ect HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 1828 of 2189

Five-Step Troubleshooting

L Verify The Complaint

Turn on all the components in the problem

circuil lo check the accuracy of the customer

complaint. Note the symptoms. Do not begin

disassembly or testing until you have

narrowed down the problem area.

2. Analyze The Schematic

Look up the schematic for the problem

circuit. Determine how the circuit is

supposed to work by tracing the current

paths lrom the power source through the

circuit components to ground. Also, trace

circuits that share wiring with the problem

circuit. The names of circuits that share the

same fuse, ground, or switch, and so on, are

referred to in each circuit schematic. Try to

operate any shared circuits you didn't check

in step 1 . lt the shared circuits work, the

shared wiring is OK, and the cause must be

in the wiring used only by the problem

circuit. lf several circuits fail at the same

time, the fuse or ground is a likely cause.

Based on the symptoms and your

understanding of the circuit's operation,

identify one or more possible causes.

3. lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis

you made in step 2. Keep in mind that a

logical, simple procedure is the key to

efficient troubleshooting. Test for the most

likely cause of failure first. Try to make tests

at points that are easily accessible.

4. Fix The Problem

Once the specific problem is identified,

make the repair. Be sure to use proper tools

and safe procedures.

5. Make Sure The Circuit Works

Turn on all components in the repaired

circuit in all modes to make sure you've

fixed the entire problem. ll the problem was

a blown fuse, be sure to test all of the

circuits on that fuse. Make sure no new

problems turn up and the original problem

does not recur.

Test Equipment

Most circuits include solid-state devices.

Test the voltages in these circuits only with

a 1o-megaohm or higher impedance digital

mUltimeter. Never use a test light or analog

meter on circuits that contain solid-state

devices. Damage to the devices may result.

Test Light and DVOM

On circuits without solid-state devices, use a

test light to check for voltage. A test light is

made up of a 12 volt bulb with a pair of leads

attached. After grounding one lead, touch the

other lead to various points along the circuit

where voltage should be present. The bulb

will go on if there is voltage at the point being

tested. lf you need to know how much

voltage is present, use a digital

volVohmmeter (DVOM).

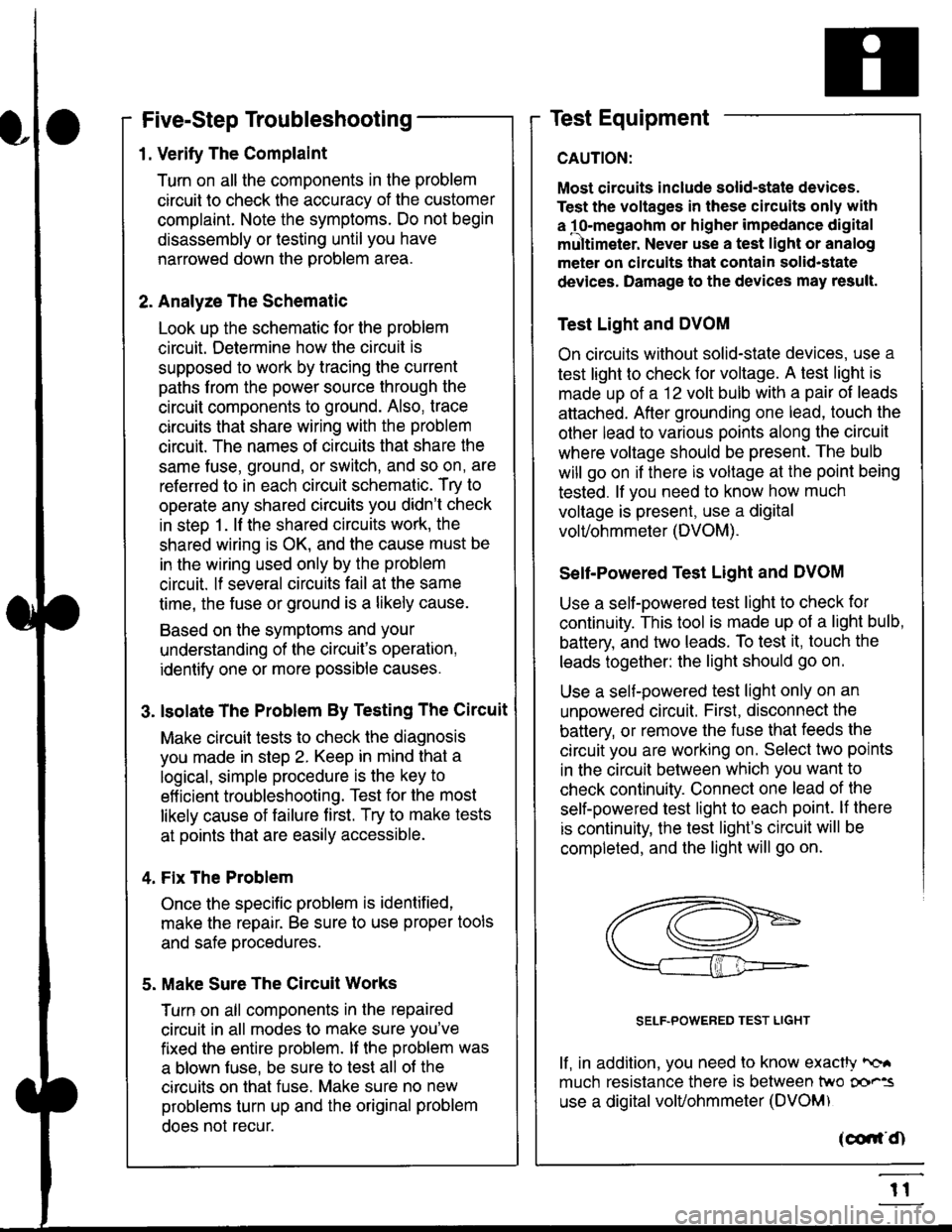

Self-Powered Test Light and DVOM

Use a self-powered test light to check for

continuity. This tool is made up of a light bulb,

battery, and tlvo leads. To test it, touch the

leads together: the light should go on.

