Relay box HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 1560 of 2189

lgnition Switch

Steering Lock Replacement

SRS components are located in this area. Review theSRS component locations. precautions, and procedures

in the SRS section (24) before performing repairs or ser-vtce.

Remove:

LMake sure you have the anti-theft code for theradio, then wire down the frequencies for theradio's preset buttons ('99 - 00 models).

Disconnect the battery negative cable.

Remove the driver's dashboard lower cover andknee bolster (see section 20).

Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connector from the mainwire harness (see previous page).

Remove the steering column covers, then removethe mounting bolts and nuts from the steering col-umn (see section l7).

Lower the steering column assembly,

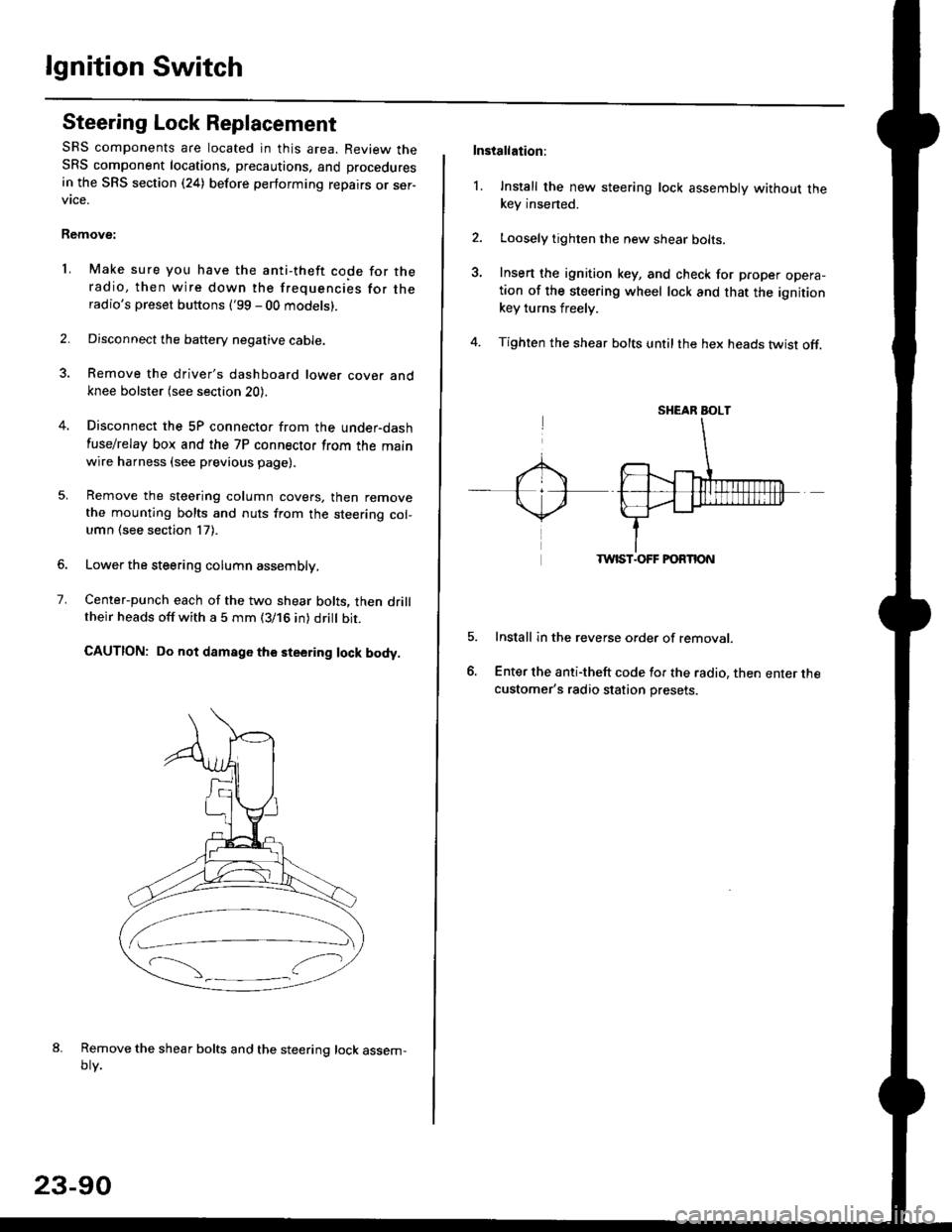

Center-punch each of the two shear bolts, then drilltheir heads off with a 5 mm (3/16 in) dritt bit.

CAUTION: Do not damago the steering lock body.

Remove the shear bolts and the steering lock assem,oty.

2.

1.

23-90

Installation:

l. Install the new steering lock assembly without thekey insened.

Loosely tighten the new shear bolts-

Insert the ignition key, and check for proper opera-tion of the steering wheel lock and that the ignitionkey turns freely.

Tighten the shear bolts untilthe hex heads twist off.

TWIST.OFF FORTION

Install in the reverse order of removar.

Enter the anti-theft code for the radio, then enter thecustomer's radio station presets.

