idle pulley HONDA CIVIC 1999 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CIVIC, Model: HONDA CIVIC 1999 6.GPages: 2189, PDF Size: 69.39 MB

Page 62 of 2189

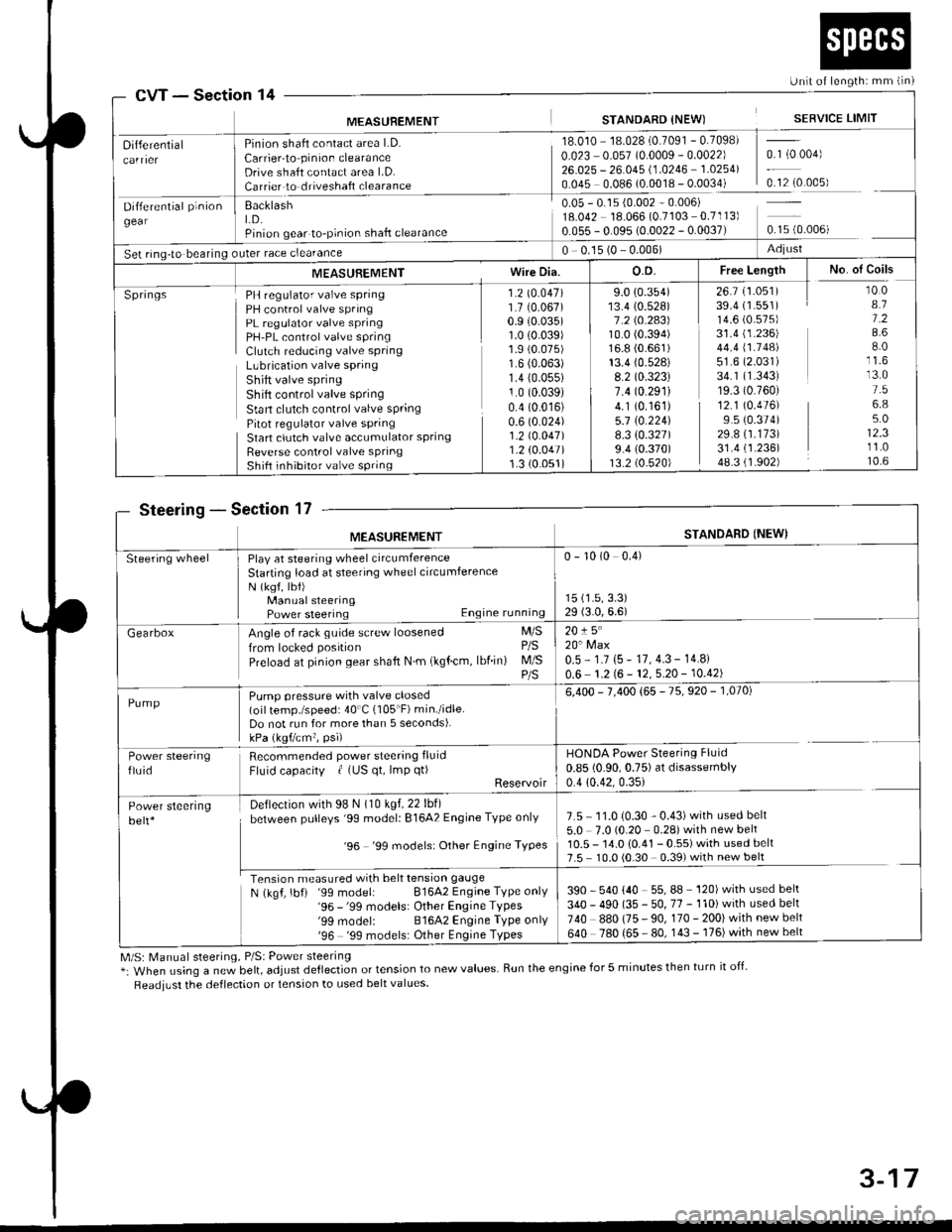

Unit of length: mm lin)

STANDARD {NEW) SERVICE LIMITMEASUREMENT

Differential

Dtri"*"t"|p'.b"gear

S"t rrg-t" b""il"s

Pinion shaft contact area LD.

Carrier-to pinion clearanceDrive shaft contact area l.D.Carrier to driveshaft clearance

BacklashLD.Pinion gear to-pinion shafl clearance

)uter race clearance

18.010 18.028'0.7091 - 0.7098)

0.023 0.057 (0.0009 - 0.0022) 0.1 (0 004)

26.025 - 26.045 (.0246 1 0254\0.045 0.086 (0.0018 - 0.0034) 0.12(0.005)

0 05 - 0.15 i0 002 0.006)18 042 18.066 {0.7103 0.7" l3)

0.055 - 0.095 (0.0022 - 0.0037) 0.15 {0.006)

0 0.15 (0 - 0.006) Adjlrst

MEASUBEMENT Wire DiaO.D. Free Length I No. of Coils

SpringsPH regulator valve spring 1 2 (0 047)

PH control valve spring 1 7 {0.067)PL regulator valve spring 0 9 (0.035)

PH'PL control valve spring 1 0 (0 039)

crutlh reduc'ns vdrve spnns ] :19 9]:lLLbrication valve spring I b (u ubJr

Shitt valve spring 1 4 (0.055)

Shift control valve spring 1 0 (0.039)

Stan clutch control valve spring 0.4 (0 016)

Pitot regulator valve spring 0.6 (0 024)

Start clutch valve accumulator spring 1 2 \0 O47)

Reverse control valve spring 1 2 (0.047)

Shift inhibitor valve spring 1 3 (0 051)

9.0 {0.354)13.4 (0.528)

1.2lO.2A3\10.0 (0.394)

16.8 (0.661)

13.4 (0.528)

8.2 (0.323)

1 .4 t0.29114.1 (0.161)

5.7 t0.224)8.3 {0.327)9.4 (0.370)

13.2 (0.520)

26.7 (1.051)

39.4 (1.551)

14.6 (0.575)

31.4 (1.236)

44.4 \1.14al51.6 (2.031)

34.1 (1.343)

19.3 (0.760)

12.1 (0.476)

9.5 (0.374)

29.8 (1.173)

31.4 (1.236)

48.3 (1.902)

r0.08.11.28.68.0

13.01.56.85.012.311.010.6

Section 14

SteeringSection 17

M/S: [,4anual steering, P/Sl Power steering*: When using a ne; bett, adjust dellection or tension to new values. Run the engine for 5 minutes then turn it off-

Readjust the deflection or tension to used belt values.

cw

MEASUREMENTSTANDARD {NEWI

Steering wheelPlay at steering wheel circumferenceStarting load at steering wheelcircumferenceN (ksf, lbf)Manual steeringPower steering Engine running

0 - 10 (0 0.4)

15 (1.5,3.3)

29 (3.0,6.6)