Use a self-powered test light only on an

unoowered circuit. First, disconnect the

battery, or remove the fuse that feeds the

circuit you are working on. Select two points

in the circuit belween which you want to

check continuity. Connecl one lead of the

self-powered test light to each point. lf there

is continuity, the test light's circuit will be

completed, and the light will go on.

SELF-POWERED TEST LIGHT

lf, in addition, you need lo know exacW hc'.

much resistance there is between two oo'^=

use a digital volUohmmeter (DVOM)

acdrt'Cn

t1

Page 1829 of 2189

In the "OHMS" range, the DVOM will measure

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting lhe measurement.

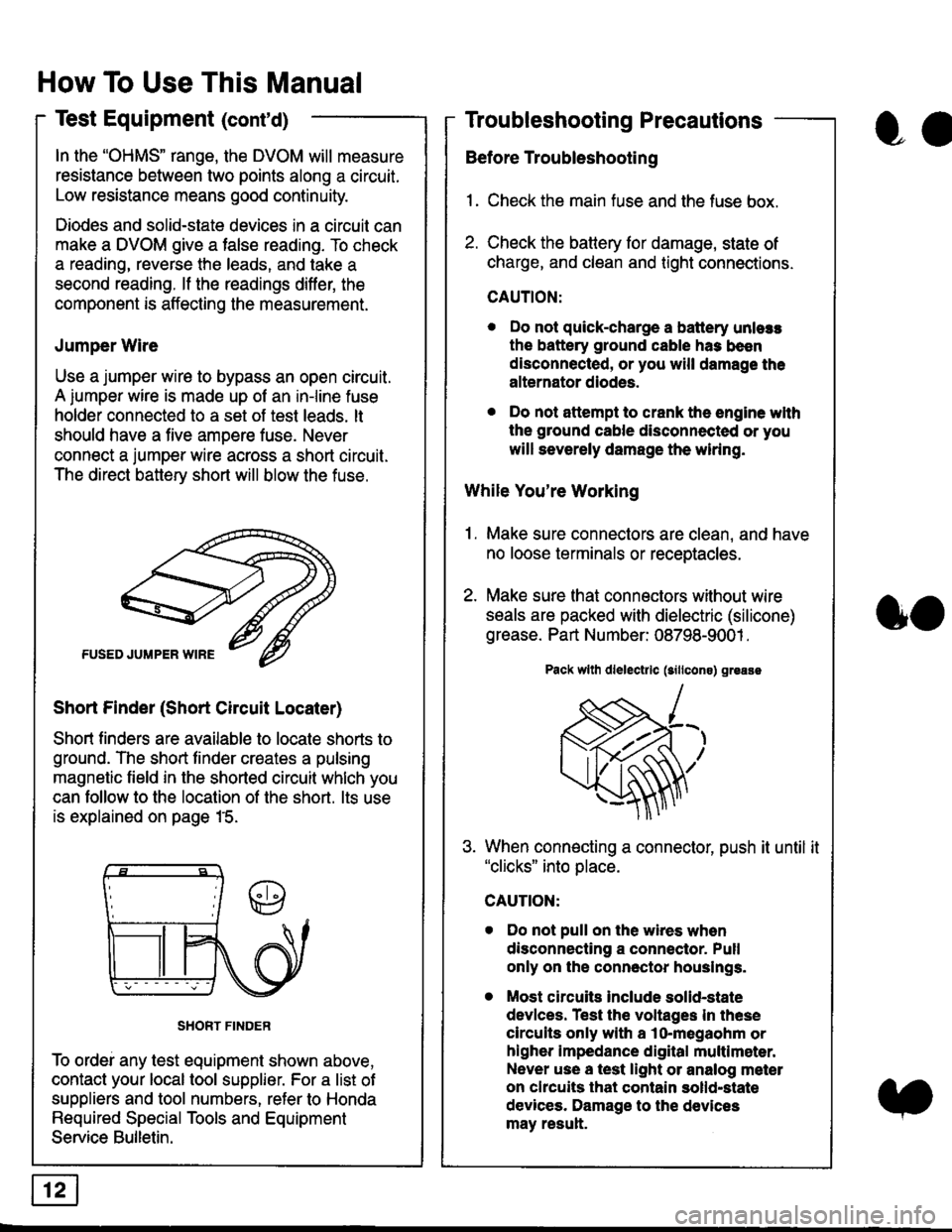

Jumper Wire

Use a jumper wire to bypass an open circuit.

A iumper wire is made up ot an in-line fuse

holder connected to a set of test leads. lt

should have a five amoere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Short finders are available to locale shorts to

ground. The short tinder creates a pulsing

magnetic field in the shorted circuit whlch you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To ordei any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Honda

Required Special Tools and Equipment

Service Bulletin.

How To Use This Manual

Test Equipment (cont'd)

oa

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage, state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unlers

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine wlth

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receptacles.

2. Make sure lhat connectors without wire

seals are packed with dielectric (silicone)

grease. Part Number: 08798-9001 .

Pack wllh dlelectrlc (sillcons) greass

When connecting a connector, push it until it"clicks" into place.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector houslngs.

Most circuits Include solid-state

devlces. Test the voltages In these

circuits only with a lo-megaohm or

higher impedance digital multlm6ter.

Never use a test light or analog meter

on chcuits that contain solld-state

devices. Damage to the devices

may result.

