boot rubber HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 573 of 2189

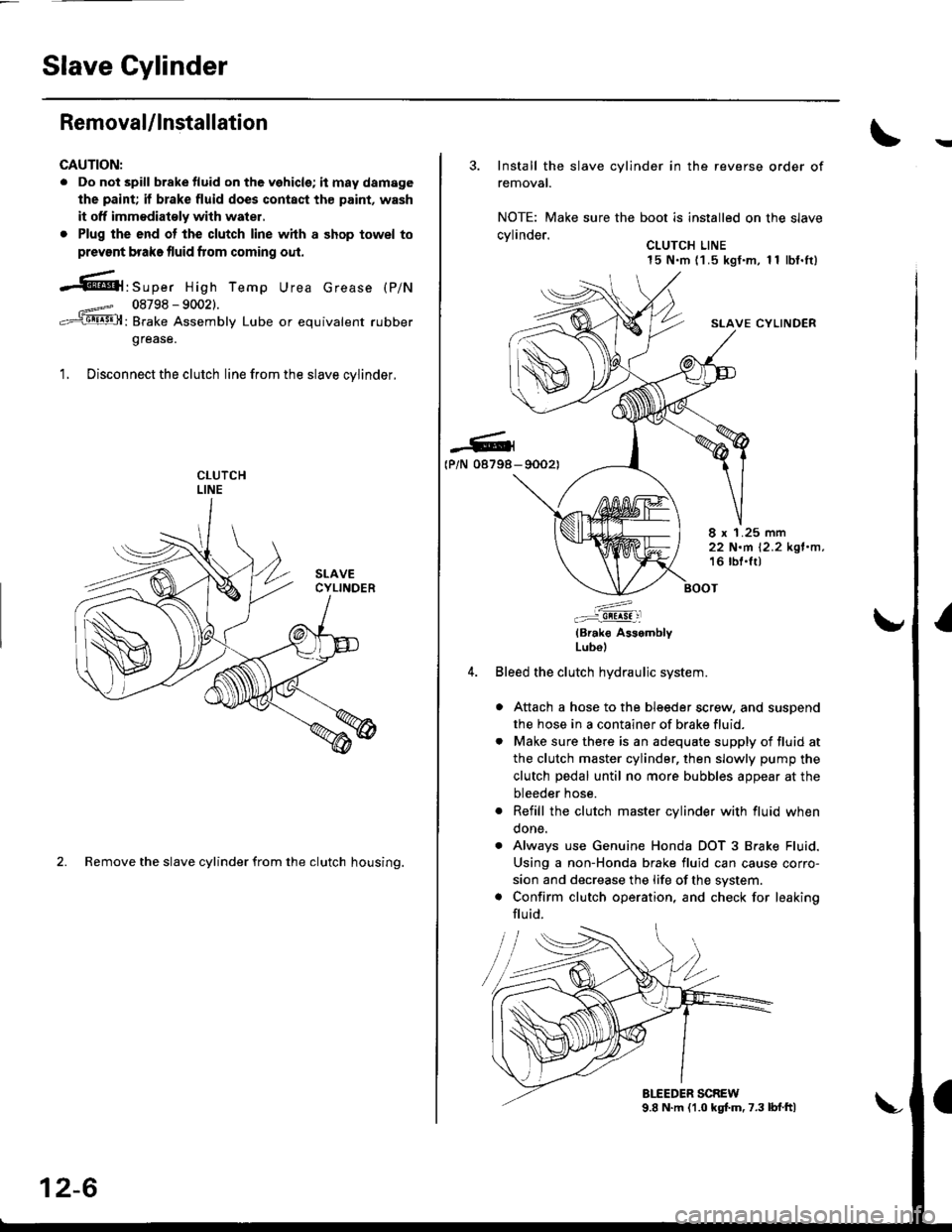

Slave Gylinder

Removal/lnstallation

CAUTION:

. Do not spill brake tluid on the vehicle; it may damage

the paint; if brake fluid does contact th€ paint, wash

it off immodiatoly with water,

. Plug the end ot the clutch line with a shop towel to

prevsnt brake fluid from coming oul.

-61'srp", High Temp Urea crease (p/N

08798 - 90021.

: Brake Assembly Lube or equivalent rubber

grease.

1. Disconnect the clutch line from the slave cvlinder.

2. Remove the slave cylinder from the clutch housing.

12-6

3. Install the slave cylinder in the reverse order of

removal.

NOTE: Make sure the boot is installed on the slave

cvlinder.. CLUTCH LINE15 N.m (1 .5 kgf.m, 1 1 lbf.It)

SLAVE CYLINDER

-G4(P/N 08798- 90021

8 x 1.25 mm22 N.m 12.2 kgl.n,16 lbl.lt)

:^..:i!!!!! :l

(Brak€ AssemblyLubol

Bleed the clutch hydraulic system.

a Attach a hose to the bleeder screw, and suspend

the hose in a container of brake fluid.

. Make sure there is an adequate supply of fluid at

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

. Refill the clutch master cylinder with fluid when

done.

. Always use Genuine Honda DOT 3 Brake Fluid.

Using a non-Honda brake fluid can cause corro-

sion and decrease the life of the system.

. Confirm clutch operation, and check for leaking

flu id.