GearboxAngle of rack guide screw loosened M/S

from locked position P/S

Preload at pinion gear shaft N m (kglcm, lbfin) M/S

20!5"20'Max0.5 - 1.7 (5 - 17,4.3 - 14.8i

0.6 1.2 (6 - 12, 5.20 - 10.42)

Pump pressure with valve closed(oil temp./speed: 40'C (105"F) min./idleDo not run for more than 5 seconds).kPa (kgtcm?, psi)

6,400 - 7,400 {65 - 75, 920 - 1,070)

Power steeringfluidRecommended power steering fluid

Fluid capacity | {US qt, lmp q0Reservoir

HONDA Power Steering Fluid

0.85 (0.90,0.75) at disassembly0.4 {0.42.0.35}

7.5 11.0 {0.30 - 0.43)with used belt

5.0 7.0 (0.20 0.28) with new belt10.5 - 14.0 10.41 - 0.55) with used belt7.5 10.010.30 0.39) with new belt

390 540 {40 55,88 '120) wrth used bek

340 - 490 (35 - 50, 77 - 110) with used belt

740 880 (75 - 90, 170 - 200) with new belt

640 780 (65 - 80, 143-176)with newbelt

Power steeringbelt*

Deflection with 98 N (10 kgf,22 lbf)

between pulleys '99 modell 81642 Engine Type only

'96 '99 models: Other Engine TYPes

ron.ionffiN (kgf, lbf) '99 model: 81642 Engine Tvpe only'96 -'99 models: Other Engine TYPes'99 modelr 81642 Engine TYPe onlY'96 '99 models: Other Engine TYPes

3-17

Page 64 of 2189

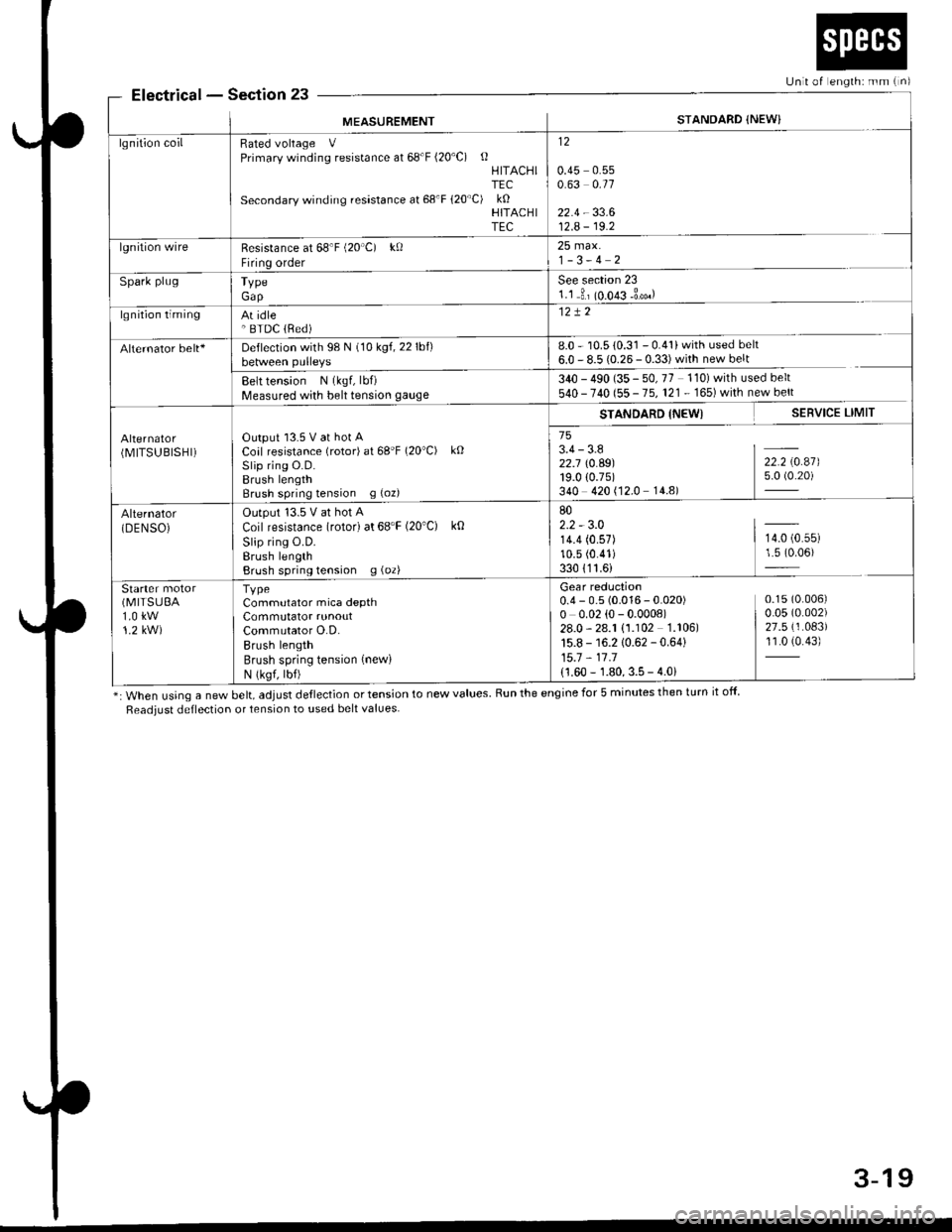

ElectricalSection 23

*: When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off

Readiust deflection or tension to used belt values

Unit of englh: mm {n)

MEASUREMENTSTANDARD {NEW}

lgnition coilRated voltage VPrimary winding resistance at 68'F (20'C) oHITACHITEC

Secondary winding resastance at 68'F 120"C) kOHITACHITEC

12

0.45 0.550.63 0.11

22.4 - 33.612.A - 19.2

lgnition wireResistance at 68'F (20'C) kf)

Firing order

25 max.1-3-4 2

Spark plugTypeGap

See section 231.1 3, (o.o€ -3*.)

lgnition timingAt idle' BTDC lRed)

Alternator belt+Deflection with 98 N (10 kgf,22lbf)between pulleys8.0 - 10.5 {0.31 - 0.41} with used belt

6.0 - 8.5 {0.26- 0.33)with new belt

Belt tension N (kgf, lbf)

Measured with belt tension gauge340 - 490 (35 - 50, 77 110) with used belt

540 - 740 (55 - 75, 121. 165)whh newbert

(MITSUBISHI)Output l3.5 V at hot ACoal resistance (rotor) at 68'F (20"C) kO

Slip rins O.D.Brush lengthBrush spring tension g (oz)

STANDARD INEWI SERVICE LIMIT

753.4-3.8 I -

Z2.j \0.A9) 22.2 \0.47)19.0 (0.75) 5.0 (0.20)

340 420 (12.0 14.8)

Alternator(DENSOiOutput '13.5 V at hot A

Coil resistance (rotor) at 68'F (20'C) k0

Slip ring O.D.Erush lengthBrush spring tension g (oz)

802.2 - 3.014.4 (0.57) | 14.0 (0.55)