oo

Page 1830 of 2189

Troubleshooting Tests

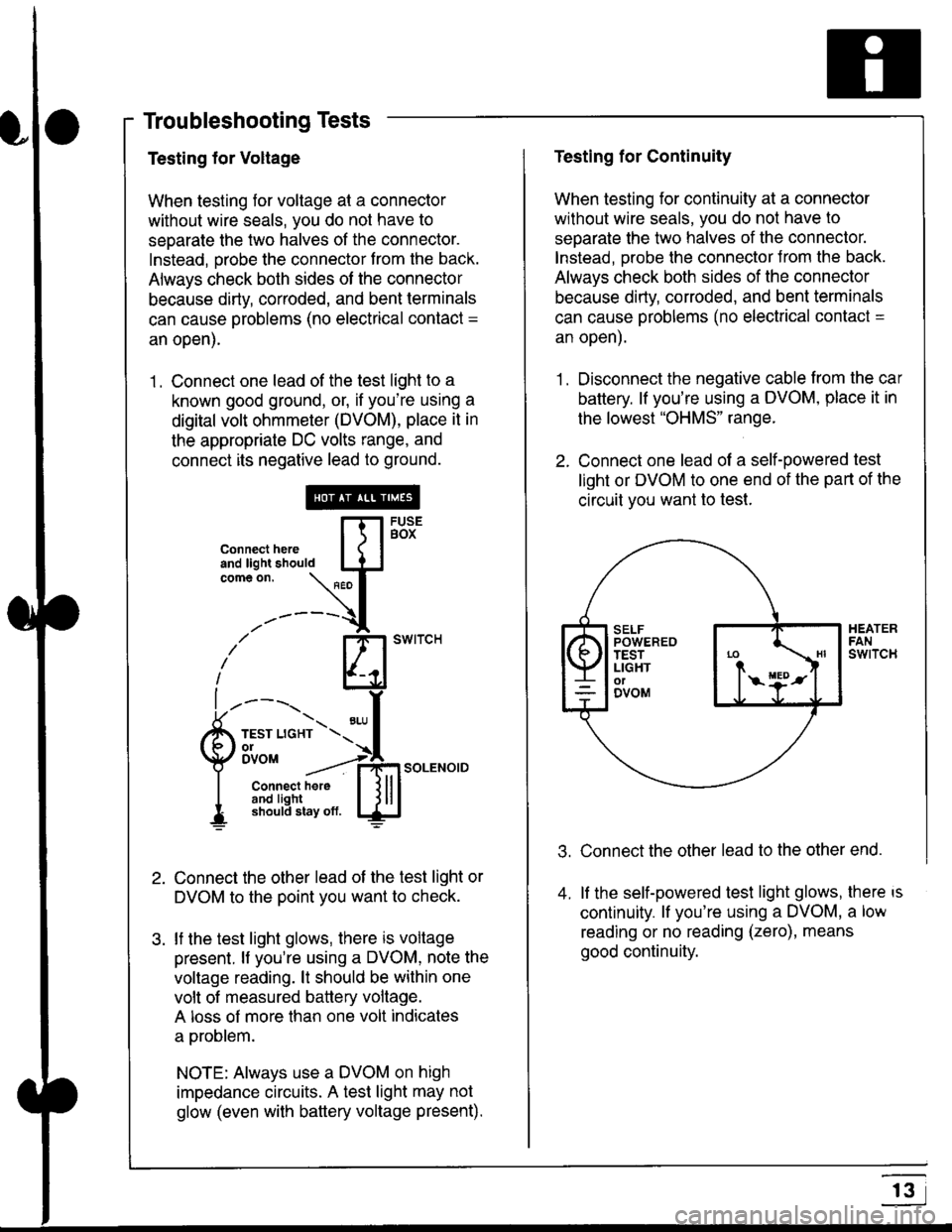

Testing for Voltage

When testing for voltage at a connector

without wire seals, you do not have to

seoarate the two halves of the connector.

Instead, probe the connector from the back.

Always check both sides of the connector

because dirty, corroded, and bent terminals

can cause problems (no electrical contact =

an open).

1 . Connect one lead of the test light to a

known good ground, or, if you're using a

digital volt ohmmeter (DVOM), place it in

the appropriate DC volts range, and

connect its negative lead to ground.

Connect the other lead of the test light or

DVOM to the point you want to check.

lf the test light glows, there is voltage

present. lf you're using a DVOM, note the

voltage reading. lt should be within one

volt of measured battery voltage.

A loss of more than one volt indicates

a problem.

NOTE: Always use a DVOM on high

impedance circuits. A test light may not

glow (even with baftery voltage present).

connecthere [fl5tst-tand light should IJJcomeon.

\" I

------{

/' BT swrrcH

lhl

l ----., I

6m""*soLENo,DI connect here I { lll

I 3#Ji8iL,* lj!!J

Testing for Continuity

When testing for continuity at a connector

without wire seals, you do not have to

separate the two halves of the connector.

lnstead. Drobe the connector Jrom the back.

Always check both sides of the connector

because dirty, conoded, and bent terminals

can cause problems (no electrical contacl =

an open).

1. Disconnect the negative cable from the car

battery. lf you're using a DVOM, place it in

the lowest "OHMS" range.

2. Connect one lead of a self-powered test

light or DVOM to one end of the part of the

circuit vou want lo test.

Connect the other lead to the other end.

lf the self-powered test light glows, there is

continuity. lf you're using a DVOM, a low

reading or no reading (zero), means

good continuity.

.t.

A

r3

Page 1831 of 2189

How To Use This Manual

Troubleshooting Tests

Testing for Voltage Drop

Wires, connectors, and switches are designed

to conduct current wilh a minimum loss of

voltage. A voltage drop of more than one volt

indicates a Droblem.

'1. Place the digital volVohmmeter (DVOM) in

the appropriate DC volts range. Connect

the positive lead to the end of the wire

(or to the connector or switch) closest to

the bafterv.

Connect the negative lead to the other

end of the wire (or the other side of the

connector or switch).

Turn on the components in the circuit.

