ECO mode HONDA CIVIC 1999 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 538 of 2189

J

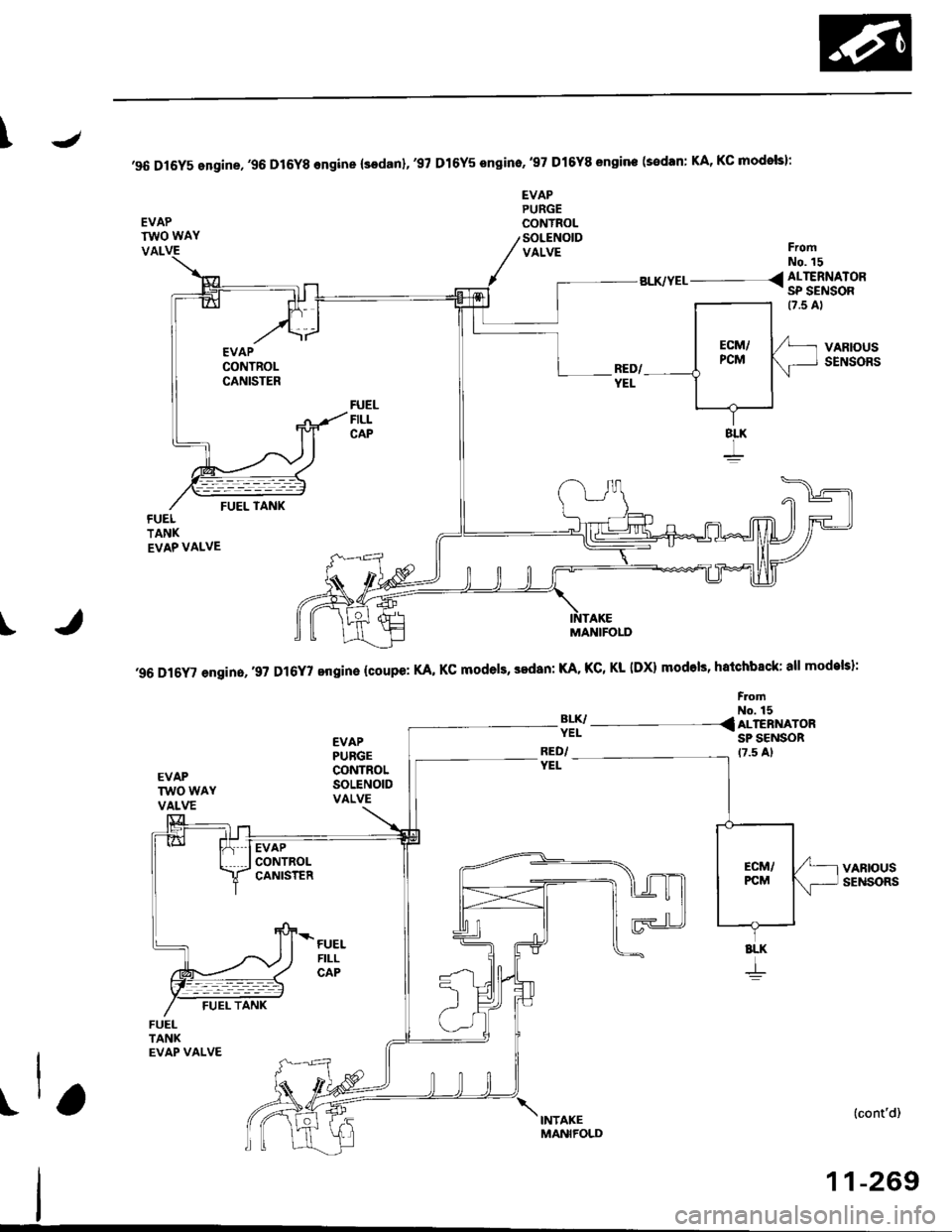

'96 Dl6Y5 engine,'96 D16Y8 engine (sodanl,'97 Dl6Y5 sngino,'97 Dl6Y8 sngine (sedan: KA, KC modols):

EVAPTWO WAY

EVAPPURGECONYROLSOLENOIDVALVEVALFromNo. 15

BLK/YEL__ _ < ALTERNATOR- SP SENSOR

FUELFILLCAP

VARIOUSSENSORS

(cont'd)

11-269

I

'96 D16Y' engin.,.9? D16Y7 engine {coupe: KA, KC models, sedan: KA. KC, Kl- IDX) modols, hatchback: all models}:

