Door switch HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 399 of 2189

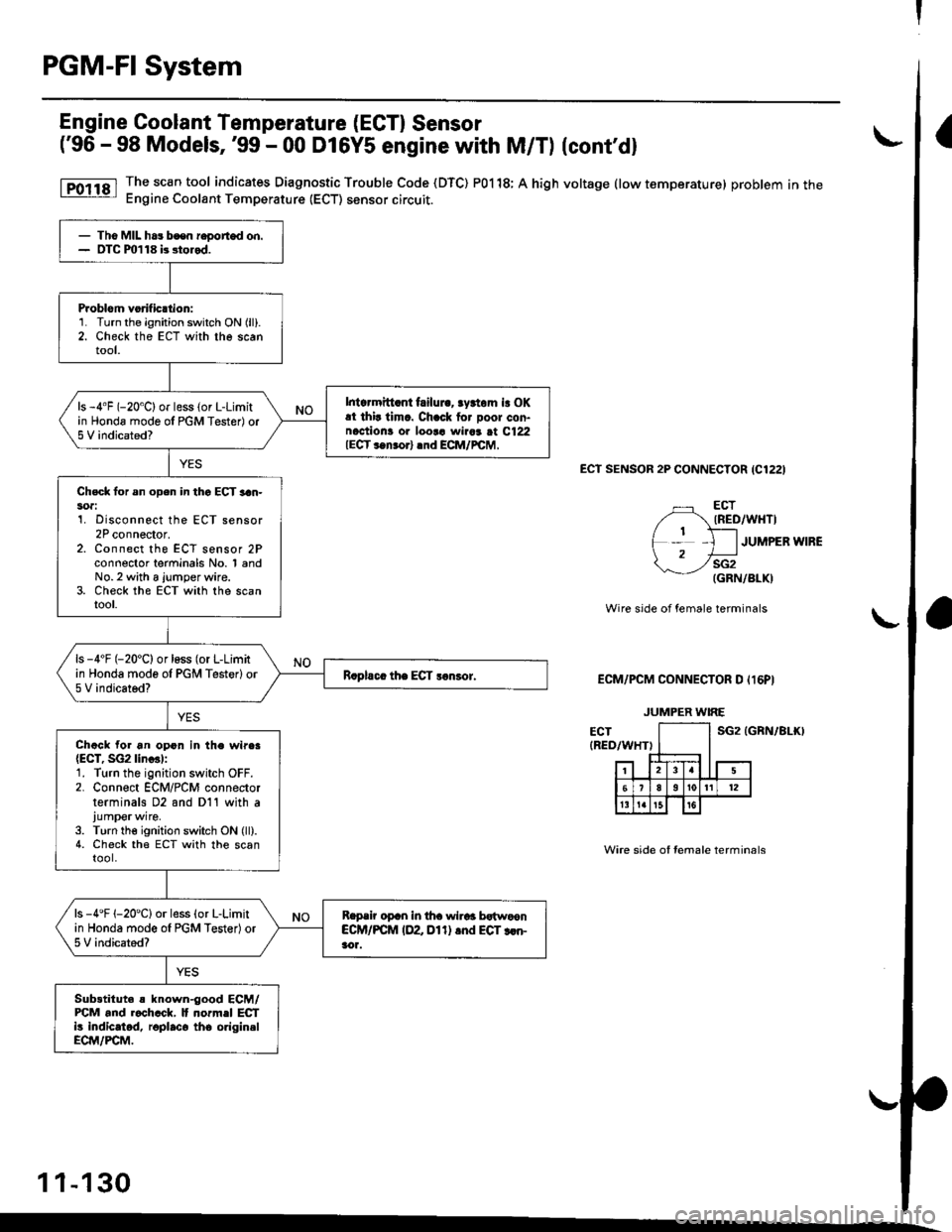

PGM-FI System

Engine Coolant Temperature (ECT) Sensor

('96 - 98 Models,'99 - 00 D16YS engane with M/T) (cont'd)

The sc€n tool indicates Diagnostic Trouble Code (DTC) P0118; A high voltage (low temperature) problem in theEngine Coolant Temperature (ECT) sensor circuit.

ECt SENSOR 2P CONNECTOR {C1221

ECTIRED/WHTI

JUMPER WIRE

sG2(GRN/BLK)

Wire side of female terminals

ECM/PCM CONNECTOR D Il6PI

sG2 tGRN/81r0

Wire side of Iemale terminals

- Tho MIL ha3 bcen r€oorted on.- OTC m118 b stored.

Problom vorificttion:1. Turn the ignition switch ON (ll).

2. Check the ECT with the scantool.

Intcrmitt.nt failui.. rydom is OKat thir timc. Chack for Door con-naction! or loor! wiaar at C122IECT ..n.orl .nd ECM/rcM,

ls -4"F (-20'C) or less (or L-Limitin Honda mode ol PGM Tester) or5 V indicated?

Chsck lor sn open in thc ECT 3an-soa:1. Disconnect the ECT sensor2P connector.z. Lonnecr rne ELt sensor zFconnector terminals No. 1 andNo.2 with a jumper wire.3. Check the ECT with the scantool.

ls -4'F (-20'C) or loss (or L-Limitin Honda mode ol PGM Testerlor5 V indicated?

Chack for an opon in the wire.{ECT, SG2lin..l:1. Turn the ignition switch OFF.2. Connect ECM/PCM connectorterminals D2 and D11 with ajump€rwire.

3. Turn the ignition switch ON (ll).4. Check the ECT with the scantool.

ls -4'F 1-20'Clor less (o. L-Limitin Honda mode ol PGM Tester)or5 V indicated?

Reprir oprn in tha wirar bstwoonCCM/PCM IDZ Dl1) .nd EGT rcn-aor.

Sub3titut. s known-good ECM/FCM and r.chcck, It normel ECTi! indicatod, roplaco tho origin.lECM/PCM.