sr{€aR SroLT

Page 1565 of 2189

-Starter Test

NOTE; The air temoerature must be between 59 and

100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described,

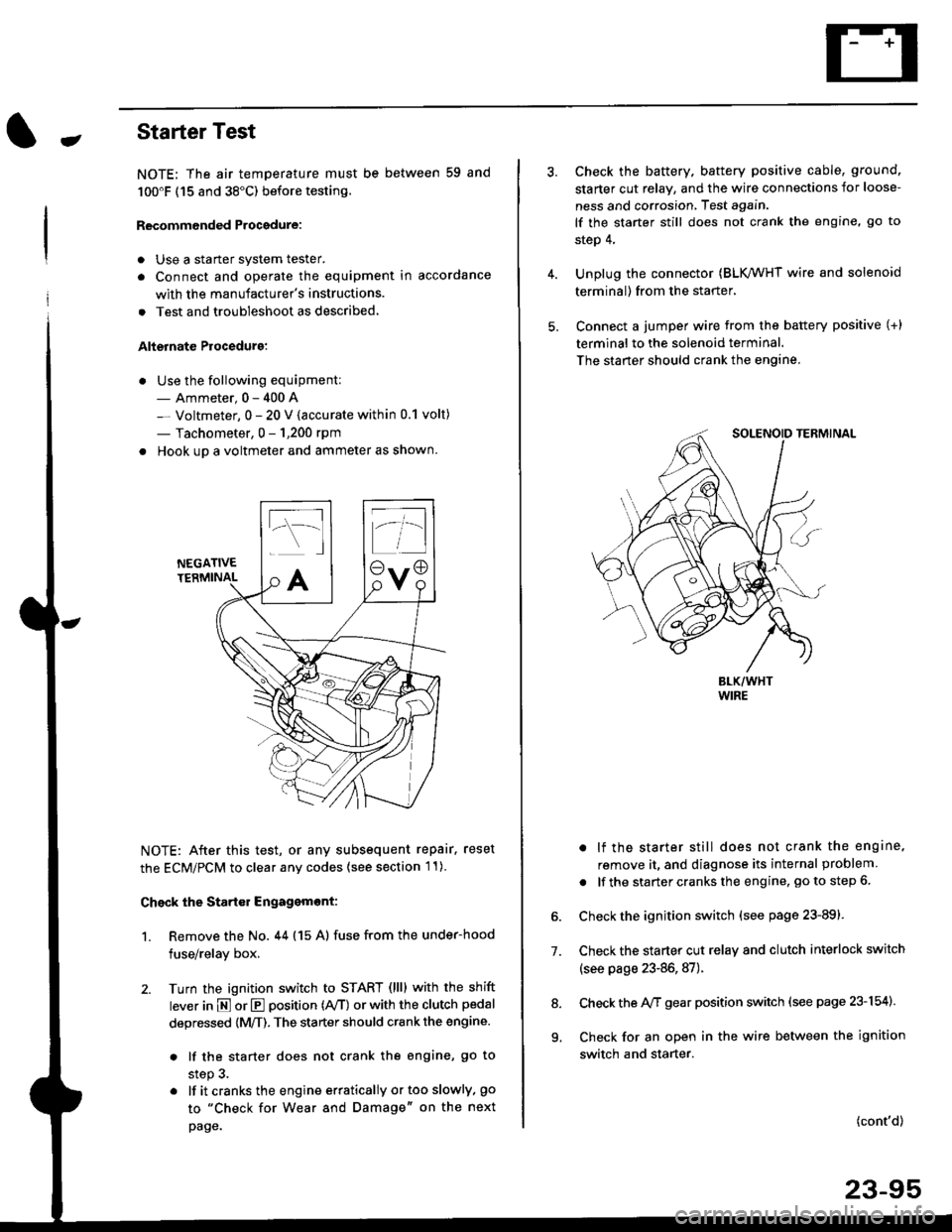

Alternate Procedurg:

. Use the following equipment:- Ammeter, 0 - 400 A

- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

- Tachometer, 0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NEGATIVETERMINAL

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section l1)

Check the Start€r Engagemont:

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

2. Turn the ignition switch to START (llll with the shift

lever in E or E position (rVT) or with the clutch pedal

depressed {M/T). The starter should crank the engine.

. lf the starter does not crank the engine, go to

step 3.

. lf itcranksthe engineerraticallyortooslowly, go

to "Check for Wear and Damage" on the next

page.

Check the battery. battery positive cable, ground,

starter cut relay, and the wire connections for loose-

ness and corrosion, Test again.

lf the starter still does not crank the engine, go to

step 4,

Unplug the connector (BLK,/WHT wire and solenoid

terminal) from the starter,

Connect a jumper wire from the battery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem

. lf the startercranksthe engine, goto step 6.

Check the ignition switch (see page 23-891.

Check the starter cut relay and clutch interlock switch

(see page 23-86,87).

Check the A/f gear position switch (see page 23-154).

Check for an open in the wire between the ignition

switch and starter.

7.

(cont'd)

23-95

9.

Page 1579 of 2189

Jlgnition Control Module (lCMl Input Test

NOTE:

. See section 1'l when the malfunction indicator lamp

(MlL) turned on.