FromNo. 15

3lI/- - - -{ ALTERNAT'RSP SENSORRED/YEL

EVAPPUBGECONTROLSOLENOIDVALVE

FUELFILLCAP

8LK

+

t\,"ro*,

MANIFOLD

Page 540 of 2189

\J

\

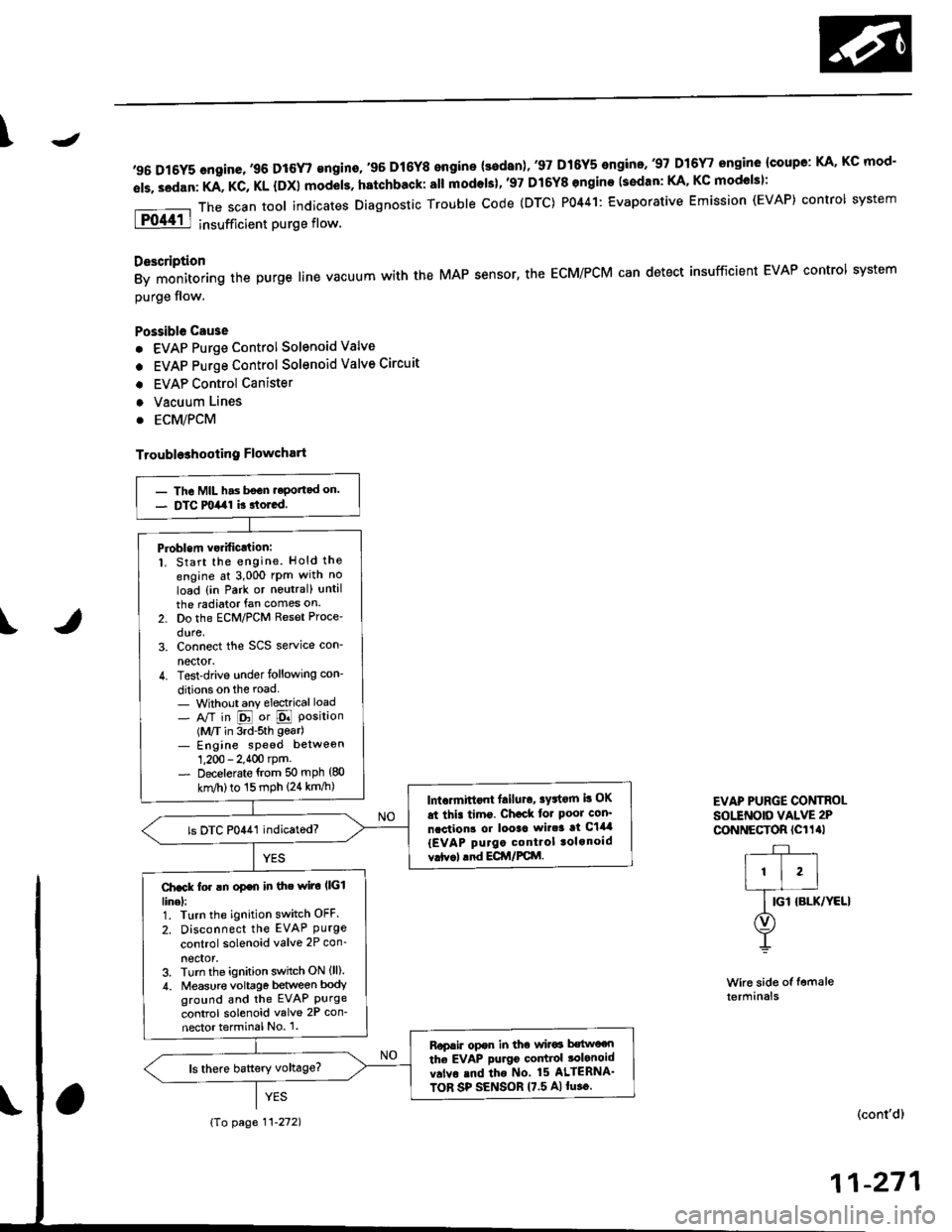

,96 D16Y5 engine,,96 D16r,gngino,,96 Dt6Y8 engine {3edan)' 37 D16Y5 engino..97 D16r, engine {coupe: KA, Kc mod-

els. sedan: KA, KC, KL {DX} models. hatchback: all modols}''97 Dl6Y8 ongine (s€dan: KA' KC mod€lsl:

The scan tool indicates Diagnostic Trouble code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the ECM/PCM can detect insufficient EVAP control system

purge flow.

Possible Cau3e

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. ECM/PCM

Troubl93hooting Flowchart

Wire side of femaleterminals

EVAP PURGE CONTROI-sottNotD vALvE 2P

CoNNECTOR (Cl1al

r-+-r

I'l'l

lG-ro.*l'rr"r

O)

Y

(cont'd)

11-271

- The MIL has bsGn.eportad on.- DTC milal k rtored.

Pioblem vsrificJtion:1. Start the engine. Hold the

engine at 3,000 rPm with no

load {in Park or noutral) until

the radiator fan comes on.

2. Do the ECM/PCM Reset Proce'

dure,3. Connect the SCS service con-

nector.4. Test-drive under following con-

ditions on the road- Without any electrical load- A/T in E or E Position(M/T in 3rd-sth gear)- Engine sPeed betweon

1,200 - 2.400 rpm.- Decelerate {rom 50 mph (80

knl/h)to 15 mph (24 km/h)lntormittont lailuro, sFtorn b OK

at thi. timo. Ch€ck tor Poor con'

ncction3 or looac wir.3 at C144

{EVAP purgo control tolonoid

vrtv.l .nd ECir/FCttl.

ls DTC P0441 indicatod?

Ch.ck fo. !n op€n in the wiro l|(illinel:1. Turn the ignition switch OFF.

2. Disconnect the EVAP Purgecontrol solenoid valve 2P con_

neclor,3. Turn the ignition switch ON (ll)

4. Measur€ voltage between bodyground and the EVAP Purgecontrol solenoid valve 2P con-

nector terminal No 1.

Rop.ir opor in tho wir6 b€two€n

the EVAP purgo codtiol tolonoid

v.lvo rnd tho No 15 ALIERNA'

TOR SP SENSOR 17.5 A)lu.o.

{To page 11-272)

Page 544 of 2189

\J

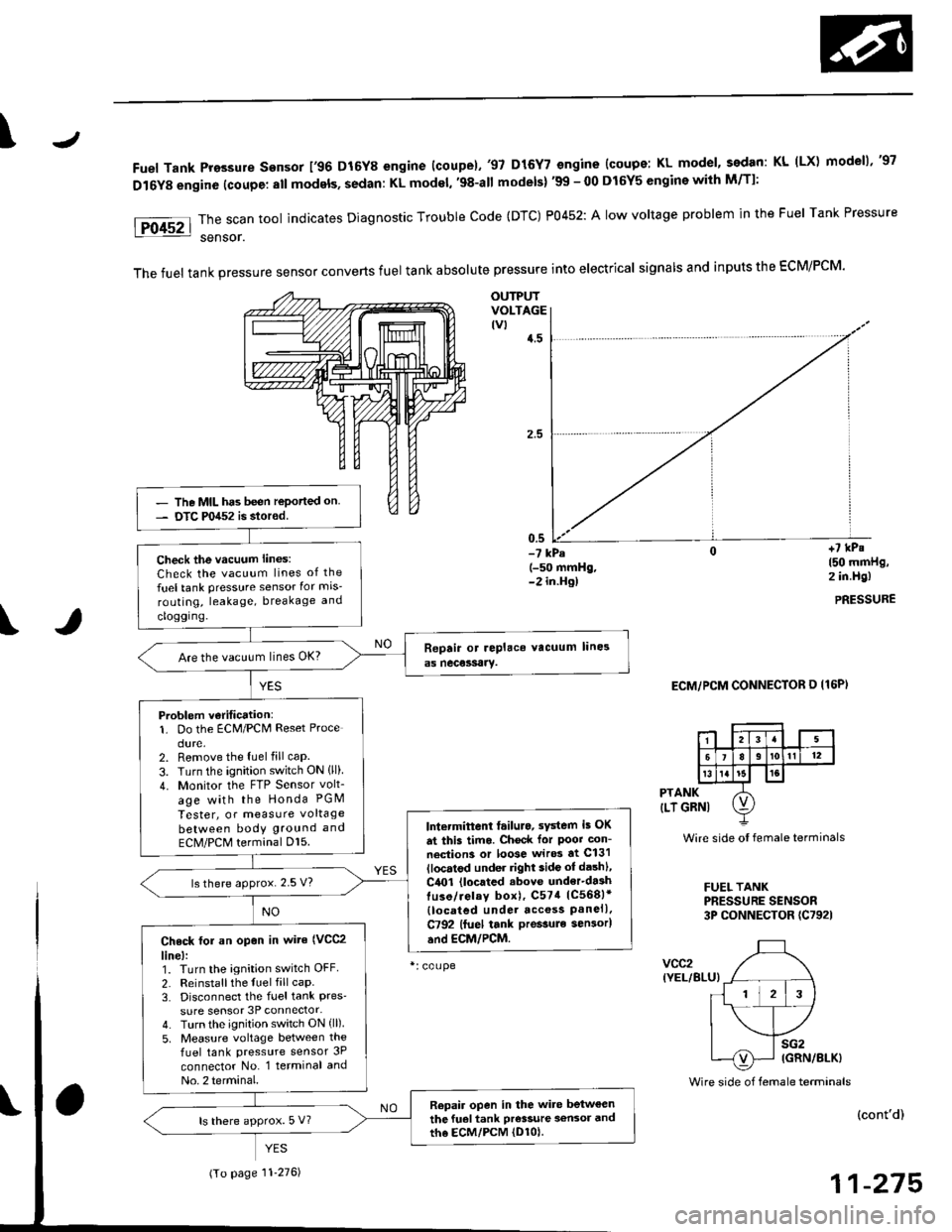

Fuel Tank Pro3sure sensor 196 D16Y8 engine (coupe).'97 D15Y7 engine {coupe: KL model, sedan: KL (LX) modeu,'97