JUMPER WIRE

1 1-130

Page 401 of 2189

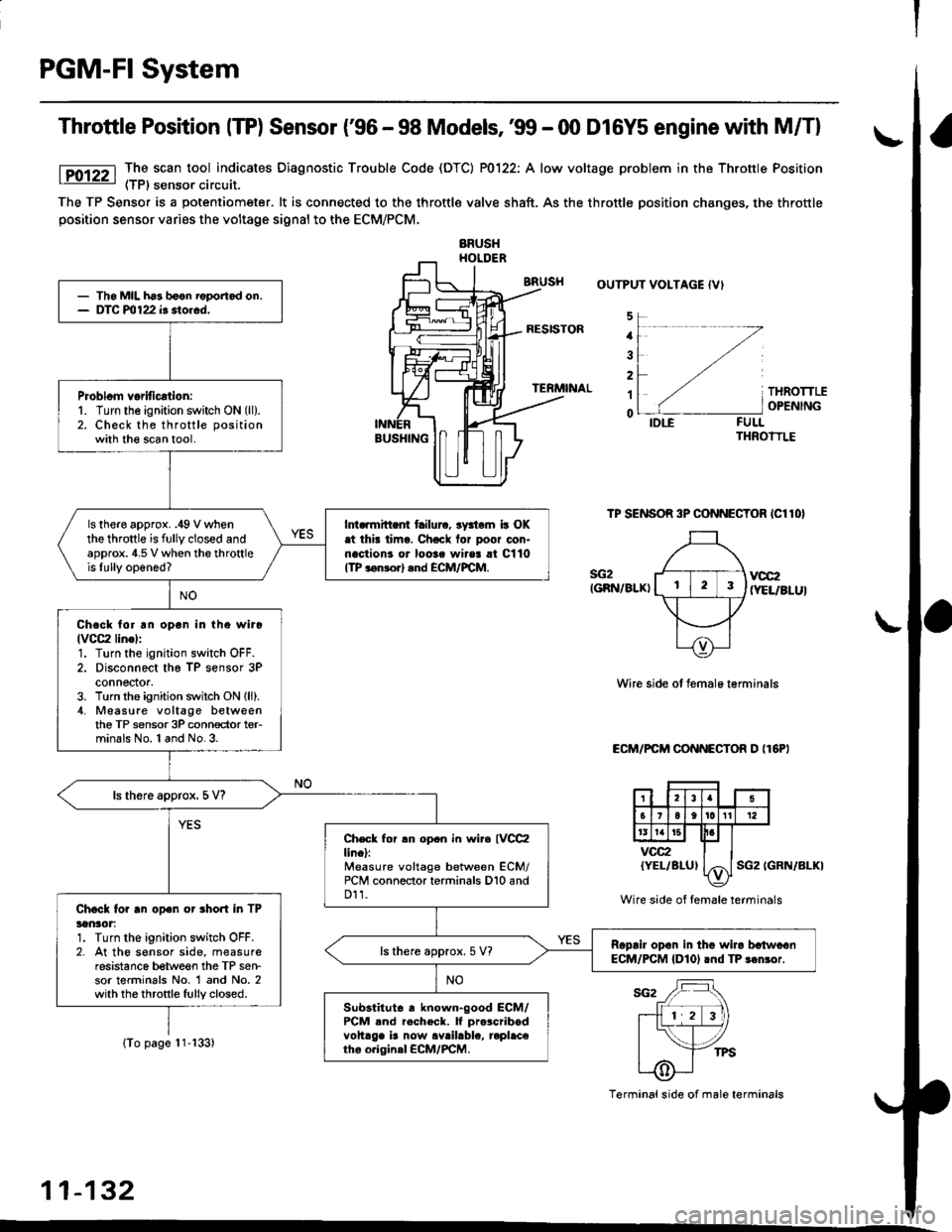

PGM-FI System

Throttle Position ITP) Sensor ('96 - 98 Models,'99 - 00 D16Y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P0122: A low voltage problem in the Throttle Position(TP) sensor circuit.

The TP Sensor is a potentiometer. lt is connected to the throttle valve shaft. As the throttle position changes, the throttleposition sensor varies the voltage signal to the ECM/PCM.

OUTPUT VOLTAGE IVI

1

2

1

0

s{i2(GRN/BLKI

THROTTLEOPENING

FULLTHROTTLE

TP SENSOR 3P CONNECTOR ICllOI

vocz(YEL/BLUI

Wire side ot femal6 terminals

ECM/PCM CONNECTOR D IT6PI

SG2 IGRN/ALKI

{To page l1-133)

Terminal side of male terminals

11-132

- Tho MIL h63 boon roportod on.- DTC m122 i. storcd.

Probl6m voritic€tion:1. Turn the ignition switch ON (ll).

2. Check the throttle positionwith the scan tool.

ls there approx. .49 V whenthe throttle is fully closed andapprox. 4.5 V when the throttleis lully op6ned?

Int..mittent tailura, rFiem ir OKat thit tima. Chock tor Door con-nections or loorc wires !t C110ITP lonrorl .nd ECM/FCM.

Ch6ck lor rn opon in the wire(VCC2linel:

1. Turn the ignition switch OFF.2. Disconnect ths TP sensor 3Pconnector.3. Turn the ignition switch ON lll).4, Measure voltage betweenthe TP sensor 3P conn€ctor ter-minals No. l and No.3.

ls there approx. 5 V?

Check for rn opcn in wire IVCC2line):Measure voltage between ECM/PCM conneclor terminals D10 and011.Chock for rn open or 3hort in TPlon30t:1. Turn the ignition switch OFF.2. At the s€nsor side, measureresistance between the TP sen-sor terminals No. 1 and No. 2with the throttle fully closed.

Roplir op€n in thg wiro batwcsnECM/PCM {DlO) rnd TP ren3or.ls there approx.5 V?

Substitut6 r known-good ECM/PCM and rach6ck. lf pro$ribodvohrge i! now avrilablc, replac€tho o.iginel €CM/FCM.