Page 624 of 2189

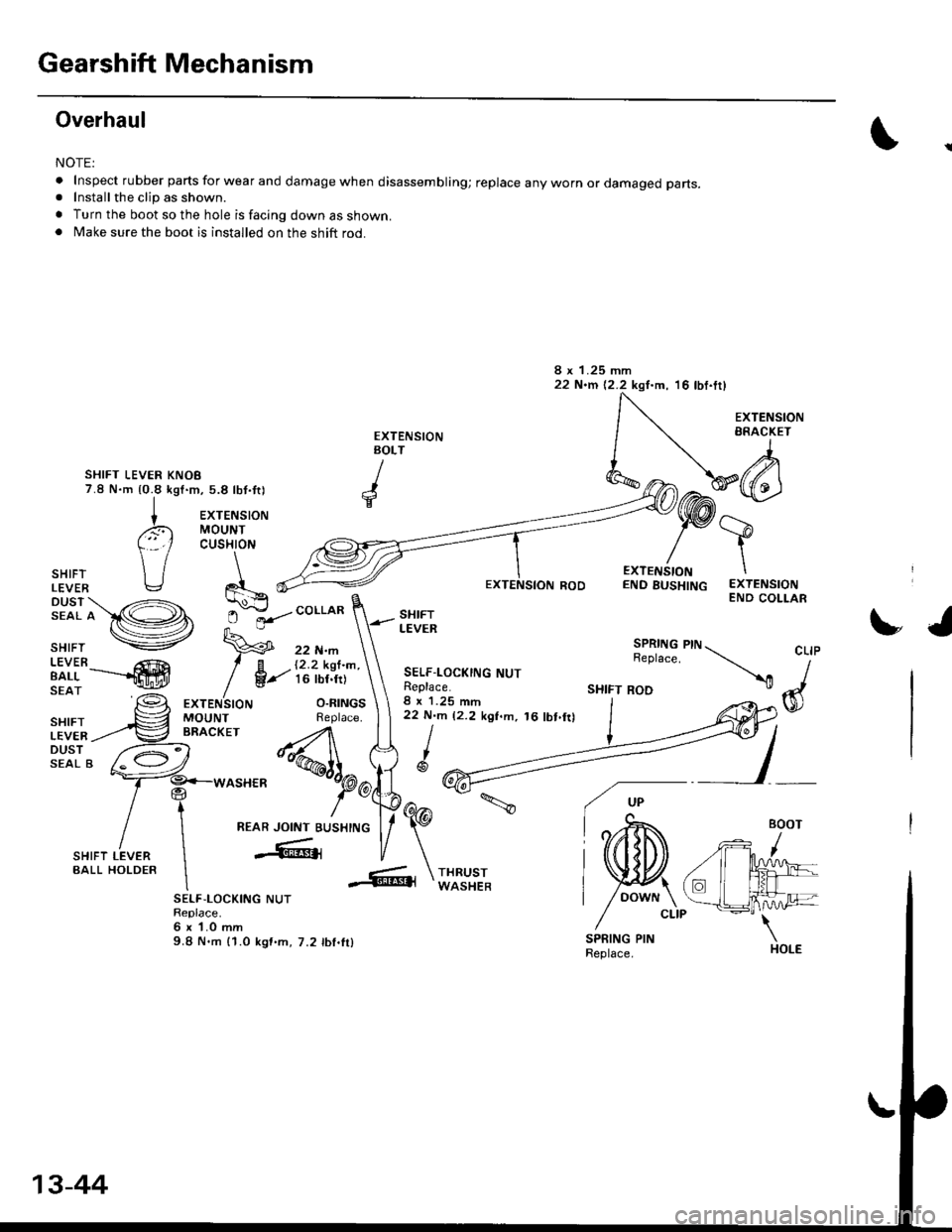

Gearshift Mechanism

Overhaul

NOTE:

.Inspectrubberpartsforwearanddamagewhendisassembling;replaceanywornordamagedparts.

. Install the clip as shown.

. Turn the boot so the hole is facing down as shown.. Make sure the boot is installed on the shift rod.

SHIFT LEVER KNOE7.8 N.m {0.8 kgf.m,5.8 lbt.tt)

EXTENSIONBOLT

)

searr'p)) p f*** \-ii,,l?'"

SHIFT -Vvvvvvvvvvvvvvvv�l tlourur Replace. | 1 22 N'm 12.2 ksf'm, 16 lbt.ftl

ii,".i'----....-.9 / g-ia',rf,',,"' sELF-LocKrNG Nur

sEAr '6 .rrr*(,o"" o-","o, ;":'i:;u --

CLIP

dul/

/,1: MOUNT

l': I cusHroN ,€\/\/-sSHIFT l / /-LEVER \, et- ffi

PY:,'\1^l lW -"or.o*Dusr .- \5".o.o)@1 -o-E "ot'o'

sHlFr \:/ Q,gD 22 N.m

IiUei__-.....p anecxer ,-/n I I I

?!il, e* ^.-.-n{wl\^fr J"r^r"

7****r

""'%ilf

t@

t1

t\sHrFT LEVER IBALL HOLDER

\

REAR JorN*lr,""17E@

_6,

L\

EXTENSION

SELF-LOCKING NUTReplace.6 x '1.0 mm9.8 N.m {1.0 kgf.m, 7.2 lbf.lr}

tJSPRING PINReplace.

