service HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 780 of 2189

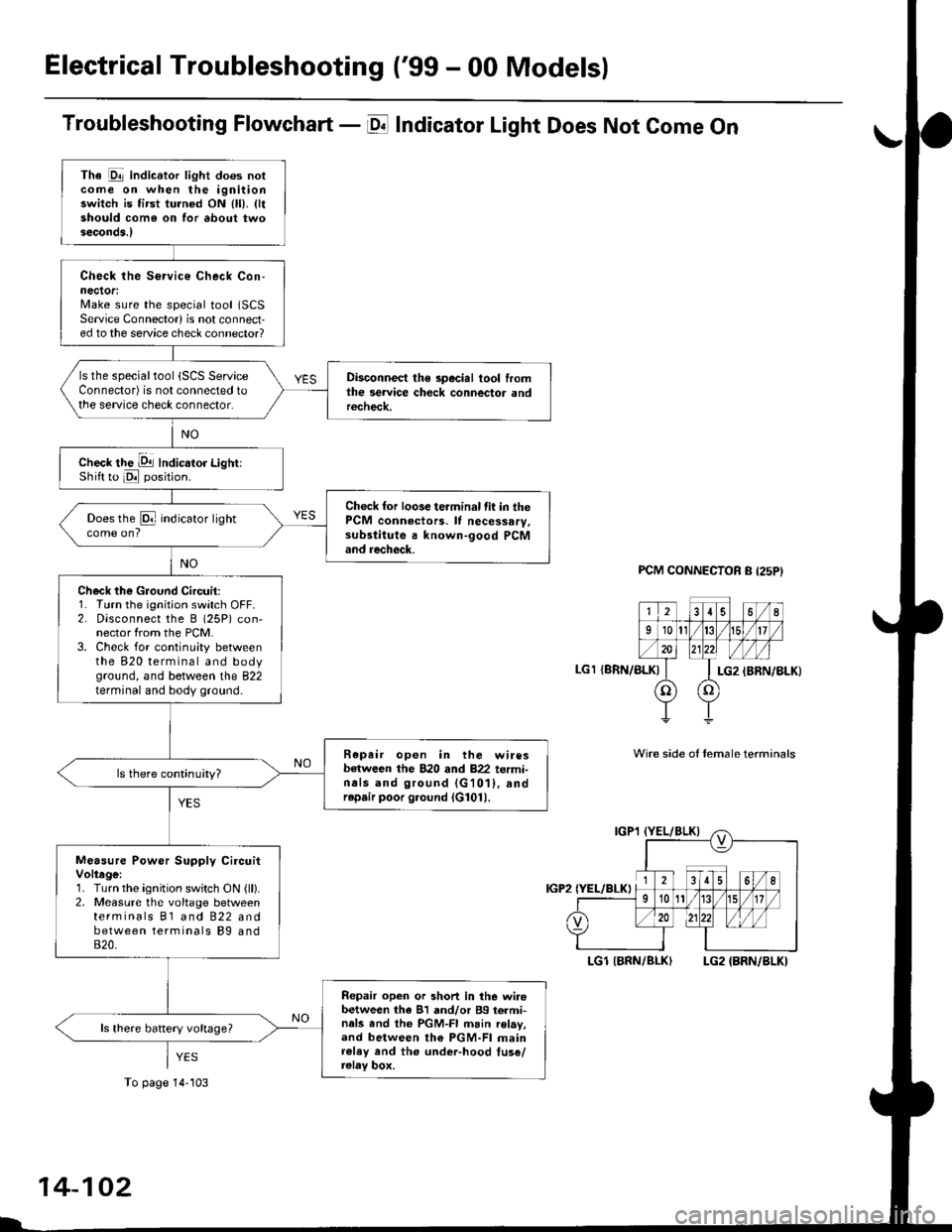

Electrical Troubleshooting ('99 - 00 Models)

Troubleshooting Flowchart - E Indicator Light Does Not Come On

FCM CONNECTOR B (25P}

LGl {8RN/ALKI{BRN/8LK}

Wire side ol temale terminals

LGl IBNN/BLK} LG2 {BRN/BLK)

i2t5 6q

910t7

LG2

o) (o

The Pll indicator light does notcome on when the ignitionswitch is fi.st turned ON (ll). lltshould come on for about twoseconda.l

Check the Service Check Con-nector:Make sure the special tool (SCS

Service Connector) is not connect-ed to the service check connector?

ls the specialtool {SCS ServiceConnector) is not connected tothe seNice check connector.

Disconnect the special tool fromthe service check connector andr6check.

Check the Dll lndicator LightiShift to d position.

Check for loose terminal fit in thePCM connecto13. It necessary.sub3titute a known-good PCMand recheck.

Does the @ indicator lightcome on?

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the B (25P) con-nector from the PCM.3. Check for continuity betweenthe 820 terminal and bodyground, and between the 822terminal and body ground.

Repair open in the wiresbetween the B20 rnd 822 termi-nals and ground (G101), andrep.ir poor ground (G1011.

Measure Power Supply CircuitVoltage:1. Turn the ignition switch ON {ll}.2. Measure the voltage betweenterminals B1 and 822 andbetween terminals Bg and820.

Repair open or short in the wi.obetween th6 81 and/or 89 termi-nals and the PGM-FI main relav,and between th€ PGM-FI mainr€ley rnd the under-hood tus€/relay box.

