover, evacuate, and

recharge with specified amount.

Evacuation: see page 22-45

Charging: see page 22-46

Reduced or no air flow through

condenser

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean.

Check voltage and fan rpm.

Check fan direction.

Line to condenser is excessively

hot.

Restricted flow of refriger-

ant in system

Restricted lines

Discharge pres-

sure abnormally

High and low pressures are bal-

anced soon after stopping compres-

sor, Low side is higher than normal.

. Faulty compressor dis-

charge valve. Faulty compressor seal

Replace the compressor.

Outlet of expansion valve is not

frosted, low pressure gauge indi-

cales vacuum.

. Faulty expansion valve. Moisture in system

. Replace,. Recover, evacuate, and

recharge with specified

amount.

Suction (low)

pressure abnor-

mally low

Expansion valve is not frosted, and

low oressure line is not cold. Low

pressure gauge indicates vacuum.

. Frozen expansion valve. Faulty expansion valve

ReDlace the exoansion valve.

Discharge temperature is low. and

the air flow from vents is restricted.

Frozen evaporatorRun the fan with compressor

off. then check A,/C thermostat.

Exoansion valve is frosted.Clogged expansion valveClean or replace.

Receiver/dryer outlet is cool, and

inlet is warm (should be warm

during operation).

Clogged receiver/dryerReplace.

Suction pres-

sure abnormally

hig h

Low pressure hose and check

joint are cooler than the tempera-

ture around evaporator.

. Expansion valve open too

long. Loose expansion capillary

tube

Repair or replace.

Suction oressure is lowered when

condenser is cooled bv water.

Excessive refrigerant in sys-

tem

Recover. evacuate, and

recharge with specified amount.

High and low pressure are equal-

ized as soon as the compressor is

stopped, and both gauges fluctu-

ate while running.

Faulty gasket

Faulty high pressure valve

Foreign particle stuck in

high pressure valve

Replace the compressor.

Suction and dis-

charge pres-

sures abnormally

h igh

Reduced air flow through con-

denser.

. Clogged condenser fins. Condenser fan not work-

ing properly

Clean condenser.

Check voltage and fan rpm.

Check fan direction.

Suction and dis-

charge pressure

abnormally low

Low pressure hose and metal end

areas are cooler than evaporator.

Clogged or kinked low pres-

sure hose parts

Repair or replace.

Temperature around expansion

valve is too low compared with

that around receiver/dryer.

Clogged high pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny,Compressor shaft seal leakingReplace the compressor.

Compressor bolt{s) are diny.Leaking around bolt(s)Tighten bolt(s) or replace com-

pressor.

Compressor gasket is wet with oil.Gasket leakingReplace the compressor.