-6r

16 tbf.trl

13-44

Page 677 of 2189

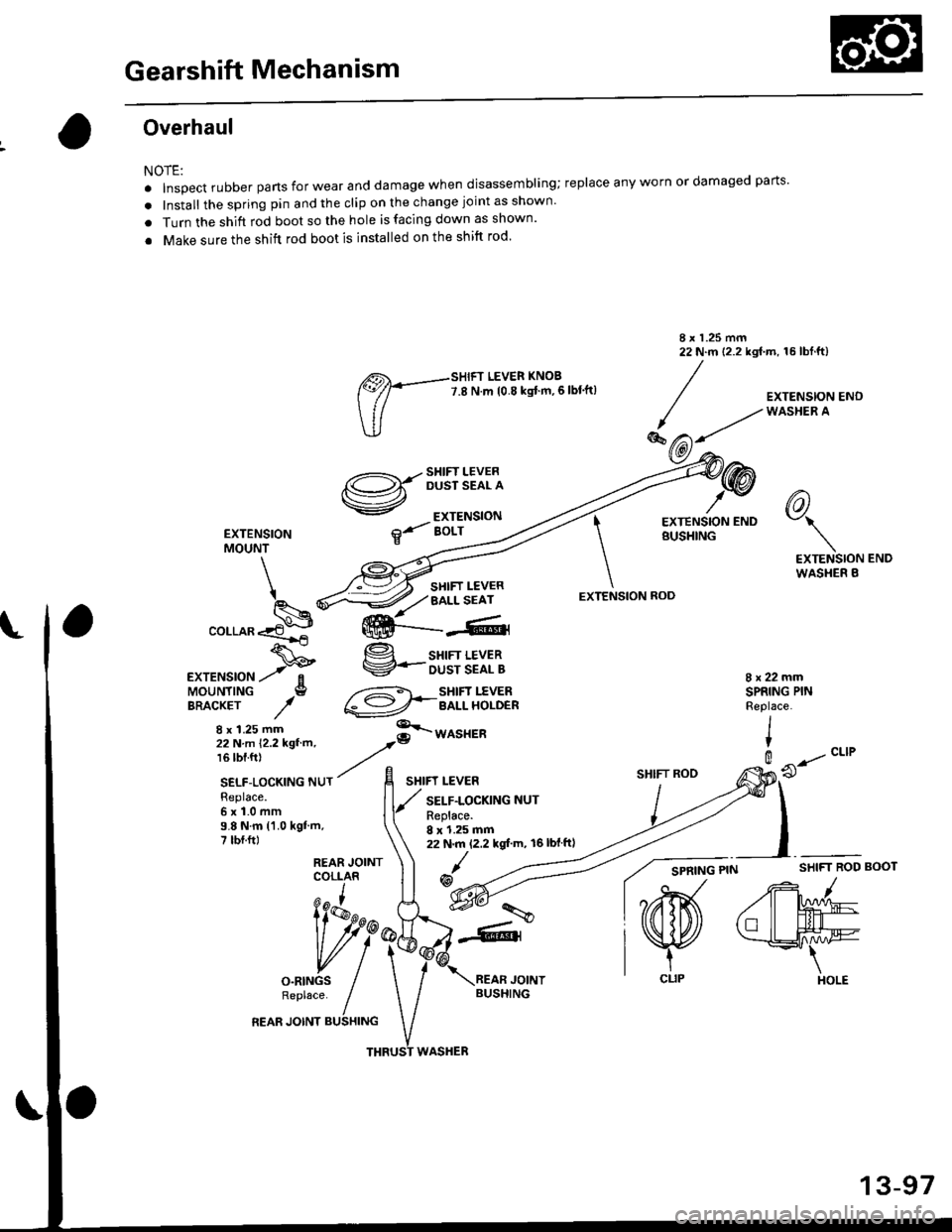

Gearshift Mechanism

Overhaul

NOTE:

. Inspect rubber parts for wear and damage when disassembling;

. Install the spring pin and the clip on the change joint as shown'

. Turn the shift rod boot so the hole is facing down as shown'

. Make sure the shift rod boot is installed on the shift rod'

reDlace any worn or damaged Parts.

I x 1.25 mm22 N.m 12.2 kgf.m, 16 lbf.ft)

ffi-:t't:il1ii51i?"'*,

TU

/g3i'51!Exii

V ExrENsroN

EXTENSfON ilr'eol.T

EXTENSION ENDBUSHING

hV\

EXTENSIONWASI{ER B

MOUNT -_.--_-_---

@2'

--1'>=2 -:liT.i'ff"

.o,-.o*&--ffi{---*,

v/,,/ BALL SEAT

8 x 1.25 mm22 N.m 12.2 kgf'm, 16lblftl

,@

EXTENSION ROD

SHIFT ROD

SPRING

END

BOOT

N: g sHrFr LEvER

.*rr"r,o"-tf V-oiliiSi[a

MOUNTING I --::=t SHIFT I"EVERBRAcxEr / €9-l--enr xoloen

8 x 1.2s mm :-,rro""a,ii-ri- ri.z rsr.-, -.Q u

16 tbf.ft) ,,,.

,rar-aoa*,"o "u, / E ,",t.ruaa

Replace.6x1.0mm9.8 N.m ('1.0 kgt'm,7 tbr.ftt

8x22mmSPRING PINReplace.

IIt

@CLIP

9.a-"t't

PIN SHIFT ROD/

ZW

€lt#-,\

HOLE

13-97

Page 1041 of 2189

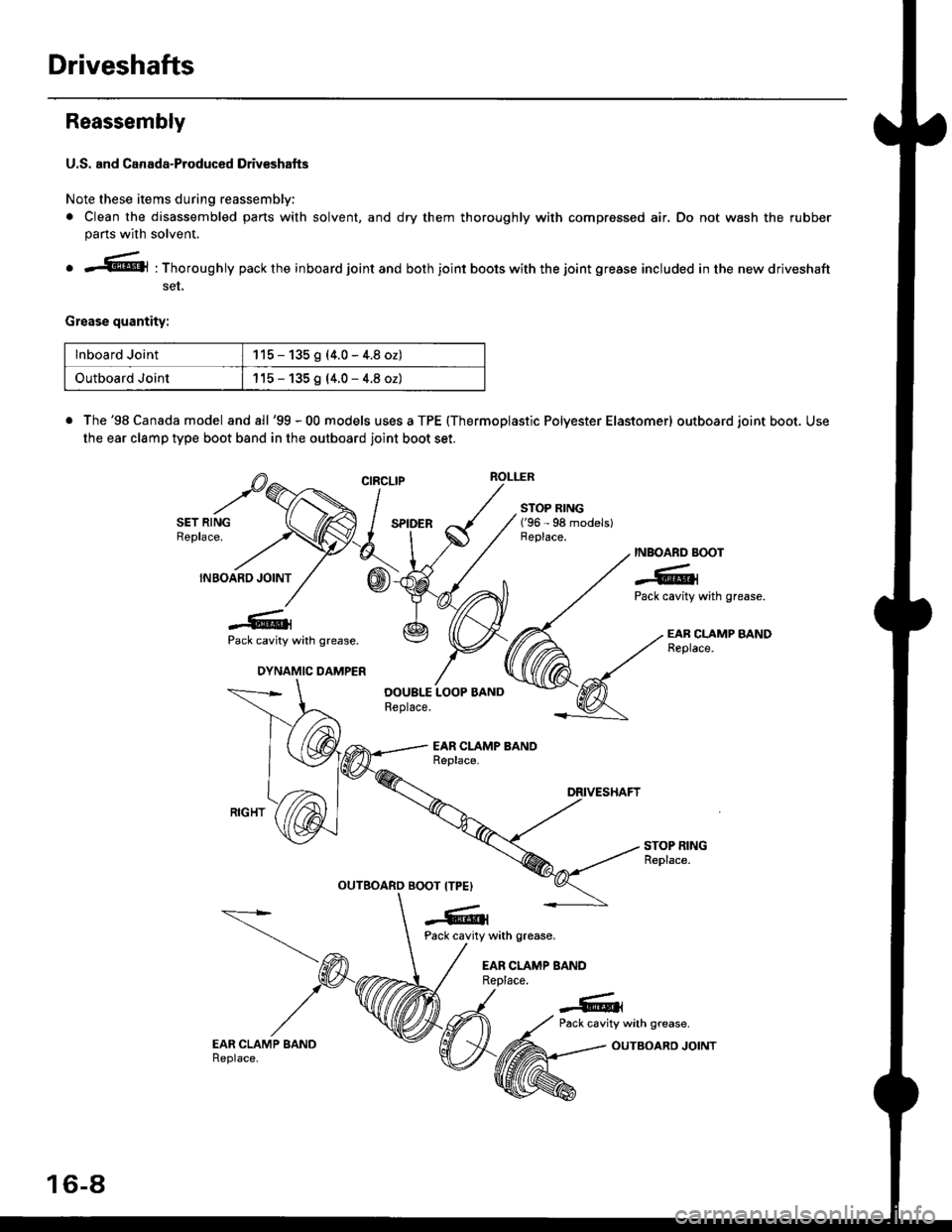

Driveshafts

Reassembly

U.S. and Canada-Producad Driv€shafts

Note these items during reassembly'

. Clean the disassembled parts with solvent, and dry them thoroughly with compressed air, Do not wash the rubberpans with solvent.

o ;..jl@l : Thoroughly pack the inboard joint and both joint boots with the joint grease included in the new driveshaft

ser,

Grease quantity:

lnboard Joint115 - 135 g (4.0 - 4.8 oz)

Outboard Joint115 - 135 g (4.0 - 4.8 oz)

. The'98 Canada model and all '99 - 00 models uses a TPE (Thermoplastic Polyester Elastomerl outboard joint boot. Use

the ear clamp type boot band in the outboard joint boot set.

