troubleshooting HONDA CIVIC 1999 6.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 774 of 2189

![HONDA CIVIC 1999 6.G Manual PDF Electrical Troubleshooting (gg - 00 Models)

Troubleshooting Flowchart - Mainshaft Speed Sensor (cont,dl

Wire side of female terminals

PCM CONNECTOR D {16PI

23/)

618

rghrll [e]

NM IREDI

(

I

NMSG {WHTI HONDA CIVIC 1999 6.G Manual PDF Electrical Troubleshooting (gg - 00 Models)

Troubleshooting Flowchart - Mainshaft Speed Sensor (cont,dl

Wire side of female terminals

PCM CONNECTOR D {16PI

23/)

618

rghrll [e]

NM IREDI

(

I

NMSG {WHTI](/img/13/6068/w960_6068-773.png)

Electrical Troubleshooting ('gg - 00 Models)

Troubleshooting Flowchart - Mainshaft Speed Sensor (cont,dl

Wire side of female terminals

PCM CONNECTOR D {16PI

23/)

618

rghrll [e]

NM IREDI

(

I

NMSG {WHTI

(REDI

MAINSHAFT SPEEDSENSOR OONNECTORRED

Wire side of female terminals

NMSG IWHTI

From page l4-95

Measure Mainshatt SpeedSensor Resistance:1. Connect the mainshaft speedsensor connector.2. Measure the resistance bet-ween the Dl1 and D12 termi-nats.

Run the Electricel Troubl€shootingFlowchart lor cod6 m?m l9).Ch€ck lor loo.o te.minol fit in th6PCM connectors. lf necossary,substitute r known-good PCMend .echeck.

ls the resistance 400 - 600 0?

Check NM Wire Continuity:1. Disconnect the 2P connectorfrom the mainshaft speed sen-sor.2. Check for continuity betweenthe D11 terminal and the No. 2terminal ot the mainshaftspeed sensor connector,

Ropair opon in the wiro lratwoentho Dll tsrminal and tha main-3hatt spe€d sensor.

Check NMSG Wire Continuity:Check for continuity between theDl2 terminal and the No. 1 termi-nal of the mainshaft spoed sen-

Repai. open in the wire betwoenthe D12 terminal and the mein-shaft 3peod sansor.

Check Ior loose terminal fit in thePCM connectors. lf necesaary.substitute a known-good PCMand recheck.

1235

678

t1vNM

o

617 89ll12

Io

t1v

WHT

1

\

14-96

Page 775 of 2189

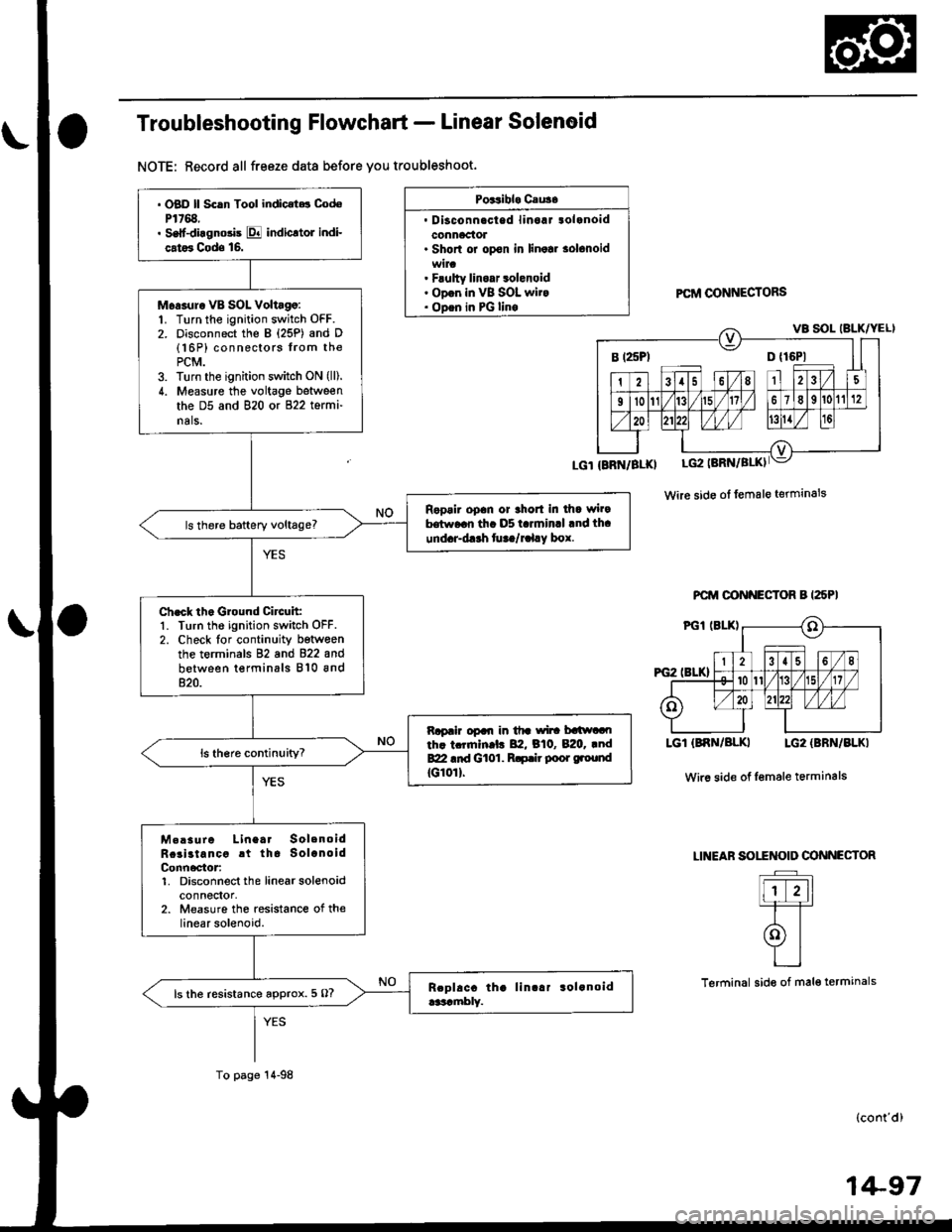

Troubleshooting Flowchart - Linear Solenoid

NOTE: Record all freeze data before you troubleshoot.