. Perform an input test for the ignition control module

(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems

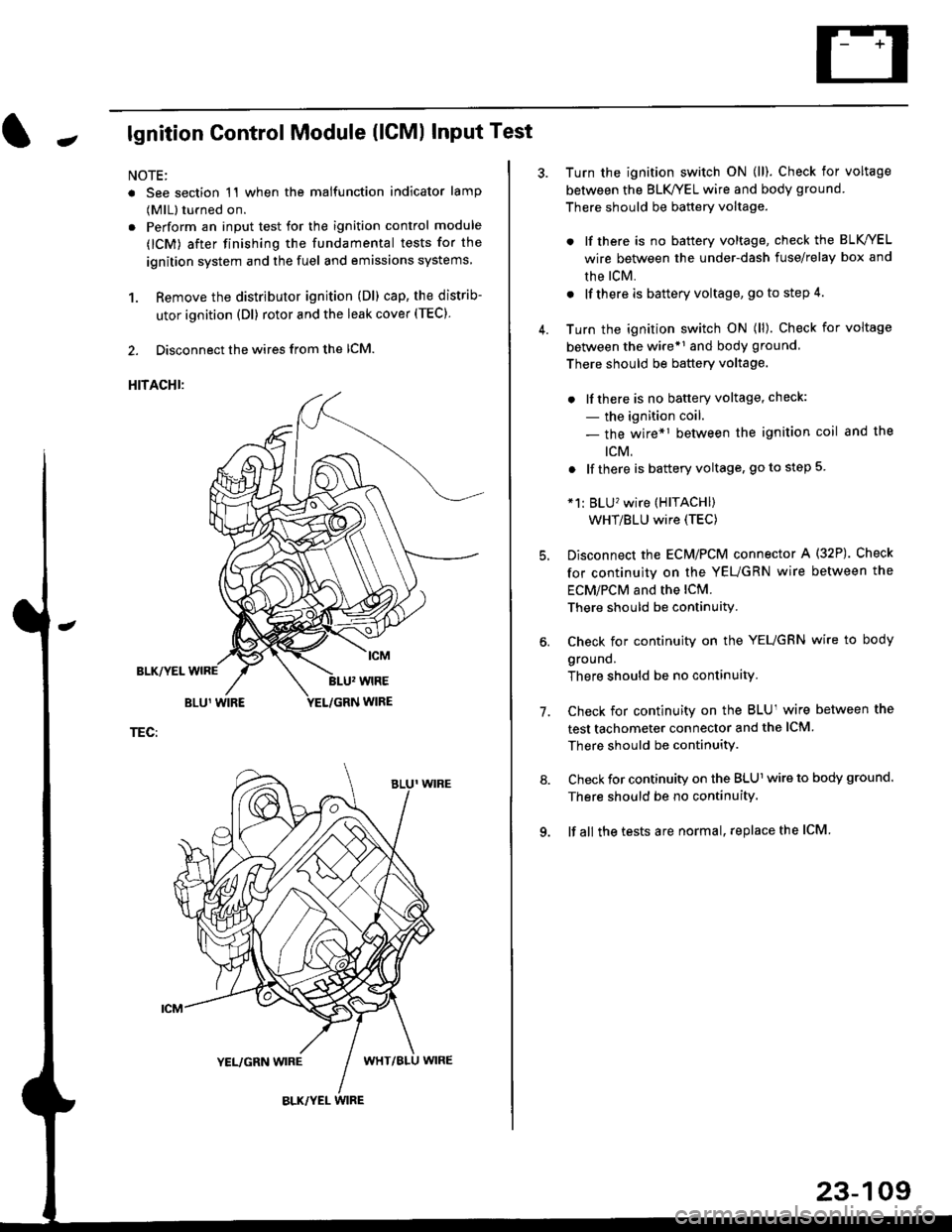

1. Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor and the leak cover (TEC).

2. Disconnect the wires from the lCM.

HITACHI:

BLK/YEL

TEC:

Turn the ignition switch ON (ll). Check for voltage

between the BLK/YEL wire and body ground.

There should be battery voltage.

. lf there is no battery voltage, check the BLK/YEL

wire between the under-dash fuse/relay box and

rhe lcM.

. lf there is battery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the wire*r and body ground

There should be battery voltage.

. lfthere is no battery voltage, check:

- the ignition coil.

- the wire*1 between the ignition coil and the

tcM.

. lf there is battery voltage, go to step 5

*1: BLU'�wire (HITACHI)

WHT/BLU wire (TEC)

Disconnect the EcM/PCM connector A (32P). Check

for continuity on the YEUGRN wire between the

ECM/PCM and the lCM.

There should be continuity.

Check for continuity on the YEUGRN wire to body

ground.

There should be no continuity.

Check for continuity on the BLUl wire between the

test tachometer connector and the ICM

There should be continuitY.

Check for continuity on the BLUl wire to body ground.

There should be no continuity.

lf all the tests are normal, replace the ICM

7.