STOP RING('96 - 98 models)

-6rPack cavity with grease.

DYNAMIC DAMPER

OOUBI.S LOOP BANDReplace.

INBOARD BOOT

-6lPack cavity with grease.

EAB CLAMP BANDReplace.

STOP RINGReplace.

EAR CLAMP BANDReplace.

DRIVESHAFT

OUTBOARDBOOT ITPE)

-6ll

, Pack cavity with grease.

EAR CLAMP BANDReplace.

-G.1

CIRCLIP

16-8

OUTBOARD JOINT

Page 1042 of 2189

l/

tt

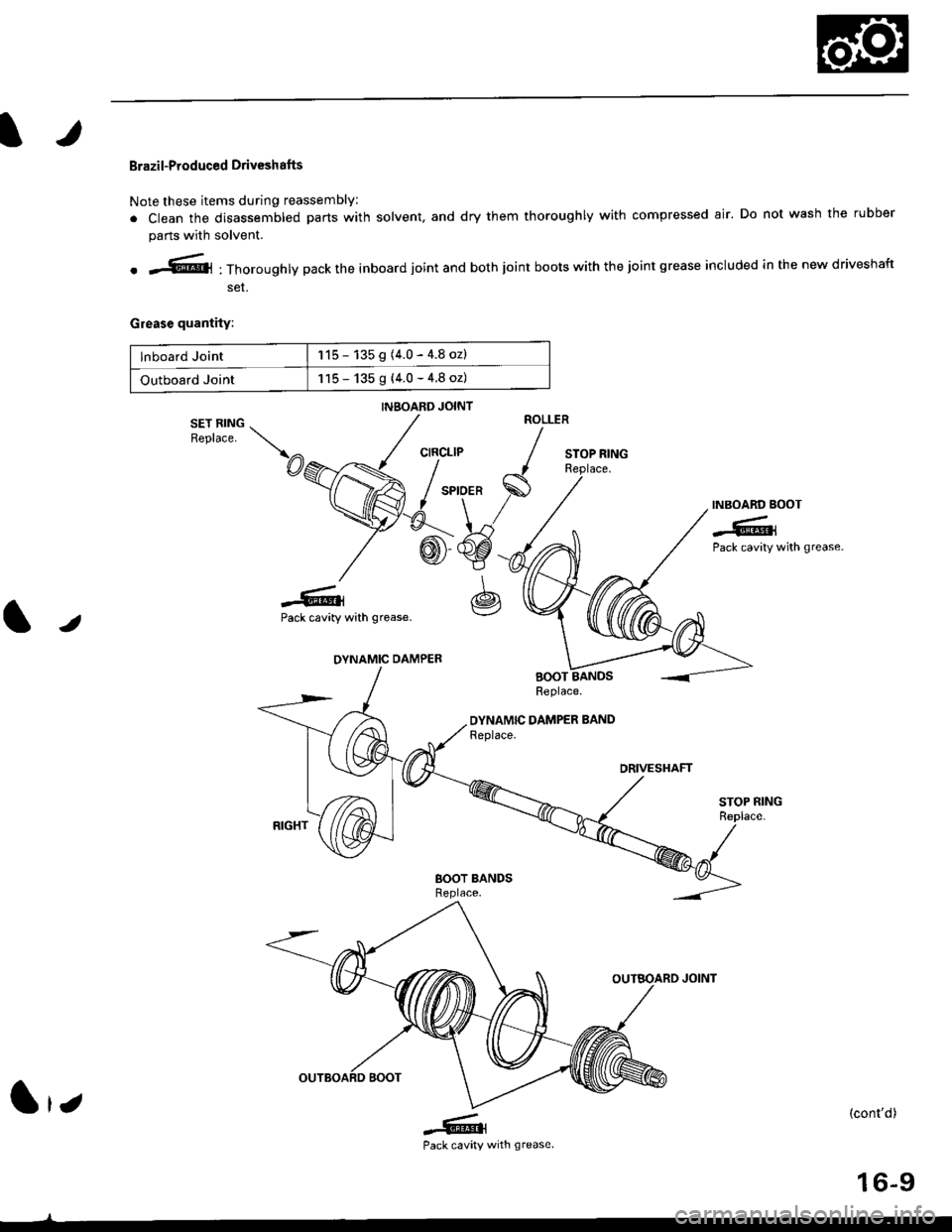

Brazil-Produced Driveshafts

Note these items during reassembly

. clean the disassembled parts with solvent, and dry them thoroughly with compressed ajr. Do not wash the rubber

parts with solvent.

. .fut :Thoroughly pack the inboard joint and both joint boots with the joint grease included in the new driveshaft

ser.

Greas€ quantity:

lnboard Joint115 - 135 g (4.0 - 4.8 ozl

Outboard Joint115 - 135 g {4.0 - 4.8 oz)

INSOARD JOINT

DRIVESHAFT

BOOT BANDSReplace.