Wire side of female terminals

Page 445 of 2189

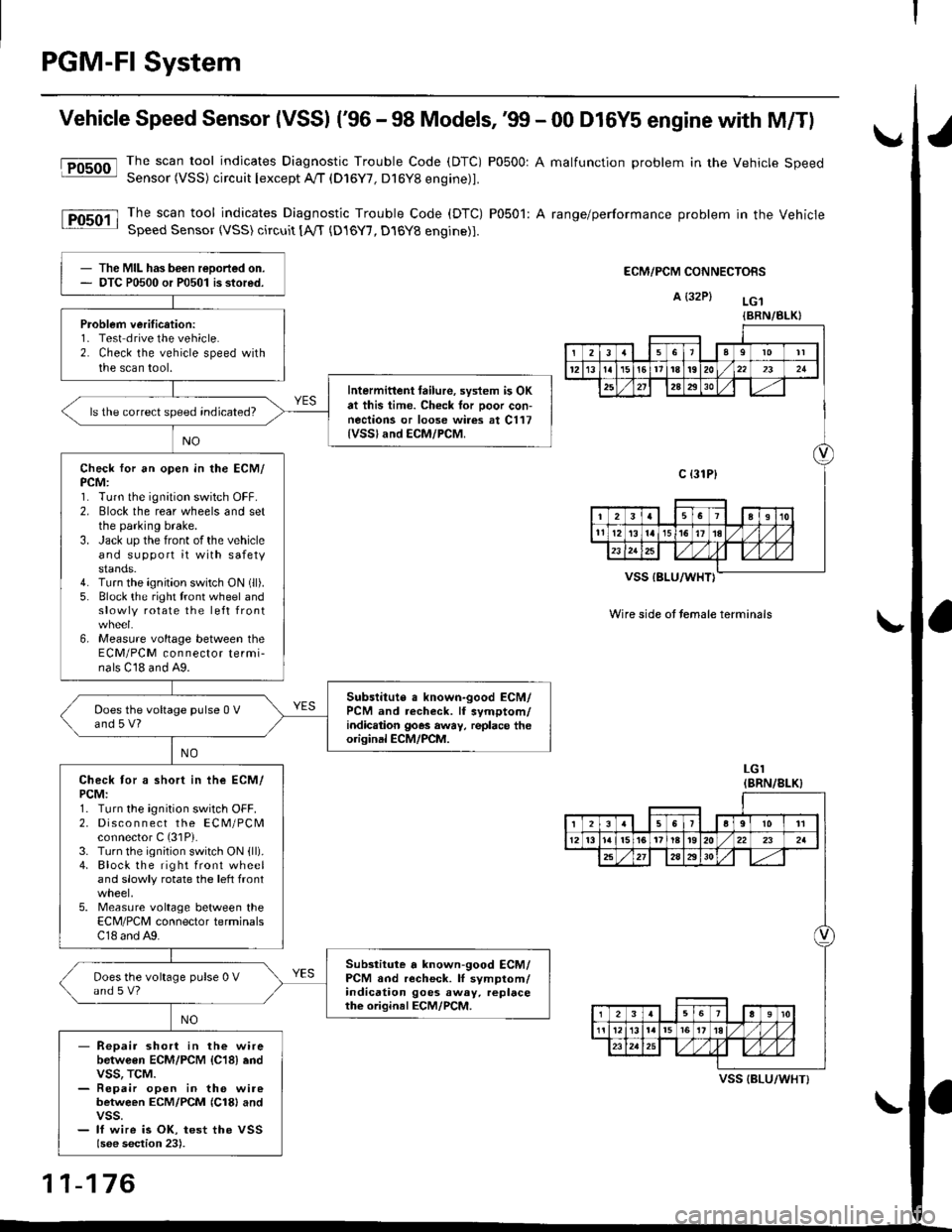

PGM-FI System

Vehicle Speed Sensor (VSSI ('96 - 98 Models,'99 - 00 D16Y5 engine with M/Tl

@The scan tool indicates Diagnostic Trouble Code (DTC) P0500: A malfunction problem in the Vehicle SpeedSensor (VSS) circuit Iexcept A!/T (D16Y7, D16Y8 engine)1.

The scan tool indicates Diagnostic Trouble Code (DTC) P0501: A range/performance problem in the VehicleSpeed Sensor (VSS) circuit [A,rT {D16Y7, D16Y8 engine)].

ECM/PCM CONNECTORS

A {32P} LG.t

VSS IBLU/WHT}

Wire side ot temale terminals

LGI(BRN/8LK}

The MIL has been reDorted on.DTC P0500 or P0501 is stored.

Problem verification:1- Test drive the vehicle.2. Check the vehicle speed withthe scan tool.

Intermittent tailure, system is OKat this time. Check tor Door con-nections or loose wires at C117{VSSland ECM/PCM.

ls the correct speed indicated?

Check for an open in the ECM/PCM:1. Turn the ignition switch OFF.2. Elock the rear wheels and setthe parking brake.3. Jack up the front of the vehicleand support it with safetystands.4. Turn the ignition switch ON (ll).

5. Block the right tront wheel andslowly rotate the left front

6, Measure voltage between theECM/PCM connector termi-nals C18 and A9.

Subslitute a known-good ECM/PCM and recheck. lf symptom/indic.tion goes away, replace theorisinal ECM/PCM.

Does the voltage pulse 0 Vand 5 V?

Check tor a short in ihe ECM/PCM:1. Turn the ignition switch OFF.2. Disco n n ect the ECM/PCMconnector C (31P).

3. Turn the ignition switch ON {ll).4. Block the right front wheeland slowly rotate the left front

5. Measure voltage between theECM/PCM connector terminalsC18 and A9.

Substitute a known-good ECM/PCM and recheck. lI symptom/indication goes away. replacethe original ECM/PCM.

Does the voltage pulse 0 Vand s V?

- Repair short in the wirebetwGen ECM/PCM {C18} endvss, TcM.- Repair open in the wirebetween ECM/PCM {Cl8} andvss.- lf wire is OK, test the VSSlsee section 23).