22-26

Page 1454 of 2189

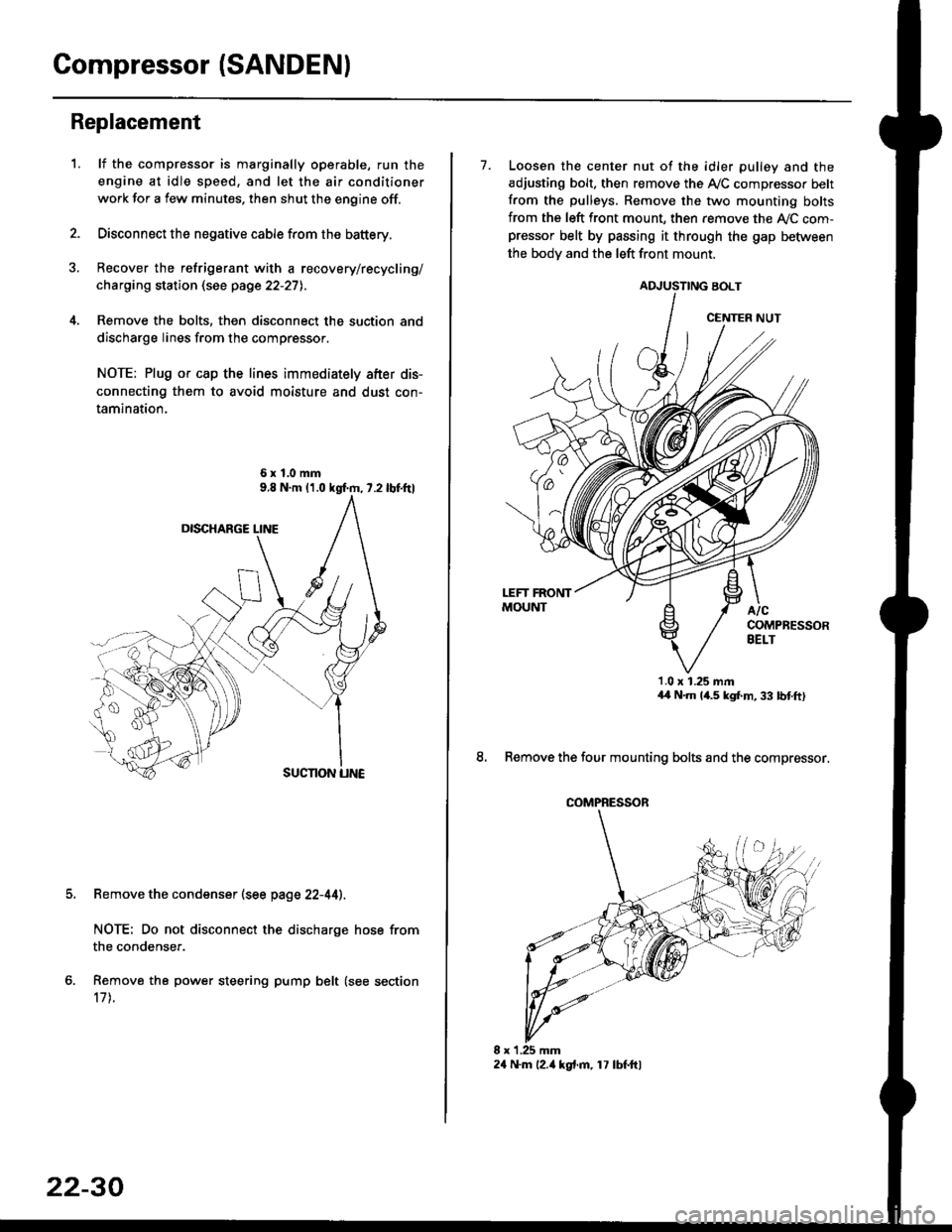

Compressor (SANDENI

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-27l..

Remove the bolts, then disconnect the suction and

discharge lines from the compressor.

NOTE: Plug or cap the lines immediately after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm

Remove the condenser (see page 22-44).

NOTE: Do not disconnect the discharge hose from

the condenser.

Remove the power steering pump belt (see section

17 t.

22-30

24 N.m l2.ia kgt.m, 17 lbf.ftl

7. Loosen the center nut of the idler pulley and the

adjusting bolt. then remove the A,/C compressor belt

from the pulleys. Remove the two mounting bolts

from the left front mount, then remove the ly'C com-pressor belt by passing it through the gap befiiveen

the bodv and the left front mount.

ADJUSTING BOLT

1.0 x 1.25 mmaa N.m 14.5 kgf,m, 33 bnft)

8. Remove the four mounting bolts and the compressor.

CENTER NUT

COMPRESSOR

Page 1455 of 2189

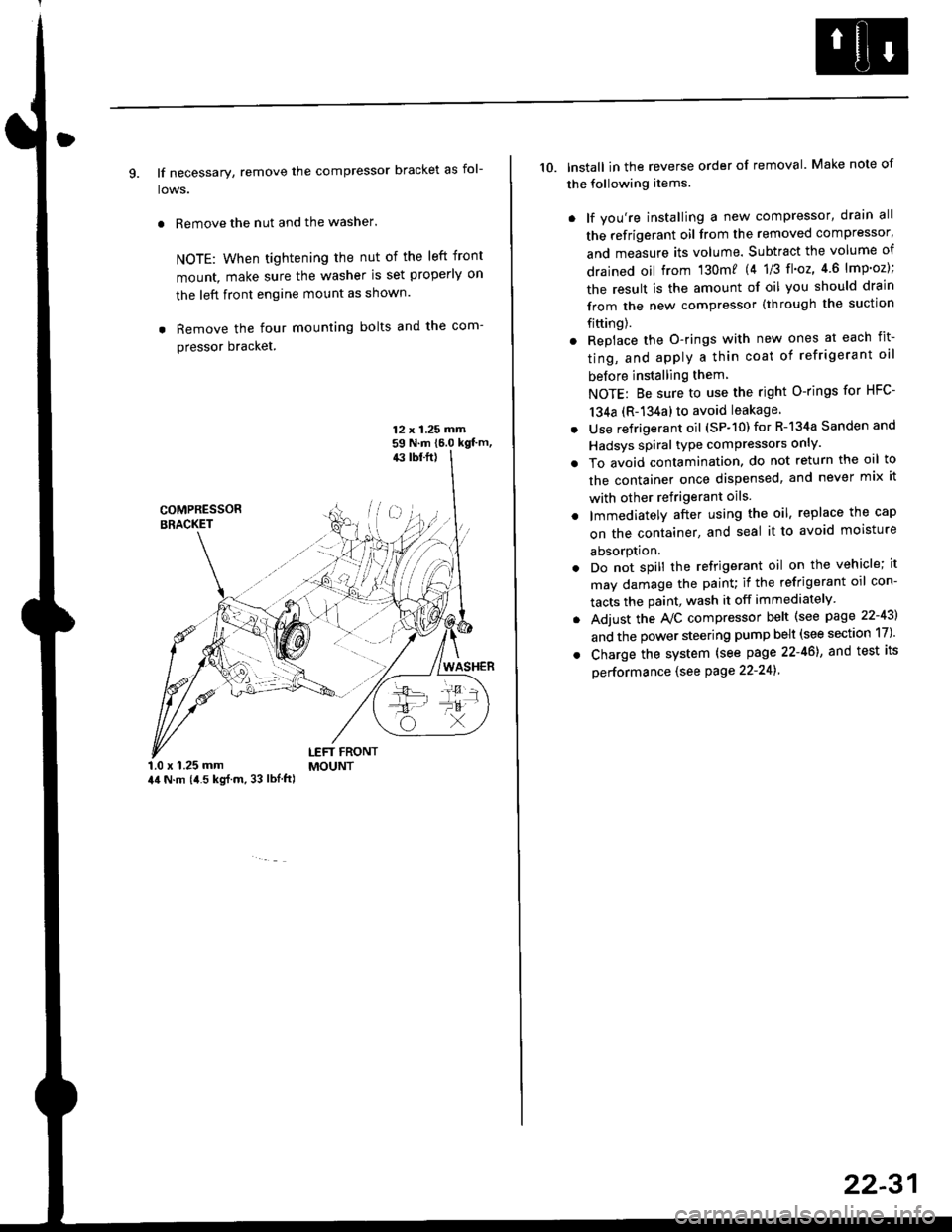

9. lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer.