D16Y8 engine (coupe: all models, sedan: KL model, '98-all models) '99 - 00 D16Y5 engine with M/Tl:

\

PTANK

{LT GRNI

vcc2(YEL/BLU}

Wire side oI female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR (C7921

sG2IGRN/8LK)

Foc2l::il":"toolindicatesDiagnosticTroublecode(DTc)P0452:A|owvo|tageprob|emintheFue|TankPressure

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the EcM/PCM.

OUTPUTVOLTAGEtvt4.5

-? kPa(-50 mmHg,-2 in.Hg)

ECM/PCM CONNECTOR O I16P)

Wire side of female terminals

+7 kPs150 mmHg,2 in.Hg)

PRESSURE

(cont'd)

11-275

- The MIL has been reported on- DTC P0452 is stored.

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum lines OK?

Problem v€ritication:1. Do the ECM/PCM Reset Proce

dure.2. Remove the luel fill caP.

3. Turn the ignition switch ON lll)4. Monitor the FTP Sensor volt_

age with the Honda PGM

Tester, or measure voltage

between bodY ground and

ECM/PCM terminal Dl5.lntermittent tailuro, sYstem i5 OK

dt this timo. Chock for Poot con-

neciion3 or loose wir* at C131

llocatod under right side ot dashl,

C4O1 (located .bove under'da3htuso/ielay box), C574 1C568)*

{located under acc€ss Panell.C792 lfuel tank pressule sen3or)

and EcM/PCM.

ls there approx. 2.5 V?

Check tol an op€n in wite (VCC2

line):1. Turn the ignition switch OFF

2. Reinstallthe fuel fill caP.3. Disconnect the fuel tank Pres'sure sensor 3P connector-4. Turn the ignition switch ON (ll)

5, Measure voltage between the

fuel tank pressure sensor 3P

connector No. l terminal and

No. 2 terminal.

Repair open in the wite betweenthe fuel tank Pr€s3ure a€n3or andth6 EcM/PcM (D1ol.ls there approx. 5 V?

(To page 11'276)

Page 548 of 2189

\

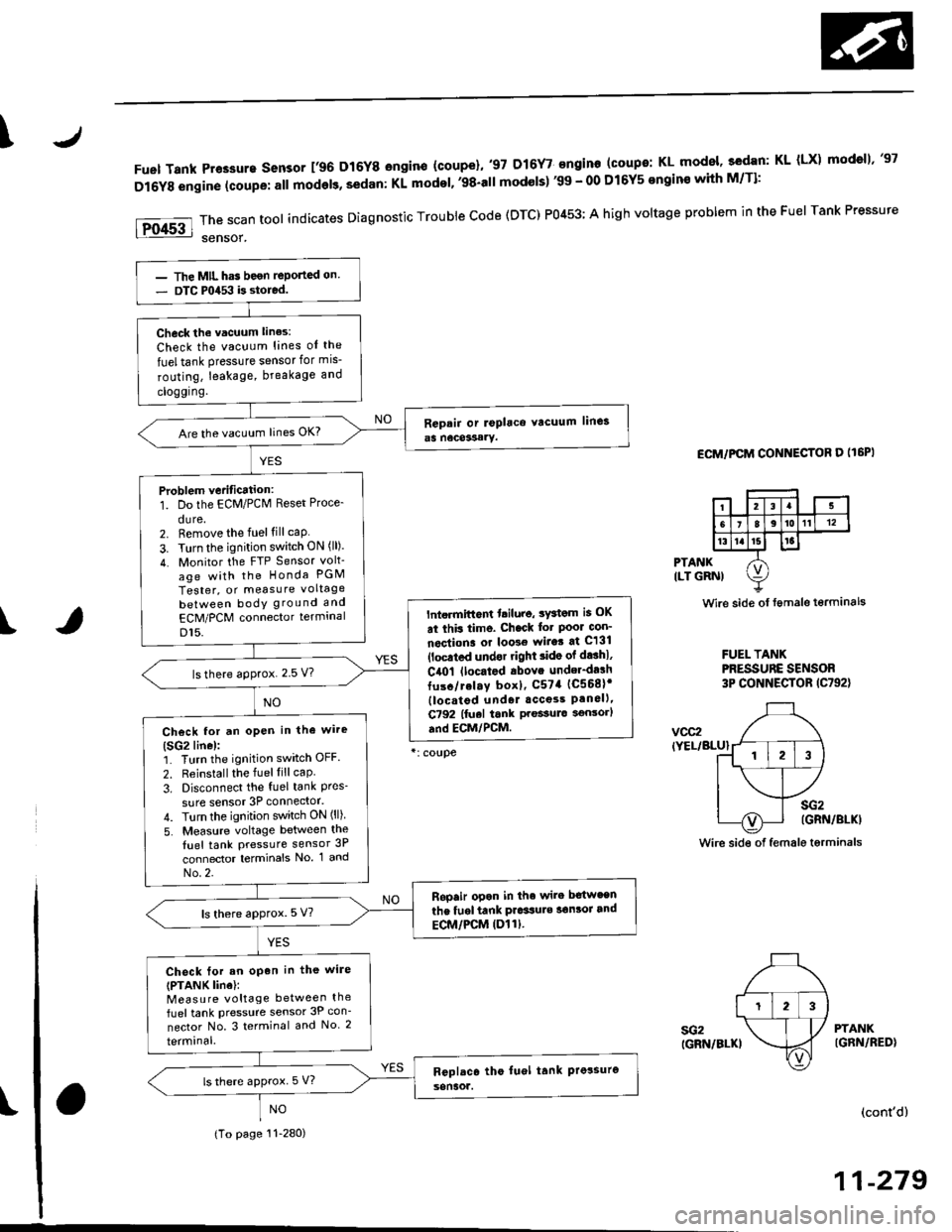

Fue| Tank Pr€ssure sensor 196 Dr6Y8 engine (coupe},,97 D16Y7 angino (coupo: KL mode|' 3edan: KL (Lxl modg||',97

Dl6Y8 engine (coupe: all modeb, sedan: Ki model.'98'all modols) 39 - 0O Dl6Y5 ongins with M/Tl:

rFoG'l::;Jl"too|indicatesDiagnosticTroub|ecode(oTc)P0453;Ahighvo|tageprob|emintheFue|TankPressure

ECM/PCM CONNECTOR D Il6PI

PTANKILT GRNI

\

Wire side of tgmale torminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR (C792)

vcc2(YEL/BLU}

sG2(GRN/BLKI

Wire sid€ of female terminals

I

sG2IGRN/BLKI

PTANKIGBN/RED}

(cont'd)

11-279

The MIL has beon reponed on

DTC P0453 b stored.