The DVOM will show the difference

in voltage between the two points. A

difference, or drop, of more than one

volt indicates a oroblem. Check the

circuit for loose, dirty, or bent terminals.

co

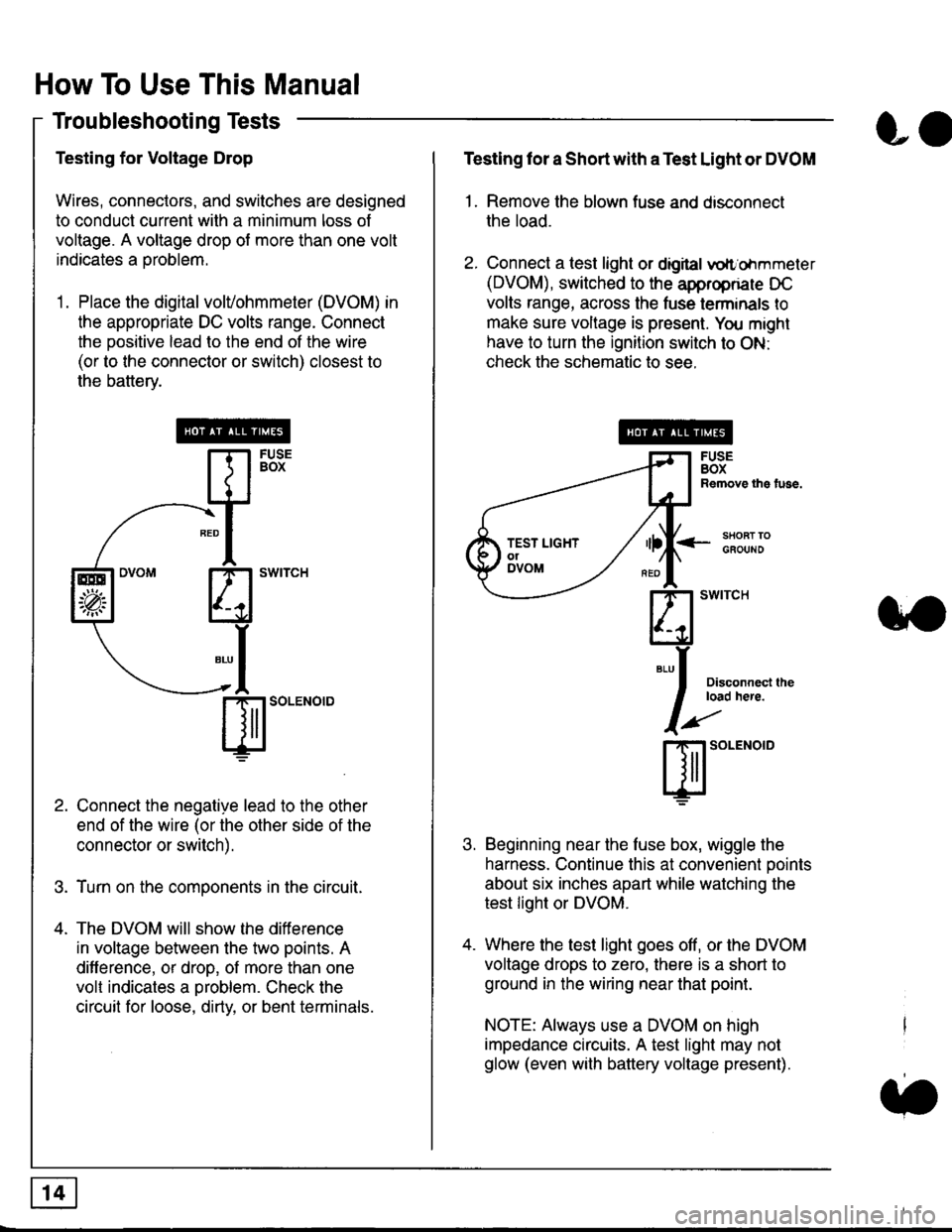

Testing lor a Short with a Test Light or DVOM

1. Remove the blown fuse and disconnect

the load.

2. Connect a test light or digital

oltr'ohmmeter

(DVOM), switched to the appropnare DC

volts range, across the tuse lerminals to

make sure voltage is present. You might

have to turn the ignition switch to ON:

check the schematic to see.

<-s80RT TOGFOUNO

Disconnecl lheload here.

Beginning near the luse box, wiggle the

harness. Continue this at convenient ooints

about six inches apart while watching the

test light or DVOM.

Where the test light goes off, or the DVOM

voltage drops to zero, there is a short to

ground in the wiring near that point.

NOTE: Always use a DVOM on high

impedance circuits. A test light may not

glow (even with battery voltage present).

3'�'

ffito.'"o'o

.t.