NOTE: When tightening the nut of the left front

mount, make sure the washer is set properly on

the left front engine mount as shown.

. Remove the four mounting bolts and the com-

pressor bracket.

12 x 1.25 rrirn59 N.m 16.0 kgt'm,43 tbf.ft)

COMPRESSORBRACKET

WASHER

1.0 x 1.25 mm44 N.m (i1.5 kg{.m, 33 lbl.ft)

LEFT FRONTMOUNT

10. lnstall in the reverse order of removal. Make note of

the following items.

. lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume. Subtract the volume of

drained oil from '130m? 14 1/3 tl'o2,4 6 lmp'oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

fifting).

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage

. Use refrigerant oil (SP-10) for R-134a Sanden and

Hadsys spiral type compressors only'

o To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediatelY after using the oil, replace the cap

on the container, and seal it to avoid moisture

absorption.

. Do not spill the refrigerant oil on the vehicle; it

may damage the painu if the refrigerant oil con-

tacts the paint, wash it off immediately

. Adjust the Ay'C compressor belt (see page 22-43)

and the power steering pump belt (see section 17)'

. Charge the system (see page 22-46), and test its

oerformance (see Page 22-241

22-31

Page 1456 of 2189

Gompressor (SANDEN)

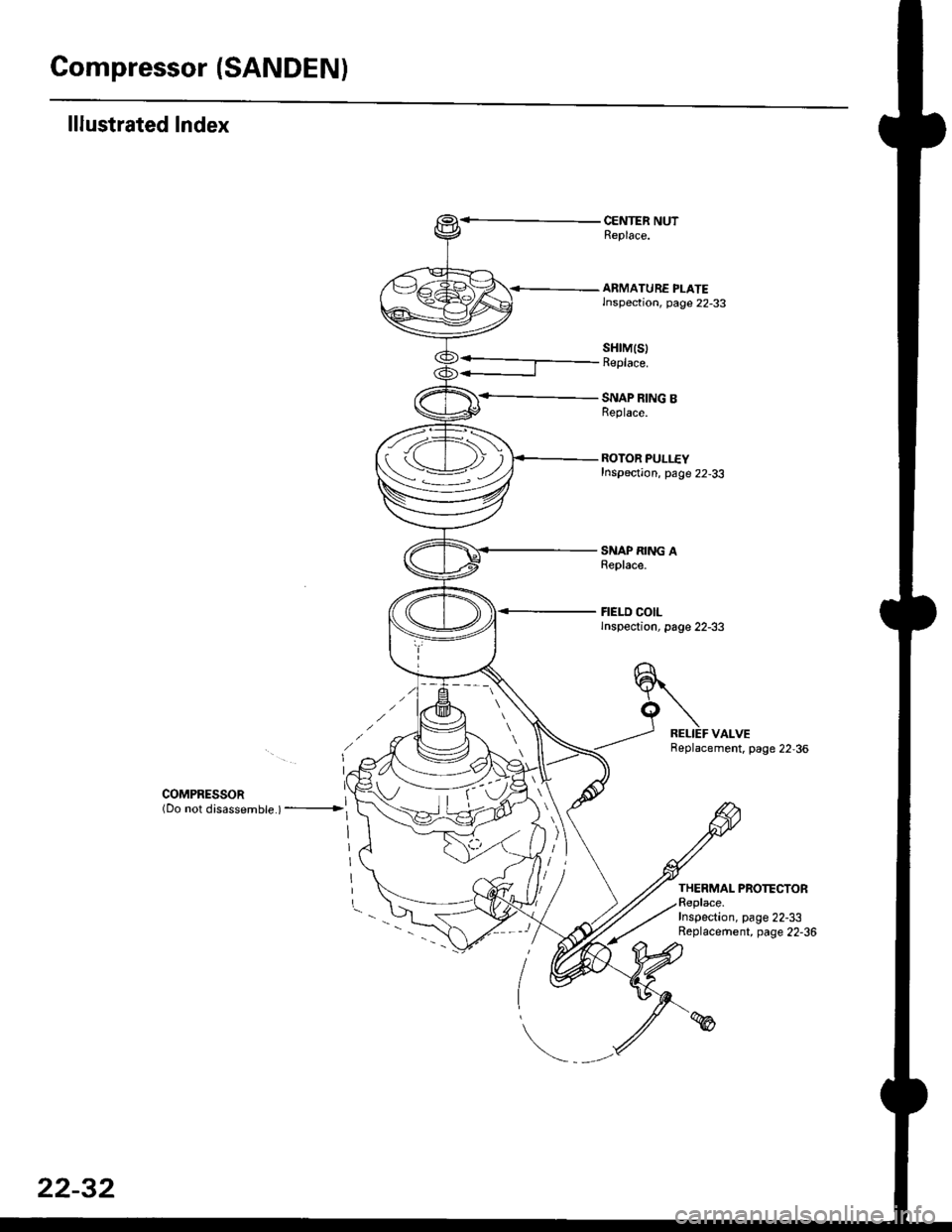

lllustrated Index

CENTER NUTReplace.