Check the vacuum lines:

Check the vacuum lines oI the

fueltank pressure sensor for mis-

routing, leakage, breakage and

clogging.

Are the vacuum lines OK?

Problem verification:1. Do the ECM/PCM Reset Proce-

dure.2. Femove the fuel fill cap

3. Turn the ignition switch oN (ll).

4. Monitor the FTP Sensor volt-

age with the Honda PGM

Tester, or measure voltage

between bodY ground and

ECM/PCM connector termrnal

D15.

lntormittont t iluro, 3Ystem is OK

at this time. Check lot Poor con_

noctiona or loo3e wirat at C131

{loc.ted undor right 3id6 of d8hl,

CaOl llocatod rbov. under-dalh

fus6/relay boxl, C574 (C568lr

llocatod und6l accoss Pan6ll,C792 lfuel tank Preasulo aonlorl

end ECM/PCM.

ls there approx. 2 5 V?

Check for an oPen in the wire(SG2line):1. Turn the ignition switch OFF.

2. Reinstall the fuellill cap

3. Disconnect the fuel tank Pres-sure sensor 3P connector.

4. Turn the ignition switch ON (ll)

5. Measure voltage between the

fuel tank Pressure sensor 3P

connector terminals No. 1 and

No.2.

Ropair opon in the wira b€tw€sn

the fuel tank prasure sonlor and

ECM/PCM (Dl1).ls there aPProx. 5 V?

Check for an open in the wire(PTANK line):Measure voltage between the

fueltank Pressure sensor 3P con-

nector No. 3 terminal and No. 2

termrnal,

ls there approx. 5 V?

*: coupe

{To page 11-280)

Page 679 of 2189

Automatic Transmission

Special Tools ......... .....'."".'-.-.' 14'2

Description .,....................-...... 14-3

power Flow ......,................. 14"6

Elestronic Control System .... . ................'..'.'.. 14-13

Hvdraulic Control .....'......" 1'l-19

Hydraulic F|ow...... .'.'.".'....11-21

Lock-up System '............ ... t/t'33

Electrical System

Component Locations....,.............'......'.............'.,. 14'39

PCM Circuit Diagram

lA/T Control Syst€m: '96 - 98 Models) .........'.. 1/t-40

PCM Tarminal Volt8ge/Measuring Condhions

{'96 - 98 ModeblA/T Control System ............

PCM Circuit Disgram(A/T Conlrol System: '99 - 00 Modsls) '..........' 14-44

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)A/T Control System ...

Troubleshooting Proceduros ....

Symptom-to-ComPonent Chari

Efectricaf SFiem - '96 - 98 Models '..-.-..."'.'..11-52

Eloqtrical System -'99 - 00 Modols ... .........". 1+54

EleclricatTroubl$hooting ('96 - 98 Models)

Valve Body

Repair .................... ........'.... 14-139

Valve

Assembly

ATF Pump

1,1-1i10

Inspection ...........'.......... 14-141

Main Valvs Body

Disass€mbf y/lnspoction/R.sssembly .'.'.'.'.. -. -. 1 1-1 12

Secondsry Valve BodY

Disa$embfy/lnspoction/Rsassembly ......'.'.'.'. 11-111

Regulator Valve Body

Disa$embly/lnspoction/Rea3sembly ..........'... 14-1{5

Servo Body

Disassombly/lnsp€ction/Reassembly .".'........ 14-146

Lock-up Valv6 Body

Dis$s.mbf y/ln3poction/Rea$embly .'.. -. -..'.'.' 1 1-1 17

Mainsh!ft

Dkassembly/lnep€ction Reassembly ..'...'........ 14'148

Inspoction .............'..........'. l it-149

Countsrshaft

Disa$embly/lnspeqtion/Rea3sembly .......'...'.. 1a-l51

Dba$ombly/Re$s.mblY11-152

til-46

I rl-48

Troubleshooting Flowcharts

Electrical Troubleshooting ('9!t - 00 Models)

Troublsshooting Flowchart3

Lock-up Control Solenoid vslvo A/B AssemblY

RePlacoment

Shift Cont.ol Solenoid Valve A/B A3sembly

Inspestion

Ona-way Clutch

Disassembh/lrupoction/Rca$embly .. "'........ l4-155

Clutch

lllustlttcd Ind.x {A48A, B4RA Transmlssion) ..' 14-156

tustr.tod Index (MrnA Transmi$ionl ............ til-158

...................... 14-153

L

14-56

1+81'

14-105

1+105

Replacoment ......

Mainshaft/Countorshaft Spo€d Sonsors

Replacemsnt ......'."'........... lit'108

Hydraulic System

Symptom-to-Componeni Chart

Hydraulic Sydemr+109

t4-113

1+116

11-117

Rea$emblY

14-106 Difforrr ial

llhdraied Index........ t4-156

B.ckhrh ln3poction. 14-167

Boaring Roplacemont..-..........11-167

..... 14-108 Diftrrsniial Carrior Repl8cemeni .'.-.............'...' lil-168

Oil Sall Romovalt4-t 59

Oil Soal ln3tallstion/Sidc Clearance'......'.....'... 1'l'169

Torqua Convertcr Housing Boarings

Mlin3haft Besring/Oil Scal Roplac.ment ."..'.. lil-172

Counio6hatt Betring R.plscem.nt ..'...... ....... 14-173

Test.....,......14-106

14-107

14-160

11-162

11-171

11-175

Replacement

Test .....,.,..........

Road Te3t

Linear Solenoid AsssmblY

Stall Speed

lllustrated Indax

Transmission/End Cover'. ....

Transmission Hou3ing,.............'.'......'....""..-.-.. 11-128

Torque Conve.ter Housing/Valvo Body ........... 14-130

End Cover

14-itB Park Stop

1+119 In3pection/Adiustmsnt...'......'.'............'...."""'14-175

Transmbgion

Reassombly

11-122 Torquo Convertet/Drivr Plsie ............'.'............'.. . l4-182

Transmission

11.726 Inrtallation

Tranlmission Housing Boarings

Msinsh.ft /CounteEhaft Bearings

B!pltcomgnt

Rcvo.3s ldlor Gear

lnrtallation

Cooler Flushing ..