23-109

Page 1582 of 2189

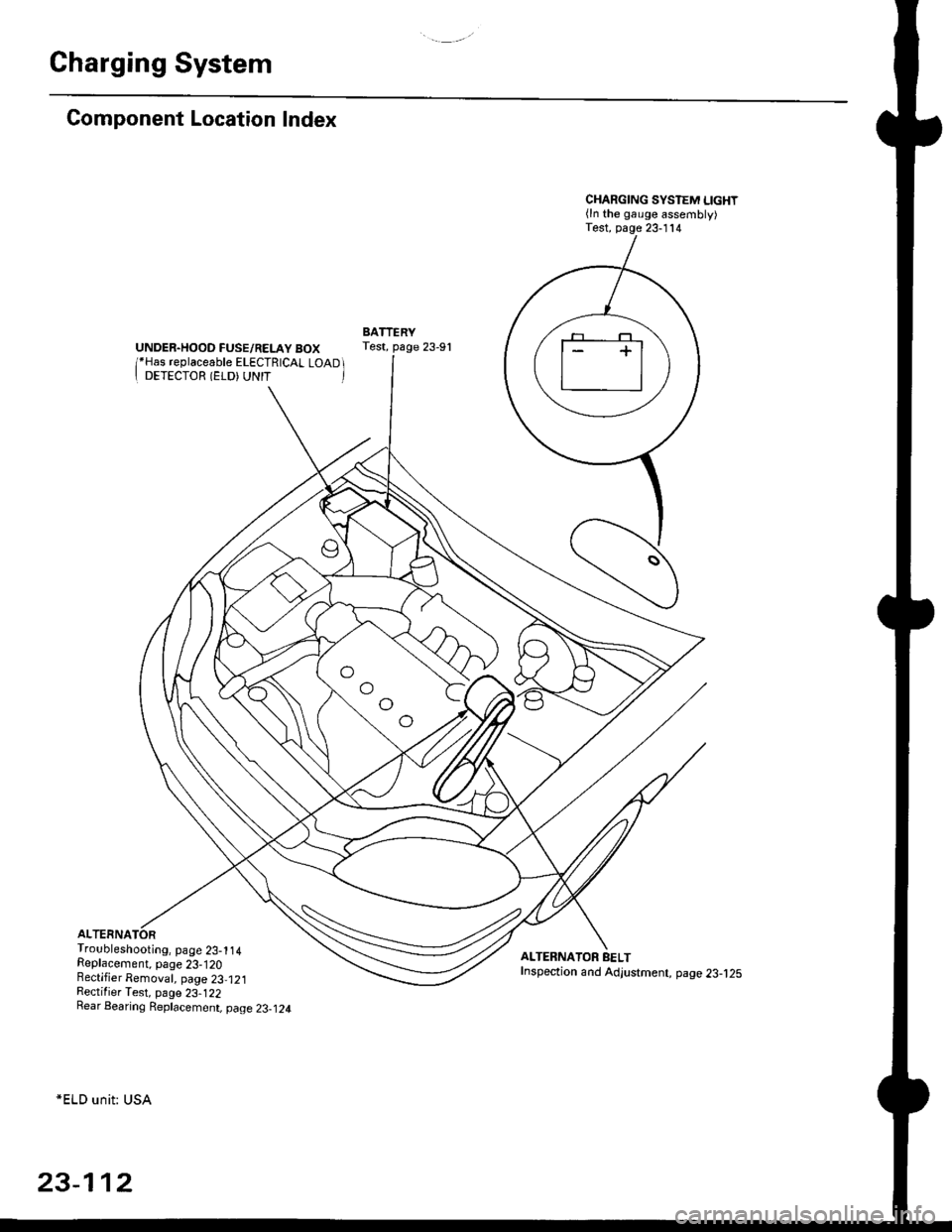

Charging System

Component Location Index

UNDER.HOOD FUSE/RELAY BOX/*Has replaceable ELECTRICAL LOAD II DETECTOR (ELD) UNIT '

Troubleshooting, page 23-1 14Replacement, page 23-120Bectifier Removal, page 23,121Rectifier Test, page 23-122Rear Bearing Replacement, page 23-j24

*ELD unit: USA

CHARGING SYSTEM LIGHT(ln the gauge assembly)Test, page 23- l14

BATTERYTest, page 23-91

ALTERNATOR BELTInspection and Adjustment, page 23-t25

[]

23-112

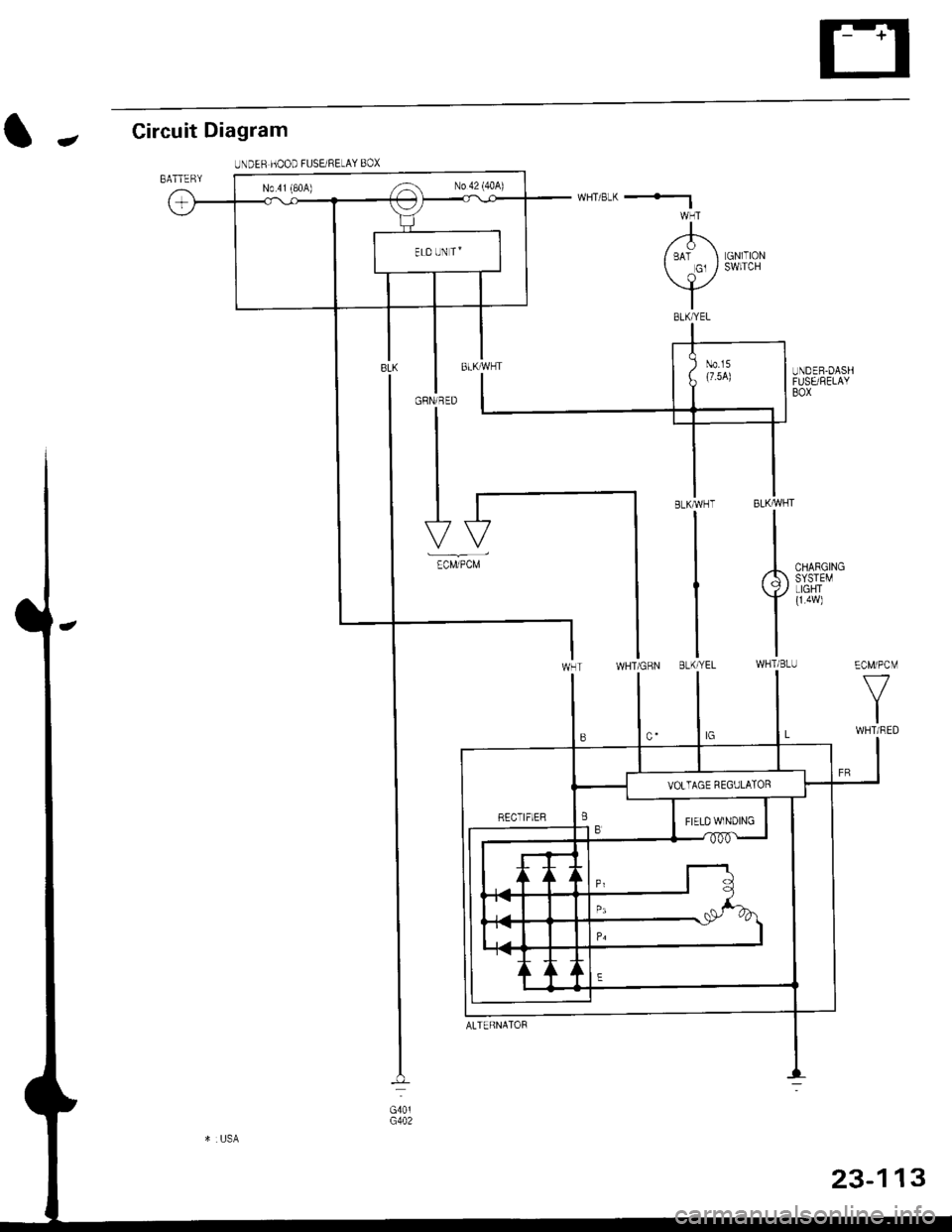

Page 1583 of 2189

Circuit Diagram

IJNDER HOOD FUSEi RELAY BOX

-

BATTERY

LGNlTIONSWITCH

I

,'-F\I BAT I Gl /

\l_/

I

GRN/RED

I

N0.41 (80A) ,-a No 42 (40A)