10.5 (0.41) 1.5 (0.06)

330 {11.6)

Starter(MITSUEA

1.0 kw1.2 kW)

TvpeCommutator mica depthCommutator runoutCommutator O.D.Brush lengthBrush spring tension (new)

N (ksf, lbf)

Gear reduction0.4 - 0.5 (0.016 - 0.020) 0.15(0.006)

o o.o2 (o - 0.000e) | o.o5 (o.oo2)

28.0-28.1 (1.102 1.106) | 27.5(1.083)

15.8 - 16.2 10.62 - 0.64) 11.0 (0.43)

15.7 - 11 .1

{1.60 - 1.80, 3.5 - 4.0i

3-19

Page 100 of 2189

Engine Removal/lnstailation

Removal (cont'dl

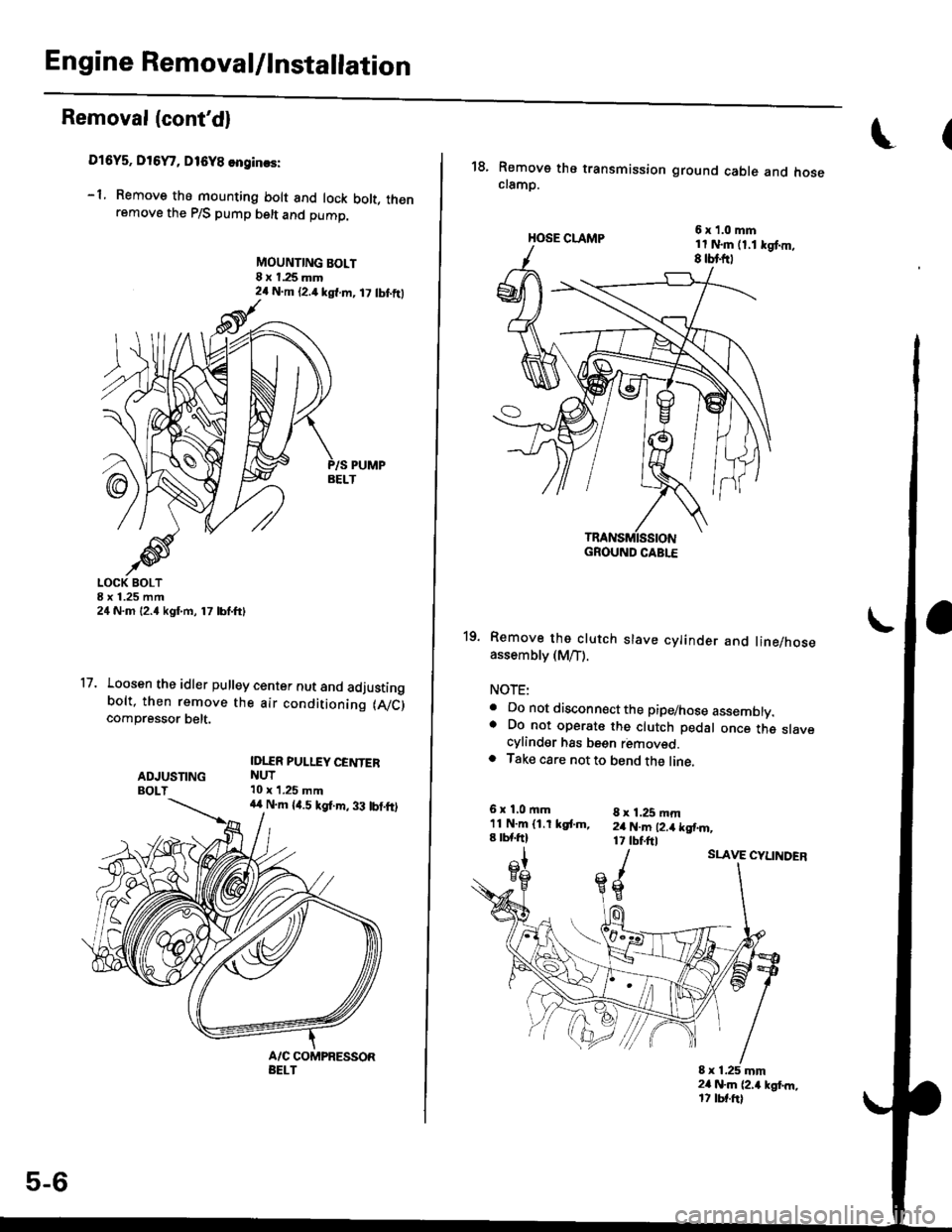

Dl6Y5. DrGYr, D16Y8 enginas:

-1. Remove the mounting bolt and lock bolt, thenremove the P/S pump belt and pump.

MOUNTING BOLT8 x 1.25 mm24 N.m {2.4 kgl.m, 17 tbf.ftl

LOCK BOLT8 x 1.25 mm24 N.m 12.4 kgf.m, 17 lbf.ftl

17. Loosen the idler pulley center nut and adjustingbolt, then remove the air conditioning (A[/C)compressor belt.

IDI.IR PULLEY CENTERNUT10 x 1.25 mma,l N.m {,1.5 kgt.m, 33 lbf.ft)

5-6

(

'18. Remove the ransmission ground cable and hosect8mo.

HOSE CLAMP6 x '1.0 mm

19. Remove the clutch slave cylinder and line/hoseassembty (M/T).

NOTE:

. Do not disconnectthe pipe/hose assembly.. Do not operate the clutch pedal once the slavecylind€r has been removed.o Take care not to bend the line.