{BRN/BLK}

239l0lt

121611t8t9202321

2A2930

c {31P}

I38191o

tl12ialr5i6l10./

I2356a9l011

12l3l5t61tl8t920222a

27202930

12910

t2l13l.l7I l,/ 1,/231r.lslt., ),rlL

VSS {BLU/WHT}

11-176

Page 451 of 2189

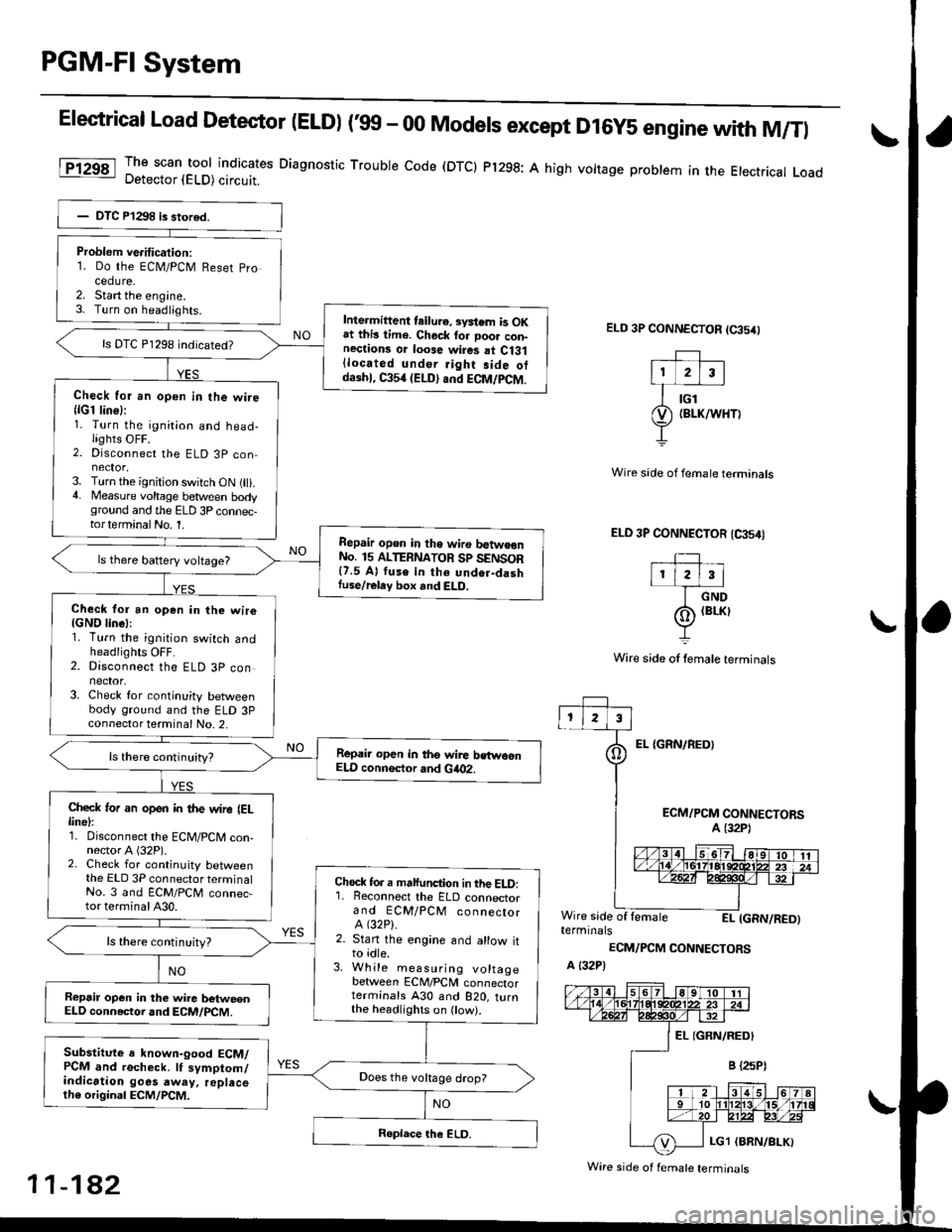

PGM-FI System

Elestrical Load Detector (ELDI ('99 - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble code (DTCI Pl298: A high vottage problem in the Etectrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR (65/0

EL {GRN/REOI

Wire side of fernale terminals

ELD 3P CONNECTOR (CA54I

TIr l2l3l

I crvo

(o) (BrKr

Y

Wire side of lemale terminals

ECM/PCM CONNECTORSA (32P1

Wire side of lemaleEI- IGRN/RED)terminals

ECM/PCM CONNECTORS

A {32P)

Problem ve.itication:1. Do the ECN4/PCM Reset pro

cedure.2. Start the engine.3- Turn on headiights.Inte.mittent teilu.e, svstem is OKat this lime. Chock for Door con-nections or loose wires at Ci31{located under Jight side otdaihl, C354 (ELD) and ECM/PCM.

ls DTC P1298 indicated?

Check for an open in the wire{lG1 line}:1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P con

3. Turn the ignition switch ON (ll).4. Measure voltage between bodyground and the ELD 3P connec-torterminalNo. 1.

Repair opon in tho wiro batwe€nNo. 15 ALTERNATOR Sp SENSOR{7.5 A} fuse in th6 undor-dashIuse/reley box and ELD.

ls there battery voltage?

Check for an open in the wiro{GND linel:1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P connector.3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2,

Repair open in the wire bstwoenELD connsctor and Gia02.

Check ,or an open in the wire IELlinel:1. Disconnect the ECM/PCM con-nector A (32P).2. Check for continuity betweenthe ELD 3P connector terminalNo. 3 and ECM/PCM connec-tor terminal A30.

Chock fo. a malfunction in the ELD:'1. Reconnect the ELD connectorand ECM/PCM connectorA (32P).

2. Stan the engine and allow itto idle.3. While measuring voltagebetween ECM/PCM connectorterminals A30 and B2O, turnthe headlighrs on ow).

ls there continuity?

Repsir op€n in the wire betweenELD connector and ECM/PCM.

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away. replacelh6 original ECM/PCM.

Does the vokage drop?

Wire side of f€male terminals

11-182

Page 581 of 2189

\

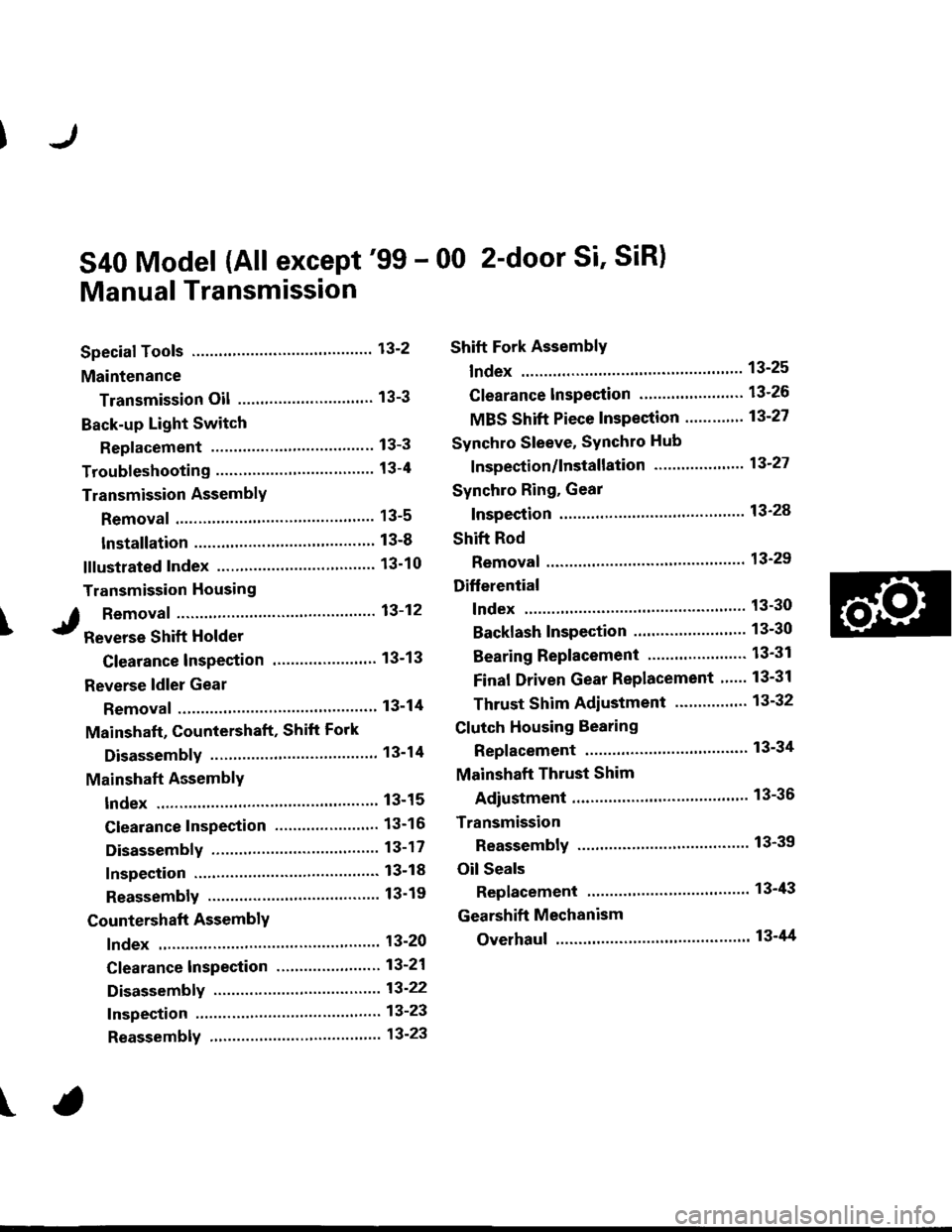

S40 Model (All except'99 - 00 2-door Si' SiR)