Poitibl. Cau3.

. Disconnacted linoaJ tolanoidconnaclol. Shorl or opon in linolr solonoid

. Flulty linoar 3olenoid. ODon in VB SOL wit.. ODen in PG linoPCftI @NNECTORS

Wire side ol female terminals

PCM OONNECTOR B I25PI

LGT (BNN/BLKI LG2 {BBN/BLKI

Wir6 side of Iemale terminals

LINEAF SOITNOID OONNECTOR

Flr-11=T=T

olYI

L_l

Terminal side of mal€ termanals

(cont'd)

B t25Pl D {16P1

. OBD ll Scln Tool indic.t.t CodoP1768.. Self-diagnosis E indicltol indi-

cat6 Cods 16.

Moasur. VB SOL Voltago:1. Turn the ignition switch OFF.2. Disconnect the B {25P) and D(16P) connectors from thePCM.3. Turn the ignition switch ON (lll.

4. Measure the voltage between

the D5 and 820 or 822 termi-

nals.

Ropair opan or thort in dla wi.9hrw..n th. D5 t.rminrl .nd th.

und.r-d.rh fu ta/r.l.y box.

Ch.ck th. Ground Circuit:1. Turn the ignition switch OFF.2. Check lor continuity betwoenthe terminals 82 and 822 and

between terminals 810 and820.

Rapair opal| in tfr wi|! batlwaoth. tcrrnln.l. 82, B10, B:20. .ndBZI .id Gt01. R.p.ir poor ground

tG10rl.

M.!sure Linea. SolenoidRcai3tancc rt tha SolanoidConn6ctor:1. Disconnect the linearsolenoidconnectol,2. Measure the resistance of thelinear solenoid.

ls the resistance approx. 5 O?