6x1,0mm 8x1.2Smm11 N.m {1.1 kgt.m, 2a N.m t2.4 kgf.m,I tbf.ftl 17 tbf.ftl

8 x 1.25 mm2a N'm {2,4 kgt m,17 tbt.ftl

Page 130 of 2189

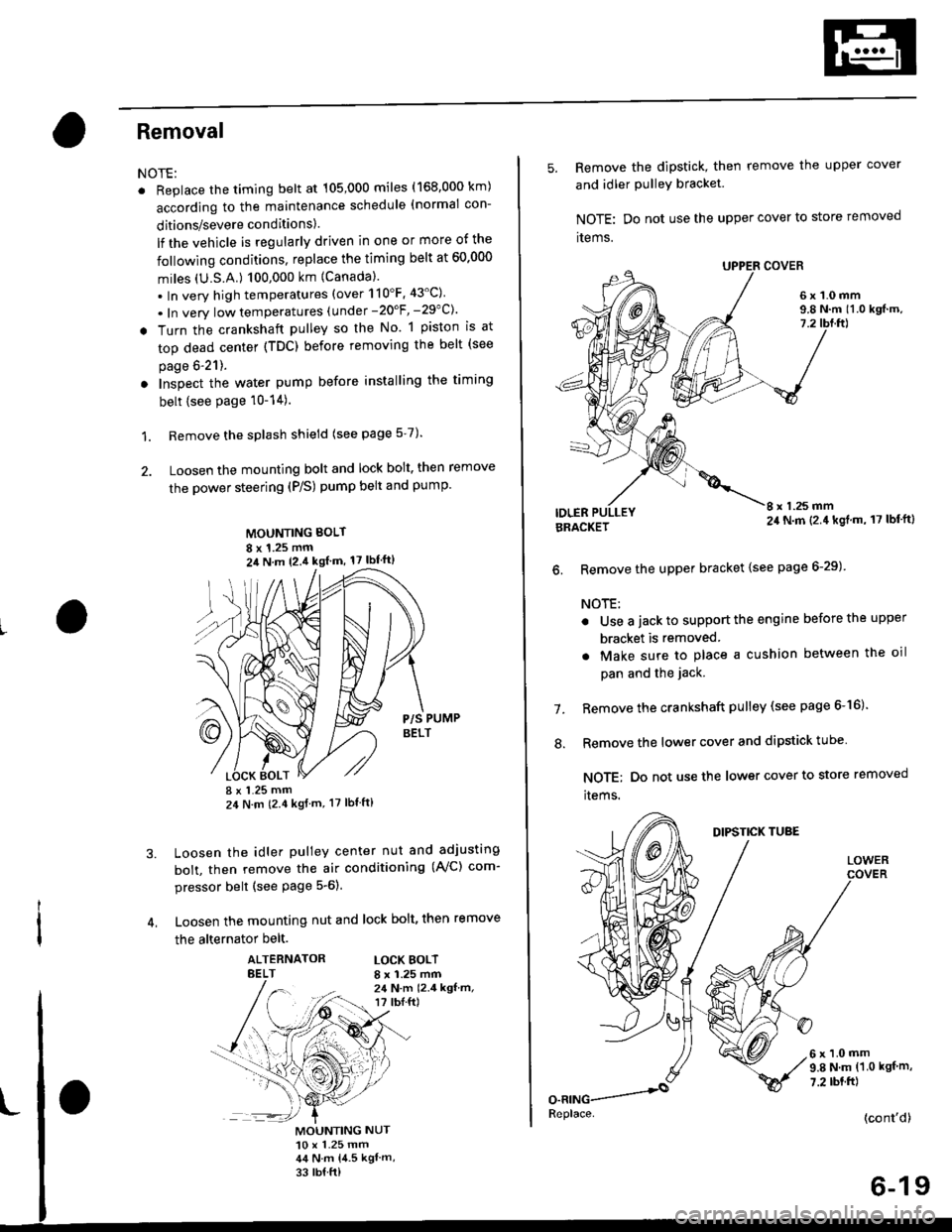

Removal

NOTE:

. Replace the timing belt at 105,000 miles (168.000 km)

according to the maintenance schedule (normal con-

ditions/severe conditions).

lf the vehicle is regularly driven in one or more of the

followlng conditions, replace the timing belt at 60.000

miles (U.S.A.) 100,000 km {Canada).

.In very high temperatures (over 110'F.43'C)

. In very low temperatures (under -20'F, -29"C)'

! Turn the crankshaft pulley so the No. 1 piston is at

top dead center (TDC) before removing the belt (see

page 6'21).

. Inspect the water pump before installing the timing

belt {see Page 10-14).

1. Remove the splash shield (see page 5-7).

2. Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt and pump

MOUNTING BOLT

8 x 1.25 mm2il N m 12.4 kgl m, 17 lbf'ft)

P/S PUMPBELT

I x 1.25 mm24 N m (2.4 kgf m, 17 lbt ft)

Loosen the idler pulley center nut and adjusting

bolt, then remove the air conditioning (AVC) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt, then remove

the alternator belt.

ALTERNATORBELTLOCK BOLTI x 1.25 mm24 N.m 12.4 kgf.m,r? tbI.ft)

3.

MOUNTING NUT10 x 1.25 mm44 N.m 14.5 kgl m,

33 rb{ ft)

5. Remove the dipstick, then remove the upper cover

and idler PulleY bracket

NOTE: Do not use the upper cover to store removed

items.

6x1.0mm9.8 N.m 11.0 kgf.m,7.2

IDLERI x 1.25 mm24 N.m (2.4 kgl.m, 17 lbf'ft)BRACKET

6. Remove the upper bracket {see page 6-29)

NOTE:

. Use a jack to support the engine before the upper

bracket is removed

. Make sure to place a cushion between the oil

pan and the jack.

Remove the crankshaft pulley (see page 6-16).

Remove the lower cover and dipstick tube

NOTE; Do not use the lower cover to store removed

items.

1.

.'.

DIPSTICK TUBE

LOWER

6x1.0mm9.8 N.m (1.0 kgf m,

7.2 rbt.ft)

(cont'd)

6-19

Replace.