Shift Cabls

Test

Fluid Level

Checkin9 .........."..'.'.....

Changing

Pressure Testing

Transmission

Transmission

Rgmoval ..

lil-176

.'..........'.'.'..... 1'l-183

.... lil-187

11-132Adiustmont

RemovaUlnttallation1,1-190

lit-191Transmisgion Housing

Removal ... '.'...... ......'..... 14-l3il

Tolque Convgrter Housing/valvs Body

Rsmoval .........,...... ............. 14-136

Valve CaDs

Description .......'................. t 4'138

Shift lndicator Panel

Adiu3tmant ..'.................. 14-192

ATF Coolor Hoses

Connection ..,............,.,....... l'l-192

Shift Lever .,........

Page 694 of 2189

Description

Electronic Control System {cont'dl

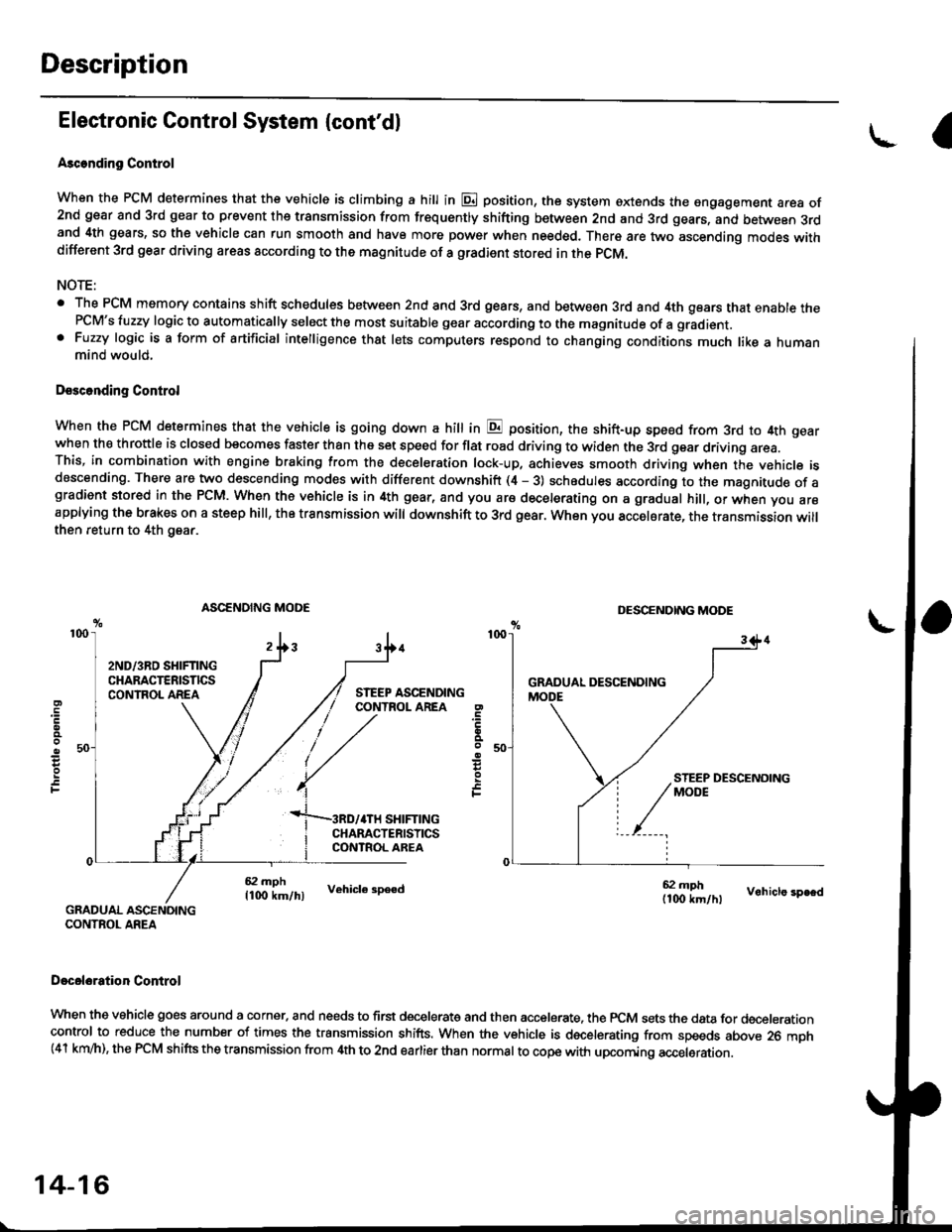

Ascending Control

When the PCM determines that the vehicle is climbing a hill in E position, the system oxtends the sngagement area of2nd gear and 3rd gear to prevent ths transmission from fr€quently shifting between 2nd and 3rd gears, and between 3rdand 4th gears, so the vehicle can run smooth and have more power when needed. There are two ascending modes withdifferent 3rd gear driving areas according to the magnitude of a gradient stored in the pCM.

NOTE:

. The PCM memory contains shift schedules between 2nd and 3rd gears, and between 3rd and 4th gears that enable thePCM's fuzzy logic to automatically select the most suitable gear according to the magnitude of a gradient. Fuzzy logic is a form of artificial intelligence that lets computers respond to changing conditions much like a humanmind would,

Dssconding Control

When the PCM determines that the vehicle is going down a hilt in E position, the shift-up speed from 3rd to 4th gearwhen th€ throftle is closed becomes faster than the set speed for flat road driving to widen the 3rd gear driving area.This, in combination with engine braking from the deceleration lock-up, achieves smooth driving when the vehicle isdescending. There are two descending modes with different downshift (4 - 3) schedules according to the magnitude of agradient stored in the PCM. When the vehicle is in 4th gear, and you are decelerating on a gradual hill, or when you areapplying the brakes on a steep hill, the transmission will downshift to 3rd gear. When you accel6rate, the transmission willthen return to 4th gear.

ASCENDING MODEDESCENDING MODE

4TH SHIFTING

L.

F

CHARACTERISIICSCONTROL AREA

ff.1"11", vehicr. 3pe€dff;Tlr., vohicre speed

GRADUAL ASCENOINGCONTROL AREA

Docel6ration Control

When the vehicle goes around a corner. and needs to first decelerate and then accelerate. the rcM sets the data for decelerationcontrol to reduce the number of times the transmission shifts. When the vehicle is decelerating from speeds above 26 mph(41 km/h), the rcM shifts the transmission from 4th to 2nd earlier than normal to cope with upcoming acceleration.