To page 14-98

1+97

Page 776 of 2189

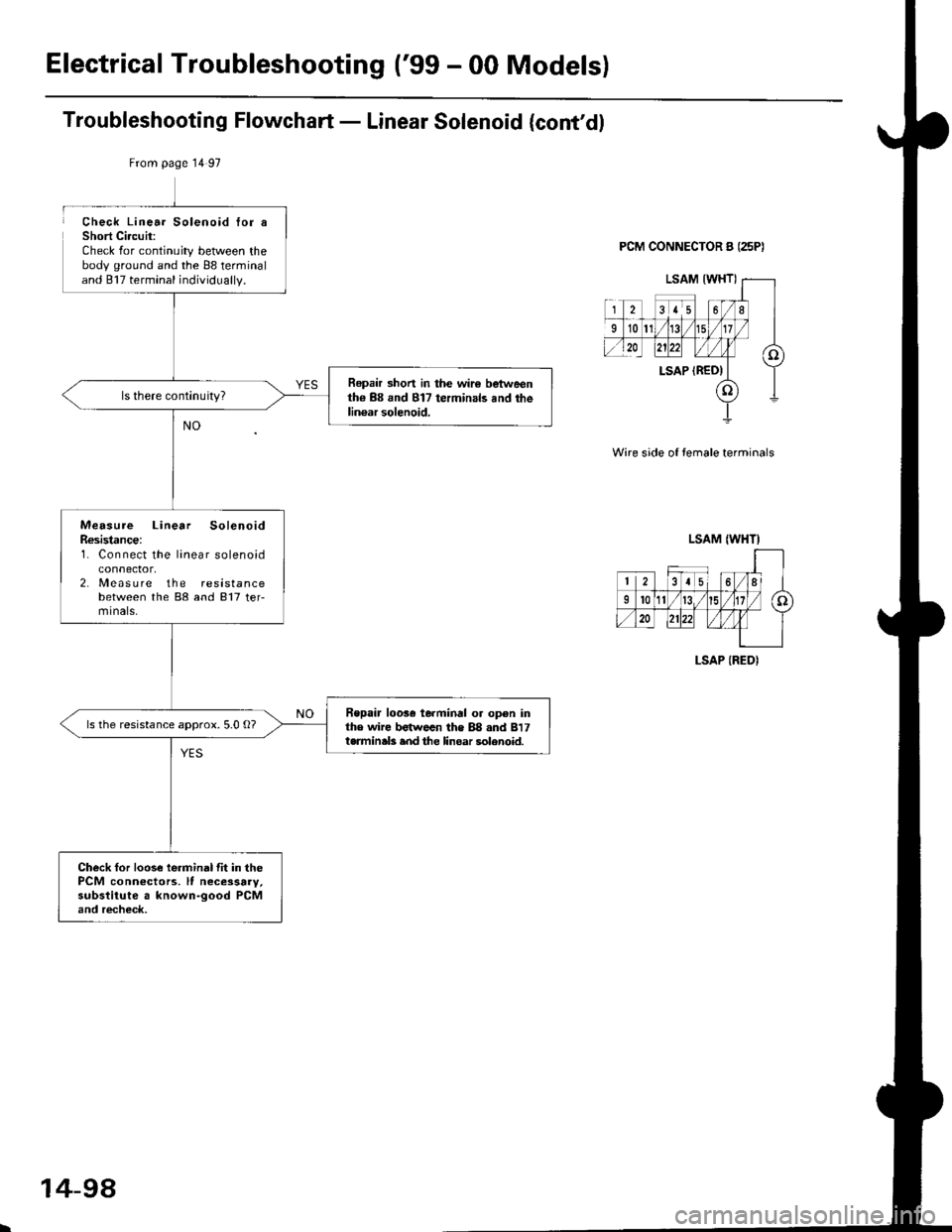

Electrical Troubleshooting ('99 - 00 Modelsl

Troubleshooting Flowchart - Linear Solenoid (cont'dl

Check Linea. Solenoid tor aShort Ci.cuit:Check for continuity between thebody ground and the 88 terminaland B17 terminal individually.

PCM CONNECTOR A {25PI

Wire side of female terminals

From page 14 97

Repair shon in the wir6 betweenth€ 88 and 817 terminals and thelin€ar solenoid,

Measure Linear SolenoidResistance:1. Connect the linear solenoidconnector,2. Meas u re the resistancebetween the Bg and 817 termtnals,

Repair loose te.minal or open inthe wire botwoen the 88 .nd Bl7t.rmin.b end the linoar 3olenoid.

ls the resistance approx. 5.0 O?

Check for loose terminal tit in thePCM conn€ctors, lf necessary,substitut6 a known-good PCMand recheck.

LSAM (WHTI

14-98

Page 777 of 2189

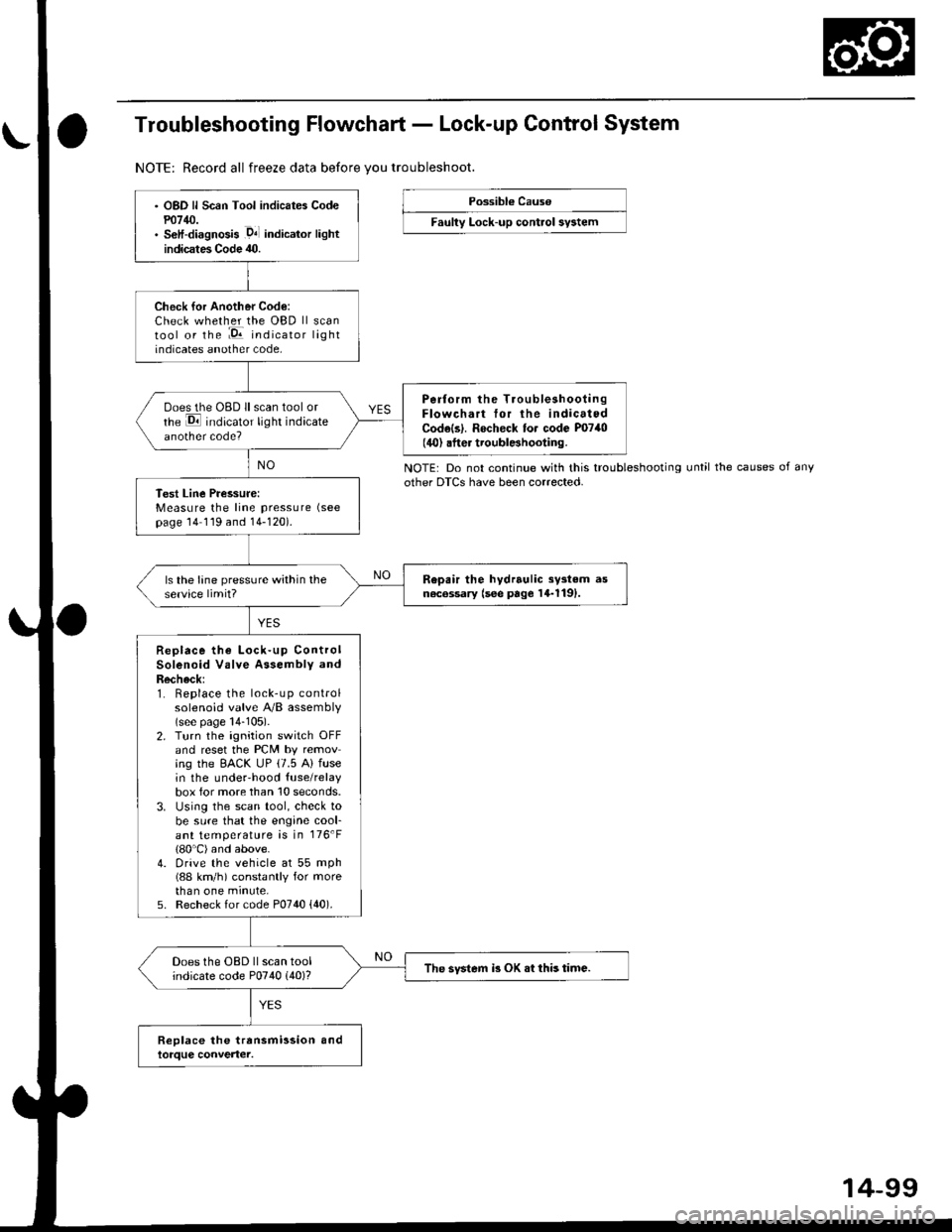

Troubleshooting Flowchart - Lock-up Control System

NOTE: Record all freeze data before vou troubleshoot.