To page 14''103

14-102

Page 794 of 2189

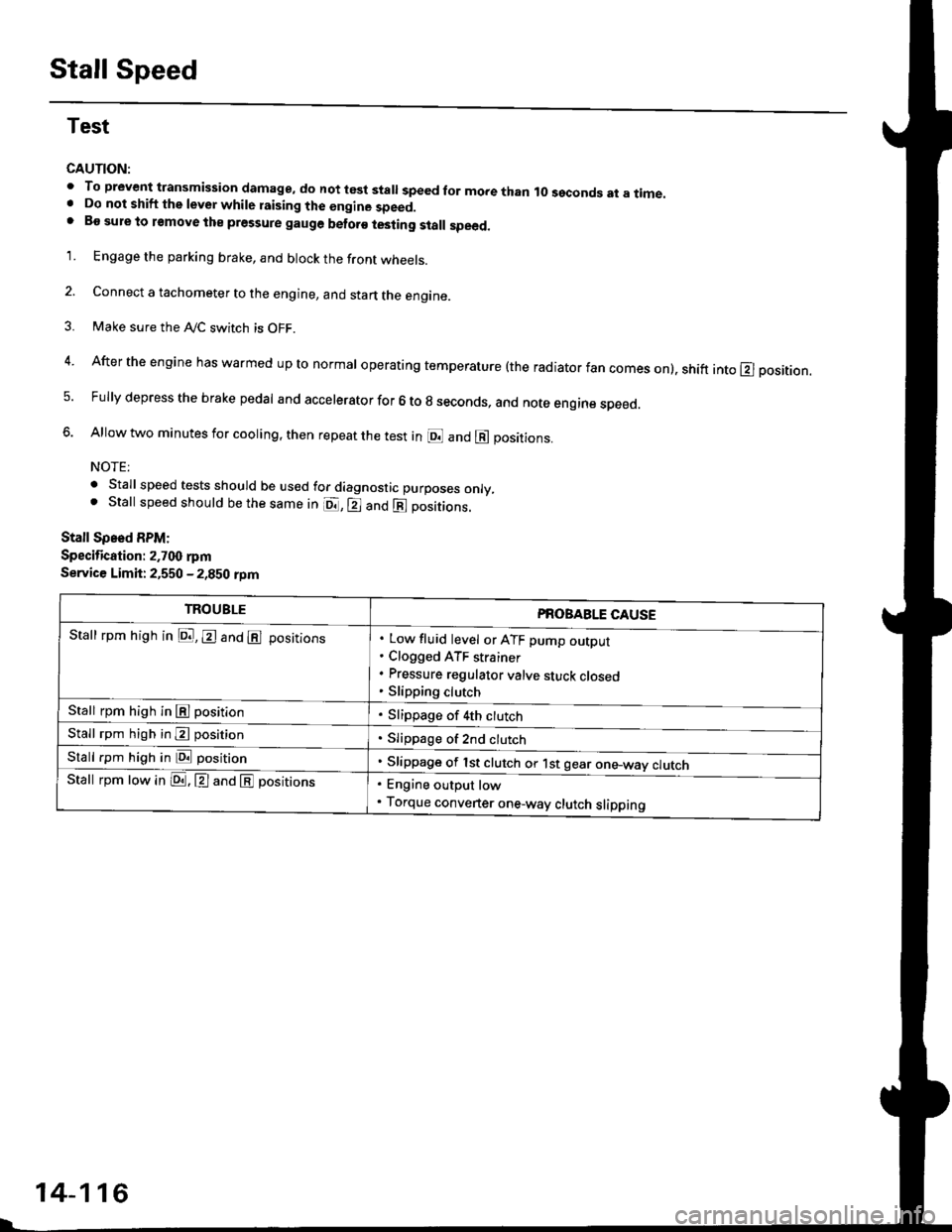

Stall Speed

Test

CAUTION:

. To prev€nt transmission damage, do not t6st stall speed for more than ro sgconds at a time.. Do not shift the levor while raising the engine speed.. Bo sule lo remove the pressure gauge betoro testing stall speed.

'1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the Ay'C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on). shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to g seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in @ and @ positions.

NOTE:

. Stall speed tests should be used for diagnostic purposes only,. Stall speed should be the same in o., E and E positions.

Stall Spsed RPM:

Specification: 2.700 rpm

Service Limit: 2,550 - 2,850 rDm

TROUBLEPROBABLE CAUSE

. Low fluid level or ATF pump outDur. Clogged ATF strainer. Pressure regulator valve sluck closeo. Slipping clutch

. Slippage of 4th ctutch

. Slippage of 2nd clutch

. Slippage of lst clut"tr or. t"t g""io*-*"y "lut"h

Stall rpm high in D., E and E positions

Stall rpm high in El position

Stall rpm high in E posirion

Stall rpm high in E position

Stall rpm low in LDa . El and E positrons. Engine output low. Torque converter one-way clutch slipping

14-116

Page 798 of 2189

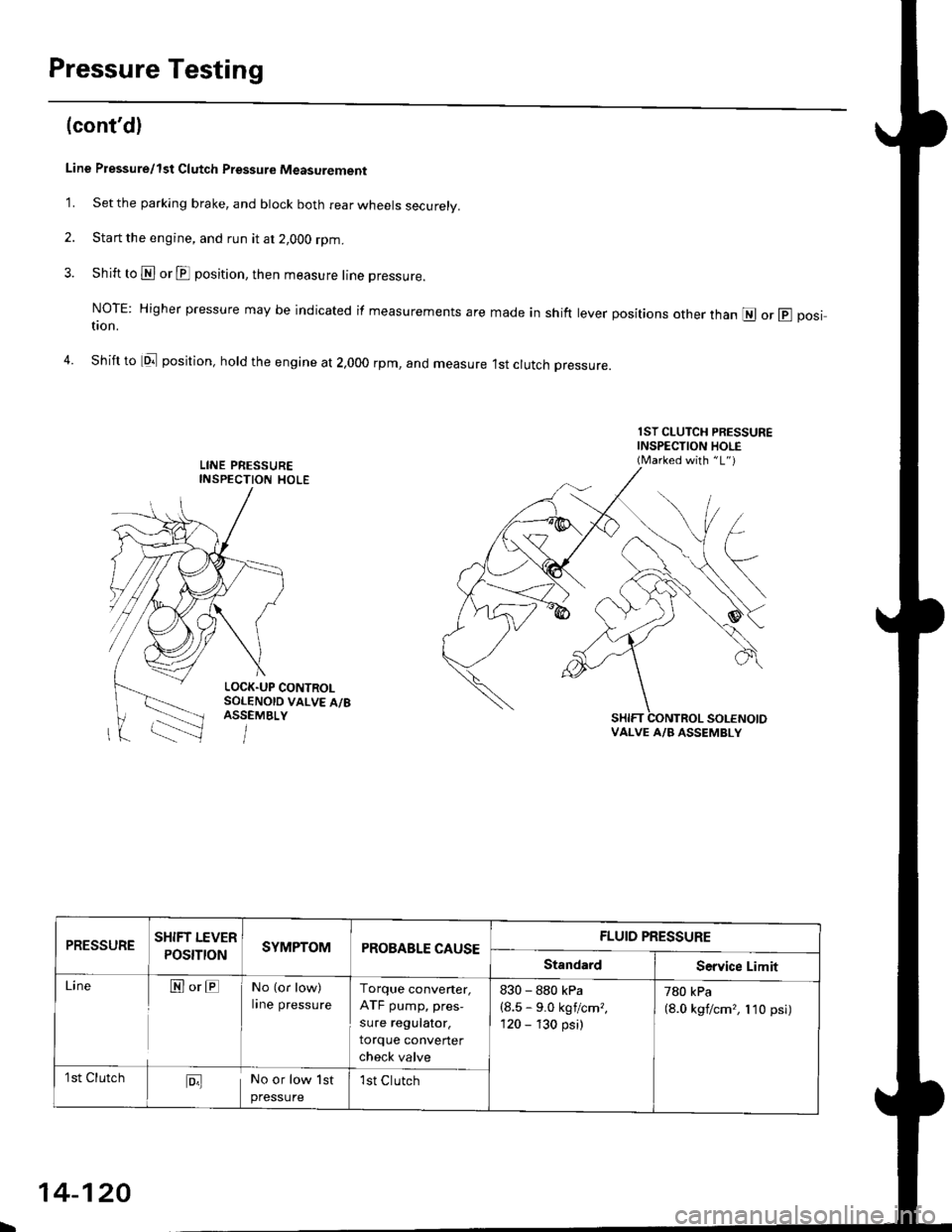

Pressure Testing

(cont'd)

Line Pressure/1st Clutch Pressurc Measurement

1. Set the parking brake, and btock both rear wheels securely.

2. Start the engine, and run it at 2,OOO rpm.

3. Shift to N or E position, then measure line pressure.

NoTE: Higher pressure may be indicated if measurements are made in shift lever positions other than @ or @ positron.