14-16

Page 701 of 2189

\

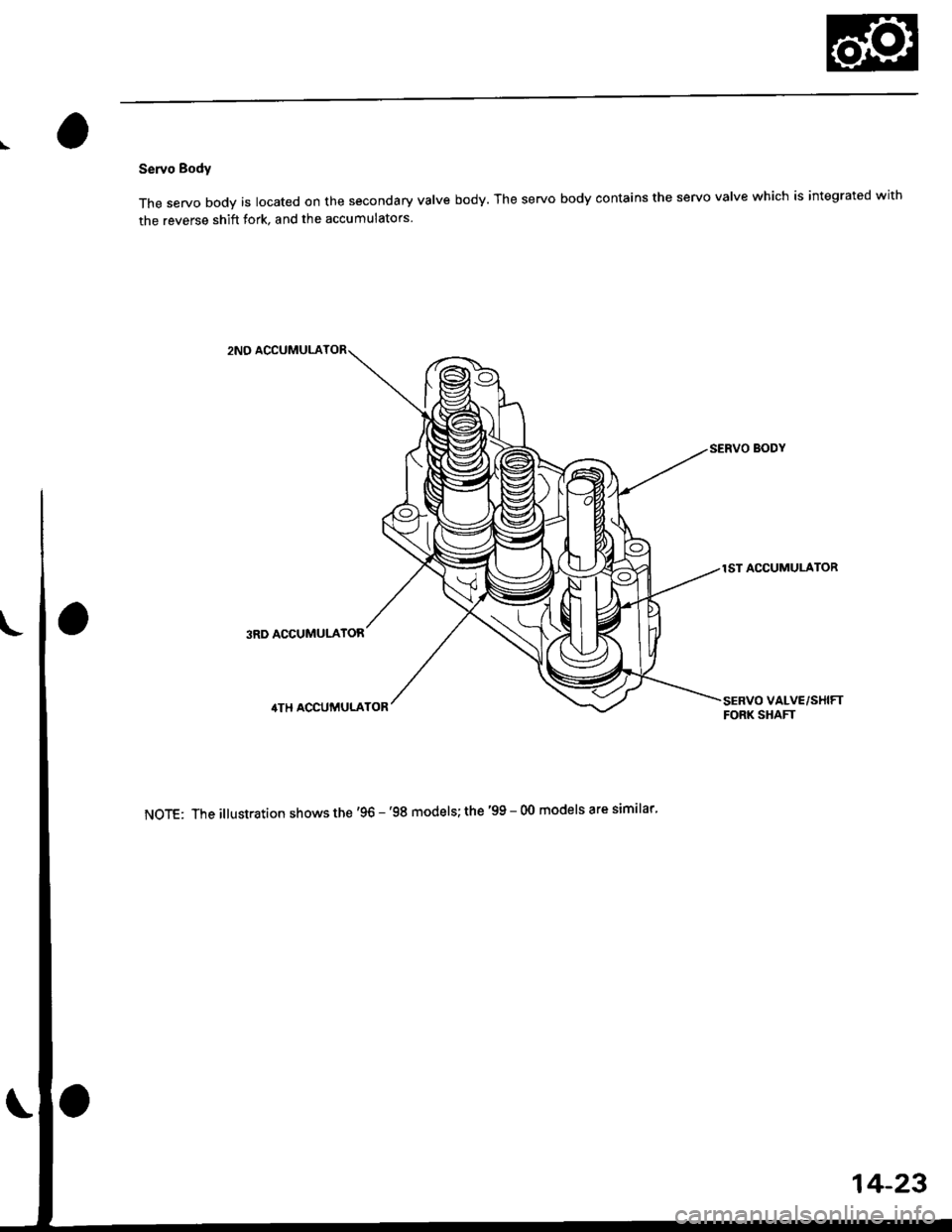

Servo Body

The servo body is located on the secondary valve body. The servo body contains the servo valve which is integrated with

the reverse shift fork, and the accumulators

2NO ACCUMULA

SERVO BODY

1ST ACCUMULATOR

3RD ACCUMULATOR

SERVO VALVE/SHIFTFORK SHAFT

NoTE: The illustration shows the'96 - '98 models; the '99 - 00 models are similar'