TEST LIGHTolDVOM

Page 1832 of 2189

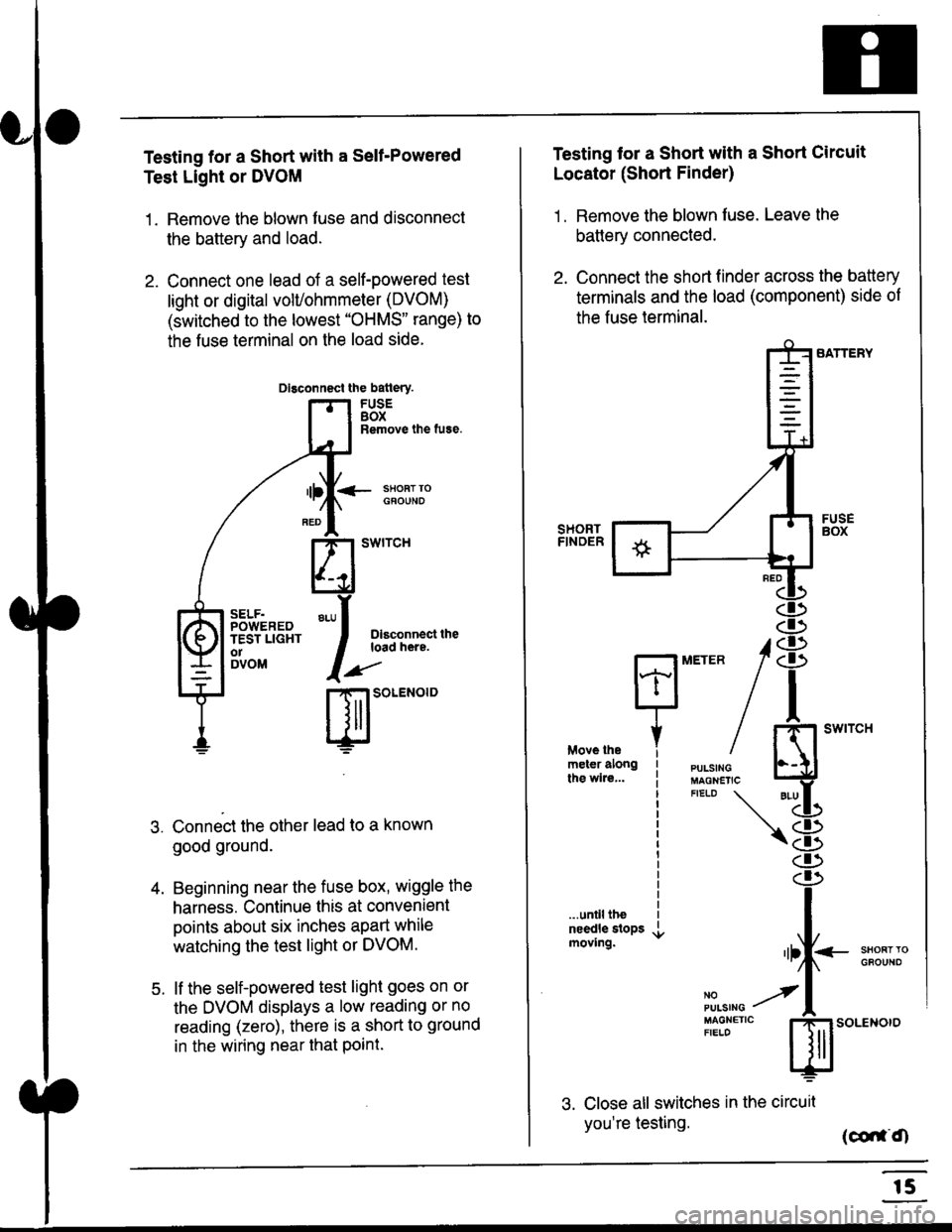

Testing for a Short with a Sell-Powered

Test Light or DVOM

1. Remove the blown fuse and disconnect

the battery and load.

2. Connect one lead of a self-powered test

light or digital volUohmmeter (DVOM)

(switched to the lowest "OHMS" range) to

the fuse terminal on the load side.

Dlsconnect the batlery.

FUSEBOXRemove the fuse.

<- ssoRr rociouNo

Dlsconnect theload here.

.)"'

r| SOLENOID

Connect the other lead to a known

good ground.

Beginning near the fuse box, wiggle the

harness. Continue this at convenient

points about six inches apart while

watching the test light or DVOM.

lf the self-powered test light goes on or

the DVOM displays a low reading or no

reading (zero), there is a short to ground

in the wiring near that Point.

SELF.POWEREDTEST LIGHTo1DVOM

4.

5.

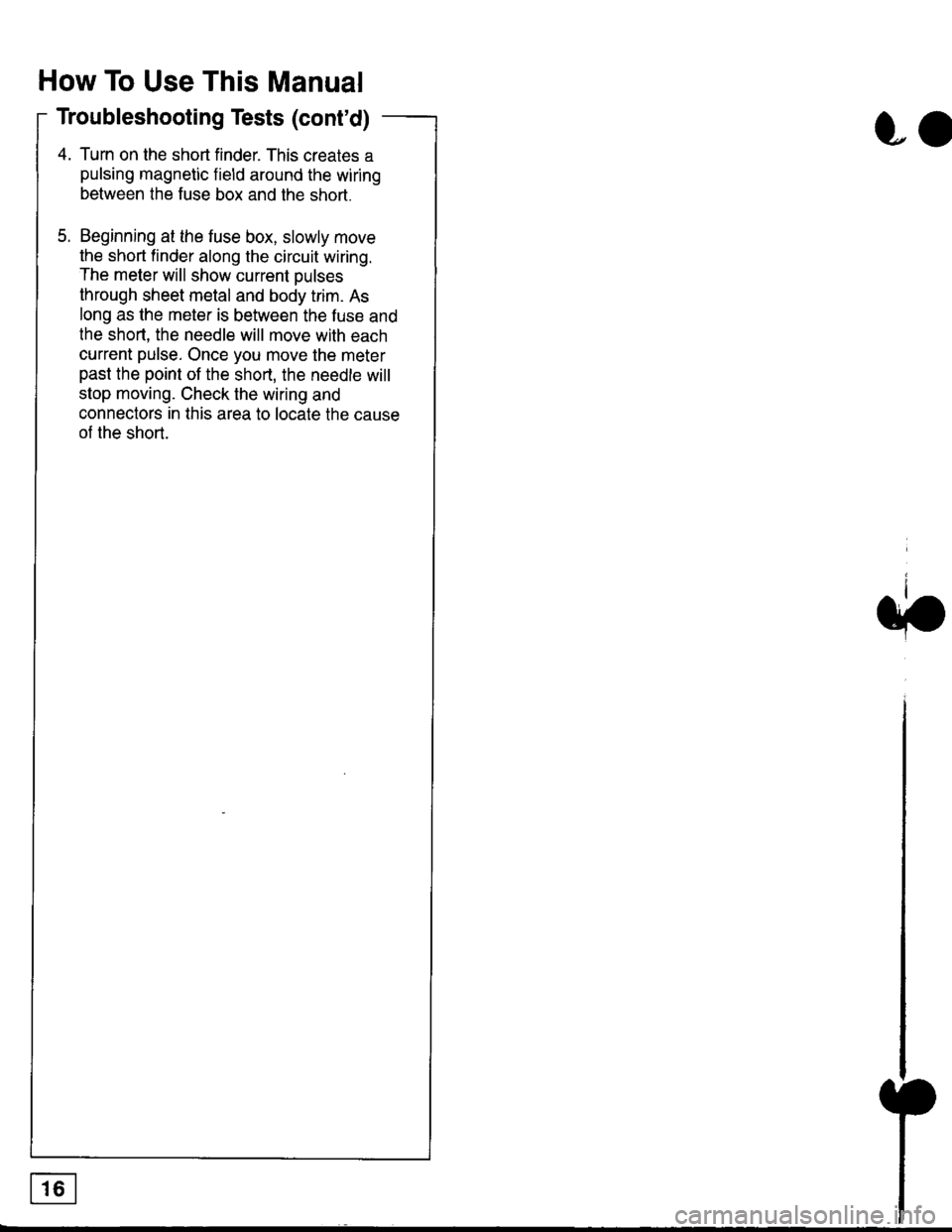

Testing tor a Short with a Short Circuit

Locator (Short Finder)

1 . Remove the blown fuse. Leave the

battery connected.