ECM/PCM

f7

IWHT/RED

CHARGINGSYSTEMLIGHTI

TWHTi BLU

1323-1

ALTERNATOF

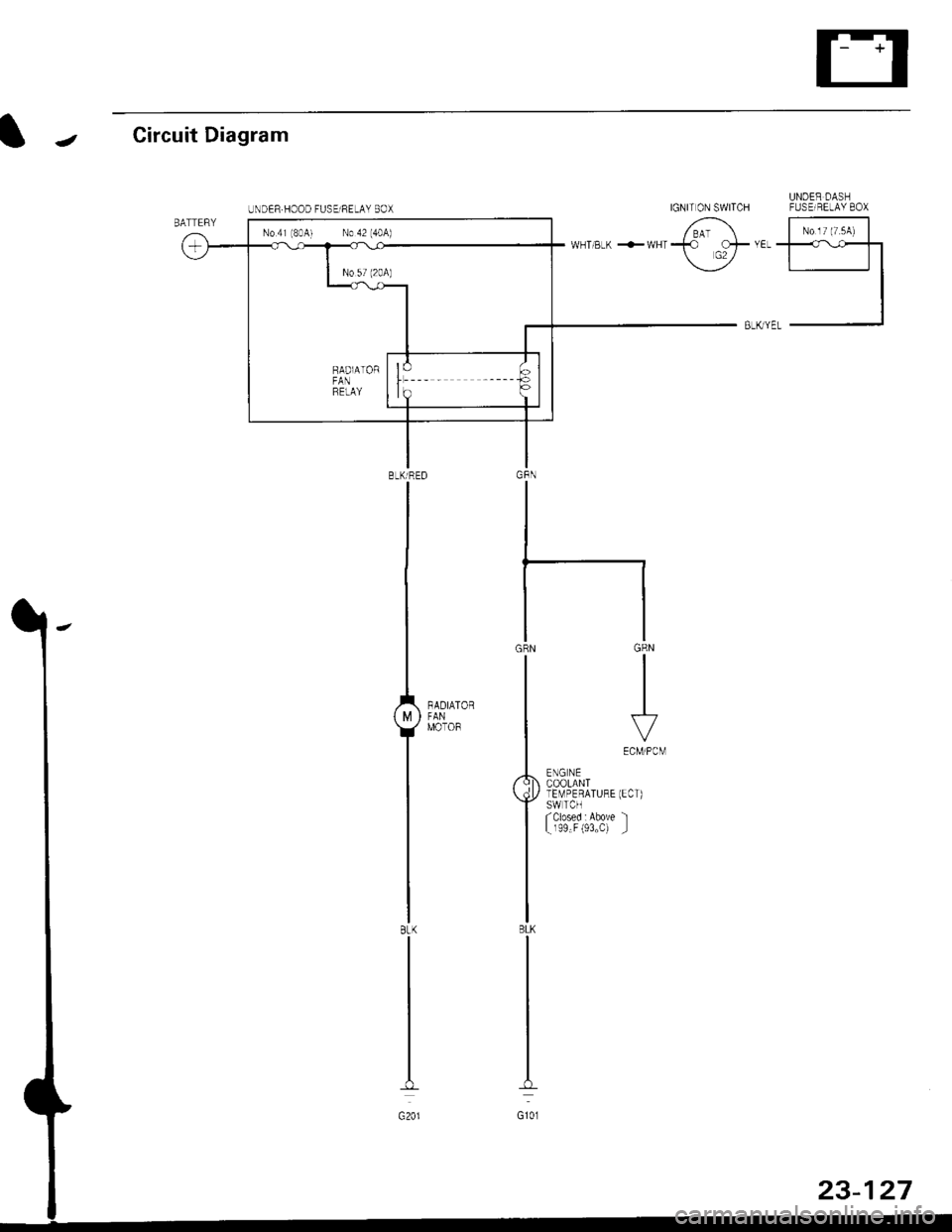

Page 1597 of 2189

IJCircuit Diagram

UNDER DASHIGNIT ON SWITCH FUSEIRELAY 8OX

6 |-;;;;lii "ir"'t*Tl-l

BLK yEL -J

GRN

III

I

\.7VECM/PCM

ENG NECOOLANTlEMPERATURE (ECT)SWTCHfclosed : Above 'l

L r99"F (93"C) _l

BLKTRED

I

I

1,,*"_

T-'

IBtK

I

I

G201

UNDER.HOOD FUSElRELAY BOX

No 41 (8041 No 42 (40A)