-6.lPack cavity

(cont'd)

16-9

l,z

wrth grease,

Page 1043 of 2189

Driveshafts

Reassembly (cont'dl

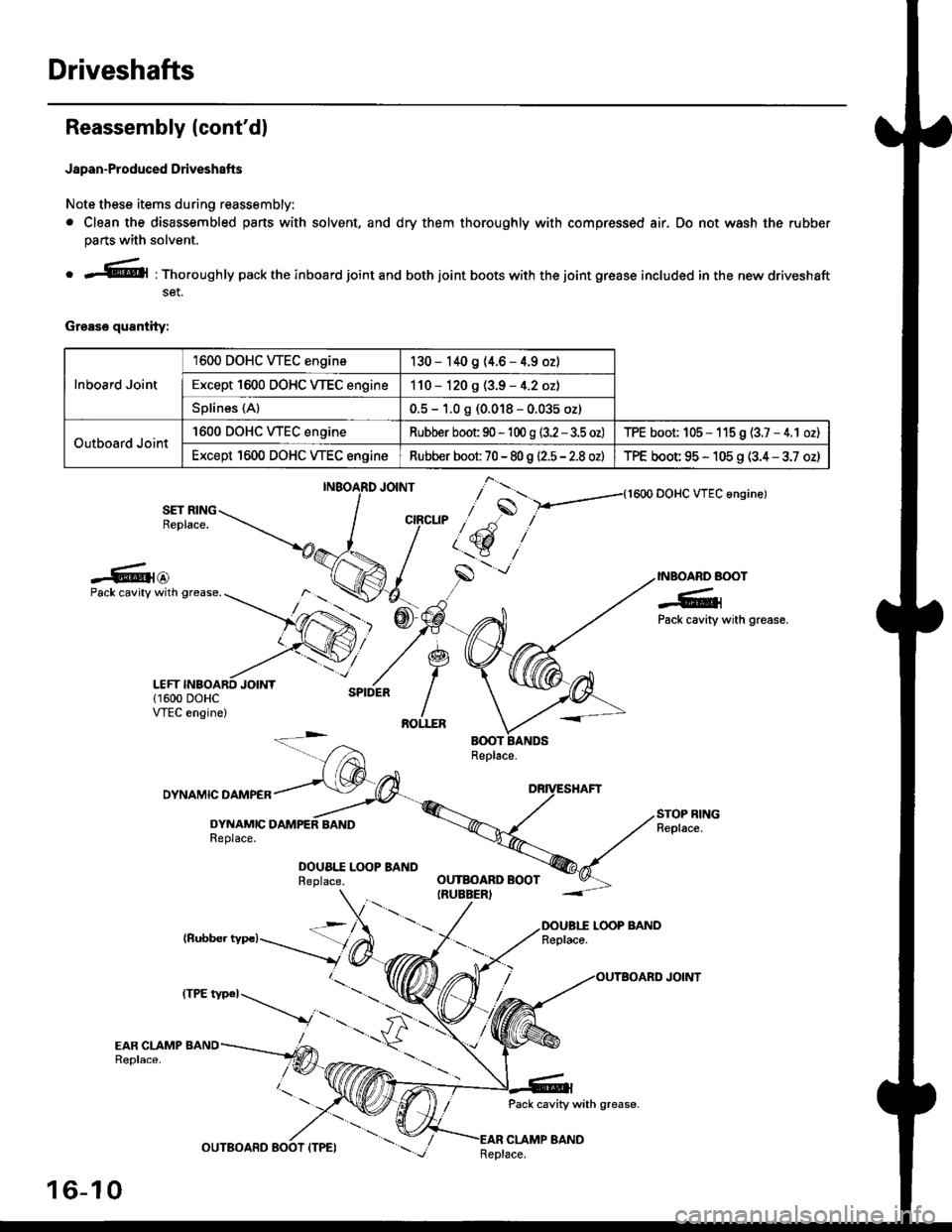

Japan-Produced Driveshafts

Note these items during reassembly.

. Clean the disassembled pans with solvent, and dry them thoroughly with compressed air. Do not wash the rubber

parts with solvent.

o r@l : Thoroughly pack the inboard joint and both joint boots with the joint grease included in the new driveshaft

set.

Grease quantity:

Inboard Joint

1600 DOHC WEC engine130 - 140 9 (4.6 - 4.9 oz)

Except 1600 DOHC VTEC engine110 - 120 g (3.9 - 4.2 oz)

Splines (Al0.5 - 1.0 g (0.018 - 0.035 oz)

Outboard Joint

'1600 DOHC WEC engineRubber boot 90 - 'l 00 g (3.2 - 3.5 oz)TPE boot; 105 - 115 9 (3.7 - 4.1 oz)

Except 1600 DOHC VTEC engineRubber boot 70 - 80 g |'2.5 - 2.8 ozlTPE boot 95 - 105 g (3.4 - 3.7 oz)

{1600 DOHC VTEC angine)

SET RINGReplace.

-6{@INBOARD BOOT

-6;Pack cavity with grease.

Pack cavity with grease.

DYNAMIC DAMPER

DYNAMICReplace.

DOUA|.I Lq)P BANDReplace.

(Rubber typc)LOOP BANDReplace.

Pack cavity with grease-

CLAMP BAND

],*"u, ,"^S

/ t'.t$ ,''

,/s

-'-

OUTBOARD BOOTIRUEBER)

16-10

tttt t*' -----_.r...-

._

Replace.