Possibl€ Cause

Faulty Lock-up control sy3tem

NOTE: Do not continue with this troubleshootingother DTCS have been corrected.until the causes of any

OBD ll Scan Tool indicates Codem14/J.S€lf-diagnosis .D4l indicalor lightindicates Code 40.

Check for Another Code:Check whether the OBD ll scantool or the :E indicator lightindicates another code,

Perform the TroubleshootingFlowchart tor the indicatedCodels|. Rocheck to. code P0740(40) .fter troublBhooting.

ooes the OBD ll scan tool orrhe E indicator light indicateanother code?

Test Line Pressure:Measure the line pressure (see

page 14 119 and 14-120).

Repair the hydrrulic sy3tem asn6c6ssary (see page 14-1191.ls the lane pressure within theservice limit?

Replace the Lock-up ControlSolenoid Valve Assembly andRecheck:1. Replace the lock-up controlsolenoid valve A/B assembly(see page 14-105).2. Turn the ignition switch OFFand reset the PCM by removing the EACK UP (7.5 A) fusein the underhood {use/relaybox for more than 10 seconds.3. Using the scan tool, check tobe sure that the engine cool-ant temperature is in 176'F(80'C) and above.4. Drive the vehicle at 55 mph(88 km/h) constantly for morethan one minute,5. Recheck for code P0740 {40).

Does the OBD ll scan toolindicate code P0740 (40)?The svstem i3 OK .t this time.

14-99

Page 778 of 2189

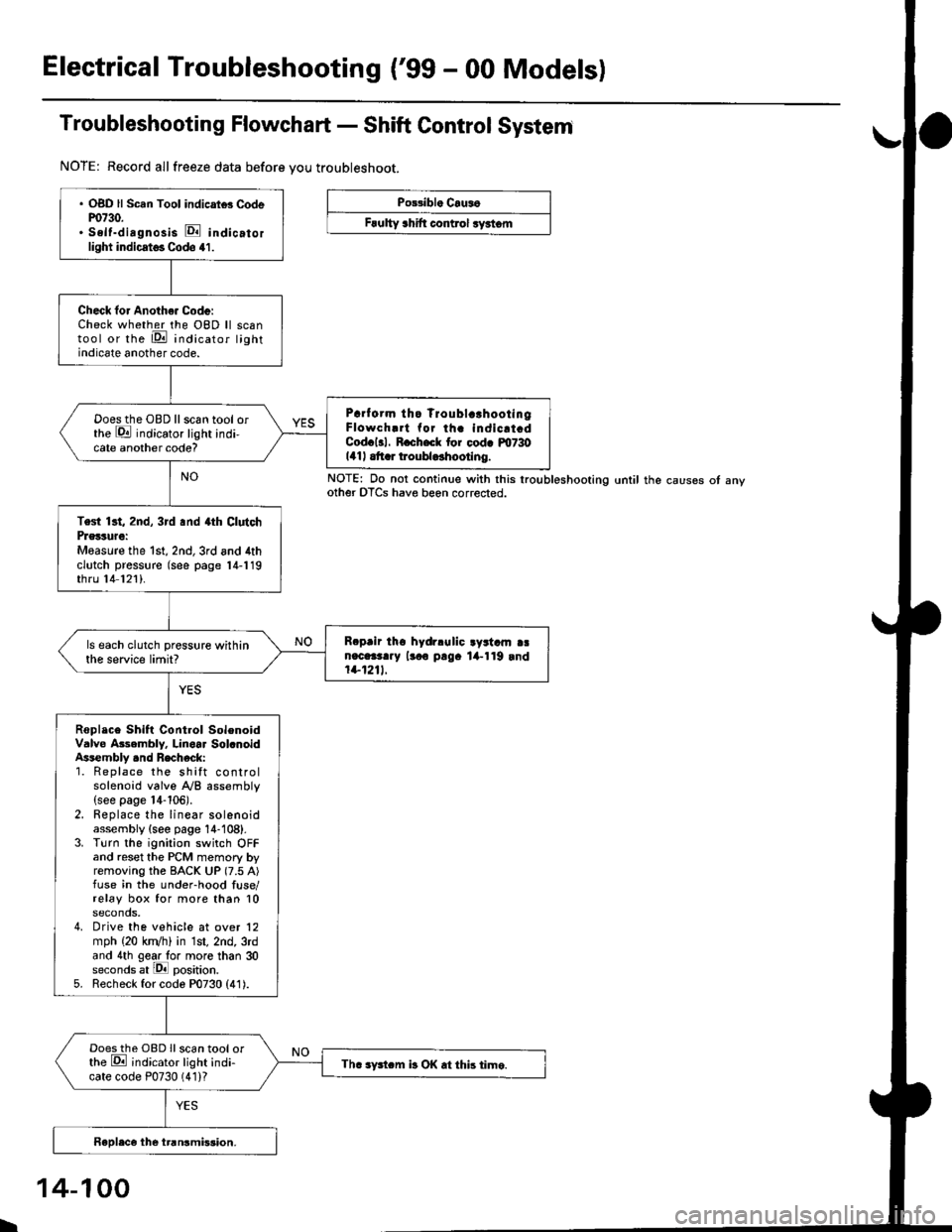

Electrical Troubleshooting ('99 - 00 Modelsl

Troubleshooting Flowchart - Shift Control System

NOTE: Record allfreeze data before you troubleshoot.

Po33ibl. Crus6

Frulty 3hift control ryrtom

. OBD ll Scan Tool indicrtd Codem730.. Self-dirgnosis E indicatorlight indicst€. Codo 41.