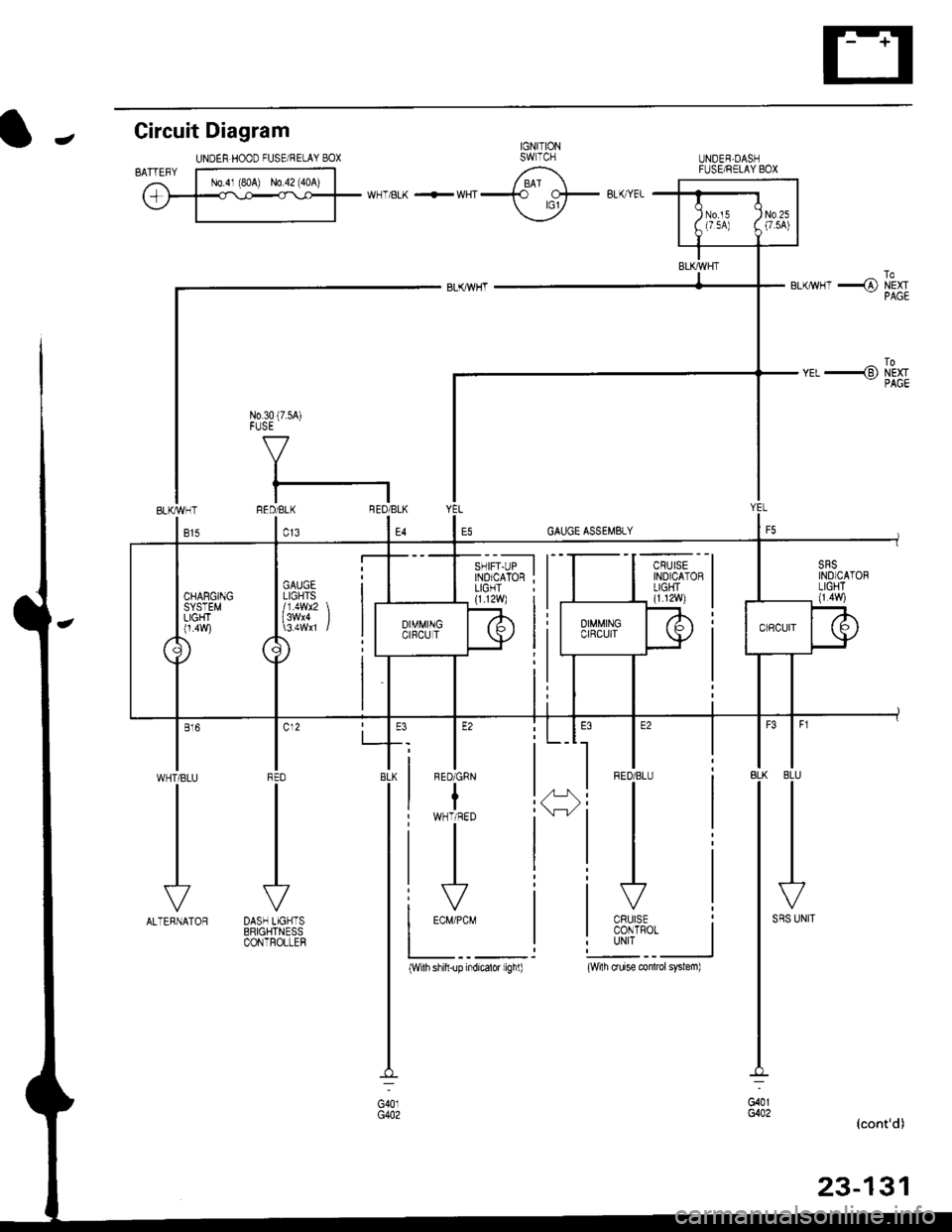

Page 1601 of 2189

IJNOER,DASHFUSE/RELAY BOX

GAUGELIGHTS

l3wx4 l

CHARGINGSYSTEMLIGHT0.4w)

Gircuit Diagram

UNDEN HOOD FUSE/RELAY BOXIJ

N0.30 (7.54)FUSE

f7

I

tlRED/BLK BEO/BLK

l"l"8LK BLU

IJ

l'"^*

I

t-

G401G402

__l

tE2

IFED/BLU

CRUISECONTROTUNIT

fl ,,1:

tH

I c12

IFFD

VDASH LIGHTSBRIGHTNESSCONTROLLEF

l"'WHT/BLU

vALTERNATOR

(With shifi-up indicatd lighl)(wi1h cruise conlrcl system)

Page 1610 of 2189

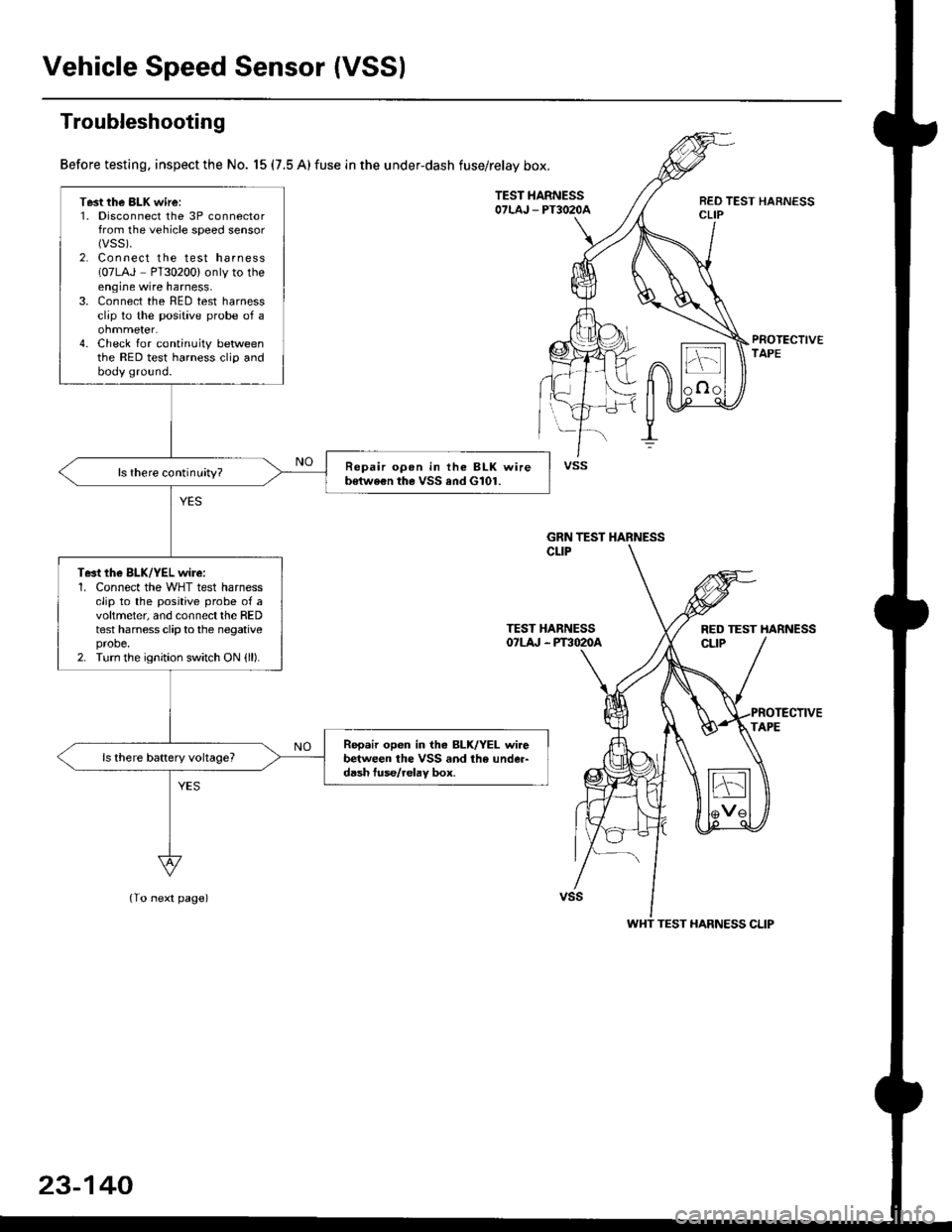

Vehicle Speed Sensor (VSSI

Troubleshooting

Before testing, inspect the No. 15 (7.5 A) fuse in the under-dash fuse/relay box.