Page 133 of 2189

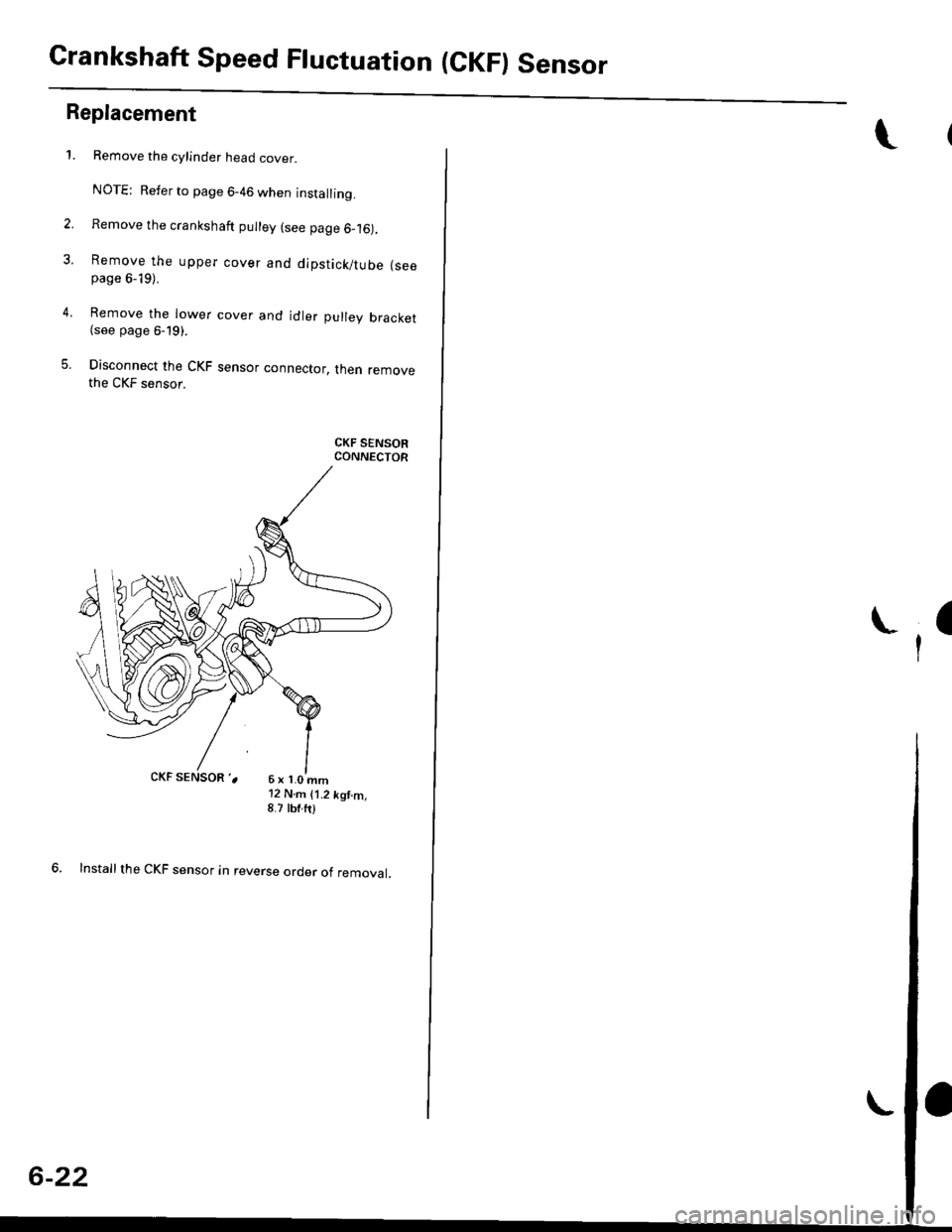

Crankshaft Speed Fluctuation (CKF) Sensor

2.

3.

5.

Replacement

4.

1.

6x1.0mm'12 N.m {1.2 kgt.m,8.7 tbf.ft)

6. Installthe CKF sensor in reverse order of removal.

Remove the cylinder head cover.

NOTE: Refer to page 6-46 when installing.

Remove the crankshaft pulley (see page 6_16),

Remove the upper cover and dipstick/tube {seepage 6-19).

Remove the lower cover and idler pulley bracket(see page 6-19).

Disconnect the CKF sensor connector, then removethe CKF sensor.

CKF SENSORCONNECTOR

6-22

:(

I

Page 138 of 2189

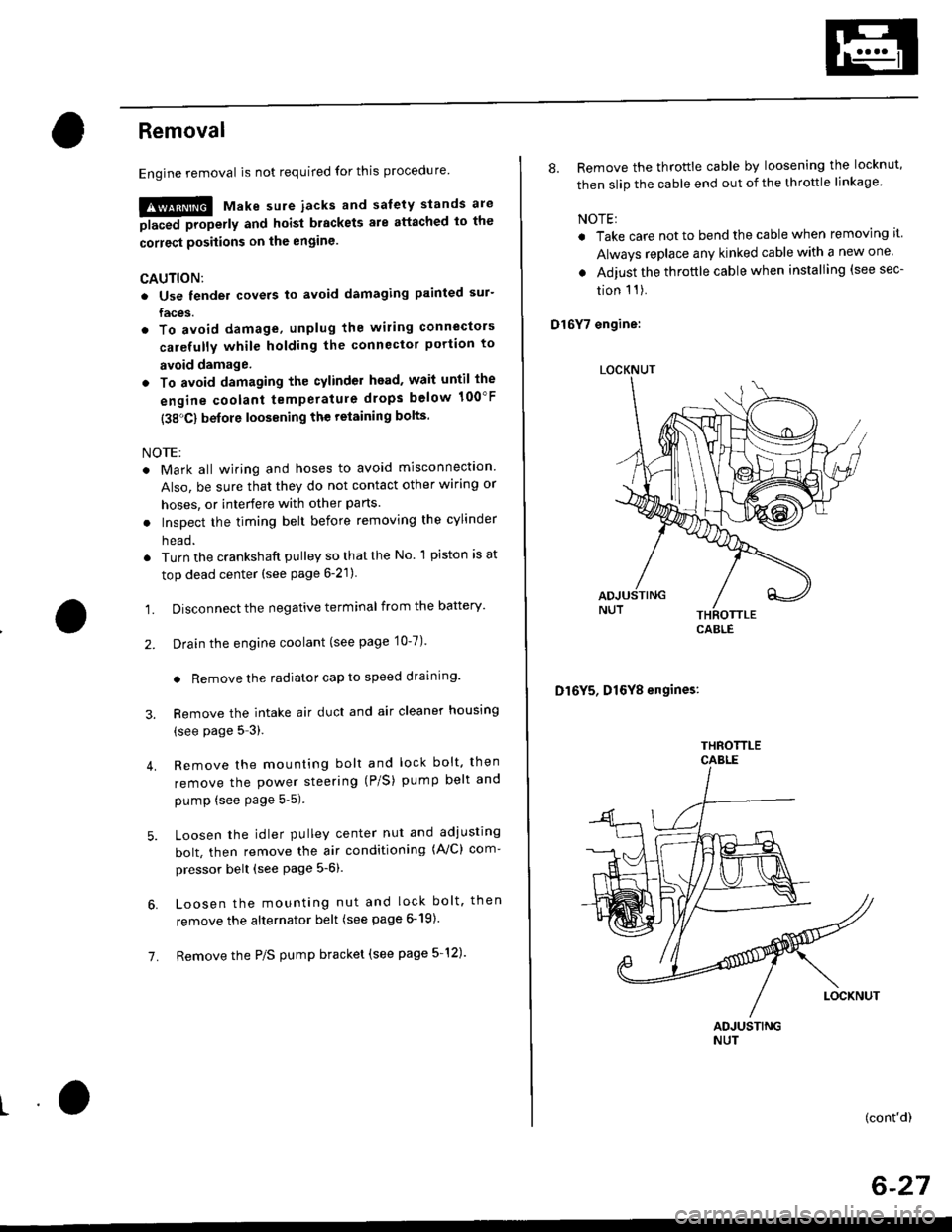

Removal

Engine removal is not required for this procedure

!!!s@ Make sure iacks and salety stands are

f ta"eata"ea propetty and hoist brackets are attached to the

correct positions on the engine.

CAUTION:

. Use tender covels to avoid damaging painted sul-

faces.

o To avoid damage, unplug the wiling connectors

carefully while holding the connector portion to

avoid damage.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F

{38"C} before loossning the tetaining bolts.

NOTE:

o Mark all wiring and hoses to avoid misconnectlon

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

. Inspect the timing belt before removing the cylinder

h ead.

. Turnthe crankshaft pu lley so that the No. lpistonisat

top dead center (see Page 6-21)

'1. Disconnect the negative terminal from the battery'

Drain the engine coolant (see page'10-7).

a Remove the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing

(see page 5 3).

Remove the mounting bolt and lock bolt. then

remove the power steering (P/S) pump belt and

pump (see page 5'5).

Loosen the idler pulley center nut and adjusting

bolt' then remove the air conditioning (A'lc) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt. then

remove the alternator belt (see page 6-19).

Remove the P/S pump bracket (see page 5-12).