Manual Transmission

Special Tools ..'.......... 13-2

Maintenance

Transmission Oil .............................. 13-3

Back-up Light Switch

Replacement ......... 13-3

Troubleshooting '....... 13-4

Transmission AssemblY

Removal ................. 13-5

lnstallation ............. 13-8

lllustrated Index ...............'........."........ 13-10

Transmission Housing

I Removaf .."""""""' 13-12

J R"rr"r"" Shift Holder

Clearance lnspection ....................... 13-13

Reverse ldler Gear

Removal ....'.........." 13-14

Mainshaft, Countershaft, Shift Fork

Disassembly ......'... 13-14

Mainshaft AcsemblY

Index ............... ....... 13-15

Clearance Inspection ..'.................... 13-16

Disassembly .......... 13-17

Inspection ....'......... 13-18

Reassembly ........... 13-19

Countershaft AssemblY

lndex ................ ...... 13-20

Clearance lnspection ."..........'......." 13-21

Disassembly ..."""' 13-22

Inspection .............. 13-23

Reassembly ..'.""... 13-23

Shift Fork AssemblY

lndex ............... ."'... 13-25

Clearance lnspection ."......."........'.. 13'26

MBS Shift Piece Inspection ....-.....'.. 13'27

Synchro Sleeve, Synchro Hub

f nspection/lnstallation .......'...... ".... 13'27

Synchro Ring, Gear

Inspection '....'..".... 13'28

Shift Rod

Removal .'......".""" 13'29

Differential

lndex ......."'...... .'."' 13-30

Backlash Inspection ..........."......."... 13-30

Bearing Beplacement'.............'.".... 13'31

Final Driven Gear Replacement '..... 13-31

Thrust Shim Adiustment ..."........... 13-32

Clutch Housing Bearing

Replacement .......'. 13-34

Mainshaft Thrust Shim

Adiustment '....'..".. 13-36

Transmission

Reassembly ........... 13-39

Oil Seals

Replacement ......... 13-43

Gearshift Mechanism

Overhaul ................ 13-44

\

Page 625 of 2189

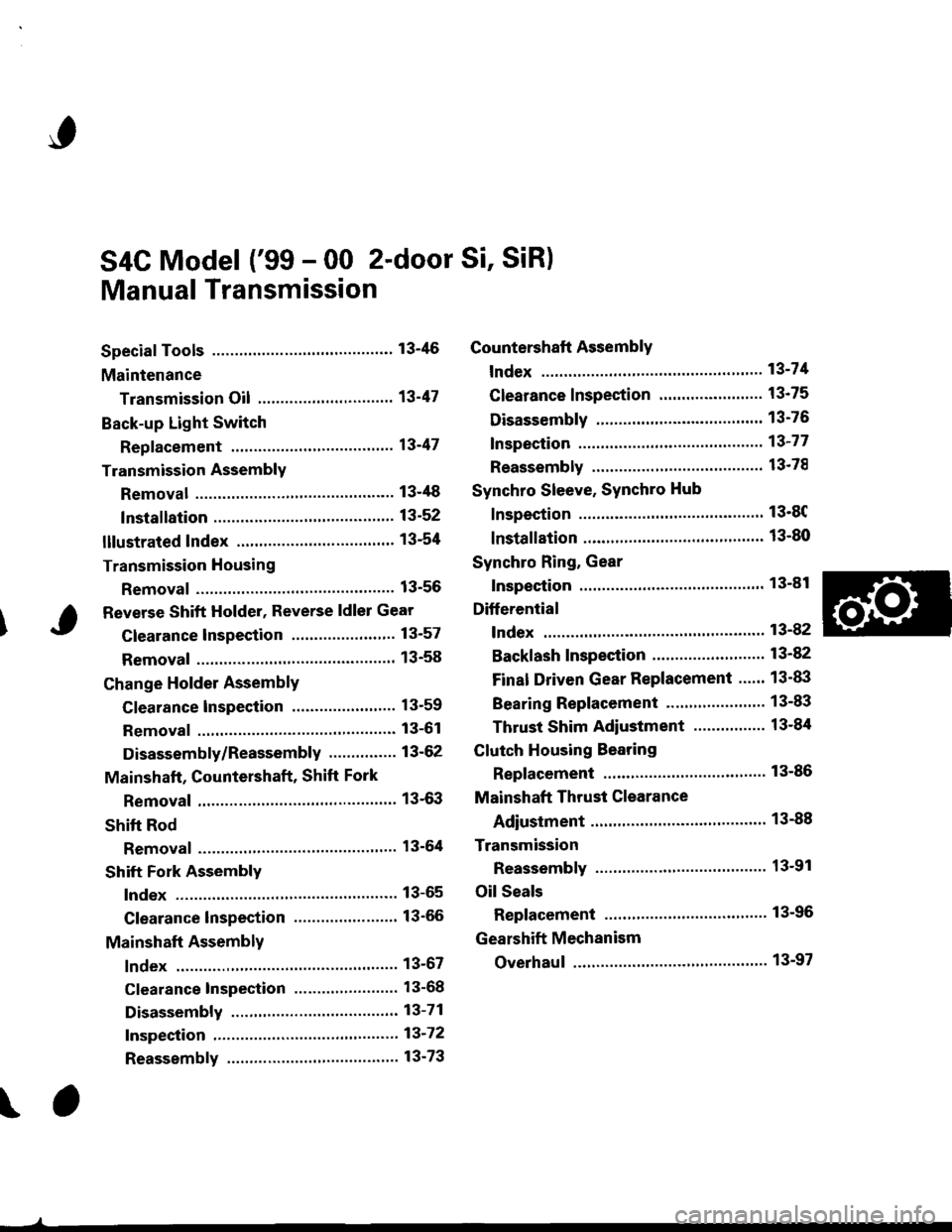

S4C Model ('99 - 00 2-door Si, SiR)