TEST HARNESSOTLAJ _ PT3O2OAREO TEST HARNESSCLIP

PROTECTIVETAPE

TEST HARNESSOTLA' . PT3O2OA

(To next page)

Test the BLK wire:1. Disconnect the 3P connectorfrom the vehicle speed sensor(vss).

2. Connect the test harness(07LAJ PT30200) only to theengine wire harness,3. Connect the RED test harnessclip to the positive probe of a

4. Check for continuity betweenthe RED test harness clip andbody ground.

Repair opon in the BLK wireb€twe€n the VSS and G101.ls there continuity?

Te3t the BLK/YEL wire:1. Connect the WHT test harnessclip to the positive probe of avoltmeter, and connectthe REDtest harness clip to the negativeprobe.2. Turn the ignition switch ON {ll).

Repair open in iho BLK/YEL wirebetween the VSS and the under-d6sh tuse/relav box.

vss

GRN TEST HARNESS

RED TEST HARNESS

WHT TEST HARNESS CLIP

23-140

Page 1612 of 2189

Fuel Gauge

Gauge/Sending Unit Test

!@ Do not smoke while working on tho fuel

system. Keep open tlame away trom your wotk atea.

NOTE: Refer to page 23-133 for the fuel gauge system

circuit.

'1. Check the No. 25 (7.5 A) fuse in the under-dash fuse/

relay box before testing.

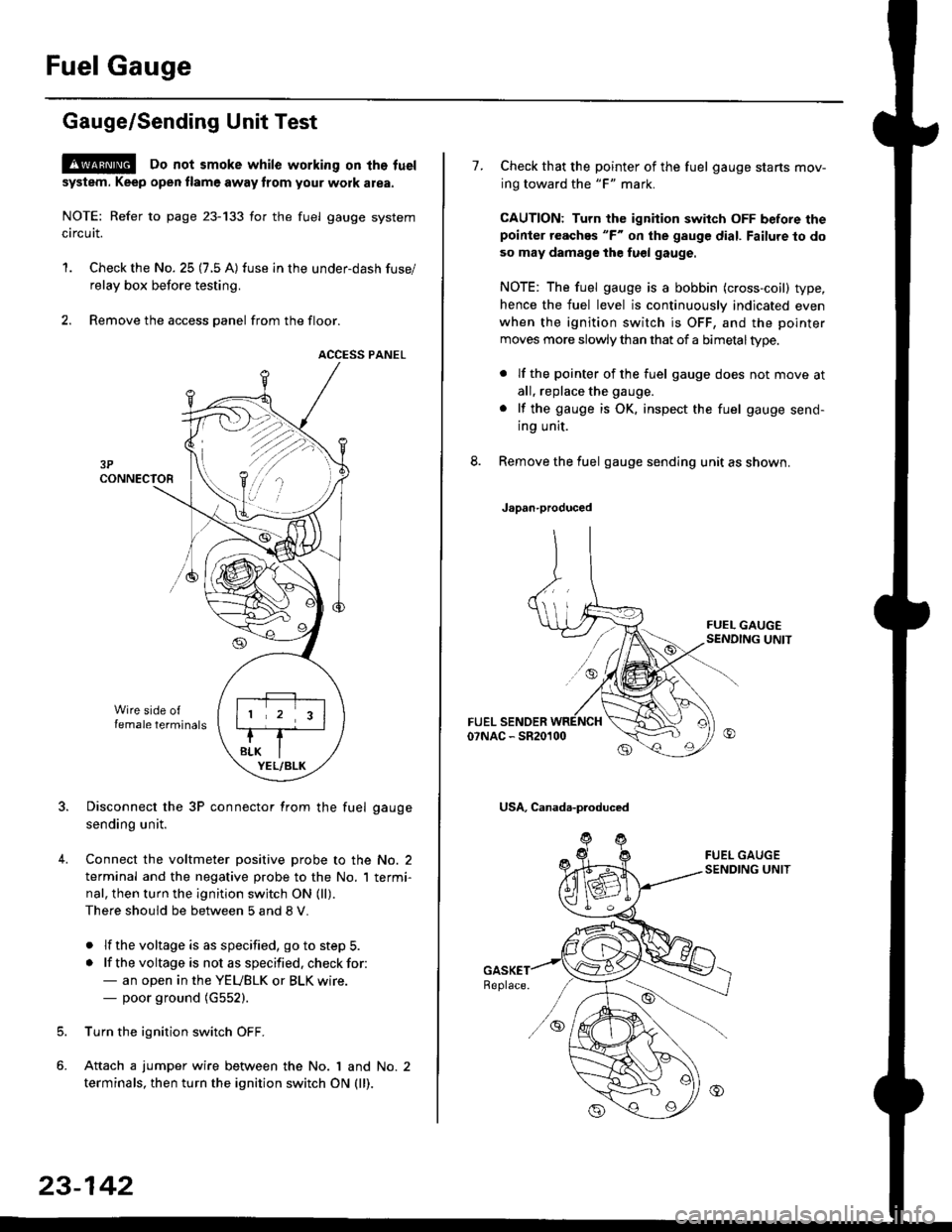

2. Remove the access panel from the floor.

ACCESS PANEL

Disconnect the 3P connector from the fuel gauge

sending unit.

Connect the voltmeter positive probe to the No. 2

terminal and the negative probe to the No. I termi-

nal, then turn the ignition switch ON (ll).

There should be between 5 and 8 V.

. lf the voltage is as specified, go to step 5.

. lf the voltage is not as specified. check for:- an open in the YEUBLK or BLK wire.- poor ground (G552).

Turn the ignition switch OFF.

Attach a jumper wire between the No. 1 and No. 2

terminals, then turn the ignition switch ON (ll).

)\

23-142

1.Check that the pointer of the fuel gauge starts mov-

ing toward the "F" mark.