Check for Anoth€. Code:Check whether the OBD ll scantool or the E indicator lightindicate another code.

Prrf orm tho Troublc!hootingFlowch.rt for th. indicrt.dCod.l3l. R.ch.ck tor cod. m730141| .tt r troubldhootlng.

Doesthe OBD llscan tool orthe E indicator light indi-cate another code?

Test 13t, 2nd, 3rd .nd 4th ClutchPrglture:Measure the 1st, 2nd,3rd and 4thclutch pressure (see page 14-119thru 14 121).

R.prir tho hydrlulic ayrtam aan.c.3t..y lr.o p!9. lil-119 rnd1+1211.

ls each clutch pressure withinthe service limit?

Roplace Shift Control SolenoidValve Asembly. Linoar Sol.noidAssembly .nd Recheck:1. Replace the shift controlsolenoid valve A/B assembly(see page 14-106).2. Replace the linear solenoidassembly {see page 14-108}.3. Turn the ignition switch OFFand reset the PCM memory byremoving the BACK UP (7.5 A)fuse in the under-hood fuse/relay box for more than 10seconds,4. Drive the vehicle at over 12mph (20 kn/h) in 1st, 2nd, 3rdand 4th gear lo. more than 30seconds at lPll position.5. Recheck for code P0730 (41).

Doesthe OBD Ilscan tool orthe E ;ndicator light indi-cate code P0730 (41)?Th. sFtcm b OK .t this time.

NOTE: Do not continue with this lroubleshooting until the causes ot anyother OTCS have beon corrected.

I

14-100

Page 779 of 2189

Troubleshooting Flowchart - El Indicator Light On Constantly

PCM CONNECTOR A I32P)

Wire side of lemale terrnanals

PCM CONNECTOR D {16P)

ATP D'

25

61e 11(12

t{Iro

(YELI

Wire side of female terminals

The Dll indicator lighi is on con-stantly {not blinking) whenever

the ignition switch is ON (lll.

Moasure D4 IND Voltage:1. Turn the ignition switch OFF.2. Disconnect the A {32P} con-nector from the PCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe A14 terminal and bodyground.

Repsir short to power in the wire

between the A14 torminal andthe gauge assembly.

Measure ATP D4 Voltagel1. Turn the ignition switch OFF.2. Connect the A (32P) connector to the PCM.3. Turn the ignition switch ON (ll).

4. Shitt to any position othertha n [ql.5. Measure the voltage betweenthe D9 terminal and bodyground.

ls there approx. 5 V?

Test the A/T gear position switch(see section 23).

Check Ior a short to ground inthe wire betweon the D9 termi-

nal and A/T gear position switch.It wire is OK, substitute a known-good PCM and recheck.

Page 780 of 2189

Electrical Troubleshooting ('99 - 00 Models)