14-23

Page 724 of 2189

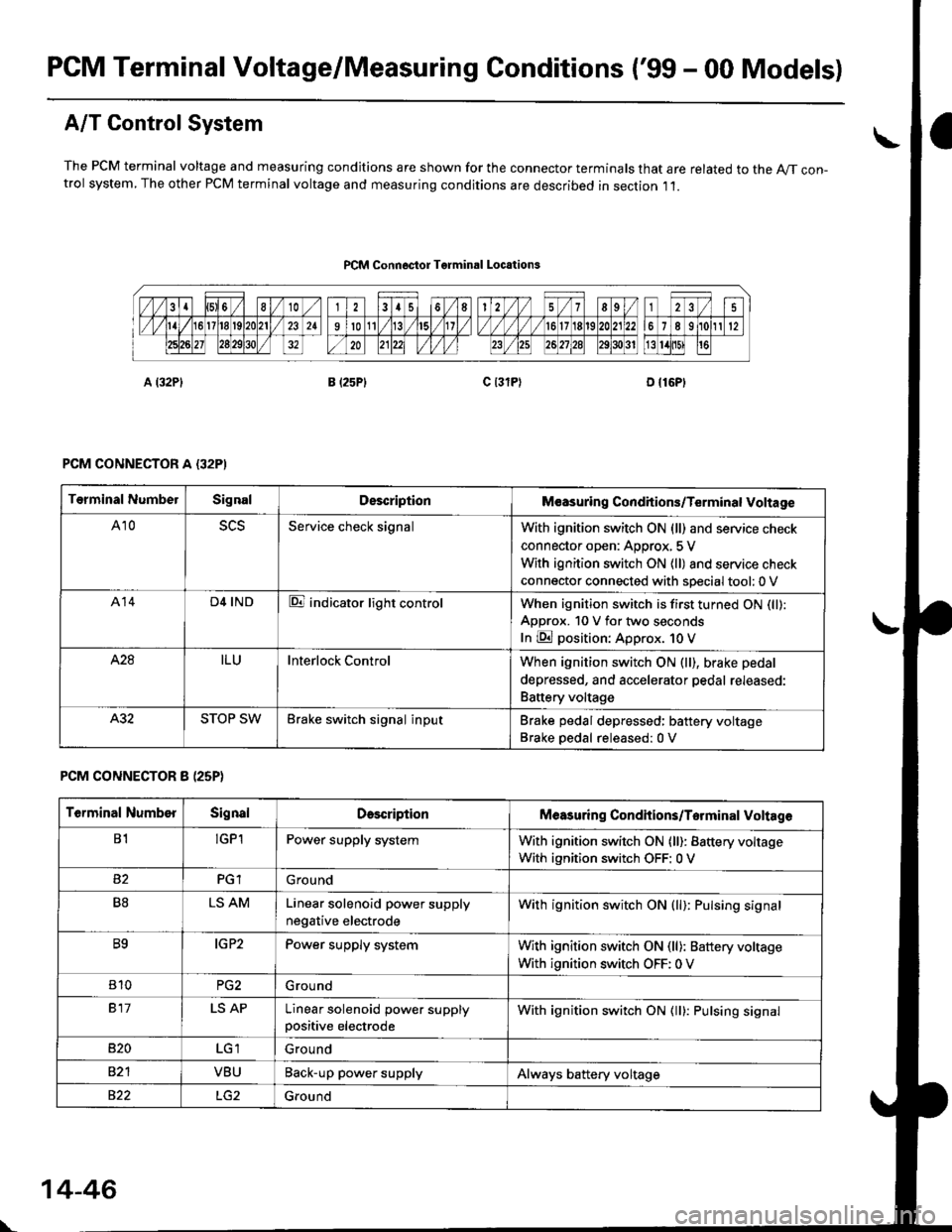

PCM Terminal Voltage/Measuring Conditions ('99 - 00 Models)

A/T Control System

The PCM terminal voltage and measuring condjtions are shown for the connector terminals that are related to the A//T con-trol system, The other PCM terminal voltage and measuring conditions are described in section ,11.

PCM Connoctor Tgrminrl Locations

PCM CONNECTOR A {32PI

PCM CONNECTOR 8 (25P}

Terminal NumbelSignalDescriptionM€asuring Conditions/Terminal Voltage

A105L5Service check signalWith ignition switch ON (ll) and service check

connector open: Approx, 5 V

With ignition switch ON (ll) and service check

connector connected with sDecial tool: 0 V

A14D4 INDE indicator light controlWhen ignition switch is first turned ON (ll):

ApDrox. 10 V for two seconds

In E position: Approx. 1O V

428ILUInterlock ControlWhen ignition switch ON (ll), brake pedal

depressed, and accelerator pedal rereaseo:

Battery voltage

A.32STOP SWBrake switch signal inputBrake pedal depressed: battery voltage

Brake oedal released:0 V

Terminal NumberSignalDescdptionMeasuring Condhions/Torminal Voltag6

B1!GP1Power supply systemWith ignition switch ON (ll): Battery voltage

With ignition switch OFF: 0 V

PGlGround

B8LS AMLinear solenoid power supply

negative electrode

With ignition switch ON (ll): Pulsing signal

B9IG P2Power supply systemWith ignition switch ON (ll): Baftery voltage

With ignition switch OFF: 0 V

810PG2G rou nd

917LS APLinear solenoid power supplypositive electrode

With ignition switch ON (ll): Pulsing signal

B�20Ground

VBUBack-up power supplyAlways battery voltage

822Ground

\

14-46

Page 726 of 2189

Troubleshootin g Procedures

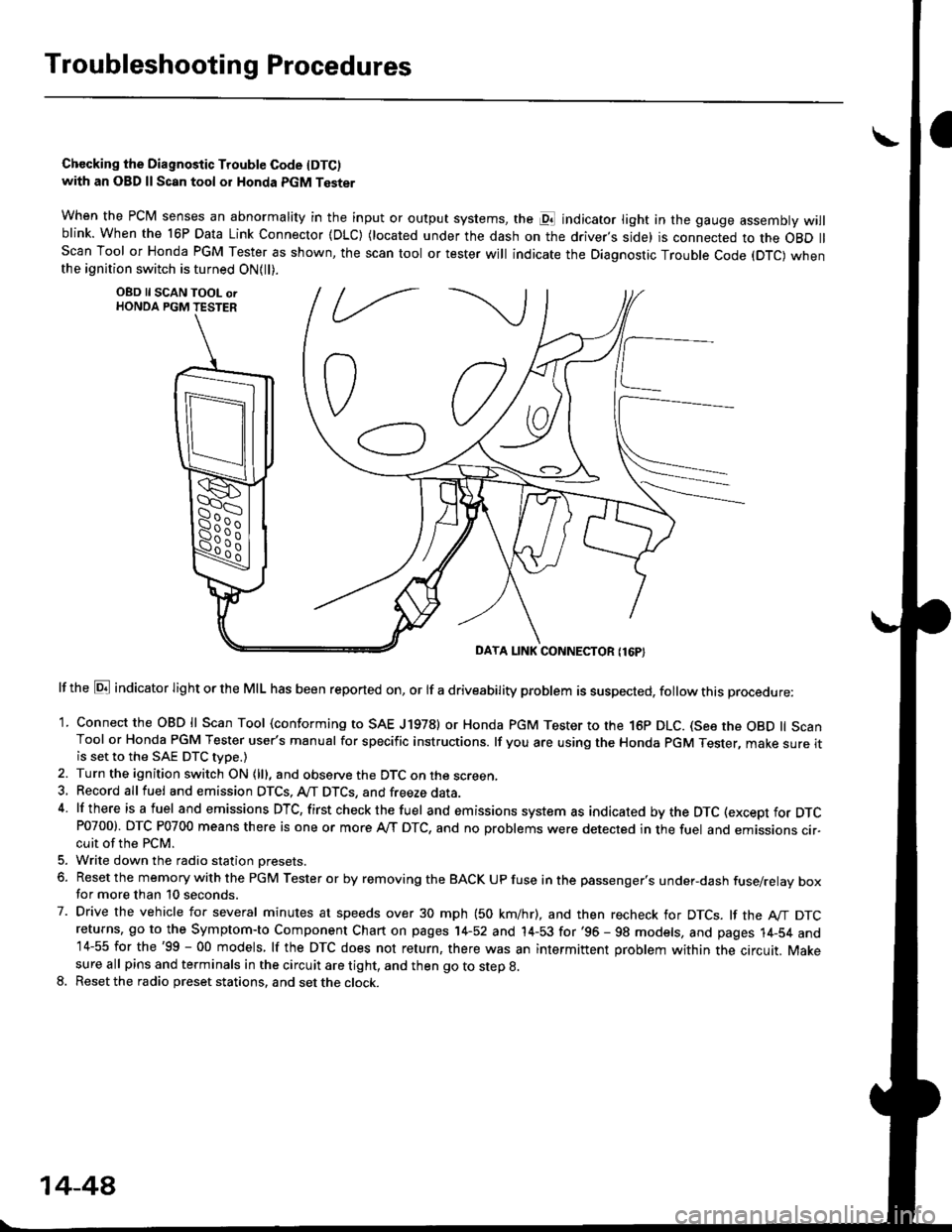

Chccking the Diagnostic Trouble Code IDTC)with an OBD ll Scan tool or Honda PGM Tester

when the PCM senses an abnormality in the input or output systems, the pl indicator light in the gauge assembly willblink. When the 16P Data Link Connector (DLC) (located under the dash on the driver,s side) is connected to the OBD llScan Tool or Honda PGM Tester as shown, the scan tool or tester will indicate the Diagnostic Trouble Code (DTC) whenthe ignition switch is turned ON{ll).

lf the El indicator light or the MIL has been reported on, or lf a driveability problem is suspected, follow this procedure:

1. Connect the OBD ll Scan Tool (conforming to SAE J19781 or Honda PGM Tester to rhe 16p DLC. (See the OBD ll ScanTool or Honda PGM Tester user's manual for specific instructions. lf you are using the Honda PGM Tester, make sure itis set to the SAE DTC type.)