4. Shift to tq;l position, hold the engine at 2,000 rpm, and measure 1st crutch pressure.

1ST CLUTCH PRESSUREINSPECTION HOLE(Marked with "1")

LOCK.UP CONTROLSOLENOID VALVE A/8ASSEMBLY

VALVE A/B ASSEMBLY

PRESSURESHIFT LEVER

POS|TtONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandardService Limit

LineN orENo (or low)

lrne pressureTorque converter,

ATF pump, pres-

sure regutator.

torque converter

check valve

830 - 880 kPa

{8.5 - 9.0 kgf/cm?,

120 - 130 psi)

780 kPa(8.0 kgf/cm'�, 110 psi)

1st ClutchD;lNo or low 1st

pressure

1st Clutch

\

14-120

Page 843 of 2189

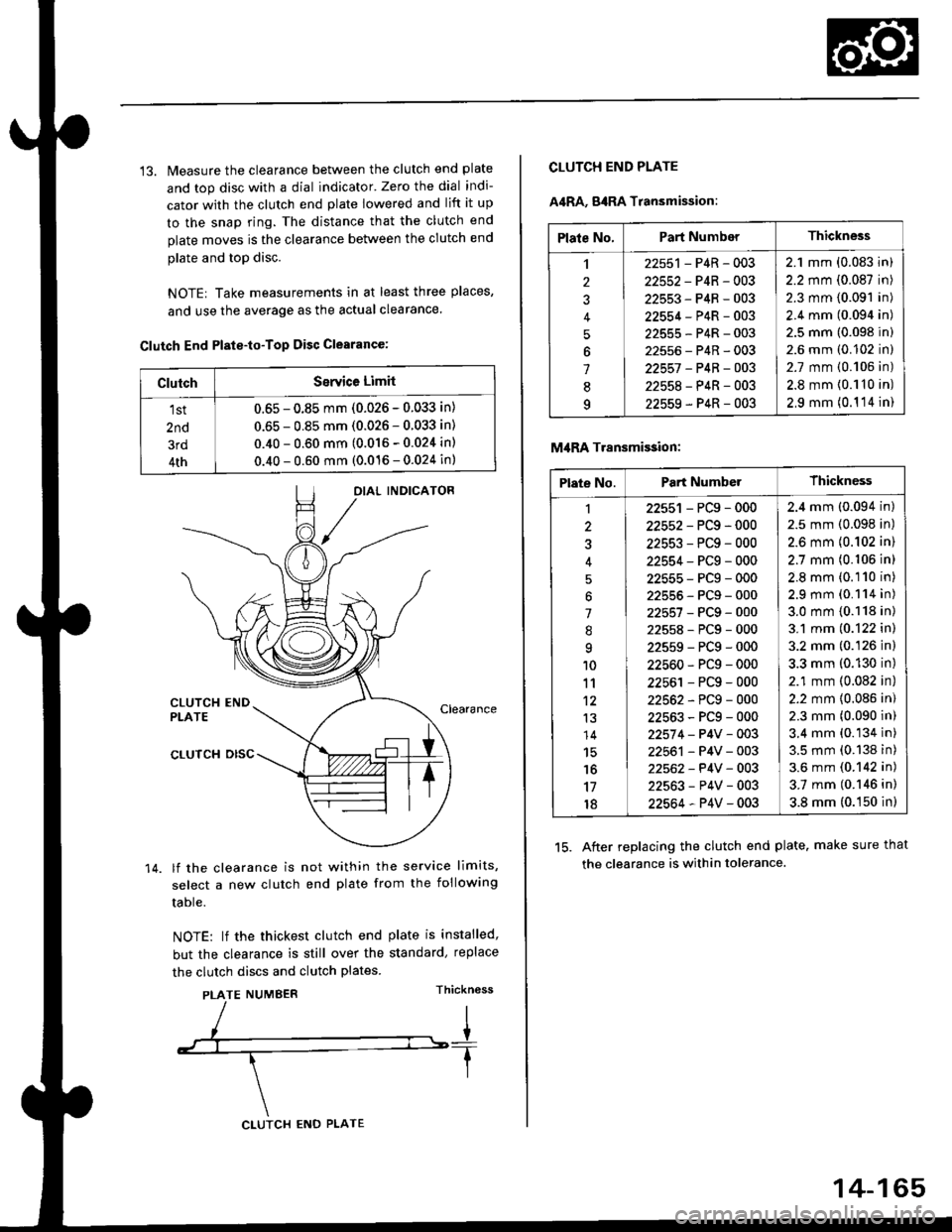

13. Measure the clearance between the clutch end plate

and top disc with a dial indicator' Zero the dial indi-

cator with the clutch end plate lowered and lift it up

to the snap ring. The distance that the clutch end

plate moves is the clearance between the clutch end

plate and top disc.

NOTE| Take measurements in at least three places,

and use the average as the actual clearance.

Clutch End Plste-to-Top Disc Clearance:

OIAL INDICATOR

CLUTCH ENDPLATEClearance

14.

CLUTCH DISC

lf the clearance is not within the service limits,

select a new clutch end plate from the following

table.

NOTE: lf the thickest clutch end plate is installed,

but the clearance is still over the standard, replace

the clutch discs and clutch plates.

PLATE NUMBERThickn6ss

ClutchSerYice Limit

1st

2nd

3rd

4th

0.65 - 0.85 mm (0.026 - 0.033 in)

0.65 - 0.85 mm (0.026 - 0.033 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

CLUTCH ENO PLATE

14-165

Plate No.Part NumberThickness

,l

2

J

4

5

6

1

8q

22551 - P4R - 003

22552-P4R-003

22553-P4R-003

22554-P4R-003

22555-P4R-003

22556-P4R-003

22557 -P4B-OO3

22558-P4R-003

22559-P4R-003

2.1 mm (0.083 in)

2.2 mm (0.087 in)

2.3 mm (0.091 in)

2.4 mm (0.094 in)

2.5 mm (0.098 in)

2.6 mm (0.102 in)

2.7 mm {0.106 in)

2.8 mm {0.110 in)

2,9 mm (0.1 '14 in)

CLUTCH END PLATE

A4RA, g4RA Transmission:

M,IRA Transmi$ion:

15. After replacing the clutch end plate. make sure that

the clearance is within tolerance.