2. Connect the short finder across the battery

terminals and the load (component) side of

the fuse terminal.

SATTERY

SHORTFINOER

FUSEBOX

PULSINGMAGNETICFIELD \

NOPUISING

\

I swtrcH

I

<- stl

Kl"I- -.T.1

"'at

\8

.r.

rlll<

,l

m

...unilltheneedle slopsmoving.SHOFTTGFOUNO'llt

No --tPULS|NG z

MAGNETTC IFIELD ISoLENOTO

3. Close all switches in the circuil

you're testing. (co,f,O

r5

Page 1833 of 2189

How To Use This Manual

Troubleshooting Tests (cont'd)

4. Turn on the short finder. This creates a

pulsing magnetic field around the wiring

between the fuse box and the short.

5. Beginning at the fuse box, slowly move

the short finder along the circuit wiring.

The meter will show current Dulses

through sheet metal and body trim. As

long as the meter is between the fuse and

lhe short, the needle will move with each

current pulse. Once you move the meter

past the point of the short, the needle will

stop moving. Check the wiring and

connectors in this area to locate the cause

of the short.

co

Page 1834 of 2189

![HONDA CIVIC 2000 6.G Workshop Manual Fuse/Relay Information

- Under-dash Fuse/Relay Box

Front View

c712(To moonroof wire harness)

. : Canadai : Not UsedO : C926 loprion (+B)l

@ : C927 loption (dash lights)]

O : C928 [Option (ACC]I

@ : C9 HONDA CIVIC 2000 6.G Workshop Manual Fuse/Relay Information

- Under-dash Fuse/Relay Box

Front View

c712(To moonroof wire harness)

. : Canadai : Not UsedO : C926 loprion (+B)l

@ : C927 loption (dash lights)]

O : C928 [Option (ACC]I

@ : C9](/img/13/6068/w960_6068-1833.png)

Fuse/Relay Information

- Under-dash Fuse/Relay Box

Front View

c712(To moonroof wire harness)

. : Canadai : Not UsedO : C926 loprion (+B)l

@ : C927 loption (dash lights)]

O : C928 [Option (ACC]I

@ : C929 loption (lc2)l

Rear View

css2

c421(To main wire harness)

c801CI-o SRS main harness)

c501(To dashboard wire harness)

^ : Not used ('96-'97 models)

c913(To ignition switch)

INTEGRATEDCONTROL UNITCONNECTOR A

c419Oo main wire harness)

REAR WINDOWDEFOGGER RELAY

TURN SIGNAUHAZARD RELAY

c423(To main wire harness)

co

c422(To main wire harness)

POWERwtNDowRELAY

c551flo lloor wire harness)c439 f96.'97 MODELSand ALL GX MOOELS)(To main wire harness)

T1 T-t T"l T"t r-r r-'l T1 F n r-l r-l r'123 24 25 26 27 28 29 30 31 32 33I-J I.J I.J IJ IJ IJ LJ IJ IJ I.J I.J I-I

r"1 r-t r-t T-l r"l r-r Fl r:1 n rJ n -12 13 14 t5 16 17 t8 19 2A 2t 22LI I.J L! LI tJ LJ (J LI IJ IJ T-I I.J

n r:l rj.l |-l T"l Tl r:t n r-l |;.l r-r r-l1 2 3 4 5 6 7 I 9 10 11LI LI IJ LJ LJ I,J T-I I.J TJ IJ I.-I tJ

c420(To main wire harness)

6

(To floor wire harness)