Page 1047 of 2189

Driveshafts

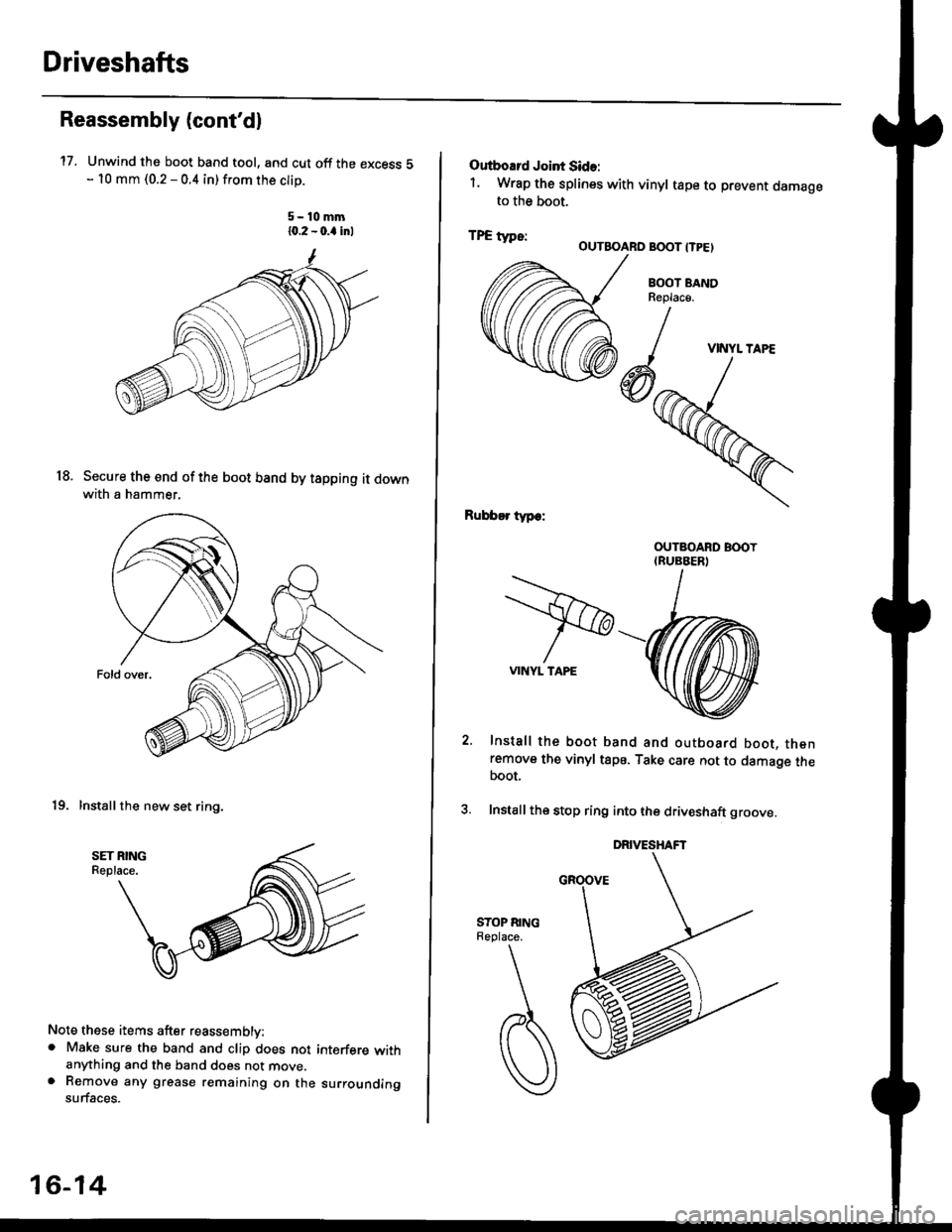

17.

Reassembly (cont'dl

Unwind the boot band tool, and cut off the excess 5- 10 mm (0.2 - 0.4 in) from the clip.

5-10mm10.2 - 0.a inl

Secure the end of the boot band by tapping it downwith a hammer,

19. Installthe new set ring,

18.

Note these items after reassembly:. Make sure the band and clip does notanything and the band does not move.a Remove any grease remaining on thesurfaces.

interfere with

su rrou nding

16-14

Outboard Joint Sid.:

1. Wrap the splines with vinyl tape to prevent damageto the boot.

TPE tvDe:-. OUTBOARO BOOT ITPE)

BOOT BANDReplac€,

Rubber typ.:

Install the boot band and outboard boot, thenremove the vinyl tape. Take care not to damage theboot,

Install the stop ring into the driv€shaft groove.

DRIVESHAFT

>VINYL TAPE

VINYL TAPE

Page 1049 of 2189

Driveshafts

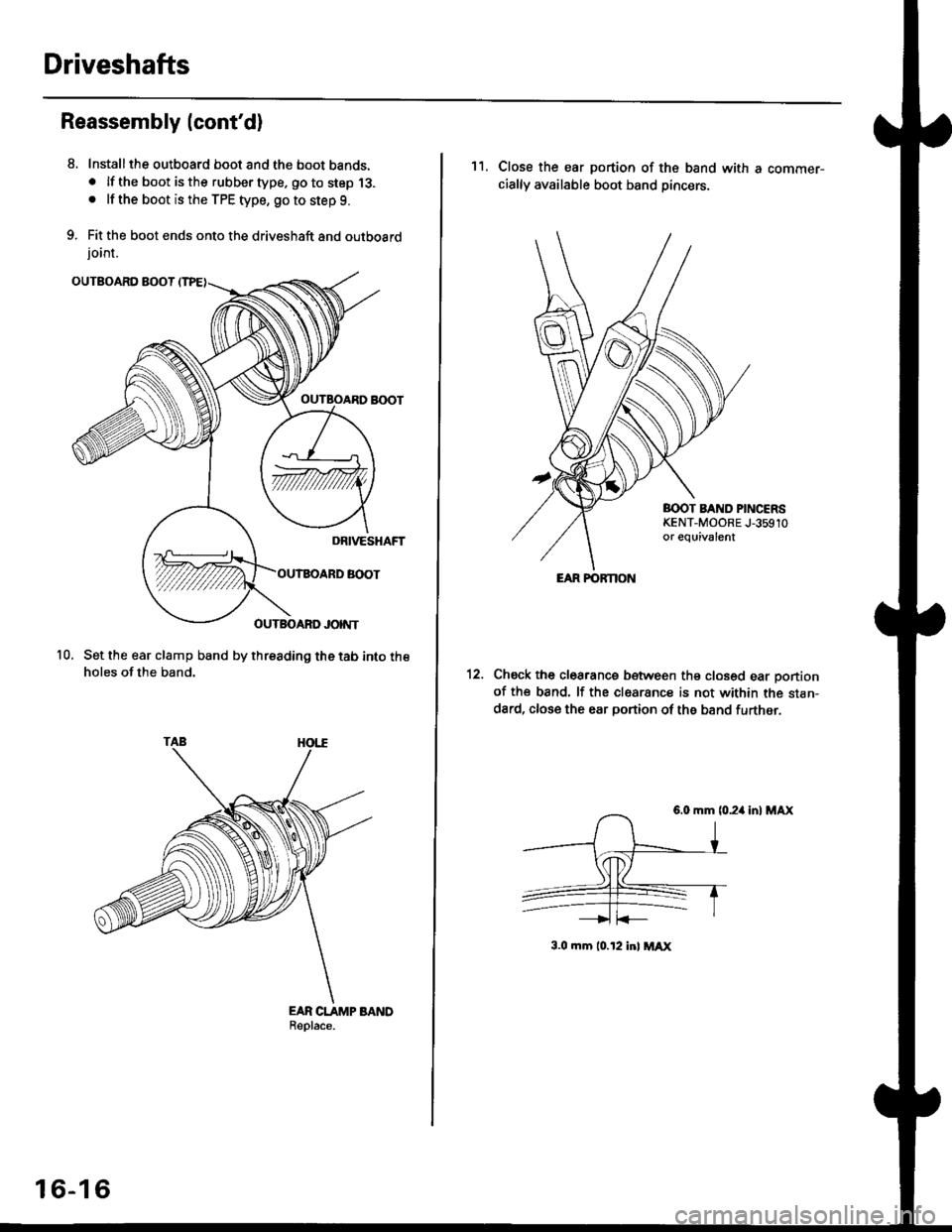

Reassembly lcont'd)

Installthe outboard boot and the boot bands.. lf the boot is the rubber type. go to step 13.. lf the boot is the TPE type, go to step 9.