Plate No.Part NumberThickness

1

3

'l

.'q

10

11't2

13

14

15'16

17

18

22551 - PCg - 000

22552-PCg-000

22553-PCg-000

22554-PCg-000

22555-PCg-000

22555-PCg-000

22557-PCg-000

22558-PCg-000

22559-PCg-000

22560-PCg-000

22561 - PCg - 000

22562-PCg-000

22563-PCg-000

22574 - P4V - 003

22561 - P4V - 003

22562- P4V - 003

22563-P4V-003

22564-P4V-003

2.4 mm (0.094 in)

2.5 mm (0.098 in)

2.6 mm {0.102 in)

2.7 mm (0.106 in)

2.8 mm (0.110 in)

2.9 mm (0.114 in)

3.0 mm {0.118 in)

3.1 mm (0.122 in)

3.2 mm (0.126 in)

3.3 mm (0.130 in)

2.1 mm (0.082 in)

2.2 mm {0.086 in)

2.3 mm (0.090 in)

3.4 mm (0.134 in)

3.5 mm (0.138 in)

3.6 mm (0.142 in)

3.7 mm (0.146 in)

3.8 mm (0.150 in)

Page 872 of 2189

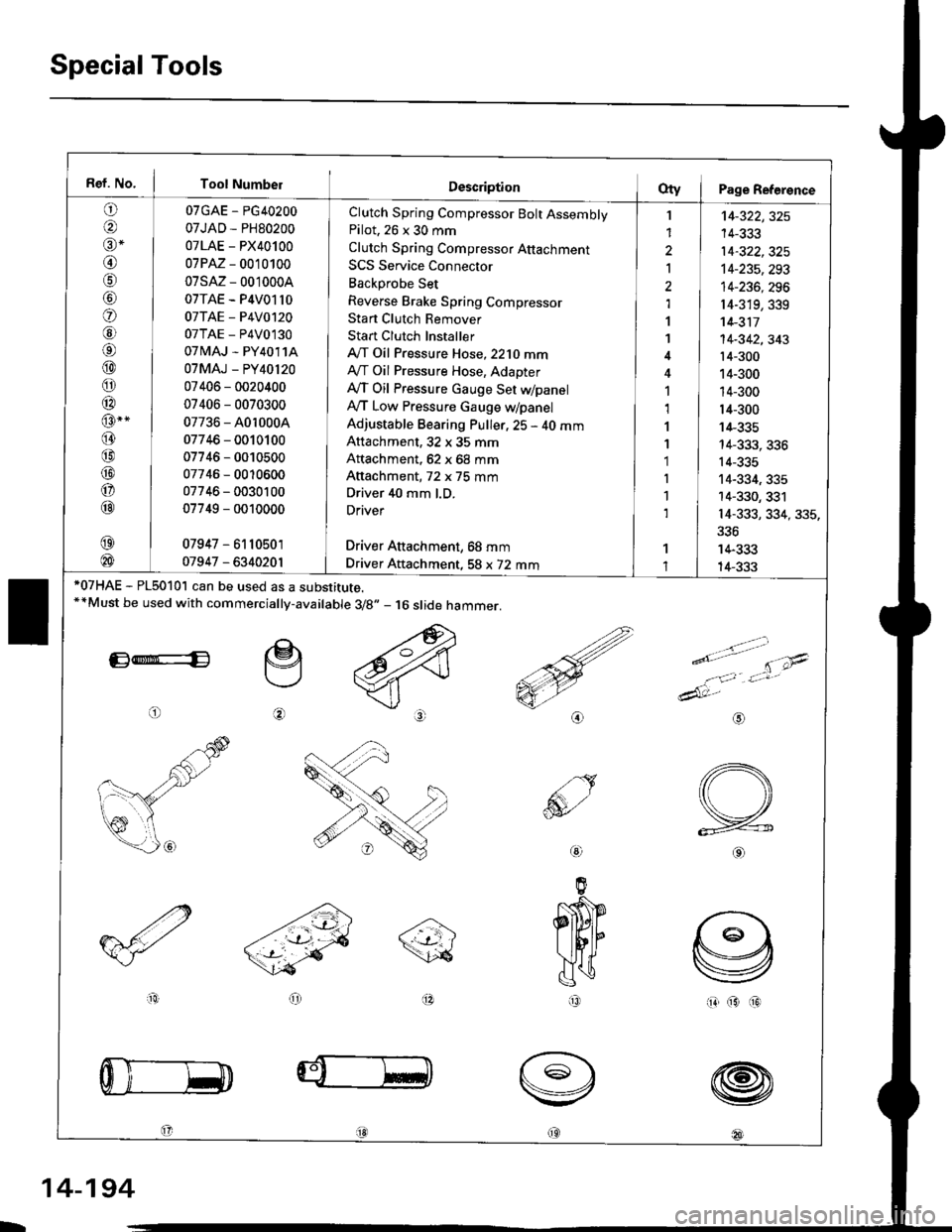

Special Tools

Ref. No. I Tool Number

o

@alr *

@

o

@6l

@

o

@

@-"

@

@

@

o

@

07GAE - PG40200

07JAD - PH80200

07LAE - PX40100

07PM - 0010100

07sM- 0010004

07TAE - P4V01l0

07TAE - P4V0120

07TAE - P4V0130

07 tvlAJ - PY4011A

07MAJ - PY40l20

07406 - 0020400

07406 - 0070300

07736 - A0r 0004

07746 - 0010100

07746 - 0010500

07746 - 0010600

07746 - 0030100

07749 - 0010000

07947 - 6110501

01947 - 6340201

Clutch Spring Compressor Bolt AssemblyPilot. 26 x 30 mm

Clutch Spring Compressor Attachment

SCS Service Connector

Backprobe Set

Reverse Brake Spring Compressor

Stan Clutch Remover

Stan Clutch Installer

A/T Oil Pressure Hose,2210 mmAy'T Oil Pressure Hose, Adapter

Ay'T Oil Pressure cauge Set WpanelAy'T Low Pressure Gauge w/panel

Adjustable Bearing Puller, 25 - 40 mmAttachment, 32 x 35 mm

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver 40 mm l.D.