Manual Transmission

Special Tools ............' 13-46

Maintenance

Transmission Oi1 ...................'.......... 13-47

Back-up Light Switch

Repfacement ...""" 13'47

Transmission Assembly

Removal ......'.......... 13-/tB

lnstallation ............. 13-52

lllustrated lndex ................................... 13-54

Transmission Housing

Removal ................. 13-55

Beverse Shift Holder, Reverse ldler Gear

Clearance lnspection ...................".. 13-57

Removal ................. 13-58

Change Holder Assembly

Clearance lnspection .................".... 13-59

Removal ....,,........... 13-61

Disassembly/Reassembly ............... 1 3-62

Mainshaft, Countershaft, Shift Fork

Removal ................. 13-63

Shift Rod

Removal .........."'.... 13-64

Shift Fork Assembly

lndex ................ ...... 13-65

Clearance lnspection .............'......... 13'66

Mainshaft Assembly

lndex ............"" ...... 13-67

Clearance lnspection ....................... 13-68

Disassembly .......... 13-71

fnspection '."'.......', 13'72

Reassembly .......'... 13-73

Countershaft Assembly

fndex ................ "....13-71

Glearance Inspection'......'...........'... 1 3'75

Disassembly .......... 13-76

fnspection .'............13'77

Reassembly "......... 13'78

Synchro Sleeve, Synchro Hub

Inspection .............. 13'8C

Installation ............. 13-80

Synchro Ring, Gear

Inspection .'............ 13-81

Differential

lndex ................ ...... 13-82

Backlash Inspection ..."..........."'...... 1 3-82

Final Driven Gear Replacement ...... 13-83

Bearing Replacement ....."'.......""'.. 13-83

Thrust Shim Adiustment ......""'..... 13-84

Clutch Housing Bearing

Replacement ..'...... 13-86

Mainshaft Thrust Glearance

Adiustment '.........'. 13-88

Transmission

Reassembly ."'....... 13-91

Oil Seals

Replacement ..'...... 13-96

Gearshift Mechanism

Overhaul ................ 13-97

\

Page 1246 of 2189

Doors

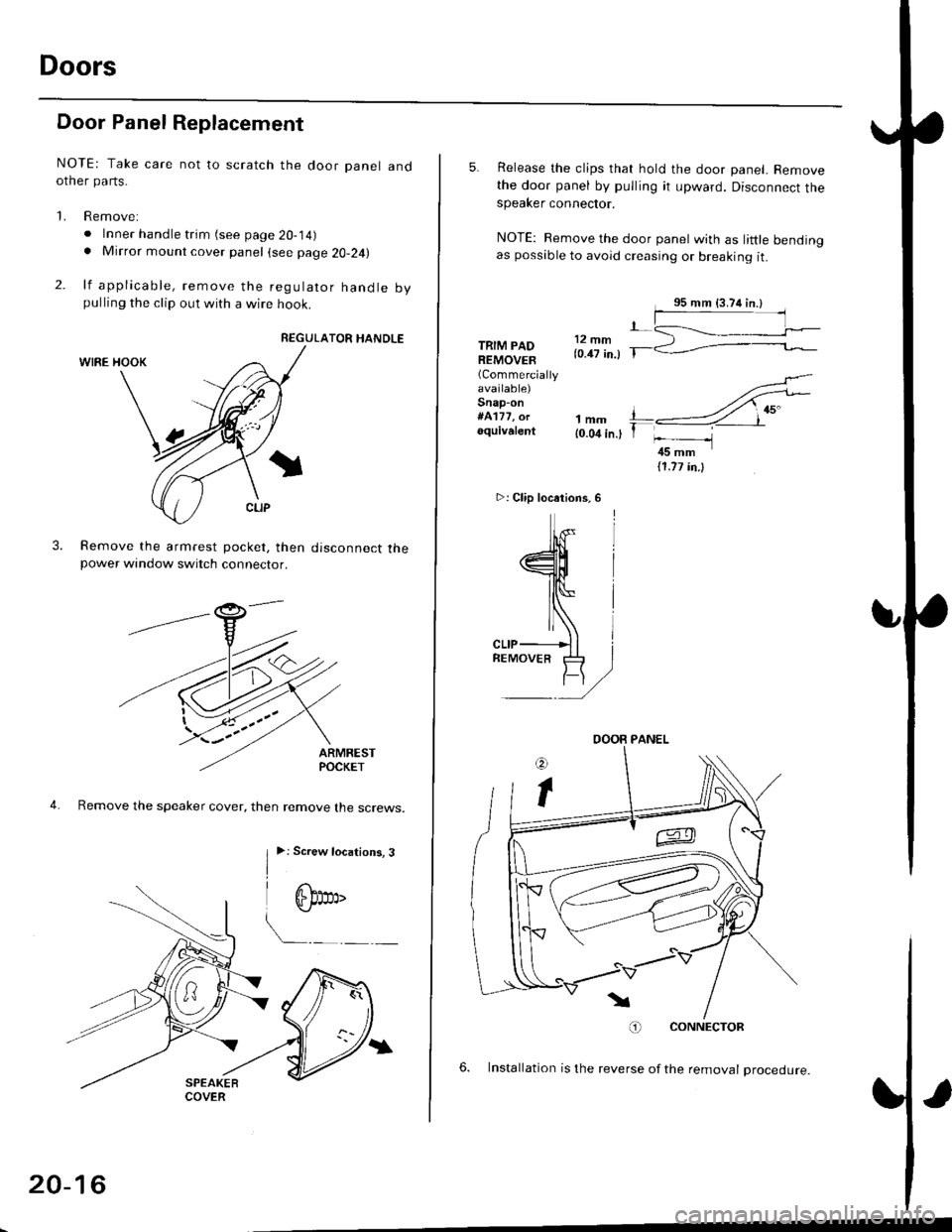

Door Panel Replacement

NOTE: Take care not to scratch the door panel andother pa rts.

'1. Remove:

. Inner handle trim (see page 20-14). Mirror mount cover panel (see page 20-24)

2. lf applicable, remove the regulator handle bypulling the clip out with a wire hook.

REGULATOR HANDLE

WIRE HOOK

Remove the armrest pocket, then disconnect thepower window switch connector.

ARMRESTPOCKET

4. Remove the speaker cover, then remove lhe screws.

3.

I

>: Screw locations, 3

| 6b:a,'

L"_

COVER

20-16

TRIM PADREMOVER(Commercially

available)Snap-on#A'177, orequivalent1mm{0.04 in.)

5. Release the clips that hold the door panel. Removethe door panel by pulling it upward. Disconnect thespeaker connector.

NOTE: Remove the door panel with as little bendingas possible to avoid creasing or breaking it.

.L12 fim(0.47 in.) T-

>: Clip locations,

l^

J[

=l$

ll,\*

atr-

,,)

REMoVER tl-)

11.77 in.l

O) CONNECTOR

6. lnstallation is the reverse of the removat oroceoure.