CAUTION: Turn the ignition switch OFF before thepoinier reaches "F" on ihe gauge dial. Failure to do

so may damage the fuel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type,

hence the fuel level is continuously indicated even

when the ignition switch is OFF, and the pointer

moves more slowly than that of a bimetaltype.

. lf the pointer of the fuel gauge does not move at

all, replace the gauge.

. lf the gauge is OK. inspect the fuel gauge send-

ing unit.

Remove the fuel gauge sending unit as shown.

Japan-produced

USA, Canada-produced

Page 1613 of 2189

J

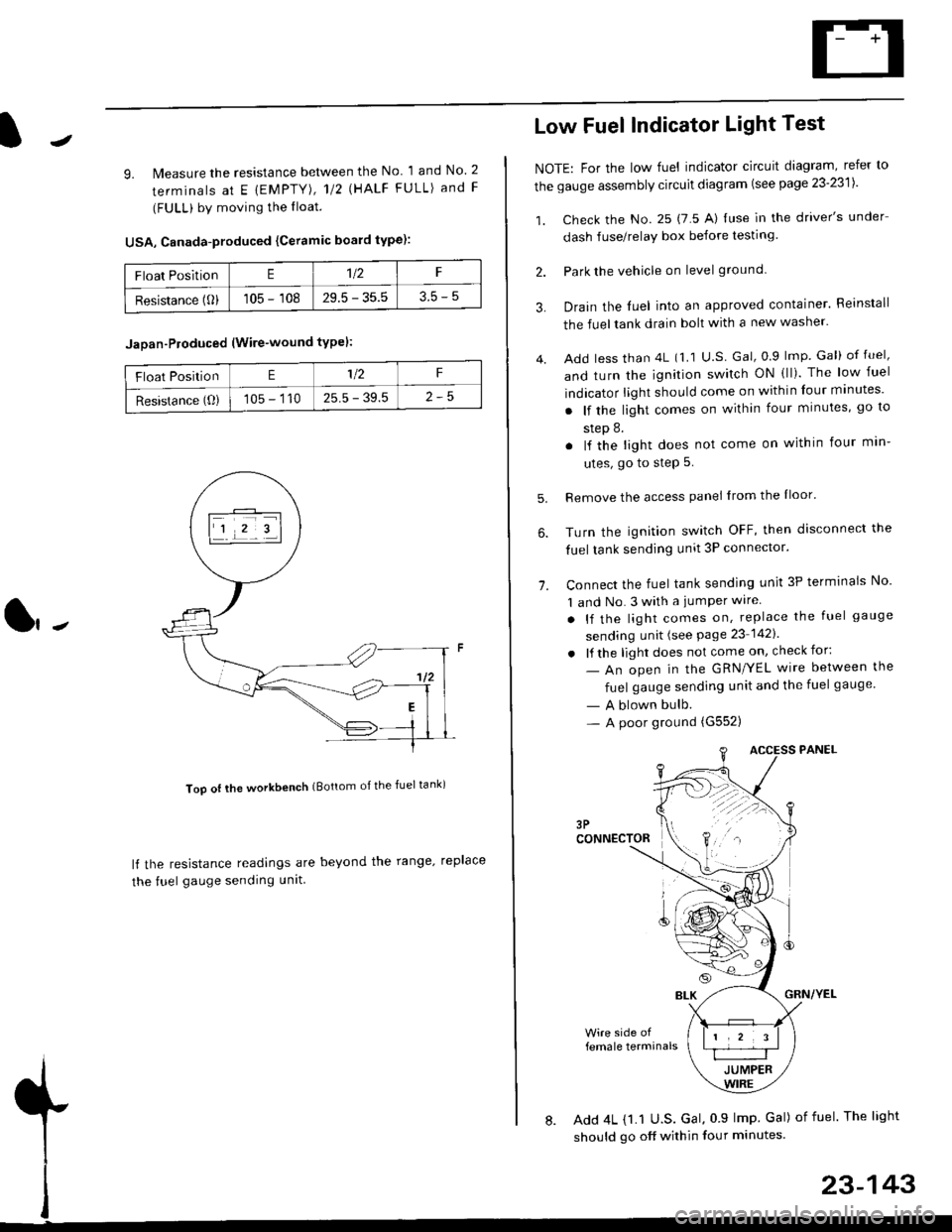

9. lMeasure the resistance between the No 1 and No. 2

terminals at E {EMPTY), 112 \HALF FULL) and F

(FULL) by moving the lloat.

USA, Canada-produced {Ceramic board type):

Too ot lhe workbench (Bottom of the fuel tank)

ll the resistance readings are beyond the range. replace

the fuel gauge sending unit

Float PositionE1t2F

Resistance (0)105 - 10829.5 - 35.53.5-5

Jaoan-Ploduced (Wire-wound typel:

Float PositionE1/2F

Resistance (O)105 - 11025.5 - 39.5

Low Fuel Indicator Light Test

NOTE: For the low fuel indicator circuit diagram, refer to

the gauge assembly circuit diagram (see page 23'2311.

1. Check the No. 25 (7 5 A) luse in the driver's under

dash fuse/relay box before testing

2. Park the vehicle on level ground.

3.

4.

Drain the luel into an approved container. Reinstall

the fueltank drain bolt with a new washer.

Add less than 4L (1 1 U.S Gal, 0.9 lmp Gal) of fuel,

and turn the ignition switch ON (ll). The low fuel

indicator light should come on within four minutes'

. lf the light comes on within four minutes, go to

step 8.

. lf the light does not come on within four min-

utes, go to step 5.

Remove the access panel lrom the Iloor'

Turn the ignition switch OFF, then disconnect the

fuel tank sending unit 3P connector.

Connect the fuel tank sending unit 3P terminals No'

1 and No. 3 with a jumPer wire

. lf the light comes on, replace the fuel gauge

sending unit (see Page 23 1421

. lf the light does not come on, check for:

- An open in the GRN/YEL wire between the

fuel gauge sending unit and the fuel gauge

- A blown bulb.- A poor ground (G552)

6.

1.

female terminals

8. Add 4L {1.1 U.S. Gal, 0 9 lmp Gal) of fuel The light

should go off within four minutes.

23-143