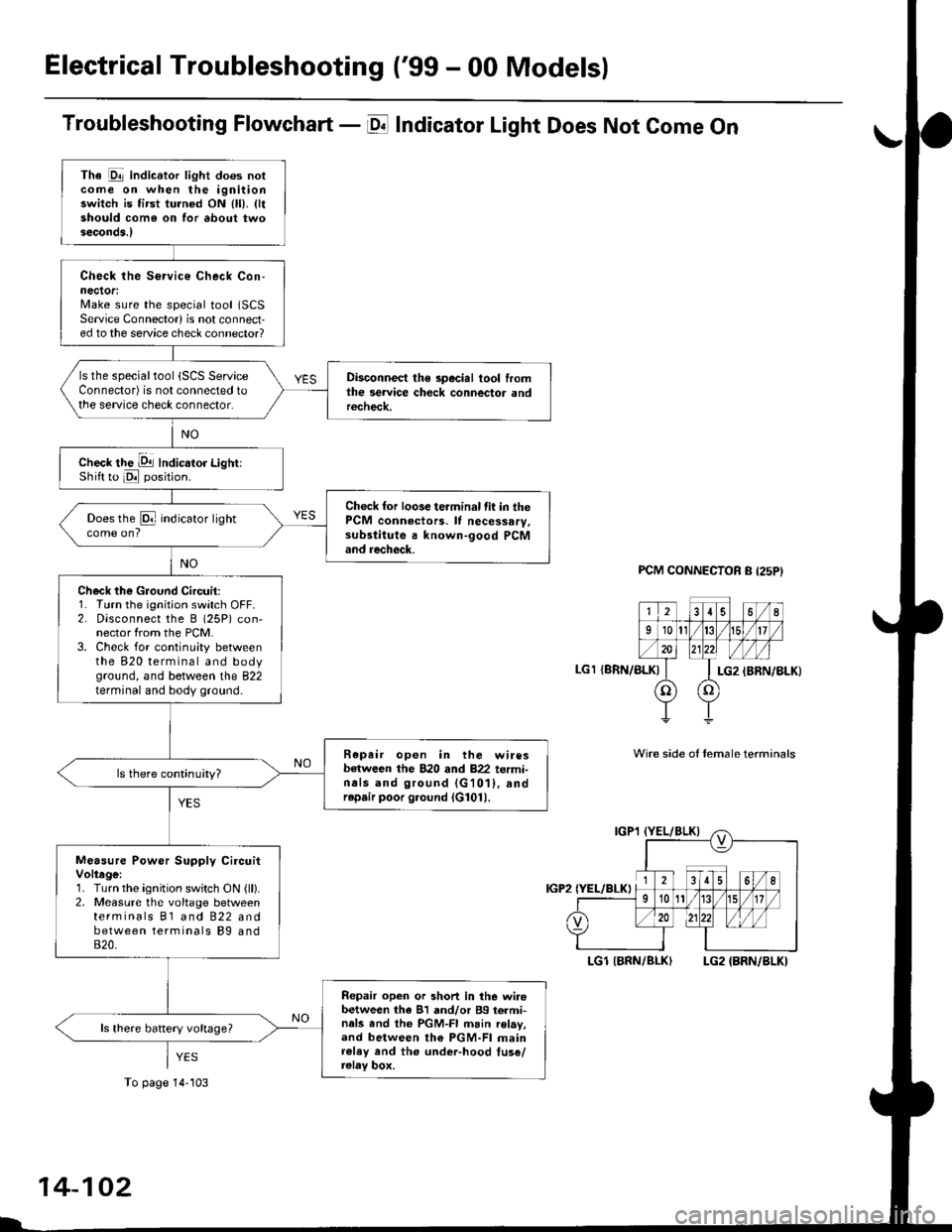

Troubleshooting Flowchart - E Indicator Light Does Not Come On

FCM CONNECTOR B (25P}

LGl {8RN/ALKI{BRN/8LK}

Wire side ol temale terminals

LGl IBNN/BLK} LG2 {BRN/BLK)

i2t5 6q

910t7

LG2

o) (o

The Pll indicator light does notcome on when the ignitionswitch is fi.st turned ON (ll). lltshould come on for about twoseconda.l

Check the Service Check Con-nector:Make sure the special tool (SCS

Service Connector) is not connect-ed to the service check connector?

ls the specialtool {SCS ServiceConnector) is not connected tothe seNice check connector.

Disconnect the special tool fromthe service check connector andr6check.

Check the Dll lndicator LightiShift to d position.

Check for loose terminal fit in thePCM connecto13. It necessary.sub3titute a known-good PCMand recheck.

Does the @ indicator lightcome on?

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the B (25P) con-nector from the PCM.3. Check for continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Repair open in the wiresbetween the B20 rnd 822 termi-nals and ground (G101), andrep.ir poor ground (G1011.

Measure Power Supply CircuitVoltage:1. Turn the ignition switch ON {ll}.2. Measure the voltage betweenterminals B1 and 822 andbetween terminals Bg and820.

Repair open or short in the wi.obetween th6 81 and/or 89 termi-nals and the PGM-FI main relav,and between th€ PGM-FI mainr€ley rnd the under-hood tus€/relay box.