Page 1835 of 2189

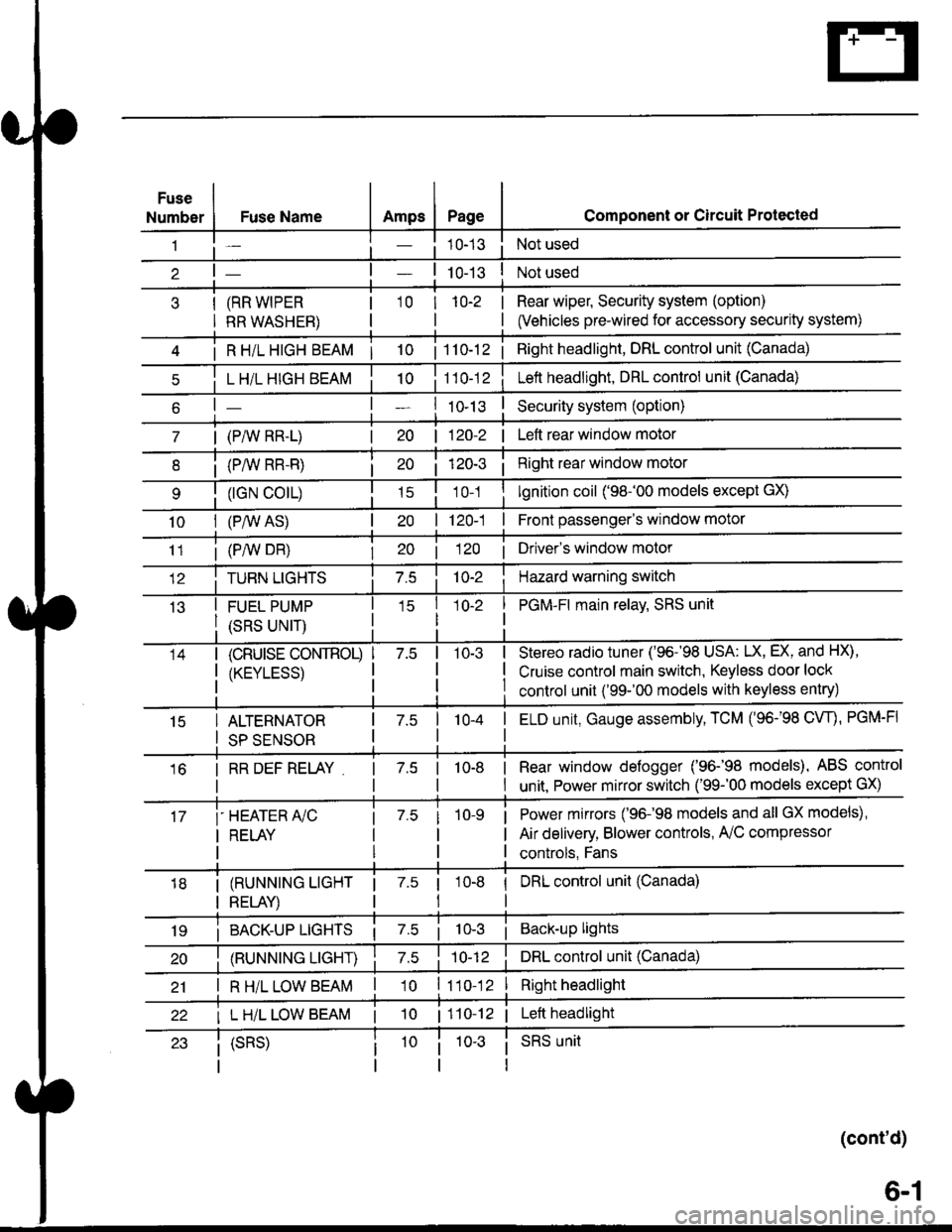

Fuse

NumberAmpsPageFuse Name

(RR WIPER

RR WASHER)

i R HiL HIGH BEAM | 10

L H/L HIGH BEAM

| (PAIV RR-L)

i (P/vv RR-R)

(rGN CO|L)

10I (P,^/V AS)

Component or Circuit Protected

Not used

Not used

Rear wiper, Security system (option)

(Vehicles pre-wired for accessory security system)

'10r 1n-2

I

| 1 10-12i Right headlight, DRL control unit (Canada)

Lett headlight, DRL control unit (Canada)

I ro-rsSecurity system (option)

| 120-2 | Left rear window motor

Right rear window motor

lgnition coil ('98-'00 models except GX)

| 120-1 | Front passenger's window motor

i (PiW DH)| 20 1 12O I Driver's window motor

TURN LIGHTSHazard warning switch

FUEL PUMP

(SRS UNIT)

PGM-FI main relav, SRS unit

(cRUrsE CoNTROL)

/KtrVt trSS\

Stereo radio tuner ('96-'98 USA: LX, EX, and HX),

Cruise control main switch, Keyless door lock

control unit ('99-'00 models with keyless entry)

15ALTERNATOR

SP SENSOR

l-a10-4I ELD unit, Gauge assembly, TCM (96-'98 CW, PGM-FI

16I RR DEF RELAY7.510-8I Rear window defogger ('96-'98 models), ABS control

I unit. Power mirror switch ('99-'00 models except GX)

i-HEATER r/C

I RELAY

Power mirrors ('96-98 models and all GX models),

Air delivery, Blower controls, AilC compressor

controls, Fans

I (RUNNING LIGHT

I RELAY)

1 7.5 1

tl

I DRL control unit (Canada)

i BACK-UP LTGHTSi Back-up lights

(RUNNING LIGHT)DRL control unit (Canada)

I R H/L LOW BEAM'10 l11o-12Right headlight

I L H/L LOW BEAM | 101110-12 | Left headlight

(cont'd)