Fit the boot ends onto the driveshaft and outboard

ioint.

10, Set the ear clamp band by threading the tab into theholes of the band.

EAR CLAMP BANDReolace.

8.

16-16

11. Close the ear portion of the band with a commer-cially available boot band Dincerc.

BOOT BAND PINCERSKENT-MOORE J,35910or eouivalent

Chsck the clearanca between the closed ear oonionof the band. lf the clesrance is not within the stan-

dard, close the ear portion of ths band further.

6.0 mm (0.24 in) MAX

3.0 mm 10.t2 inl MAX

EAR FOFNON

Page 1132 of 2189

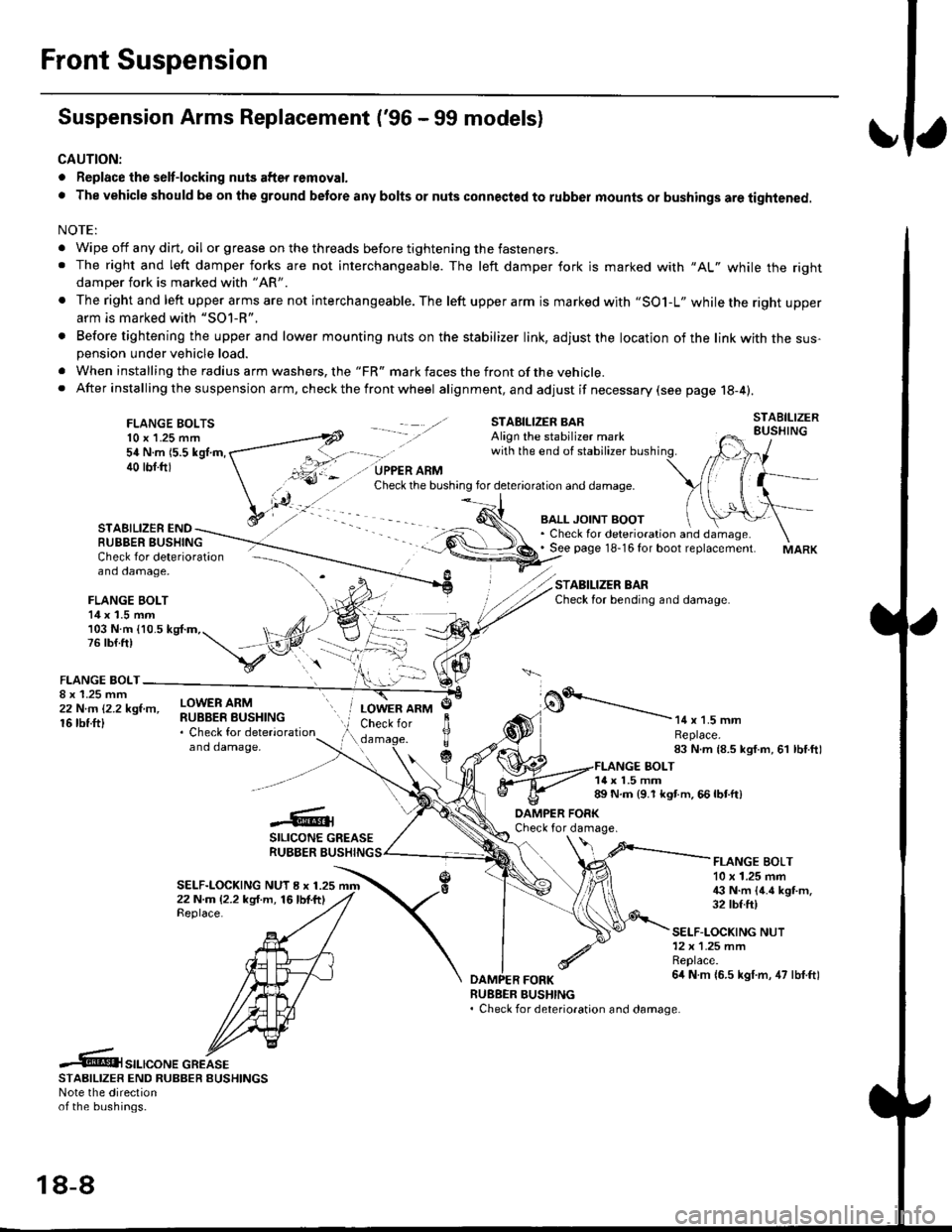

Front Suspension

Suspension Arms Replacement ('96 - 99 models)

CAUTION:

. Replace the selt-locking nuts after removal.

. The vehicle should be on the ground betore any bolts or nuts connected to rubber mounts or bushings are tightened.

NOTE:

. Wipe off any dirt, oil or grease on the threads before tightening the fasteners.. The right and left damper forks are not interchangeable. The left damper fork is marked with "AL" while the rightdamper fork is marked with "AR'

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SO1-L" while the right upperarm is marked with "SOl-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adjust the location of the link with the sus-pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front ofthe vehicle.. After installing the suspension arm, ch eck the front wheel alignment, and adjust if necessary (see page 18-4).

FLANGE BOLTS10 x 1.25 mm54 N.m 15.5 kgl.m,40 tbf.ftl

STAEILIZER ENDRUBBER BUSHING

BALL JOINT BOOT. Check for deterioration and damage.. See page 18-16 for boot replacement.

STABILIZER BARCheck for bending and damage.

Check for deterioration - ---\--

and damage, -\

FLANGE BOLT14 x 1.5 mm/)l103 N.m {10.5 kg{.m,. t, ,/4,76lb{.ft) t,,"-iV

v:\FLANGE BOLT-

;iffillr-"- ilHitffi*::,"*"

and damaoe,

o.'-----------14 x 1.5 mmReplace.83 N.m {8.5 kgf.m, 61 lbf.ftl

LOWER ARMCheck for

c

JlTTda

1{ x 1.5 mm89 N.m {9.1 kgt m. 66 lbtft)

-6;SILICONE GREASERUBBER BUSHING

DAMPER FORKCheck for damage.

SELF-LOCKING NUT I x 1.2522 N.m (2.2 kg{.m, 16lbf.ftlReplace.

FLANGE BOLT10 x 1.25 mm€ N.m {4.6 kgt m.32 tbf.ft)

SELF-LOCKING NUT12x 1.25 mmReplace.6it N m {6.5 kgf.m, 47 lbf.ftl

RUEBER BUSHING. Check for deterioration and damage.