2. Turn the ignition switch ON (lll, and observe the DTC on the screen,3, Record all fuel and emission DTCS, A/T DTCS, and freeze data.4 lf there is a fuel and emissions DTC, first checkthe fuel and emissions system as indicated bythe DTC (except for DTCP0700). DTC P0700 means there is one or more A,/T DTC, and no problems were detected in the fuel and emissions cir-cuit of the PCM.

5. Write down the radio station oresets.

6. Reset the memory with the PGM Tester or by removing the BACK UP fuse in the passenger's under-dash fuse/relay boxfor more than 10 seconds.

7. Drive the vehicle for several minutes at speeds over 30 mph (50 km/hr), and then recheck for DTCS. lf the A"/T DTCreturns, go to the Symptom-to Component Chart on pages 14-52 and 14-53 for'96 - 98 models, and pages 14-54 and14-55 for the'99 - 00 models, lf the DTC does not return, there was an intermittent problem within the circuit. Makesure all pins and terminals in the circuit are tight, and then go to step g.

8. Reset the radio preset stations, and set the clock.

OBD ll SCAN TOOL orHONDA PGM TESTER

DAYA LINK CONNECTOR {16P}

14-44

Page 734 of 2189

Electrical Troubleshooting (,96 - gg Models)

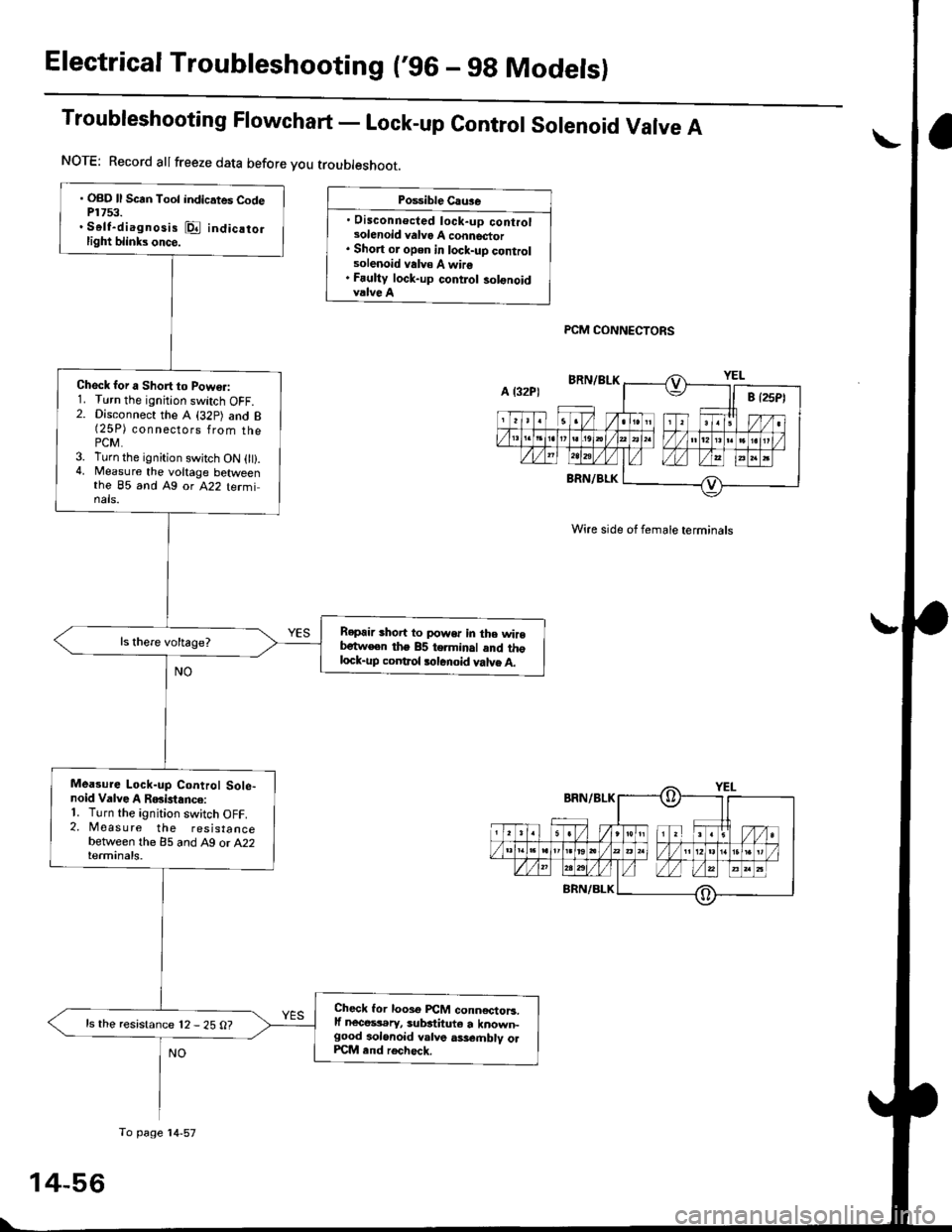

Troubleshooting Flowchart - Lock-up contror sorenoid Varve A

Po$ible Cau3e

. Disconnecled lock-up controlsolenoid valvo A connector. Short or open in lock-uD controlsolenoid valv€ A wire. Fauliy lock-up contlol solonoidvalve A

PCM CONNECTORS

Wire side of female terminals

. OBD ll Scrn Toot indicates CodeP1753.. Self-diagnosis @ indicatorlight blinks once.

Check for a Short to Powo.:1. Turn the ignition switch OFF.2. Disconnect the A (32p) and B(25P) connsgl6ps 1rq- thaPCM.3. Turn the ignition swjtch ON 0t).4, Measure the voltage betweenthe 85 and Ag or A22 terminals.

Repair shoit to power in the wirebetw€en the 85 terminal and thglock-up coDtrol tolenoid valve A.

Mea3ure Lock-up Control Sole-noid Valve A RGislance:'1. Turn the ignition switch OFF.2. Measure the resistancebetween the 85 and A9 or A22terminals.

Check lor looso PCM conn€ctoB.lf nece$.ry, substituto a known-good aolonoid valve ass€.nblv olPCM end rech6ck.

ls the resistance 12 - 25 O?

NOTE: Record allfreeze data before you troubleshoot.

A l32P)

To page'14-57