3.

4.

2.

6.

1.

8. Remove the throttle cable by loosening the locknut,

then slip the cable end out of the throttle linkage

NOTE:

. Take care not to bend the cable when removing it

Always replace any kinked cable with a new one

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

Dl6Y5, Dl6Y8 engines:

THFOTTLECABLE

(cont'd)

6-27

LOCKNUT

CABLE

Page 172 of 2189

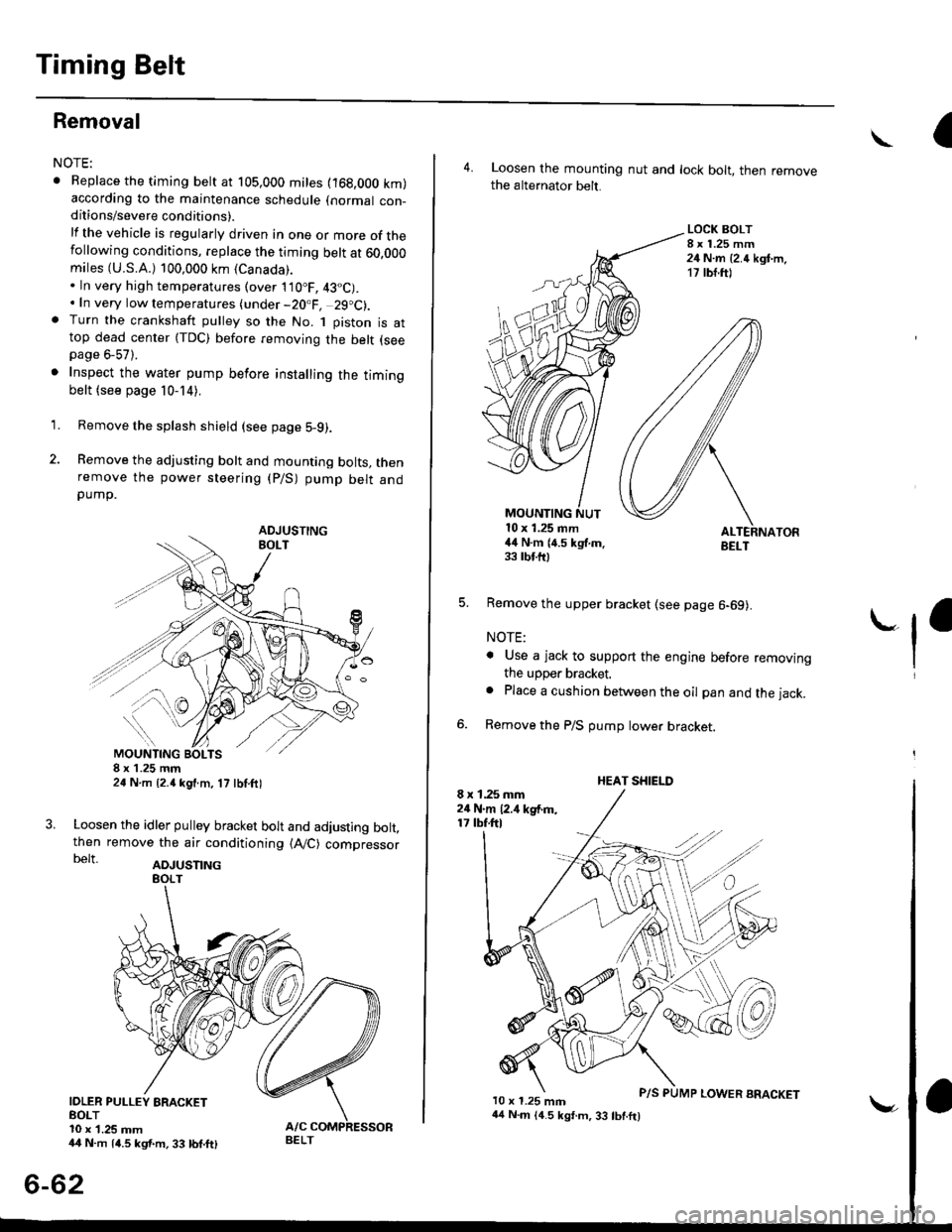

Timing Belt

Removal

NOTE:

. Replace the timing belt at 105,000 mites (168,000 km)according to the maintenance schedule (normal con-ditions/severe conditions).

lf the vehicle is regularly driven in one or more of thefollowing conditions, replace the timing belt at 60,OOOmiles (U.S.A.) 100,000 km {Canada).. In very high temperatures (over 110"F, 43"C).. In very low temperatures (under -20.F, 29.C).. Turn the crankshaft pulley so the No. 1 piston is attop dead center (TDC) before removing the belt (seepage 6-57).

. Inspect the water pump before installing the timingbelt {see page 10-14).

1.

IOLER PULLEY BRACKETEOLT10 x 1.25 mm44 N.m 14.5 kgf.m, 33 bnft)

6-62

Remove the splash shield (see page 5-9).

Remove the adjusting bolt and mounting bolts, thenremove the power steering (P/S) pump belt andpump.

8xL25mm24 N m {2.{ kgf.m, 17 lbf.ft)

Loosen the idler pulley bracket bolt and adjusting bolt,then remove the air conditioning (A,/C) compressorbelt aDJUsnNG

44 N.m 14.5 kgt.m, 33 lbf.ft)

P/S PUMP LOWER ARACKET

a\

4. Loosen the mounting nut and lock bolt, then removethe alternator belt.

LOCK BOLT8 x 1.25 mm24 N.m {2.4 kgt.m.17 rb{.ftl

5. Remove the upper bracket (see page 6-69).

NOTE:

. Use a jack to support the engine before removingthe upper bracket.

o Place a cushion between the oil pan and the jack.

Remove the P/S pump lower bracket

8 x 1.25 mm24 N.m 12.,1 kgf.m,17 tbf.ftl

l0 x 1.25 mm

'-f'