<-- ARMATURE PLATElnspection, page 22-33

SNAP RING BReplace.

ROTOR PULLEYInspection, page 22-33

SNAP RING AReplace.

FIELD COILlnspection, page 22-33

sHrM(s)Replace.

COMPRESSoR ](Do not disassembte ) ---------------->l

Replacement. page 22,36

THERMAL PROTECTORReplace.Inspection, page 22-33Replacement, page 22-36

tv

i-

22-32

Page 1458 of 2189

Compressor {SANDEN)

Clutch Overhaul

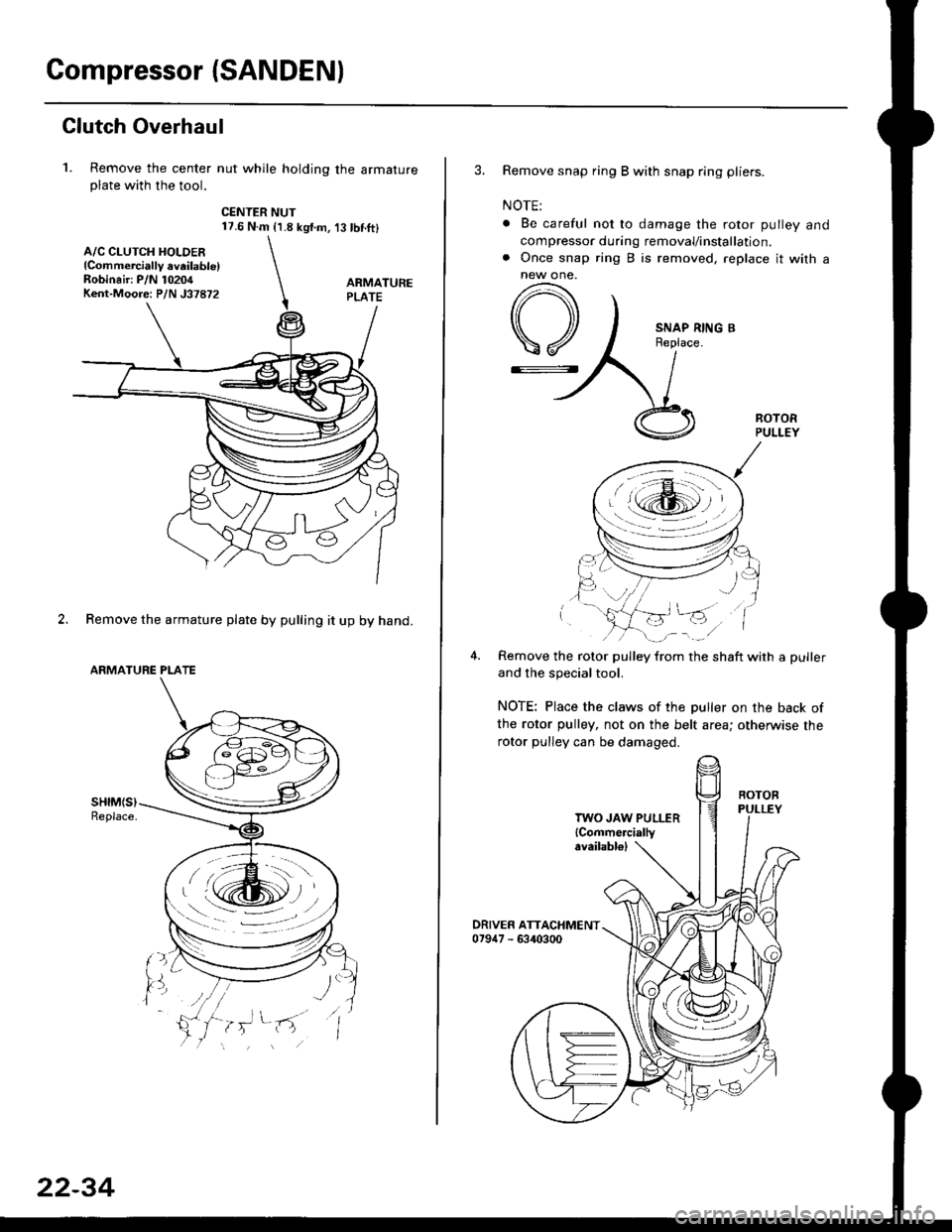

1. Remove the center nut while holding the armatureplate with the tool.

CENTER NUT17.6 N.m {1.8 kg{.m,'t3 tbnft}

2. Remove the armature plate by pulling it up by hand.

ARMATURE PLATE

A/C CLUTCH HOLDER{Commerciallv aveilable)Robinair: P/N 10204Kent-Moore: P/N J37872

22-34

3. Remove snap ring B with snap ring pliers.

NOTE:

. Be careful not to damage the rotor pulley and

compressor during removal/installation.. Once snap ring B is removed, replace it with anew one.