DOOR PANEL

Page 1304 of 2189

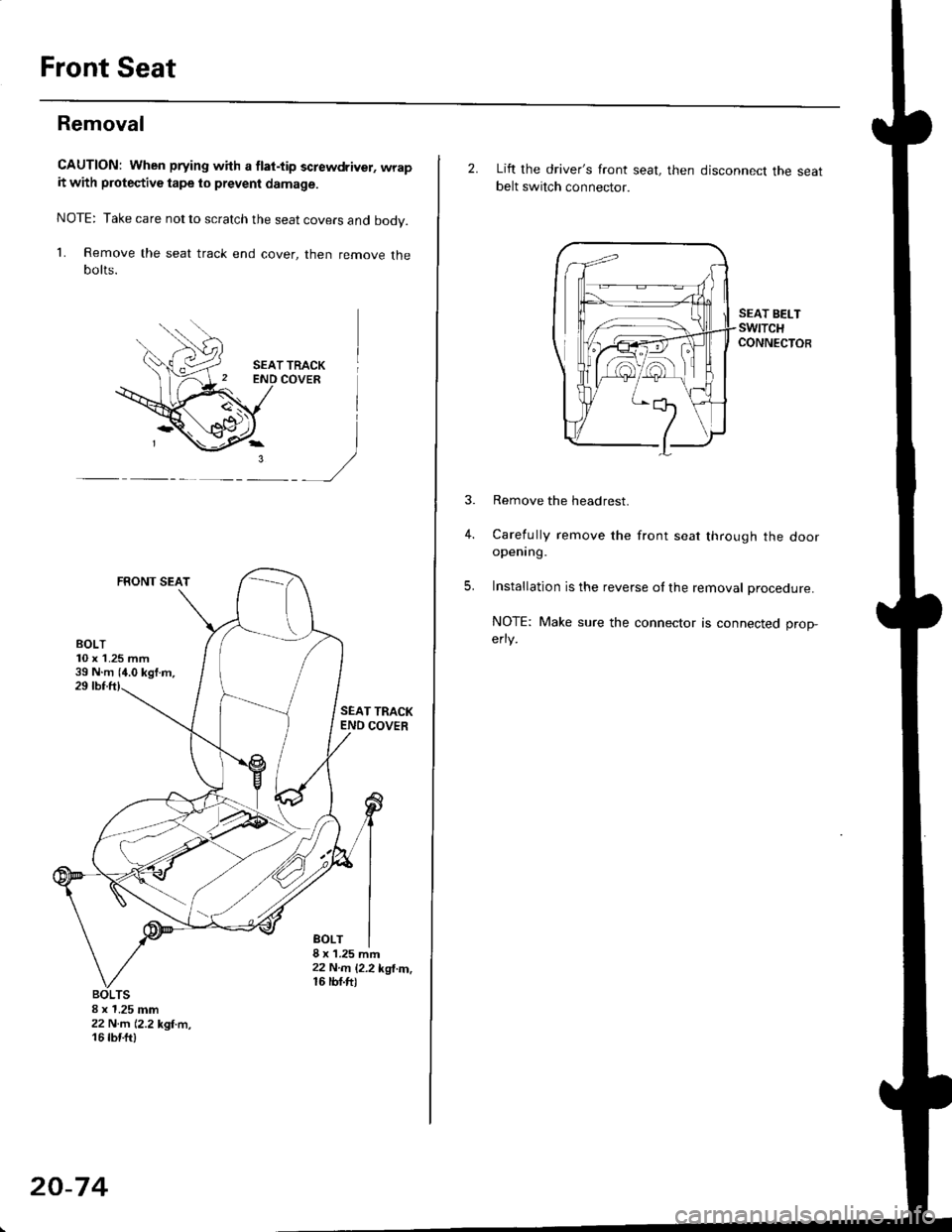

Front Seat

Removal

CAUTION: When prying with a flat-tip screwdriver, wrapit with protective tape lo prevent damage.

NOTE: Take care not to scratch the seat covers and body.

1. Remove the seat track end cover, then remove thebolts.

SEAT TRACKCOVER

FRONT SEAT

)

SEAT TRACKEND COVER

BOLT8 x'1.25 mft22 N..n 12.2 kgl.m,16 rbf.ft)

8 x 1.25 mm22 N.rn 12,2 kgl.m,16 tbtft)

20-74

2. Lift the driver's front seat, then disconnect the seatbelt switch connector.

SEAT BELTswtTcHCONNECTOR

4.

Remove the headrest.

Carefully remove the front seat through the dooropening.

Installation is the reverse ol the removal procedure.

NOTE: Make sure the connector is connected prop-

erry.

5.

Page 1305 of 2189

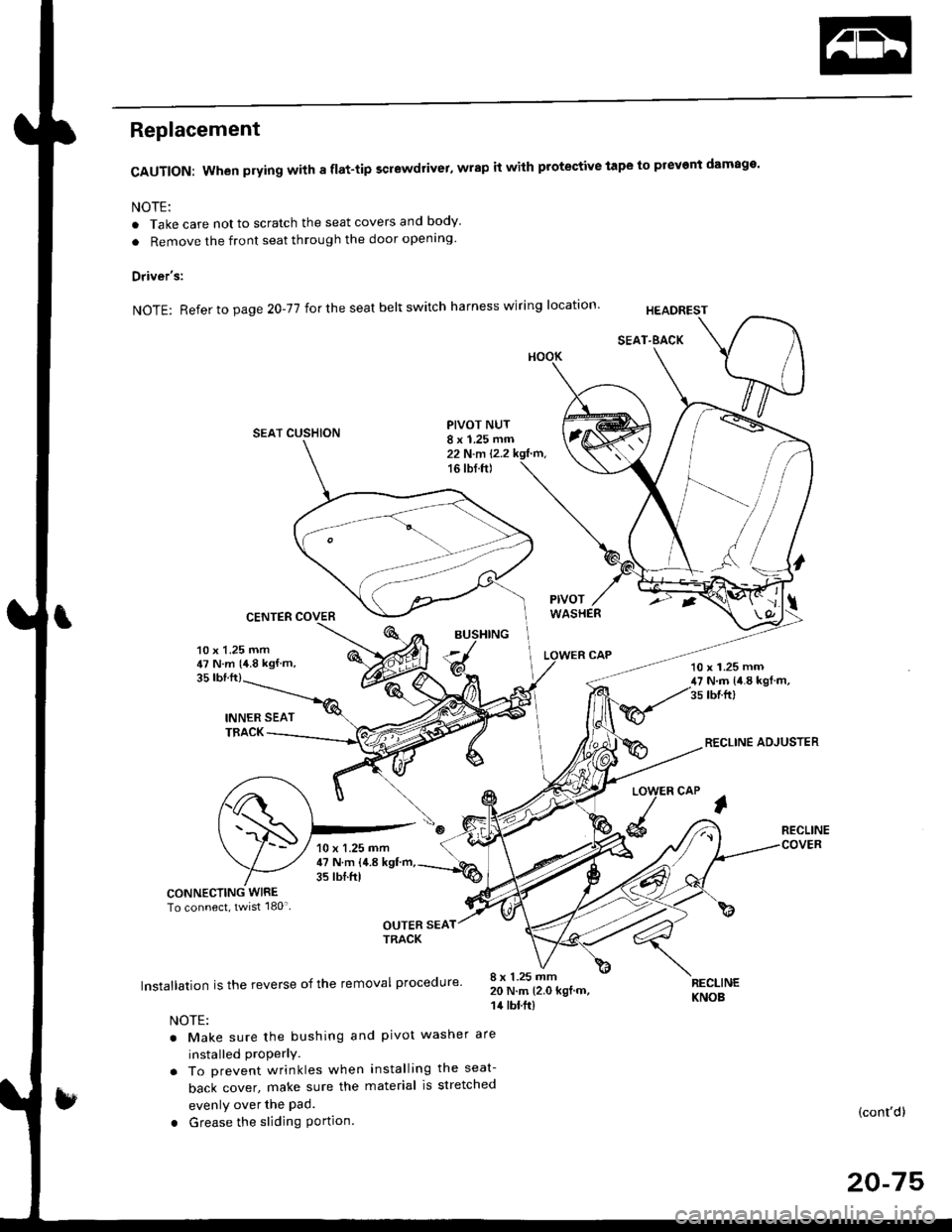

Replacement

CAUTION: When prying with a flat-tip screwdrivet, wrap it with protective tape to prevent damage'