MOUNTING10 x 1.25 mm44 N.m (4.5 kgf.m.33 rbf.fttBELT

HEAT SHIELD

Page 177 of 2189

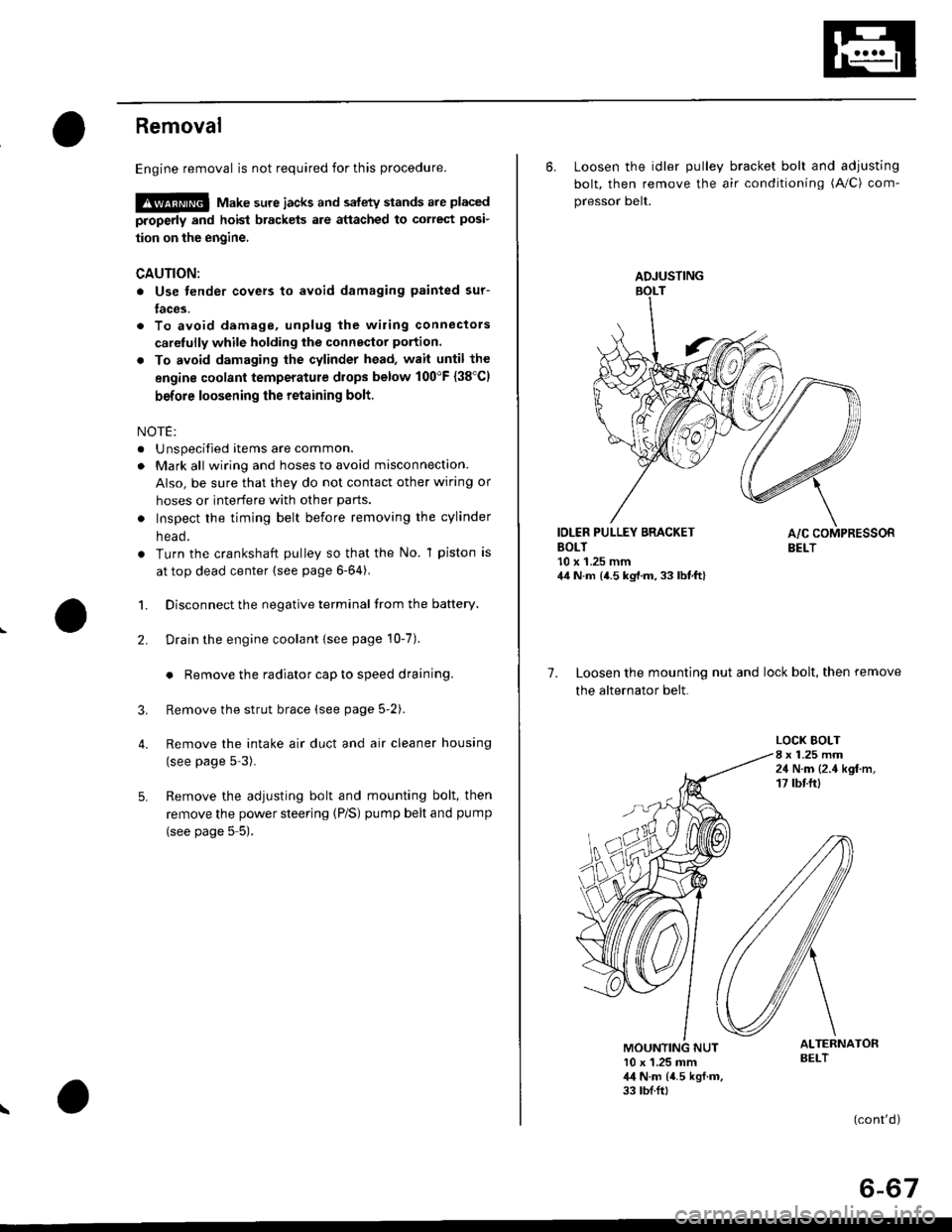

Removal

Engine removal is not required for this procedure.

!@@ Make sure jacks and safety stands are placed

properly and hoist brackels are attached to correst posi-

tion on the engine,

CAUTION:

o Use fender covers to avoid damaging painted sur-

faces.

To avoid damage, unplug the wiling connectors

carelully while holding the connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F {38'Cl

before loosening the retaining bolt.

NOTE:

. Unspecified items are common.

. Mark all wiring and hoses to avoid misconnection.

AIso, be sure that they do not contact other wiring or

hoses or interfere with other parts.

o Inspect the timing belt before removing the cylinder

n eao.

. Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (see page 6-64).

1. Disconnect the negative terminal from the battery.

Drain the engine coolant {see page 10-7).

. Remove the radiator cap to speed draining.

Remove the strut brace (see page 5-2).

Remove the intake air duct and air cleaner housing

(see page 5-3).

Remove the adjusting bolt and mounting bolt, then

remove the power steering (P/S) pump belt and pump

(see page 5 5).

2.

3.

4.

\

ADJUSTING

6. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A/C) com-

pressor belt.

IDLER PULLEY BRACKETBOLT10 x 1.25 mm44 N.m {4.5 kg,l.m, 33 lbt.ft}

7. Loosen the mounting nut and lock bolt, then remove

the alternator belt.

LOCK BOLT8 x 1.25 mm24 N.m {2.4 kgf.m,17 tbtftl

ALTERNATORBELT10 x 1.25 mm,l,l N.m {4.5 kgf.m,33 tbf.ft,

(cont'd)