A

\/

G::.

Remove the rotor pulley from the shaft with a puller

and the special tool.

NOTE: Place the claws of the puller on the back of

the rotor pulley, not on the belt area; otherwise the

rotor pulley can be damaged.

. r \:g2rl -/ /

.-!L;j'/

TWO JAW PULLER{Commercially

Page 1459 of 2189

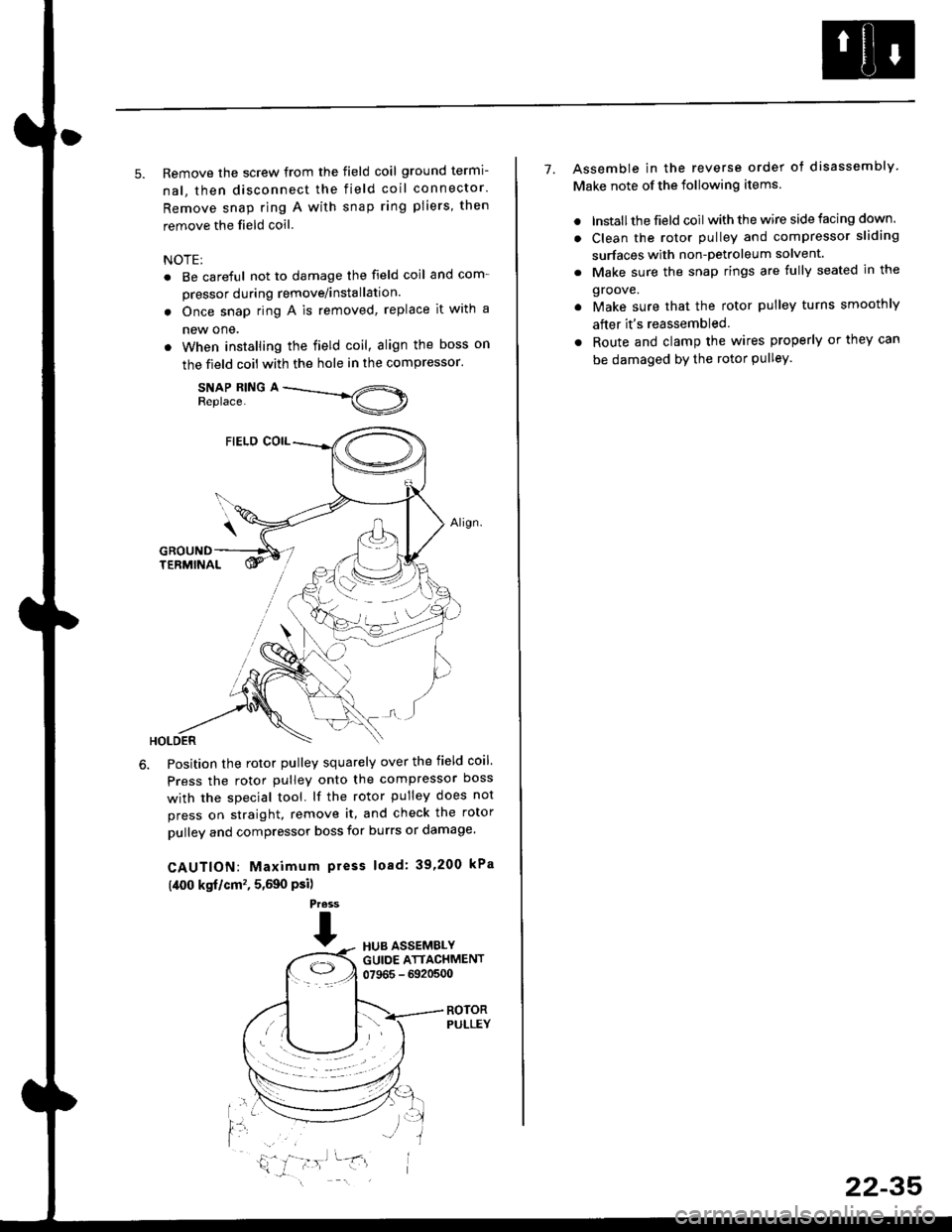

5. Remove the screw from the field coil ground termi-

nal, then disconnect the field coil connector.

Remove snap ring A with snap ring pliers, then

remove the field coil

NOTE:

. Be careful not to damage the field coil and com-

pressor during remove/installation.

. Once snap ring A is removed, replace it with a

new one.

. When installing the field coil, align the boss on

the field coil with the hole in the compressor.

SNAP RING AReplace.

Position the rotor pulley squarely over the field coil.

Press the rotor pulley onto the compressor boss

with the special tool. lf the rotor pulley does not

press on straight, remove it, and check the rotor

pulley and compressor boss for burrs or damage.

CAUTION: Maximum press load: 39,200 kPa

(,[00 kgf/cm'�, 5,590 Psi)

Press

THUB ASSEMBLYGUIDE ATTACHMENT07965 - 6920500

ROTORPULLEY

t'l

i,'

7. Assemble in the reverse order of disassembly

Make note of the following items.

. lnstall the field coil with the wire side facing down.