(SRS)SRS unit

6-1

Page 1836 of 2189

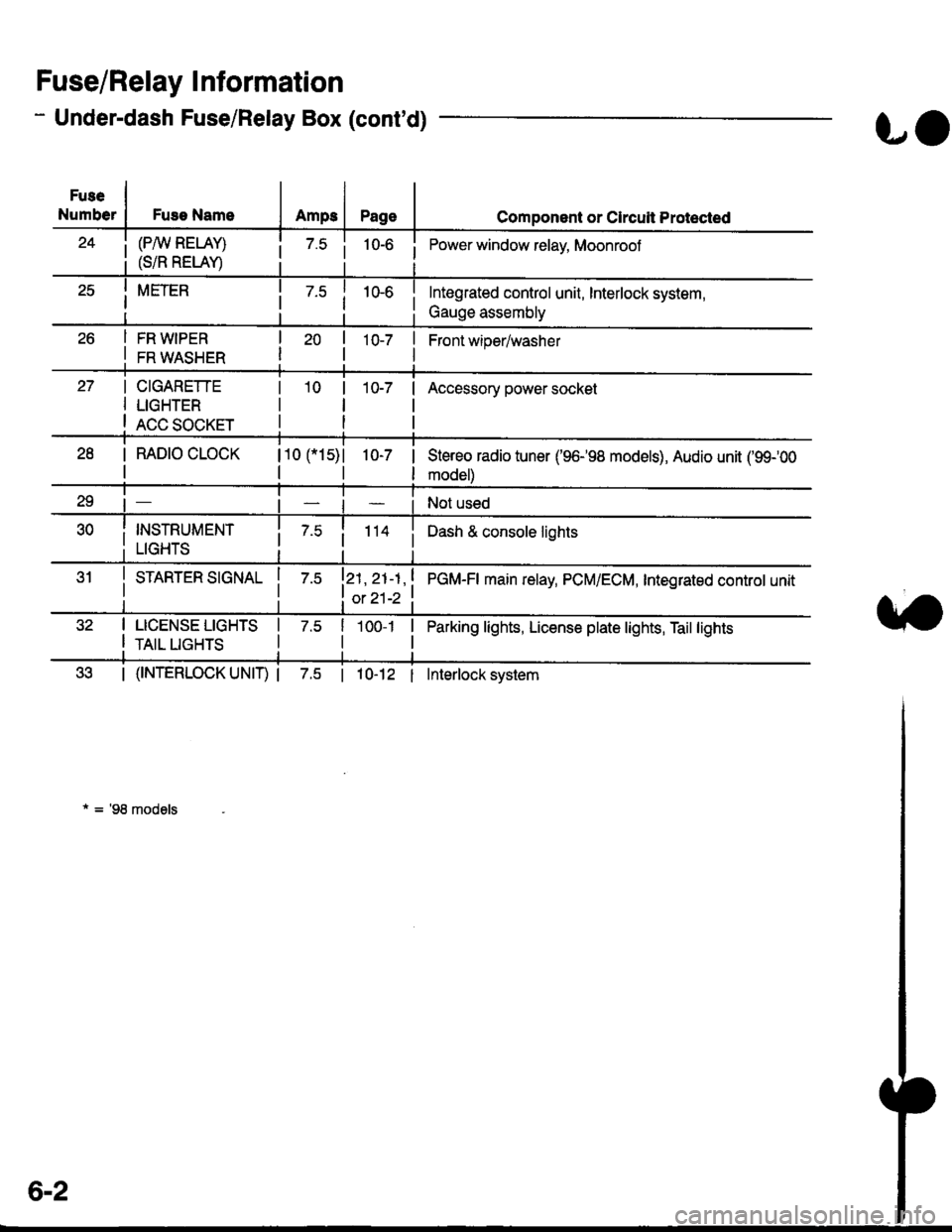

- Under-dash Fuse/Relay Box (cont'd)

Fuse/Relay I nformation

Fuse

NumberFuse NameAmps

(P/W RELAY)

(S/R RELAY)

FR WIPER

FR WASHER

LO

Page

10-7 |

I

Component or Clrcuit Protected

i Power window relay, Moonrool

Front wioer/washer

CIGARETTE

LIGHTER

ACC SOCKET

10-7Accessory power socket

I RAD|O CLOCK

I

110 115)l

tl

1O-7 |

I

Stereo radio tuner ('96198 models), Audio unit ('99100

model)

Not used

i 7.5i 114 iDash & console lights

I srnnrensrorunl | 7.slzl , zt -t , ! eCU-n main retay, PCM/ECM, Integrated controt unit

I ot 21-2 t

I LICENSE LIGHTS I 7.5

I rerr uesls I

Parking lights, License plate lights, Tail lights| 1oo-1 |

tl

| (f NTERLOCK UNIT) | 7.5 | 10-12 I Interlock system

* = '98 models

6-2

Page 1837 of 2189

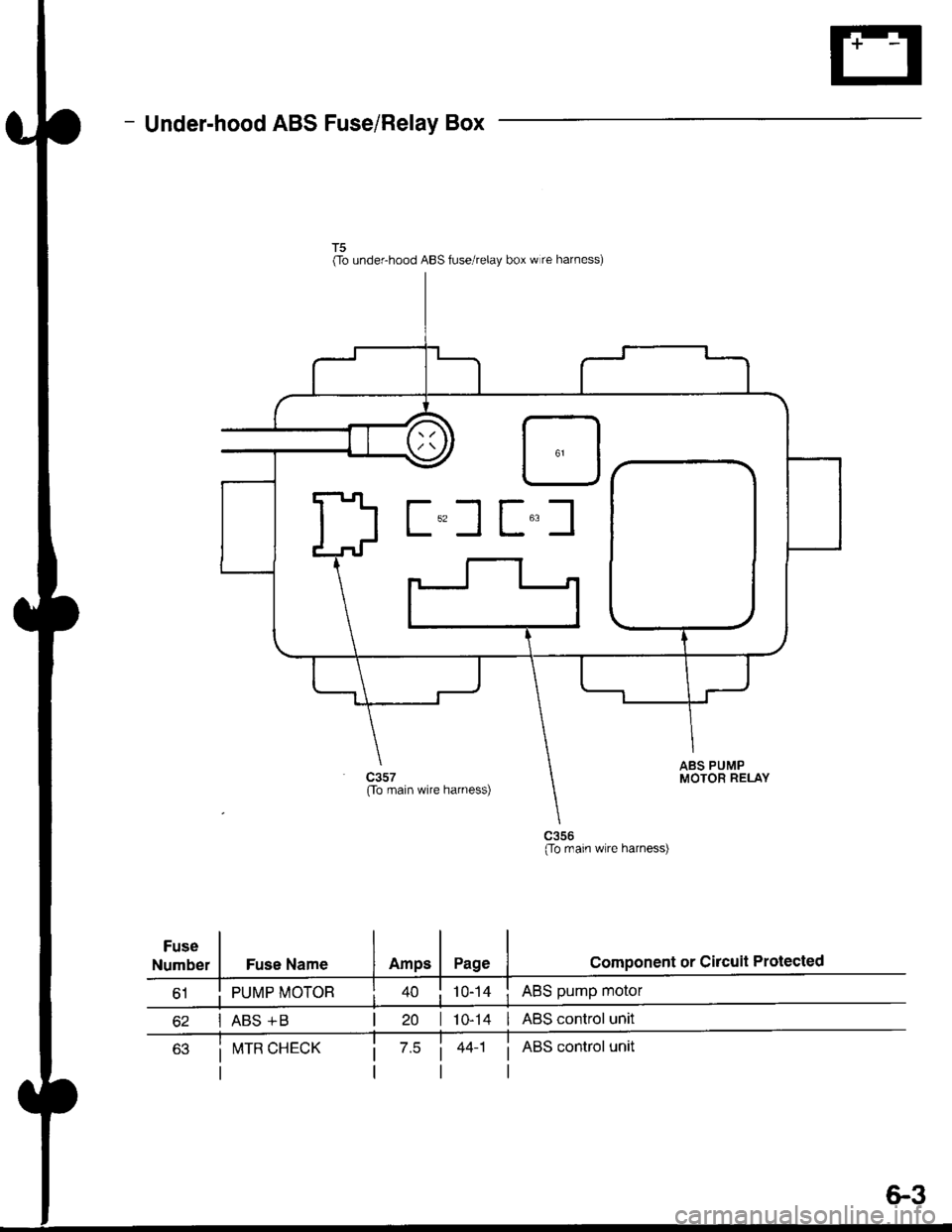

- Under-hood ABS Fuse/Relay Box

Fuse

Number

(To underhood ABS fuse/relay box w re harness)

ABS pump motor

| 10-14 I ABS control unit

i ABS control unit

component or circuit ProiectedFuse Name

PUMP MOTOR

I ABS +B

ABS PUMPMOTOR RELAY(To main wire harness)

(To rnain wlre harness)

I!,ITR CHECK

6.3