Driver

Driver Aftachment, 68 mm

Driver Attachment, 58 x 72 mm

I

1

2

Ia,l

1

1

1,1

1

1'1

I

1

1

't4-322,325

14-333

14-322,325't4-235,293

14-236, 296

r4-319,339't 4-311

14-342,343't4-300

14-300

14-300

14-300

14-335

14-333, 336

14-335

14-334, 335

14-330, 331

14-333, 334, 335,

336

14-333

14-333*07HAE - PL5010l can be used as a substitute.**Must be used with commercially-available 3/8.,- 16 slide hammer.

E*E

o

e

@

>.'.- -t-'- t'\;4

e'o

1:,'Jt*

dAt:-

io(313

@

@

@

@18l

aio

@

IR

L

14-194

Page 906 of 2189

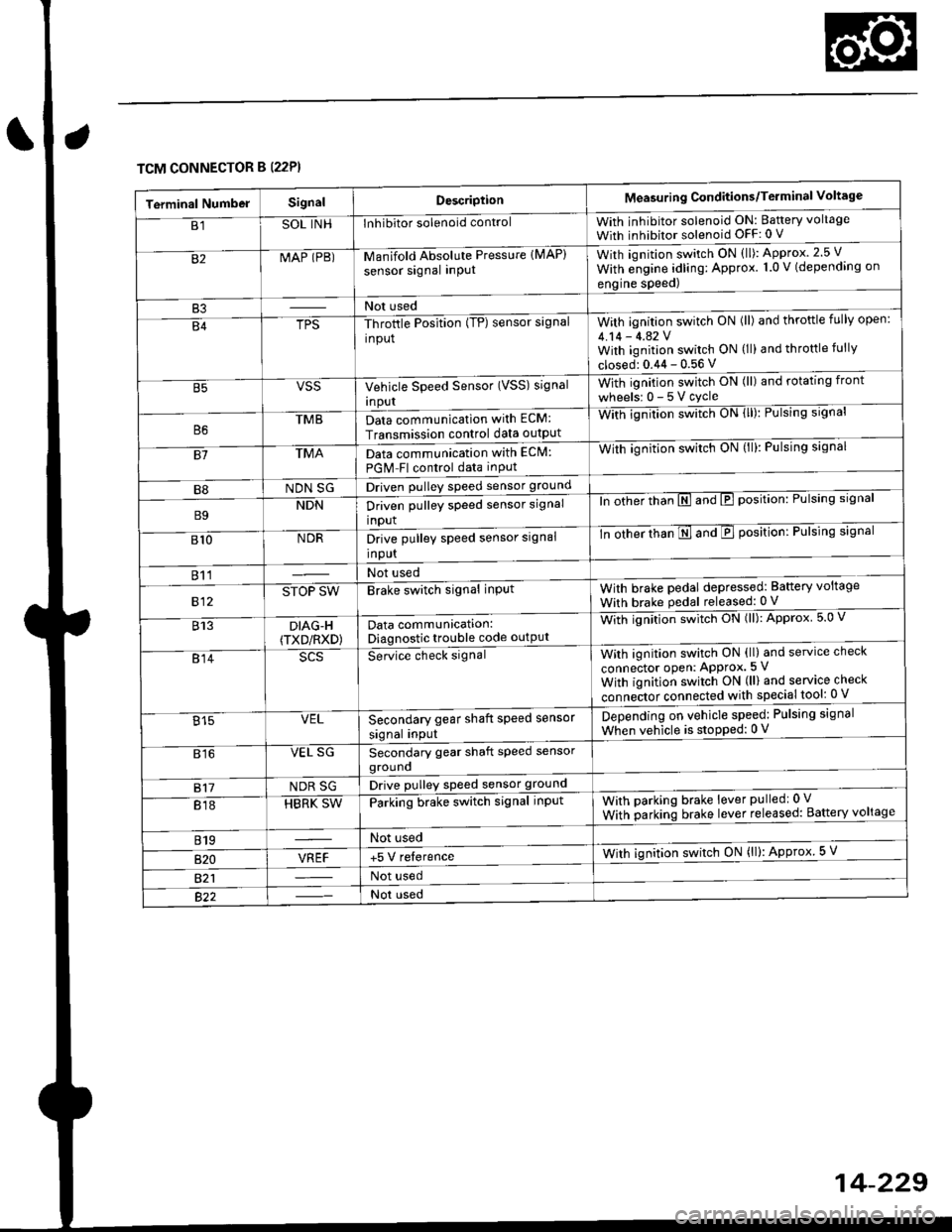

TCM CONNECTOR B (22P}

Terminal NumbelSignalDescriptionMeasuring Conditions/Terminal Voltage

B1SOL INHInhibitor solenoid controlWith inhibitor solenoid ON: Baftery voltage

With inhibitor solenoid OFF: 0 V

82MAP (PB)-M an if old Absol r-rte Pressure IMAP)

sensor signal inPUtWith iqnition switch ON (ll): Approx.2.5 V

With e;gine adling: Approx. 1.0 V (depending on

engine speed)

B3Not used

B4TPS-Throttle Position (TP) sensor signal

input

With ignition switch ON (ll) and throftle fully open:

4.14 - 4.42 VWith ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

VSSVehicle Speed Sensor (VSS) signal

Inpur

With ignition switch ON (ll) and rotating front

wheelsr 0-5Vcycle

TMBData communication with ECM:

Transmission control data outpUt

With ignilion swltch UN lll): rulslng slgnar

81TMAData communication with EClvl:

PGM Fl control data inPut

With ignition swltch uN {ll,: l-ulslng slgnal

B8NDN SGDriven pulley speed sensor ground

B9NDNDriven pulley speed sensor signal

input

ln other thTnE and E position: Pulsing signal

810NDRDrive pulley speed sensor signal

Input

-tn ottrer ttran E ana E position: Pulsing signal

811Not used

812STOP SWBrake switch signal inPutWith brake pedal depressed: Battery voltage

With brake pedal released: 0 V

813DIAG-H(TXD/RXD)Data communication:Diagnostic trouble code outPut

Wittr ignitio.r s*itct' ON (ll): Approx 5.0 V

814Se-ice ctrect signatWith ignition switch ON (ll) and service check

connector oPen: APProx.5 V

With iqnition switch ON (ll) and service check

"onn"itot. connect"d with special tool: 0 V

Secondary gear shaft speed sensor

signal input

Depending on vehicle speed: Pulsing signal

When vehicle is stoPped: 0 V815VEL

816VEL SGSecondary gear shaft speed sensorgrouno

817NDR SGDrive pulley speed sensor ground

818HBRK SWParking brake switch signal inPutWith parking brake lever pulledr 0 V

With parking brake lever released: Battery voltage

819Not used

B�20VREF+5 V relerenceWith ignition switch ON (ll): Approx 5 V

821Not used

Not used

Page 909 of 2189

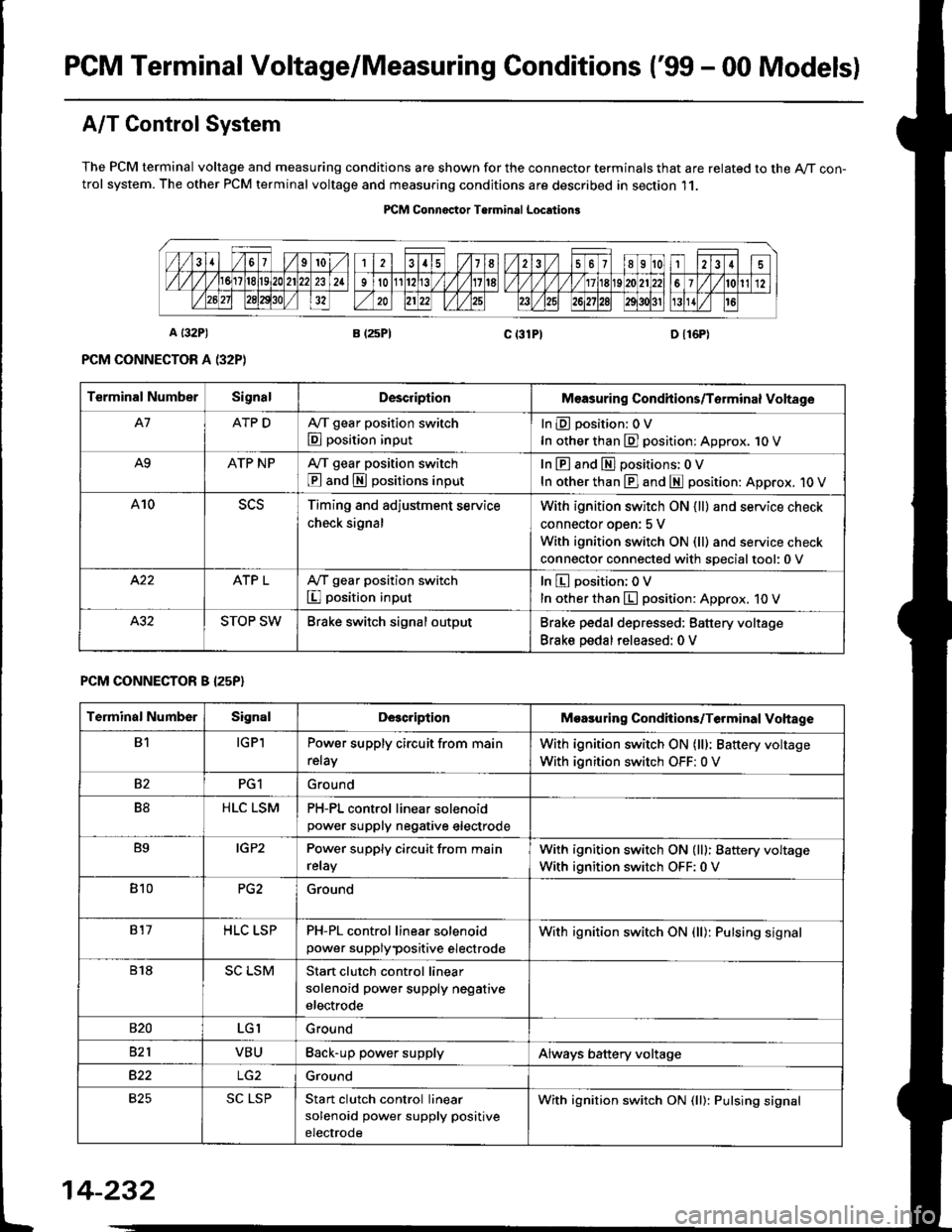

PGM Terminal Voltage/Measuring Conditions ('99 - 00 Modelsl

A/T Control System

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A/T con-trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

PICM Connoctor Terminrl Location3

Terminal NumberSignalDescriplionMeasuring Condhions/Torminal Voltage

A7ATP DA,/T gear position switch

E position input

InEposition:OV

In other than E] position: Approx. 1O V

A9ATP NPA/T gear position switch

@ and S positions input

In E and El positions: 0 V

In other than E] and E position: Approx. 1O V

A10Timing and adjustment service

check signal

With ignition switch ON {ll} and service check

connector oDen: 5 V

With ignition switch ON (ll) and service check

connector connected with soecialtool:0 v

ATP LA,/T gear position switch

I position input

In E position; OV

In other than E position: Approx. 10 V

STOP SWBrake switch signal outputBrake pedal depressed: Battery voltage

Brake pedal released: 0 V

PCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMoasuring Condhions/Terminal Vohage