To page 14''103

14-102

Page 782 of 2189

ElectricalTroubleshooting ('99 - 00 Modelsl

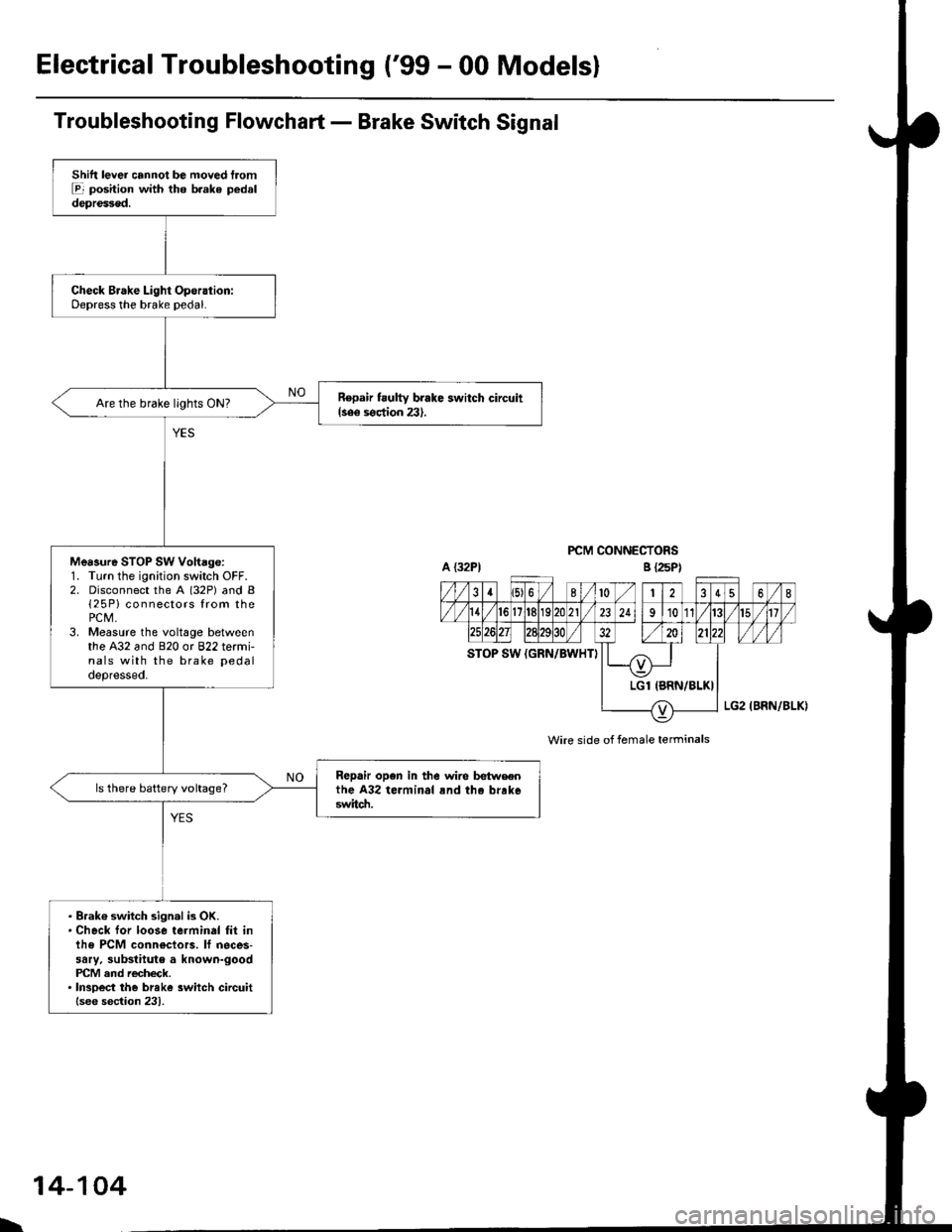

Troubleshooting Flowchart - Brake Switch Signal

PCM CONNECTORS

Wire side of female terminals

Shift lever cannot be moved tromE position with tho b.ake pedaldepressod.

Check Brake Light Operation:Depress the brake pedal.

Repair t ulty brake switch circuit{see s€ction 23}.Are the brake llghts ON?

Mea3ure STOP SW Vohage:1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B{25P} connectors from thePCM,3. Measure the voltage betweenthe A32 and 820 or 822 termi-nals with the brake pedal

depressed.

Repair open in the wire betwsenthe A32 terminal rnd tho brrk6switch.

ls there battery voltage?

. Brak€ switch sign.l is OK.. Check for loose terminal fil inlhe PCM conn€ctors. lf neces-sary. substitute a known-goodPICM and recheck.. InsDect the breke 3witch circuitlsee section 231.

B {25P)

\

14-104

Page 868 of 2189

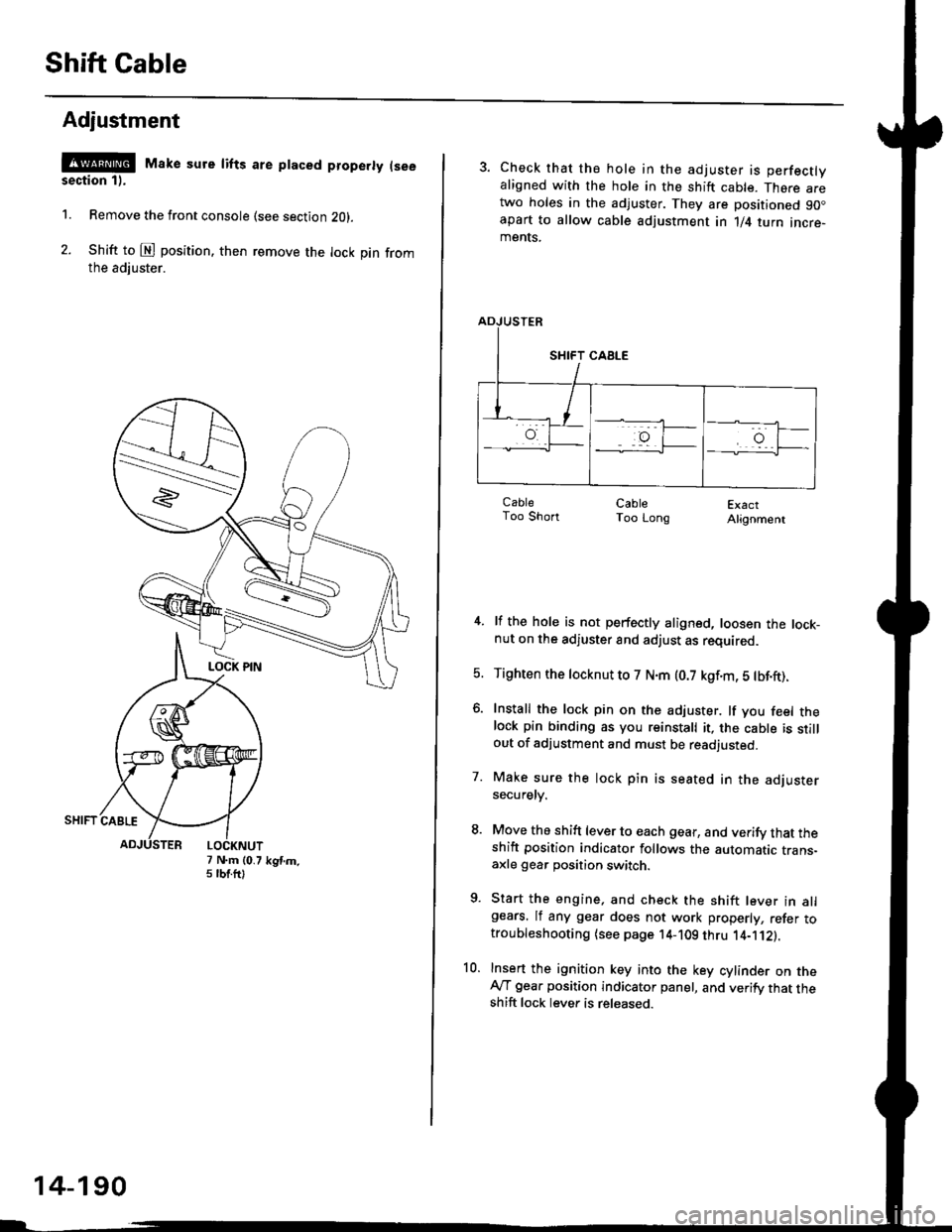

Shift Cable

Adjustment

@ Make sure lifts are ptaced properly (see

section 1).