6-67

Page 1454 of 2189

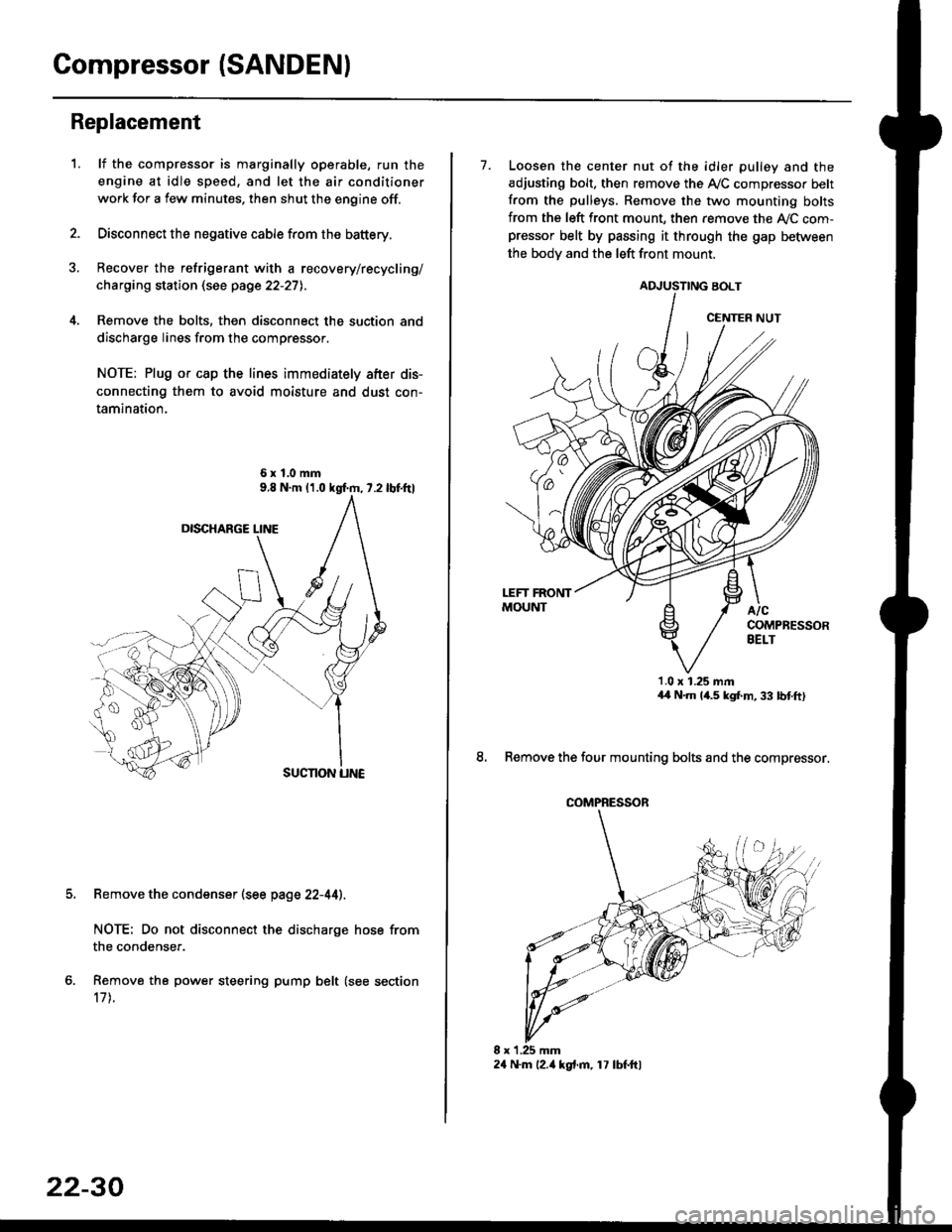

Compressor (SANDENI

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-27l..

Remove the bolts, then disconnect the suction and

discharge lines from the compressor.

NOTE: Plug or cap the lines immediately after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm

Remove the condenser (see page 22-44).

NOTE: Do not disconnect the discharge hose from

the condenser.

Remove the power steering pump belt (see section

17 t.

22-30

24 N.m l2.ia kgt.m, 17 lbf.ftl

7. Loosen the center nut of the idler pulley and the

adjusting bolt. then remove the A,/C compressor belt

from the pulleys. Remove the two mounting bolts

from the left front mount, then remove the ly'C com-pressor belt by passing it through the gap befiiveen

the bodv and the left front mount.

ADJUSTING BOLT

1.0 x 1.25 mmaa N.m 14.5 kgf,m, 33 bnft)

8. Remove the four mounting bolts and the compressor.

CENTER NUT

COMPRESSOR

Page 1461 of 2189

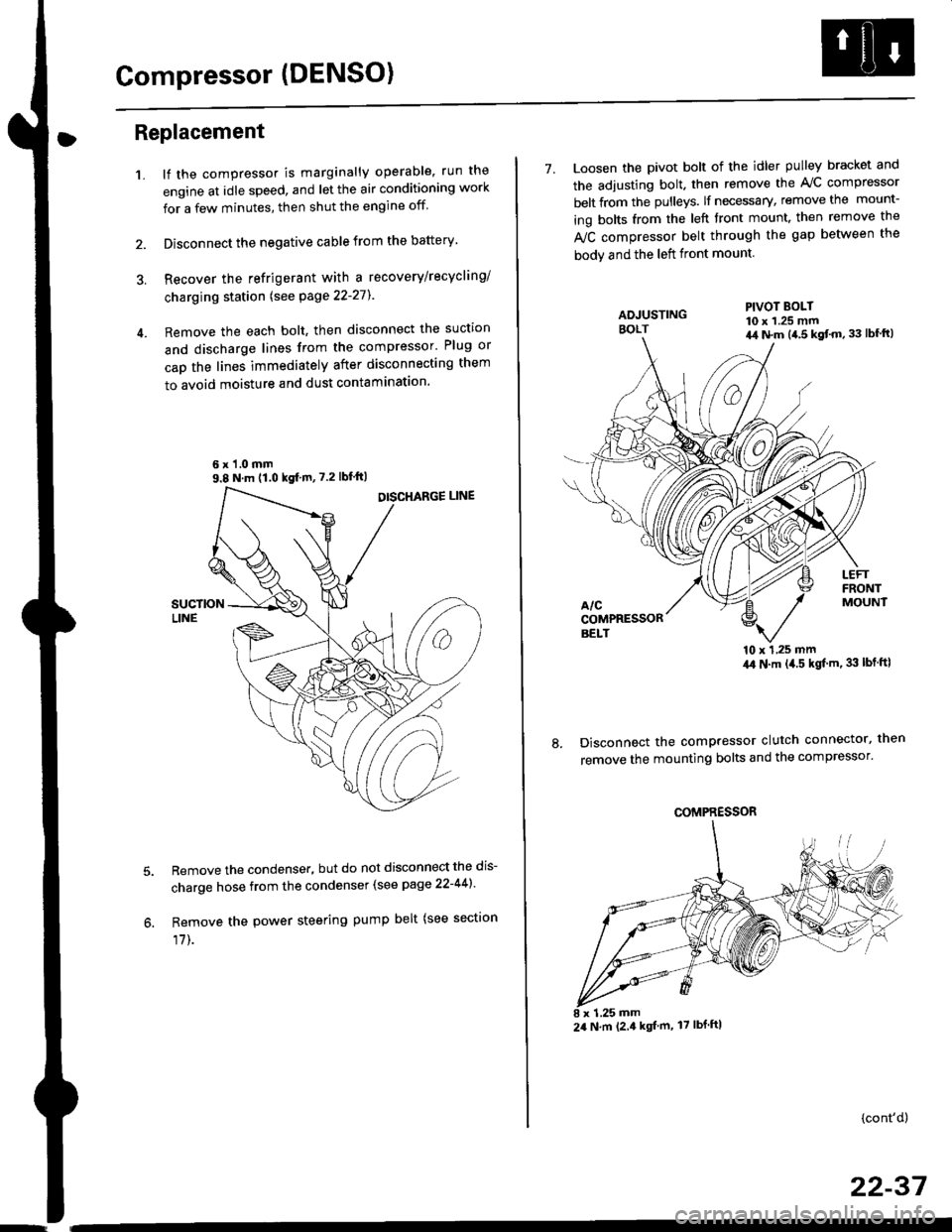

Compressor (DENSO)

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning work

for a few minutes, then shut the engine off

Disconnect the negative cable from the battery'

Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271

Remove the each bolt, then disconnect the suction

and discharge lines from the compressor' Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contaminatlon.

6 x '1.0 mm9.8 N.m (1.0 kgf m,7.2 lbfft)

Remove the condenser, but do not disconnect the dis-

charge hose from the condenser (see page 22-441'

Remove the power steering pump belt (see sectron

17]-.

7. Loosen the pivot bolt of the idler pulley bracket and

the adjusting bolt. then remove the A,/C compressor

belt from the pulleys. lf necessary, remove the mount-

ing bolts from the left front mount. then remove the

fuC compressor belt through the gap between the

bodv and the left front mount.

'10 x 1,25 mm4,0 N.m (,1.5 kgf'm. 33 lbt ftl

Disconnect the compressor clutch connector, then

remove the mounting bolts and the compressor'

PIVOT BOLT10 x 1.25 mm4,1 N.m (4.5 kgt'm,33 lbfft)

COMPRESSOR

24 N.m (2.4 kgf m, 17 lbf ftl

(cont'd)

22-37