B1IGPlPower supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF: 0 V

82PG1Ground

B8HLC LSMPH-PL control linear solenoidpower supply neqative electrode

B9IGP2Power supply circuit from main

relay

With ignition switch ON (lll: Battery voltage

With ignition switch OFF:0 V

810PG2Ground

817HLC LSPPH-PL control linear solenoid

power supplypositive electrode

With ignition switch ON {ll): Pulsing signal

818SC LSMStart clutch control linear

solenoid power supply negative

electrode

s20LGIGround

821VBUBack-up power supplyAlways battery voltage

B22Ground

825SC LSPStan clutch control linear

solenoid power supply positive

electrode

With ignition switch ON (ll): Pulsing signal

t

14-232

Page 912 of 2189

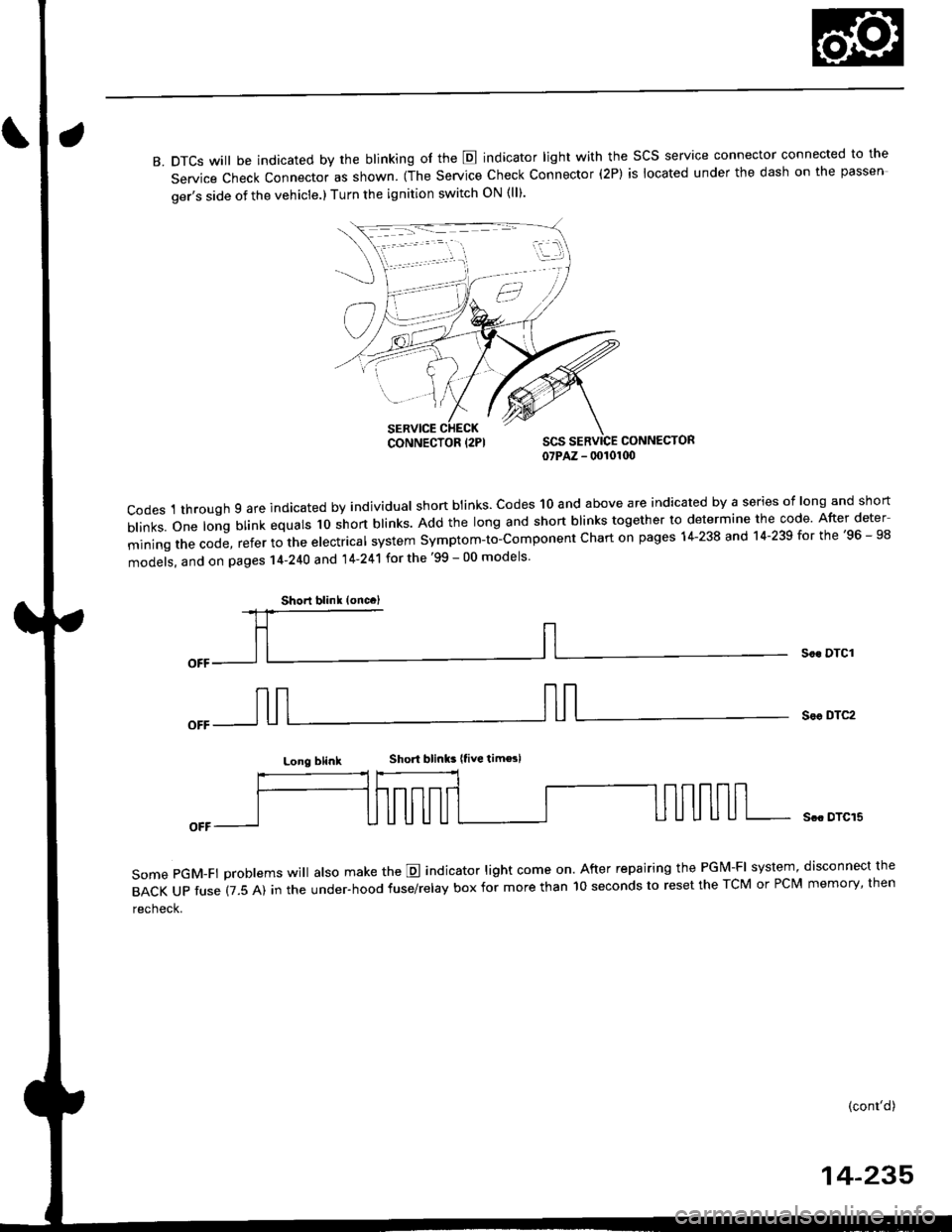

B. DTCS will be indicated by the blinking of the E indicator light with the SCS service connector connected to the

Service Check Connector as shown. (The Service Check Connector (2P) is located under the dash on the passen

ger's side of the vehicle.) Turn the ignition switch ON (ll).

CONNECTOR07PAZ - 00101(x)

codes 1 through 9 are indicated by individual shon btinks. codes 10 and above are indicated by a series of long and short

b|inks.one|ongblinkequa|sloshortb|inks.Addthe|ongandshortb|inkstogethertodeterminethecode.Afterdeter

miningthecode,refertothee|ectrica|systemsymptom-to-componentchartonpagesl4-238and14.239forthe,96_98

models, and on pages 14-240 and 14'241 for the '99 - 00 models

Soc DTCI

Sor DTC2

Long blinkShort blinks |tive tim€sl

some pGM-Ft problems wi

atso make the E indicator light come on. After repairing the PGM-FI system, disconnect the

BACKUPfuse(7.5A)intheUnder.hoodfuse/re|ayboxformorethanl0secondstoresettheTcMorPcMmemory,then

recheck.

Scc DTCI5

(cont'd)

14-235

iii:j

,,,/

CONNECTOR {2PI

Shorl blink (oncc)

Page 914 of 2189

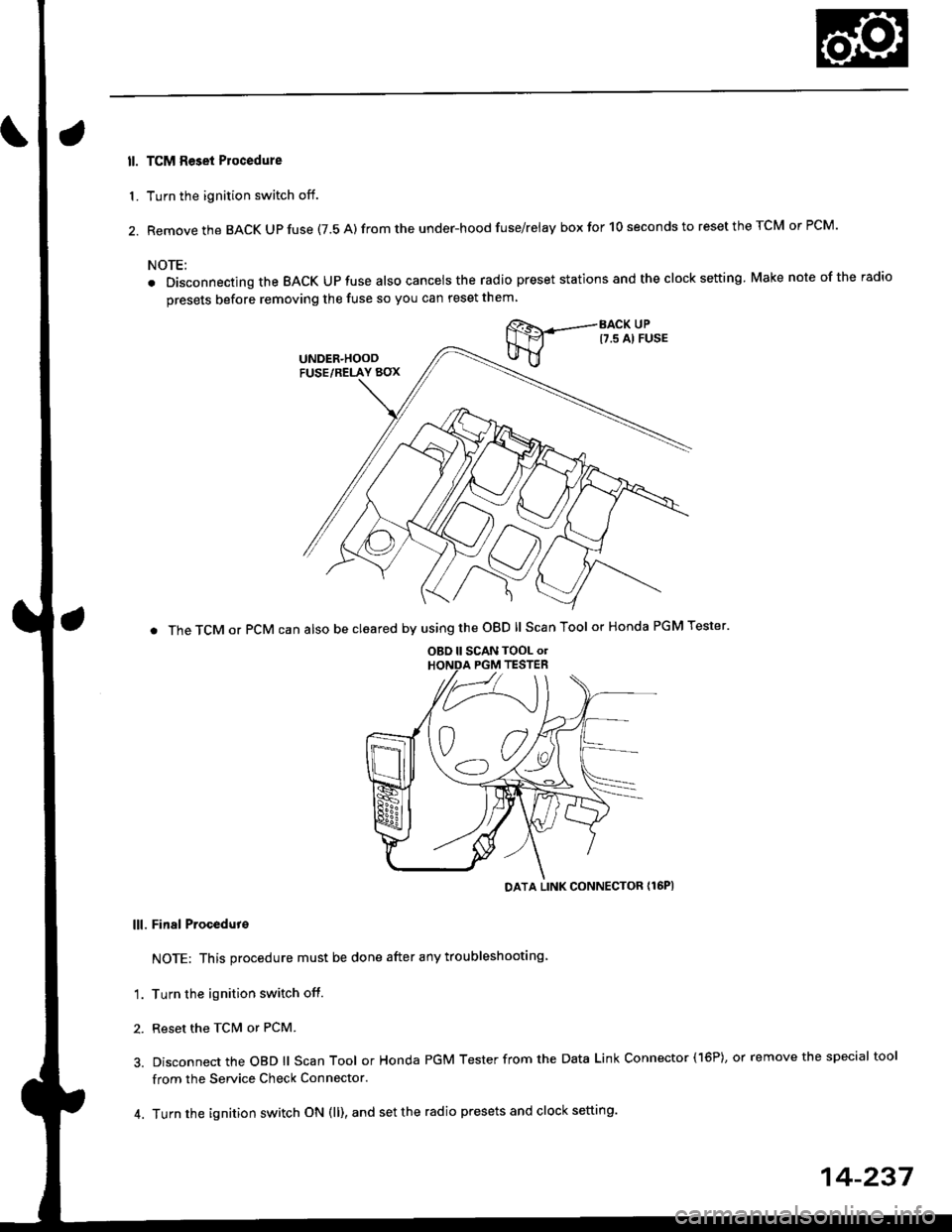

ll. TCM Reset Plocedure

1. Turn the ignition switch off.

2. Remove the BACK Up fuse (7.5 A) from the under-hood fuse/relay box for 10 seconds to reset the TCM or PCM.

NOTE:

. Disconnecting the BACK UPfuse also cancelsthe radio preset stations and the clock setting Make nole ofthe radio

presets before removing the fuse so you can reset them

BACK UPt7.s Al FusE

. The TCM or PCM can also be cleared by using the OBD ll Scan Tool or Honda PGM Tester'

DATA LINK CONNECTOR {16PI

lll. Final Procedut€

NOTE: This procedure must be done after any troubleshooting

'1. Turn the ignition switch off.

2. Reset the TcM or PCM.

3. Disconnect the OBD ll Scan Tool or Honda PGM Tester from the Data Link Connector (16P), or remove the special tool

from the Service Check Connector.

4. Turn the ignition switch ON (ll), and set the radio presets and clock setting.

OBD ll SCAN TOOL o.PGM TESTER

14-237

Page 939 of 2189

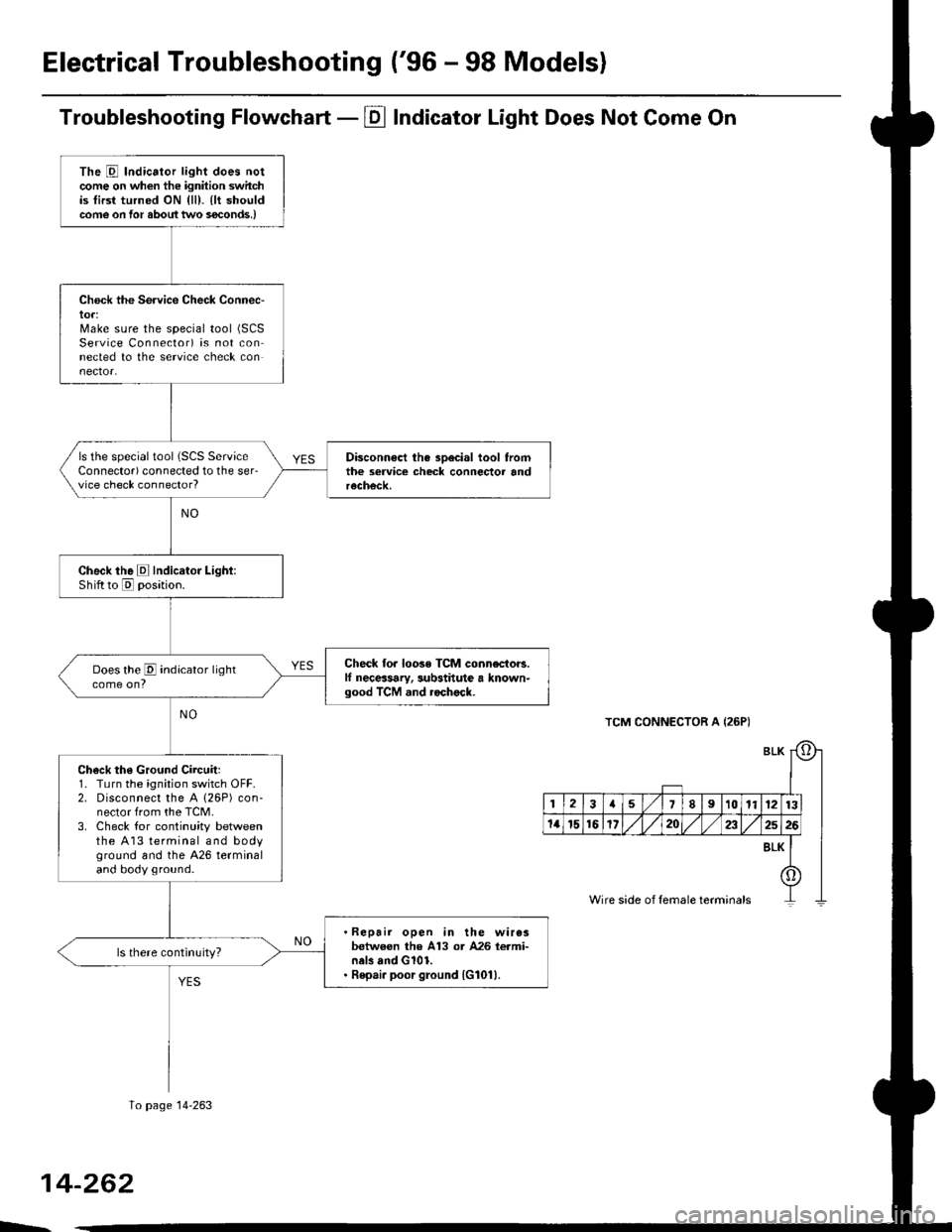

Electrical Troubleshooting ('96 - 98 Modelsl

Troubleshooting Flowchart - Pl Indicator Light Does Not Gome On

TCM CONNECTOR A {26P)

BLI

l-I

123a589101t12nl

1a151617202325rt

o

8LK

Wire side of female terminals

The E Indicator light does notcome on when the ignition switchis tirst turned ON {ll). {lt shouldcome on for aboul two s€conds,)

Chock the Service Check Connec-lot:Make sure the special tool (SCS

Service Connector) is not connected to the seryice check connector,

ls the special tool (SCS ServiceConnector) connected to the ser-vice check connector?

Disconn€ct the sDecial tool fromthe seruice check connector andrecheck.

Check the E Indicator Light:Shift to [5] oosition.

Check fo. loose TCM connectors.lf neceasary, substitute a known-good TCM .nd rochock.

Does the E indicator lightcome on?

Ch€ck th6 Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the A 126P) con-nector from the TCM.3. Check tor continuity betweenthe A13 terminal and bodyground and the 426 terminaland body ground.

.Repair open in the wiresbetwoon lhe A13 or A26 termi-nel3 and G101.. Repai. poor ground {G1011.

To page 14-263

14-262

>.