. Clean the rotor pulley and compressor sliding

surfaces with non-petroleum solvent.

. Make sure the snap rings are fully seated in the

groove.

. Make sure that the rotor pulley turns smoothly

after it's reassembled

. Route and clamp the wires properly or they can

be damaged bY the rotor Pulley.

22-35

Page 1460 of 2189

Compressor (SANDENI

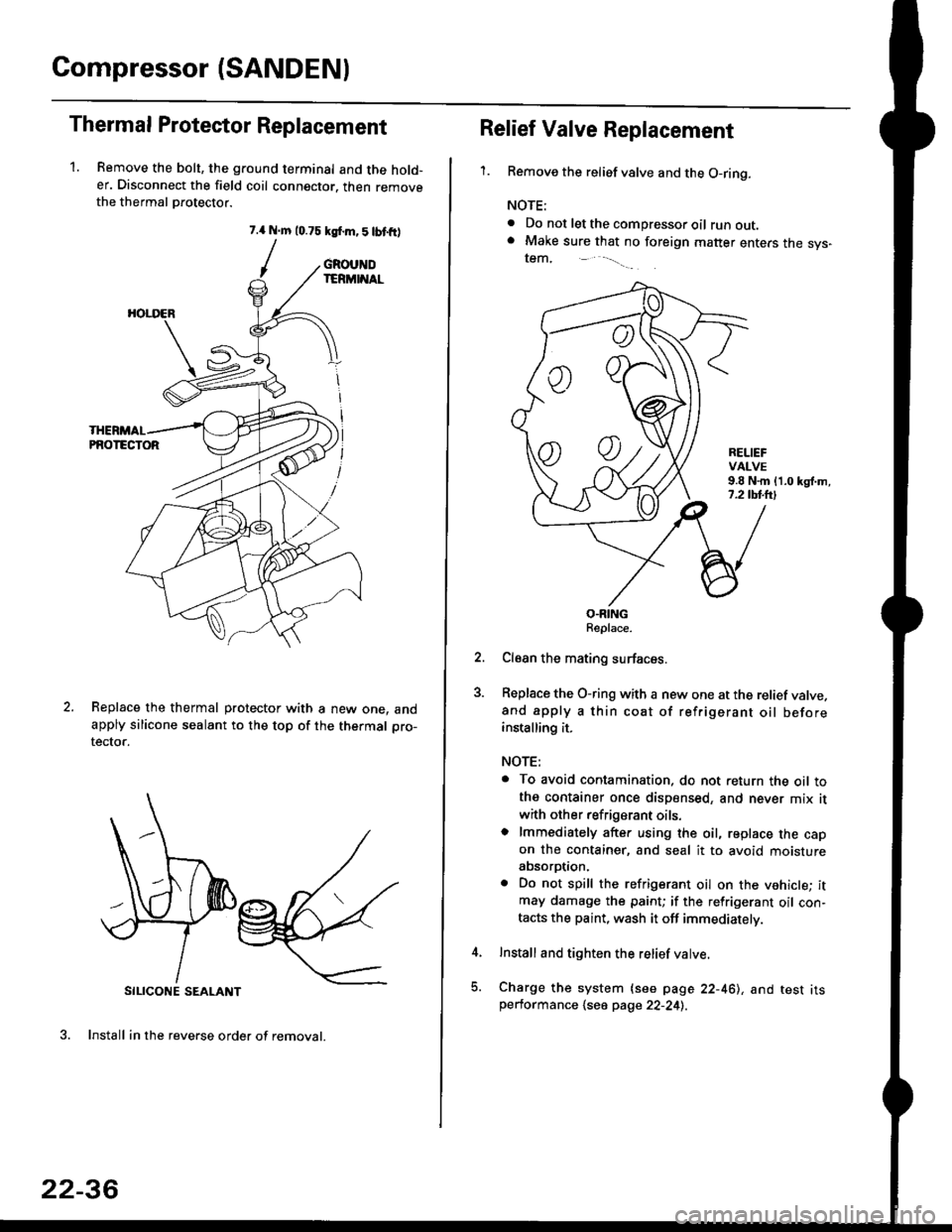

Thermal Protestor Replacement

1. Remove the bolt, the ground terminal and the hold-er. Disconnect the field coil connector. then removethe thermal Drotector.

7.{ N.m 10.75 ksf.m,5lbtfr)

/

SILICONE SEALANT

3. Install in the reverse order of removal.

GROUNDIERMINAL

HOI.I'ER

PNOTECTOR

Replace the thermal protector with a new one. andapply silicone sealant to the top of the thermal pro-

tector.

22-36

oo

Relief Valve Replacement

'1.Remove the relief valve and the O-ring.

NOTE:

. Do not let the compressor oil runout.. Make sure that no foreign matter enters the sys-tem,

RELIEFVALVE9.8 N.m {1.0 kgl.m,7.2 tbl.lrl

O.RINGReplace.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve.and apply a thin coat of refrigerant oil beforeinstalling it.

NOTE:

. To avoid contamination. do not return the oil tothe container once dispensed, and never mix it

with other refrigerant oils.o lmmediately after using the oil, replace the capon the container, and seal it to avoid moistureabsorption.

. Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediately.

Install and tighten the relief valve.