1. Remove the front console (see section Z0l.

2. Shift to @ position. then remove the lock pin fromthe adiuster.

7 N.m (0.75 tbtftlkgtm.

14-190

3. Check that the hole in the adjuster is perfectlyaligned with the hole in the shift cable. There aretwo holes in the adjuster. They are positioned 90.apart to allow cable adjustment in 1/4 turn incre-ments.

ExactAlignment

4. lf the hole is not perfectly aligned, loosen the lock-nut on the adjuster and adjust as required.

5. Tighten the tocknut to 7 N.m (0.7 kgf.m, 5 tbf.ft).

6. Install the lock pin on the adjuster. lf you feel thelock pin binding as you reinstall it, the cable is stillout of adjustment and must be readjusted.

7. Make sure the lock pin is seated in the adjustersecuretv.

8. Move the shift lever to each gear, and verify that theshift position indicator follows the automatic trans-axle gear position switch.

9. Start the engine, and check the shift lever in allgears. lf any gear does not work properly, refer totroubleshooting (see page 14-109 thru 1'4-'112).

10. Insert the ignition key into the key cylinder on theAy'T gear position indicator panel, and verify that theshift lock lever is released.

CableToo ShortCableToo Long

Page 871 of 2189

Continuously Variable Transmission (CVTI

Special Tools ................ 14-194

Description .................... 14-195

Clutches/Reverse Brake/Planetary

Gear/Pulleys .......... 14-198

power Flow ..............,..... 14-200

Electronic Control SYstem(,96 - 98 Modets) ......14-203

Electronic Control System

('99 - oo Models) " 14-205

Hydraulic Control '....... 14-208

Hydraulic Flow .'..-.....'... '14-212

Park Mechanism .....-...'.' 14-222

Eleqtrical Systom

Component Locations'96 - 98 Models """"""' 14-224,99 - 00 Modets ............. 14-225

TCM Circuit Diagram ('96 - 98 Models) ............. 14-226

TCM Terminal Voltage/Measuring Condiiions ('96 - 98 Models) '.... 14-228

PcM Circuit Oiaqram{A/T Control System: '99 - 00 Models} ...--.... 14-230

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)

A/4 Control System .'.'...14-232

Troubleshooting Procedures ... . .... .....',........."' '14-234

Symptom-to-ComPonent Chart

Electrical System - '96 - 98 Models ......'..... '14-234

Electrical System -'99 - 00 Models ..'....-..-. '11-210

Electrical Troubleshooting

Troubleshooting Flowcharts('96 - 98 Models) """'11-242

Troubleshooting Flowchart

('99 - 0O Modets) ...... 14-265

Linear Solenoids/lnhibitor Solenoid

Test ......................... . ...... 14-29f

Drive Pulley/Driven Pulley/Secondary Gear

Shaft Speed Sensors

Replacement .........'...... .14-292

Start Clutch Control

Start Clutch Calibration Procedure ....... ....,. 14-293

Hydraulic SYstem

Symptom-to-ComPonent Chart

Hydraulic System '.'.......14-294

Road Test ............................ 14-296

Stall Speed

Test......................... ...... 14-294

Fluid Level

Checking/Changing ....... 14-299

Pressure Testing ................. 14-300

Lower Valve BodY AssemblY

Replacement ..........,... 14-302

ATF Filter

Removal/lnstallation ..... 14-303

Transmission

Transmission

Removal ........... . 14-304

lllustrated Index

Transmission/Lower Valve BodY

Assembly ................. 14-308

Transmission Housing/Flywheel Housing ... 14-310

End Cover/f ntermediate Housing ..........'.'.... 14-312

Transmission Housing/Lower Valve Body Assembly

Removal ..........'.... .. " 14-314

Transmission Housing/Flywhesl Housing

Removal ................. ........ 1+316

End Cover/lntermediate Housing

14-318Removal .........,...............

Manual Valve Body

Disassembly/lnspection/Reassemblv .'.'.'..... 1 4-320

Forward Clutch

lltustrated Index ........................................ 14-321

Disassemblv .................. 14-322

Reassemblv , ,, . ',','......14-324

Secondary Gear Shaft

25 x 35 mm Thrust Shim Selection ..'.'....-... 14-324

Differential

lllustrated lndex ...,.....................,.,...-.-.-...'... 14-329

Backlash Inspection .-....14-329

Bearing Replacement ......'........'....'... ....'... 14-330

Differential Carrier Replacement ........'........ 14-330

Oil Seal Removal ........... 14-331

Oil Seal Installation/Side Clearance ....... . . 14-331

Flywheel Housing Input Shaft Oil Seal

Replacement .....,.... ...'.'.. 14-333

Transmission Housing Bearings

Driven Pulley Shaft Bearing

Replacenient ...................'. . ...................'.. 14-334

Secondary Gear Shaft Bearing

Reolacbment ...................... . .......... . ........ 14-335

Flywheel Housing Beating

Secondary Gear Shaft BearingReo1acement..................,........................... 14-335

Ring Gear Bearing

Replacement......... ........ 14-336

Control Shaft Assembly

Removal/lnstallation ....................'........... 14-336

Transmission

Reassembly .................. 14-338

Flywheel/Drive Plate .. . ...... . ...... ... . ....-.....'.'...14-341

Transmission

lnstalation ..................... 14-348

Cooler Flushing .'......... 14-352

shift cable

Removal/lnstallation....'........." """ 14-354

Adjustment .......'........ 14-355

Shift Lever ........................,. 14'356

Shift Indicator Panel

Adjustment ................ 14-357

ATF Cooler/Hoses

lnsta llation ......,,...... .... 14-357