NOTE:

. Take care not to scratch the seat covers and body

. Remove the front seat through the door openlng'

Driver's:

NOTE: Refer to page 2O-77 for the seat belt switch harness wiring location'

SEAT CUSHION

CENTER COVER

INNER SEATTBACK

PIVOT NUT8 x 1.25 mm22 N.m l.2.216 tbf.ft)

v

l

35 tbt.ft)

10 x 1.25 mm47 N.m {4.8 kgf m,10 x 1.25 mm47 N.m {i1.8 kgl m,35 tbr.ft)

RECLINE ADJUSTER

LOW

d

ER CAP

l

RECLINE

CONNECTING WIRETo connect, twist 180'

OUTER SEATTRACK

Installation is the reverse of the removal procedure'

NOTE:

. Make sure the bushing and pivot washer

installed ProPerly.. To prevent wrinkles when installing the seat-

back cover, make sure the material is stretched

evenly over the Pad.

. Grease the sliding Portion

8 x 1.25 mm20 N.m 12.0 kgf.m,14 tbt.ft)

are

RECLINEKNOB

(cont'd)

20-75

10 x 1.25 mm47 N.m {4.8 kgf'm,35 tbtftl

Page 1317 of 2189

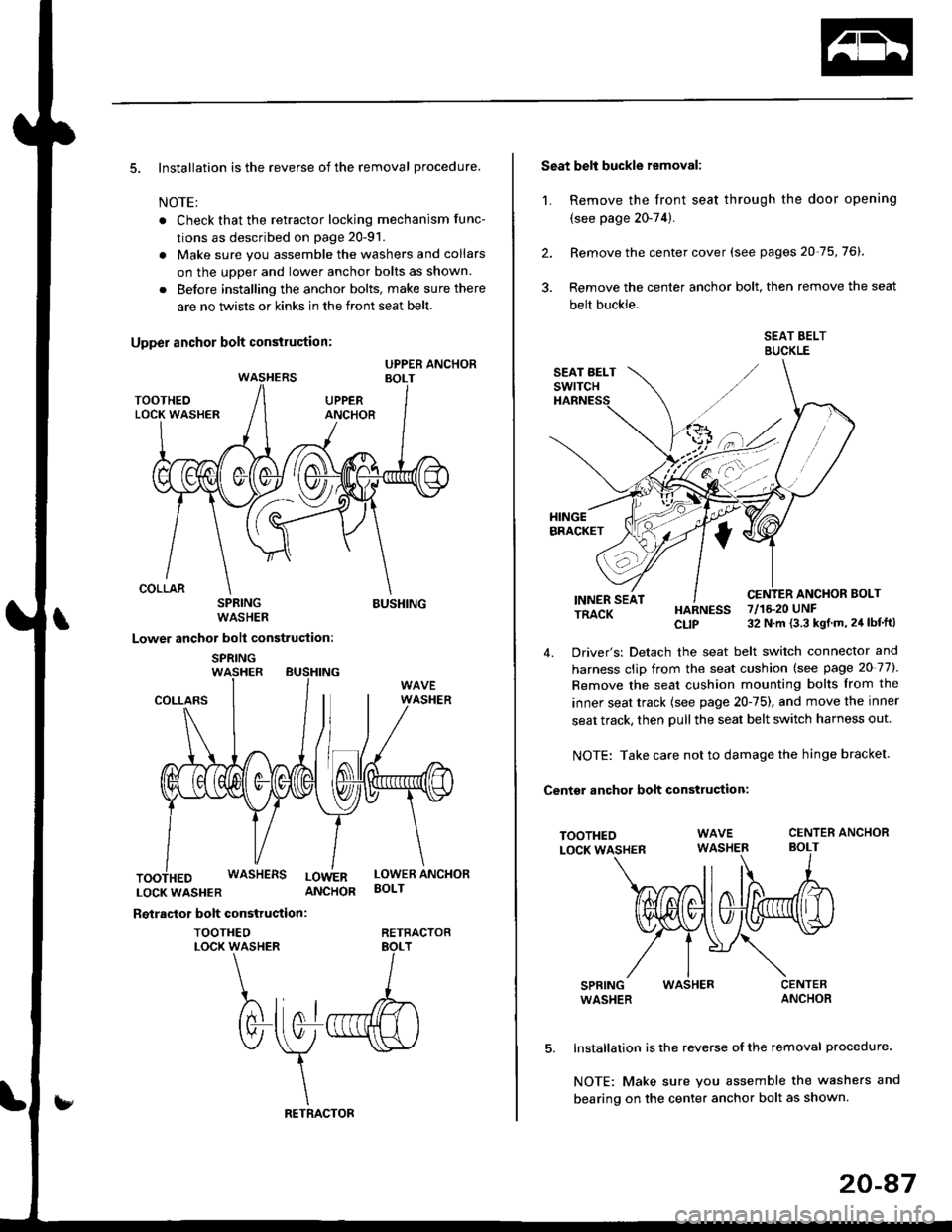

5. Installation is the reverse of the removal procedure.

NOTE:

. Check that the retractor locking mechanism func-

tions as described on page 20-91.

. Make sure you assemble the washers and collars

on the uoDer and lower anchor bolts as shown.

. Before installing the anchor bolts, make sure there

are no twists or kinks in the front seat belt.

SPRINGWASHER

Lower anchor bolt construction:

SPRINGWASHER BUSHING

BUSHING

COLLARS

LOCKWASHER ANCHOR

Reiractor bolt construction:

TOOTHEOLOCK WASHER

WASHERS LowERLOWER ANCHORBOLT

RETRACTOB

Seat belt buckle removal:

1. Remove the front seat through the door opening

{see page 20-74).

2. Remove the center cover (see pages 20-75,76).

3. Remove the center anchor bolt, then remove the seat

belt buckle.

SEAT BELTBUCKLE

ANCHOR BOLTINNER SEATTRACK

TOOTHEOLOCK WASHER

SPRINGWASHER

HARNESS 7/16.20 UNF

CLIP 32 N m (3.3 kgt m, 24 lbf'ft)

4. Driver's: Detach the seat belt switch connector and

harness clip from the seat cushion (see page 20 77).

Remove the seat cushion mounting bolts from the

inner seat track {see page 20-75), and move the inner

seat track, then pull the seat belt switch harness out.

NOTE: Take care not to damage the hinge bracket.

Centsr anchor bolt construction:

CENTER ANCHORBOLT

WASHER

Installation is the reverse of the removal procedure.

NOTE: Make sure you assemble the washers and

bearing on the center anchor bolt as shown.

20-47