.6t",.,"o".c"KeSTAAIL|zER END RUBBER EUSHINGSNote the directionof the bushings.

18-8

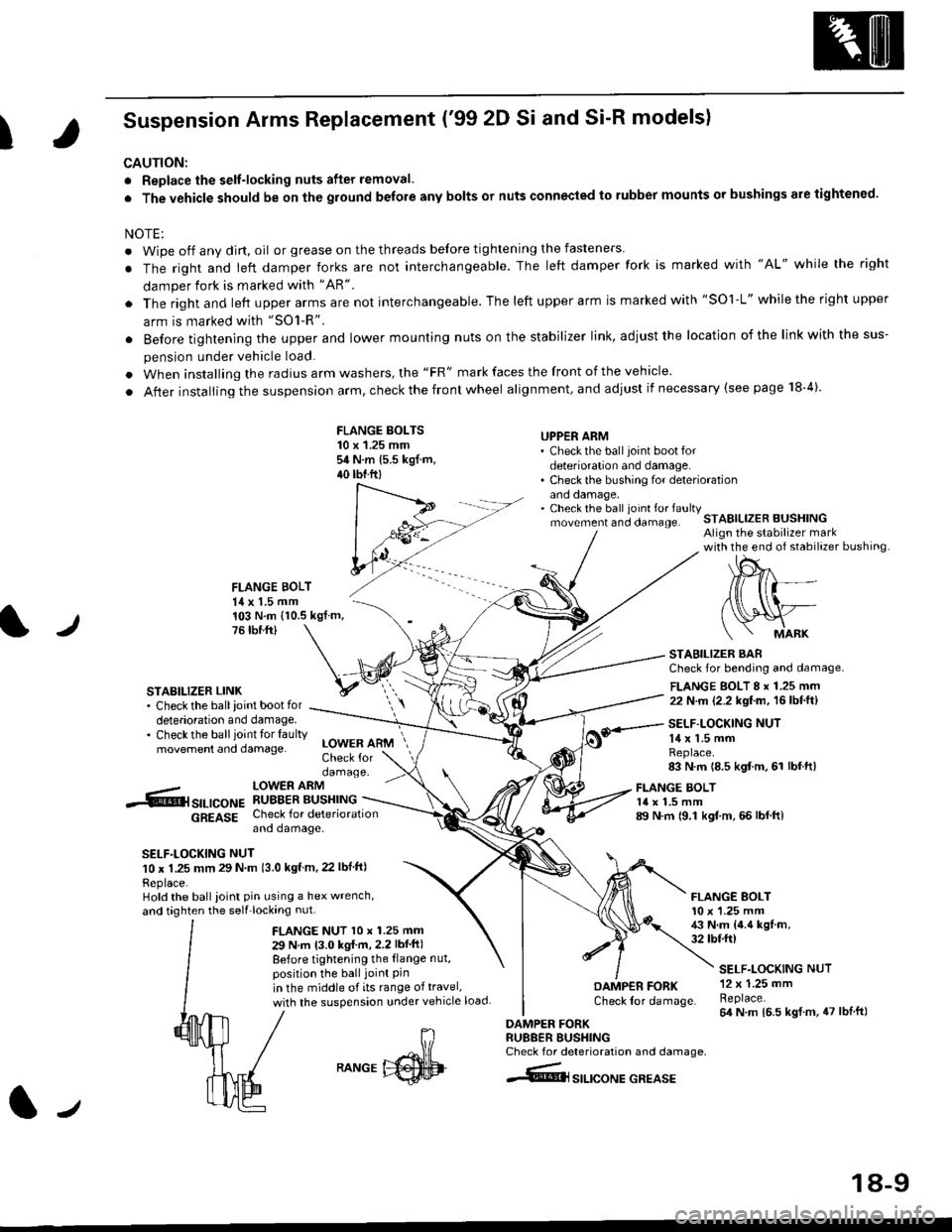

Page 1133 of 2189

I

Suspension Arms Replacement ('99 2D Si and Si-R models)

CAUTION:

. Replace the selt-locking nuts after removal.

. The vehicle should be on the ground belore any bolts or nuts connected to rubber mounts or bushings are tightened.

NOTE:

. Wipe off any dirt, oil or grease on the threads before tightening the fasteners

. The right and ieft damper forks are not interchangeable. The left damper fork is marked with "AL" while the right

damper fork is marked with "AR"

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SOl-L" while the right upper

arm is marked with "SO1-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adiust the location of the link with the sus-

pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front of the vehicle.

. After installing the suspension arm, check the front wheel alignment, and adjust if necessary (see page 18-4).

FLANGE BOLTS10 x 1.25 mmsit N.m 15.5 kgf.m,40 tbtftl

UPPER ARM' Check the ball joint boot fordeterioration and damage.. Check the bushing for deteriorationano oamage,. Check the ball ioint fo. faultymovement and clamage.STABILIZER BUSHINGAlign the stabilizer markwith the end of stabilizer bushing

FLANGE BOLT14 x 1.5 mm

l./

103 N.m (10.5 kgf.m,76 tbr.ftl

STABILIZER LINK. Check the ballioint bootfordeterioration and damage.. Checkthe ballioint tor faultymovement and damage.

STABILIZER BARCheck for bending and damage.

FLANGE BOLT 8 x 1.25 mm22 N.m (2.2 kgf.m, 16lbf.ft)

SELF-LOCKING NUT14 x 1.5 mmReplace.83 N.m 18.5 kgf m, 61 lbf.ft)

-.6r srr-,co", hSHrtlrT.[*"u

6g619g Check for deteriorationano oamage.

SELF.LOCKING NUT10 x 1.25 mm 29 N m 13.0 kgf m, 22 lbf ftl

Replace.Hold the ball ioint pin using a hex wrench,

and taghten the self'locking nut.

LOWER ARMCheck fordamage.

FLANGE NUT l0 x 1.25 mm

29 N.m 13.0 kgI m,2.2 lbf ft)

Before tightening the {lange nut,position the ball joint Pinin the middle of its range of travel,

with the suspension under vehicle load

FLANGE BOLT14 x 1.5 mm89 N.m 19.1 kgf.m, 66 lbf.ft)

FLANGE BOLT10 x '1.25 mm43 N.m {4.4 kgf.m,32 tbtft)

DAMP€R FORKCheck lor damage.

DAMPER FORKRU88ER BUSHINGCheck for deterioration and damage.

4@lsrlrcoNE GREASE

SELF.LOCKING NUT12 x 1.25 mmReplace.64 N m 16.5 kgl.m, 47 lblft)

J

RANGE

18-9