Charge the system {see page 22-461, and test itsperformance 1se6 page 22-241.

Page 1461 of 2189

Compressor (DENSO)

Replacement

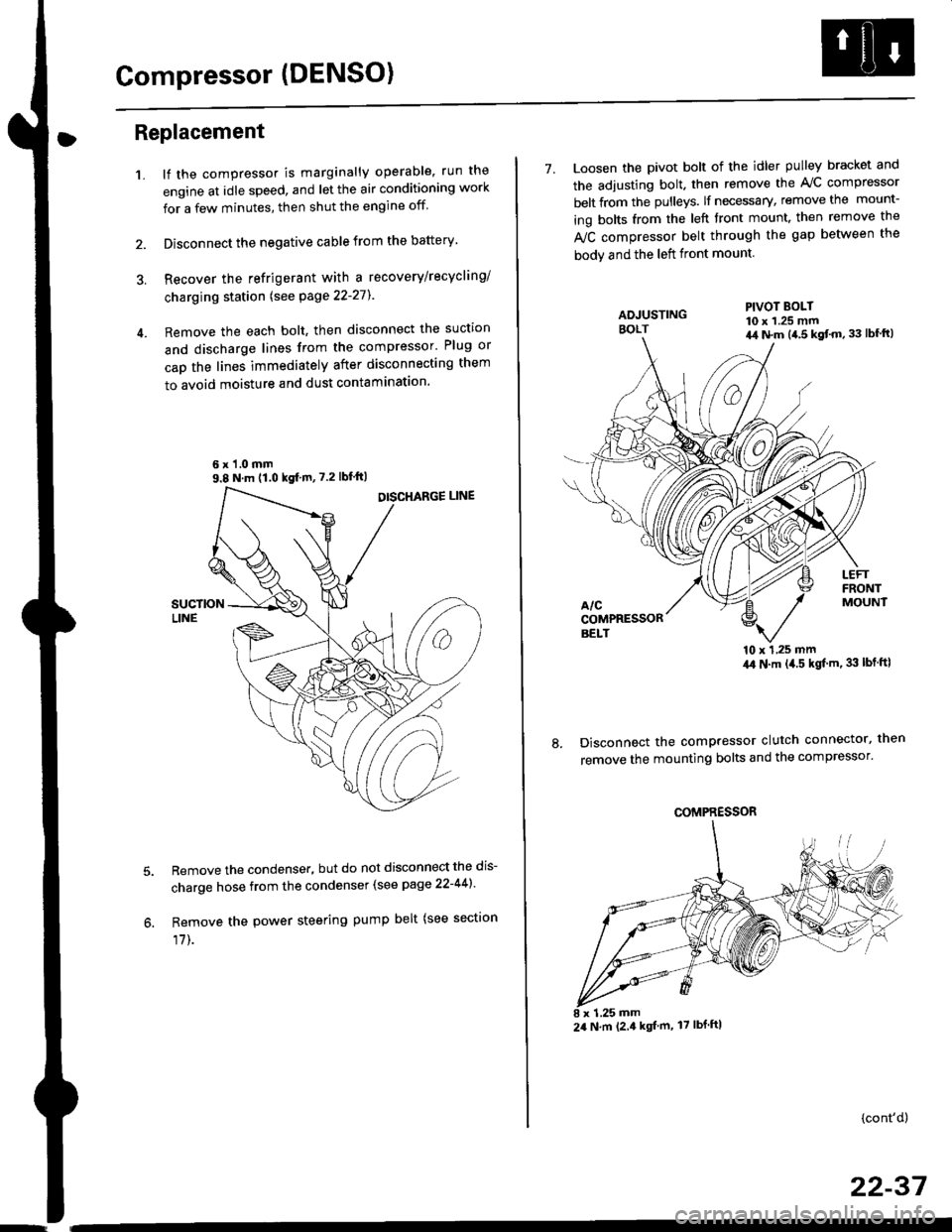

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning work

for a few minutes, then shut the engine off

Disconnect the negative cable from the battery'

Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271

Remove the each bolt, then disconnect the suction

and discharge lines from the compressor' Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contaminatlon.

6 x '1.0 mm9.8 N.m (1.0 kgf m,7.2 lbfft)

Remove the condenser, but do not disconnect the dis-

charge hose from the condenser (see page 22-441'

Remove the power steering pump belt (see sectron

17]-.

7. Loosen the pivot bolt of the idler pulley bracket and

the adjusting bolt. then remove the A,/C compressor

belt from the pulleys. lf necessary, remove the mount-

ing bolts from the left front mount. then remove the

fuC compressor belt through the gap between the

bodv and the left front mount.

'10 x 1,25 mm4,0 N.m (,1.5 kgf'm. 33 lbt ftl

Disconnect the compressor clutch connector, then

remove the mounting bolts and the compressor'

PIVOT BOLT10 x 1.25 mm4,1 N.m (4.5 kgt'm,33 lbfft)

COMPRESSOR

24 N.m (2.4 kgf m, 17 lbf ftl

(cont'd)

22-37

Page 1462 of 2189

Compressor (DENSOI

Replacement (cont'd)

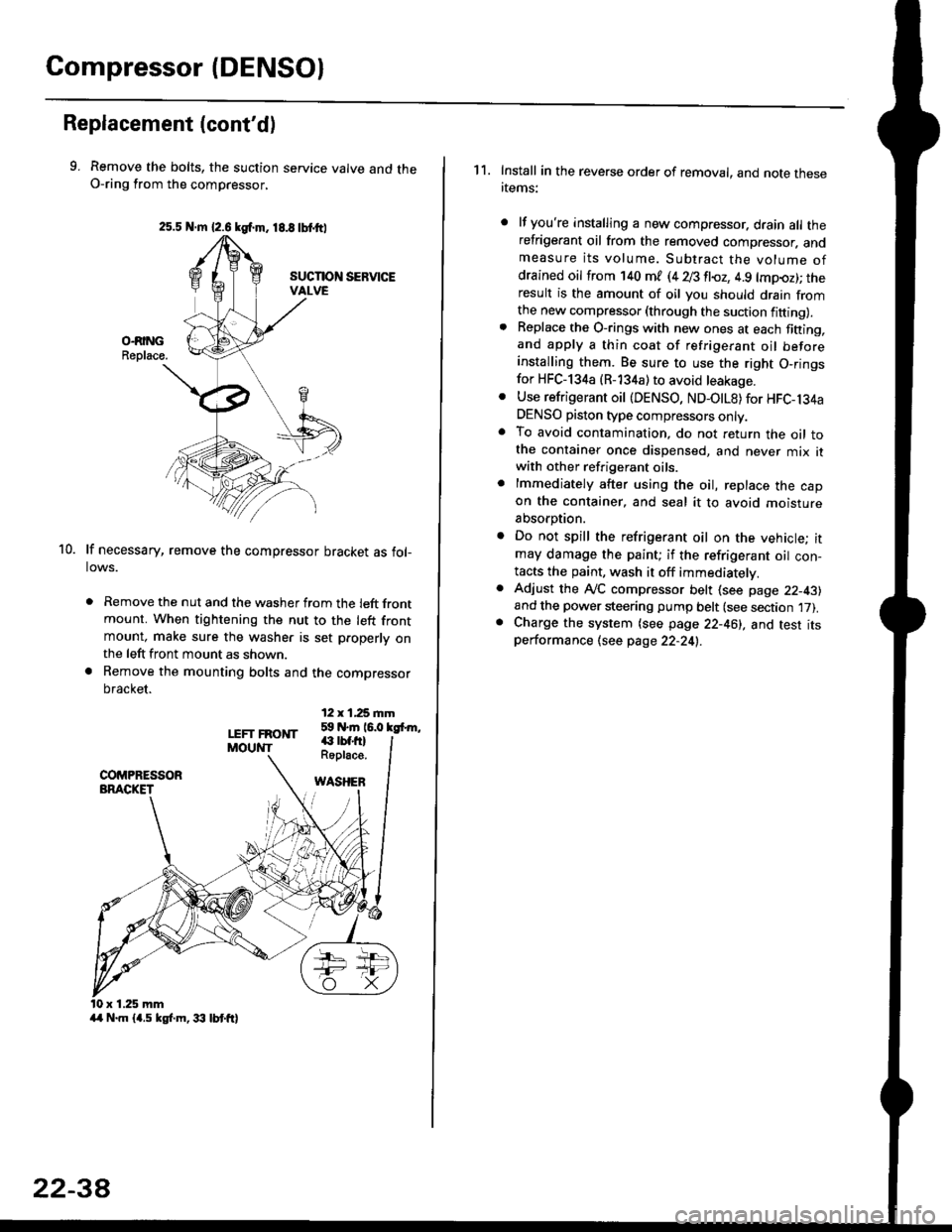

9. Remove the bolts, the suction service valve and theO-ring from the compressor,

lf necessary, remove the compressor bracket as fol-lows.

. Remove the nut and the washer from the left frontmount. When tightening the nut to the left frontmount, make sure the washer is set p.operly onthe left front mount as shown.

a Remove the mounting bolts and the compressor

bracket.

12 x 1,25 rnm59 N.m 16.0 kgfrm,

10.

LEFT FRONTMOUNT€ rbf.fi)Roplace.

WASHEB

x 1.25 mm

2s.5 N.m {2.6 kgf.m. 18.8 tbtttl

4/r N.m {4.5 kgf.m, 33 lbt ft}

22-3A

1 1. Install in the reverse order of removal, and note thesertems:

lf you're installing a new compressor. drain all therefrigerant oil from the removed compressor. andmeasure its volume. Subtract the volume ofdrained oil from '140 ml (4 28 fl{,z, 4.9 lmpoz); theresult is the amount of oil you should drain fromthe new compressor (through the suction fifting).Replace the O-rings with new ones at each fining,and apply a thin coat of refrigerant oil beforeinstalling them. Be sure to use the right O,ringsfor HFC-134a (R-134a) to avoid leakage.

Use refrigerant oil {DENSO, ND-OtL8) for HFC-134aDENSO piston type compressors only.To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refrigerant oils.

lmmediately after using the oil, replace the capon the container, and seal it to avoid moisture

absorption.

Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediatelv.

Adjust the ly'C compressor belt (see page 22-43)and the power steering pump belt (see section 17).Charge the system (see page 22-46), and test itsperformance (see page 22-24!..